Patents

Literature

36results about How to "Guaranteed stress requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

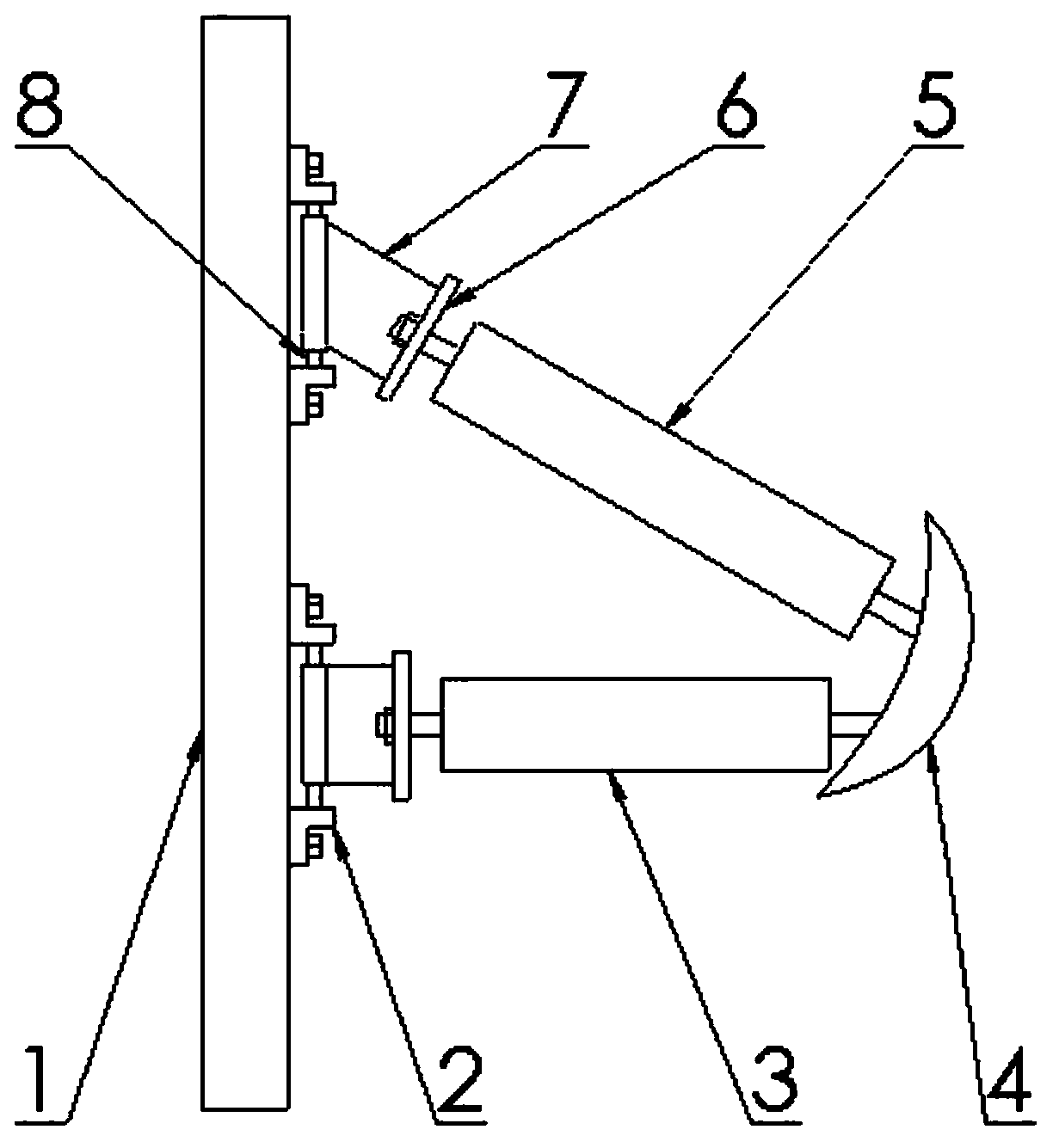

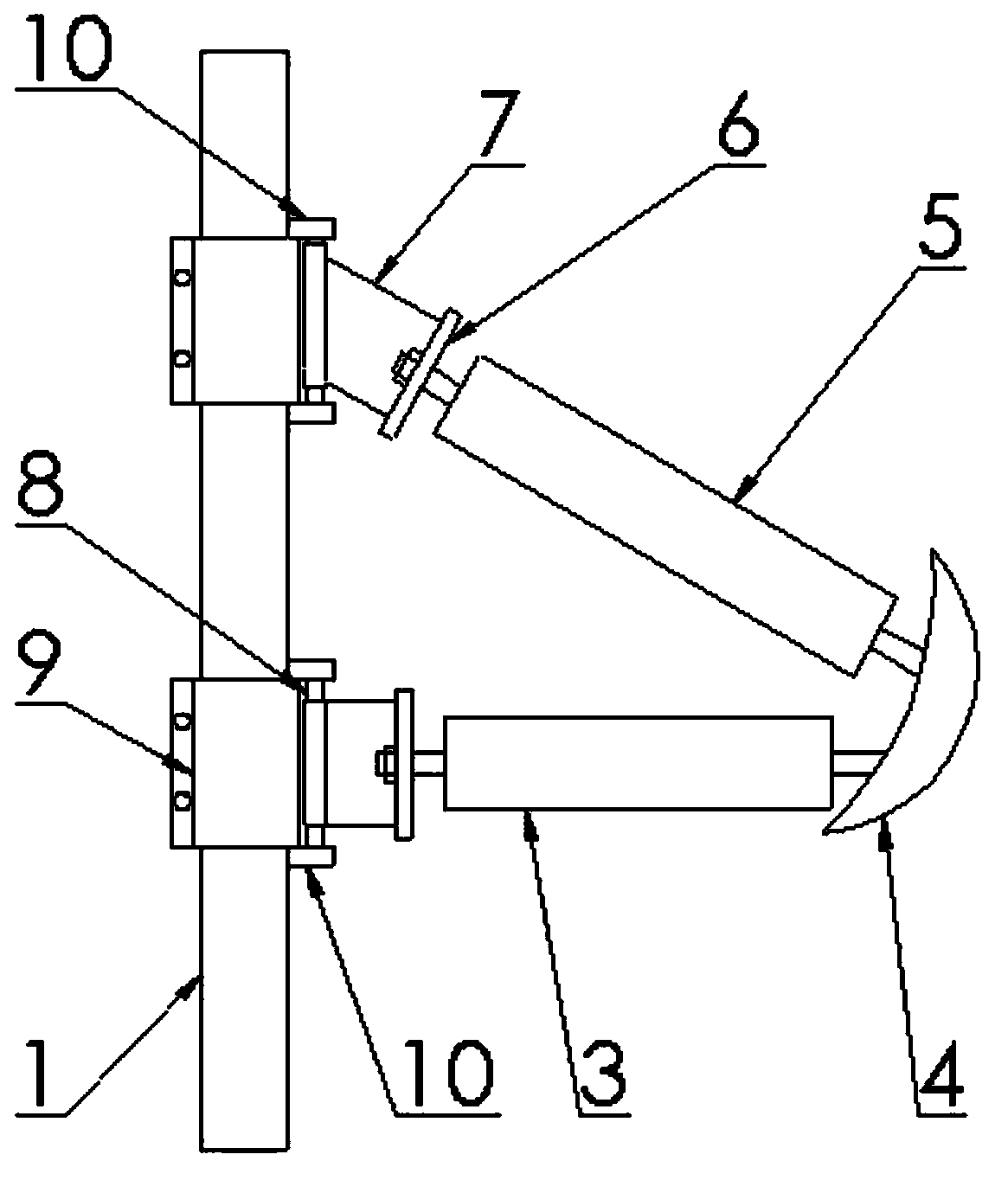

Composite rotary cross arm

The invention discloses a composite rotary cross arm. The composite rotary cross arm comprises a supporting insulator and a composite insulator, wherein the supporting insulator and the composite insulator are hinged to the same side of a tower body; the supporting insulator is vertical to the tower body; the tail end of the composite insulator points to the tail end of the supporting insulator in an inclined manner, and the tail end of the composite insulator is connected with the tail end of the supporting insulator through a wire hanging clipper connected with a ground wire; the supporting insulator is arranged below the composite insulator, and an included angle between the supporting insulator and the composite insulator is 30-45 degrees; components for hinging the supporting insulator and the composite insulator with the tower body comprise two steel angles arranged up and down, two sides, oppositely arranged, of the two steel angles are respectively provided with a hinging shaft, the other sides of the two steel angles are respectively and fixedly connected with the tower body, each hinging shaft is provided with a hinge, the other end of each hinge is provided with a hanging plate, and the hanging plates are vertical to the hinges and are used for respectively connecting the supporting insulator and the composite insulator. The composite rotary cross arm disclosed by the invention has the advantages of simple structure, convenience in implementation, reasonable design, light weight and effective protection on the main body of a tower.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

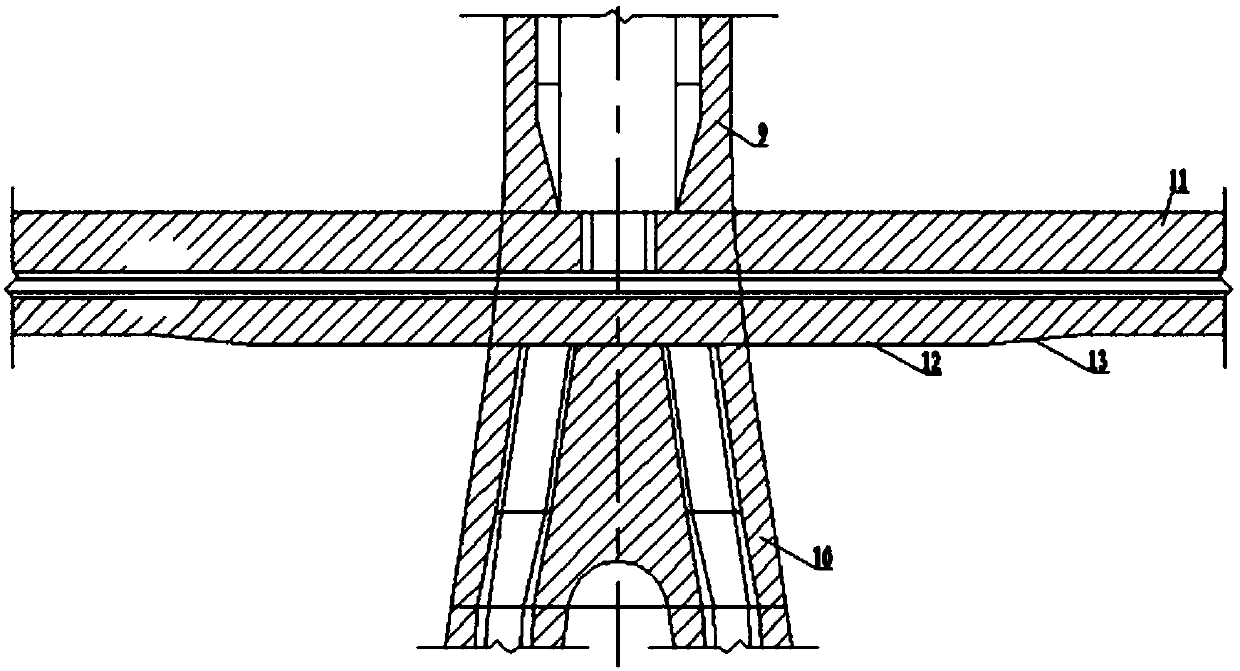

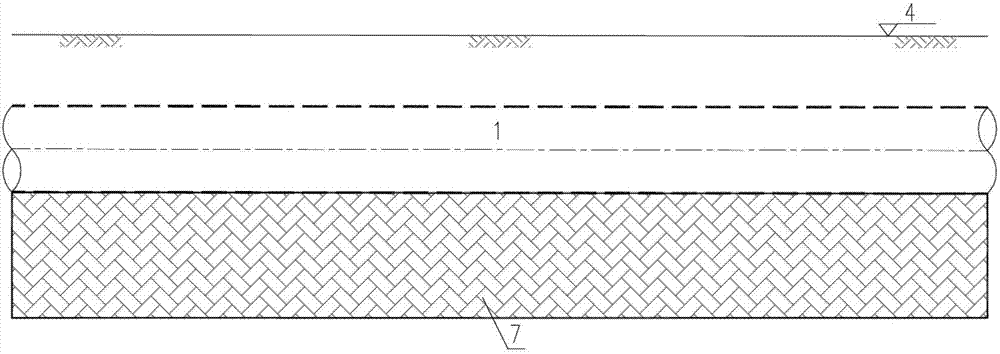

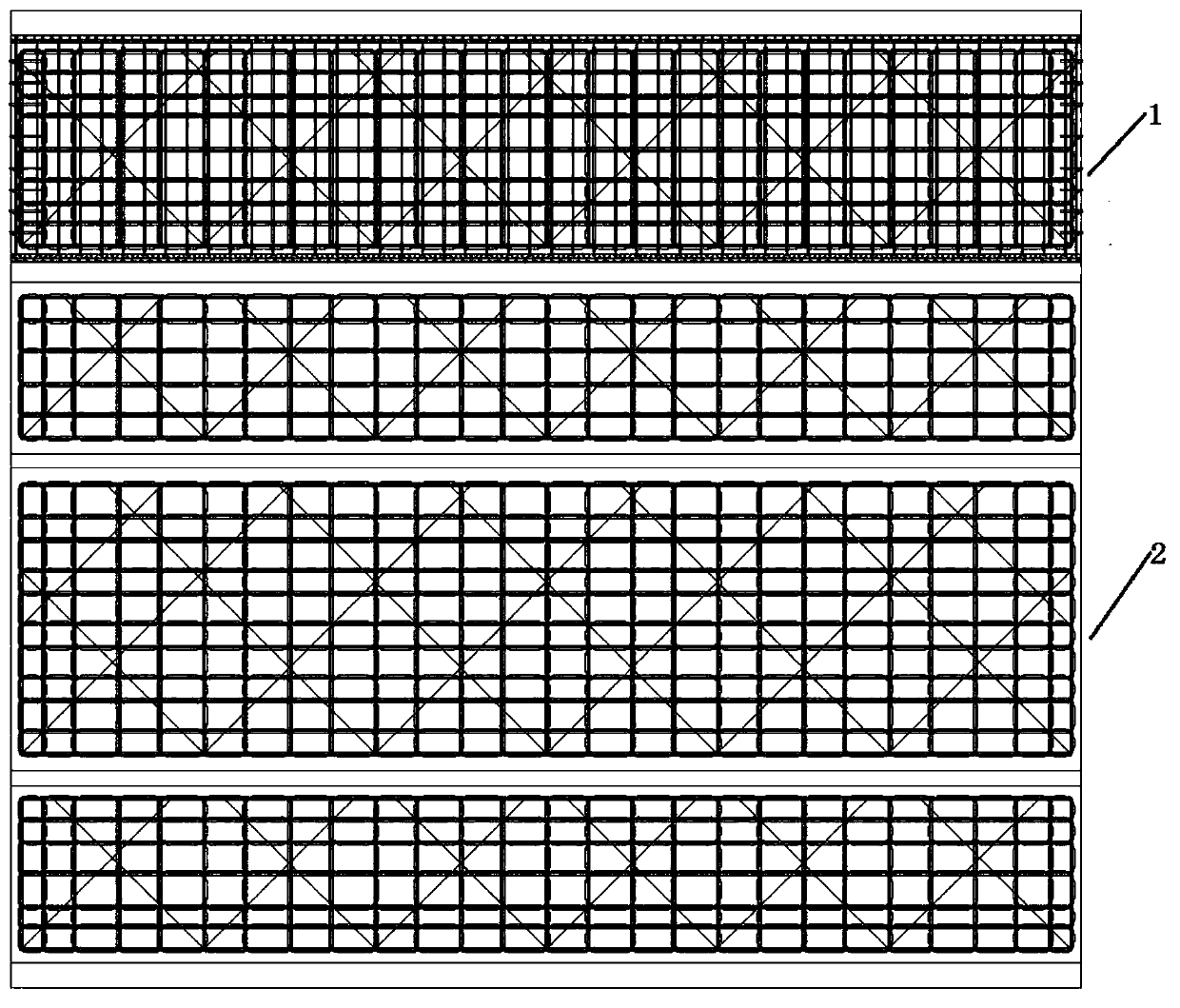

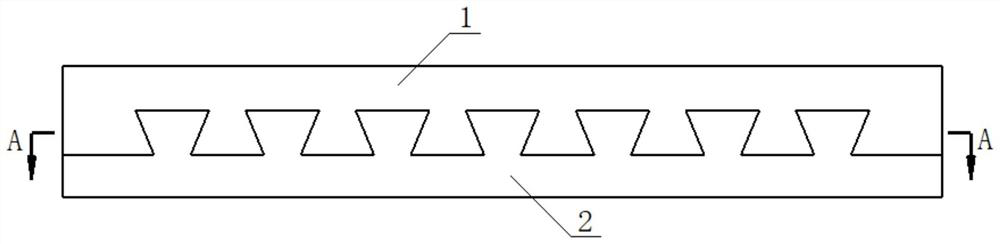

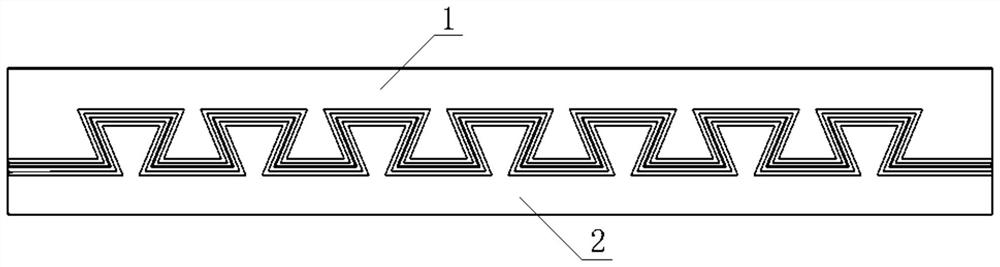

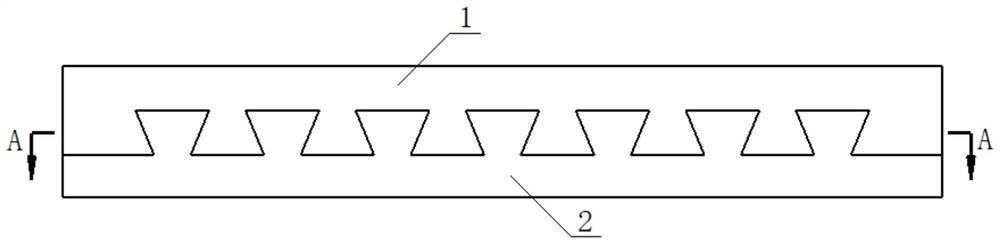

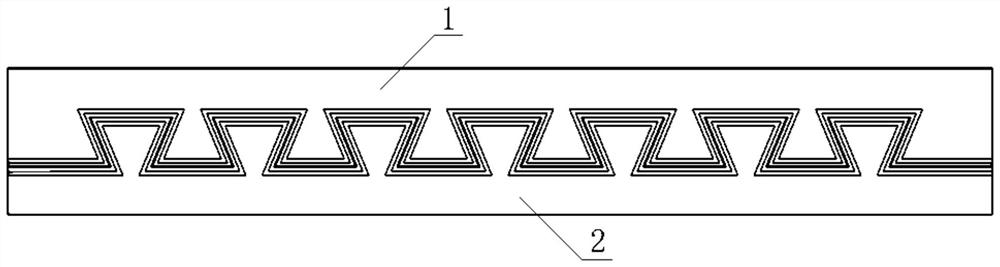

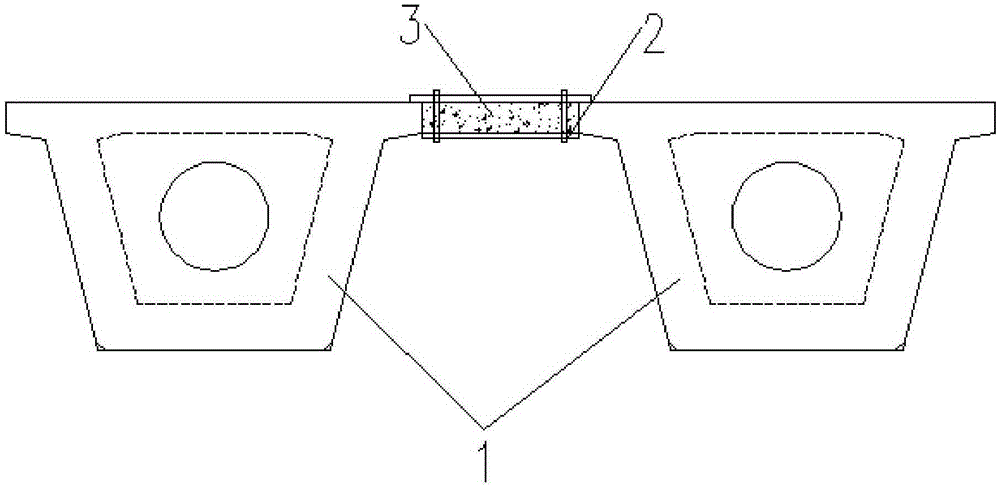

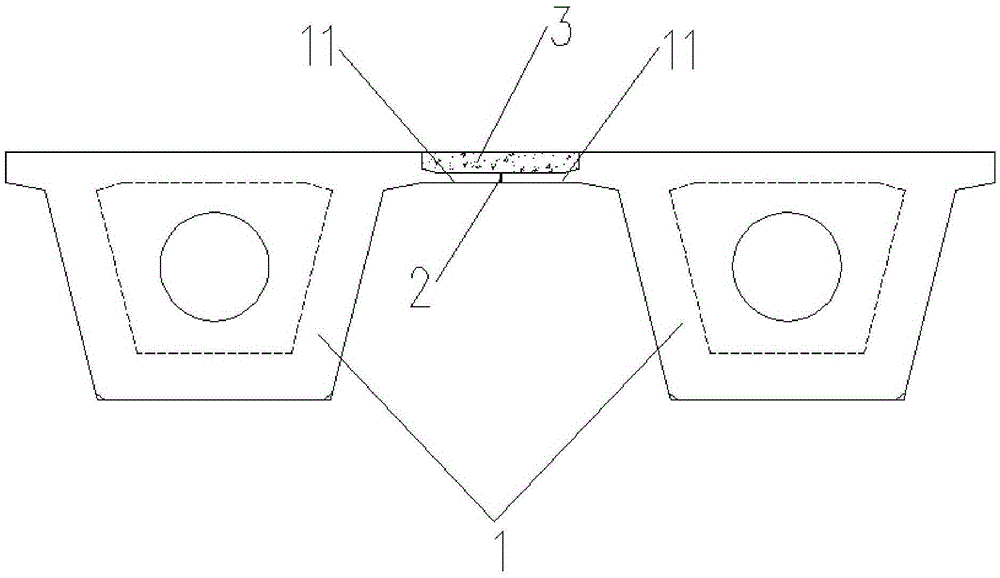

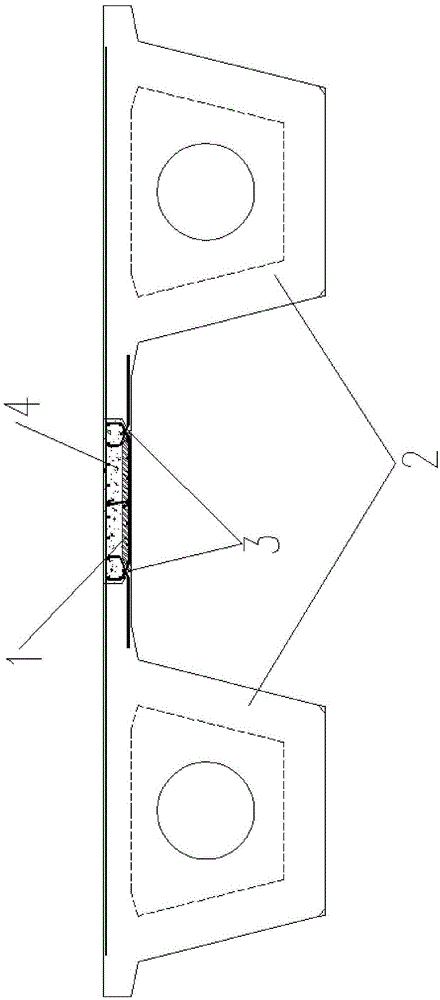

Composite steel fiber-concrete steel bridge deck based on cohesive cotter groups

ActiveCN107237259AHigh compressive strengthHas tensile strengthBridge structural detailsBridge deckHigh pressure

The invention provides a composite steel fiber-concrete steel bridge deck based on cohesive cotter groups. The preparation method comprises the following steps that 1, cleaning and shot blasting are conducted on the cover plate of the steel bridge deck by means of a high-pressure air gun; 2, cotter connecting components are arranged on the cover plate of the steel bridge deck in a bonding mode; 3, a fiber-concrete pavement layer is casted on the cover plate of the steel bridge deck with the cohesive cotter groups and the cotter connecting components in situ. By means of the composite steel fiber-concrete steel bridge deck based on the cohesive cotter groups, the structure stiffness can be improved, the stress amplitude of a fatigue detail place is reduced, and long service life design of an orthotropic steel bridge deck is achieved.

