Patents

Literature

58results about How to "Assembly time is short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

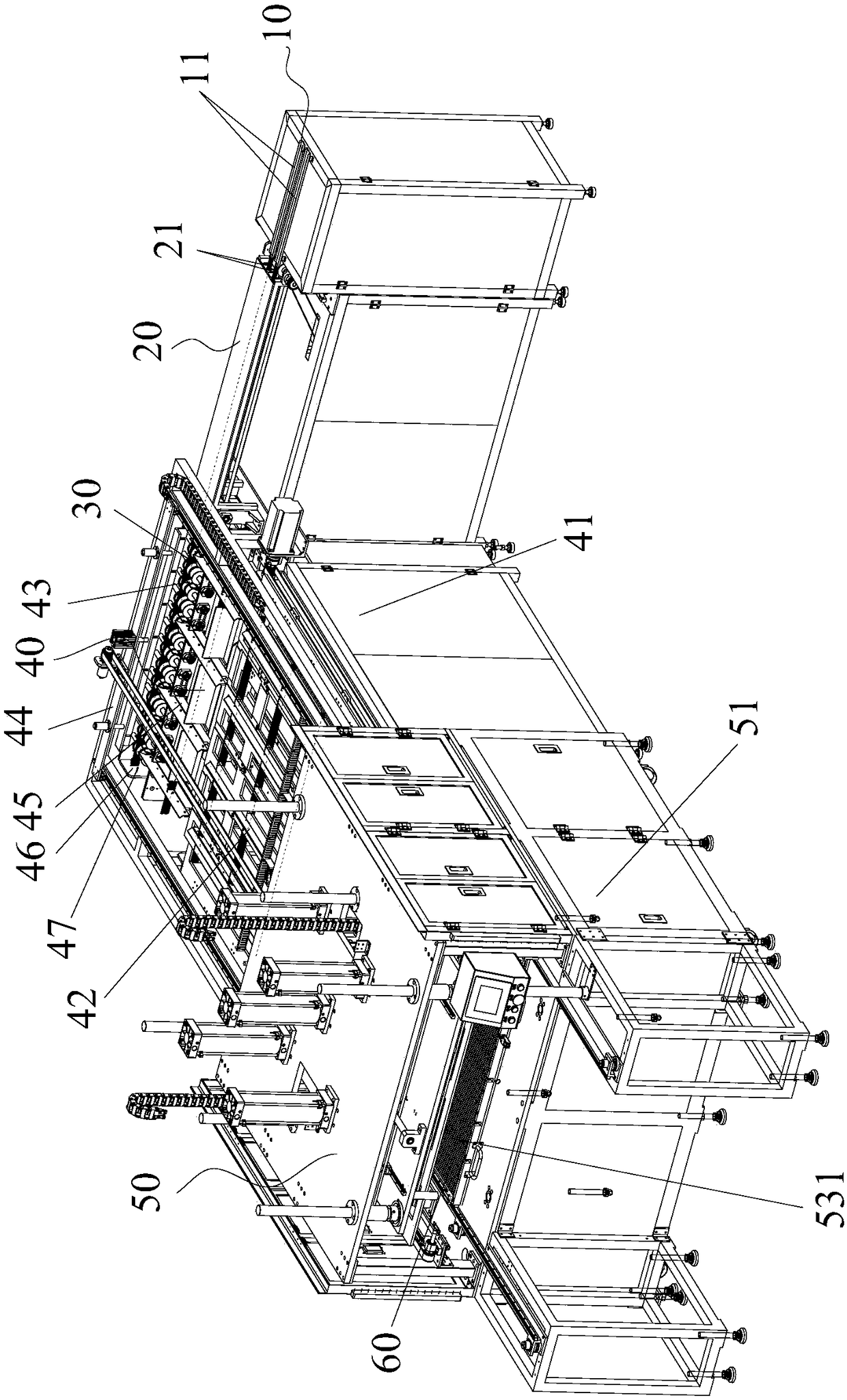

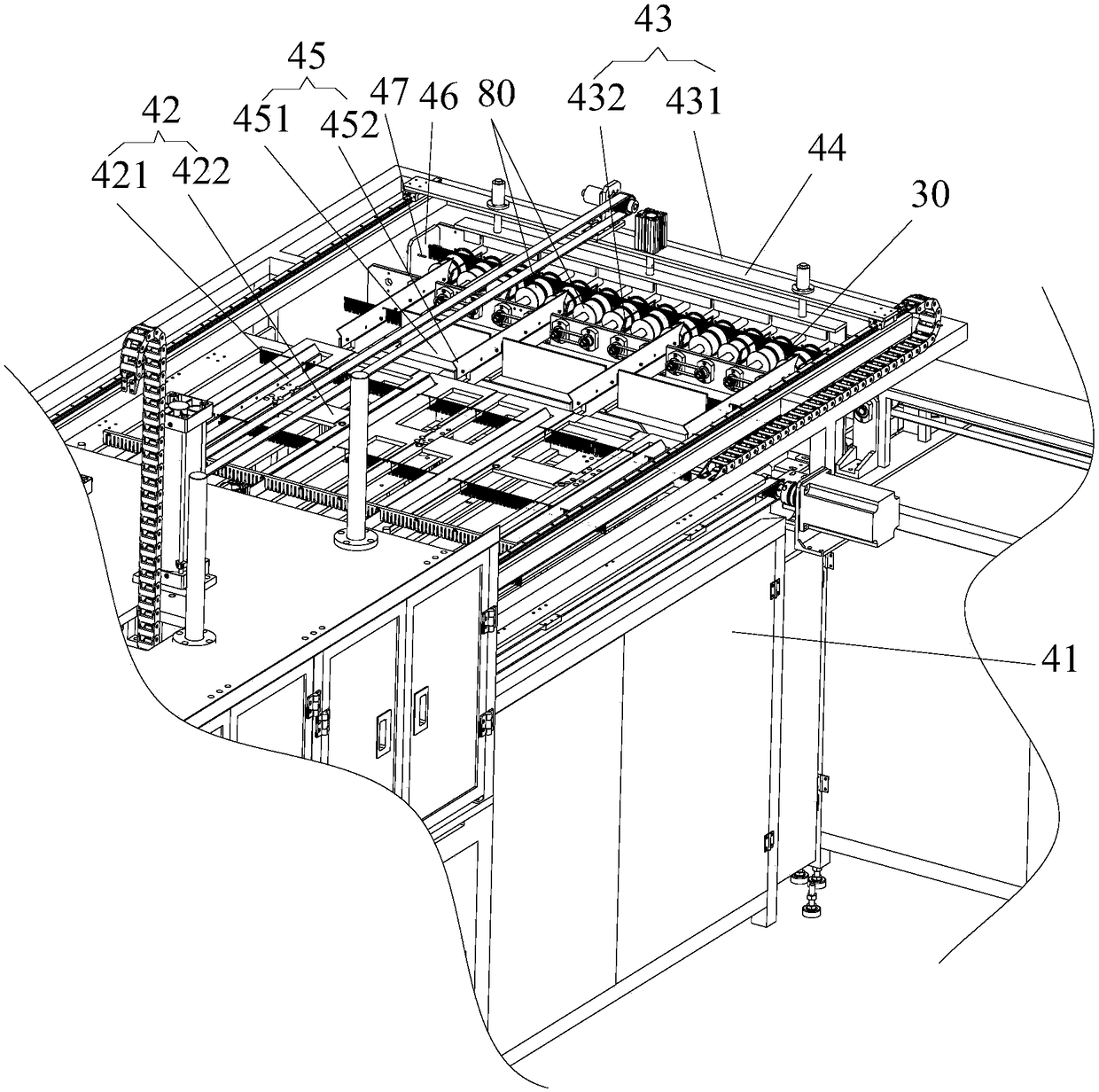

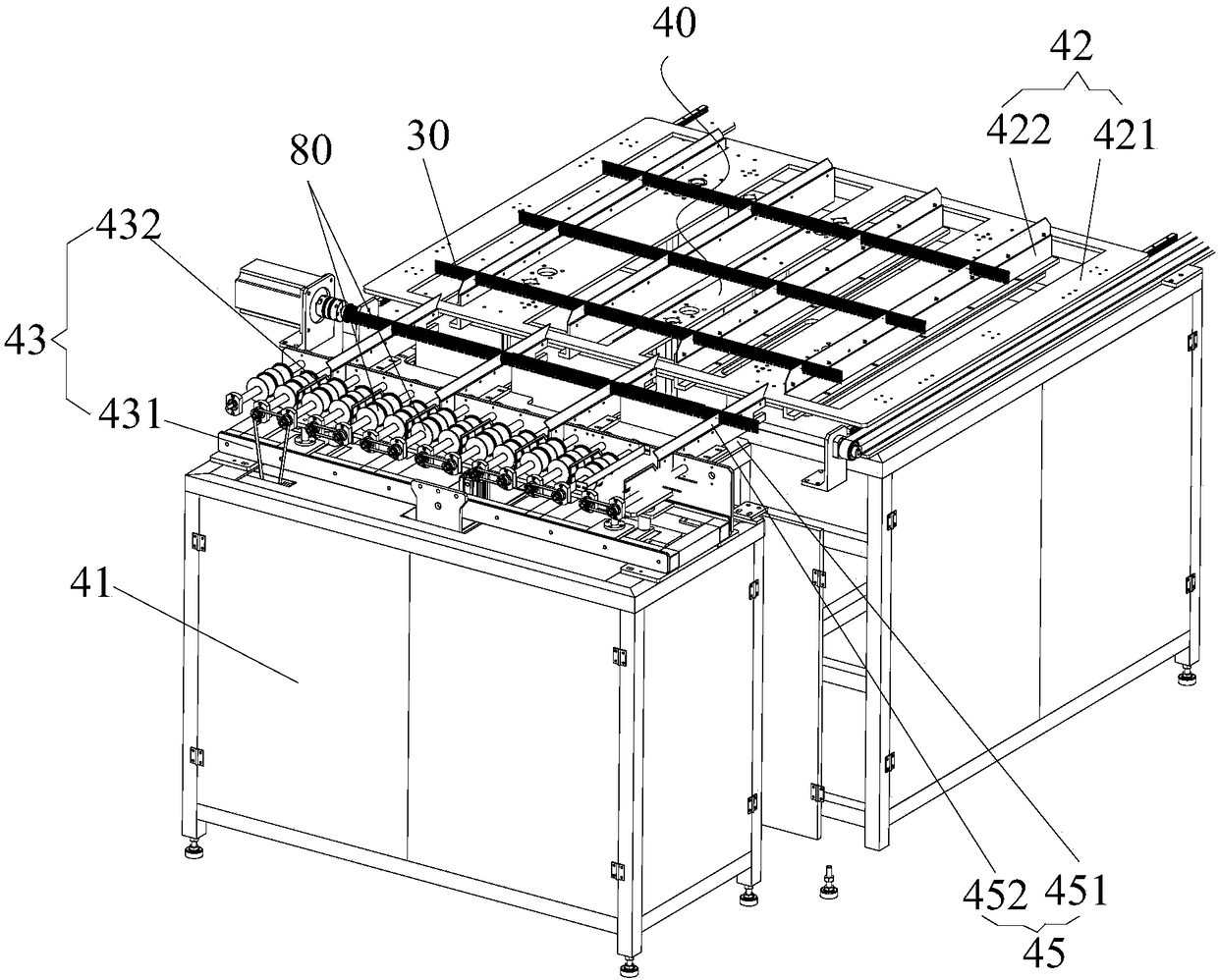

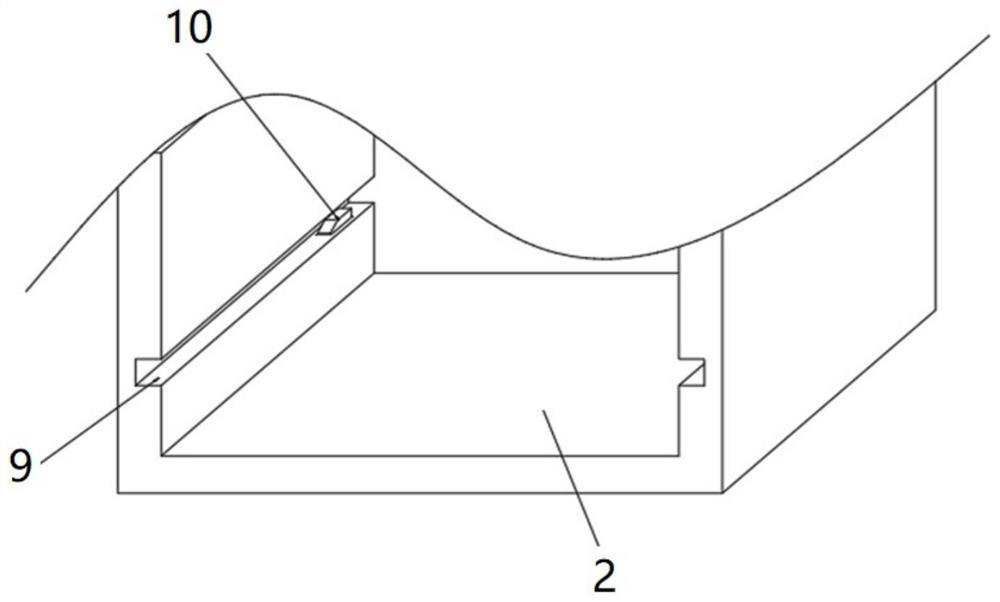

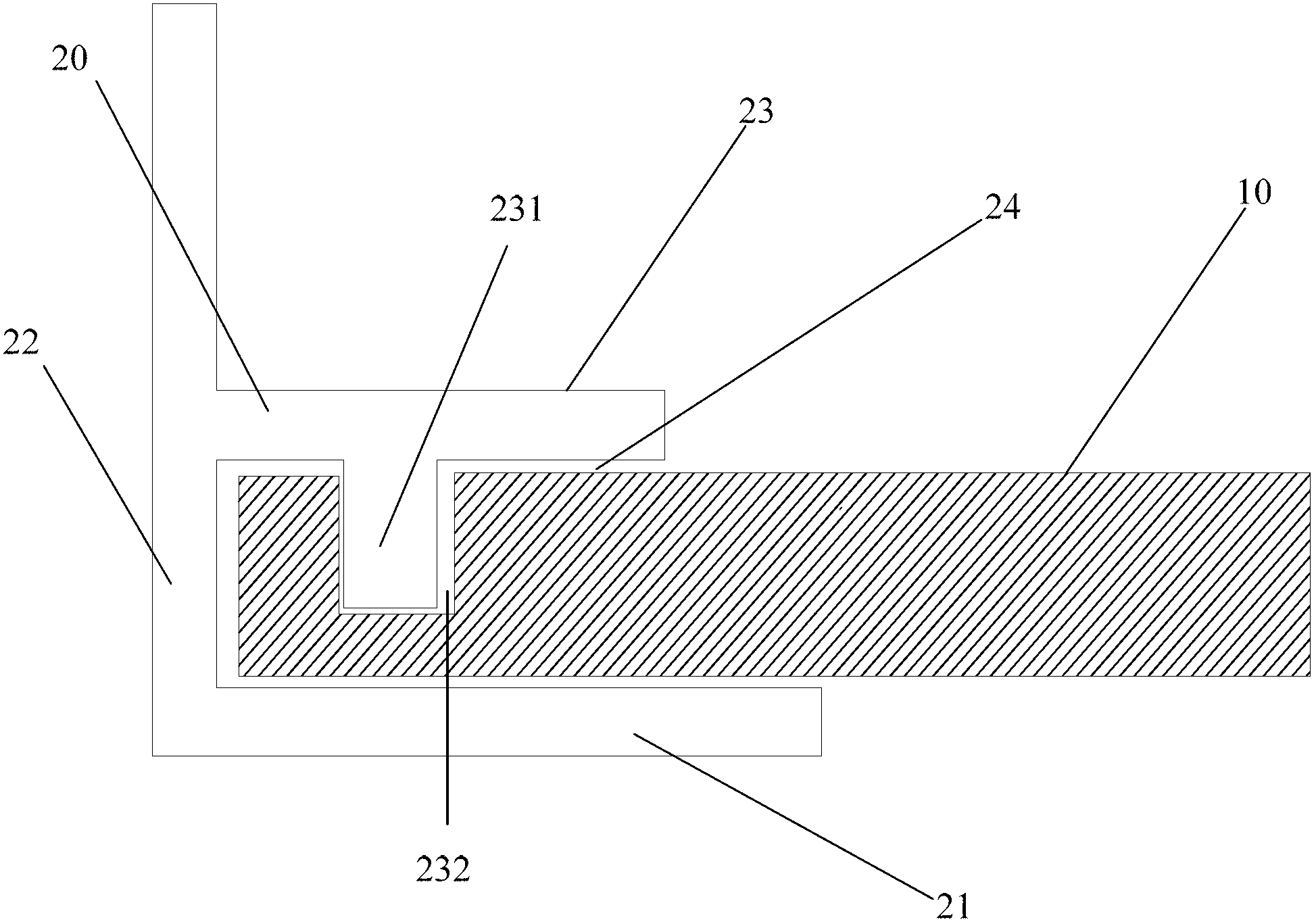

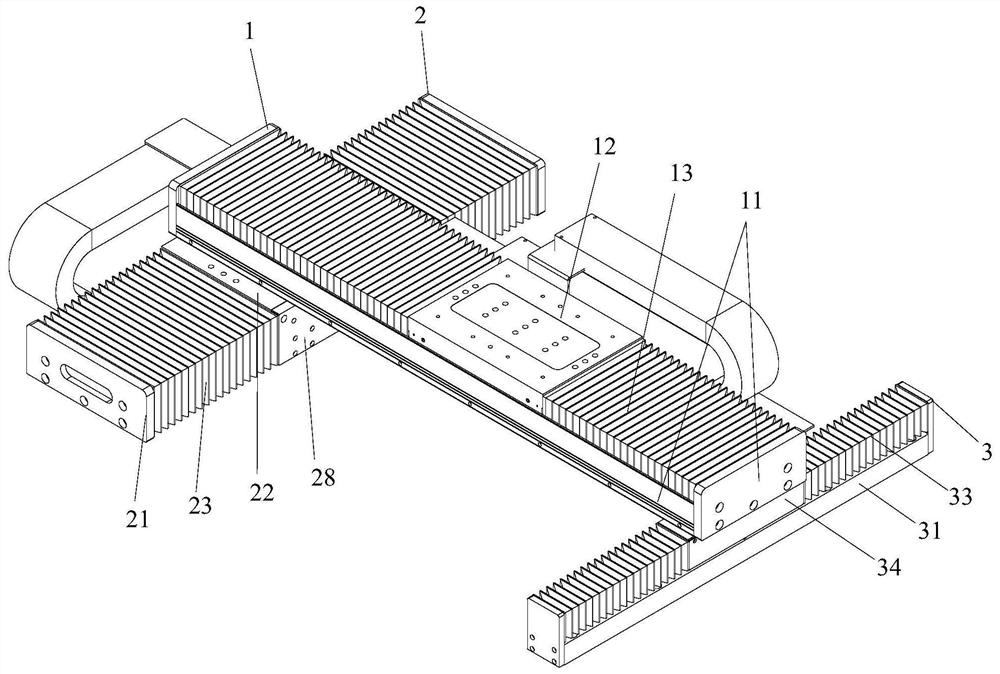

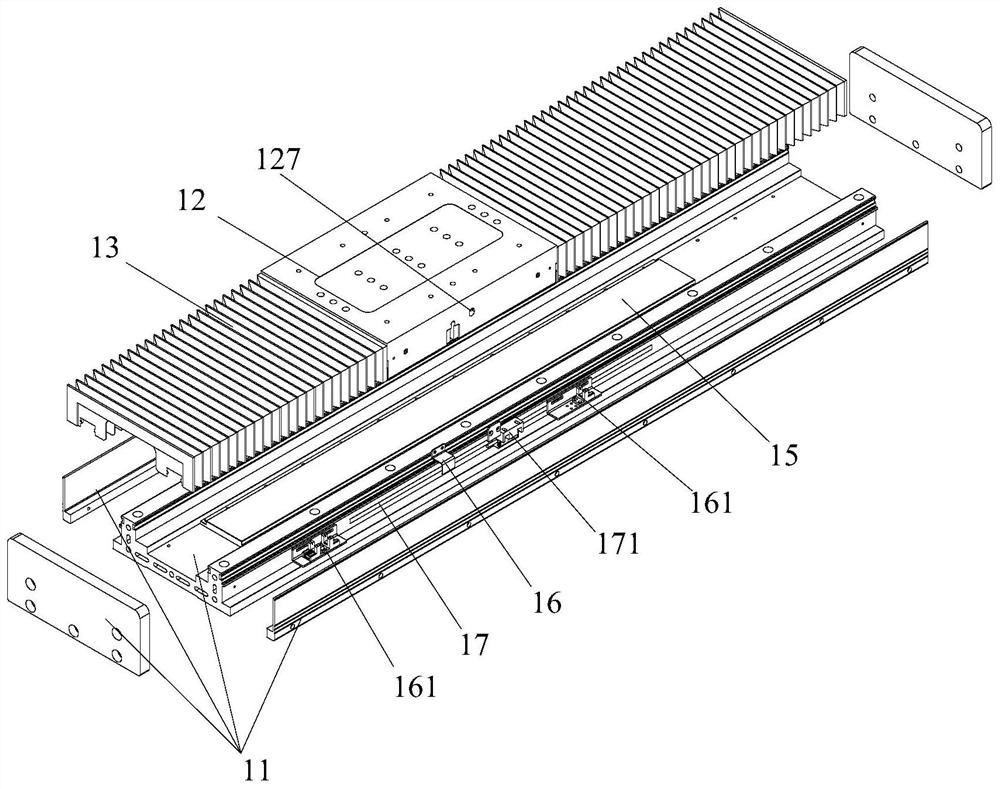

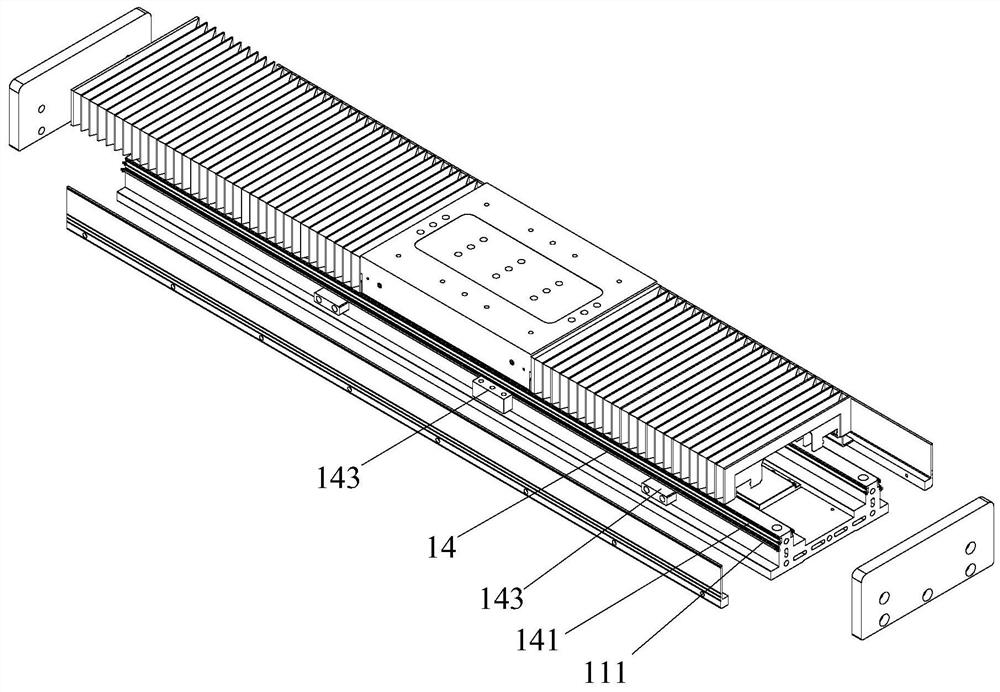

Assembling mechanism applied to heat exchangers and assembling method thereof

ActiveCN108422164ALower assembly costsReduce in quantityMetal working apparatusSoftware engineeringMicro heat exchanger

Owner:GREE ELECTRIC APPLIANCES INC

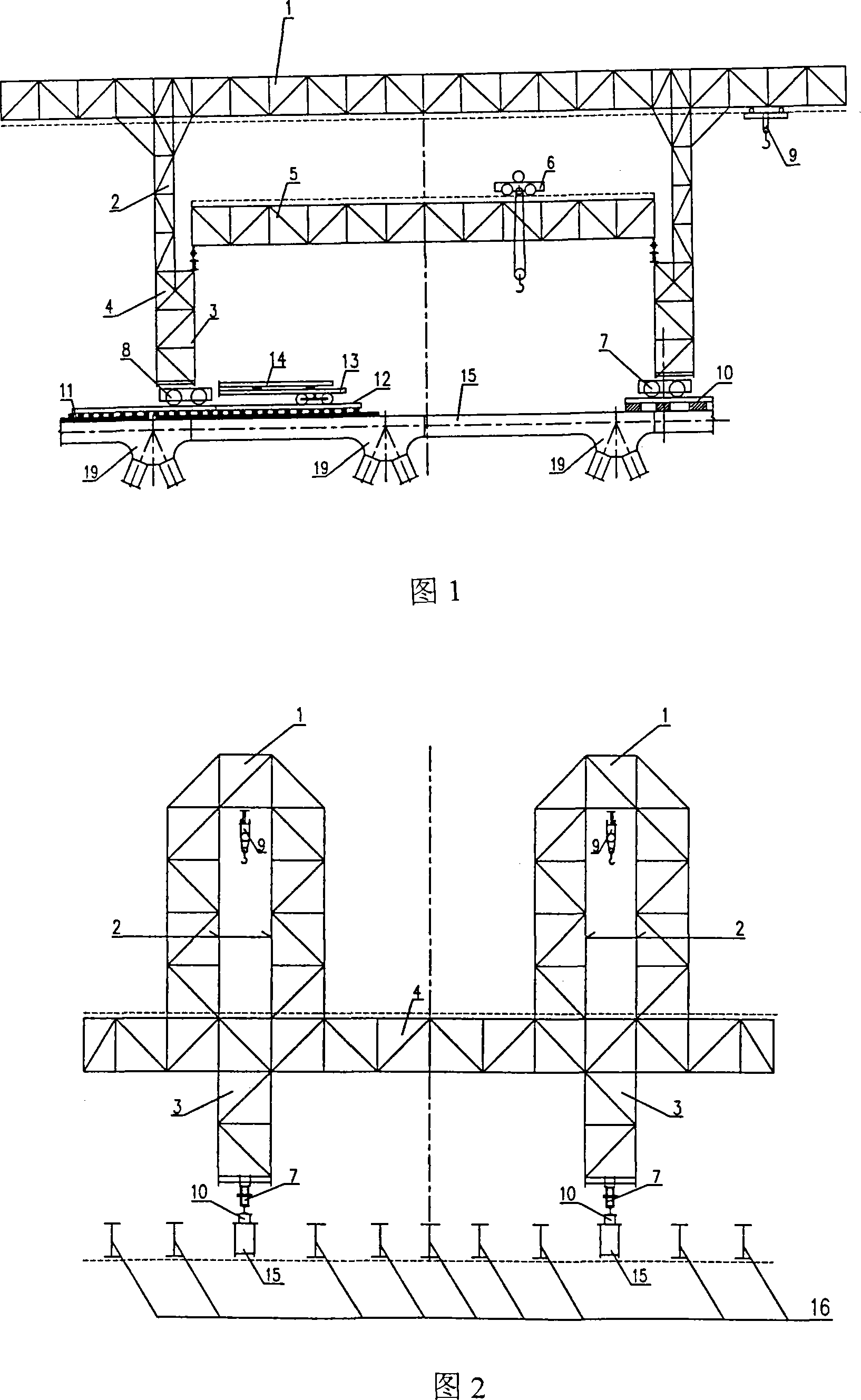

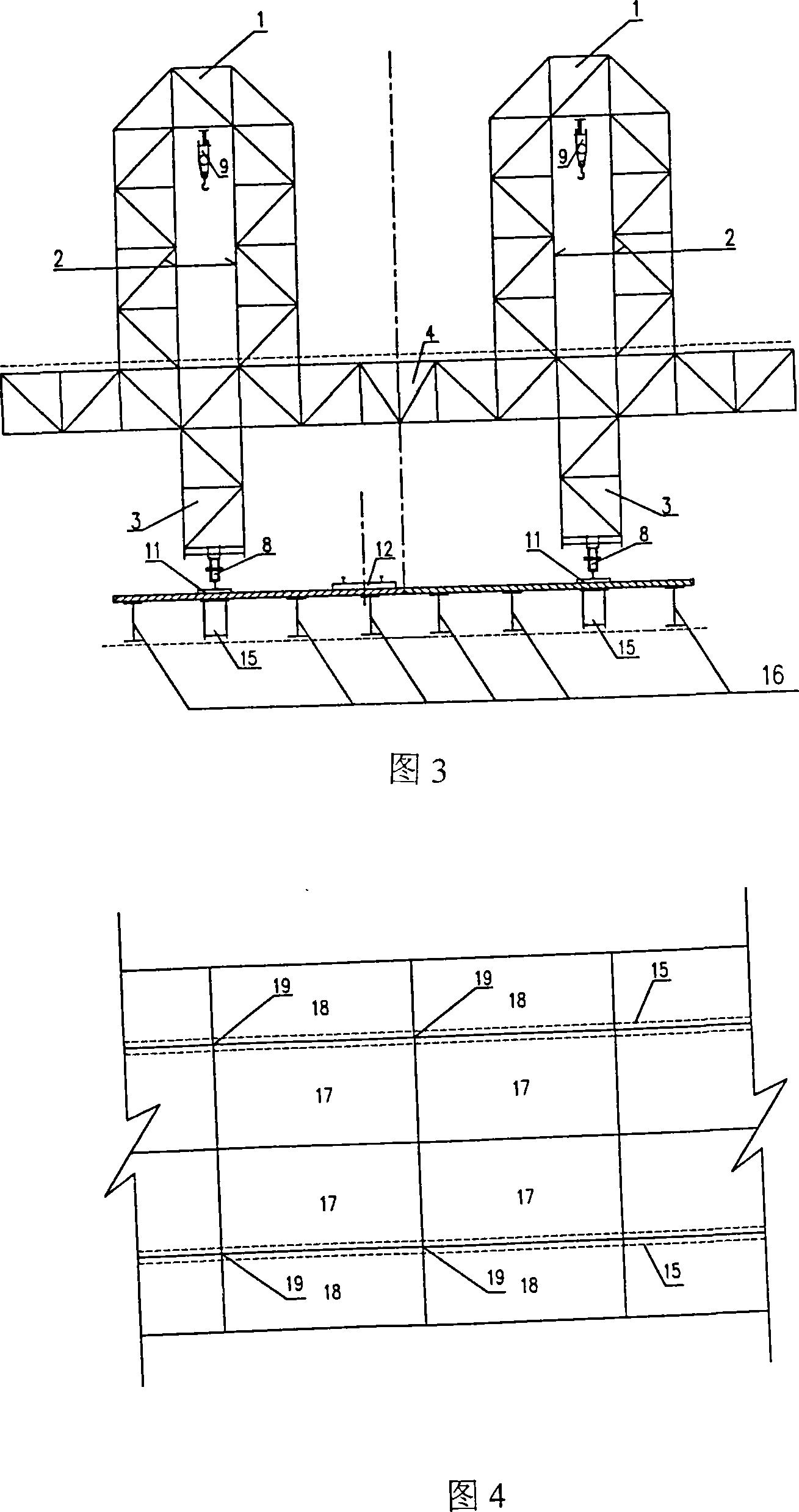

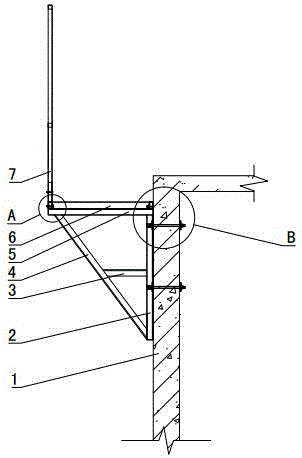

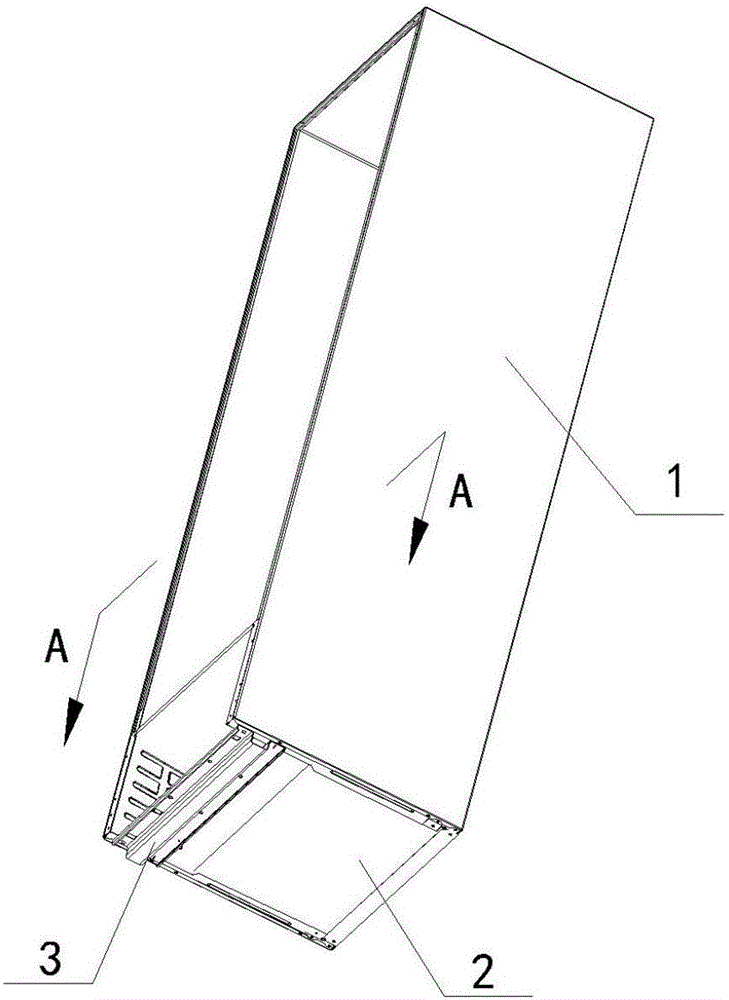

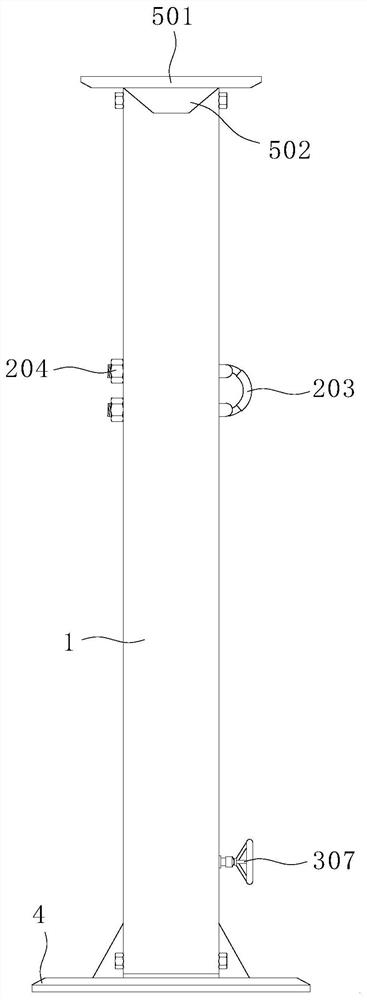

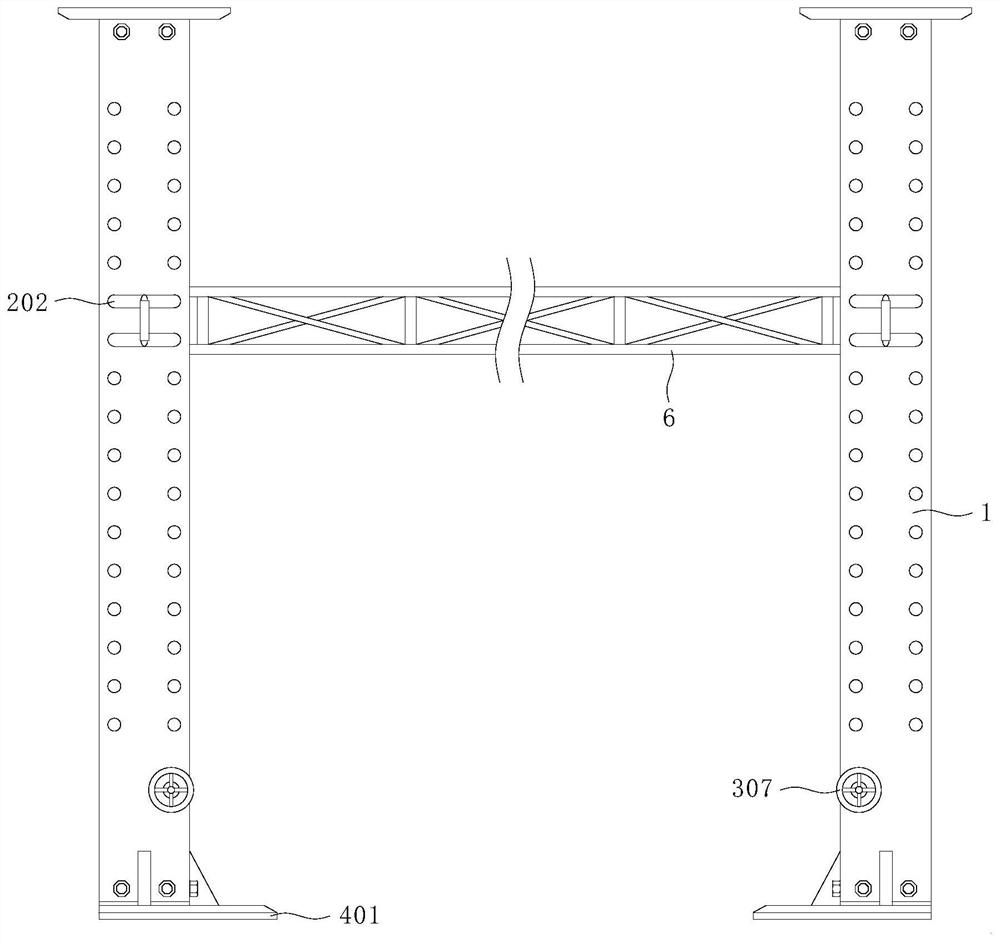

High-altitude framework type simple plate supporting machine

ActiveCN101117794AImprove wind load resistanceAssembly time is shortBridge erection/assemblyLoad resistanceBridge deck

The present invention relates to a high altitude frame simple machine for an erecting plate, the structure is stated below: a gantry binding beam is connected with an upper column of the gantry, which is connected with a walkway beam of a hoisting truss, which is connected with a lower column of the gantry. The hoisting trolley is arranged on the hoisting truss. The front end and the rear end of the hoisting truss are positioned on the hoisting truss. A front walking wheel box group and a rear walking wheel box group are arranged under the lower column of the gantry; the front walking wheel box group and the rear walking wheel box group are arranged at a walkway of a transportation board of a trolley and a front walking wheel rail and a rear walking wheel are arranged at the lower position of the walkway of the transportation road; a plurality of upper stringer joints of the steel truss are arranged on an upper stringer rod of the steel truss, a longitudinal beam of the steel truss beam is connected with the upper string rod of the steel truss beam, and an electric hoist is positioned at the bottom of the gantry binding beam. The present invention has the advantages of free transverse and longitudinal travel, four concrete bridge decks between joints are erected one time; normal universal rod structures are used to make a frame structure. the present invention has the advantages of sound stability, high air-load resistance, short manufacturing time and low production cost, easy and convenient use.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP

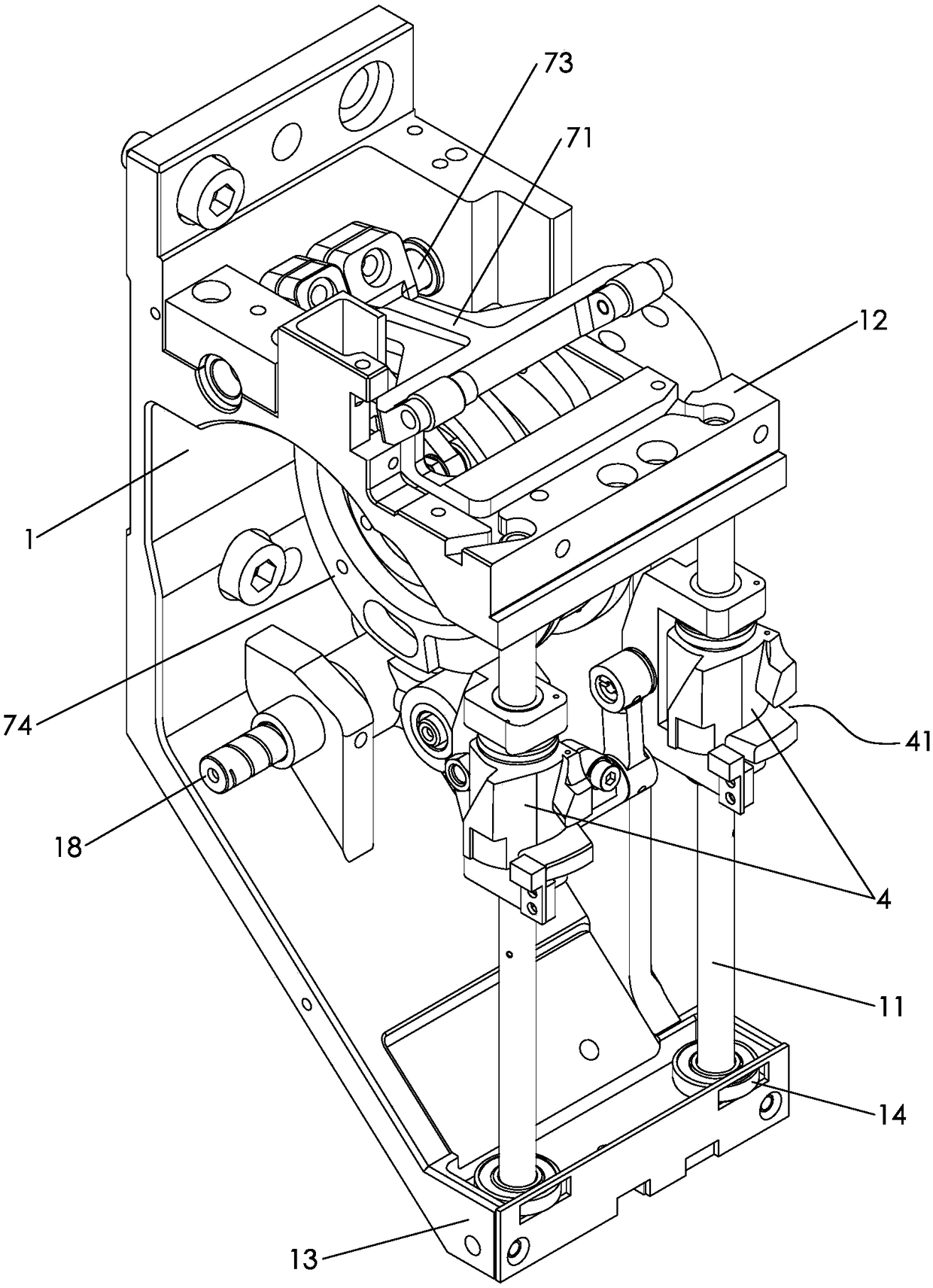

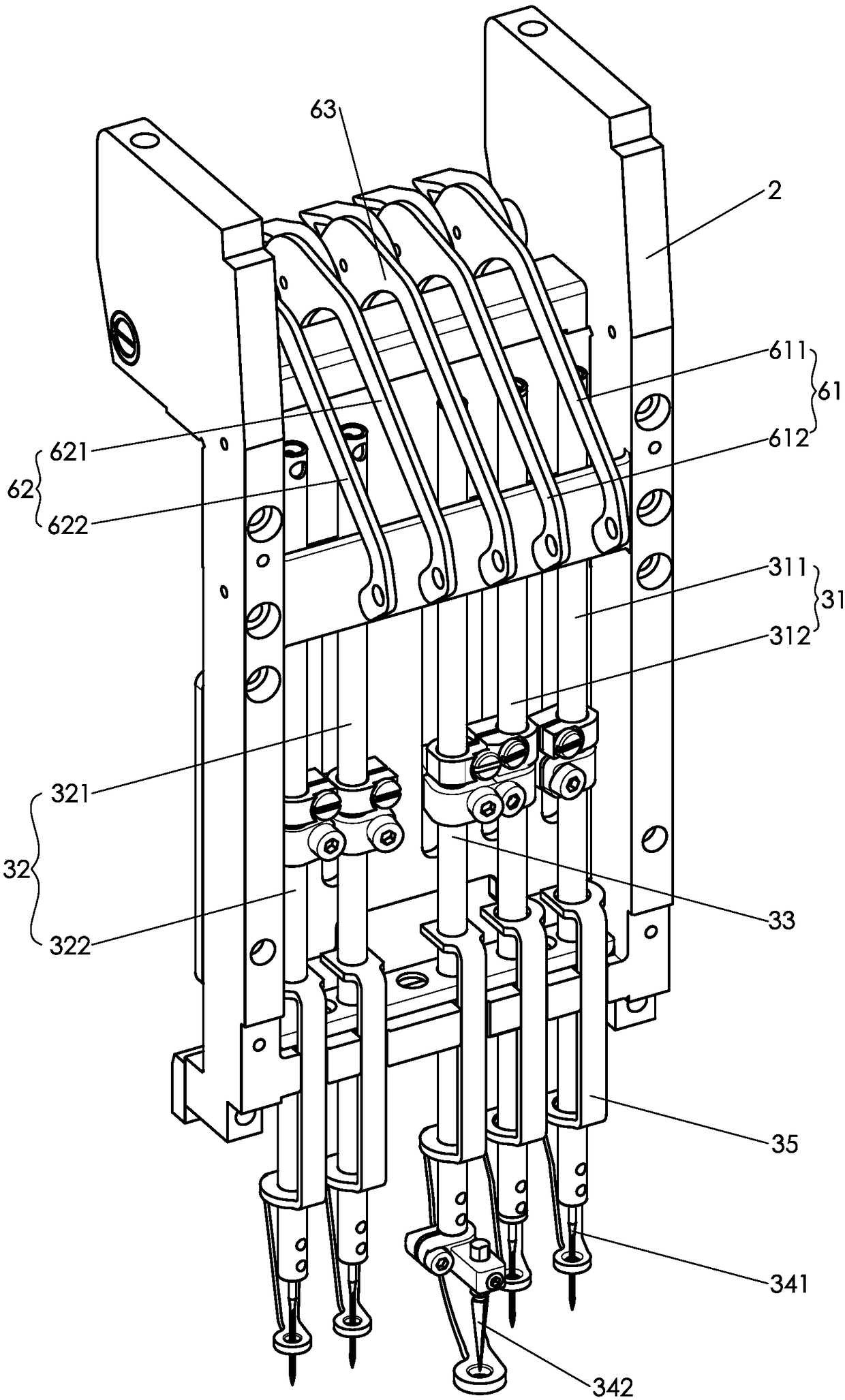

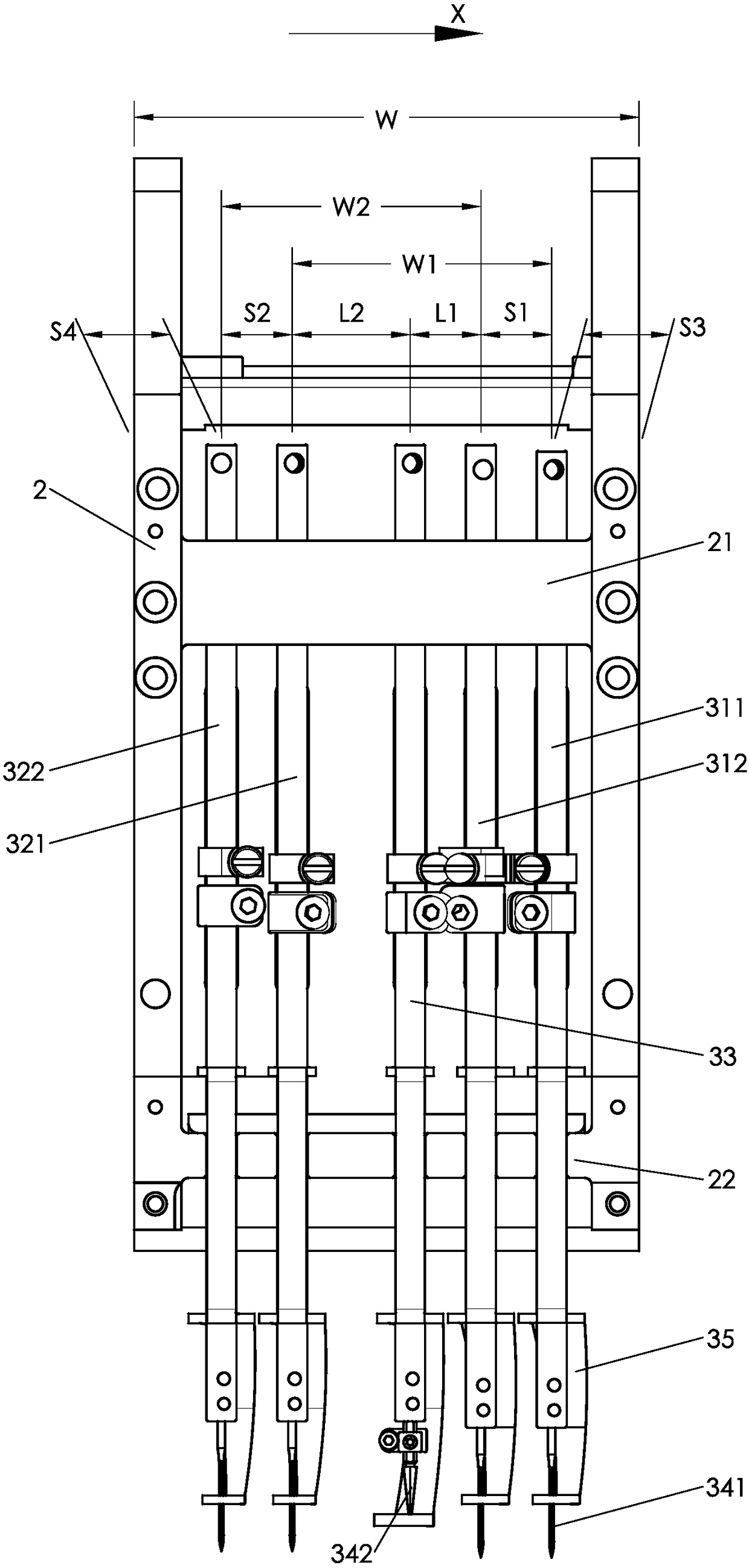

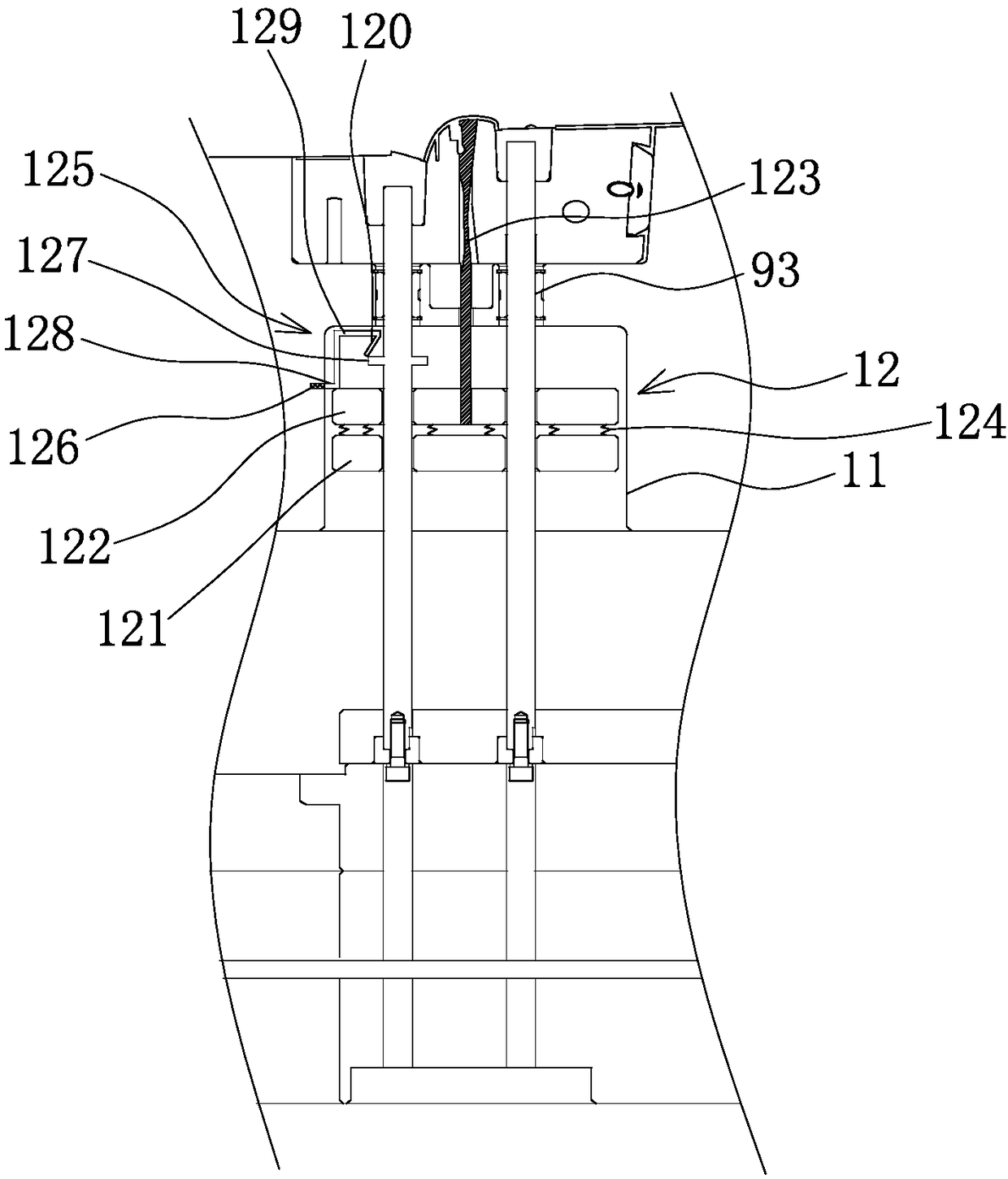

Embroidery machine head and embroidery machine

PendingCN108193396ARich functionsSimple structureAutomatic machinesAuxillary devicesBiomedical engineeringElectromagnet

The invention discloses an embroidery machine head and an embroidery machine and belongs to the technical field of embroidery machines. The head comprises a casing and a needle bar frame arranged on the casing, wherein the needle bar frame can horizontally move back and forth relative to the casing, a first needle bar, a second needle bar and a boring needle bar are arranged on the needle bar frame, and two needle bar drivers are arranged on the casing; when one needle bar driver drives the boring needle bar, the other needle bar driver is staggered with the first needle bar and the second needle bar in the moving direction of the needle bar frame and is in a no-load state. Alternative head boring is realized through back and forth movement of the boring needle bar under the drive of the needle bar drivers, the head is not required to be shut down for replacement of needles, and the functions and applications of the head are enriched. Separation and reunion are realized by corresponding or staggering the needle bar drivers with the needle bars in the moving direction of the needle bar frame, electromagnets and drive parts driving the needle bar drivers to rotate under the drive ofthe electromagnets are not required to be added to the head, the structure of the head is advantageously simplified, time consumption for assembling of the head is reduced, and the production cost ofthe head is controlled.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