Owner:CHANGAN UNIV

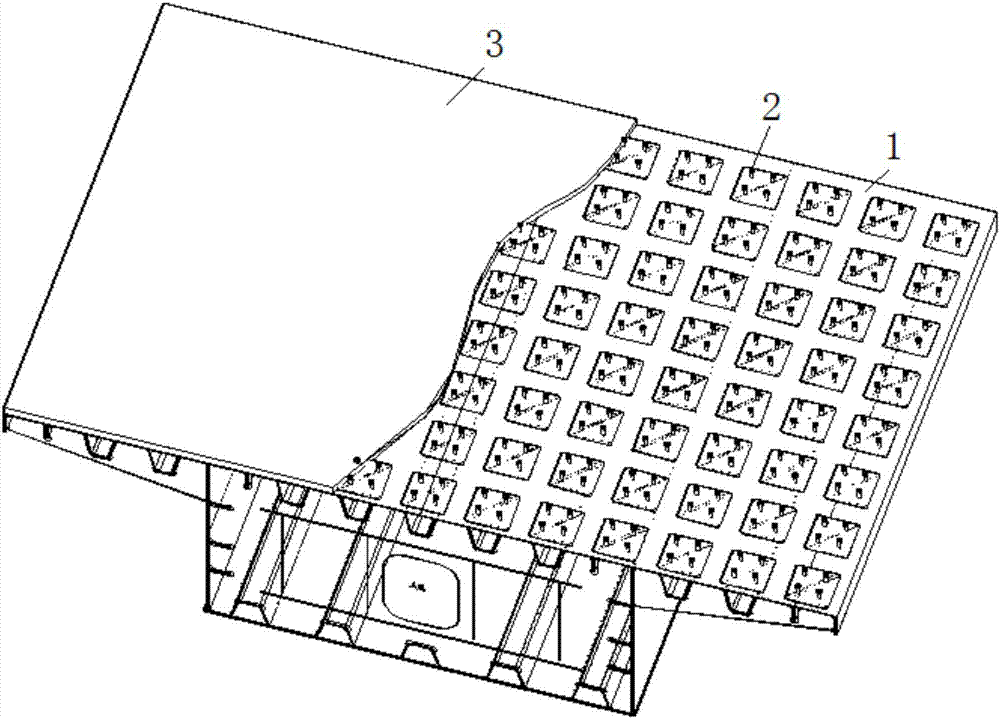

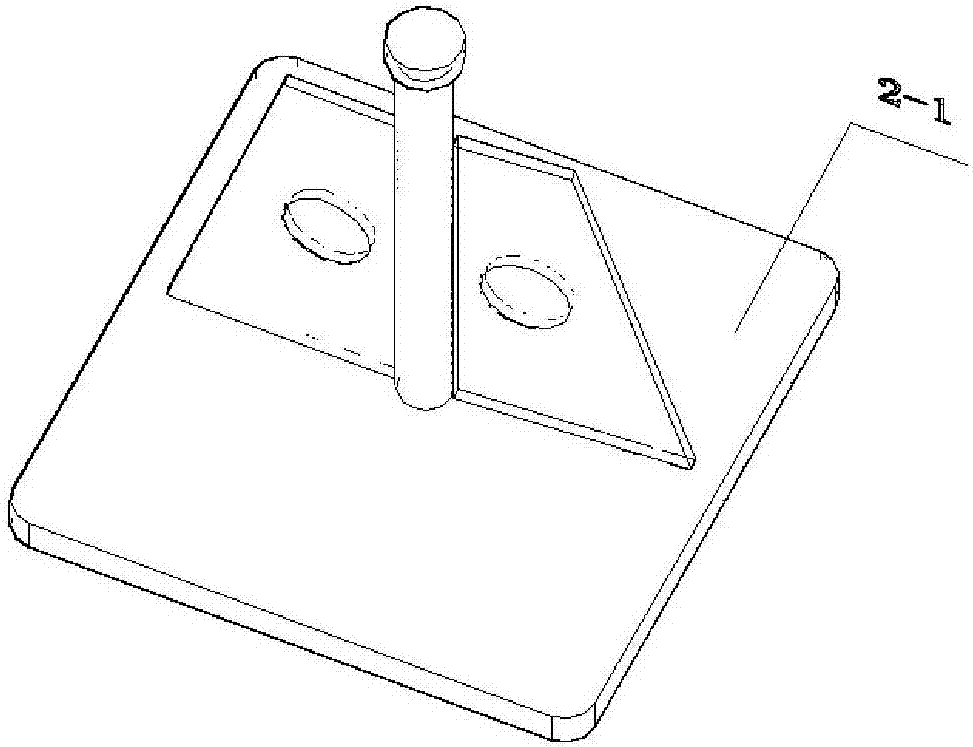

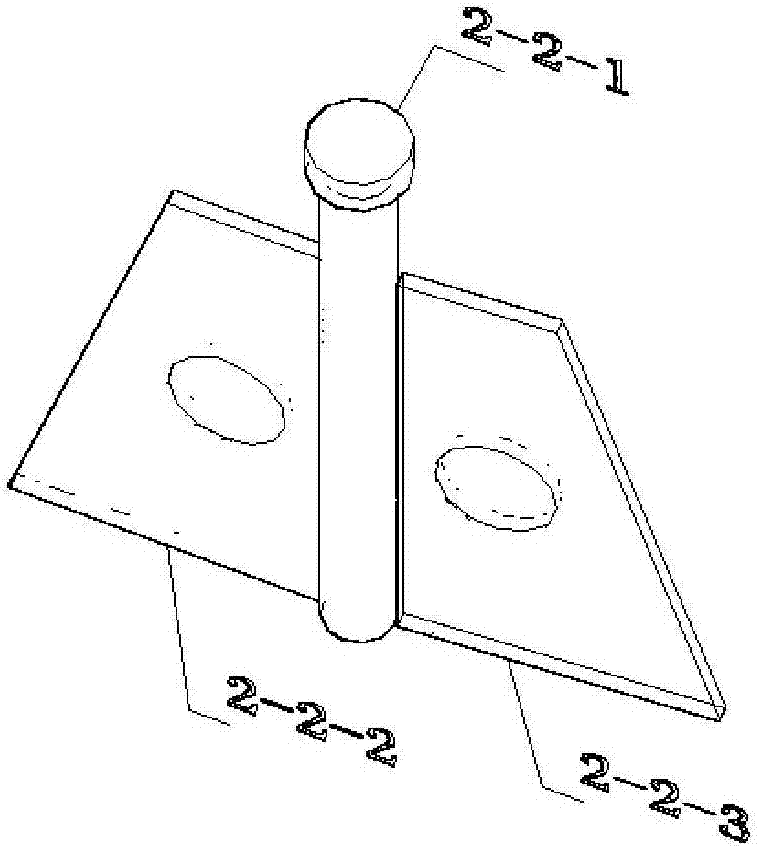

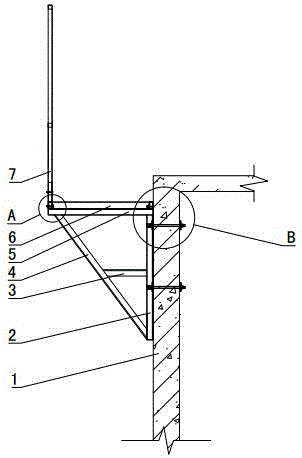

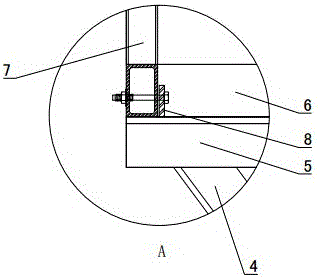

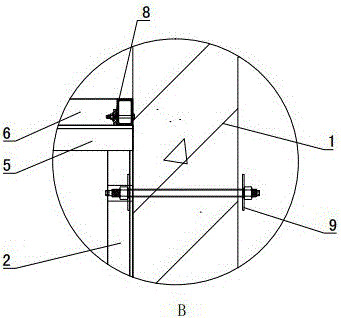

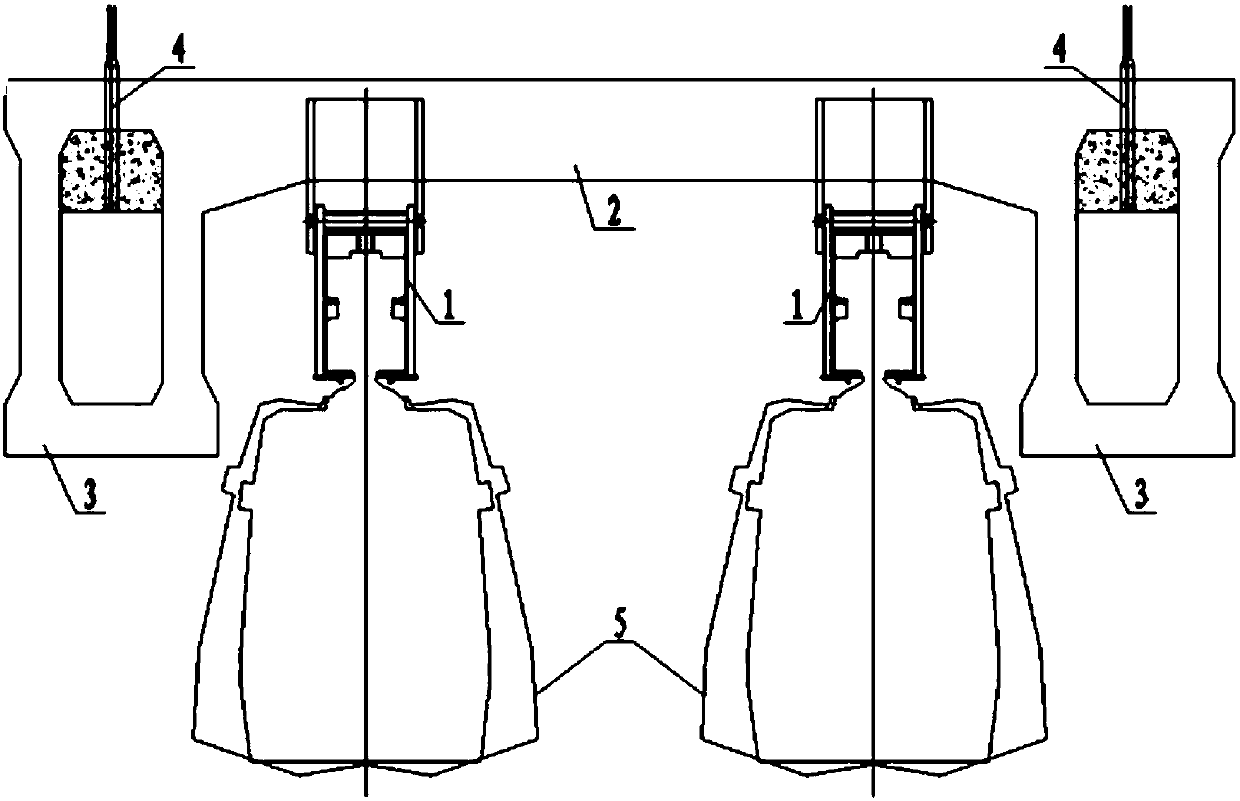

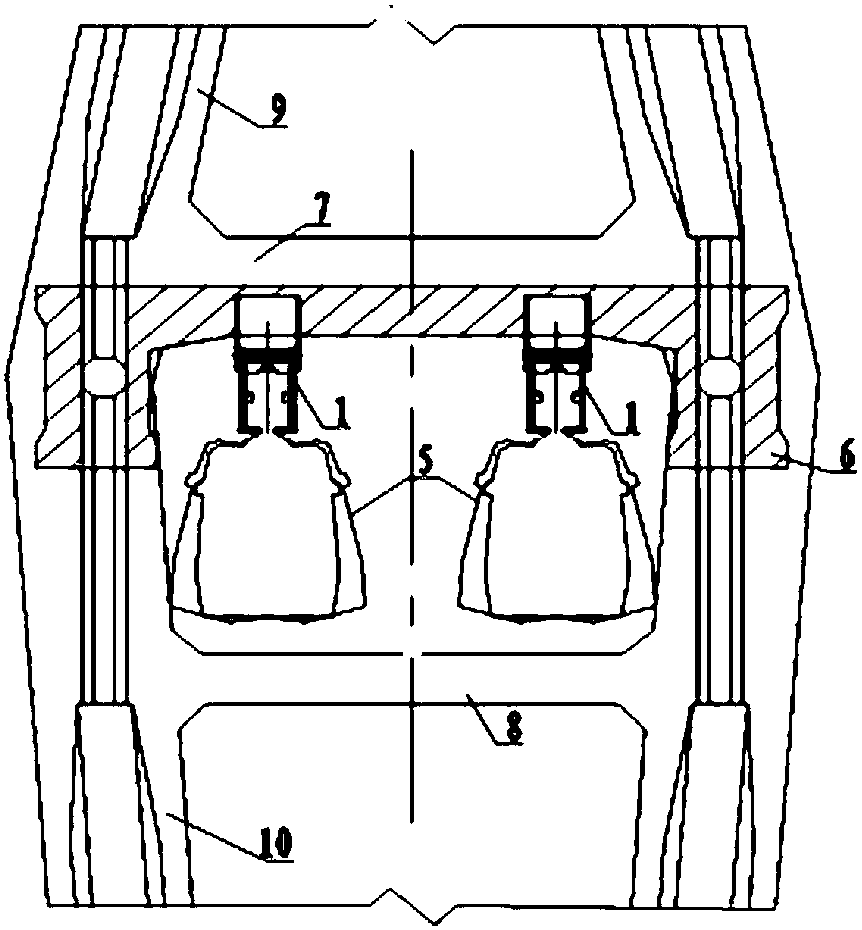

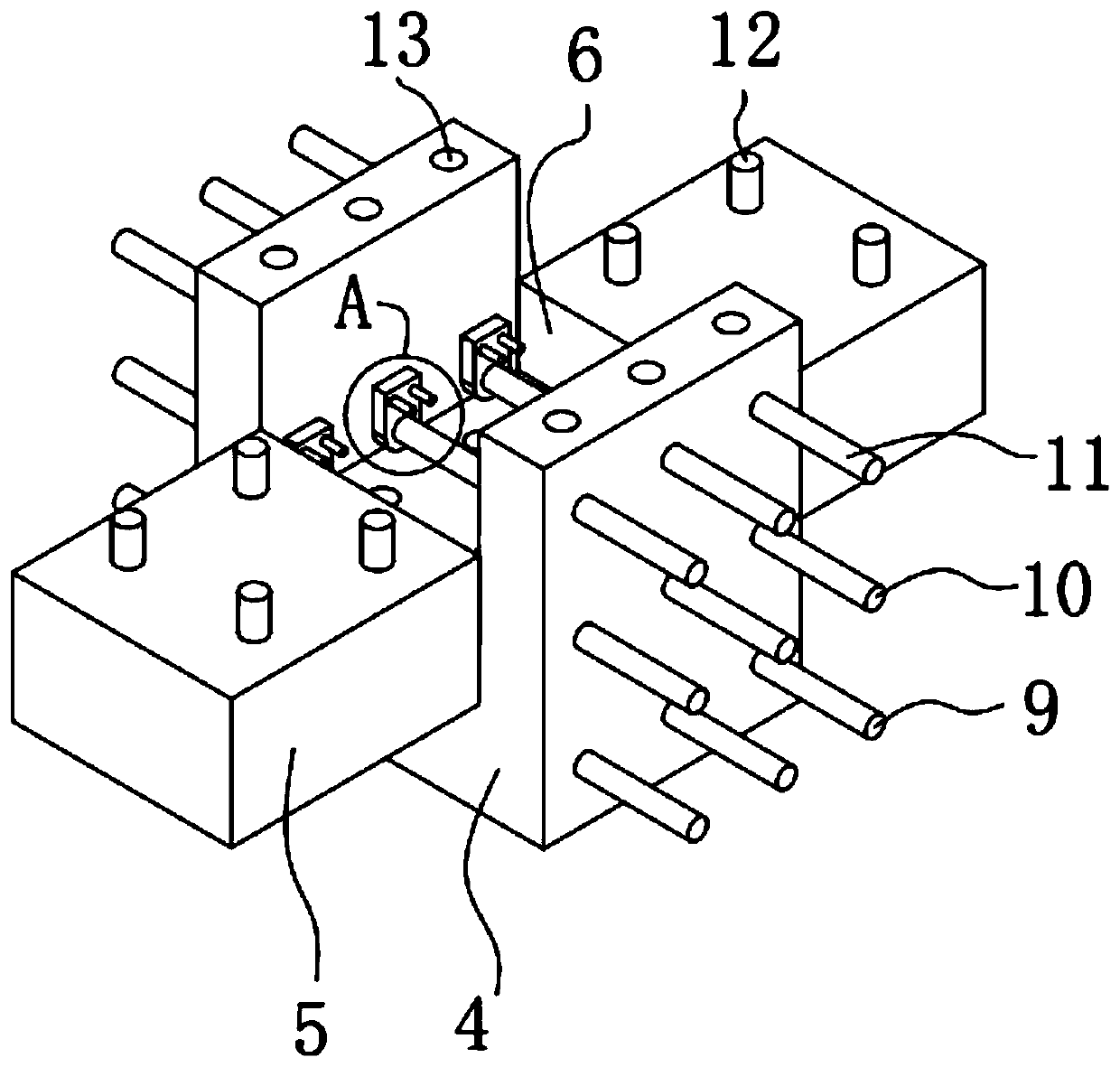

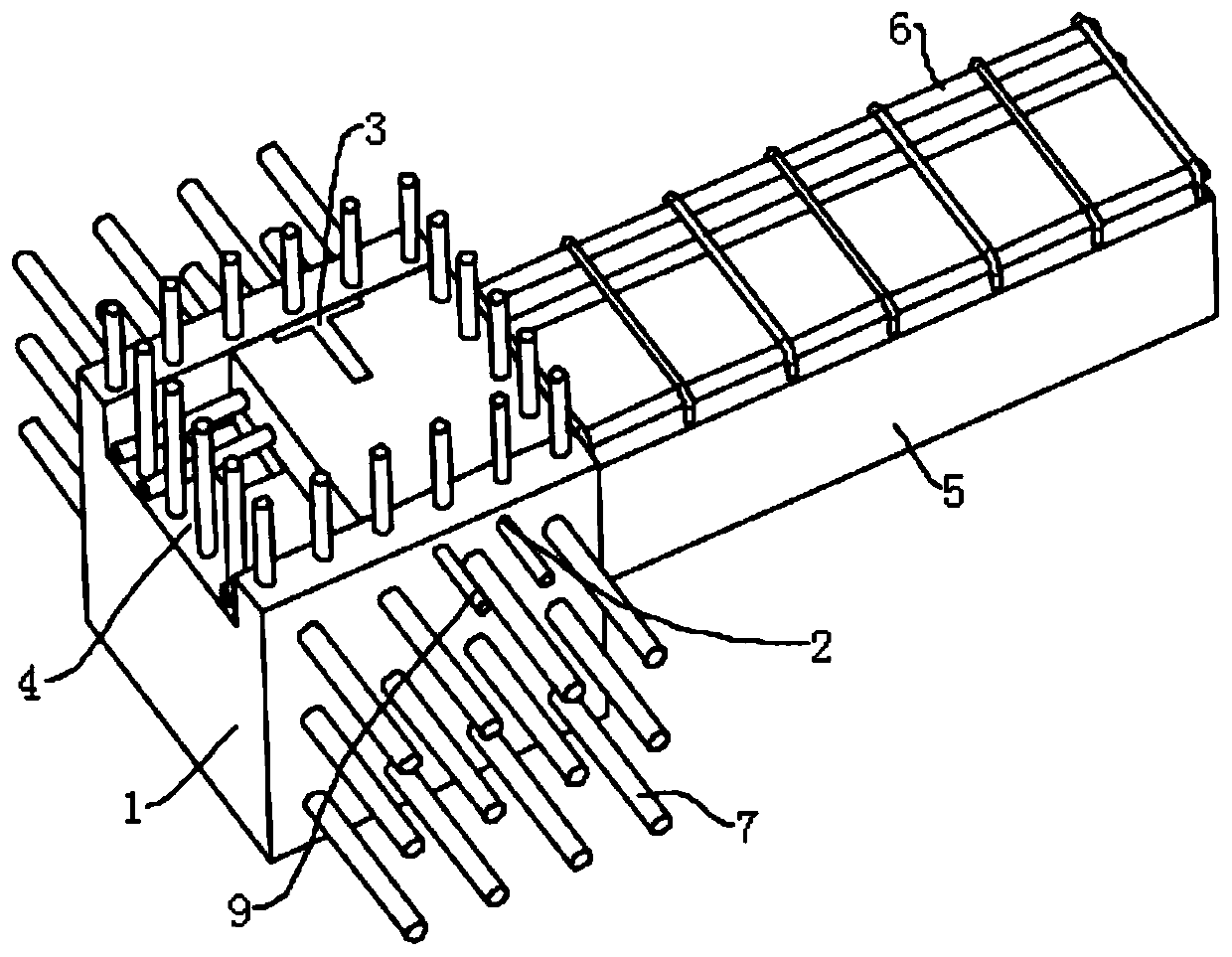

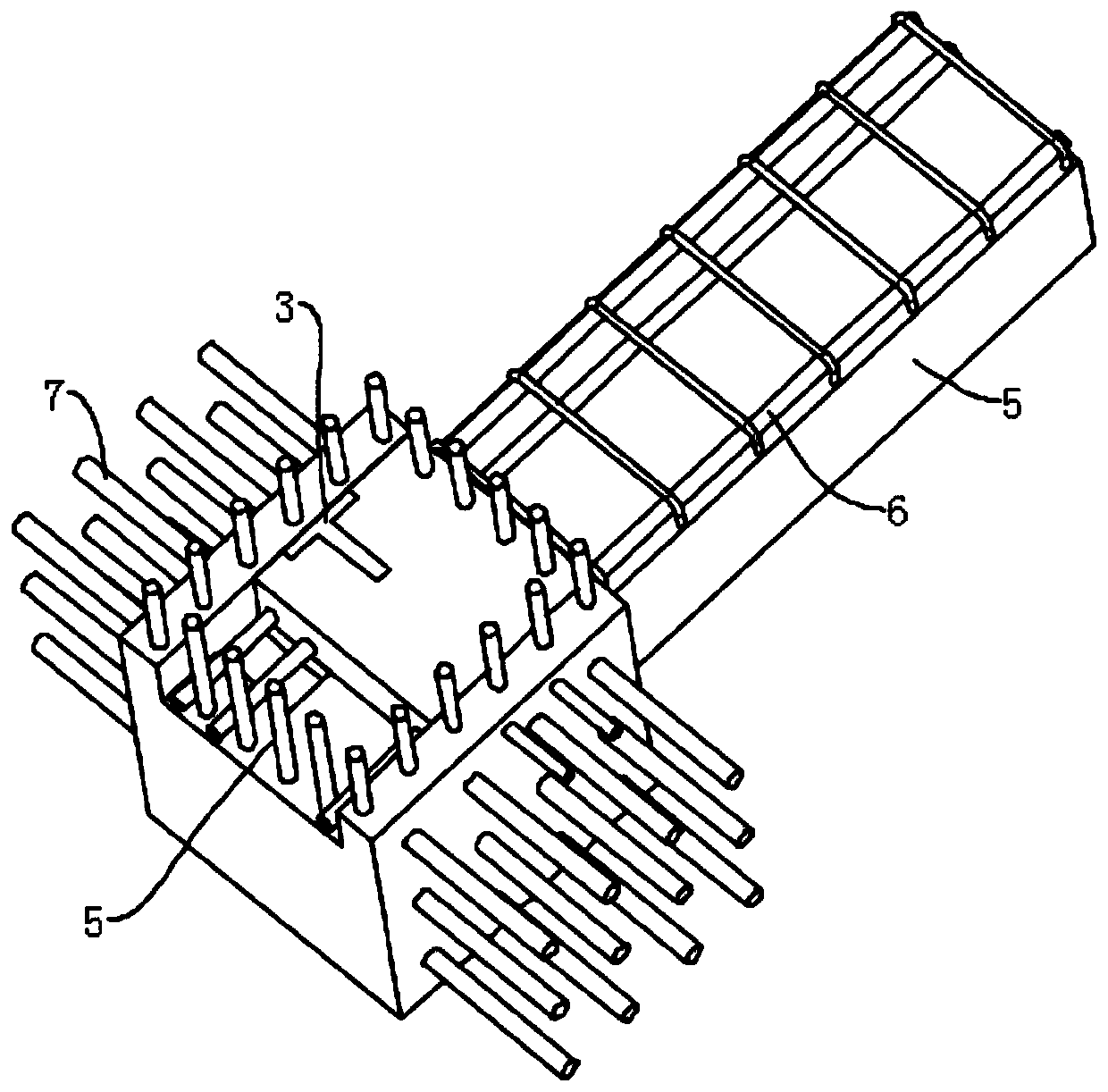

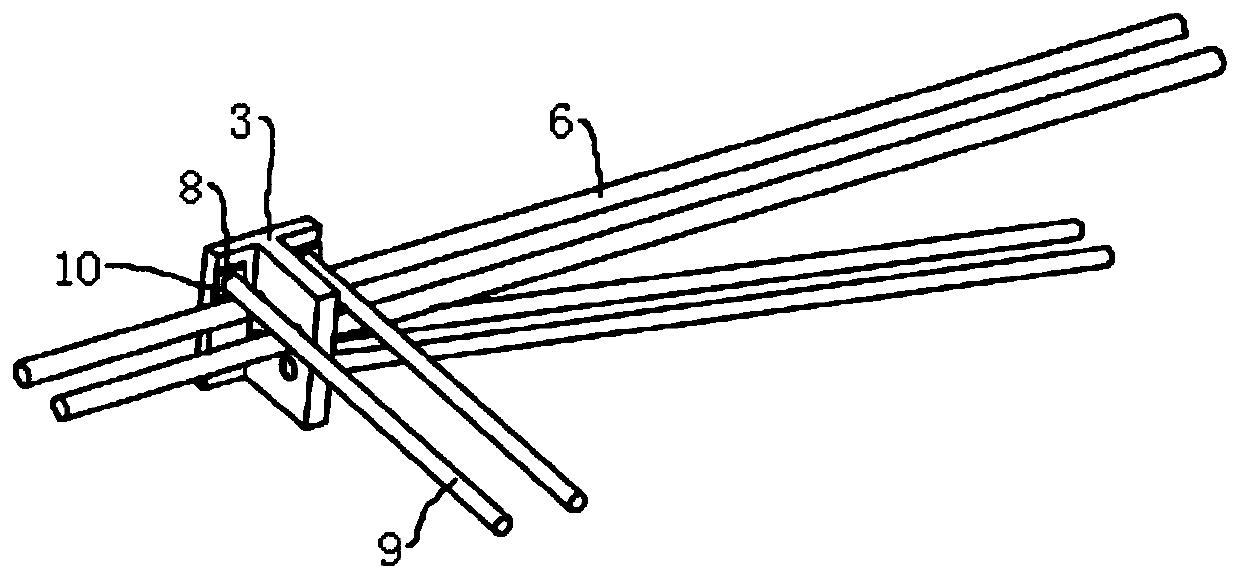

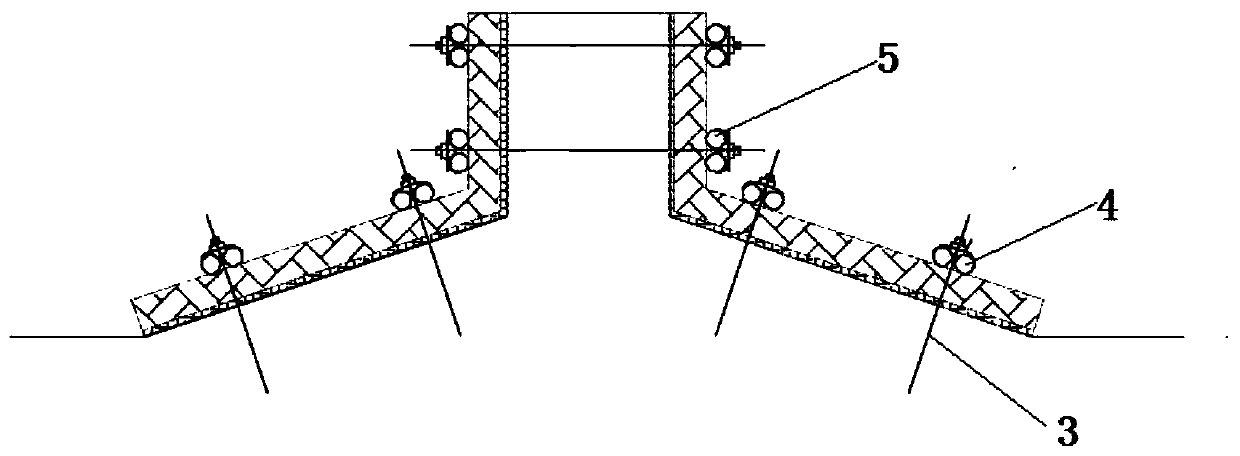

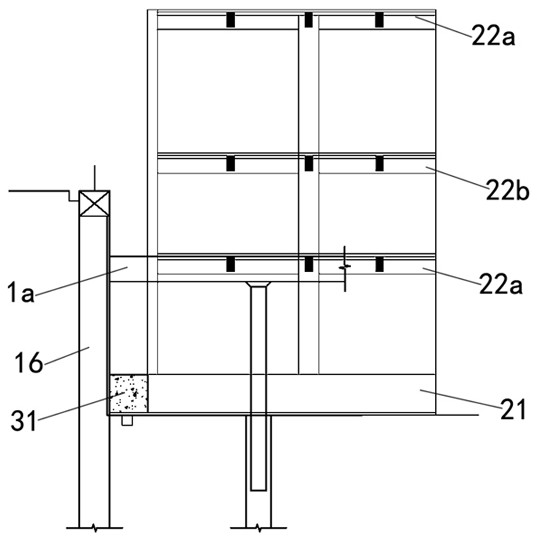

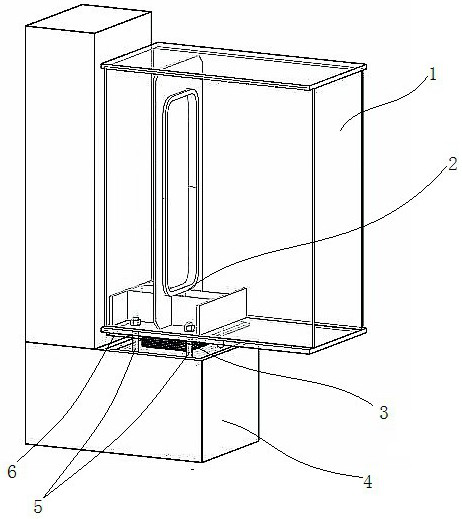

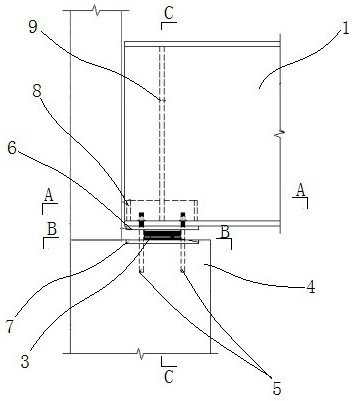

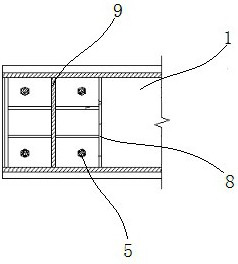

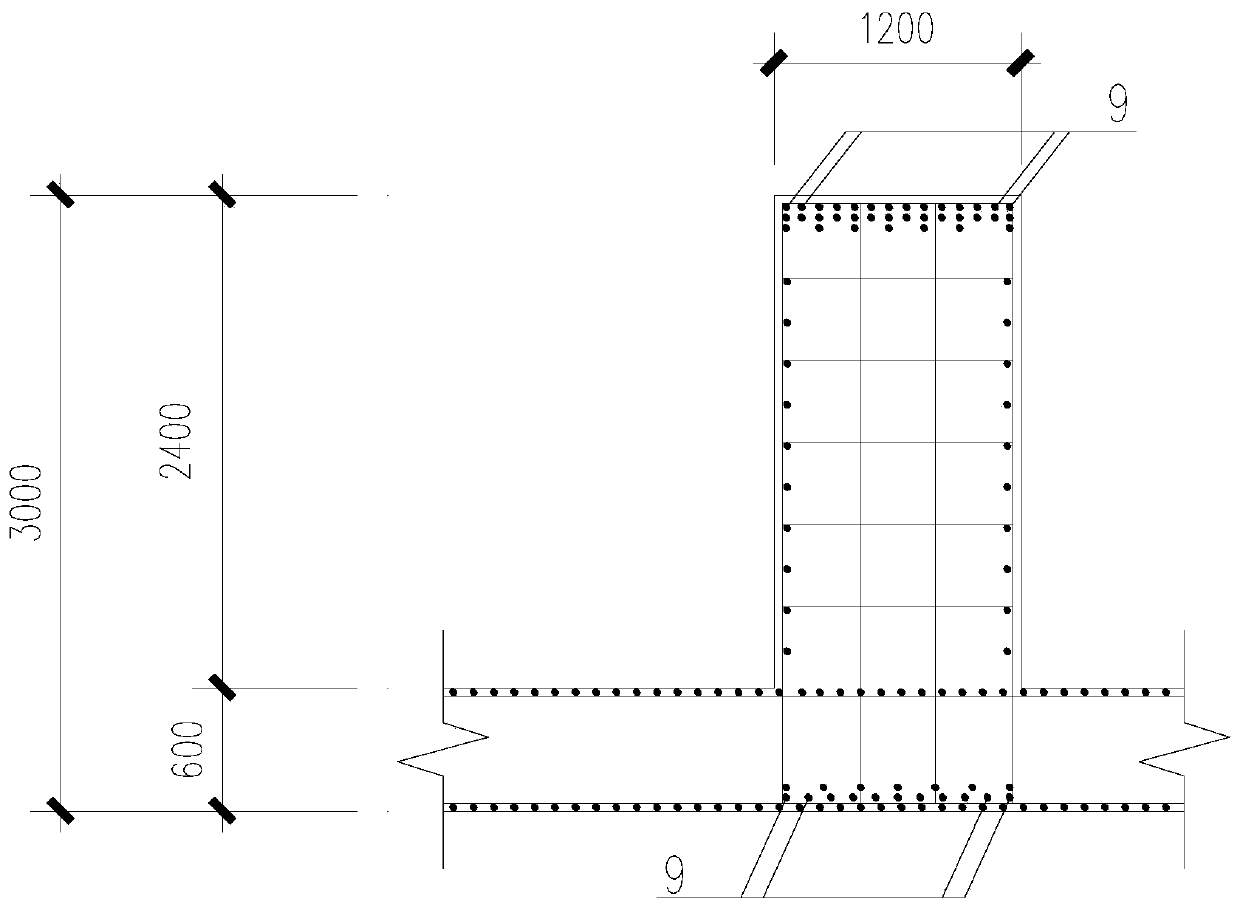

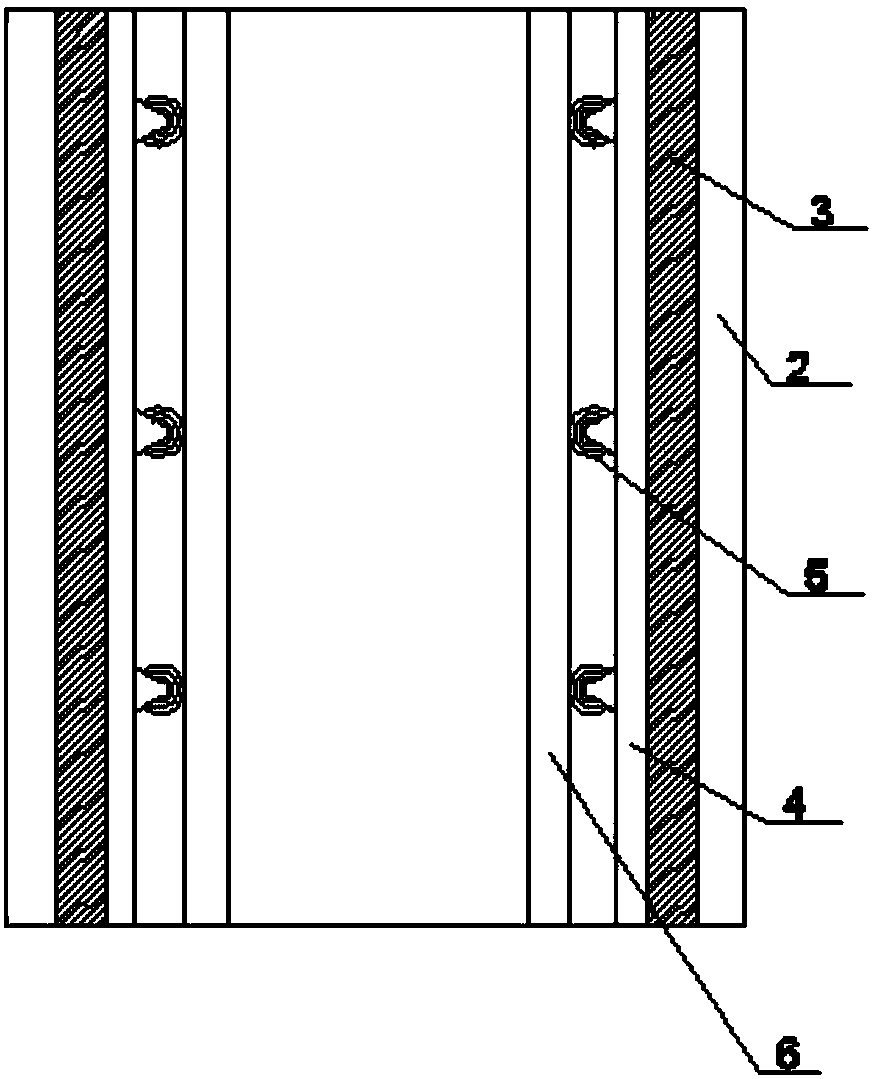

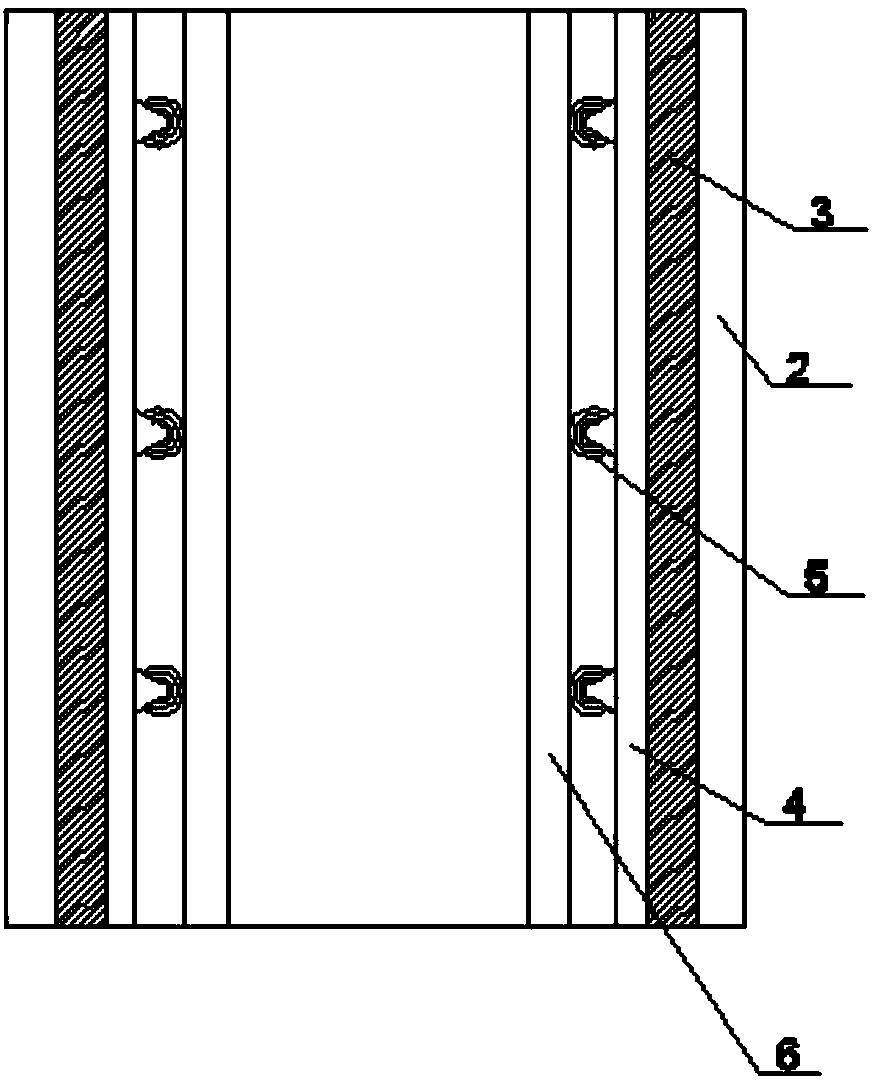

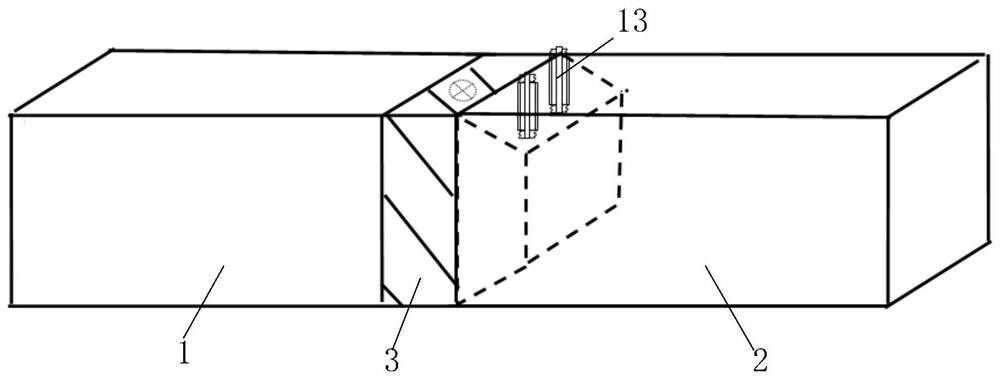

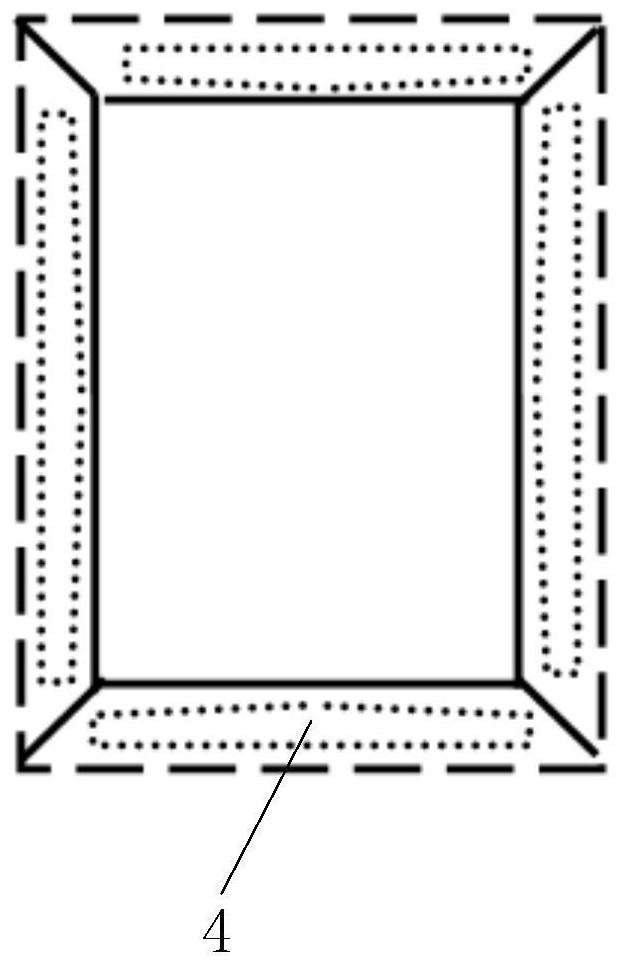

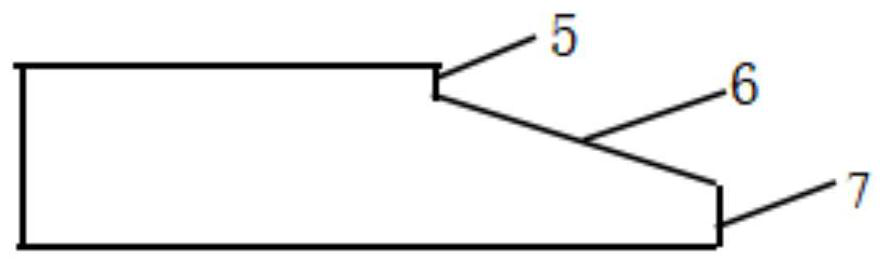

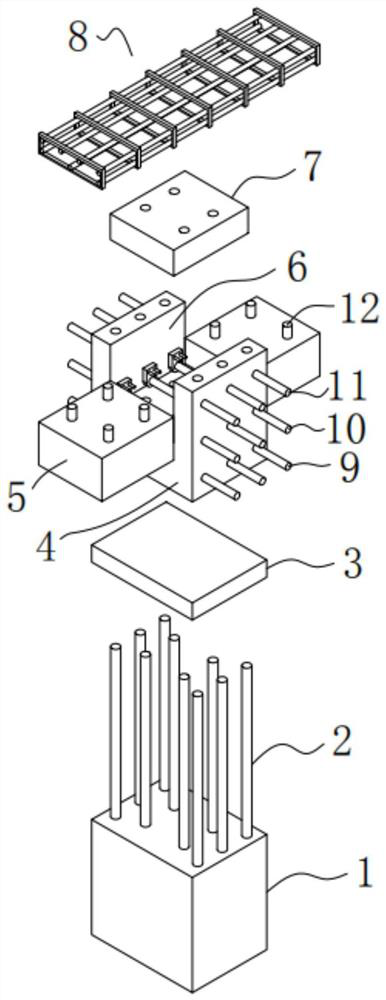

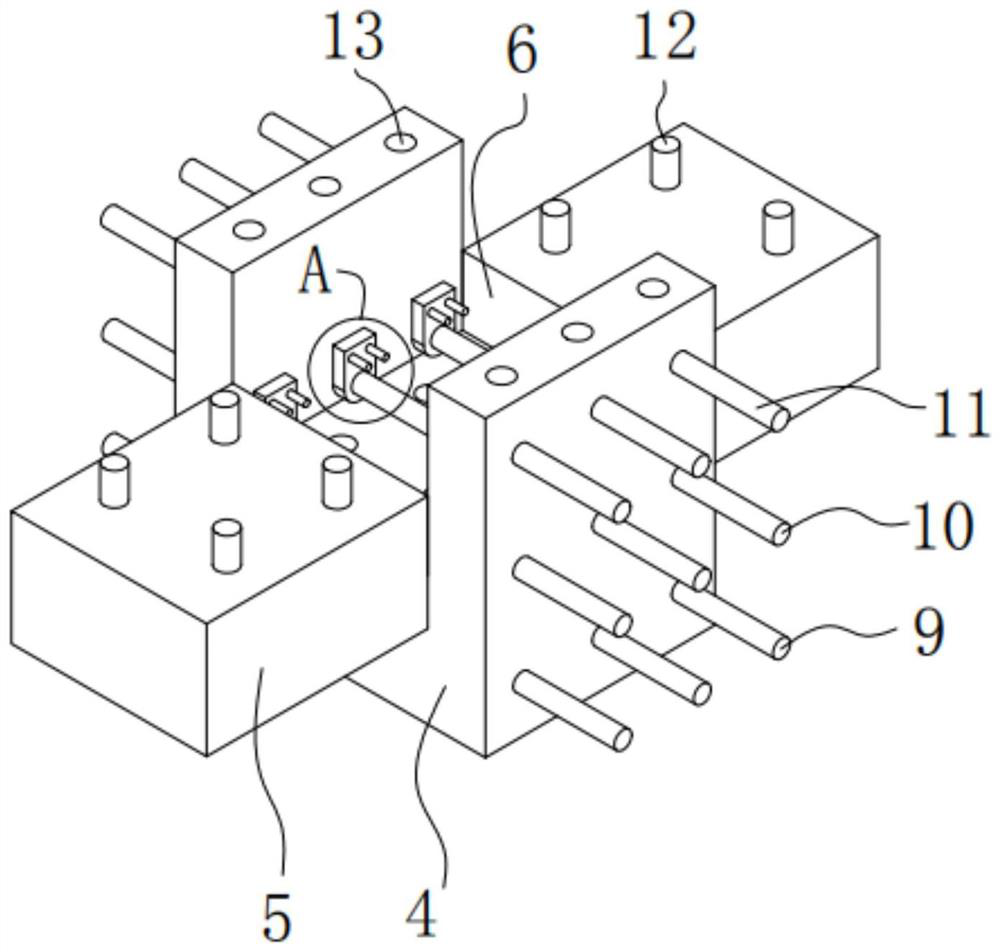

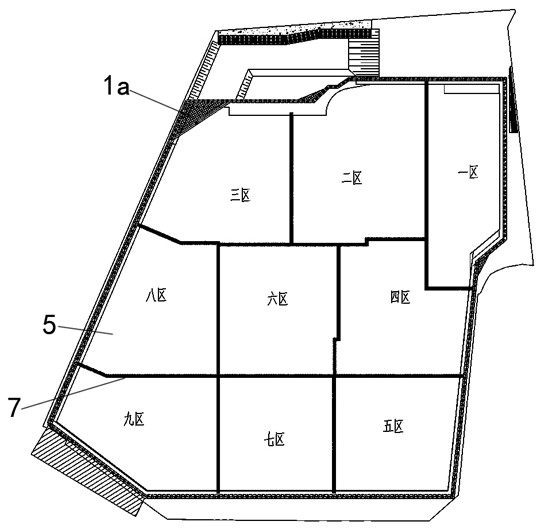

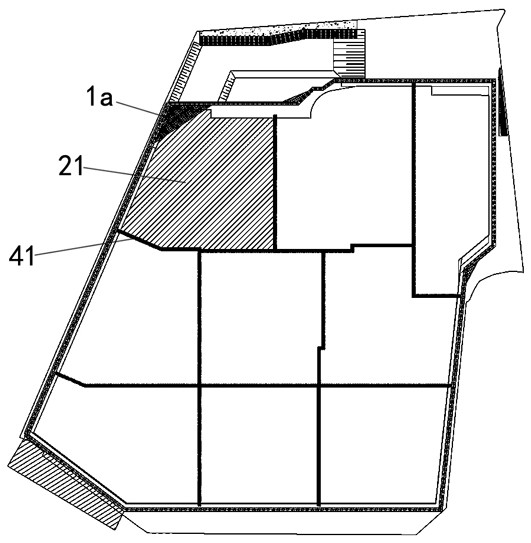

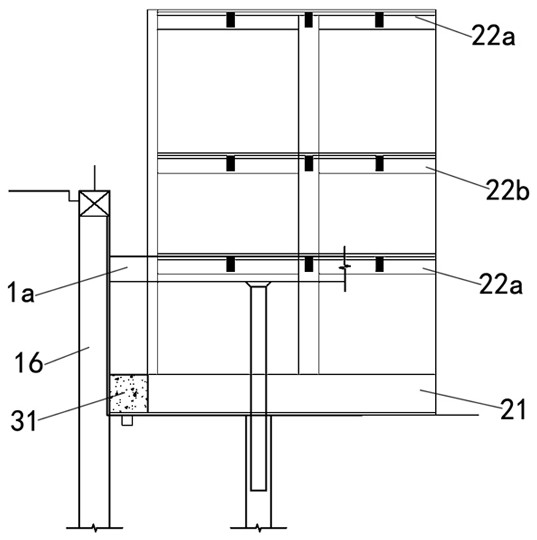

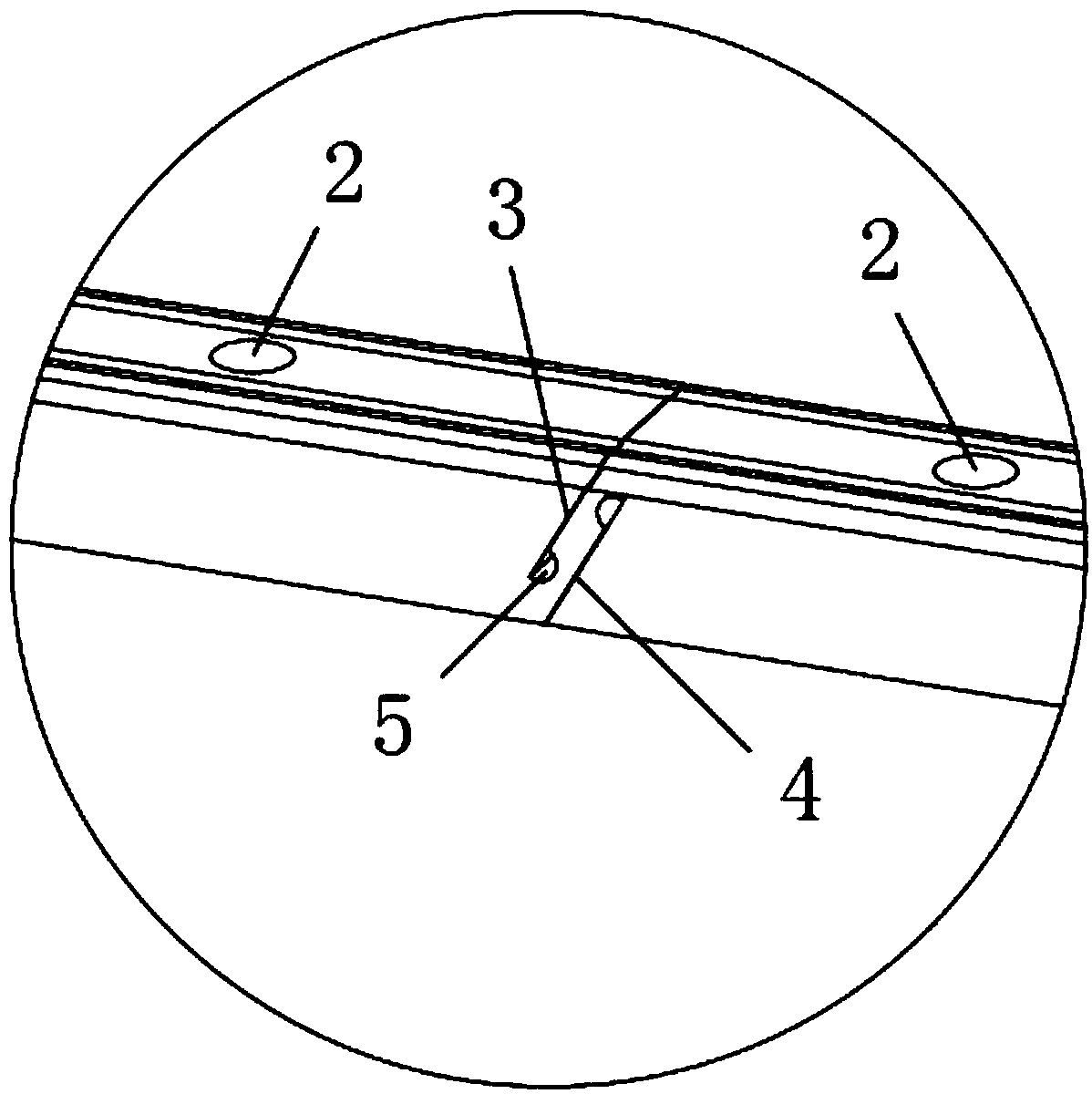

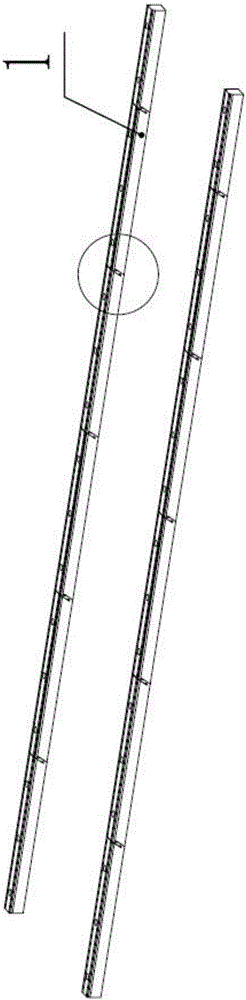

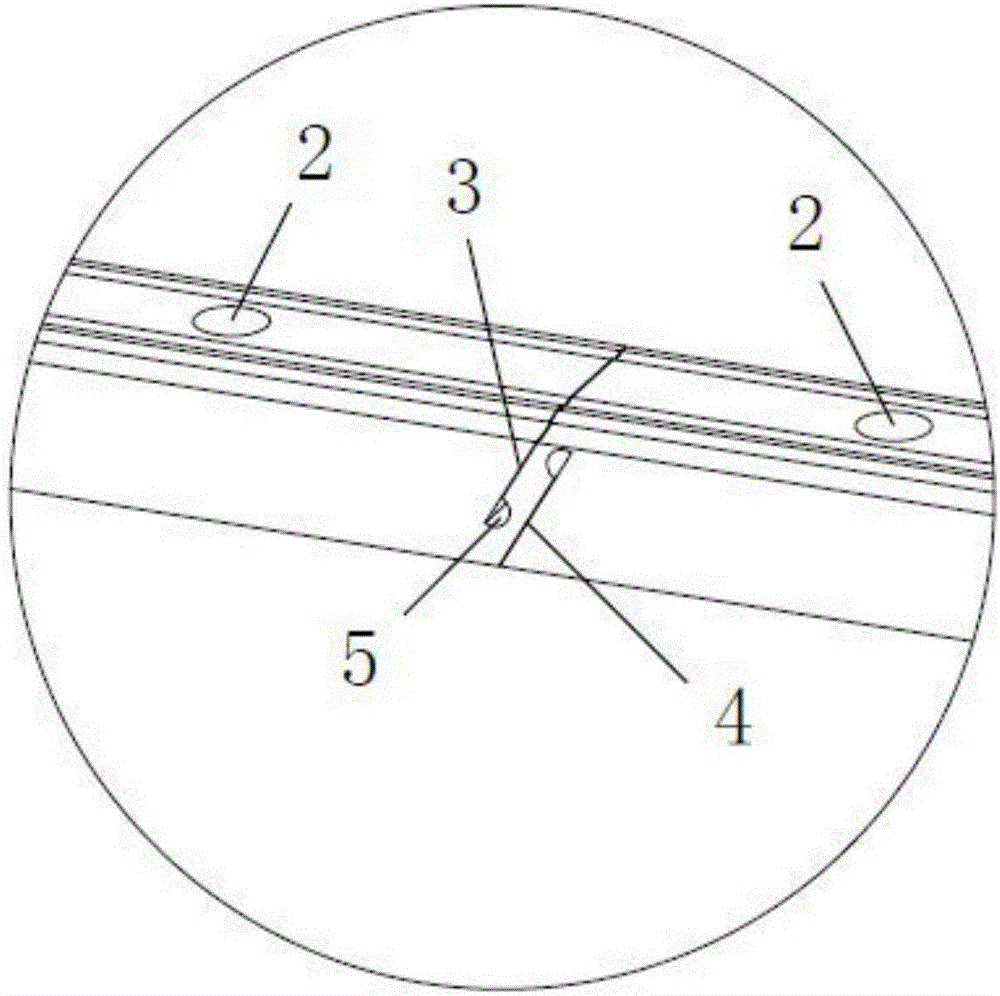

Shaped external-hanging-bracket protective system and installation method

InactiveCN107524284AGuaranteed stress requirementsGuaranteed Protection RequirementsScaffold accessoriesBuilding support scaffoldsEngineeringProtective system

The invention discloses a shaped external-hanging-bracket protective system and an installation method, and belongs to the technical field of assembly building construction. The shaped external-hanging-bracket protective system comprises a plurality of protective devices, and is characterized in that each protective device comprises a plurality of triangular support frames, an operating platform (6) arranged on the upper sides of the support frames and a protective bracket (7) arranged on the operating platform (6), the support frames are arranged on the outer side of a prefabricate external wall (1) and detachably connected with the prefabricate external wall (1), the operating platforms (6) are arranged on the support frames and detachably connected with the support frames, and the protective brackets (7) are arranged on one sides, away from the prefabricated external wall, of the operating platforms (6). According to the shaped external-hanging-bracket protective system, the structure is stable, construction turnover is convenient, labor and materials are saved, the protective effect is good, the appearance is elegant, and the problem of assembly building construction peripheral protection is solved; and according to the installation method of the shaped external-hanging-bracket protective system, operation is convenient, fixing among different floors is flexible, and the installation method is suitable for assembly building construction.

Owner:山东天齐置业集团股份有限公司

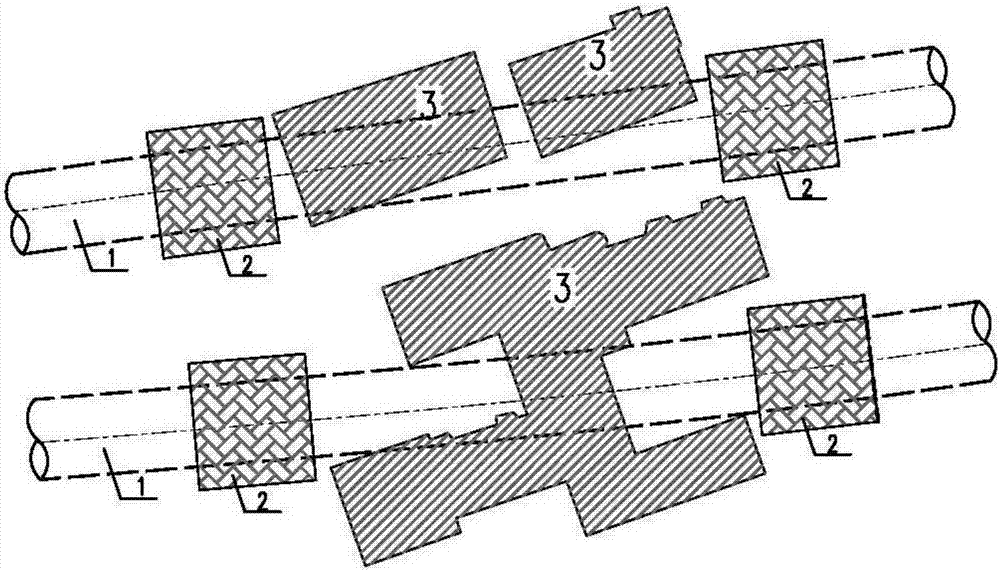

Suspended single-track large-span track beam system

ActiveCN107724225AAddress structural securityAddress structural requirementsBridge structural detailsTowerControl theory

The invention belongs to the technical field of track traffic and discloses a suspended single-track large-span track beam system. The suspended single-track large-span track beam system comprises a main beam and steel box track beams, wherein a longitudinal direction of the main beam extends along a front-rear direction; the main beam comprises a top beam and two side boxes; the two side boxes are parallel to each other and respectively arranged at the left and right ends at the bottom of the top beam; the left and right side boxes respectively penetrate through bridge towers on correspondingsides and are nested on the bridge towers on the corresponding sides, so that fixed connection between the bridge towers and the main beam is realized; in addition, each of the side boxes is respectively connected with the bridge tower on the corresponding side by virtue of a stay cable; two steel box track beams are arranged; a longitudinal direction of each of the steel box track beams extendsalong the front-rear direction; each of the steel box track beams is suspended on the top beam; and the two steel box track beams are positioned between the two side boxes. The suspended single-tracklarge-span track beam system disclosed by the invention has the characteristics of being simple in structure and clear in stress, and the requirements on structural safety and service function in thesuspended single-track large-span track beam are met.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

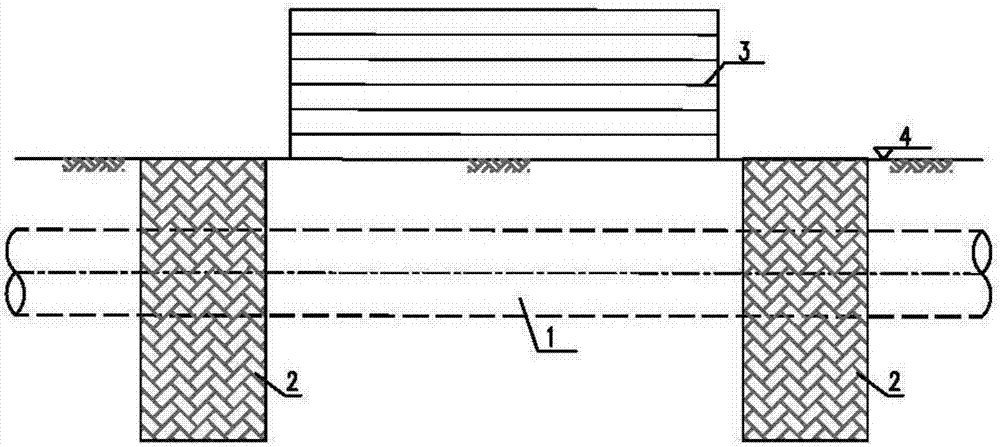

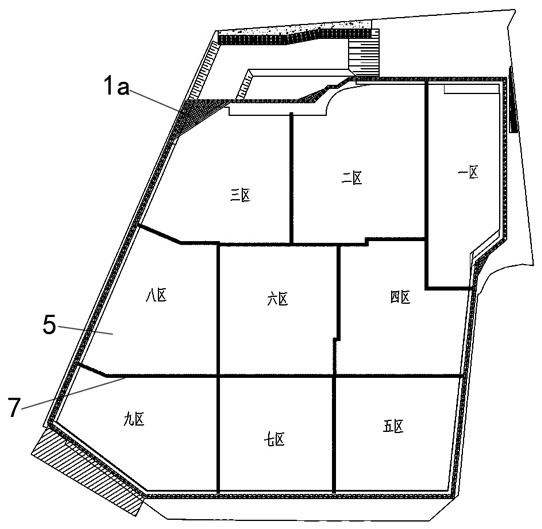

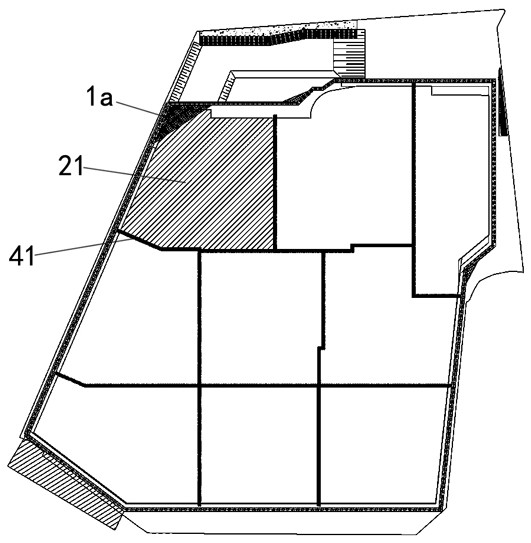

Control method and structure for shield tunnel underlying soft soil layer plastic deformation

PendingCN107100629AGuaranteed deformation requirementsGuaranteed stress requirementsTunnelsStructural engineeringShield tunnelling

The invention discloses a control method and structure for shield tunnel underlying soft soil layer plastic deformation. The control method and structure for the shield tunnel underlying soft soil layer plastic deformation are suitable for a shield tunnel of underneath pass buildings / structures. The control method includes the following steps that a soft soil layer within a certain depth range is reinforced on the spaces at the two ends of the underneath pass buildings / structures so as to form soil bearing platform support structures, and the shield tunnel penetrates through the soil bearing platform support structures at the two ends; and support for bearing loads is achieved by utilizing the shield