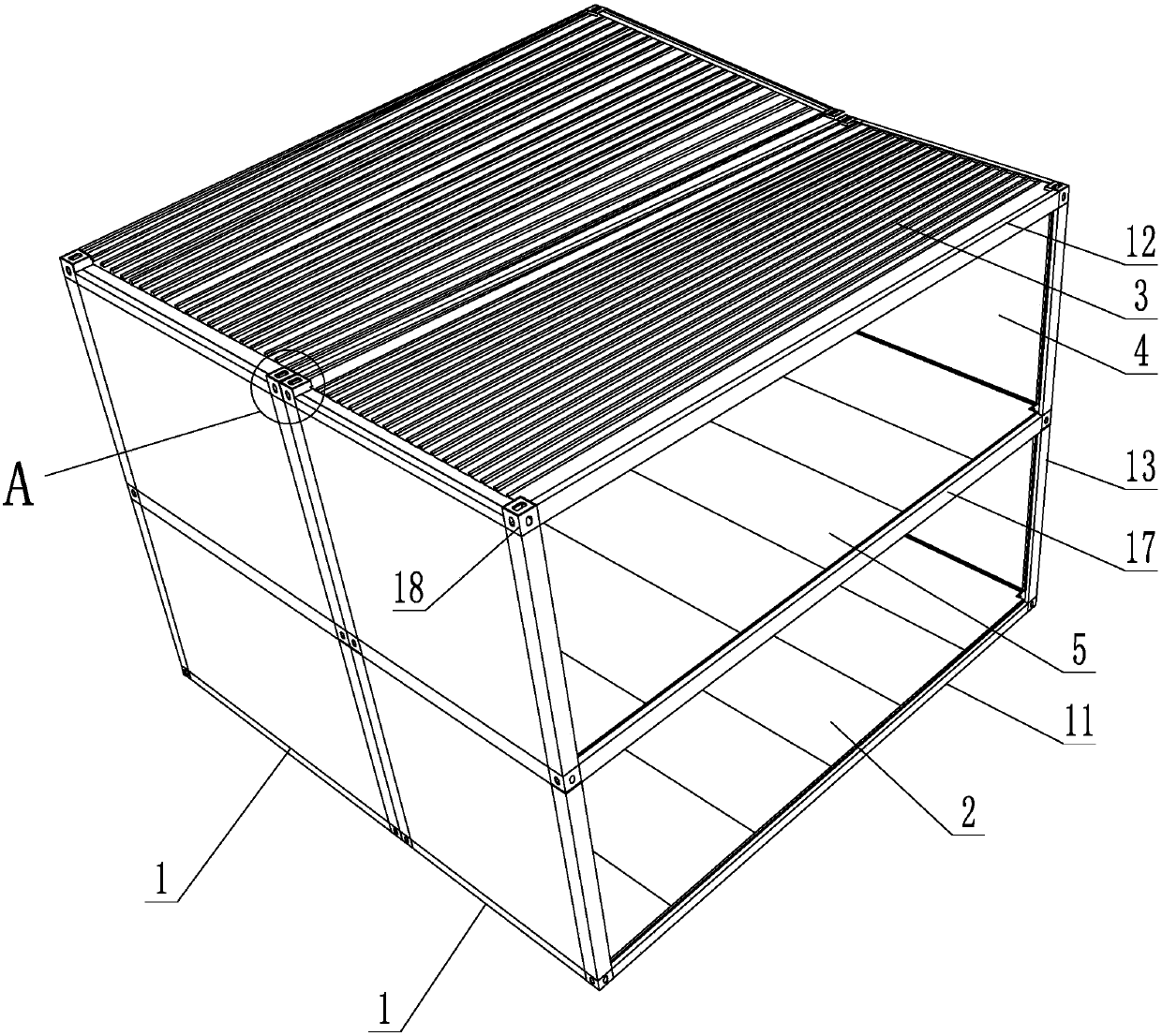

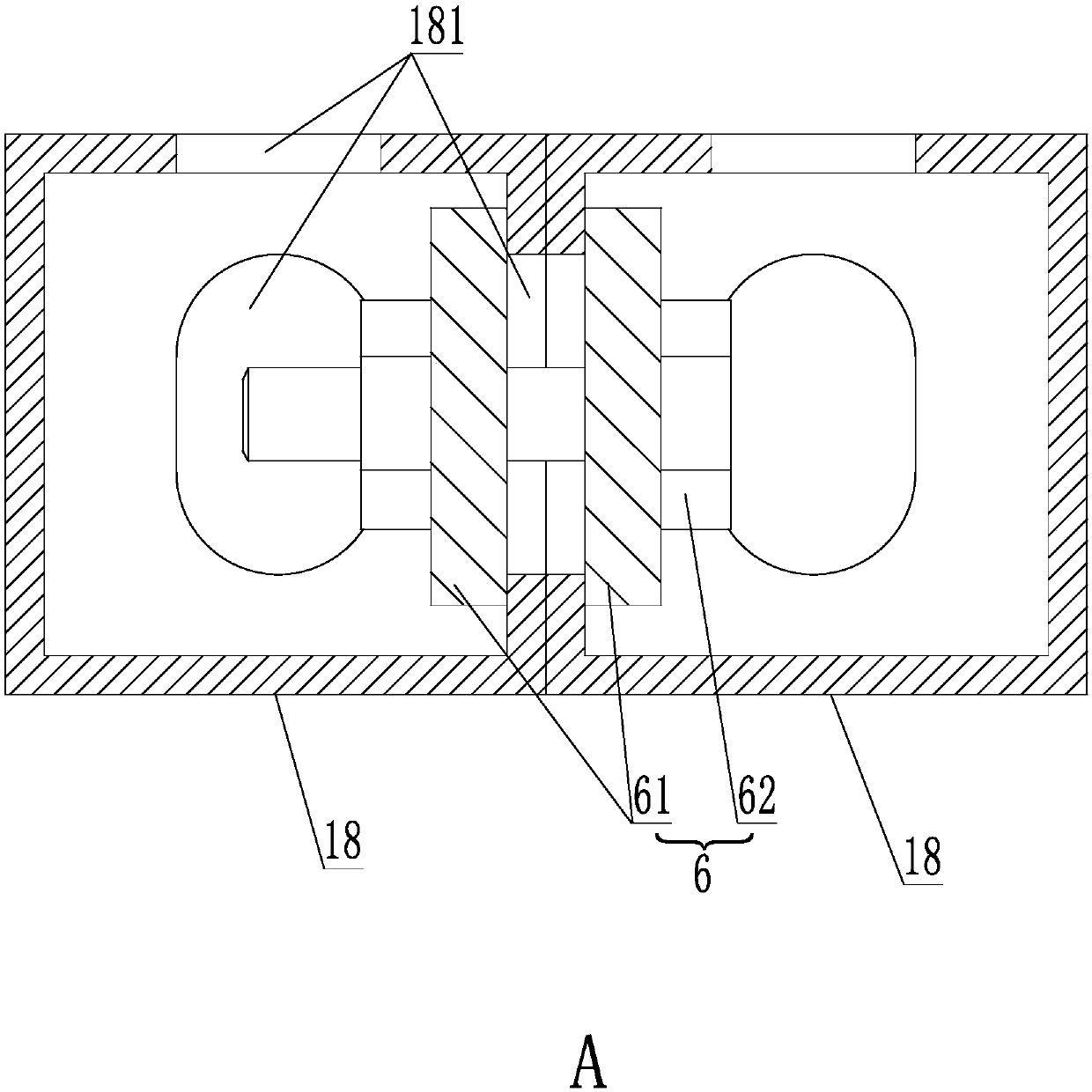

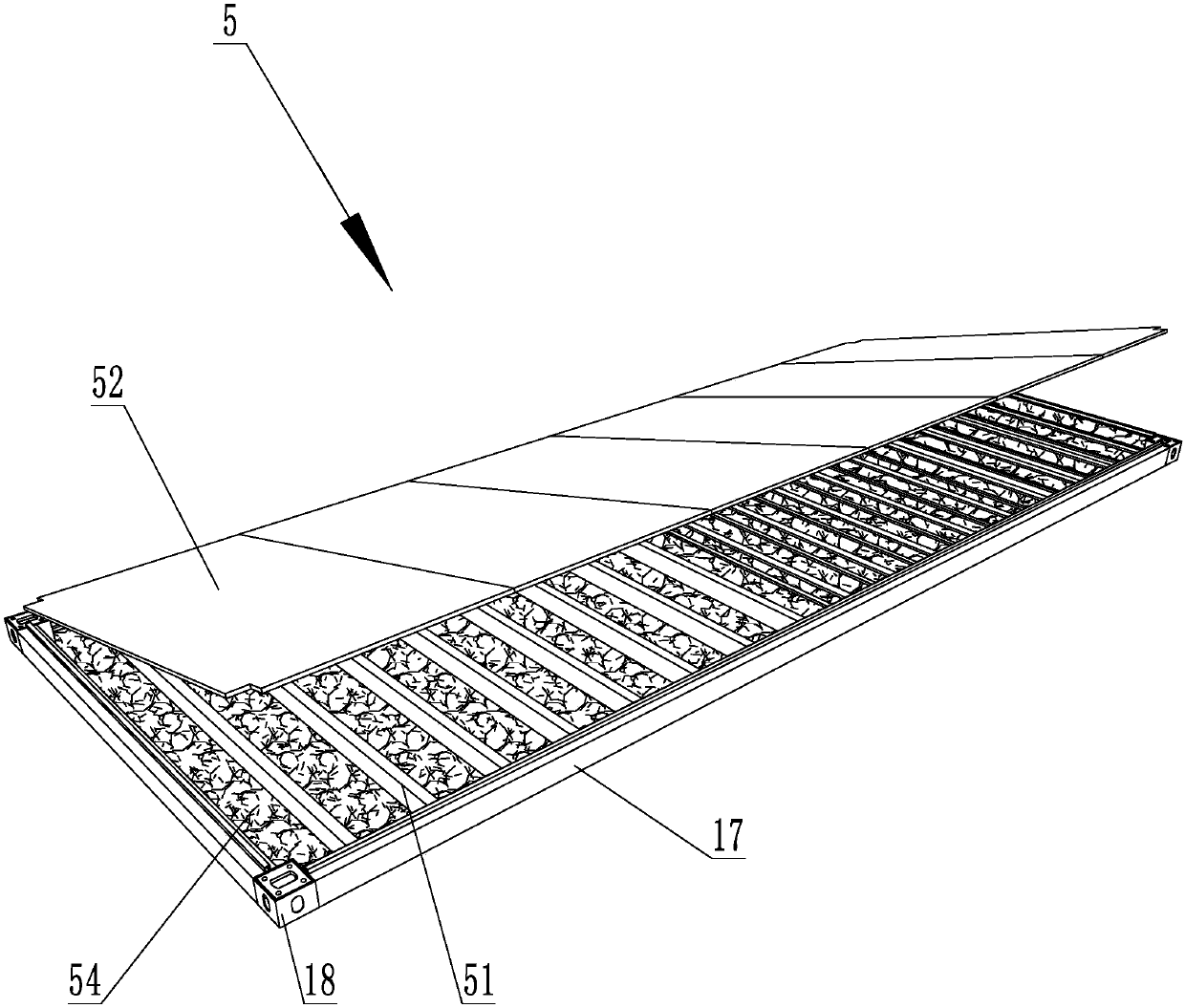

Assembly-type prefabricated-steel frame module house

The invention relates to an assembly-type prefabricated-steel frame module house. The module house includes multiple monomer houses, and each monomer house includes a floor installed on the bottom surface of a house body, a roof installed on the top surface of the house body, and wallboards installed on the side surfaces of the periphery of the house body; the floor includes a bottom frame with asupport function, the roof includes a top frame with a support function, and uprights are arranged between the floor and the roof for connection; the upper side surface of the bottom frame is providedwith a lower flange arranged along the frame, and the lower flange is connected with a lower clamping piece in a clamping mode; the end, away from the room interior, of the lower clamping piece is provided with a lower clamping groove with an upward opening, and the lower side surface of the top frame is provided with an upper flange arranged along the frame; the side, positioned in the room interior, of the top frame is connected with a support piece for supporting the roof, and the support piece is connected with an upper clamping piece; an upper clamping groove, with a downward opening andopposite to the lower clamping groove, is formed between the upper clamping piece and the upper flange, and the upper and lower ends of each wallboard are arranged in an inserting mode in the lower clamping groove and the upper clamping groove through sliding. The wallboards and roofs of the module house can be recycled repeatedly, which not only saves the costs, but also protects the environment.

Owner:BEIJING CHENGDONG INT MODULAR HOUSING

Shaped external-hanging-bracket protective system and installation method

InactiveCN107524284AGuaranteed stress requirementsGuaranteed Protection RequirementsScaffold accessoriesBuilding support scaffoldsEngineeringProtective system

The invention discloses a shaped external-hanging-bracket protective system and an installation method, and belongs to the technical field of assembly building construction. The shaped external-hanging-bracket protective system comprises a plurality of protective devices, and is characterized in that each protective device comprises a plurality of triangular support frames, an operating platform (6) arranged on the upper sides of the support frames and a protective bracket (7) arranged on the operating platform (6), the support frames are arranged on the outer side of a prefabricate external wall (1) and detachably connected with the prefabricate external wall (1), the operating platforms (6) are arranged on the support frames and detachably connected with the support frames, and the protective brackets (7) are arranged on one sides, away from the prefabricated external wall, of the operating platforms (6). According to the shaped external-hanging-bracket protective system, the structure is stable, construction turnover is convenient, labor and materials are saved, the protective effect is good, the appearance is elegant, and the problem of assembly building construction peripheral protection is solved; and according to the installation method of the shaped external-hanging-bracket protective system, operation is convenient, fixing among different floors is flexible, and the installation method is suitable for assembly building construction.

Owner:山东天齐置业集团股份有限公司

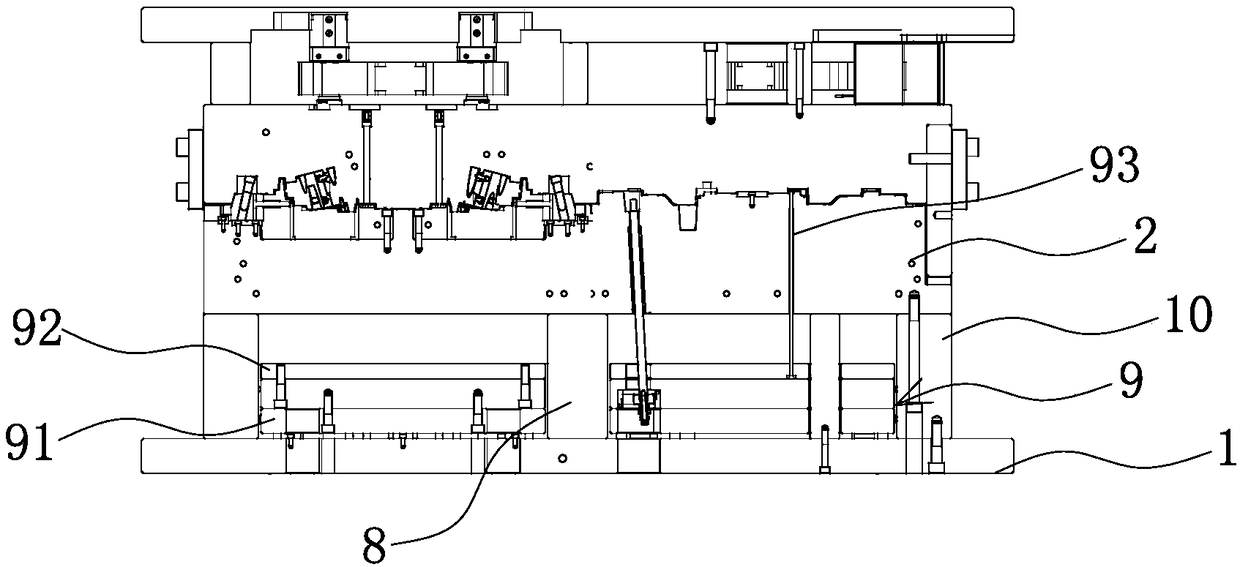

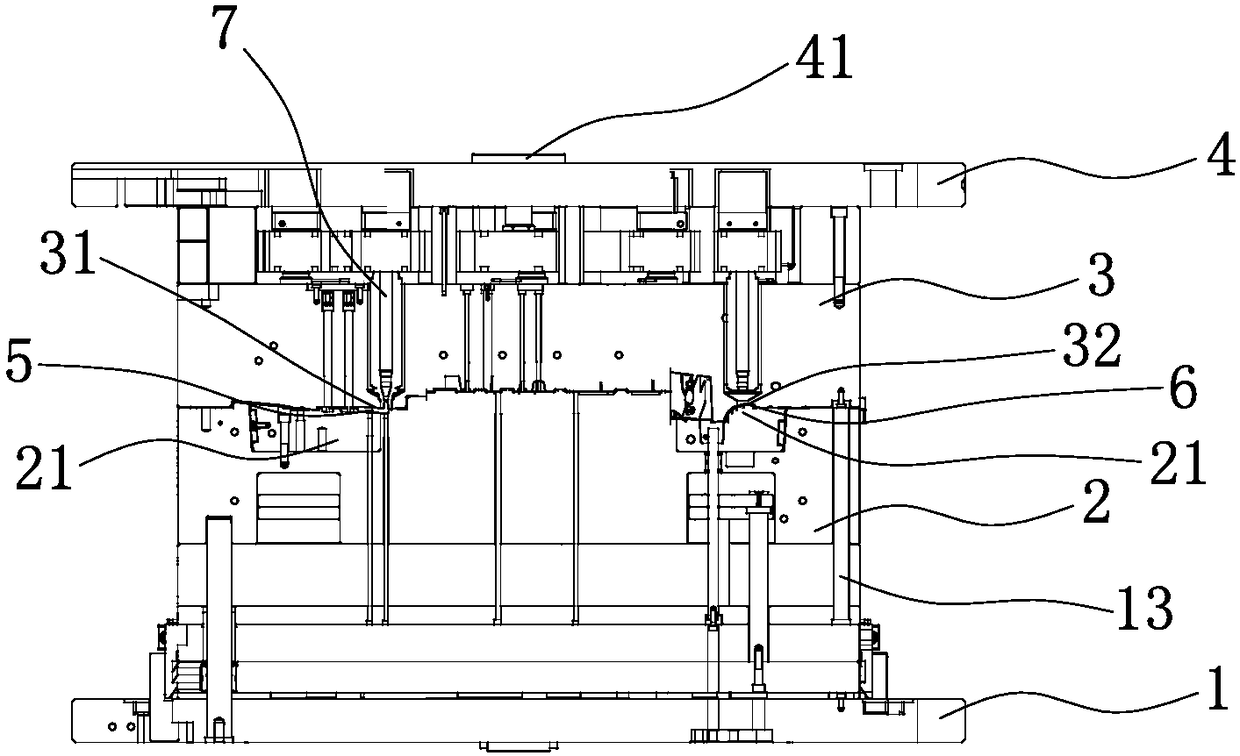

Mold mechanism with popup after ejection in automatic demoulding

PendingCN108501318AReduce in quantityReduce the difficulty of assemblyEngineeringMechanical engineering

The invention belongs to the technical field of automobile supplies, in particular to a mold mechanism with popup after ejection in automatic demoulding. The mold mechanism with popup after ejection in automatic demoulding comprises a base plate, a movable mold plate, a fixed mold plate and an injection molding plate. The movable mold plate is provided with two mold cores protruding out of the surface of the movable mold plate. The fixed mold plate is provided with a first mold cavity and a second mold cavity. The first mold cavity and the second mold cavity concave towards the interior of thefixed mold plate. The first mold cavity and one mold core are used in cooperation to form a first forming cavity. The second mold cavity and the other mold core are used in cooperation to form a second forming cavity. The first forming cavity communicates with an injection molding port through an injection molding flow pass arranged in the fixed mold plate. The first forming cavity communicates with the injection molding port through an injection molding flow pass arranged in the fixed mold plate. With the mold mechanism with popup after ejection in automatic demoulding, multiple parts of anautomobile handle support can be formed integrally, the later assembly difficulty is reduced, the time consumed for assembly is shortened, and the combination strength of a product is guaranteed; andbecause of the design that the mold mechanism is provided with a slingshot ejector pin, the problem that because demoulding travel is not enough, film drawing is prone to happening according to a traditional ejection manner is solved, the product quality is guaranteed, and the production efficiency is improved.

Owner:TAIZHOU SAILING MOLD & PLASTIC TECH

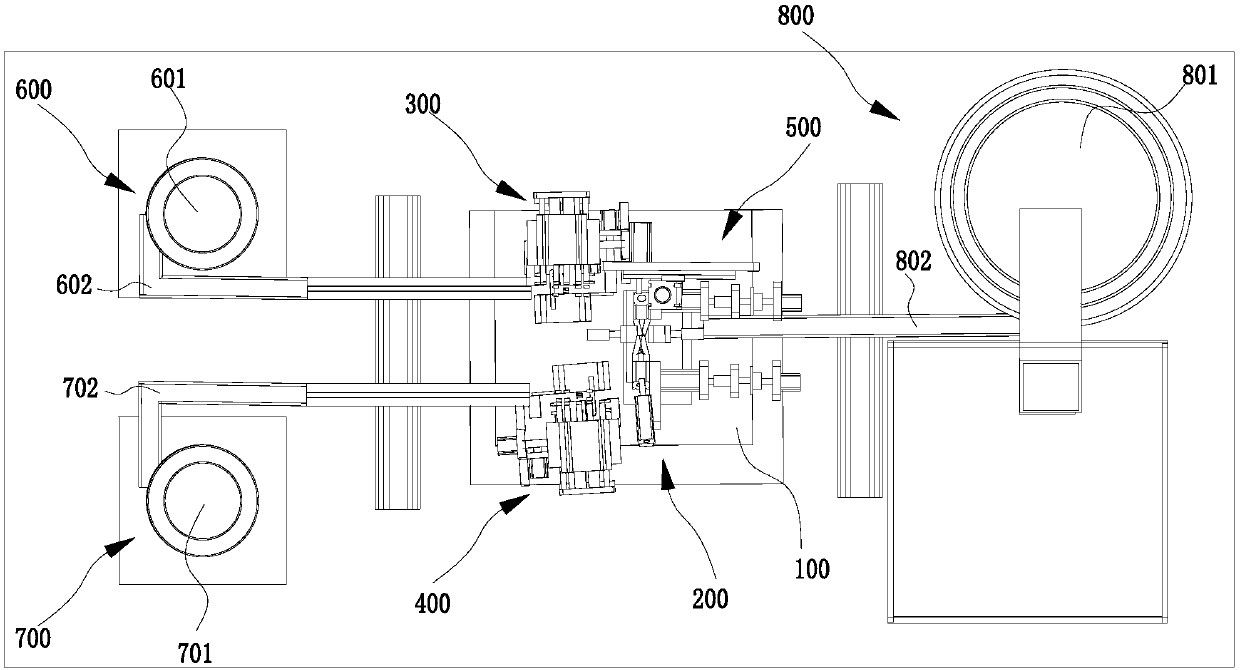

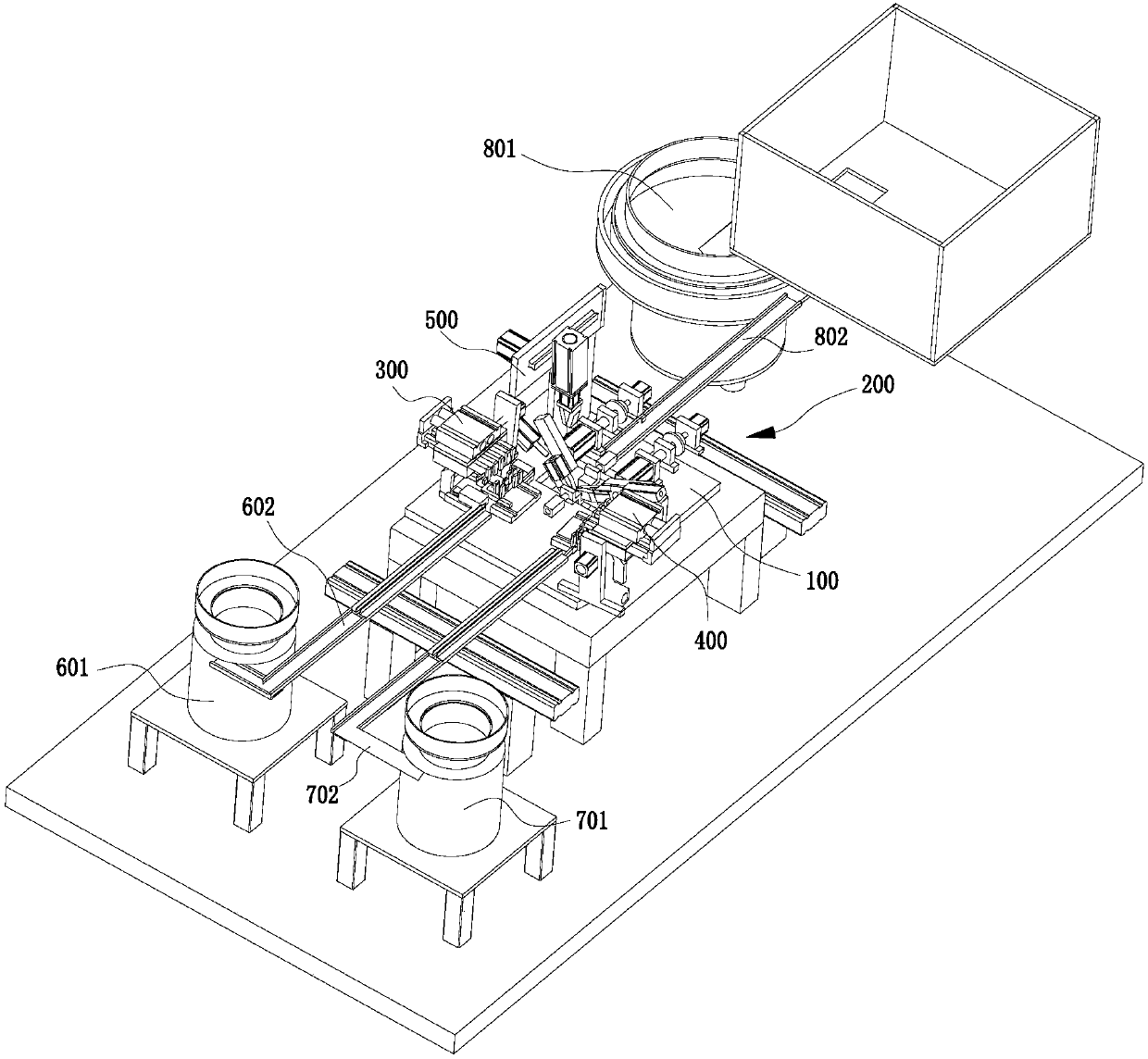

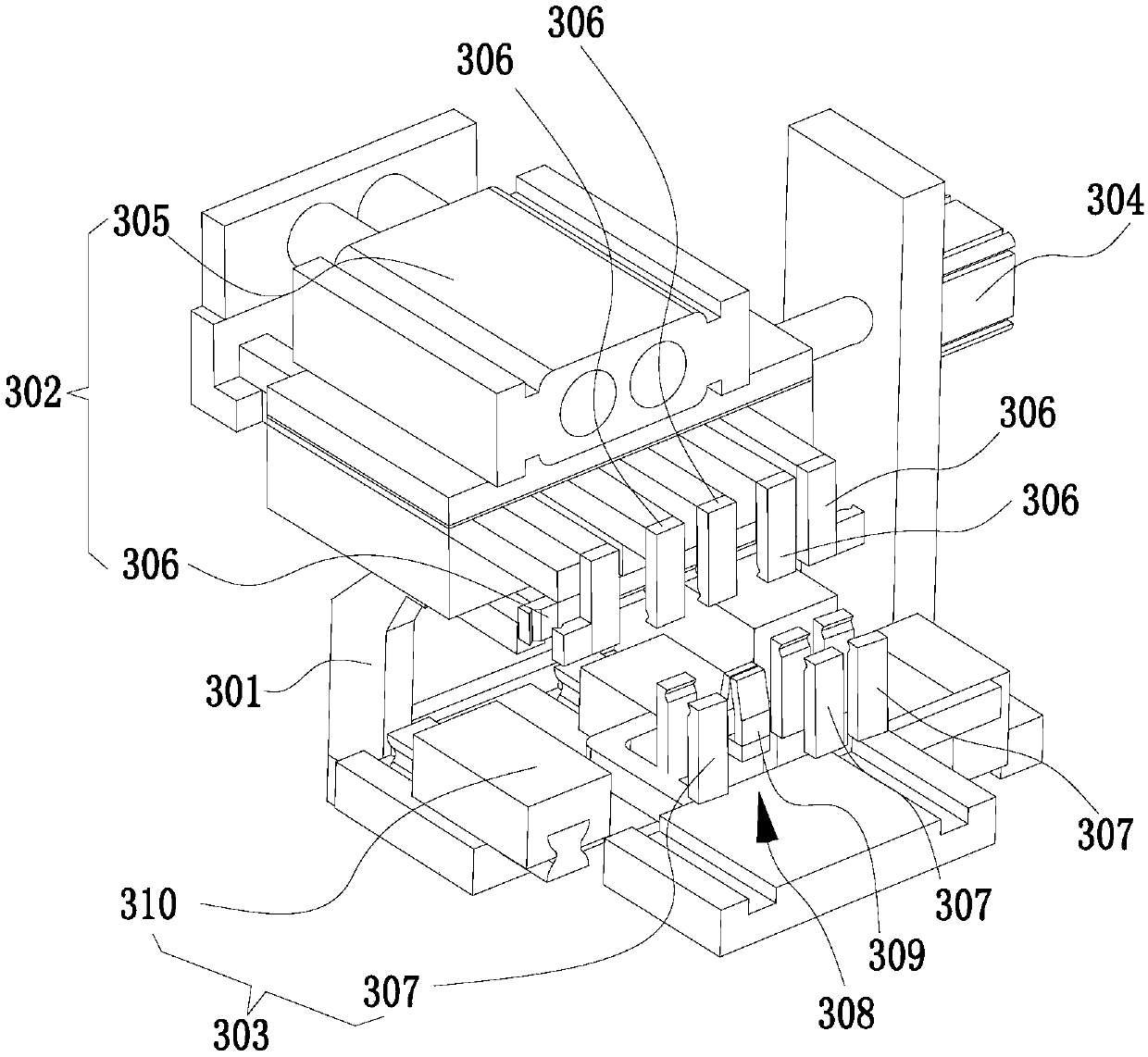

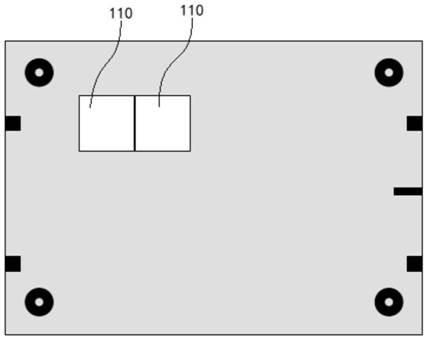

Automatic plug-in mounting device for pair-tube bases of photoelectric detectors

PendingCN108032059AThe same installation orientationImprove yieldMetal working apparatusPhotovoltaic detectorsTransfer procedure

The invention relates to the technical field of automation equipment and provides an automatic plug-in mounting device for pair-tube bases of photoelectric detectors. The automatic plug-in mounting device comprises a support platform, a symmetrical plug-in mounting device, a left detection conveying device, a right detection conveying device and a transferring device, wherein emitting diodes are transmitted to the symmetrical plug-in mounting device through the left detection conveying device; in the transmitting process, the positive and negative poles of the emitting diodes are detected, andreversing is carried out so as to ensure the mounting directions of all emitting diodes at the part of the symmetrical plug-in mounting device are consistent; receiving diodes are transmitted to thepart of the symmetrical plug-in mounting device through the right detection conveying device; in the transmitting process, the positive and negative poles of the receiving diodes are detected, and reversing is carried out so as to ensure the mounting directions of all receiving diodes at the part of the symmetrical plug-in mounting device are consistent; and base bodies are transmitted to the partof the symmetrical plug-in mounting device through the transferring device, and the emitting diodes and the receiving diodes are symmetrically plugged onto the base bodies by utilizing the symmetrical plug-in mounting device. The whole process adopts automatic operation, and assembly spends short time.

Owner:SHENZHEN TANDA TECH

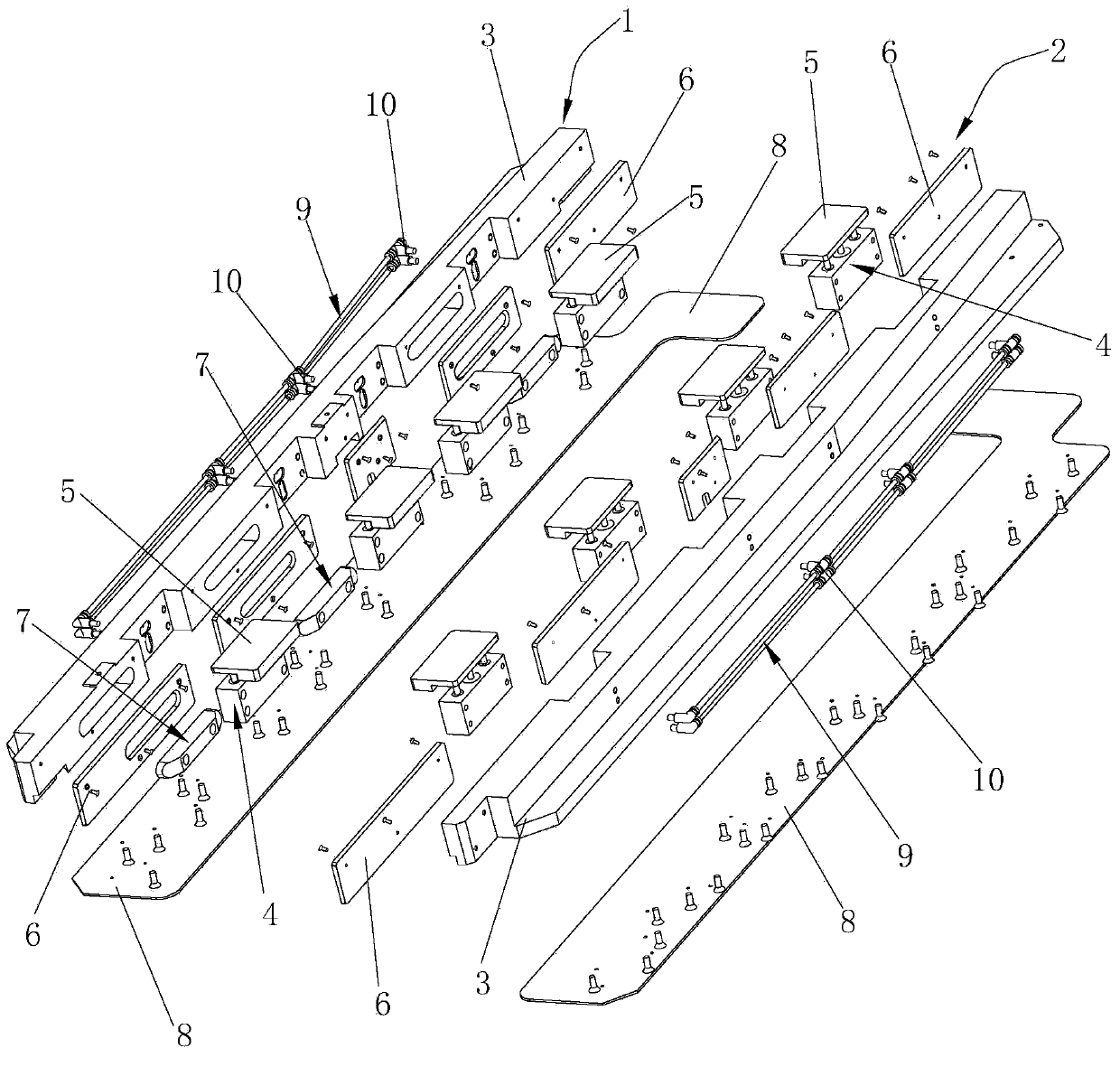

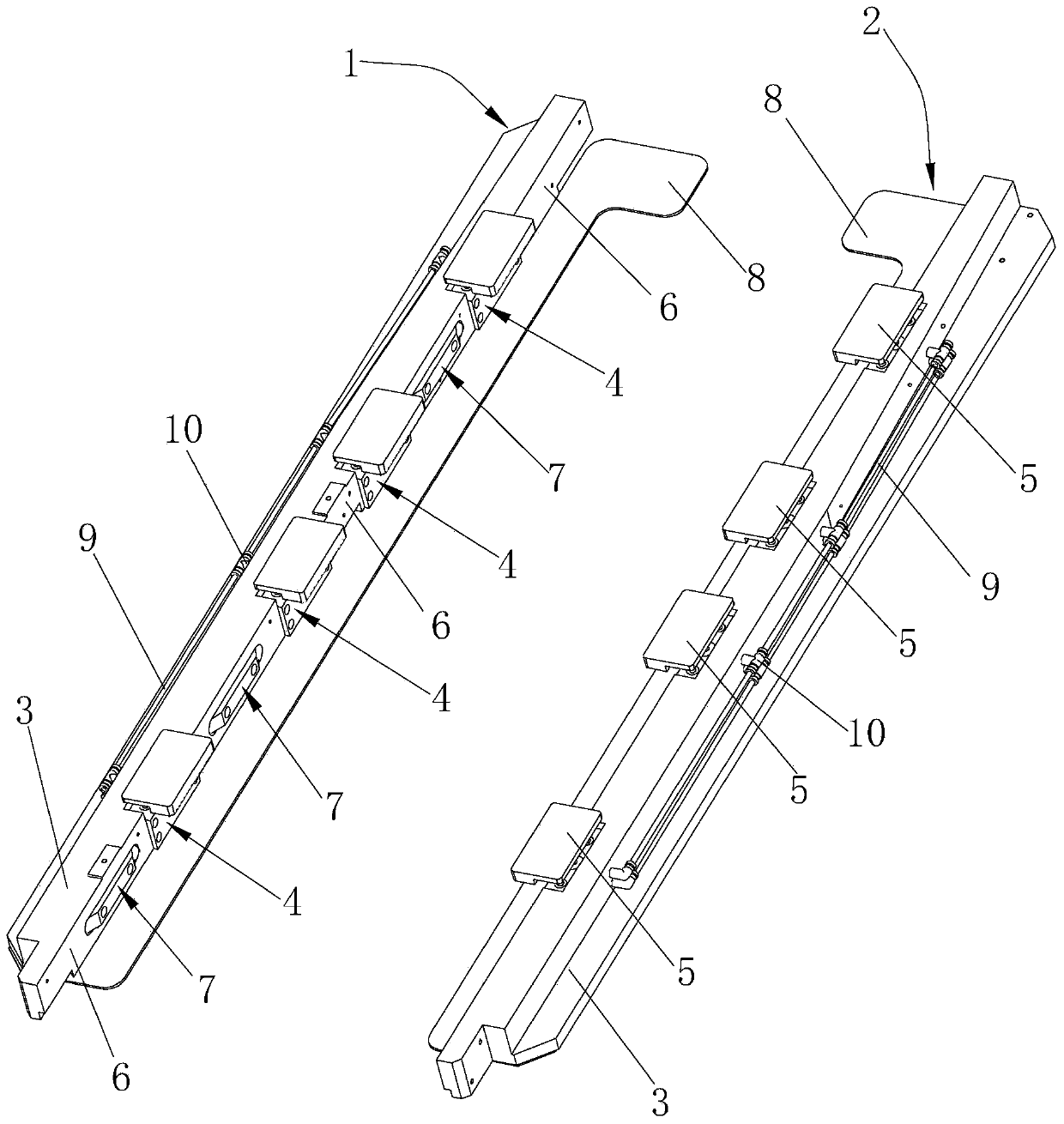

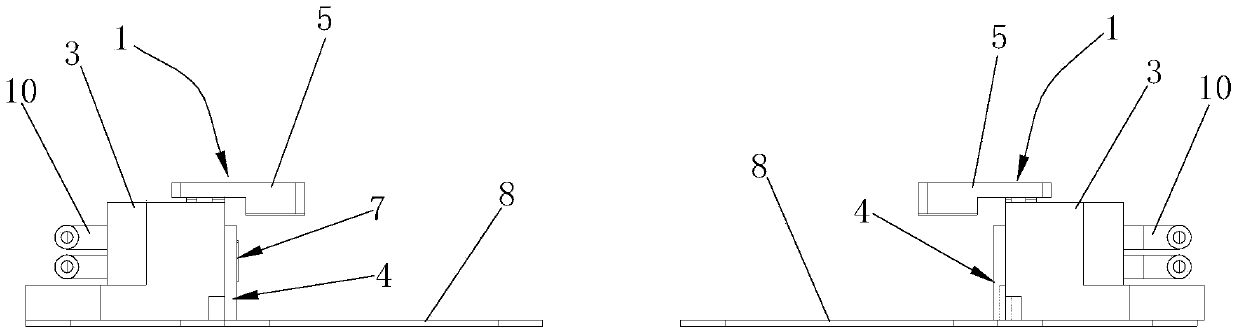

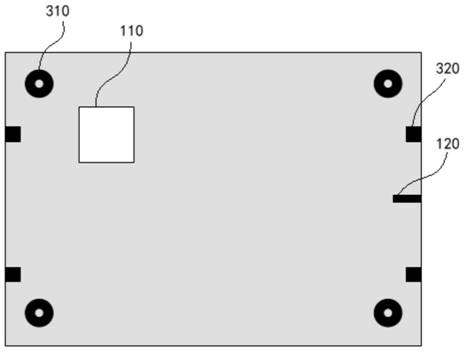

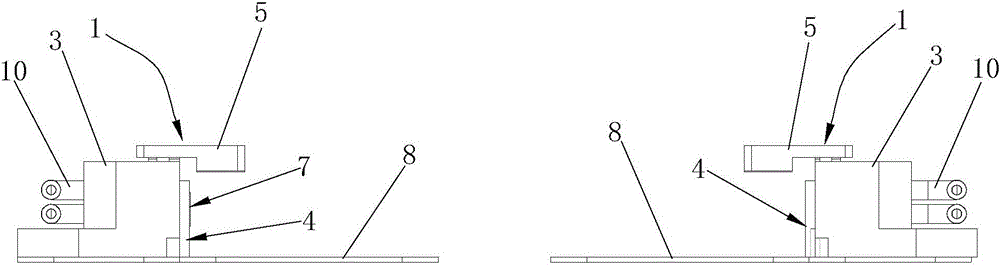

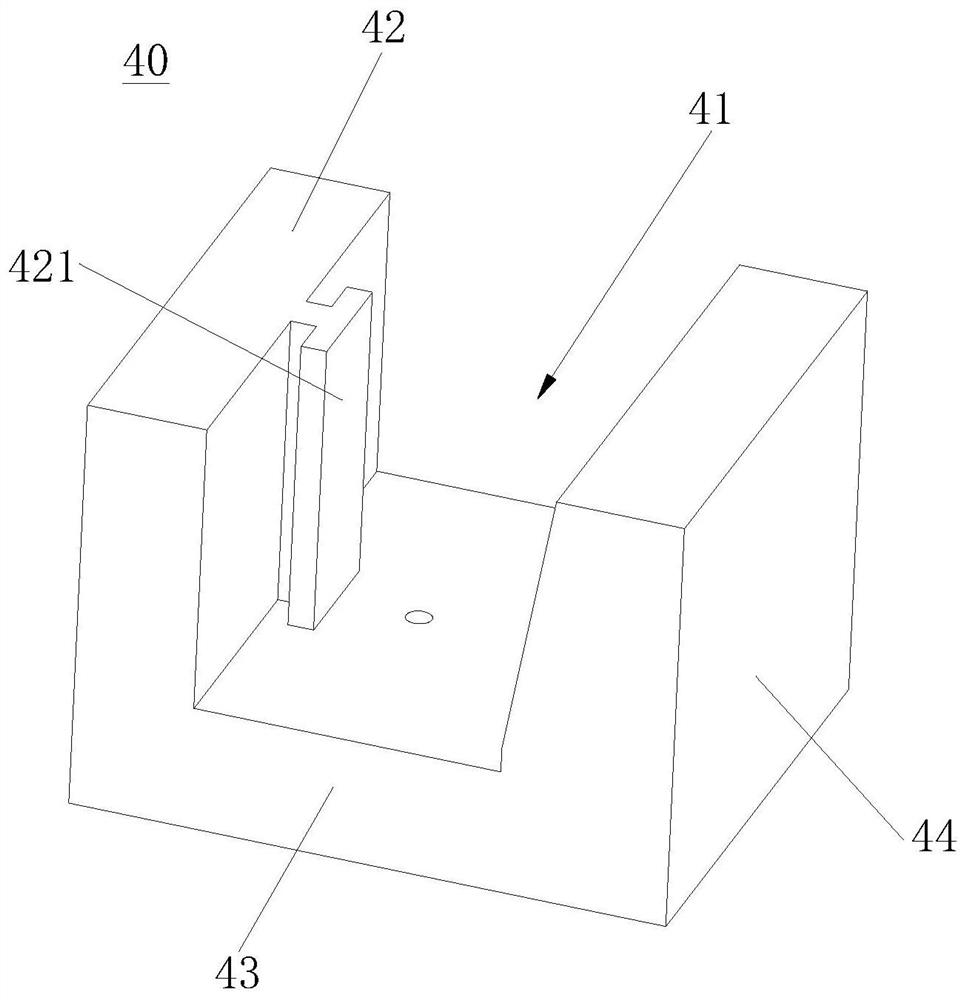

SMT printer stencil positioning device

The invention discloses an SMT printer stencil positioning device comprising a first positioning mechanism and a second positioning mechanism facing to each other. Each of the first and second positioning mechanisms comprises a stencil positioning frame, at least one compressing positioning cylinder, and a pressure plate, wherein the compressing positioning cylinders are mounted on the stencil positioning frame in an embedded manner and the pressure plate is mounted on the compressing positioning cylinders. The compressing positioning cylinders can drive the pressure plates to move up and down, thus an SMT printer stencil can be accurately positioned, positioning is highly accurate and stable, and printing precision and production efficiency are high. In addition, the compressing positioning cylinders and the pressure plates coordinate to accurately and reliably position the stencil, so that the SMT printer stencil positioning device is simple to assemble, assembly time is short, assembly efficiency is high, the SMT printer stencil positioning device is long in service life, simple to maintain later, maintenance time is short, and maintenance cost is low.

Owner:东莞市九方电子设备有限公司

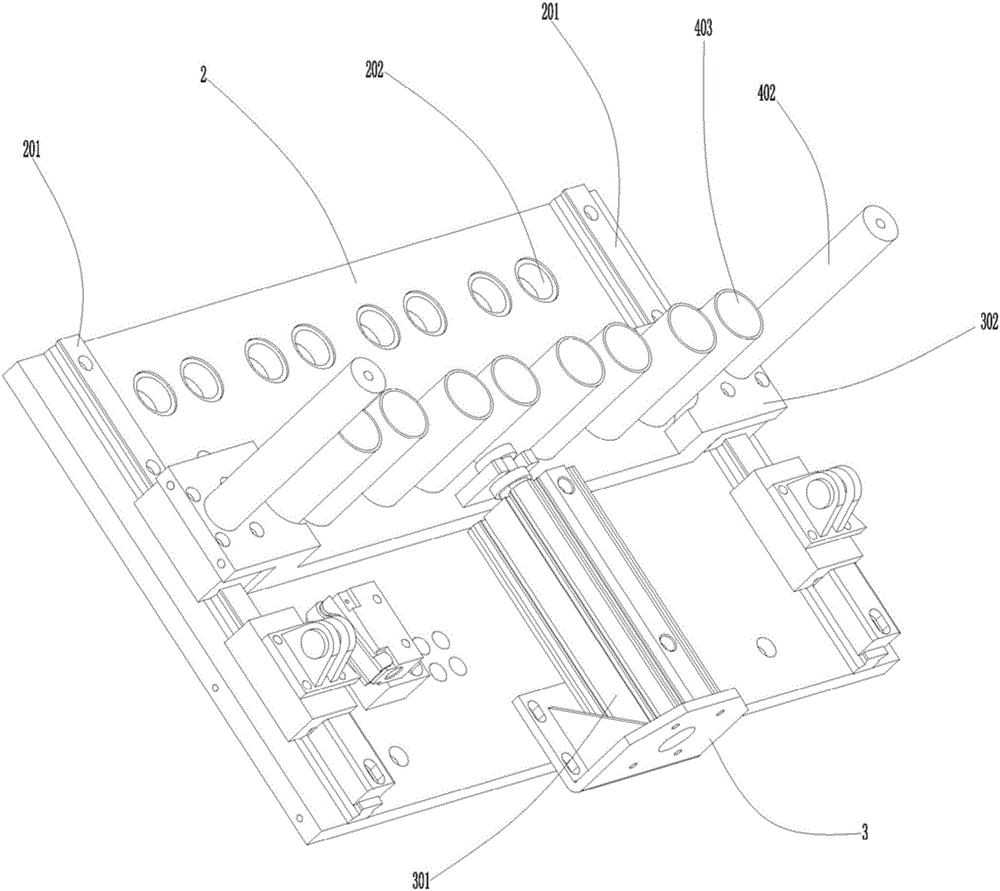

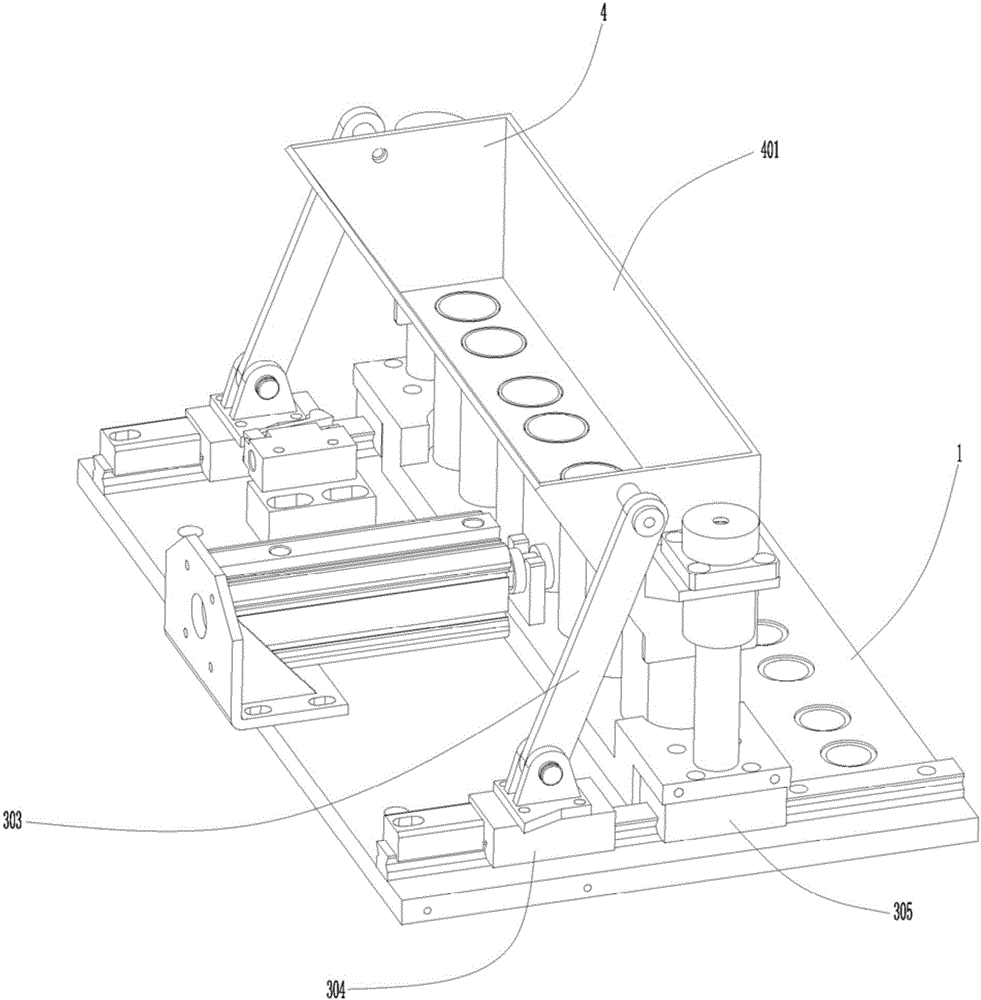

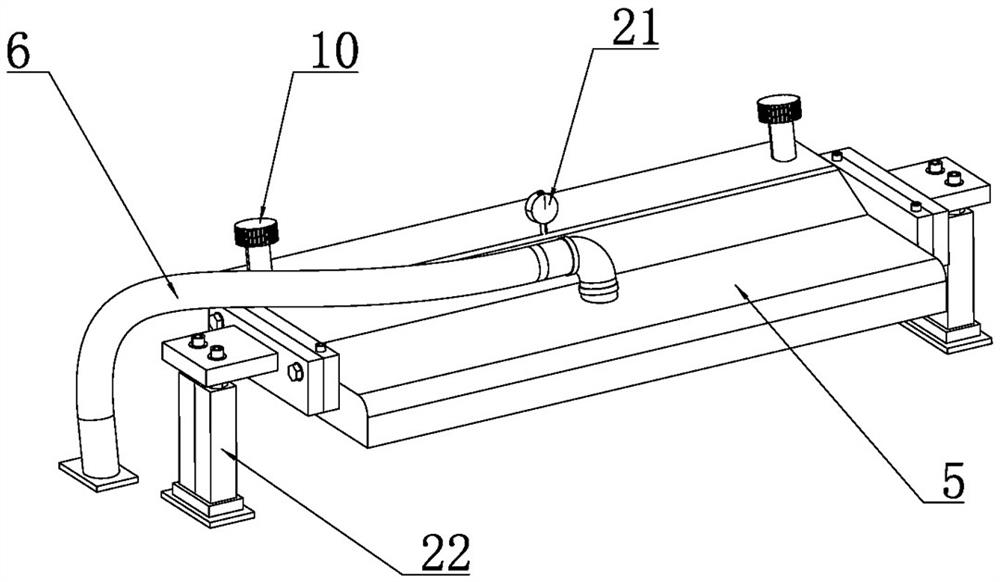

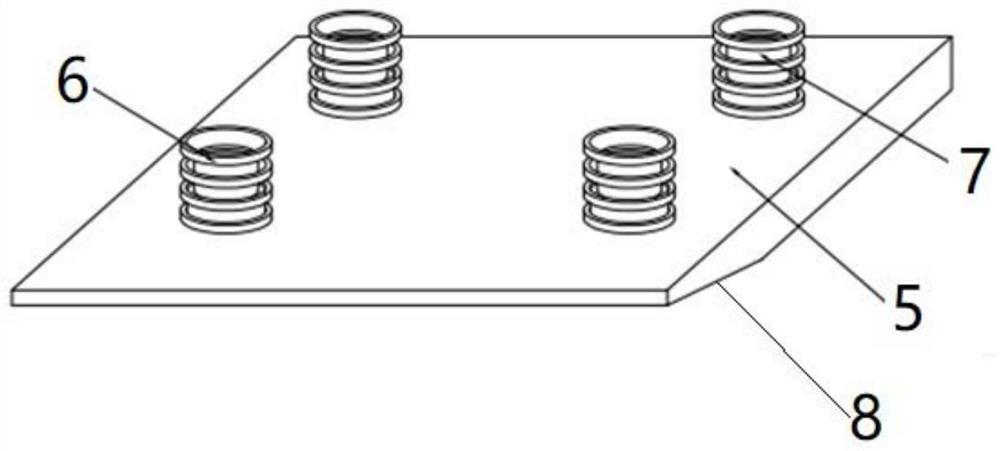

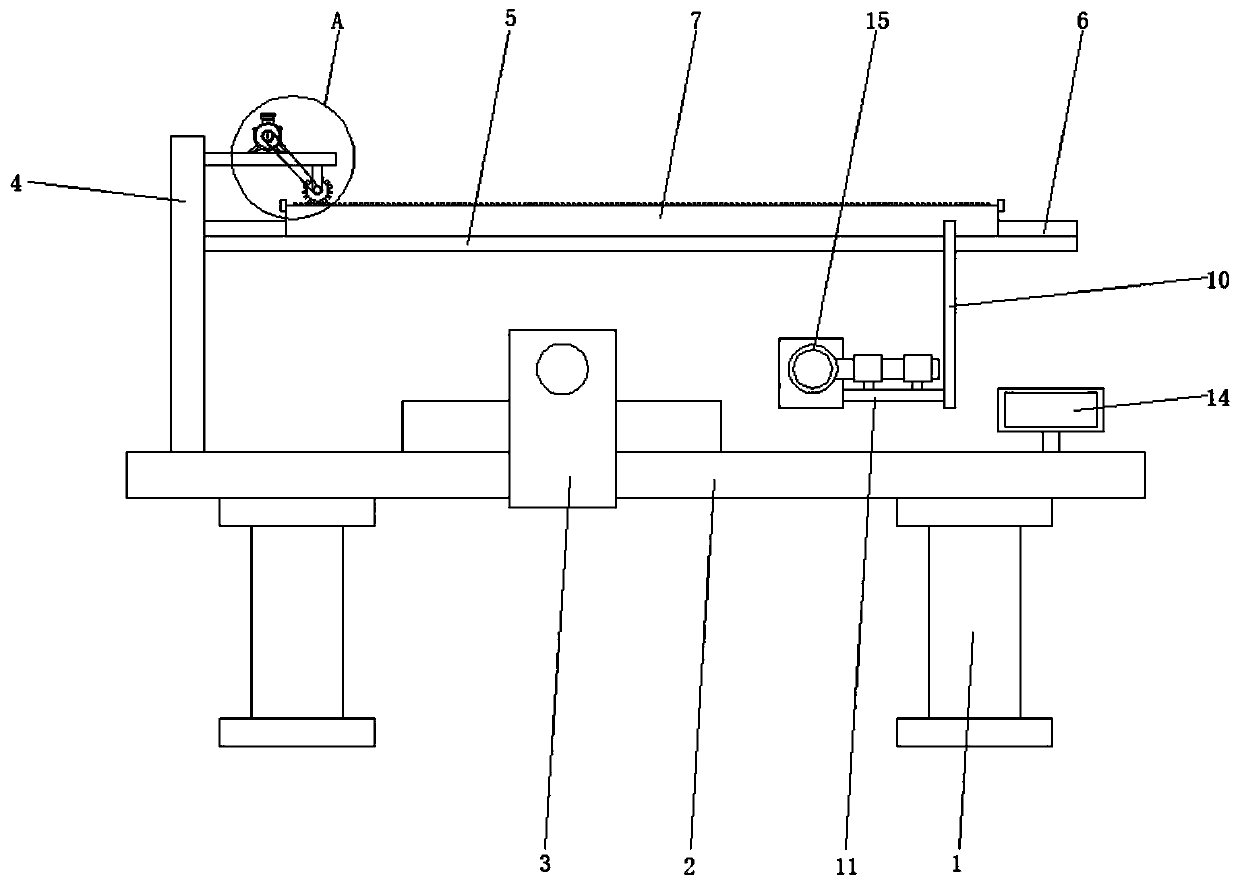

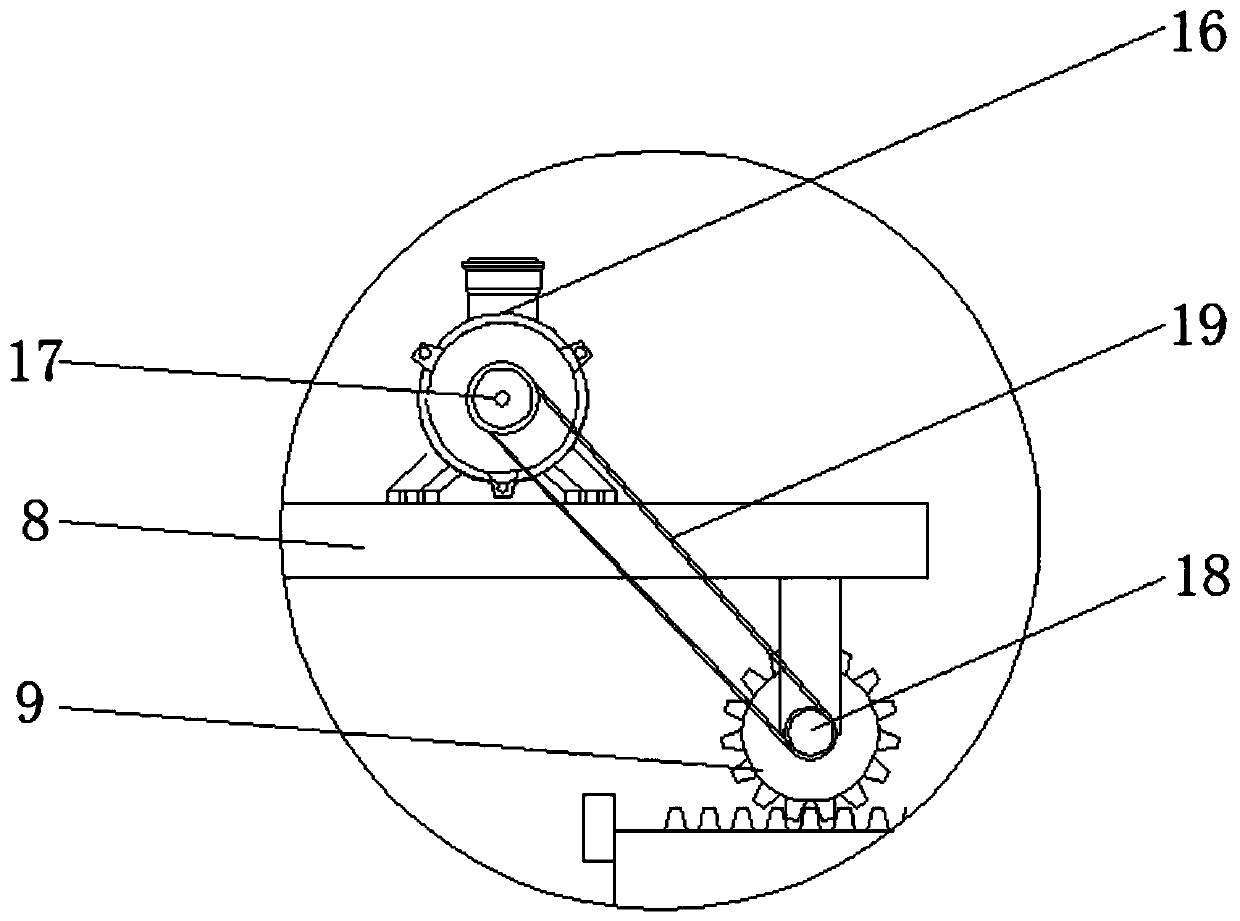

Automatic gasket ordering system

ActiveCN106736366AImplement automatic sortingAssembly time is shortMetal working apparatusEngineeringAutomatic testing

The invention provides an automatic gasket ordering system. The automatic gasket ordering system comprises an automatic ordering device which comprises a base plate, a pushing mechanism and a feeding mechanism. The base plate is provided with a slide rail and a plurality of material holes. The pushing mechanism comprises a driving device, a sliding base, a connection rod and a substrate; the driving device is fixed to the base plate, and the output end of the driving device is fixedly connected with the sliding base; the sliding base is installed on the base plate; the substrate is fixed to the slide rail, and one end of the connection rod is hinged to the substrate.; and the sliding base is provided with a plurality of lower pipe holes, and the lower pipe holes and the material holes are in one-to-one correspondence. The feeding mechanism comprises a material hopper, a stand column and a plurality of material pipes; the material pipes and the stand column are fixedly connected with the sliding base; the other end of the connection rod is hinged to the material hopper; the material pipes and the lower pipe holes are in one-to-one correspondence; and a plurality of upper pipe holes are formed in the bottom of the material hopper, the material pipes and the upper pipe holes are in one-to-one correspondence, and the material pipes penetrate through the upper pipe holes. By adoption of the automatic gasket ordering system, automatic ordering of gaskets can be achieved, and manual counting is not needed; and by adoption of automatic ordering and jig installing, the assembling consumed time of an engine is greatly saved.