tunnel structure and an underground bridge span type anti-sedimentation structure formed by the soil bearing platform support structures at the two ends, so that plastic deformation of a tunnel underlying soft soil layer is controlled. The invention further discloses a corresponding control structure for the shield tunnel underlying soft soil layer plastic deformation. According to the control method and structure for shield tunnel underlying soft soil layer plastic deformation, through optimized reinforcement way design, the plastic deformation of the underlying soft soil layer is controlled, and the control method and structure cannot damage the tunnel structure and are especially suitable for the shield tunnel of the underneath pass buildings / structures.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

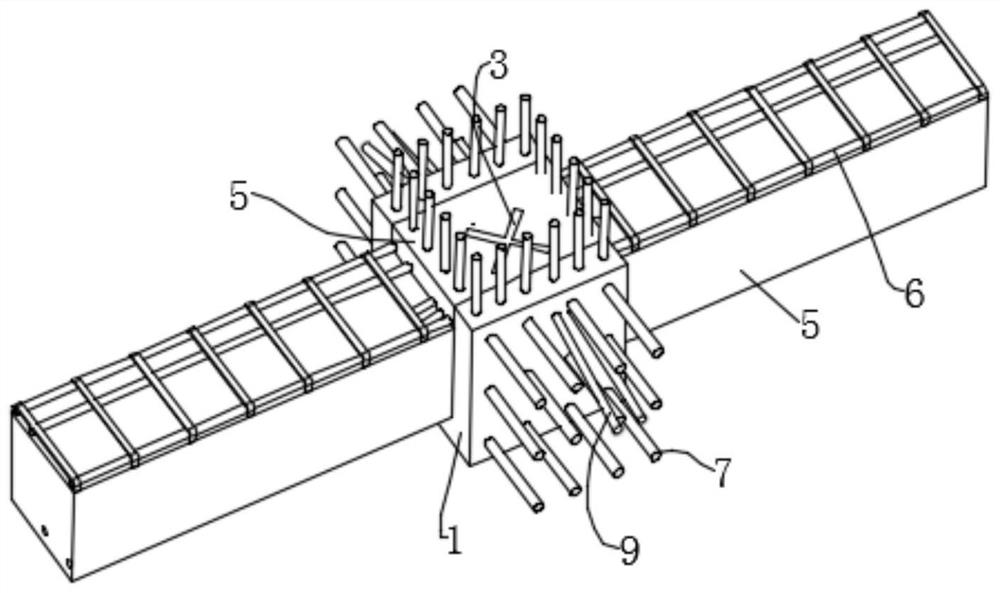

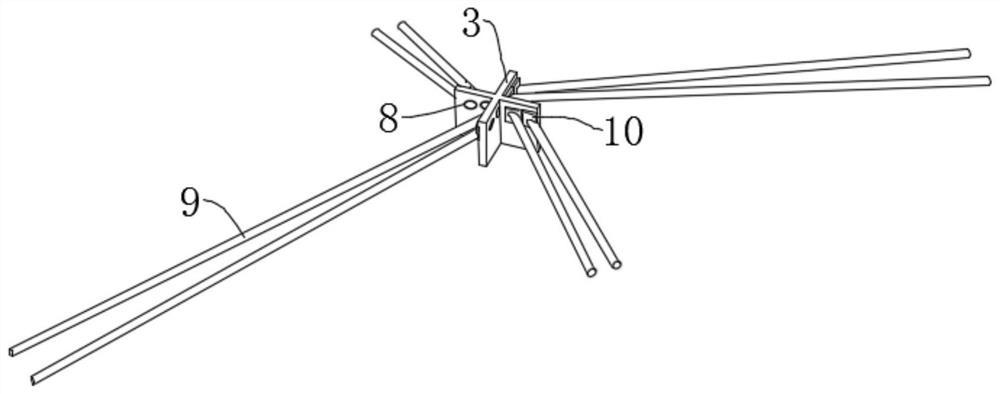

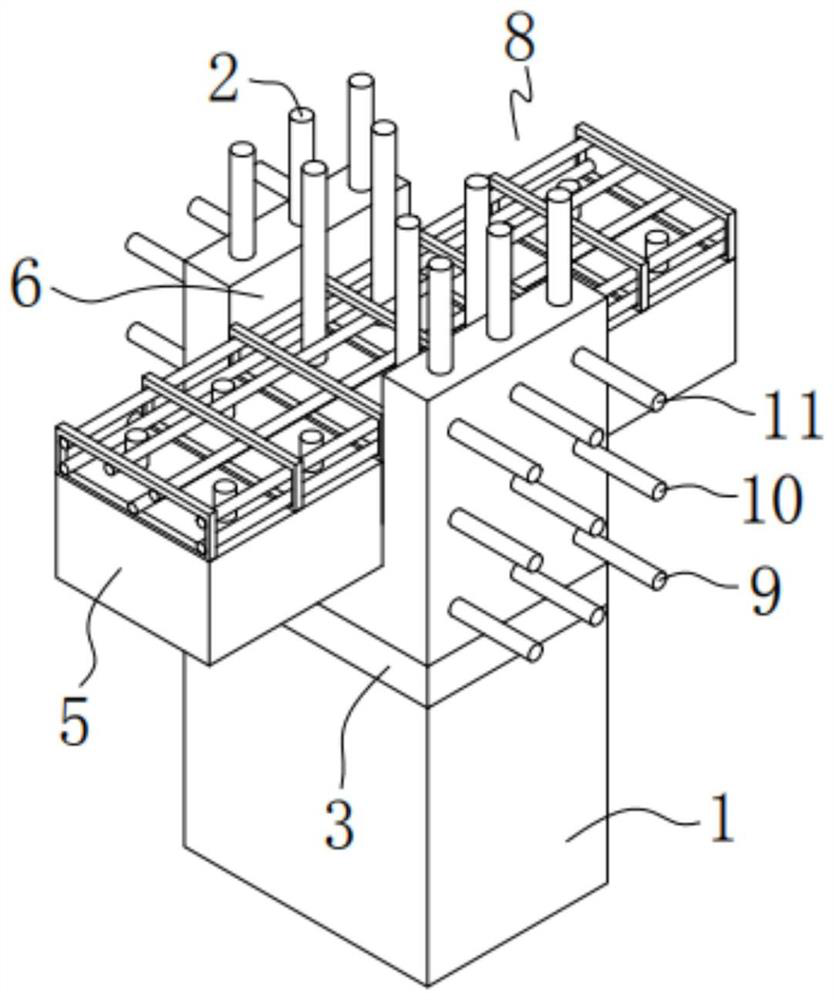

Fabricated building lotus-root-type beam pre-buried heat-preservation plate post-tensioned anchorage joint structure and construction method thereof

ActiveCN110512727AImprove the force characteristicsGood anti-negative bending moment effectHeat proofingBuilding material handlingBending momentLotus root

The invention discloses a fabricated building lotus-root-type beam pre-buried heat-preservation plate post-tensioned anchorage joint structure. The fabricated building lotus-root-type beam pre-buriedheat-preservation plate post-tensioned anchorage joint structure comprises a precast column, precast column vertical outward-extending steel bars, a composite lotus-root-type beam column head, lotus-root-type beam outward-extending composite beams, a composite lotus-root-type beam reserved groove, composite lotus-root-type beam edge side outward-extending steel bars, an XPS heat-preservation plate, unbonded prestressed tendons, outward-extending steel bars at composite grooves, composite lotus-root-type beam upper part exposed steel bars and a flat hidden beam steel bar net. The invention further discloses a construction method of the fabricated building lotus-root-type beam pre-buried heat-preservation plate post-tensioned anchorage joint structure, and the construction method comprises the ten construction steps. According to the fabricated building lotus-root-type beam pre-buried heat-preservation plate post-tensioned anchorage joint structure, the force bearing characteristics of abeam-column joint is effectively improved, through an overall post-cast concrete face layer, the overall force bearing requirement of the beam-column joint is well ensured, and the hogging moment resisting effect of the joint is good; and the hoisting cost is low, the hoisting speed and precision are high, building construction is greatly assisted, and the positive effect on promoting industry modernization of prefabricated building hoisting is realized.

Owner:江苏晟功建设集团有限公司

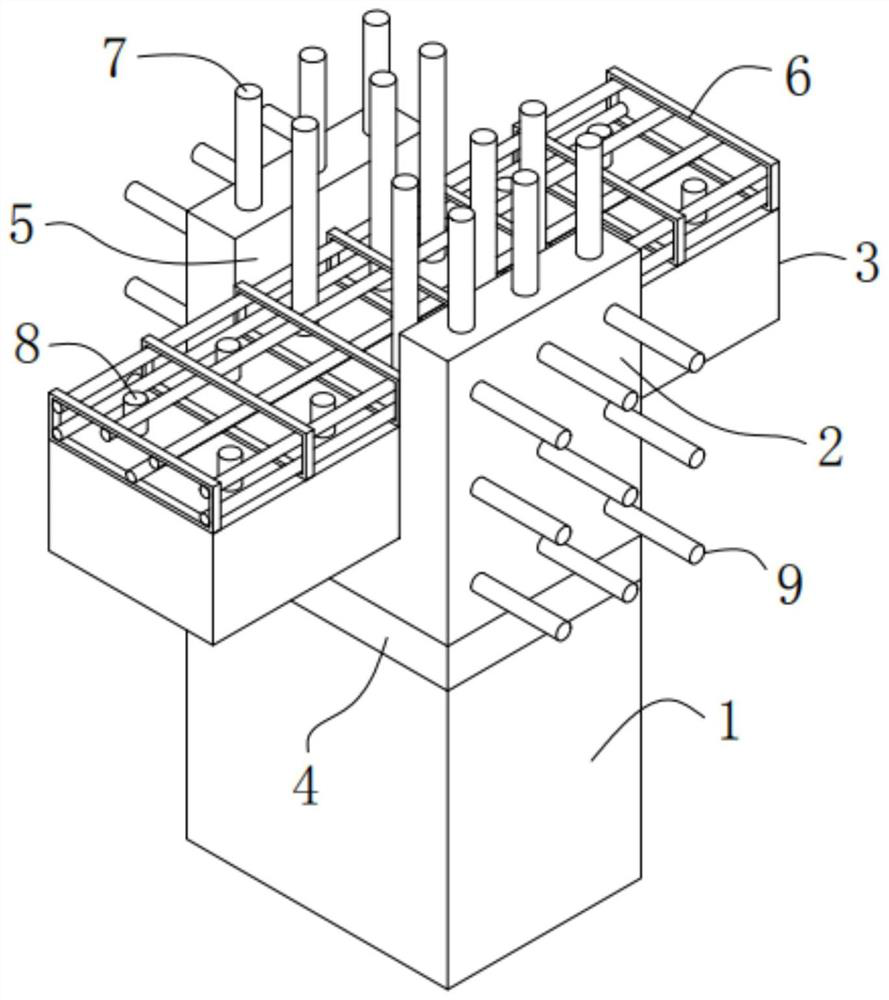

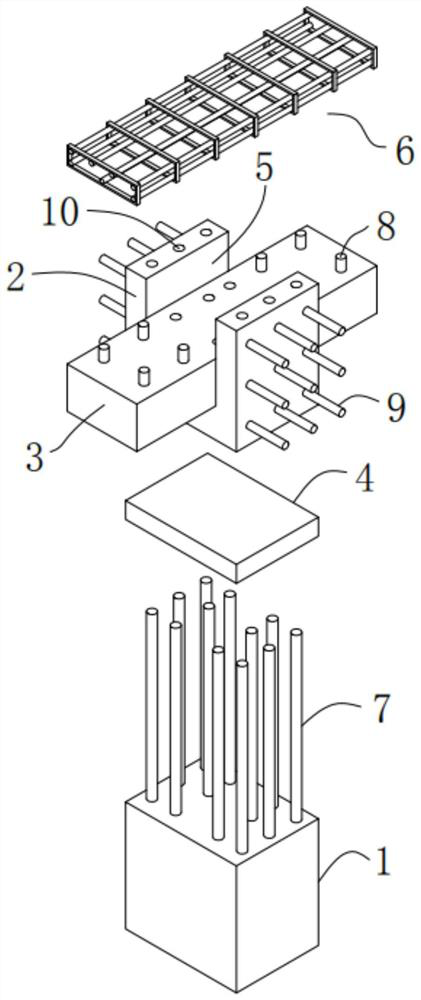

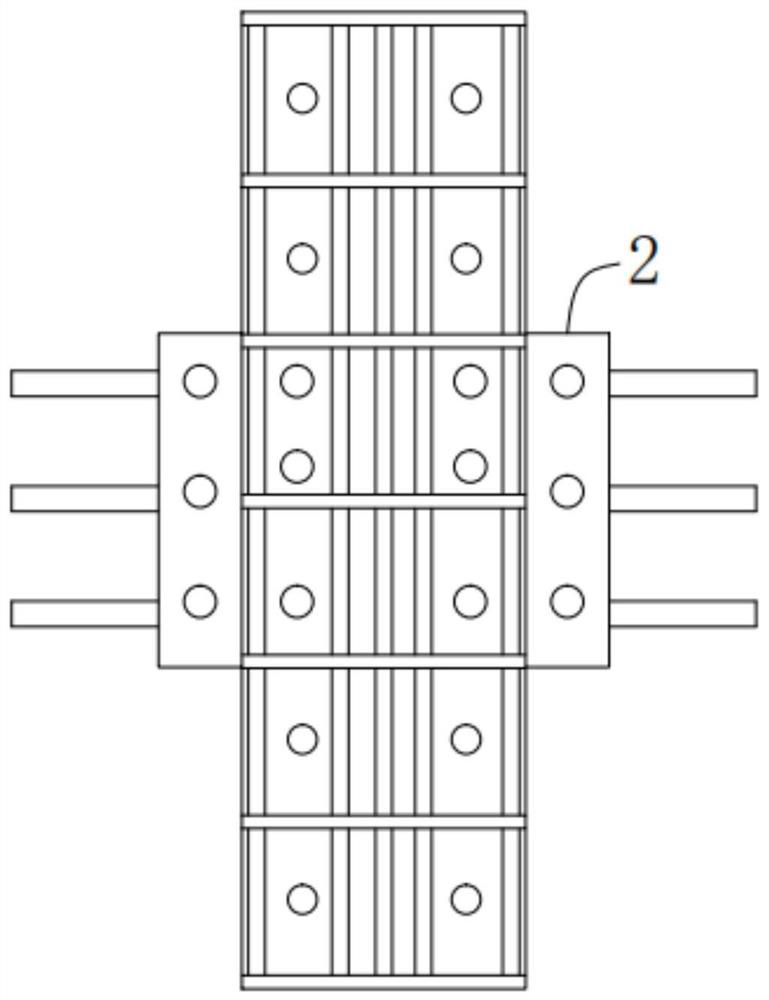

Fabricated building prefabricated steel reinforced concrete end column-beam joint prestressing tendon interlaced tension anchoring structure and construction method

ActiveCN111364681AHigh strengthImprove the force characteristicsBuilding reinforcementsReinforced concretePre stress

The invention discloses a fabricated building prefabricated steel reinforced concrete end column-beam joint prestressing tendon interlaced tension anchoring structure. The fabricated building prefabricated steel reinforced concrete end column-beam joint prestressing tendon interlaced tension anchoring structure comprises prefabricated columns, and further comprises reserved hole channels reservedin the prefabricated columns, T-shaped steel columns integrated with the prefabricated columns, prefabricated column laminated layers arranged on the upper parts of the prefabricated columns, superimposed beams arranged at one ends of the prefabricated columns, top steel bars exposed to the upper parts of the superimposed beams, external extension steel bars extending outside the sides of the prefabricated columns, a plurality of reserved penetrating holes formed in the T-shaped steel columns, prestressing tendons penetrating through the multiple reserved penetrating holes, and prestressing tendon anchoring devices fixed to the T-shaped steel columns, and the prestressing tendons are fixed to the T-shaped steel columns through the prestressing tendon anchoring devices. The structure ensures the overall stress requirements of beam-column joints and enables the joints to have a good hogging moment resisting effect.

Owner:刘荣春

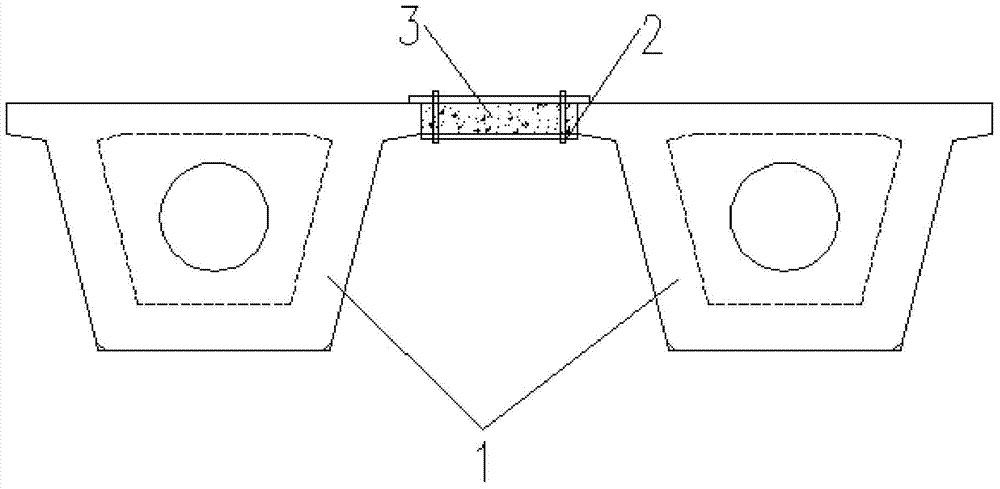

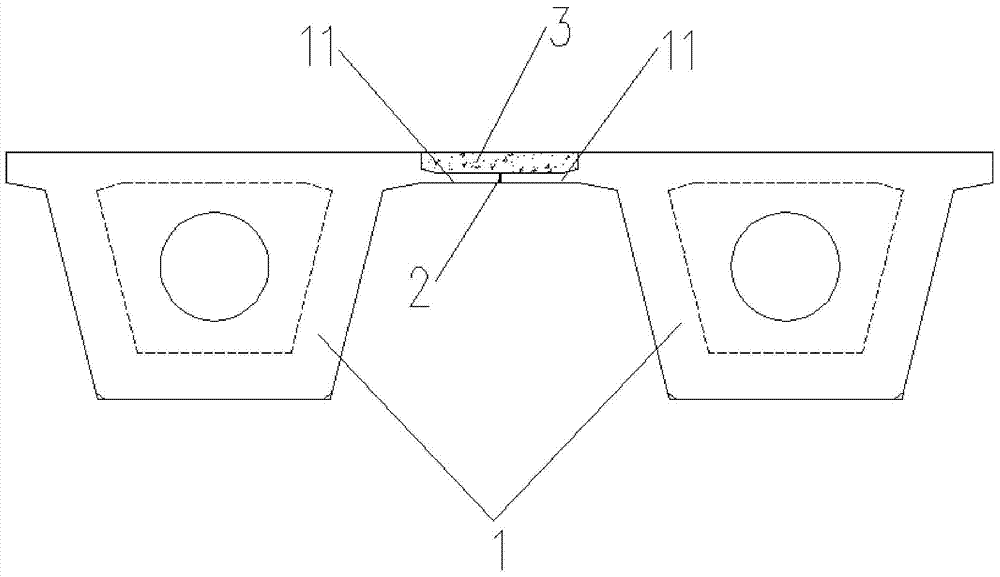

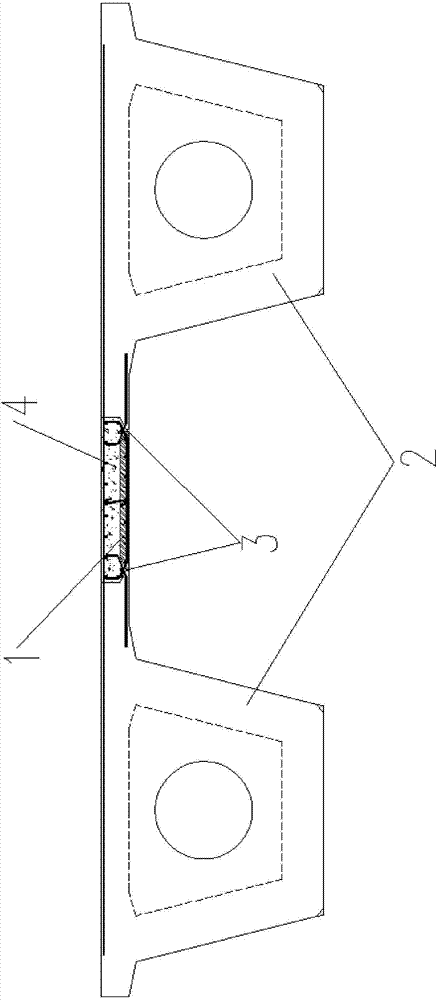

Wet connection section connection structure used between fully prefabricated assembled bridge girders

ActiveCN104499430AAvoid installation and disassemblyFlexible settingsBridge structural detailsBridge materialsRebarSurface plate

The invention discloses a wet connection section connection structure used between fully prefabricated assembled bridge girders. The wet connection section connection structure comprises a prefabricated lower layer bridge slab with a certain thickness, wherein a convex rebar structure is arranged at the upper edge of the prefabricated lower layer bridge slab. The prefabricated lower layer bridge slab is arranged on a wet connection section of the two prefabricated girders, a concave structure is arranged on the two prefabricated girders on the wet connection section side, and the convex rebar structure extends into the concave structure. The wet connection section connection structure does not need to use a hanger formwork and can ensure the force bearing requirement of the bridge girder structure.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

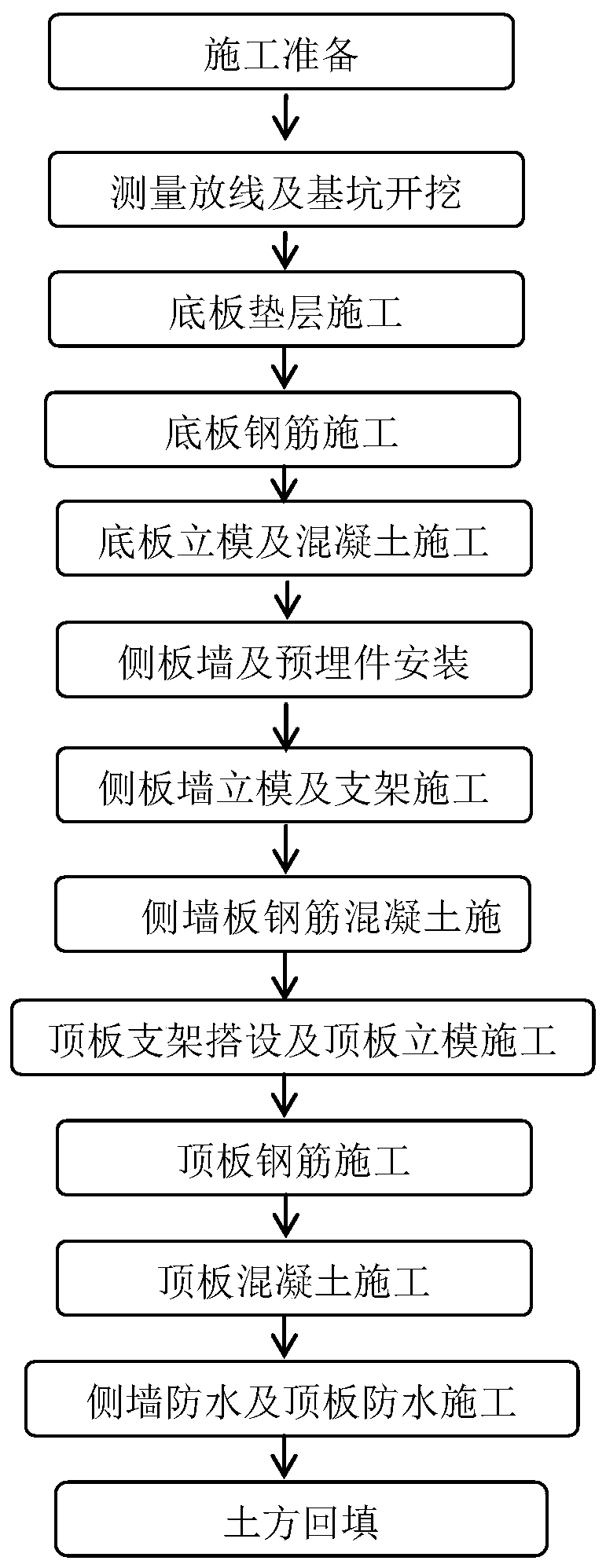

Cable tunnel construction method

PendingCN110607805AReduce constructionReliable constructionCable installations on groundArtificial islandsControl lineEngineering

The invention discloses a cable tunnel construction method, and relates to the field of urban tunnel construction. The construction method comprises the construction steps of bottom plate construction, side wall plate construction, roof construction and waterproofing construction of side walls and a roof. Before bottom plate construction, a plurality of steel bars are uniformly distributed and embedded in an excavated cushion foundation pit in the transverse direction and the longitudinal direction, and after concrete pouring of the cushion layer is finished, the axis line, the sideline line and the control line are laid off on the cushion layer; side wall plate construction needs to be started after the bottom plate concrete has certain strength, a formwork support is erected, then binding construction of rear side wall plate steel bars is conducted, and casings and embedded parts are installed in time; the roof structure needs to be supported by a spigot-and-socket plate buckle fullsupport frame before roof construction; waterproofing construction of the side walls and the roof comprises laying an upper waterproofing coiled material and a lower waterproofing coiled material, andthen laying a layer of grid cloth on the upper waterproofing coiled material. The construction method is relatively low in cost and reliable and safe in construction, and can ensure quality of a mainbody structure.

Owner:STATE GRID JIANGSU ELECTRIC POWER ENG CONSULTING CO LTD +1

Construction method for removing inner support in vertical section mode

ActiveCN113463653AThe force characteristics are clearAbsolute duration shortenedArtificial islandsExcavationsArchitectural engineeringUltimate tensile strength

Owner:CHINA CONSTR FIRST GROUP THE FIFTH CONSTR +1

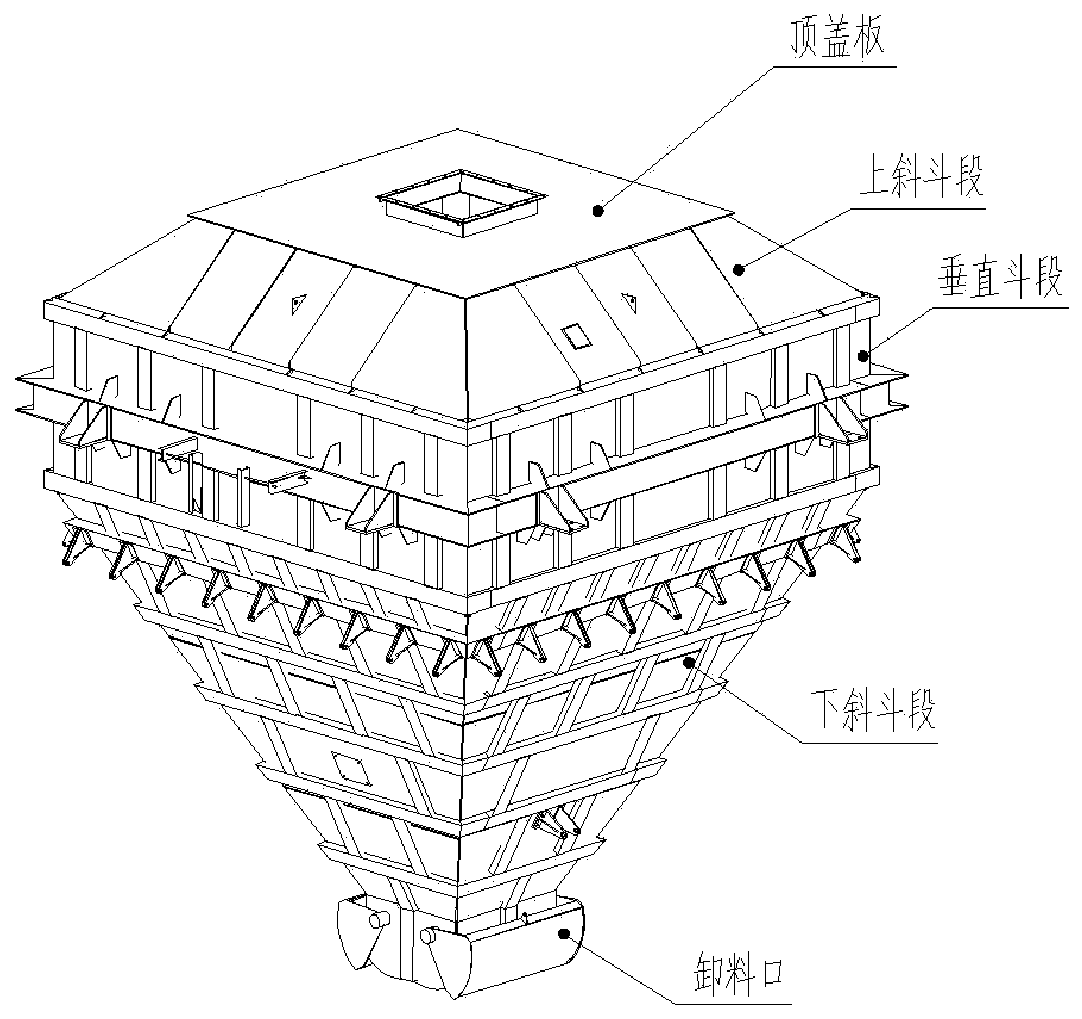

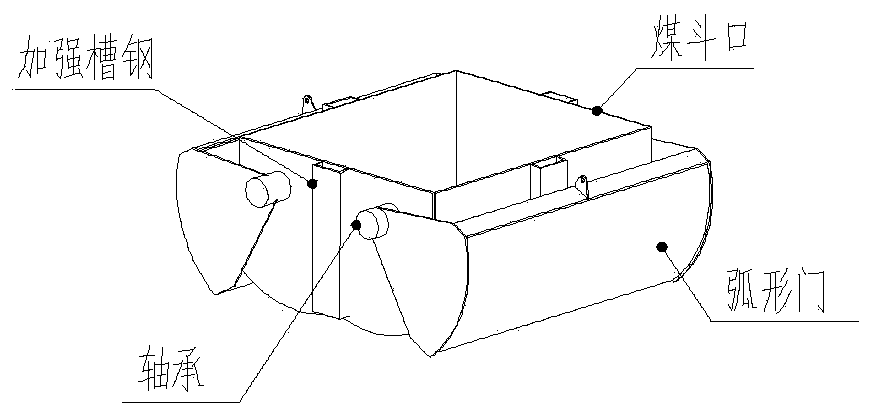

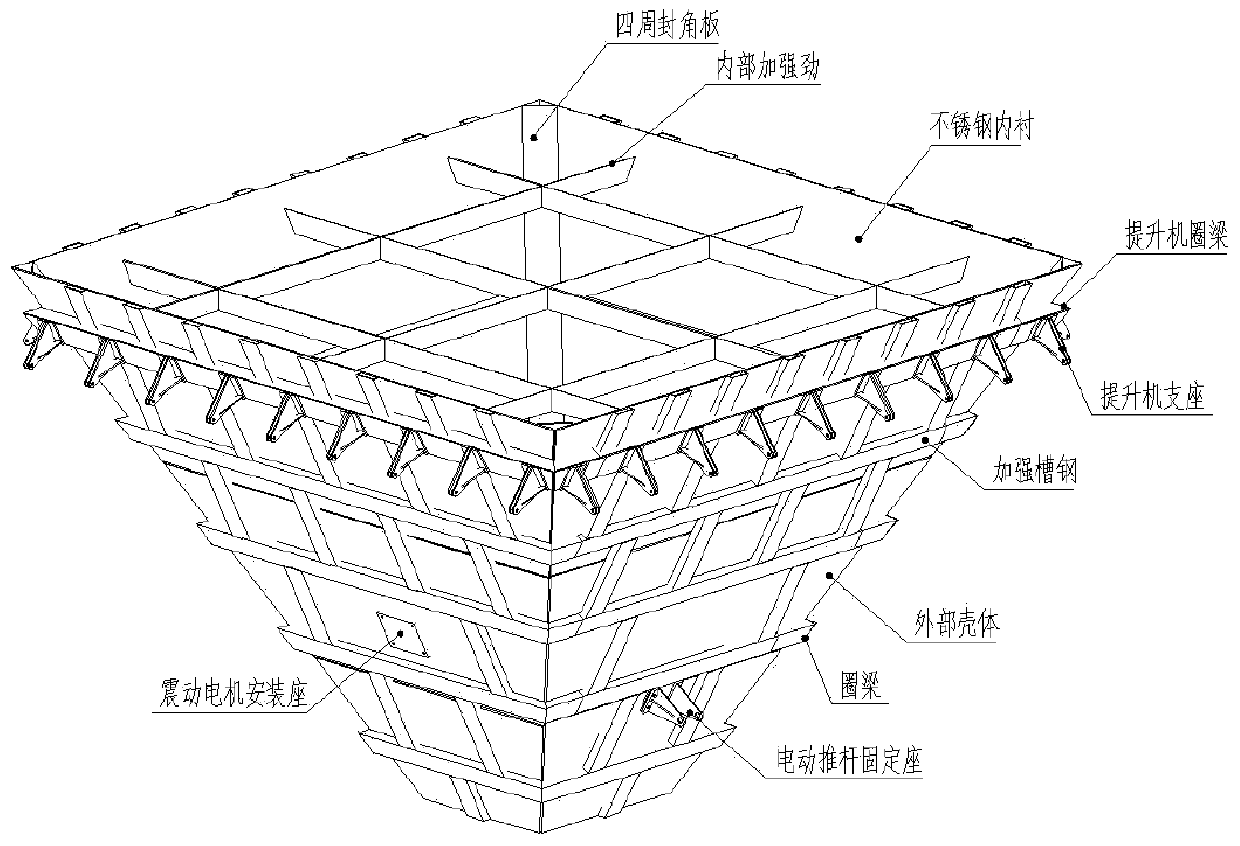

Square non-standard coal hopper with bin cover and manufacturing method

ActiveCN110977351AUnique shapeFlow principleLarge containersWelding apparatusStructural engineeringMechanical engineering