Owner:DONGFENG MOTOR CO LTD

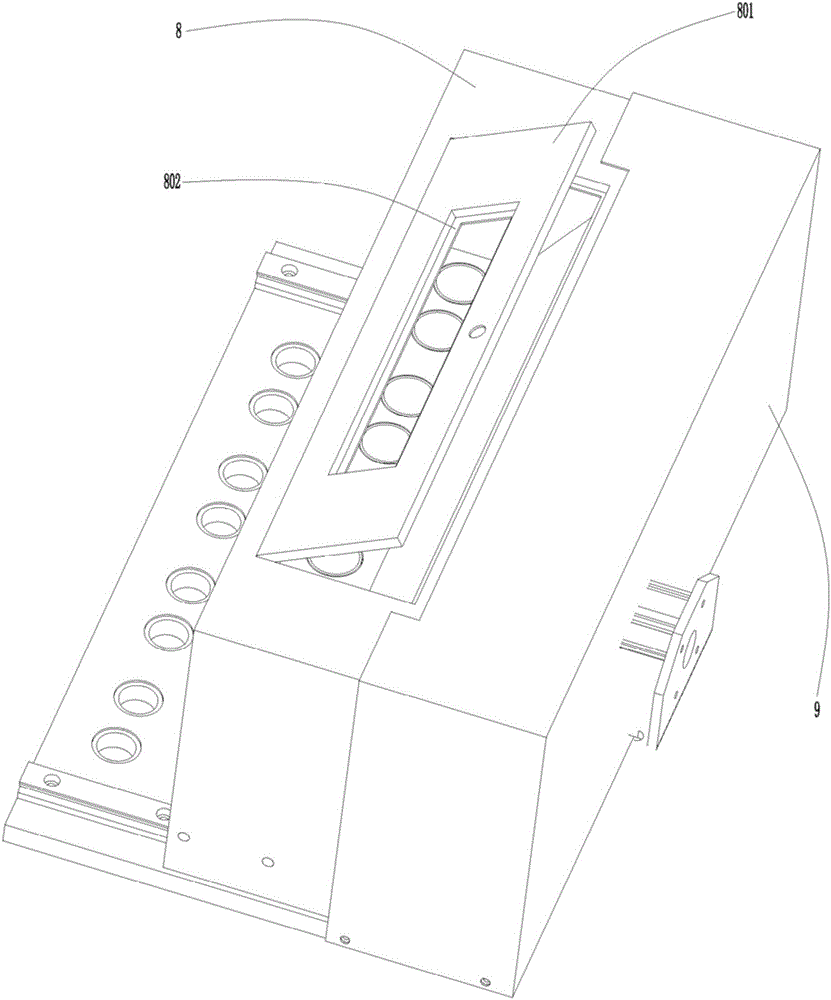

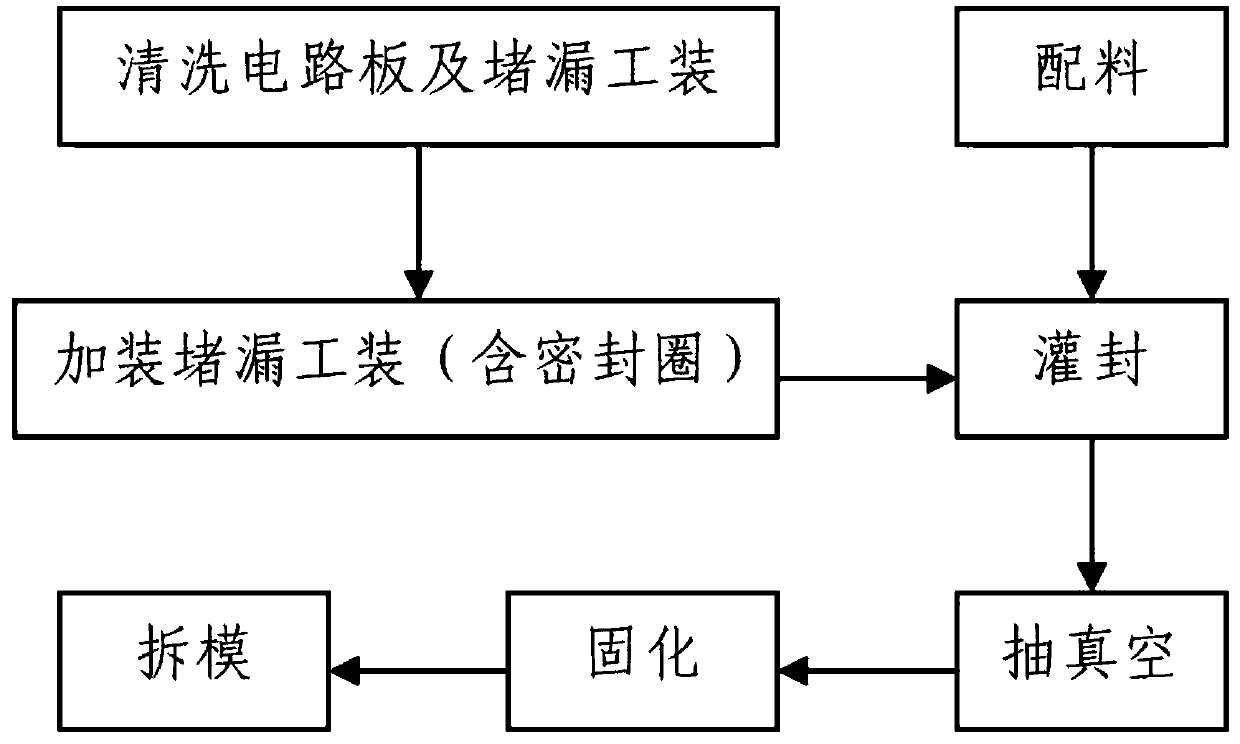

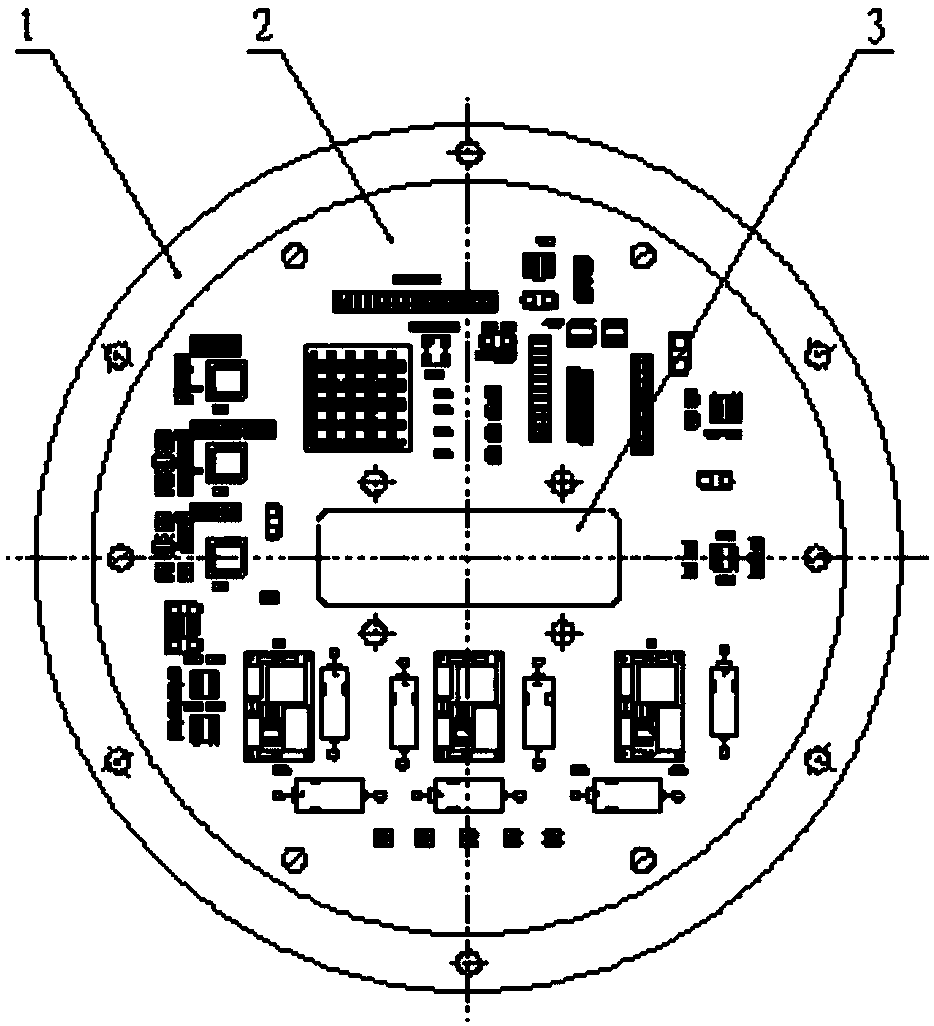

Electronic product encapsulation device and method

InactiveCN109590159AAssembly time is shortShort processing timePretreated surfacesCoatingsBiomedical engineeringFlange

The invention provides an electronic product encapsulation device. The encapsulation device comprises a plugging tool, and the plugging tool is of a flange structure. A circuit board is fixedly arranged in a box body, a through cavity is formed in the middle of the circuit board, and a concave platform is arranged on the back face of the box body. The main body part of the plugging tool is matchedwith the through cavity structure, and the flange part is matched with the concave platform structure. According to the electronic product encapsulation device , the process time is short, the reliability of the circuit board and the device is improved, the production efficiency is improved, the cost is reduced, and the filling performance and the safety of product are improved.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH CO LTD

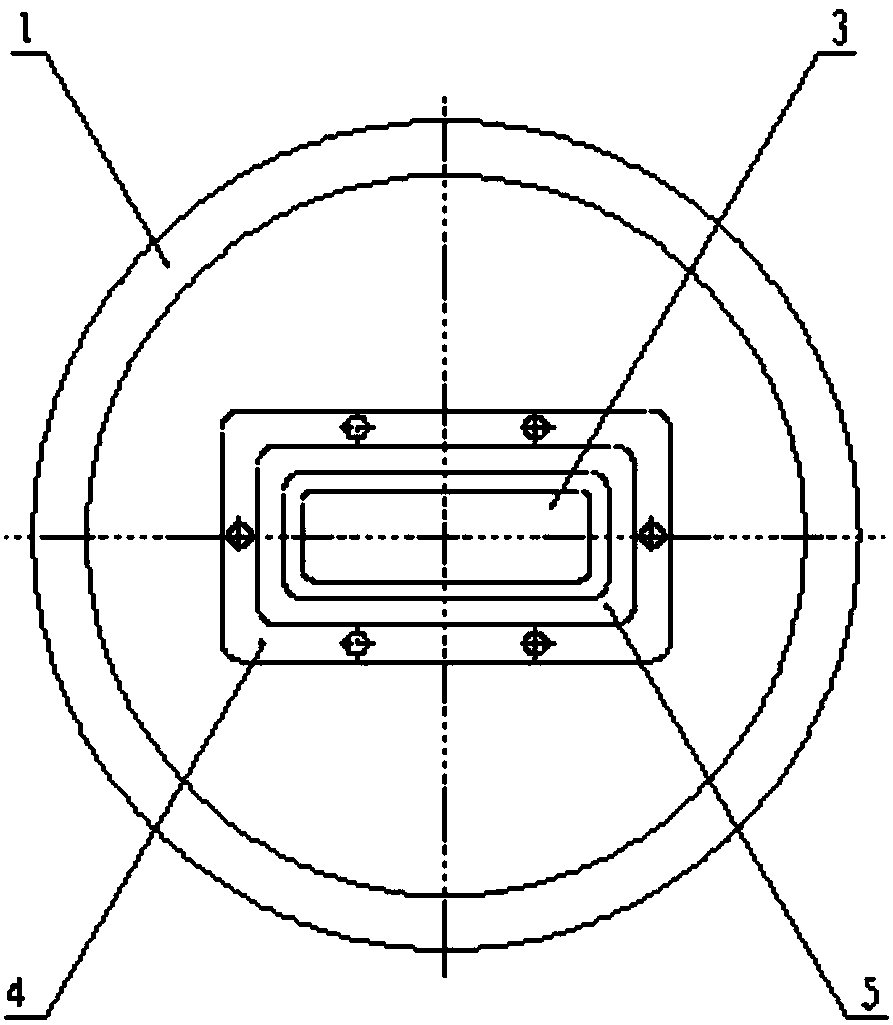

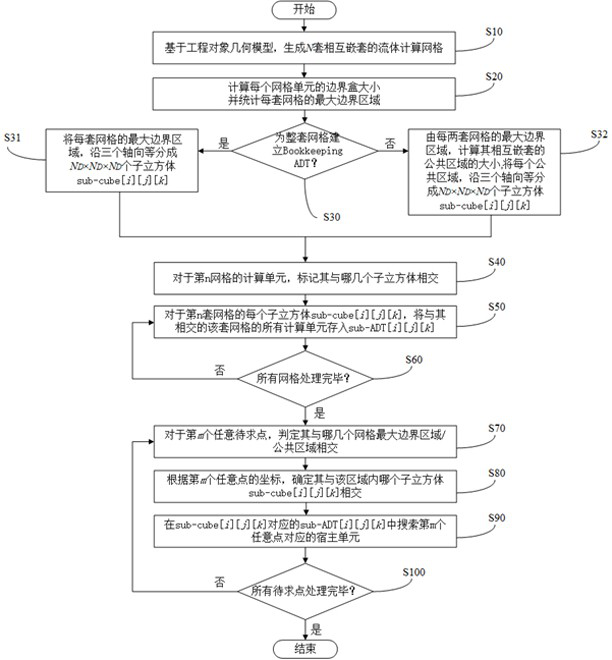

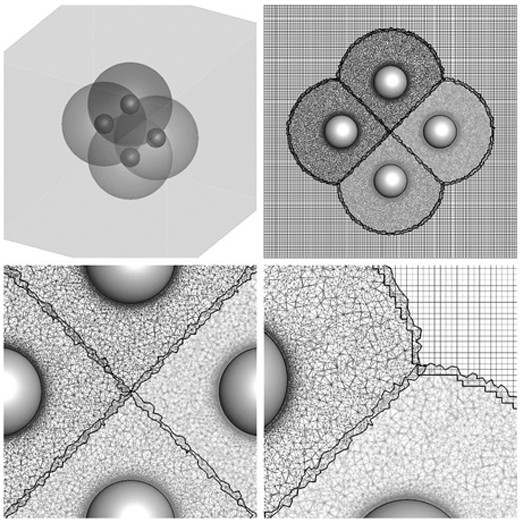

Efficient nested grid host unit searching method in aircraft dynamic flow field analysis

ActiveCN114119882AReduce depthGood balanceSustainable transportationDesign optimisation/simulationFlight vehicleMesh point

The invention provides an efficient nested grid host unit searching method in dynamic flow field analysis of an aircraft, which comprises the following steps of: creating more than one sub-ADT tree of a series for grid units in a given area, and registering storage addresses of the sub-ADT trees to a register book in an array form; firstly, grid points to be checked are freeze-framed on sub-ADT corresponding to a specific local area according to coordinate positions of the grid points to be checked, then corresponding host units of the grid points to be checked are searched in a conventional ADT mode, and therefore multiple sets of mutually-nested grids are assembled, and aircraft dynamic motion flow field analysis is carried out. According to the method, the depth of each sub ADT is greatly reduced, so that each sub ADT tree structure has better balance, meanwhile, the to-be-searched point is quickly positioned to a very small local area, the area range searched by the host unit is reduced, the search time is effectively reduced, and the numerical simulation time of the dynamic motion process of the aircraft is shortened.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

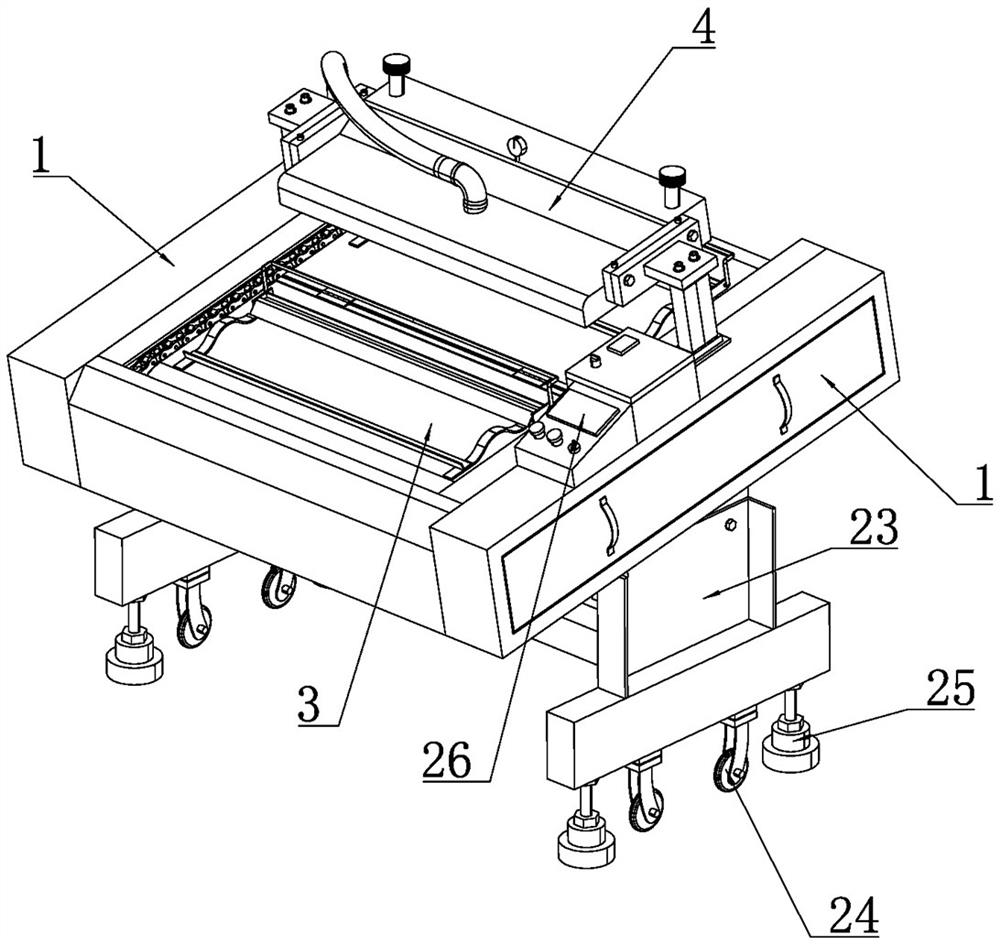

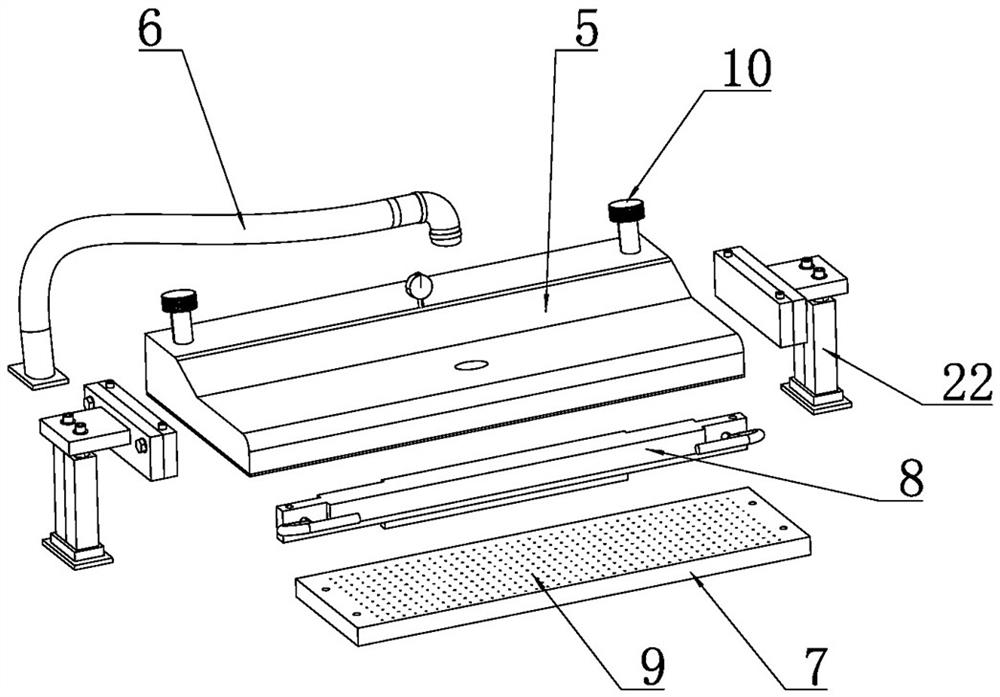

Rolling vacuum body-fitted shaping packaging machine

PendingCN111824497AAvoid breakingImprove fitPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringPhysics

The invention provides a rolling vacuum body-fitted shaping packaging machine, and belongs to the technical field of mechanical packaging equipment. The problem that a packaging bag with gaps inside is prone to breakage due to the fact that the bag face of an existing packaging bag cannot be effectively attached to the surface of a product in the air exhaust process is solved. The rolling vacuum body-fitted shaping packaging machine comprises a box body, a mounting plate, a conveying device and a heat sealing device, wherein the heat sealing device comprises a vacuum plate, a vacuum pipeline,a hot melting plate and a heat sealing rod, the interior of the vacuum plate is of a cavity structure to form a vacuum chamber, the vacuum pipeline is located at the top of the vacuum plate and communicates with the vacuum chamber, and the hot melting plate is fixed into the vacuum plate through screws; a panel of the hot melting plate is provided with a plurality of rows of vertically-through airholes, a heat pipe is installed in the hot melting plate to achieve heat transfer, and the heat sealing rod is located behind the hot melting plate and fixed in the vacuum plate through adjusting knobs arranged at the two ends of the heat sealing rod. The packaging bag provided by the invention has the advantages that the packaging bag can be better attached to the surface of a product, and the sealing performance of the bag opening is better.

Owner:温岭市鼎丰包装厂(普通合伙)

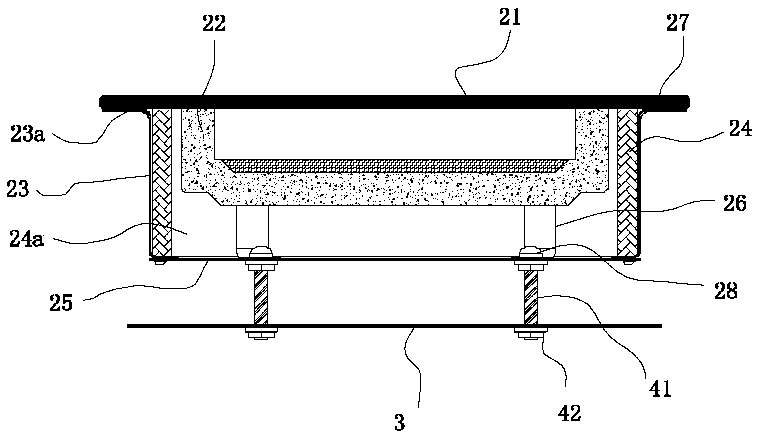

Baseplate structure for refrigerator

ActiveCN106839612ALow costSimplified installation stepsDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention discloses a baseplate structure for a refrigerator, and relates to the technical field of refrigeration equipment. A refrigerator shell, a baseplate assembly and a compressor baseplate are in assembly connection by rotary fixed buttons. The baseplate assembly is arranged at the bottom of the refrigerator shell through a clamping groove; two groups of supports being of platy structures and strip-shaped supporting side supports are respectively arranged at the two sides of a baseplate to form the baseplate assembly; the fixed buttons are arranged at the bottom of the baseplate assembly; a linear hole is formed in the compressor baseplate; the fixed buttons sequentially pass through a space-keeping hole and the linear hole, then rotate by 90 degrees and are fixed by clamping; the compressor baseplate is fixed at the bottom of the refrigerator shell. Compared with a traditional bolt fixed mode, the baseplate structure has the beneficial effects that the cost of materials is low; installation steps are simple; the assembly labor hour is short; the production efficiency is high; a cavity is formed between the refrigerator shell and the baseplate assembly and can be filled with a foaming material; the impact resistance performance of the refrigerator is improved; the damage of the refrigerator due to falling and impacting is reduced; the baseplate structure is simple in structure, low in cost, convenient to produce and manufacture and suitable for modernized volume production.

Owner:CHANGHONG MEILING CO LTD

Piston type nut locking device

ActiveCN109483213AScrew in accuratelyImprove versatilityMetal working apparatusPneumatic toolEngineering

The invention discloses a piston type nut locking device. The piston type nut locking device comprises a nut absorbing part, a piston part, a lengthening rod part, and a connector part used for beingconnected with an external electric / pneumatic tool. The piston part drives the nut absorbing part to move when moving. During mounting, the nut absorbing part attracts a hex nut to align a screw for penetrating. The piston part is in the original state at this moment. The hex nut is jacked onto the screw, the external electric / pneumatic tool is started to drive the piston type nut locking device to rotate. The hex nut is screwed into the screw, the top of the screw jacks upwards, and the piston part is in the compression state. When the hex nut is locked, a clutch of the external electric / pneumatic tool is separated and turned off, so that the piston type nut locking device is separated from the screw, and the piston part reverts to the original state. The piston type nut locking device has the advantages that the assembling time is shortened, assembling efficiency is improved, assembling difficulty is lowered, and the piston type nut locking device is suitable for mounting nuts in mounting environments with different mounting depths.

Owner:NINGBO HAIMAIKE AUTOMATION TECH CO LTD

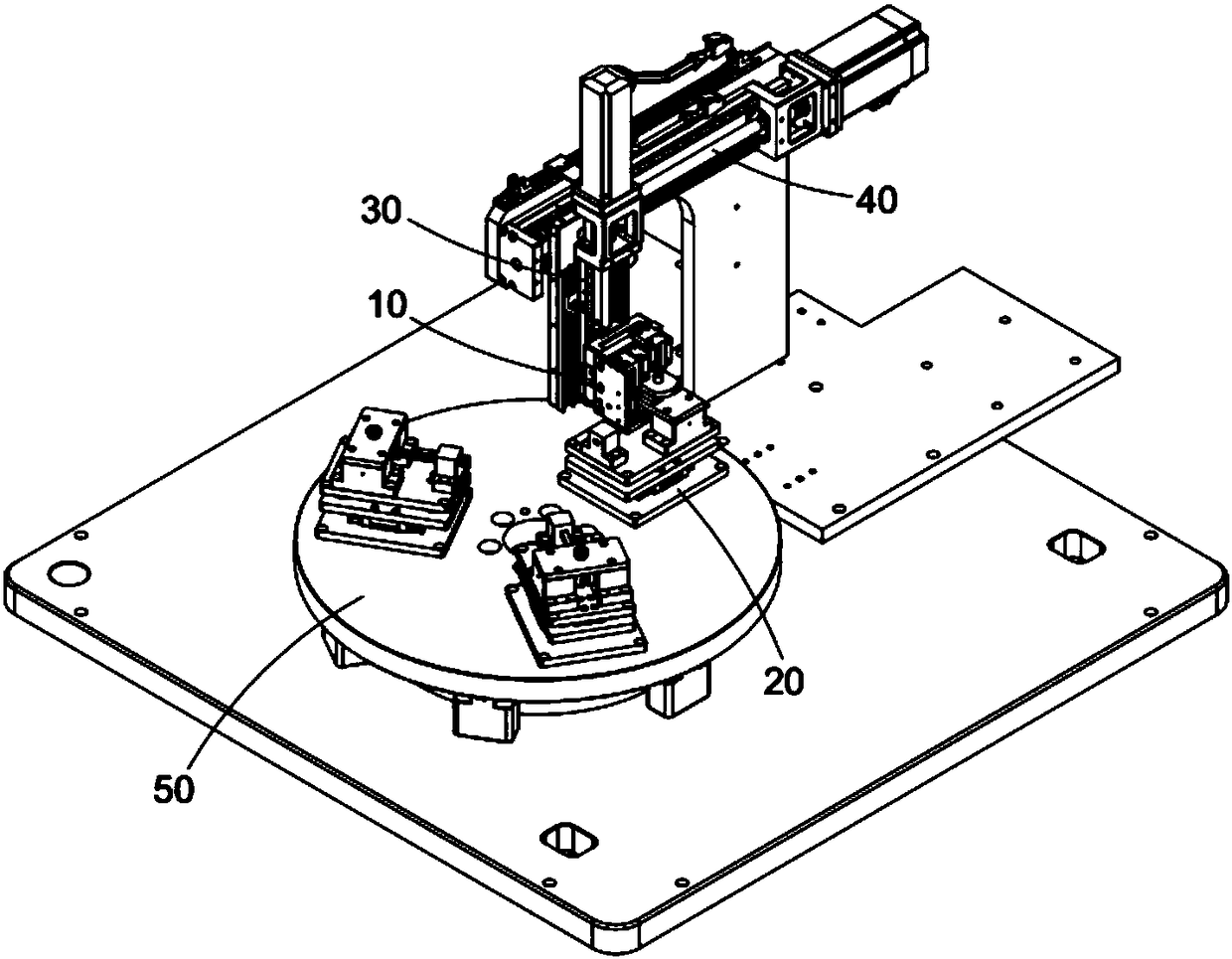

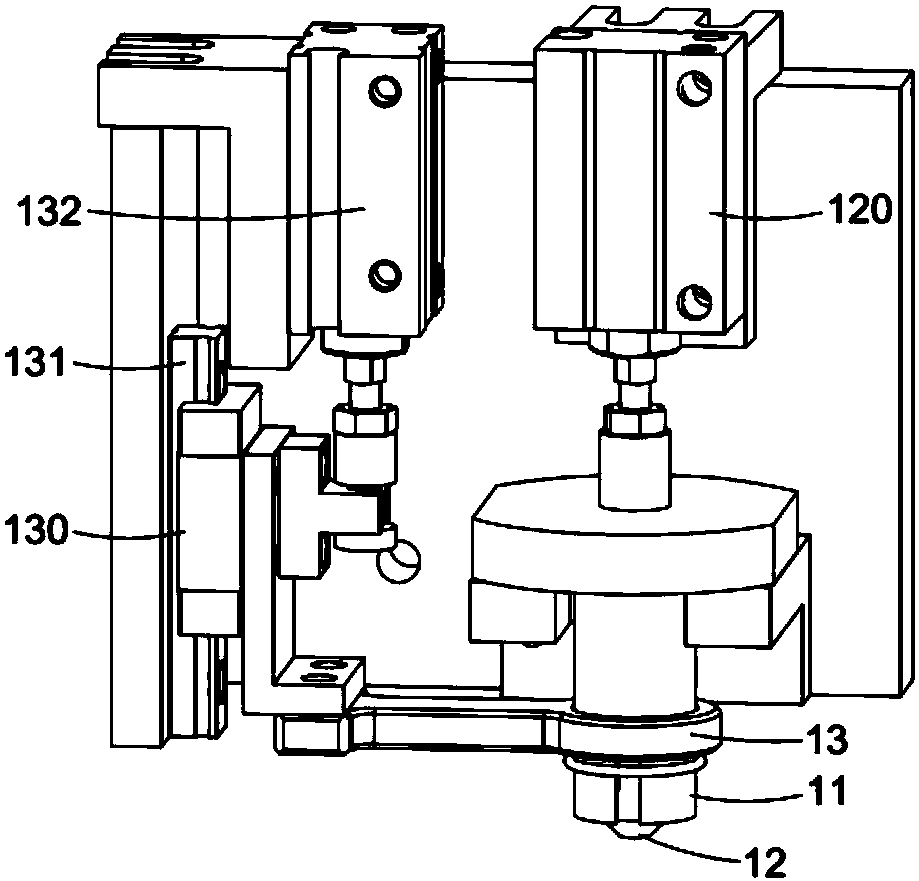

Multifunctional manipulator and rotating platform

ActiveCN109227080AAvoid Scrap SituationsHigh precisionMetal working apparatusManipulatorEngineeringOblique angle

The invention relates to the field of automated assembly equipment, in particular to a multifunctional manipulator and a rotating platform. The multifunctional manipulator and the rotating platform comprise a hole alignment detection device and a C-axis rotating anti-backlash device, the hole alignment detection device comprises four distance measuring sensors annularly and uniformly arrayed at ashaft part of the upper end of a workpiece, an X-axis feeding device is mounted on the C-axis rotating anti-backlash device, a Y-axis feeding device is mounted on the X-axis feeding device, a Z-axis lifting device is mounted on the Y-axis feeding device, a clamping device is mounted on the Z-axis lifting device, and a deflection adjusting device, an oblique angle adjusting device and a rotating adjustment device are arranged at the junction between the clamping device and the Z-axis lifting device. Four-dimensional feeding and three-dimensional fine adjustment are adopted, high-precision automatic assembly of a steam generator pipe connector can be completely achieved, the time consumed for assembly is short, the precision is high, the situation that the workpiece is scrapped due to irreparable defects such as friction and crush injuries of the pipe wall is avoided, and economic losses caused by the assembly process are reduced.

Owner:CHENGDU NANFANG ELECTRONICS METER CO LTD

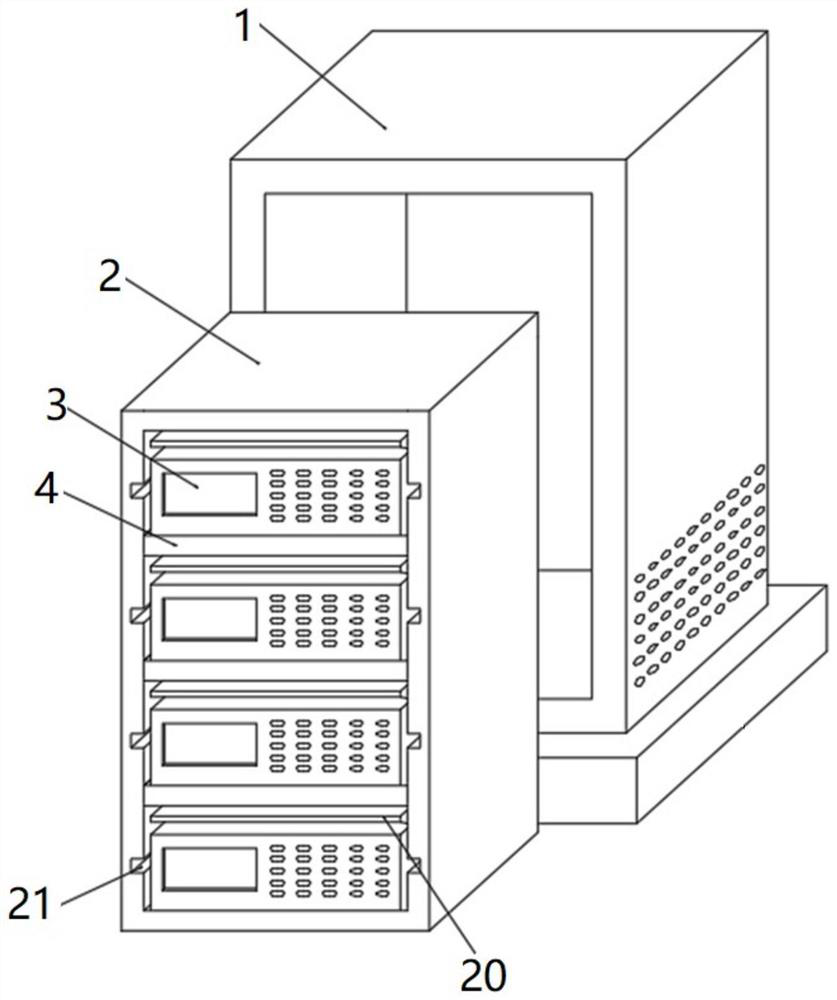

Control box, assembling method thereof and electric equipment

PendingCN111787731ACompact structureRealize heat dissipationCasings/cabinets/drawers detailsMounting boards securingEngineeringStructural engineering

The invention provides a control box, an assembling method thereof and electric equipment. The control box comprises a box body, a control assembly, a fastening structure and a radiator, wherein a limiting groove is formed in the bottom of the box body, the fastening structure is arranged in the box body and used for fastening the printed circuit board in the box body, so a distance is formed between the printed circuit board and the limiting groove, one end of the radiator is arranged in the limiting groove, and the other end of the radiator is connected with the component. The control box ismore compact in structure, the whole assembly process is simpler, the assembly time can be shortened, and the cost can be reduced.

Owner:深圳数联天下智能科技有限公司

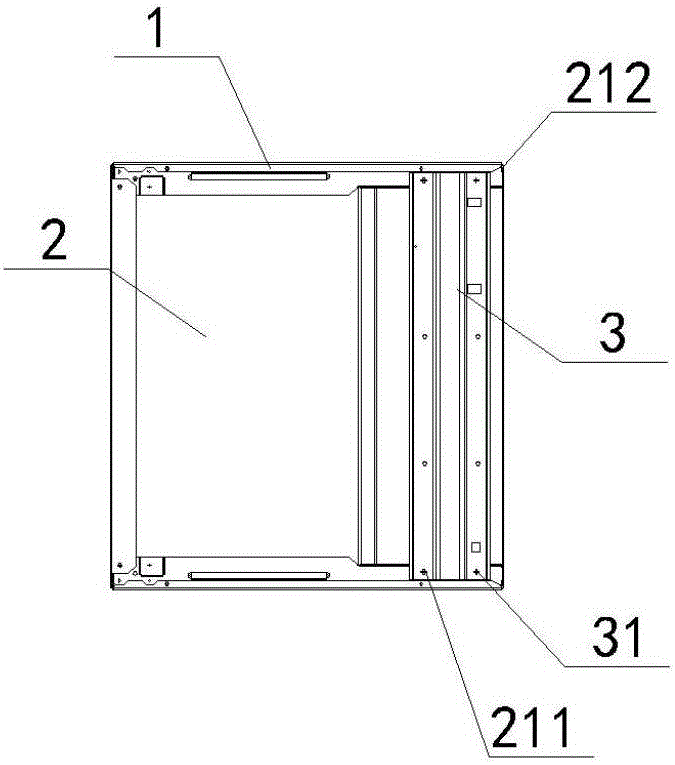

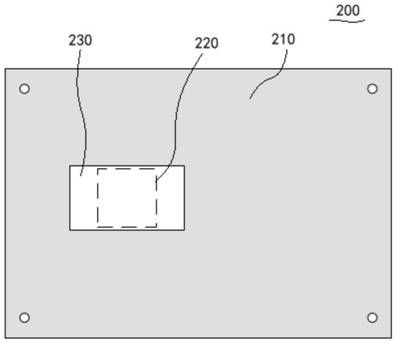

Electrical cabinet convenient to assemble

PendingCN113939133AEasy to assembleAssembly time is shortBus-bar/wiring layoutsCasings/cabinets/drawers detailsMachineElectrical element

The invention provides an electrical cabinet convenient to assemble. The electrical cabinet comprises: a machine shell; and a fixed box detachably mounted in the machine shell, wherein the fixed box is provided with a front-back through cavity, the cavity is provided with a plurality of mounting chambers which are distributed at intervals up and down, the mounting chambers are used for accommodating electrical elements, a vertically arranged first elastic assembly and a horizontally arranged second elastic assembly are arranged in the mounting chamber, the first elastic assembly is provided with a pressing plate for locking the electrical element up and down, and the second elastic assembly is provided with a clamping block for locking the electrical element front and back. According to the invention, the fixed box is installed in the inner cavity of the machine shell, then the electrical element is pushed into the mounting chamber of the fixed box, and the first elastic assembly and the second elastic assembly lock the electrical element; and the first elastic assembly and the second elastic assembly replace fasteners to fix the electrical elements, so that assembly is convenient, and assembly time is greatly shortened.

Owner:华能黑龙江发电有限公司

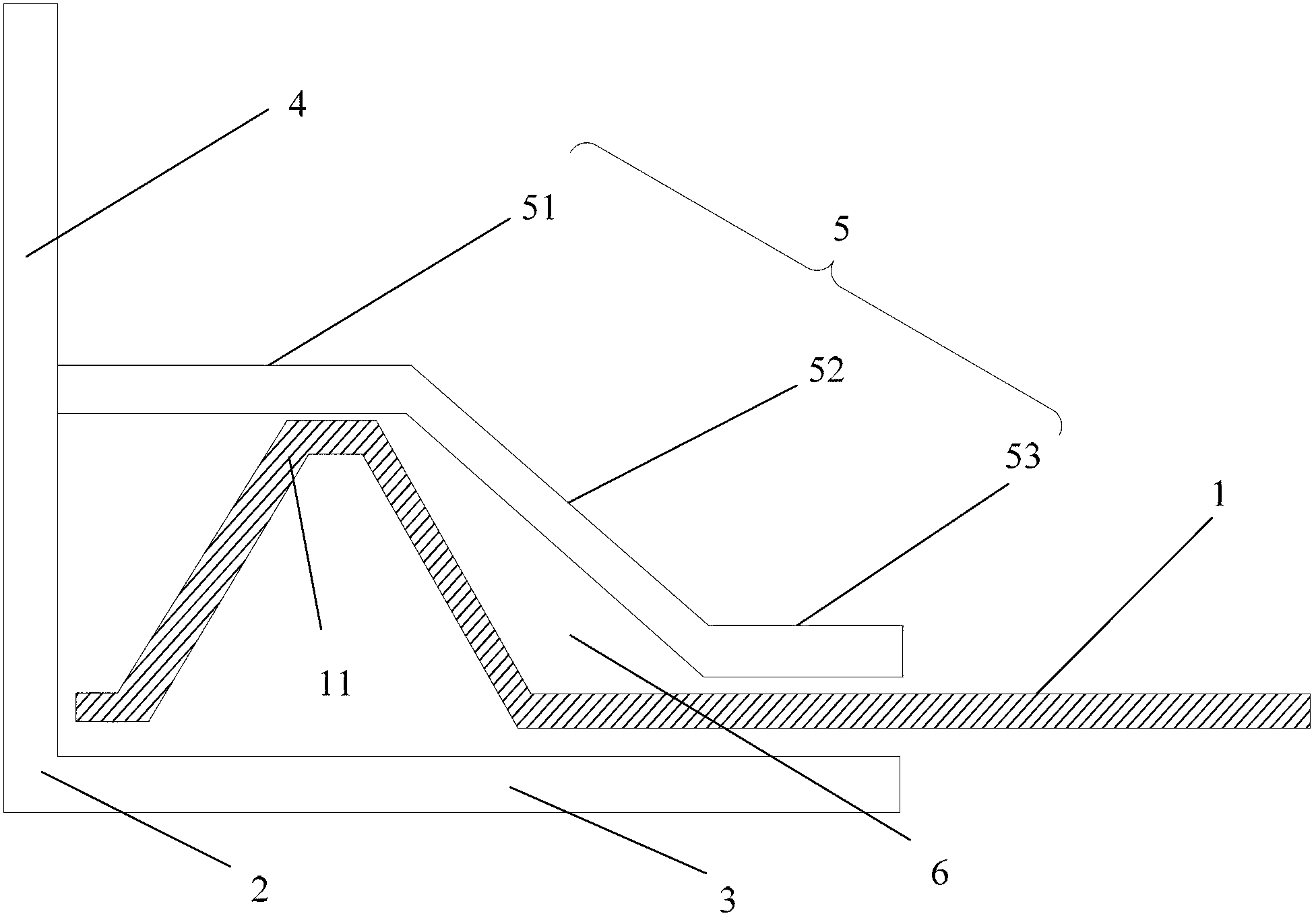

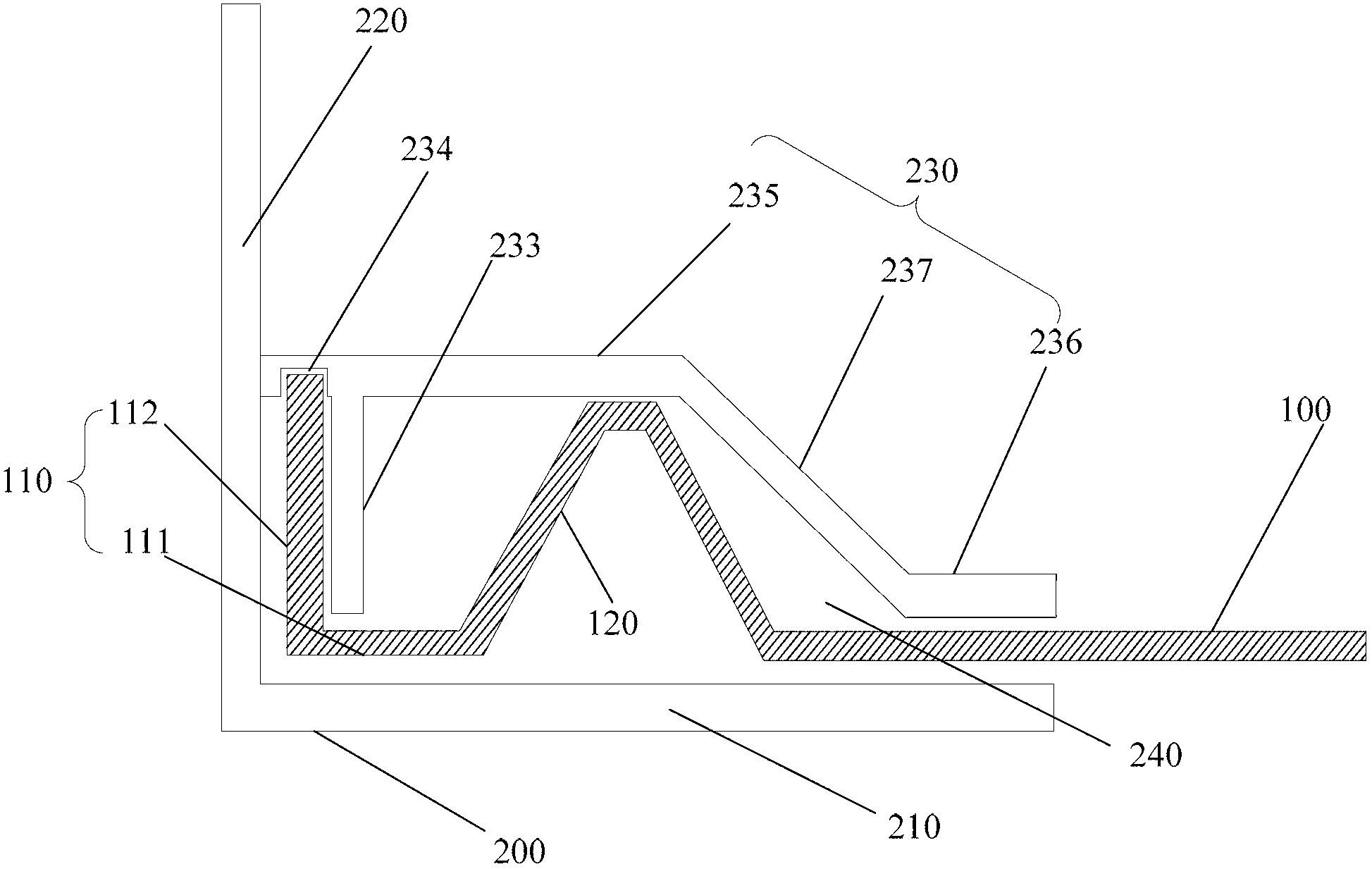

Large-size backlight module backboard splicing structure and LCD device

ActiveCN103292267ALess consumablesTo achieve the purpose of fastening installationLighting support devicesNon-linear opticsLarge sizeTime-Consuming

The invention discloses a large-size backlight module backboard splicing structure. A backboard includes a bottom flat plate, and a splicing piece spliced on the end side of the bottom flat plate; the splicing piece includes a side plate, as well as an upper support plate and a lower support plate both arranged on the same side of the side plate and vertical to the side plate; the lower bottom surface of the upper support plate, the upper top surface of the lower support plate and the side plate form a clamping mouth used for clamping the bottom flat plate; column groove assembling structures are arranged on the lower bottom surface of the upper support plate and the bottom flat plate; and fastening screws are arranged between the bottom flat plate and the splicing piece. Compared with the mounting manner in the prior art, the large-size backlight module backboard splicing structure provided by the invention has the advantages that fixing in the two-dimensional direction of the three-dimensional direction is realized, fixing in the third-dimensional direction is realized through the several screws, so that the fastened mounting is realized, working procedures are greatly reduced, consumed screws are greatly reduced, the time consumed in the assembly is shortened, and the labor efficiency is greatly improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

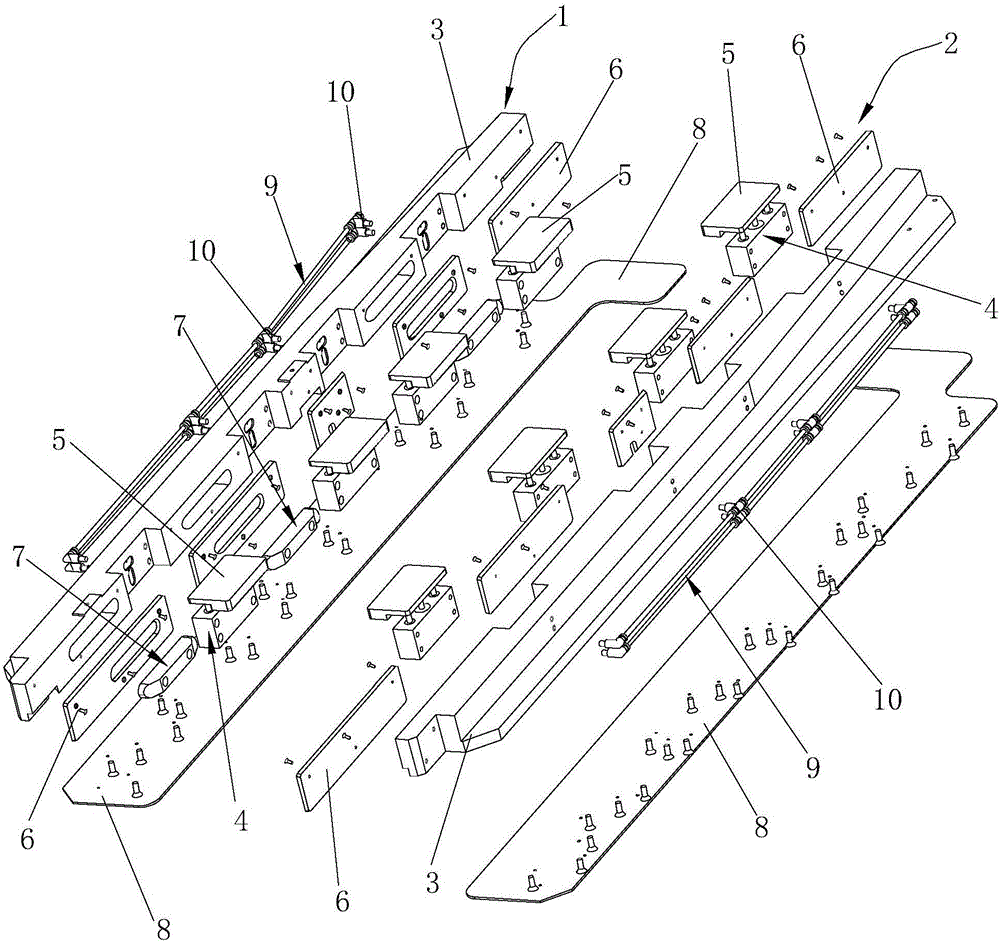

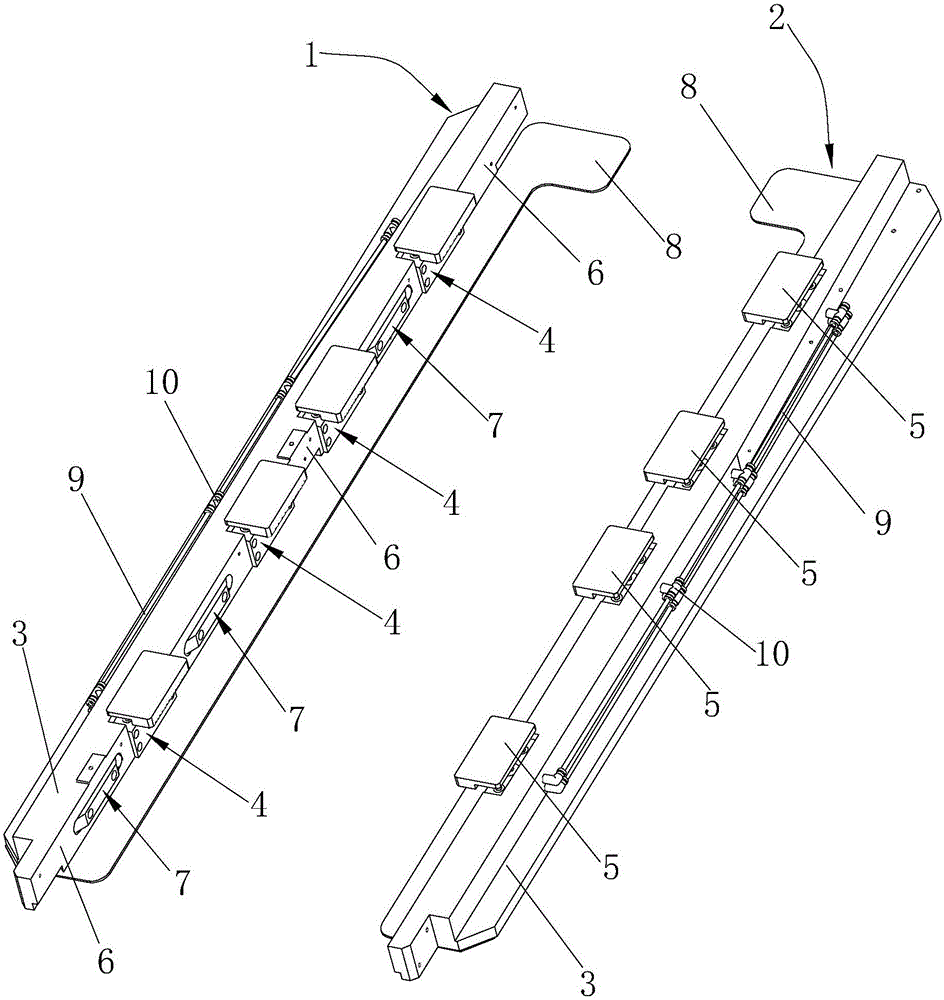

ASM adjustable steel mesh clamping device

ActiveCN106211624AImprove efficiencySimplify the assembly processPrinted circuit assemblingMechanical engineering

The invention discloses an ASM adjustable steel mesh clamping device. The device comprises a first positioning mechanism and a second positioning mechanism opposite to the first positioning mechanism. The first positioning mechanism and the second positioning mechanism both comprise a steel mesh positioning rack, a driving device erected at one end of the steel mesh positioning rack, at least one guide block erected on the steel mesh positioning rack, a transmission connection rod which is erected on the guide block and in transmission connection with the driving device, and at least one clamping unit which is erected on the steel mesh positioning rack and in transmission connection with the transmission connection rod. Each positioning mechanism only needs one driving cylinder to drive multiple clamping units to precisely position an ASM adjustable steel mesh. The device has the advantages of being high and stable in positioning precision, high in printing precision and high in production efficiency. The ASM adjustable steel mesh clamping device is very easy to assemble, assembly time is short, efficiency is high, equipment purchasing cost is low, service life is long, later maintenance is easy, and time for maintenance is short.