The invention relates to a square non-standard coal hopper with a bin cover and a manufacturing method. The coal hopper is characterized by comprising components of a discharge port, a lower inclinedhopper section, a vertical hopper section, an upper inclined hopper section and a top cover plate, wherein the discharge port is positioned at a lowermost end of a coal hopper, a lower end of the lower inclined bucket section is welded with an upper end of the discharge port, an upper end is welded with a lower end of the vertical bucket section, a lower end of the vertical bucket section is welded with an upper end of the lower inclined bucket section, an upper end is welded with a lower end of the upper inclined bucket section, a lower end of the upper inclined bucket section is welded withan upper end of the vertical bucket section, an upper end is welded with a lower end of the top cover plate, the top cover plate is located at an uppermost end of the coal hopper. The coal hopper is advantaged in that materials used in all sections meet the requirement for saving, and the functional requirements for feeding, storing, distributing and weighing of coal are integrally met.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE +2

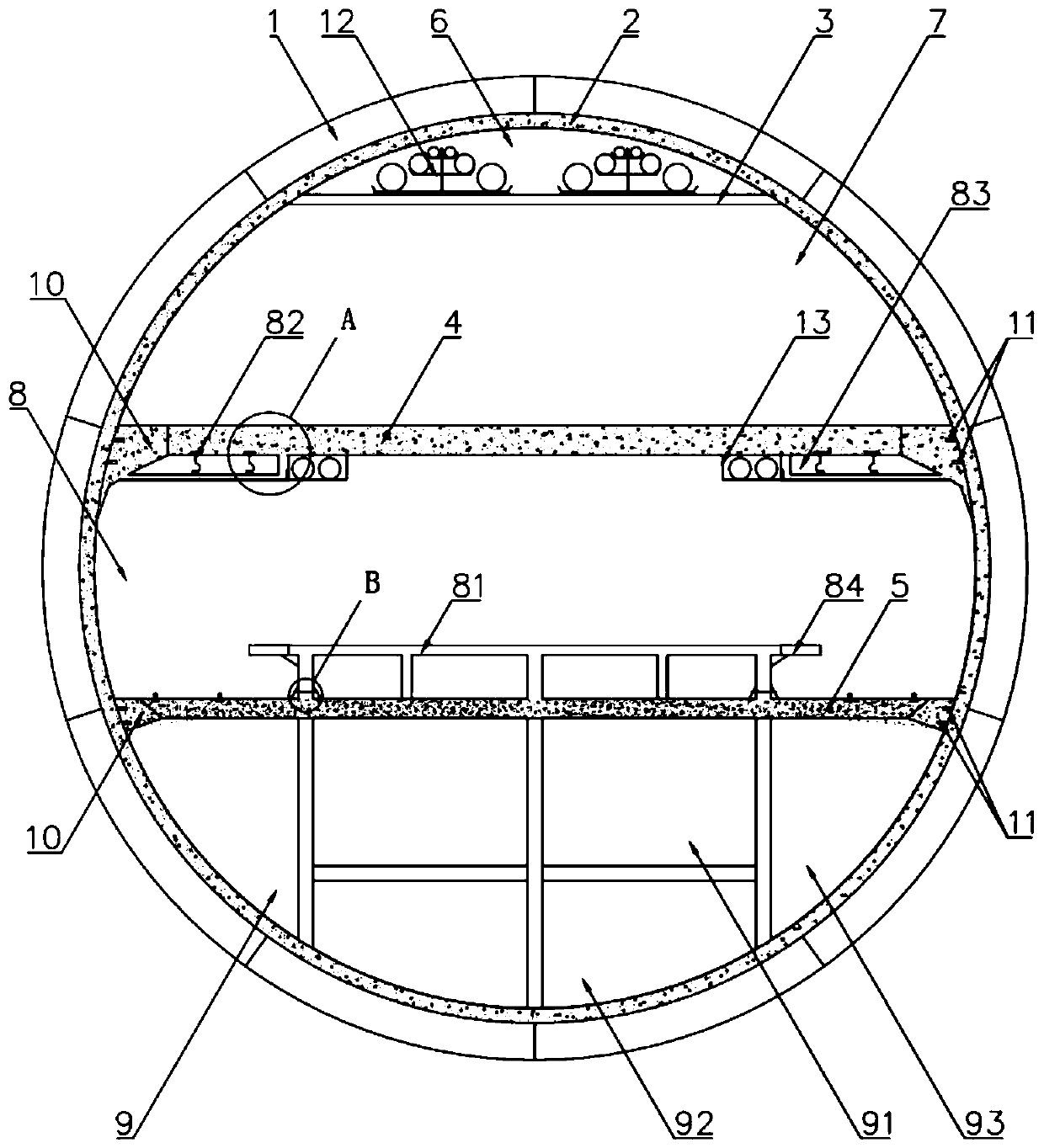

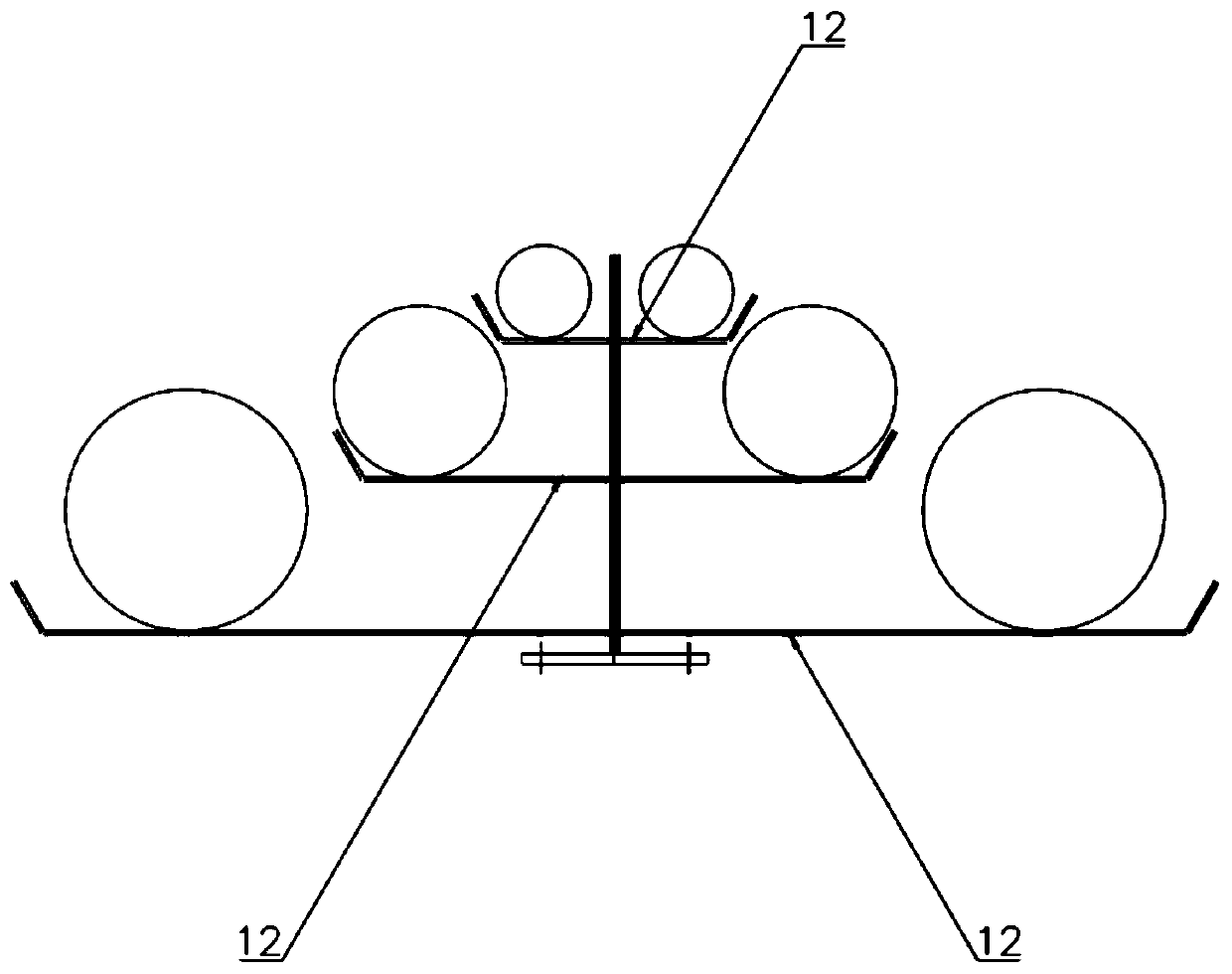

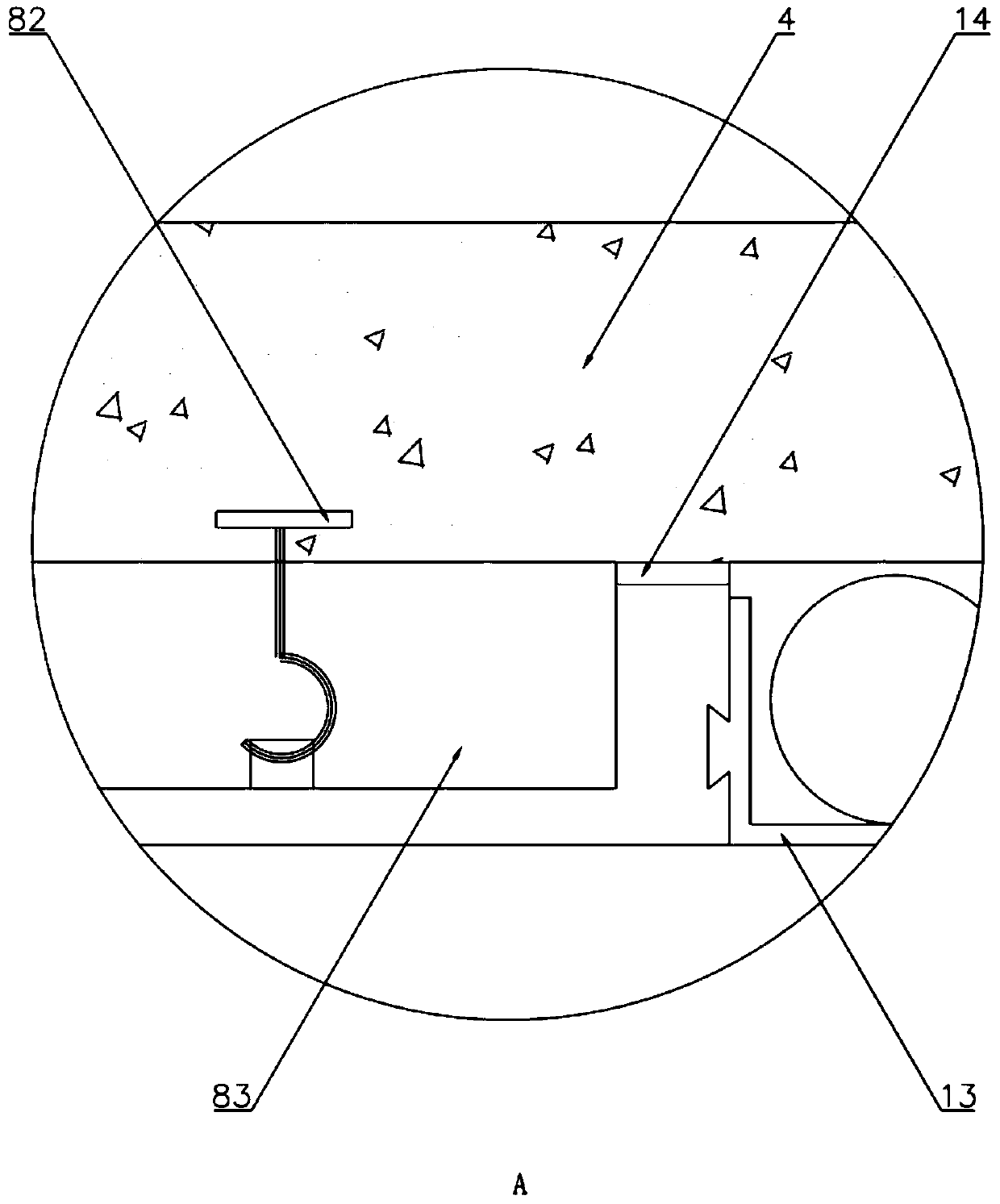

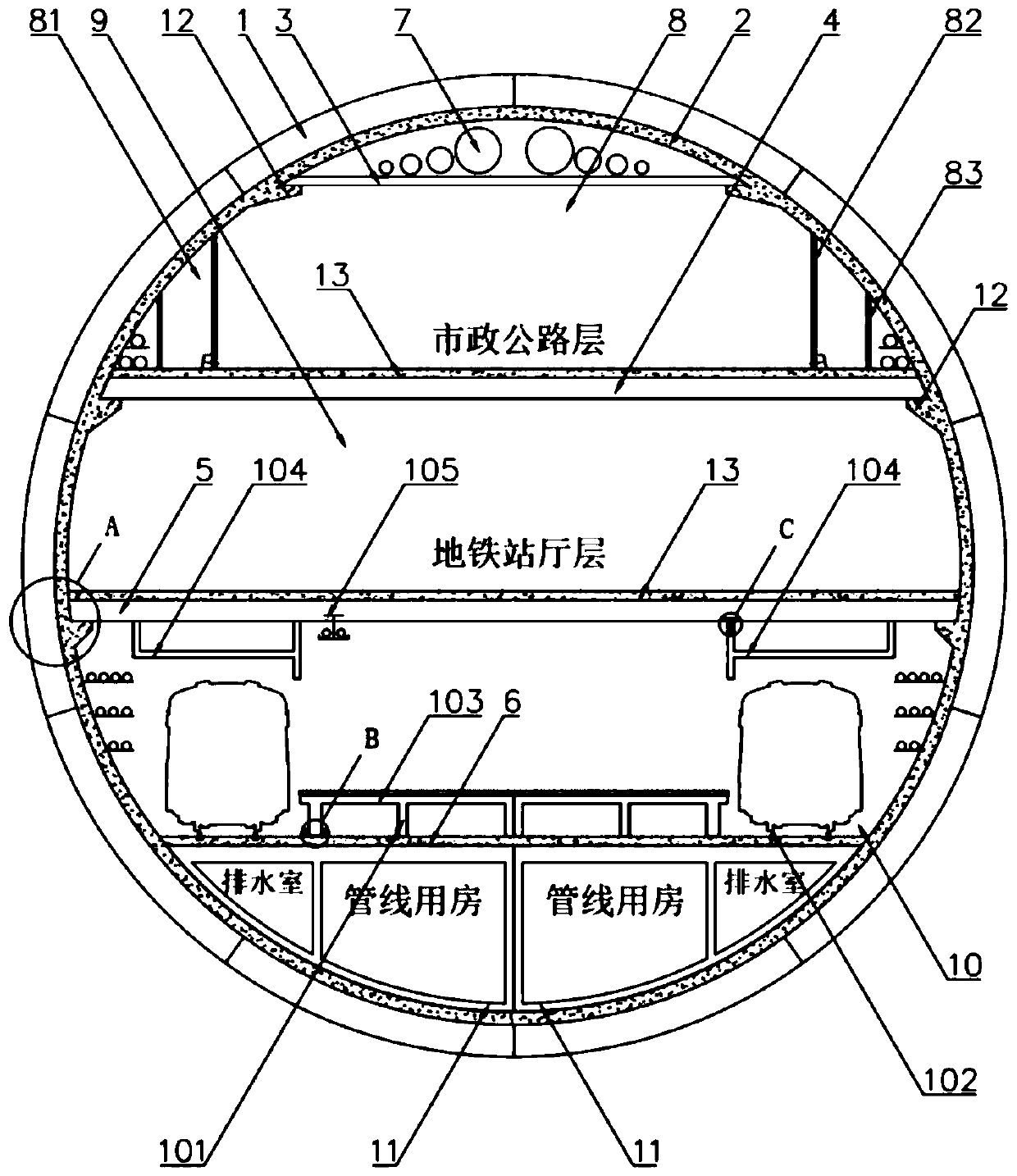

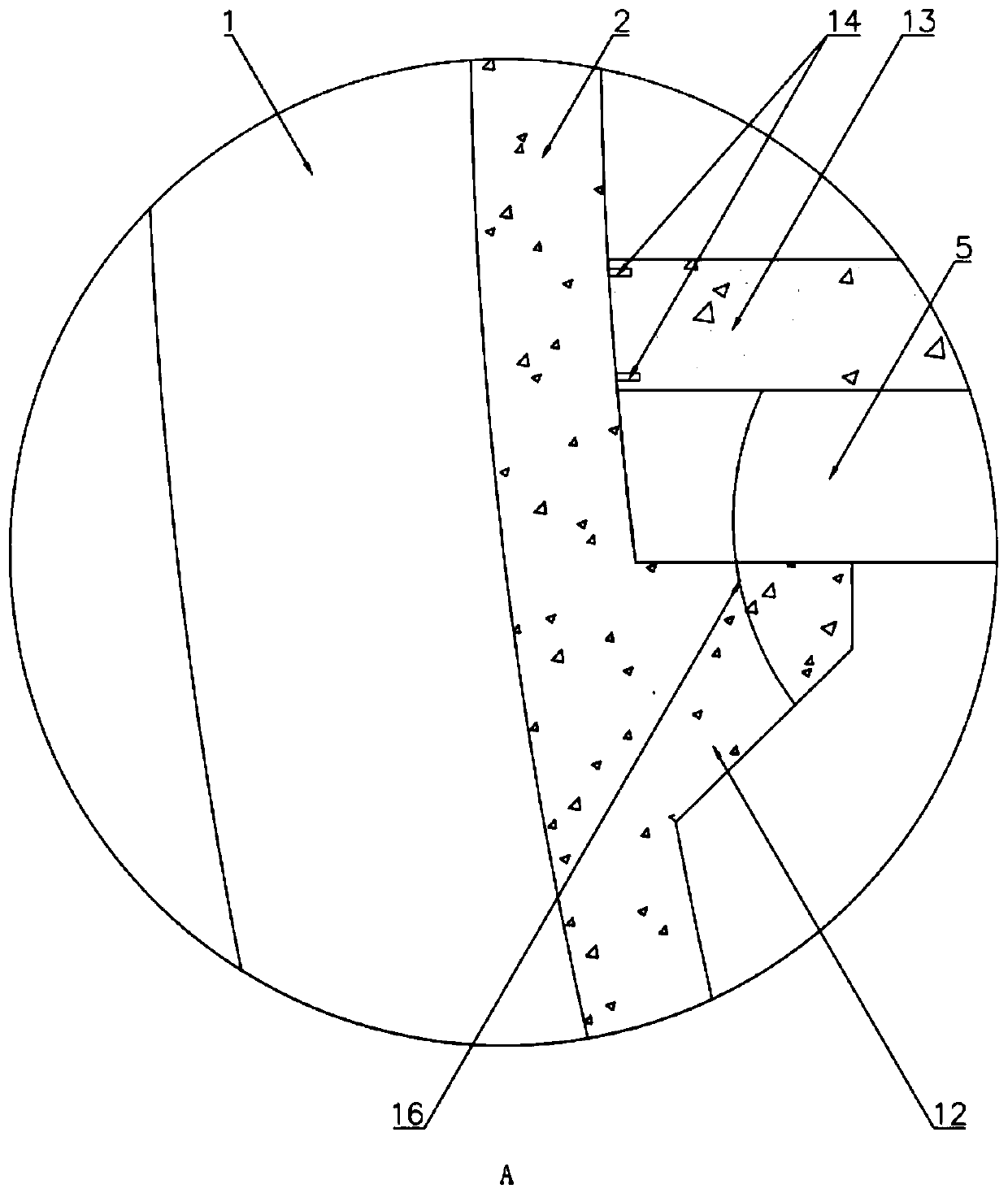

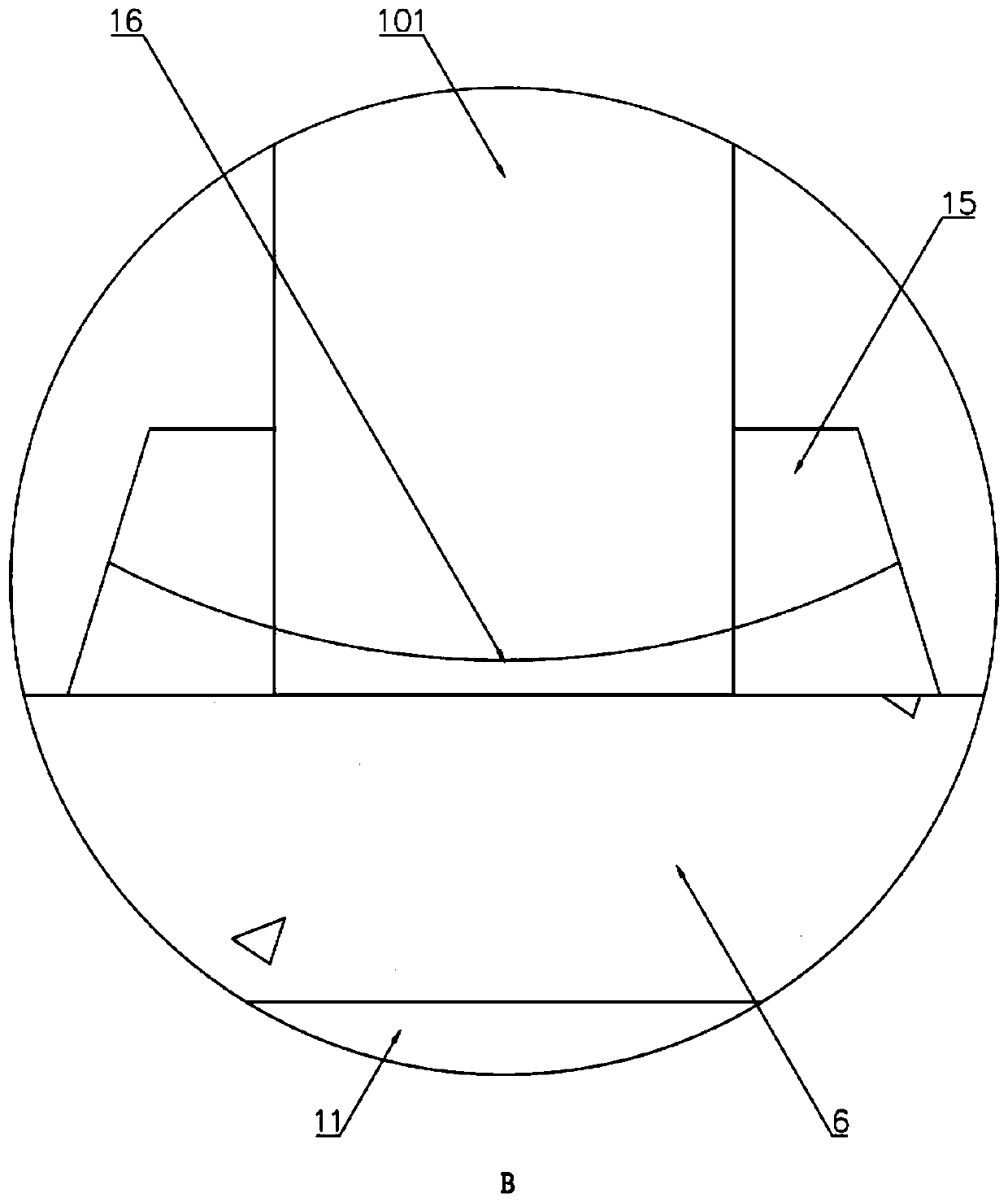

Large shield subway station structure and construction method thereof

PendingCN111365019AImprove space utilizationQuality improvementMining devicesUnderground chambersArchitectural engineeringStructural engineering