Owner:东莞市九方电子设备有限公司

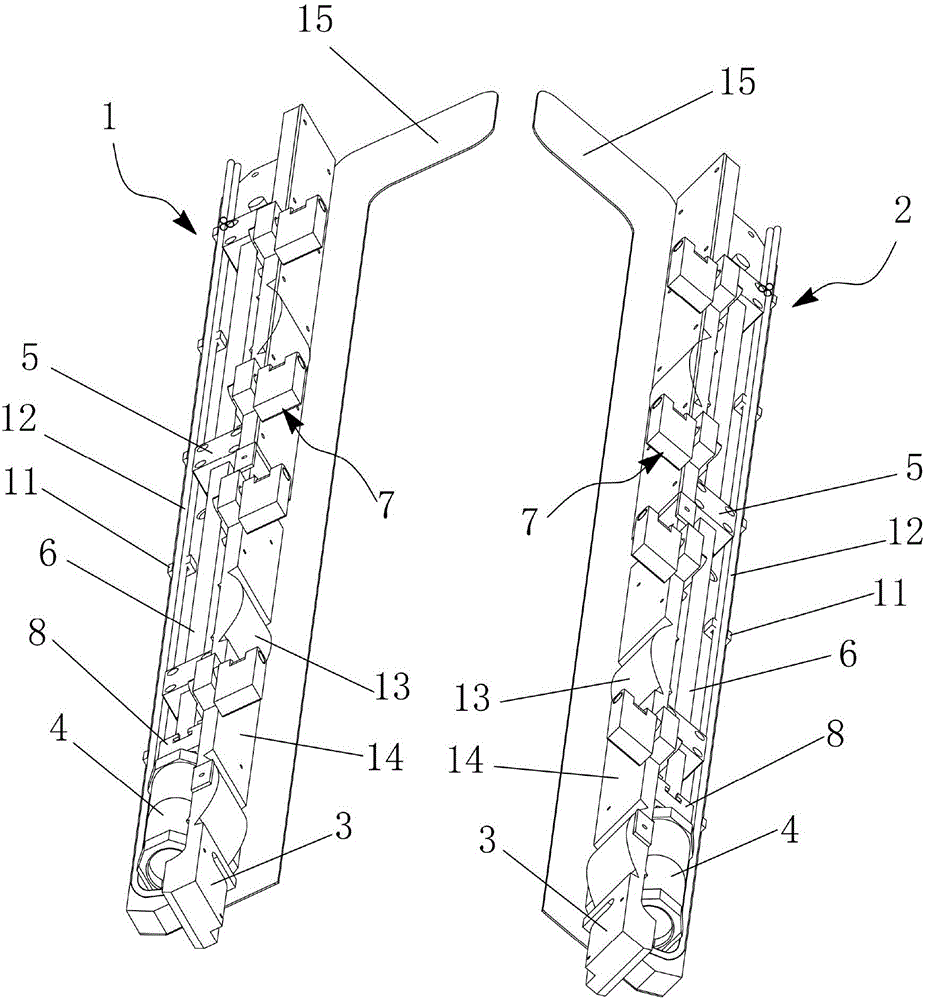

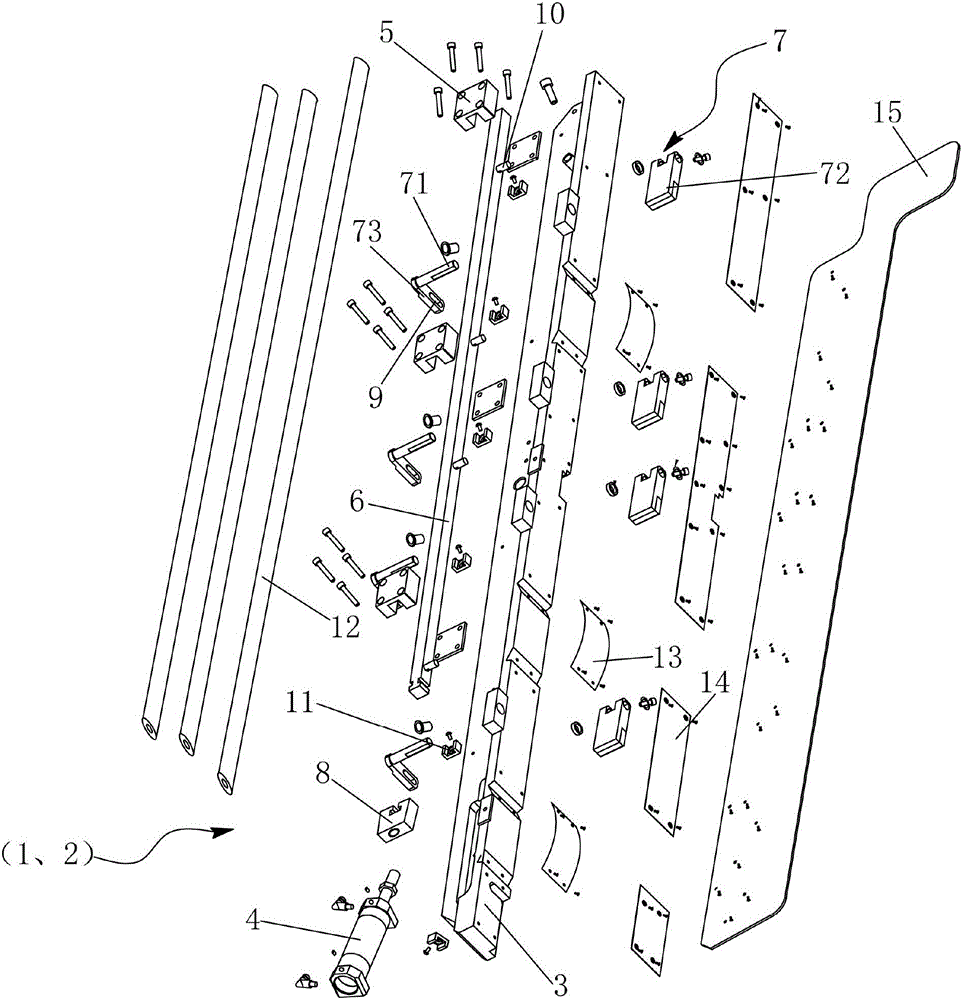

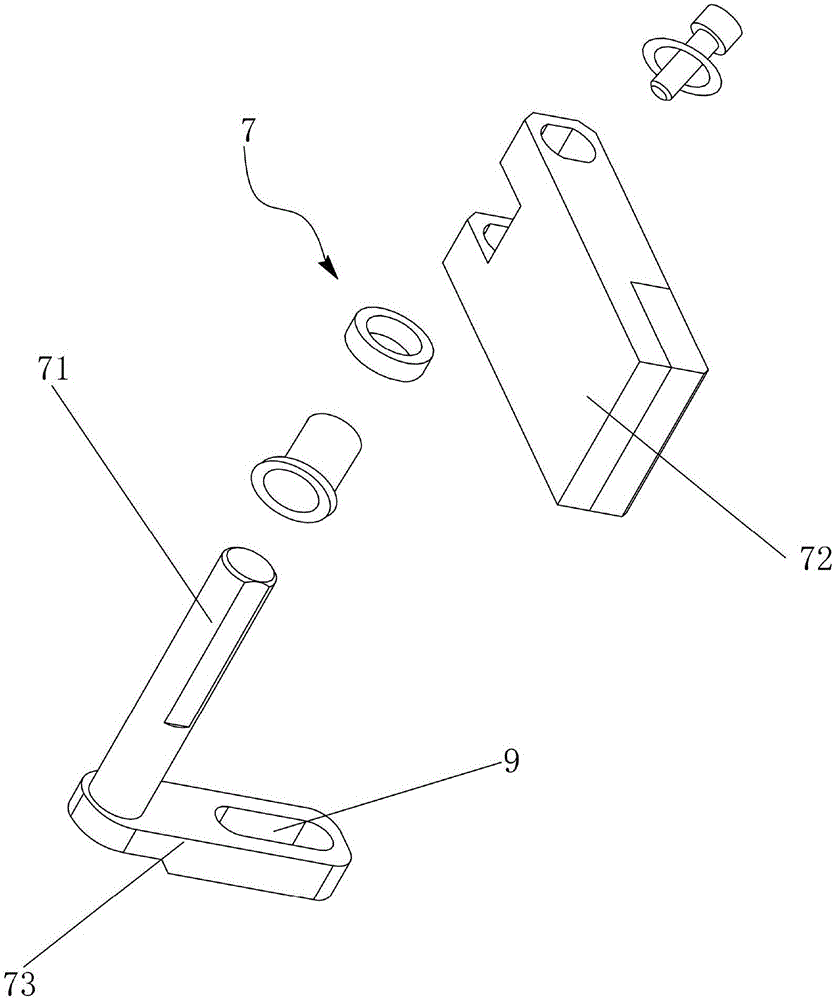

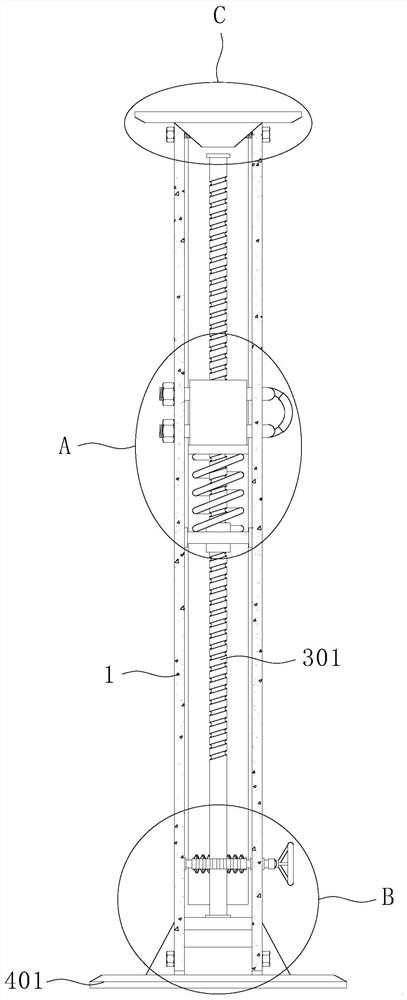

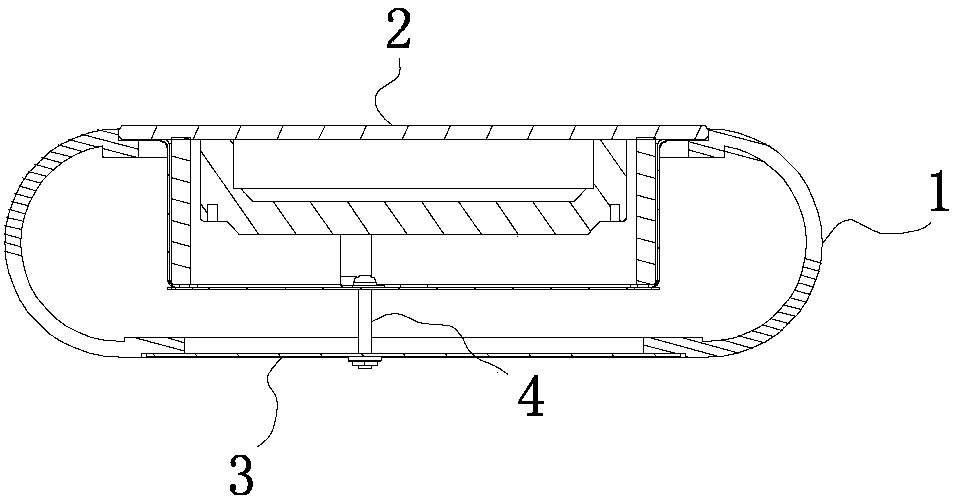

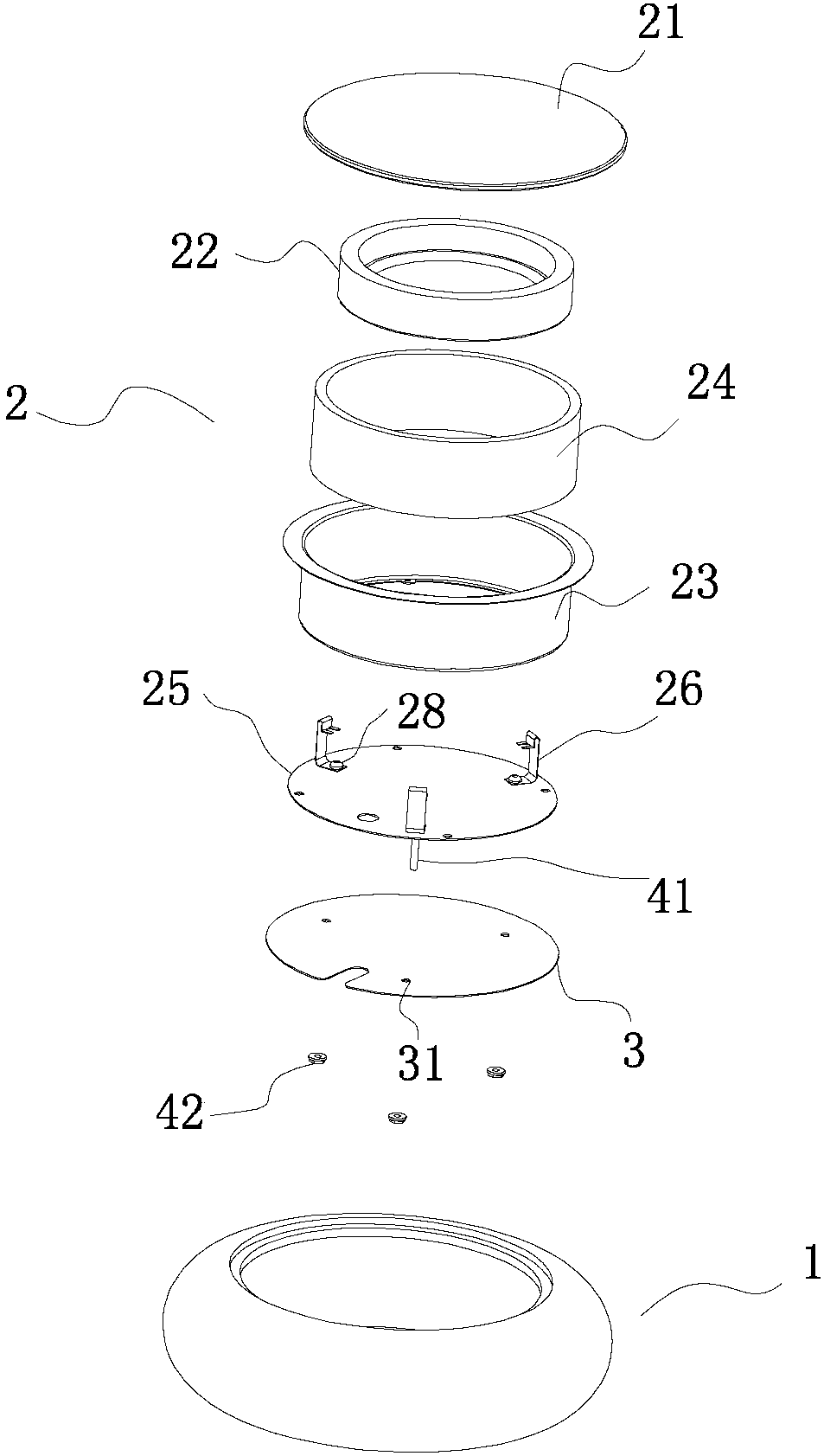

Prefabricated building all-aluminum assembly component

ActiveCN113026953AEasy to useExpand the scope ofShock proofingArchitectural engineeringStructural engineering

The invention discloses a prefabricated building all-aluminum assembly component, and relates to the technical field of prefabricated buildings. The prefabricated building all-aluminum assembly component comprises two aluminum main frames, wherein support mechanisms, damping and stabilizing mechanisms, bottom support mechanisms and top support mechanisms are arranged on the aluminum main frames, and an aluminum cross beam is arranged between the two aluminum main frames. According to the prefabricated building all-aluminum assembly component, damping support can be performed on a fixed table which is integrally designed with an aluminum cross beam, so that the support capacity of the aluminum cross beam is increased, the damage to the component when the component is impacted by external factors is reduced, and the service life of the component is prolonged. The component has high flexibility, additionally, the support capacity is guaranteed, the practicability is greatly increased, the use range is greatly widened, the structure is simple, the effects of safety, stability, flexibility and adjustability are achieved, and various requirements needed by the prefabricated buildings at the present stage are met to a large extent.

Owner:重庆中昆新材料科技有限公司

Infrared oven adopting integrated oven plate assembly

InactiveCN105371315AAssembly time is shortEasy to assembleDomestic stoves or rangesLighting and heating apparatusInfraredEngineering

The invention discloses an infrared oven adopting an integrated oven plate assembly. The infrared oven comprises an oven outer shell, the integrated oven plate assembly, a fixed bottom plate and a controller. The integrated oven plate assembly comprises a devitrified glass plate, an oven plate, an oven shell, a heat insulating ring, an oven shell bottom plate and oven plate fixing elastic pieces. The integrated oven plate assembly is installed on the oven outer shell. The oven outer shell is fixed between the integrated oven plate assembly and the fixed bottom plate. The fixed bottom plate is installed at the bottom of the oven outer shell. The integrated oven plate assembly is fixedly connected with the fixed bottom plate installed at the bottom of the oven outer shell through fixing studs and fixing nuts. The devitrified glass plate of the integrated oven plate assembly is stuck to the devitrified glass plate fixing face horizontally extending out of the top of the oven shell through silicone glue. The heat insulating ring is installed on the inner wall of the oven shell. The upper end of the heat insulating ring makes contact with the devitrified glass plate, and the lower end of the heat insulating ring makes contact with the oven shell bottom plate. A cavity between the heat insulating ring and the oven plate is filled with heat insulating materials. The infrared oven adopting the integrated oven plate assembly has the advantages of being short in assembly time, convenient to assemble, high in assembly and production efficiency and good in heat insulating effect.

Owner:罗敏聪

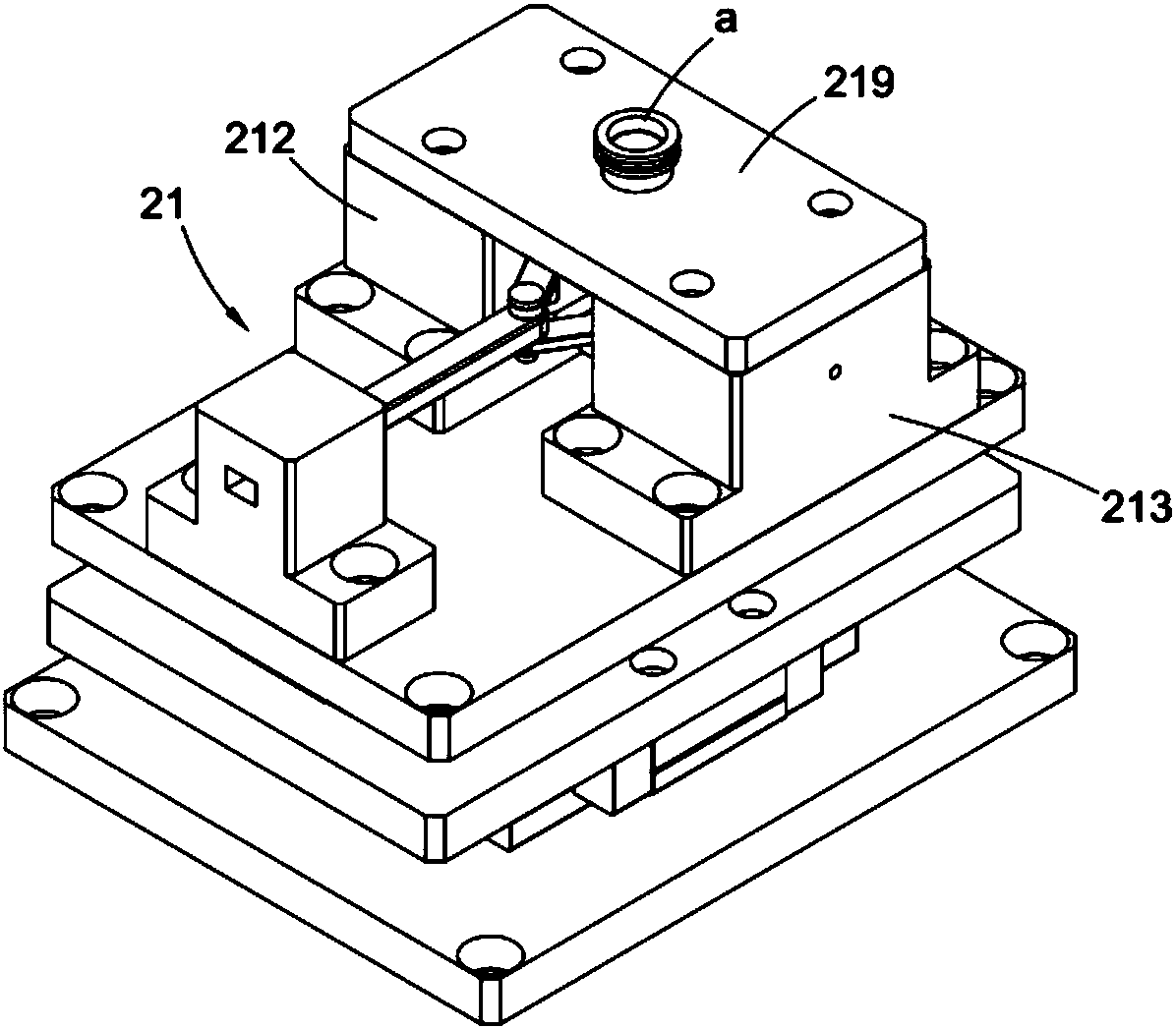

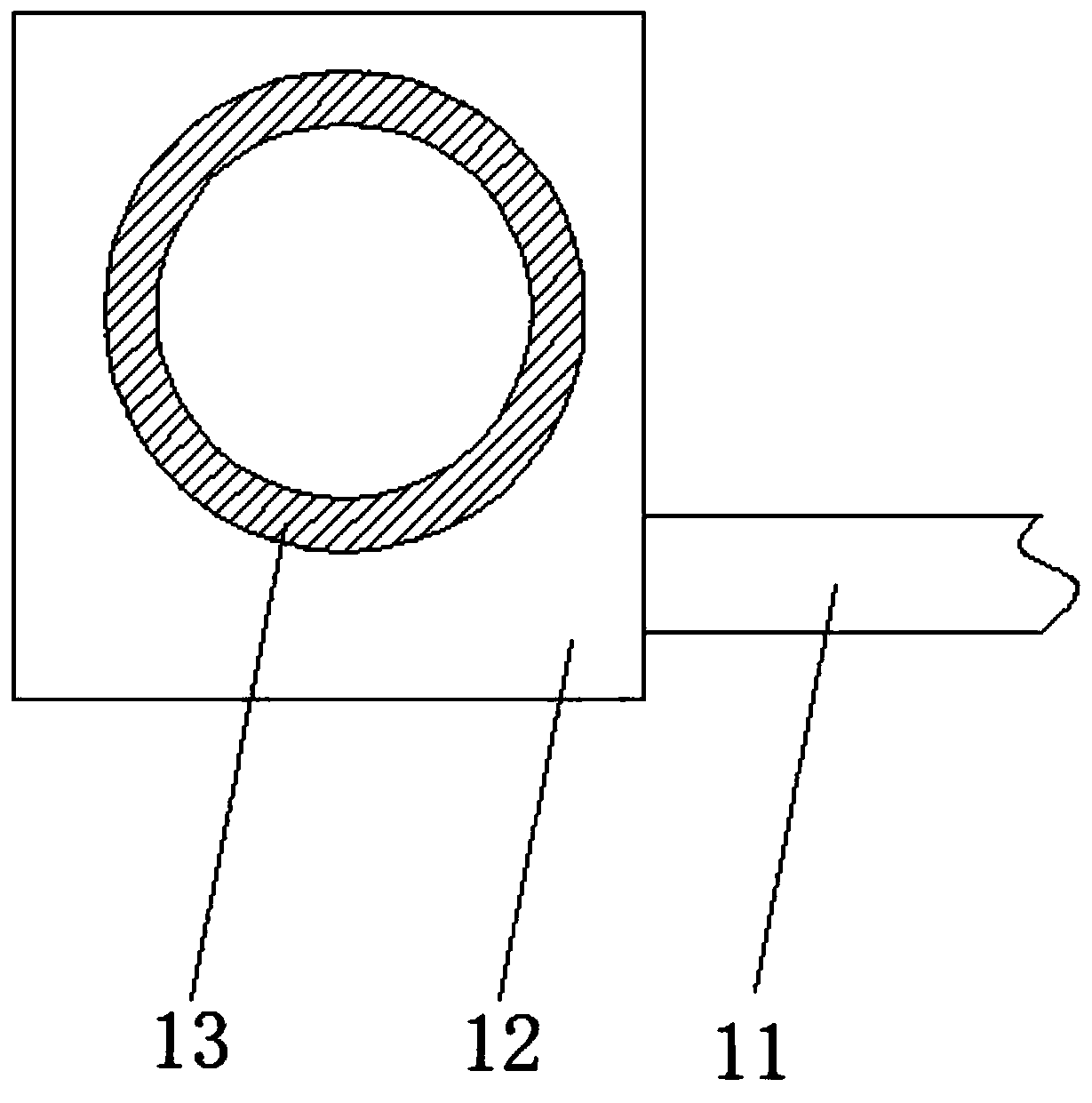

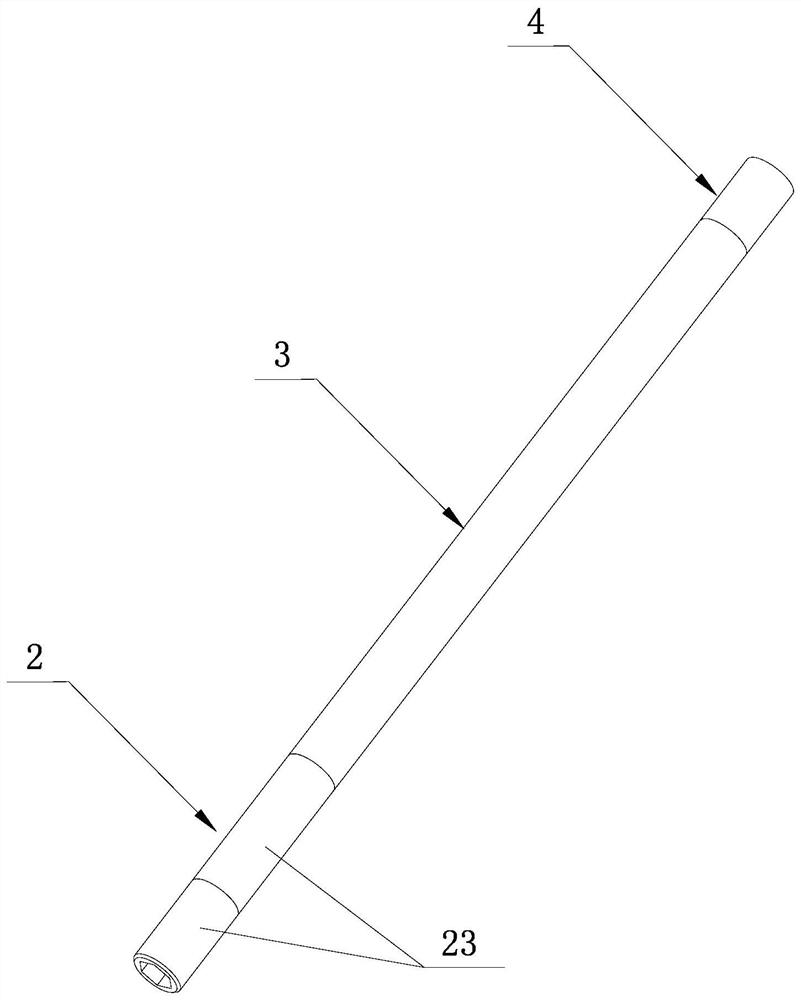

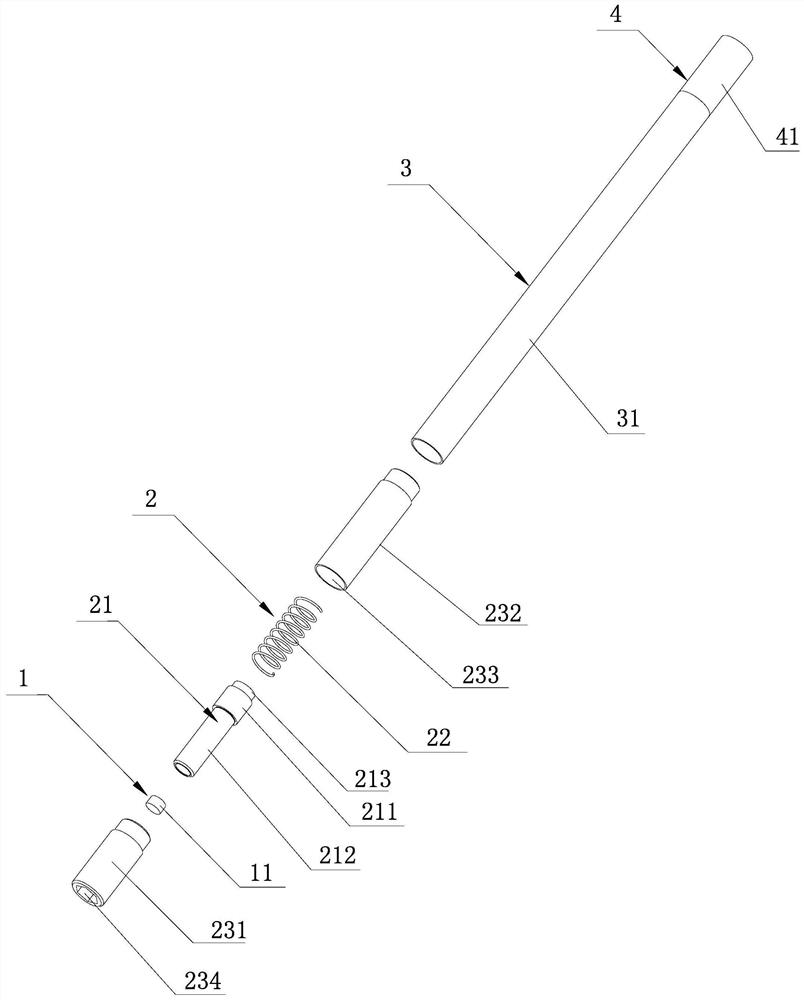

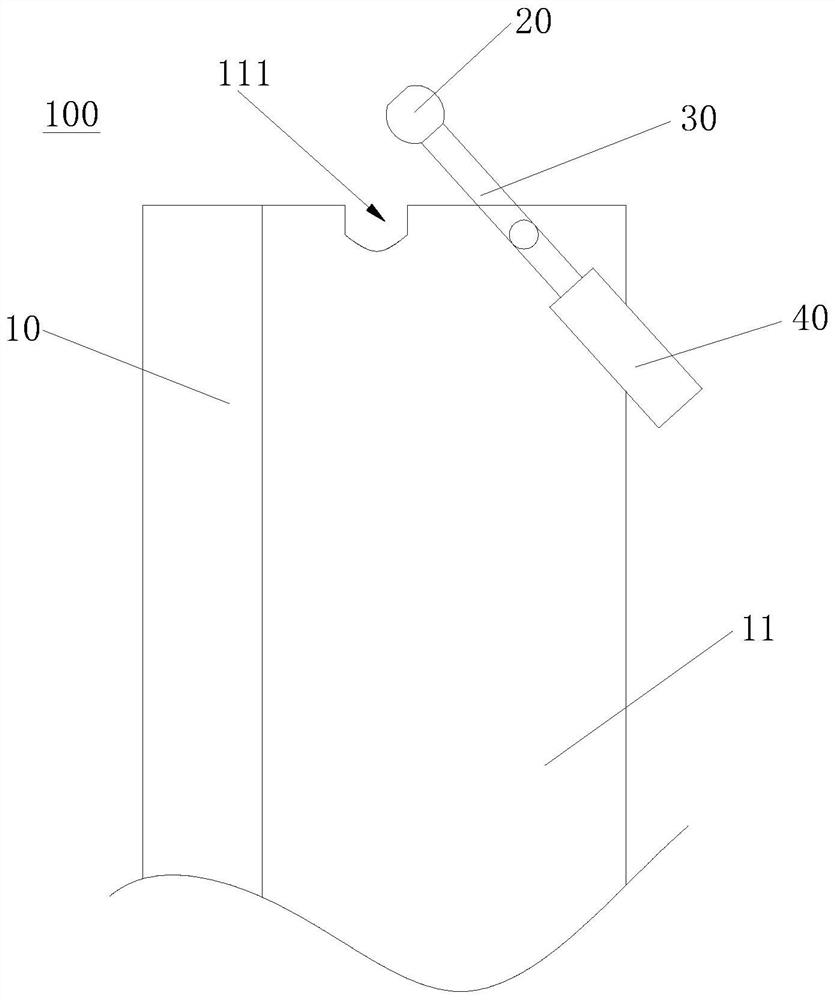

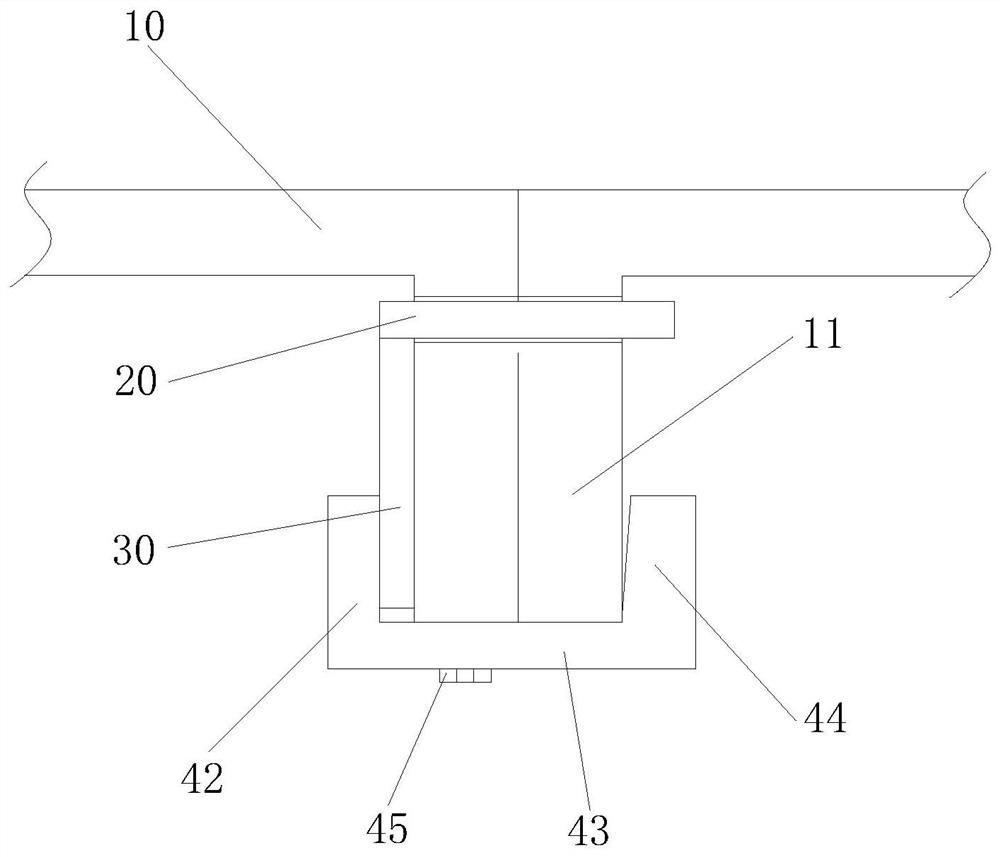

A sealing ring assembly device

ActiveCN106217014BReduced precision requirementsLow costMetal working apparatusDegrees of freedomEngineering

The invention discloses an assembly device for a seal ring. The assembly device comprises a locating assembly part and floating assembly jigs which are arranged up and down, wherein the floating assembly jigs are of three-layer structures; clamping locating mechanisms are arranged at the uppermost layers; the lower two layers adopt vertical crossed linear slide rails, so that the uppermost layers have finite degrees of freedom in the X and Y directions; before seal ring assembly, a locating cone head in the locating assembly part is inserted into a product for guide locating, floating in the X and Y directions is limited, and the to-be-assembled product is forced to be coaxial with the locating cone head and a charging head; and then, the seal ring on the charging head passively slides downwards to a groove of the to-be-assembled product, and assembly is completed. According to the assembly device, a two-time locating manner is utilized, the precision requirement on a rotary disc driving part, a horizontal carrying module and a vertical carrying module is greatly reduced, and the cost is greatly reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