The invention relates to a large shield subway station structure. The large shield subway station structure comprises a plurality of sections of tube segments; concrete layers are arranged on the inner sides of the tube segments; waterproof layers are arranged between the concrete layers and the tube segments; subway station space is formed within the concrete layers; top plates, middle plates and bottom plates are connection into the concrete layers; the subway station space is divided into a pipeline layer, a station hall layer, a platform layer and a functional layer; thickening parts areintegrally manufactured at the end parts, close to the concrete layers, of the middle plate and the bottom plate; the platform layer comprises a prefabricated platform positioned in the middle and subway tracks on two sides of the prefabricated platform; at least one row of hooks are buried at the bottom and above the subway tracks; the hooks are connected with an air duct; the inner sides of thesubway tracks are provided with evacuation channels; a plurality of partition walls are arranged in the functional layer; and each partition wall is divided into an equipment room, a pipeline room anda drainage room; The invention also relates to a construction method of the large shield subway station structure. The construction method comprises six steps. The large shield subway station structure can greatly improve the space utilization rate of the subway station, and effectively solves the problem of constructing the subway station by tunneling under complex environmental conditions.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Method for manufacturing transition leading tape for rolling dissimilar metal connecting structure and titanium coil

ActiveCN113084338AEnsure safetyPrevent falling offWorkpiece edge portionsLaser beam welding apparatusSteel platesDissimilar metal

The invention discloses a method for manufacturing a transition leading tape for rolling a dissimilar metal connecting structure and a titanium coil, relates to the field of metallurgy, and firstly solves the problem that after existing dissimilar metal which is difficult to weld is connected, the thicknesses of connecting parts are unequal, and related equipment is possibly damaged. According to the technical scheme, the dissimilar metal connecting structure comprises at least two layers of connecting pieces arranged in a stacked mode, each layer of connecting piece comprises a first connecting plate and a second connecting plate which are mutually embedded, the at least two layers of connecting pieces are stacked to form a connecting body, the first connecting plates of every two adjacent layers of connecting pieces are connected in a welded mode, and the second connecting plates of every two adjacent layers of connecting pieces are connected in a welded mode. The first connecting plates and the second connecting plates are mechanically connected through mutual embedding of notches and protruding bodies, and the stress requirement between the two connecting plates is guaranteed. The first connecting plates are titanium plates, the second connecting plates are stainless steel plates, and the connecting body formed by stacking the connecting pieces is the transition leading tape for titanium coil rolling and can be used for titanium coil rolling production.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Highway-railway combined construction underground station structure and construction method thereof

PendingCN111364513ARealize mechanized assembly constructionQuality improvementArtificial islandsUnderwater structuresArchitectural engineeringStructural engineering

The invention relates to a highway-railway combined construction underground station structure. The highway-railway combined construction underground station structure comprises a plurality of shieldsegments, wherein concrete linings are arranged in the shield segments; underground station spaces are formed in the concrete linings; top plates, underground second-layer plates, underground third-layer plates and underground fourth-layer plates are arranged in the concrete linings; the underground station spaces are divided into highway pipeline layers, municipal highway layers, subway station hall layers, subway station platform layers and comprehensive bottom layers, and brackets are arranged on the bottom sides of the top plates, the underground second-layer plates and the underground third-layer plates of the concrete linings; the municipal highway layers comprise highways and evacuation passages, first partition walls are arranged between the evacuation passages and the highways, and a plurality of escape doors are formed in the first partition walls; the subway station platform layers comprise prefabricated platforms and subway tracks, platform cast-in-place layers are arrangedon the prefabricated platforms, and prefabricated air ducts are formed in the bottoms of the underground third-layer plates; and prefabricated box-shaped frames are arranged in the comprehensive bottom layers. The invention further relates to a construction method of the highway-railway combined construction underground station structure. The construction method comprises seven steps. According to the highway-railway combined construction underground station structure and the construction method thereof, the problem of underground excavation construction of underground stations under complexenvironmental conditions can be solved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Steel box beam and concrete column hinged joint and construction method thereof

PendingCN111827467AImprove reliabilityHigh implementabilityBuilding constructionsArchitectural engineeringSteel box girder

The invention provides a steel box beam and concrete column hinged joint and a construction method thereof. The steel box beam and concrete column hinged joint comprises a concrete column and a steelbox beam. The end of the steel box beam is located on the column side bracket of the concrete column, and a rubber support is arranged between the steel box steam and the column side bracket. The steel box beam and the column side bracket are fixed through multiple foundation bolts. An inner supporting assembly is arranged in the steel box beam and located in the foundation bolt installation area.According to the steel box beam and concrete column hinged joint, the rubber support and the inner supporting assembly are adopted to jointly connect the steel box beam and the concrete column, so that shear force transmitted by the steel box beam can be transmitted, rotation deformation of the steel box beam in the bent direction is reasonably released, and reliability and implementation performance of joint connection are improved; and meanwhile, a bolted fixation manner is adopted, on-site fixation of the steel box beam and the concrete column is adjusted into the steel box beam, on-site welding operation is canceled, the space in the steel box beam is fully utilized, the space problem of on-site installation is solved, and on-site construction quality and component stress requirementsare effectively guaranteed.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

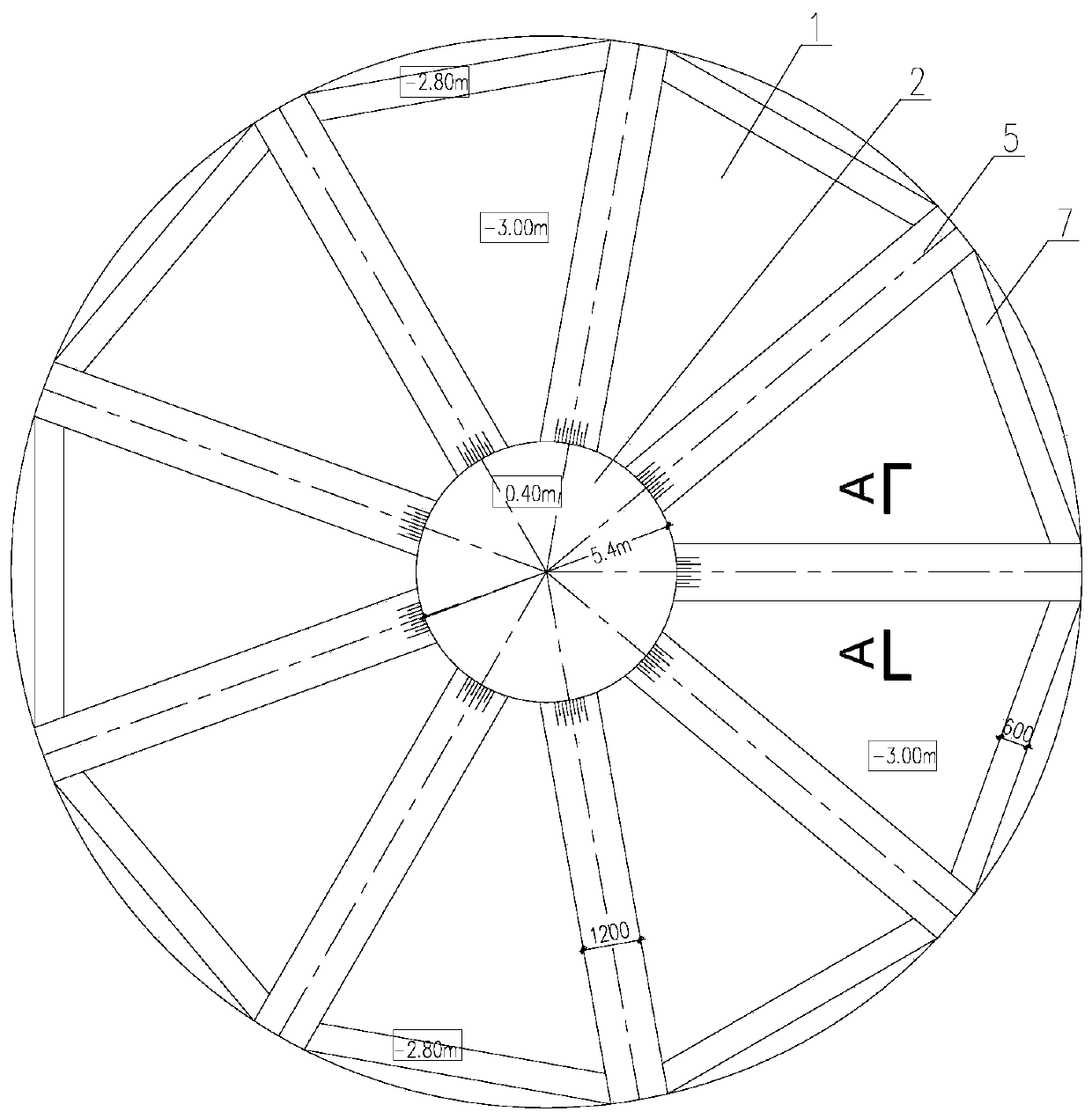

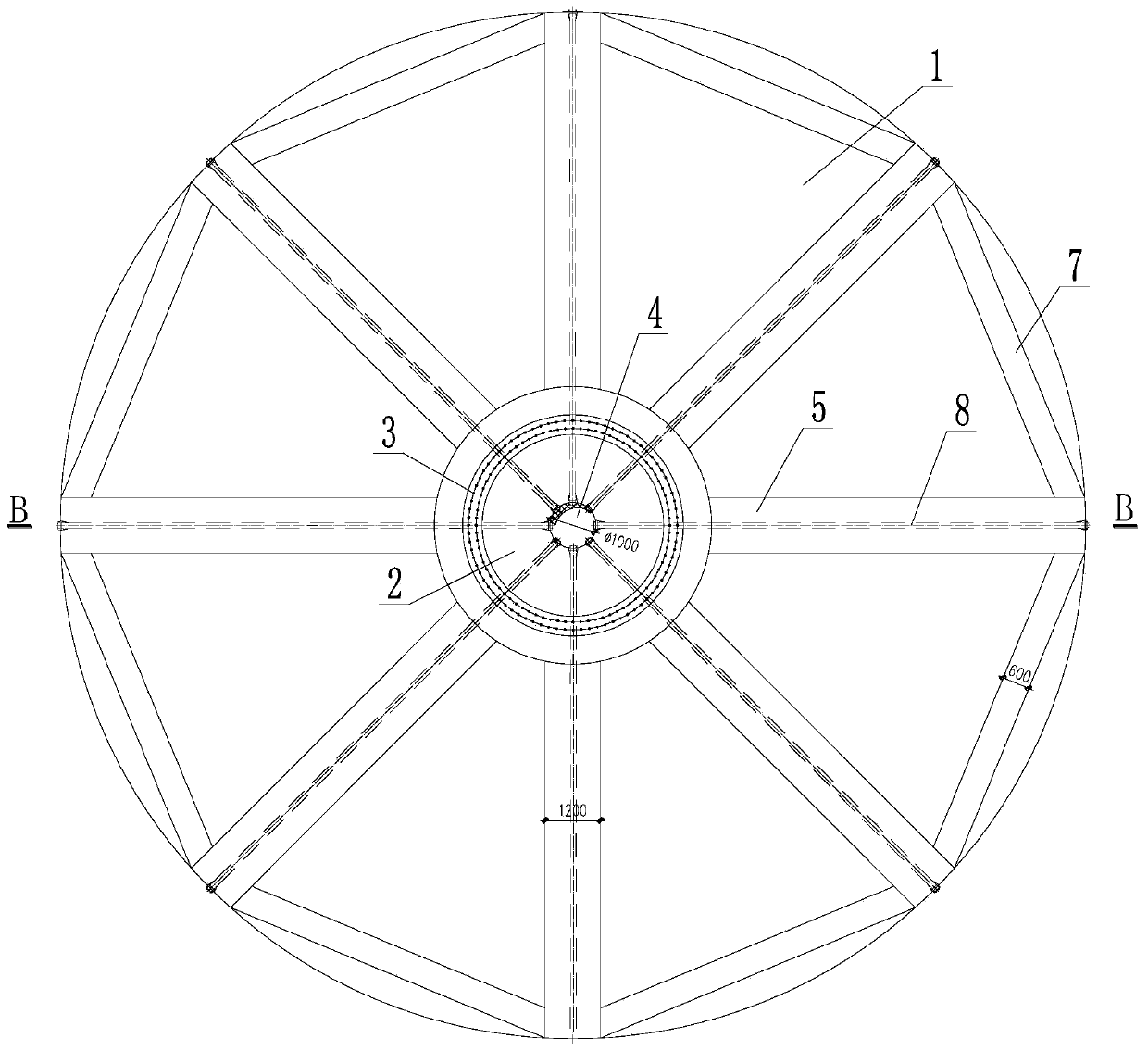

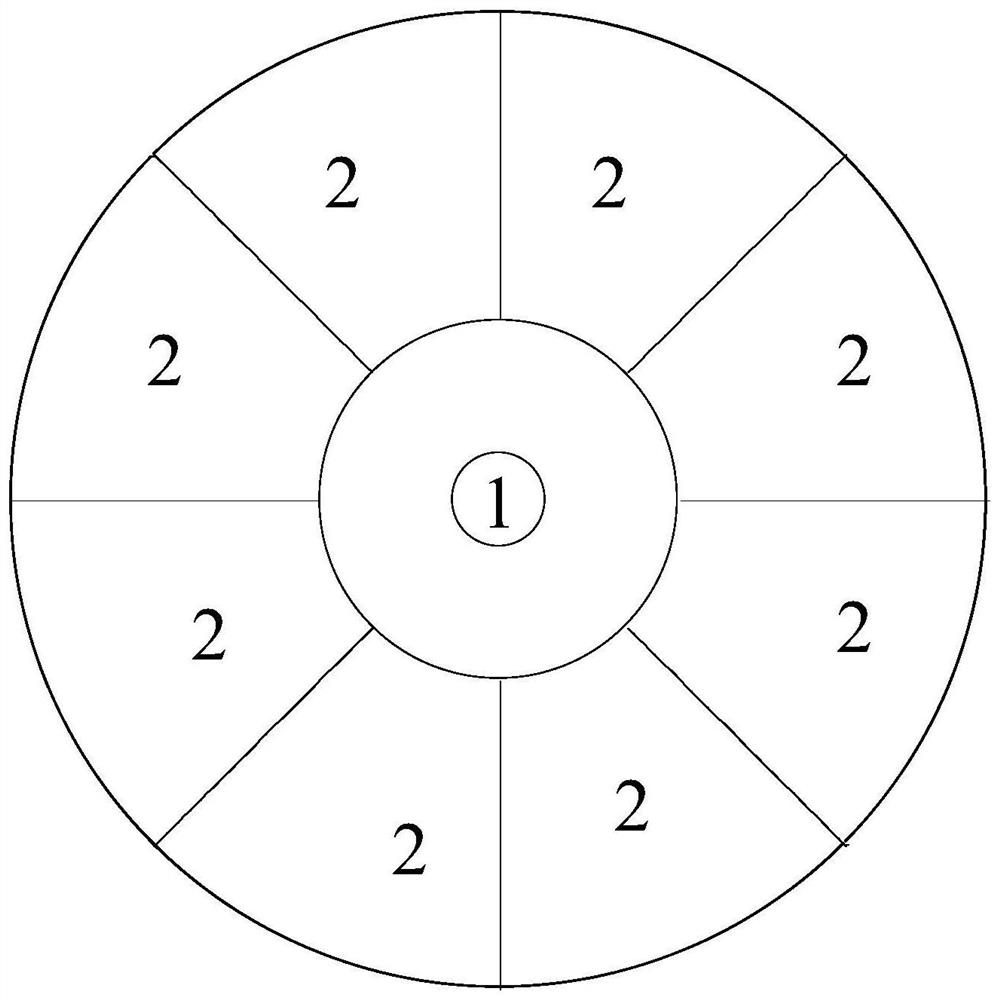

Wind Turbine Prestressed Foundation Structure

ActiveCN107829444BReduce reinforcement ratioGuaranteed stress requirementsFoundation engineeringPre stressArchitectural engineering

The invention discloses a wind turbine generator prestress foundation structure, relates to the field of wind turbine generator foundation structures, and solves the problems of obvious increment of the reinforcement ratio of main beams, cost increment, small reinforcement gap, bad construction operation and influence on the structural concrete safety in a beam slab type wind turbine generator foundation structure adopted by a large wind turbine generator. The wind turbine generator prestress foundation structure is in a beam slab form, and comprises a foundation baseplate; the middle part ofthe foundation baseplate is a table column; a maintenance hole is formed in the table column; discrete main beams are uniformly distributed around the table column; prestress steel ropes are arrangedin the main beams to replace traditional longitudinal ribs; foundation structure concrete is mainly prestress concrete; the prestress steel ropes are tensioned by adopting a back tension method; and the maintenance work of the prestress steel ropes can be performed by entering a foundation through the maintenance hole. Through the idea of introducing the prestress concrete, the steel consumption is reduced, the cost is saved, the construction is convenient, the casting quality is guaranteed, and the maintenance is convenient.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

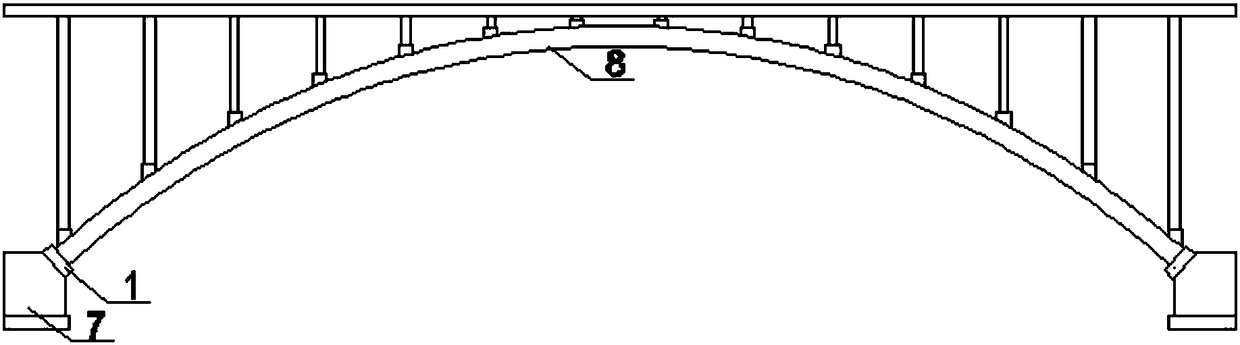

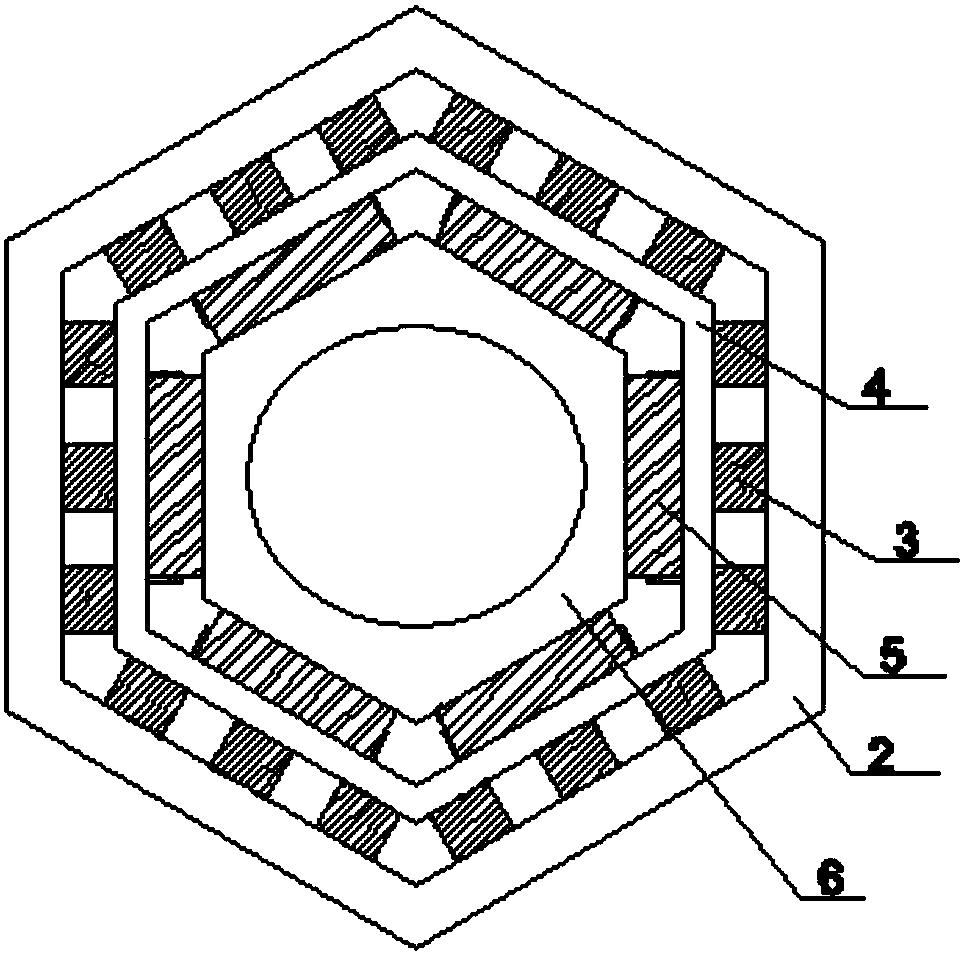

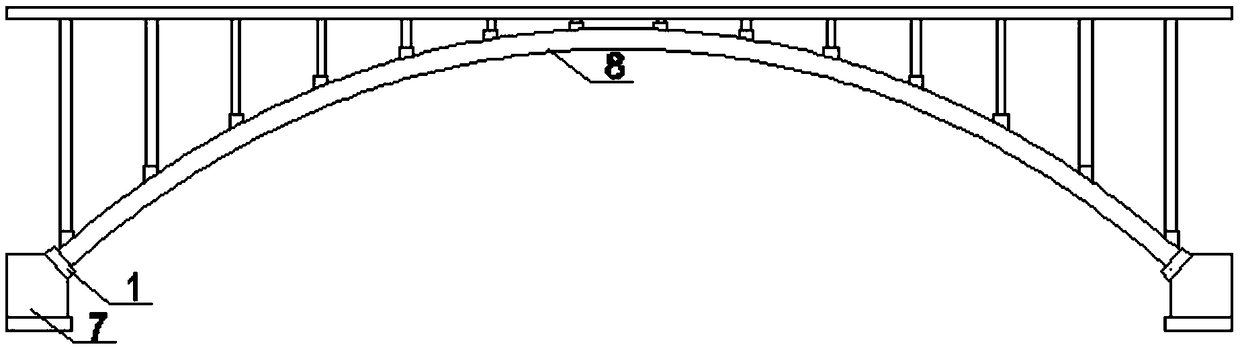

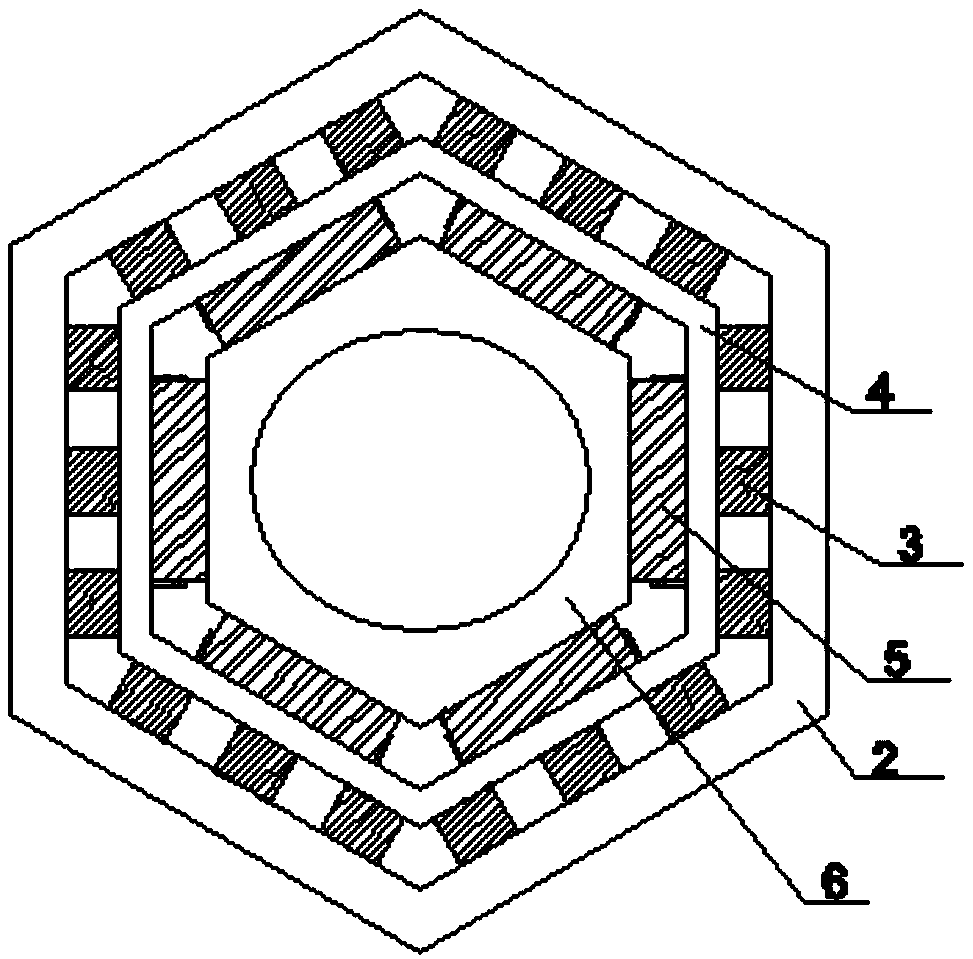

Hexagonal damping device for arch bridge

InactiveCN108166380AGuaranteed stress requirementsSimple structureBridge structural detailsArch-type bridgeAbutmentEngineering