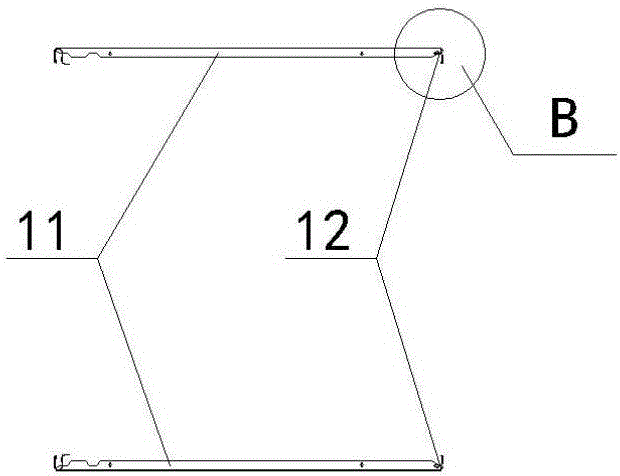

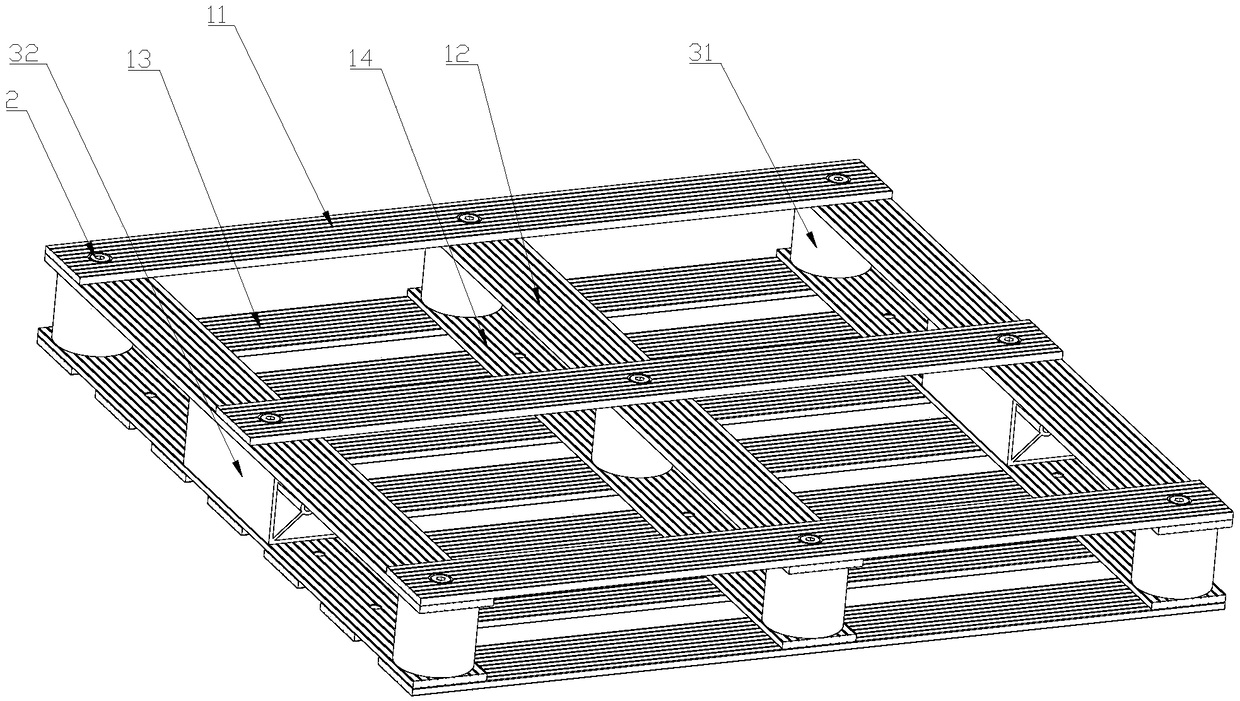

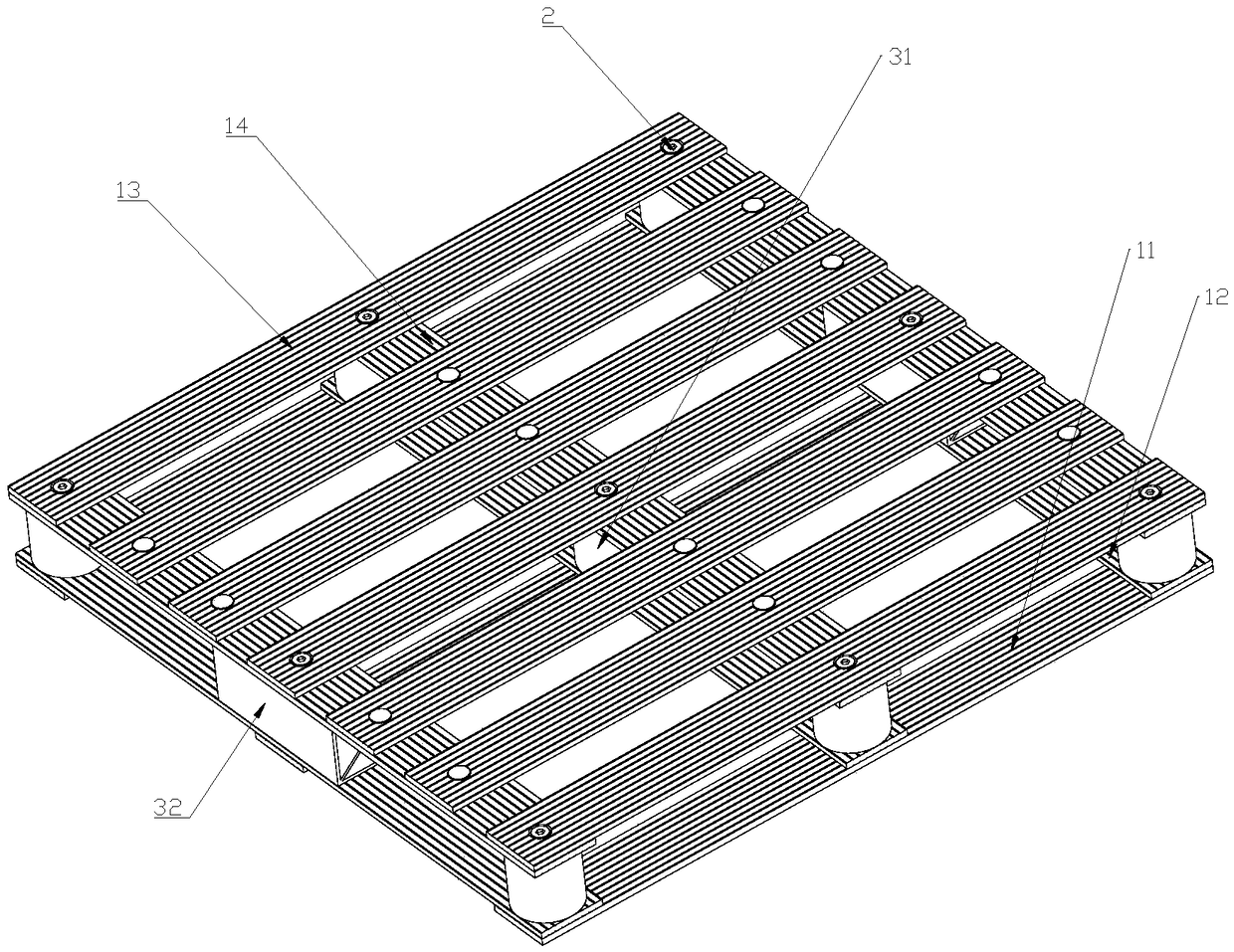

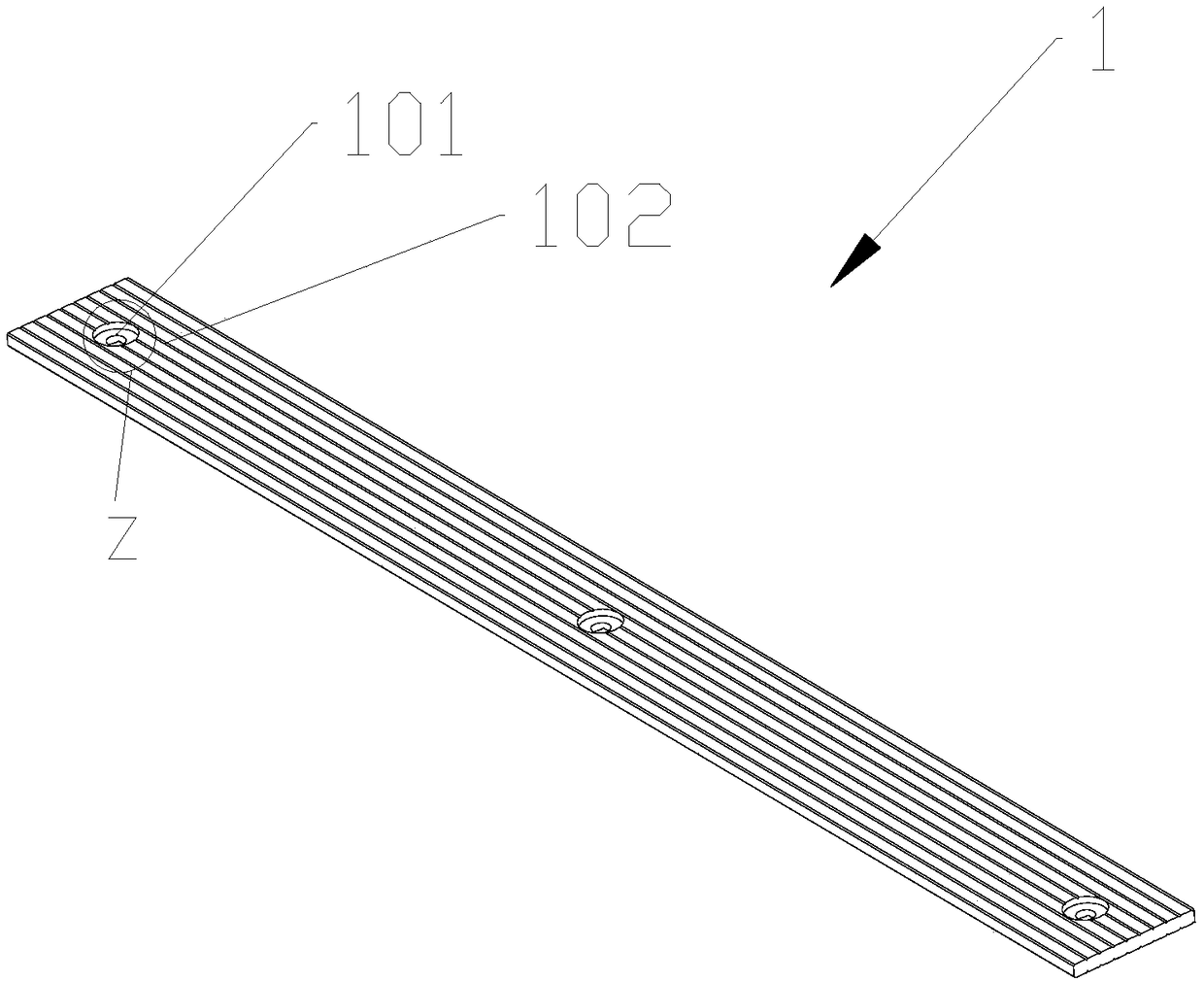

Pallet

The embodiment of the invention discloses a pallet. The pellet comprises an upper supporting piece, a lower supporting piece, a connecting piece and a supporting piece; the upper supporting piece comprises facing plates, the multiple face plates are arranged in an included angle so as to form the upper supporting piece, and anti-sliding parts are arranged on the upper surfaces and the lower surfaces of the face plates correspondingly; a plurality of face plates are arranged in the included angle so as to form the lower supporting piece; the upper supporting piece and the lower supporting pieceare detachably connected through the connecting piece, and after being assembled, the upper supporting piece and the lower supporting piece are aligned; and the supporting piece is fixed between theupper supporting piece and the lower supporting piece. The pallet has the beneficial effects that the face plates can be cut according to the actual needs, so that the length and width requirements ofthe pallets are met; when the face plates at the local positions are damaged, the face plates at the positions can be removed in a free-dismounting mode, the undamaged face plates are properly cut and then mounted so as to replace the damaged face plates, overall scrapping caused by local damage is avoided, and the loss cost is lowered.

Owner:王建新

A pin shaft assembly device between workpieces for intelligent manufacturing

ActiveCN109014855BRealize the pin connectionHigh matching precisionMetal working apparatusGear wheelSmart manufacturing

Owner:江苏骏森工程机械有限公司

SMT printing machine steel mesh positioning device

The invention discloses an SMT printer stencil positioning device comprising a first positioning mechanism and a second positioning mechanism facing to each other. Each of the first and second positioning mechanisms comprises a stencil positioning frame, at least one compressing positioning cylinder, and a pressure plate, wherein the compressing positioning cylinders are mounted on the stencil positioning frame in an embedded manner and the pressure plate is mounted on the compressing positioning cylinders. The compressing positioning cylinders can drive the pressure plates to move up and down, thus an SMT printer stencil can be accurately positioned, positioning is highly accurate and stable, and printing precision and production efficiency are high. In addition, the compressing positioning cylinders and the pressure plates coordinate to accurately and reliably position the stencil, so that the SMT printer stencil positioning device is simple to assemble, assembly time is short, assembly efficiency is high, the SMT printer stencil positioning device is long in service life, simple to maintain later, maintenance time is short, and maintenance cost is low.

Owner:东莞市九方电子设备有限公司

Full-dustproof single-drive gantry

PendingCN113783395AEliminate the adjustment link of installation accuracyEnsure mobile positioning accuracyStructural associationPropulsion systemsElectric machineClassical mechanics

The invention belongs to the technical field of gantries, and particularly relates to a full-dustproof single-drive gantry. The single-drive gantry comprises a cross beam shaft module used for bearing an object to drive the object to move, a lower shaft module used for bearing the cross beam shaft module to drive the cross beam shaft module to move, and an auxiliary shaft used for assisting in bearing the cross beam shaft module. The cross beam shaft module is arranged on the lower shaft module and the auxiliary shaft, the cross beam shaft module and / or the lower shaft module comprise / comprises a base, a sliding platform and a telescopic dust cover, two guide rails are arranged on the base, the guide rails and the base are integrally formed, first sliding grooves are formed in the side edges of the two guide rails, a linear motor used for driving the sliding platform to move is further fixedly arranged on the base, the sliding platform is movably arranged on the two guide rails through the first sliding grooves, and the sliding platform is connected with the linear motor. The guide rails and the base are integrally formed, so that the moving positioning precision of an uppermost sliding table is guaranteed, and the rigidity and the bearing capacity of the platform lower shaft module are improved.

Owner:德康威尔苏州智能科技有限公司

A piston type nut locking device

ActiveCN109483213BScrew in accuratelyImprove versatilityMetal working apparatusEngineeringPneumatic tool

The invention discloses a piston type nut locking device. The piston type nut locking device comprises a nut absorbing part, a piston part, a lengthening rod part, and a connector part used for beingconnected with an external electric / pneumatic tool. The piston part drives the nut absorbing part to move when moving. During mounting, the nut absorbing part attracts a hex nut to align a screw for penetrating. The piston part is in the original state at this moment. The hex nut is jacked onto the screw, the external electric / pneumatic tool is started to drive the piston type nut locking device to rotate. The hex nut is screwed into the screw, the top of the screw jacks upwards, and the piston part is in the compression state. When the hex nut is locked, a clutch of the external electric / pneumatic tool is separated and turned off, so that the piston type nut locking device is separated from the screw, and the piston part reverts to the original state. The piston type nut locking device has the advantages that the assembling time is shortened, assembling efficiency is improved, assembling difficulty is lowered, and the piston type nut locking device is suitable for mounting nuts in mounting environments with different mounting depths.

Owner:NINGBO HAIMAIKE AUTOMATION TECH CO LTD

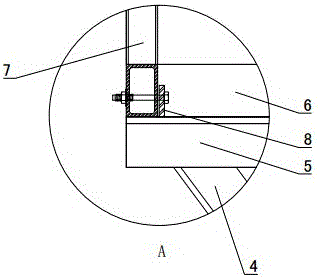

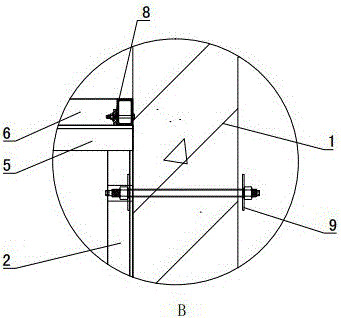

A rapid assembly template mechanism for semi-solid forming

ActiveCN109518961BFast assembly and positioningAssembly time is shortAuxillary members of forms/shuttering/falseworksForming/stuttering elementsSemi solidEngineering

The invention discloses a semi-solid forming quick assembly template mechanism, comprising a template, a folded edge is arranged on the edge of the template, and includes a limit piece, a rotating piece and a clamping piece. One end of the piece is fixedly provided with a limiting piece, and the other end of the rotating piece is slidably provided with a clamping piece. The limiting piece can be clamped on the folded edges of two adjacent templates. The two folded edges of the adjacent template are clamped in the accommodating opening, and one end of the clamping piece away from the rotating member abuts on the folded edge of the adjacent template. The semi-solid forming quick assembling template mechanism of the present invention has the advantages of fast assembling and positioning, short assembling time and high assembling efficiency.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

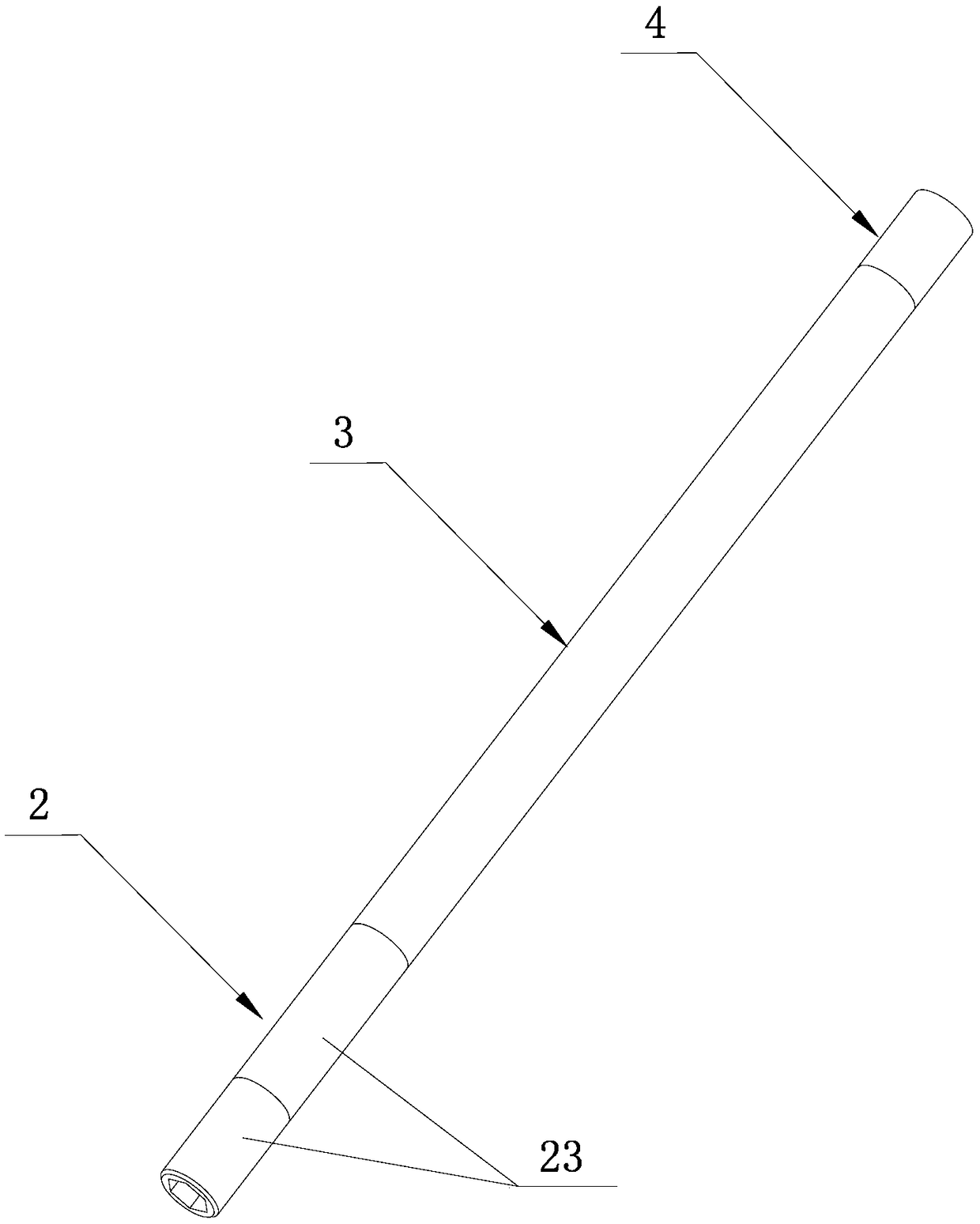

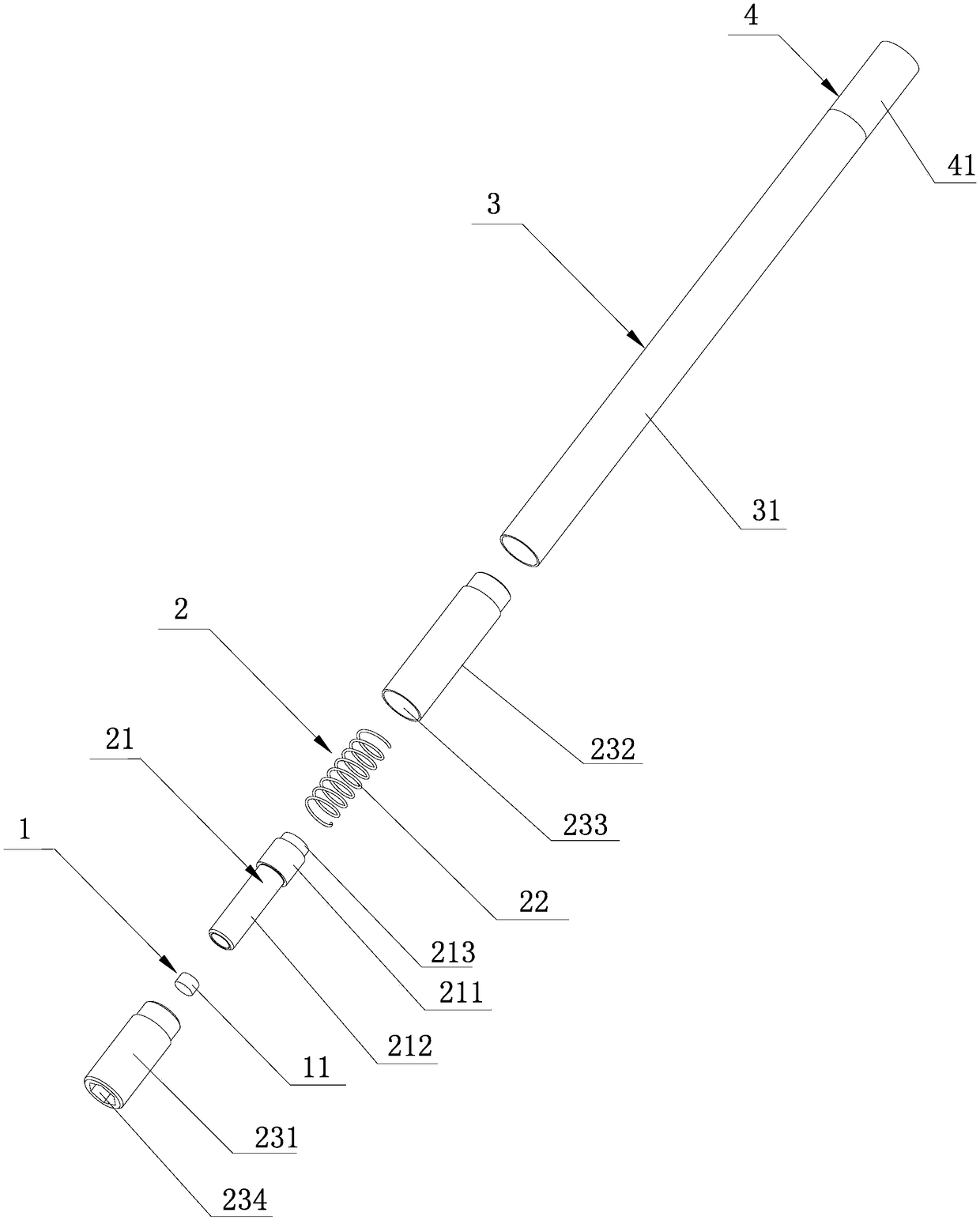

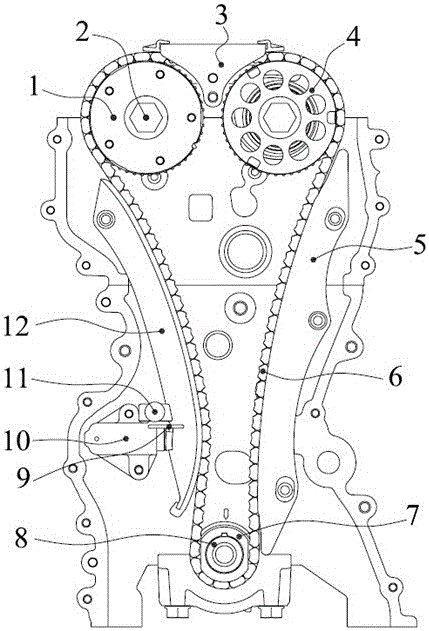

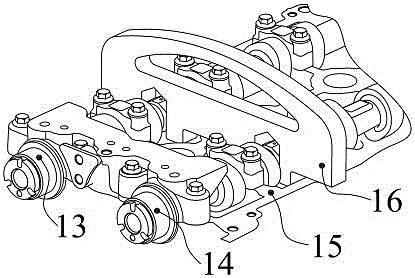

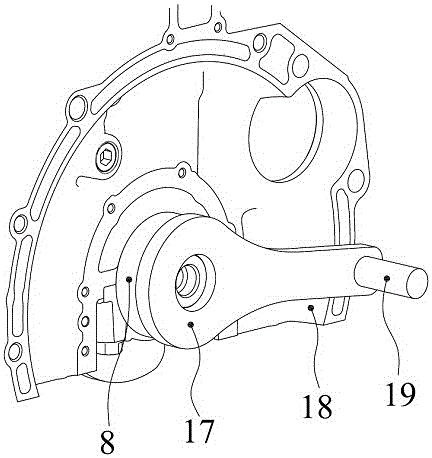

An engine timing chain system assembly tool and assembly method

ActiveCN104493787BReduce phase deviationReduced Timing Mark DesignMetal-working hand toolsEngineeringCam

The invention discloses an engine timing chain system assembly tool and an assembly method. The assembly tool comprises a crank timing tool, a cam shaft timing tool and a tensioner tool. Through the adoption of the assembly tool provided by the invention, the assembly positioning accuracy can be effectively improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

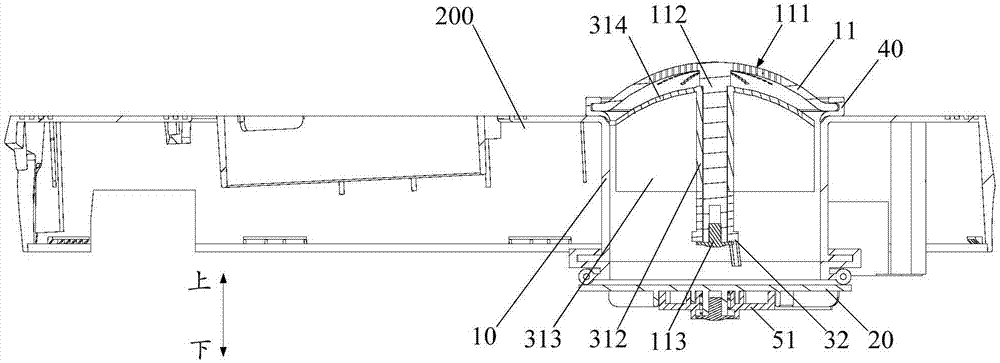

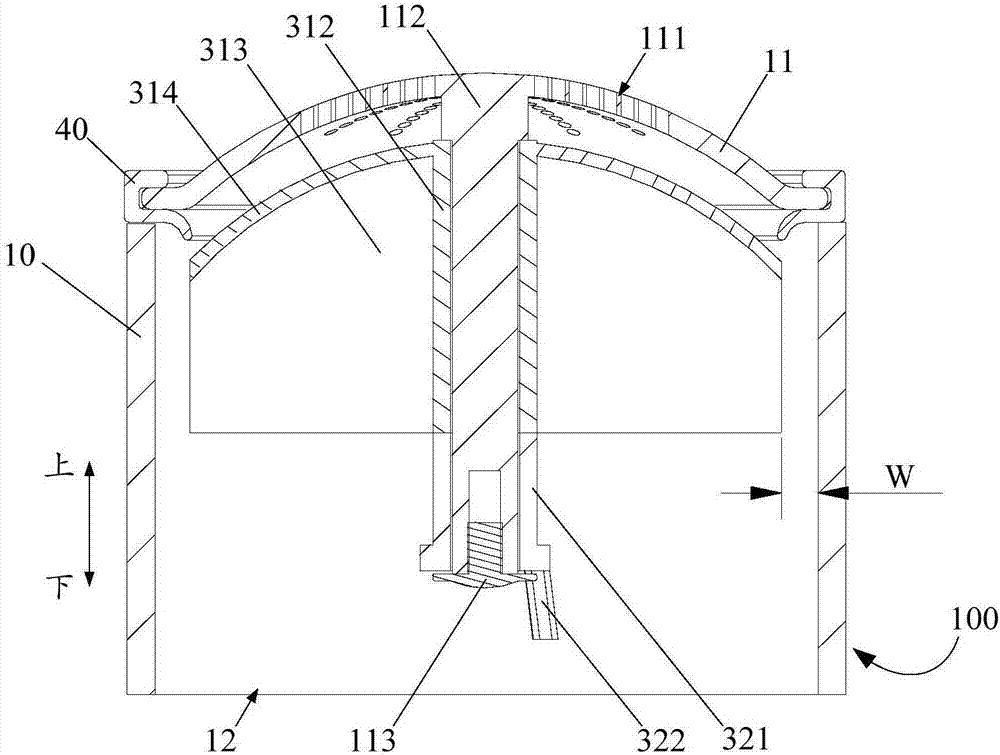

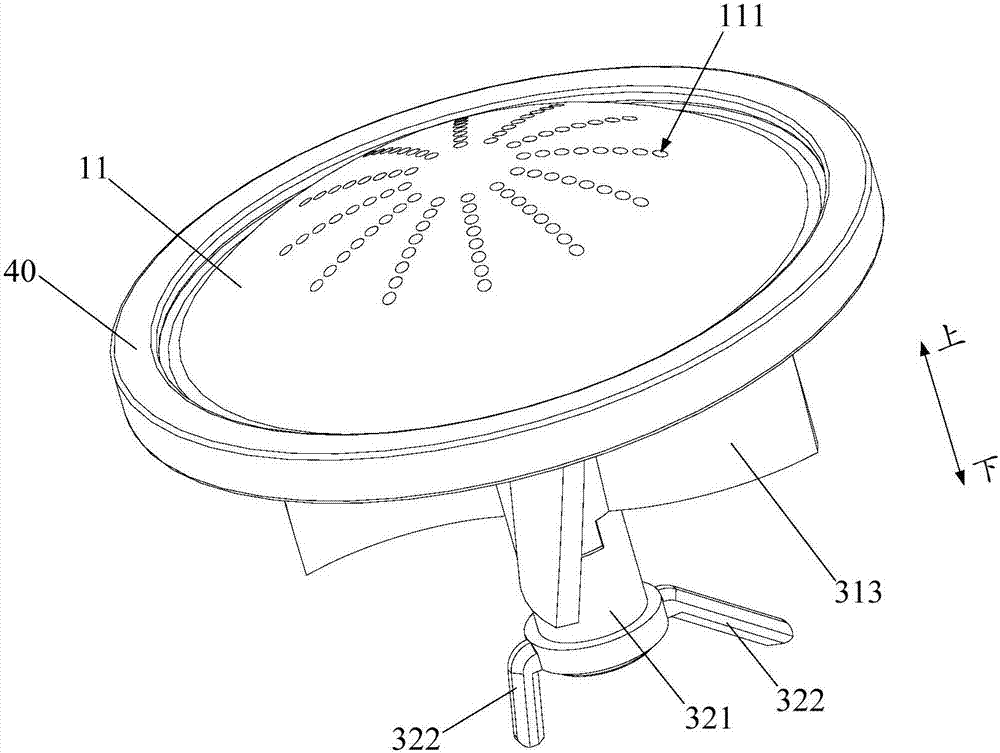

Material cleaning device and cooking appliance

PendingCN107960906AAvoid getting stuckReduce vibrationCooking vesselsPlastic recyclingAirflowNoise reduction

The invention provides a material cleaning device and a cooking appliance. The material cleaning device comprises a cleaning cavity, a rotating fan blade and a stirring claw, wherein the cleaning cavity is provided with a gas inlet and an exhaust structure; the rotating fan blade is arranged in the cleaning cavity; a gap is defined between the outer edge of the rotating fan blade and the inner surface of the cleaning cavity, and the rotating fan blade, under the driving of an airflow which enters from the gas inlet, can be rotated; the stirring claw and the rotating fan blade are connected; and the stirring claw, which is driven via the rotating fan blade, can be used for stirring materials in the cleaning cavity when the rotating fan blade is rotated. According to the material cleaning device provided by the scheme, the rotating fan blade is driven to rotate via wind power, so that the stirring claw is driven to stir the materials; and in comparison with a motor-driven structure in the prior art, an effect of vibration and noise reduction can be achieved, and a problem of water leakage in a shaft seal position can be avoided.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com