The invention discloses a hexagonal damping device for an arch bridge. The hexagonal damping device for the arch bridge includes an arch bridge body, a bridge abutment, concrete damping baffle blocksand damping assemblies, wherein the concrete damping baffle blocks are arranged on the bridge abutment and are used for obliquely supporting the arch bridge body, and the damping assemblies are fixedinside insertion holes in the concrete damping baffle blocks; each damping assembly includes an orthohexagonal outer sleeve hoop, an orthohexagonal middle sleeve hoop, a damping device and a support roller, wherein the damping device is arranged between the orthohexagonal outer sleeve hoop and the orthohexagonal middle sleeve hoop in a supporting mode, and the support roller is rotatably fixed tothe inner wall of the middle sleeve hoop; inner core rods are fixed to arch sprinings of the arch bridge body, wherein the inner core rods can be inserted into the insertion holes in the concrete damping baffle blocks, and the sections of the inner core rods are orthohexagonal; the inner core rods are slidably matched with the support rollers. By the adoption of the hexagonal damping device for the arch bridge, the damping performance of the arch bridge can be effectively improved, and meanwhile, the stability of the arch bridge is ensured; the hexagonal damping device for the arch bridge is simple in damping mechanism structure and convenient to mount, and the service life of the arch bridge is long.

Owner:CHONGQING JIAOTONG UNIVERSITY

Hexagonal shock absorbers for arch bridges

InactiveCN108166380BGuaranteed stress requirementsSimple structureBridge structural detailsArch-type bridgeAbutmentEngineering

The invention discloses a hexagonal damping device for an arch bridge. The hexagonal damping device for the arch bridge includes an arch bridge body, a bridge abutment, concrete damping baffle blocksand damping assemblies, wherein the concrete damping baffle blocks are arranged on the bridge abutment and are used for obliquely supporting the arch bridge body, and the damping assemblies are fixedinside insertion holes in the concrete damping baffle blocks; each damping assembly includes an orthohexagonal outer sleeve hoop, an orthohexagonal middle sleeve hoop, a damping device and a support roller, wherein the damping device is arranged between the orthohexagonal outer sleeve hoop and the orthohexagonal middle sleeve hoop in a supporting mode, and the support roller is rotatably fixed tothe inner wall of the middle sleeve hoop; inner core rods are fixed to arch sprinings of the arch bridge body, wherein the inner core rods can be inserted into the insertion holes in the concrete damping baffle blocks, and the sections of the inner core rods are orthohexagonal; the inner core rods are slidably matched with the support rollers. By the adoption of the hexagonal damping device for the arch bridge, the damping performance of the arch bridge can be effectively improved, and meanwhile, the stability of the arch bridge is ensured; the hexagonal damping device for the arch bridge is simple in damping mechanism structure and convenient to mount, and the service life of the arch bridge is long.

Owner:CHONGQING JIAOTONG UNIVERSITY

Dissimilar metal connection structure and manufacturing method of transition lead for titanium coil rolling

ActiveCN113084338BPrevent disengagementAvoid warpingLaser beam welding apparatusWorkpiece edge portionsEngineeringSS - Stainless steel

The invention discloses a method for manufacturing a dissimilar metal connection structure and a transition lead band used for rolling a titanium coil, and relates to the field of metallurgy. First, after the existing difficult-to-weld dissimilar metal connection is solved, the thickness of the connecting part varies, which may affect related equipment. the problem of causing damage. The technical scheme adopted in the present invention is as follows: a dissimilar metal connection structure includes at least two layers of connecting sheets arranged in a stack, each layer of the connecting sheets includes a first connecting plate and a second connecting plate that are embedded with each other, and at least two layers of connecting sheets are stacked to form In the connecting body, the first connecting plates of two adjacent layers of connecting sheets are connected by welding, and the second connecting plates of two adjacent layers of connecting sheets are connected by welding. The mechanical connection between the first connecting plate and the second connecting plate is achieved by mutual fitting of the notches-protrusions, so as to ensure the force requirement between the two connecting plates. The first connecting plate is a titanium plate, the second connecting plate is a stainless steel plate, and the connecting body formed by stacking the connecting sheets is a transition lead for titanium coil rolling, which can be used for titanium coil rolling production.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

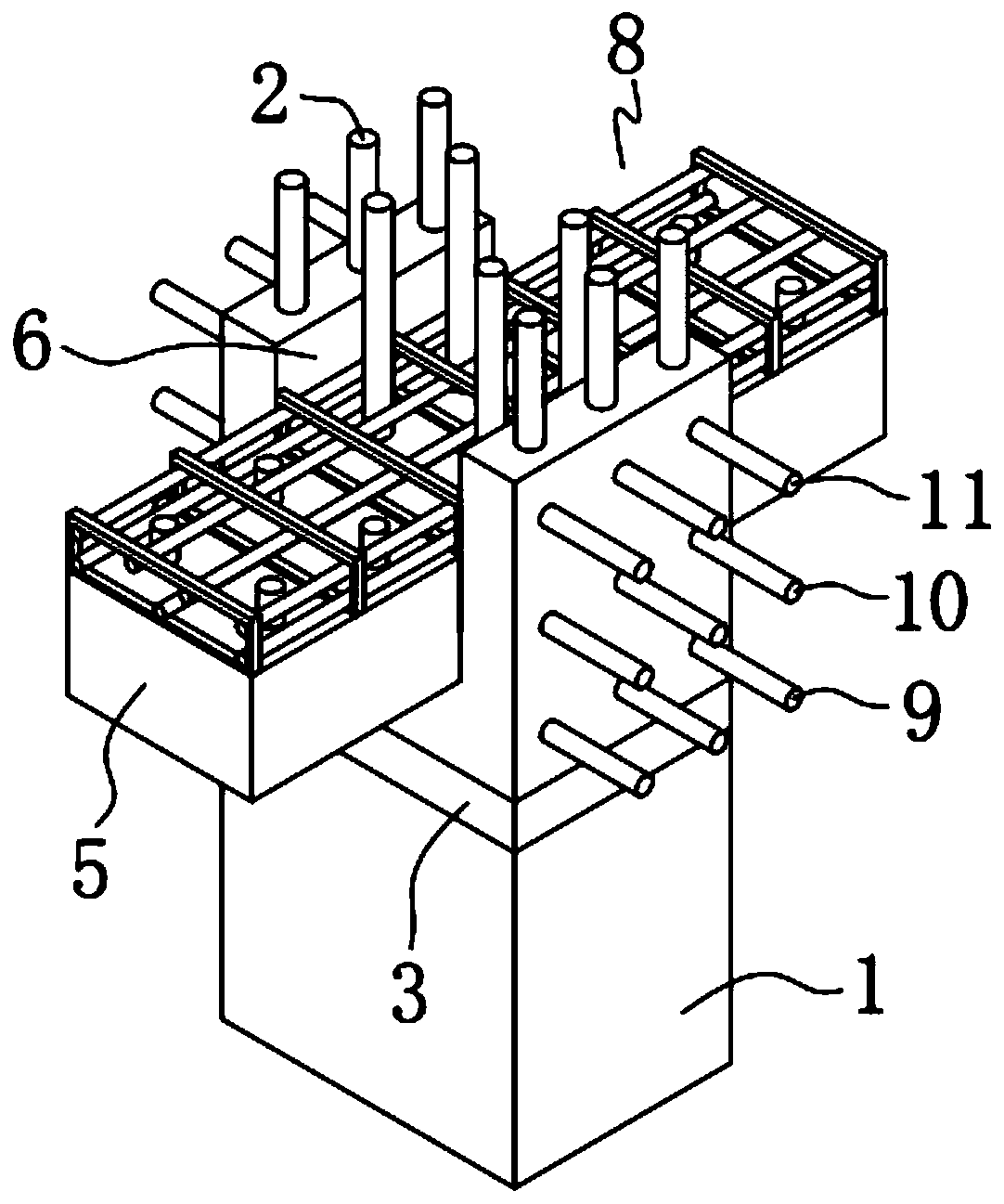

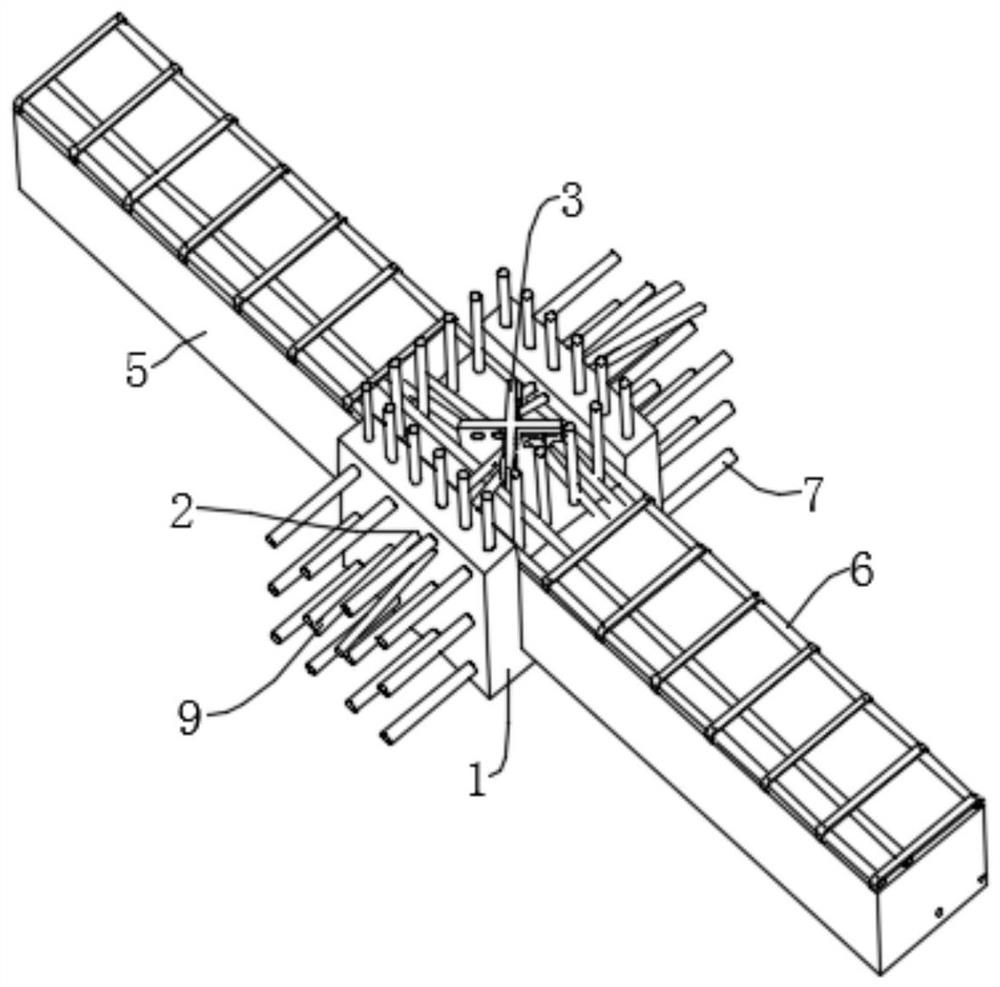

Prefabricated building prefabricated steel concrete intermediate column-beam joint prestressed tendon interlaced tension anchorage structure and construction method

ActiveCN111335485BHigh strengthImprove the force characteristicsBuilding constructionsPre stressSteel columns

The invention discloses a prefabricated steel-concrete intermediate column-beam node interlaced tension anchoring structure for prefabricated buildings. Formed cross-shaped steel column; prefabricated column laminate layer arranged on the upper part of the prefabricated column; laminated beam arranged at one end of the prefabricated column; top steel bars exposed on the upper part of the The outstretched reinforcement on the side of the prefabricated column; the multiple reserved perforations on the cross-shaped steel column; the prestressed tendons passing through the multiple reserved perforations; the prestressed steel bars fixed on the cross-shaped steel column A tendon anchoring device, the prestressed tendons are fixed on the cross-shaped steel column through the prestressed tendon anchoring device; this structure ensures the integral stress requirements of the beam-column joints, and makes the joints have a good anti-negative bending moment effect.

Owner:钱野

A Construction Method for Improving the Seismic Ability of Tunnel

ActiveCN113446028BSolve support problemsImprove seismic performanceUnderground chambersTunnel liningStructure supportWall rock

The invention relates to a construction method for improving the seismic capacity of a tunnel, which comprises the following construction steps: (1) determining the surrounding rock area to be strengthened within the tunnel construction range; (2) grouting reinforcement to the surrounding rock area to be strengthened, and The rock surface is repaired with anti-seismic damping materials; (3) construction of the initial support structure; (4) construction of the inverted arch structure of the tunnel; (5) multiple anti-seismic devices are installed on the completed initial support structure; (6 ) to carry out the construction of the secondary support structure, there is a gap between the secondary support structure and the primary support structure along the radial direction of the tunnel, and the secondary support structure is composed of steel truss supports and composite structural plates; (7) in the above The anti-seismic material is injected into the gap to fill the entire gap. The construction method of the invention adopts a combination of various anti-seismic measures to achieve a good anti-seismic effect, fundamentally solves the problem of tunnel support, and improves the anti-seismic capacity of the tunnel.

Owner:CENT SOUTH UNIV +2

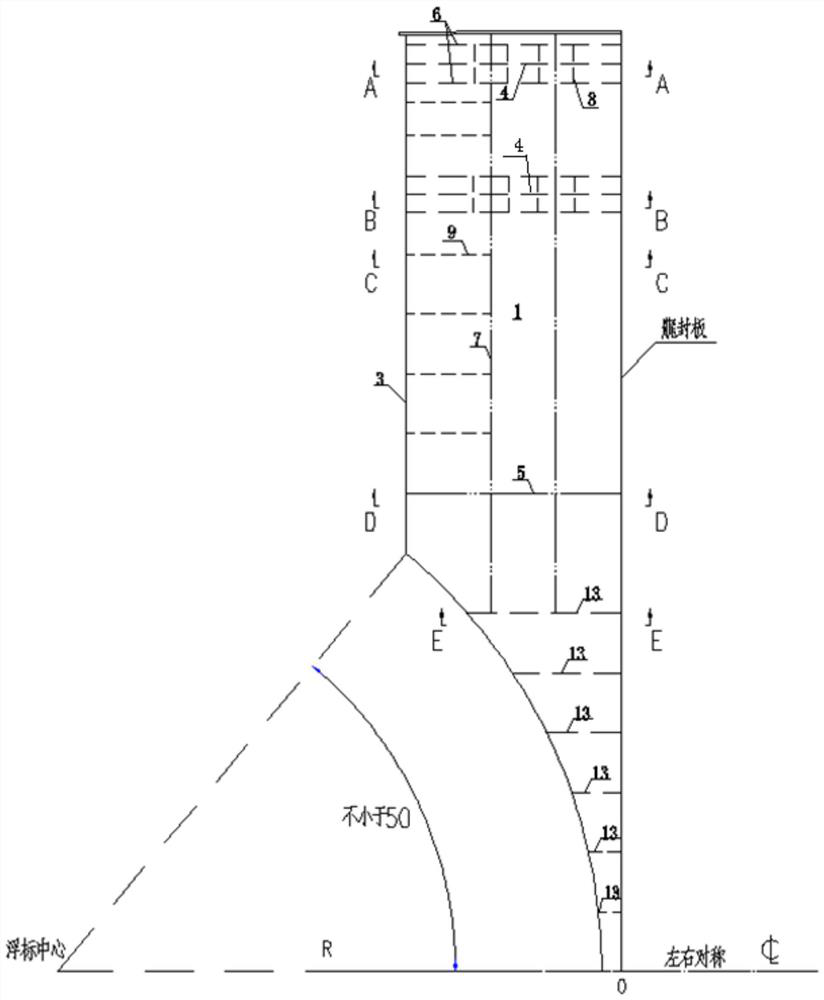

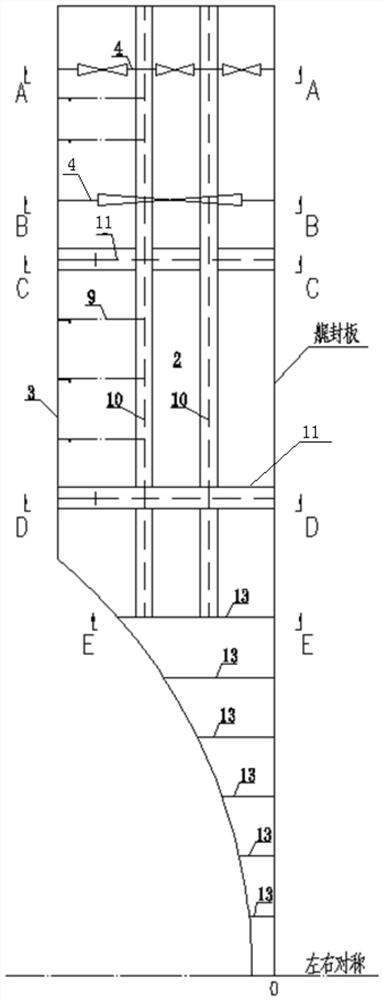

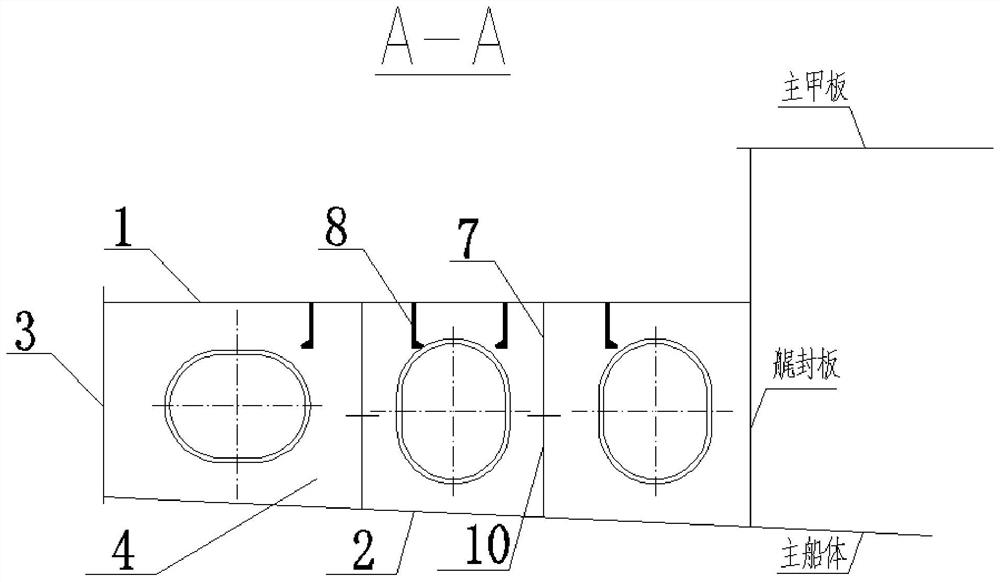

Stern boarding platform structure for ship

PendingCN113562122AAvoid direct collisionSign up fastCargo handling apparatusPassenger handling apparatusStructural engineeringGunwale

The invention relates to a stern boarding platform structure for a ship. The stern boarding platform structure is arranged on the outer side of a ship stern transom plate, the bottom of the stern boarding platform structure is along the bottom line type of a main ship body, the top of the stern boarding platform structure is a platform, the width extends to a gunwale, and the middle of the tail end of the stern boarding platform structure is of an arc structure so as to be close to a buoy. The structure comprises a top plate structure, a bottom plate structure and an end wall structure, the end wall structure is arranged at the tail end, and the top and bottom of the end wall structure are connected with the top plate structure and the bottom plate structure respectively; the top plate structure comprises a top plate and a top plate reinforcing structure arranged on the lower surface of the top plate. The bottom plate structure comprises a bottom plate and a bottom plate reinforcing structure arranged on the upper surface of the bottom plate, and the bottom plate extends along the molded line of the bottom of the main ship body; the end wall structure comprises an end wall and an end wall reinforcing structure. The stern boarding platform structure serves as a buoy boarding channel during buoy operation, the regular maintenance of the buoy and the rapid buoy boarding function during emergency repair are achieved, and meanwhile the buoy can be prevented from directly colliding with the main ship body during operation; the middle of the tail end of the platform structure is of an arc structure, and the radius of the platform structure is consistent with that of the buoy so as to facilitate buoy approaching and achieve rapid buoy boarding.

Owner:CHINA SHIP DEV & DESIGN CENT

Wet joint connection structure for fully prefabricated bridges

ActiveCN104499430BAvoid installation and disassemblyFlexible settingsBridge structural detailsBridge materialsEngineeringRebar

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Waterproof and shock-absorbing system device and installation method of prefabricated rectangular comprehensive pipe gallery interface

ActiveCN109898554BImprove water resistanceIncrease useArtificial islandsUnderwater structuresWater flowIndustrial engineering

A waterproof and shock-absorbing system device for the interface of a prefabricated rectangular comprehensive pipe gallery and its installation method belong to the technical field of underground structure comprehensive pipe gallery. The waterproof and cushioning system device of the prefabricated rectangular comprehensive pipe gallery interface includes correspondingly connected segment socket parts and segment socket parts. The segment socket part includes a vertical part one, an inclined part one and a vertical part two, so The segment socket portion includes a vertical portion 3, an inclined portion 2 and a vertical portion 4. The inclined portion 1 is provided with at least one wedge-shaped groove, and a U-shaped rubber block is provided in the wedge-shaped groove. The surface of the U-shaped rubber block is The cemented rubber layer expands when exposed to water, and the segment socket part and the segment socket part are connected through several shock-absorbing bolts. The gap between the vertical part one and the vertical part three is provided with a waterproof reserve system. The waterproof cushioning system device and installation method of the prefabricated rectangular integrated pipe gallery interface can effectively prevent water from entering the integrated pipe gallery cabin, improve the service life and safety performance of the structure, and improve the smooth operation capability of the interface.

Owner:NORTHEASTERN UNIV LIAONING

A post-tensioned anchorage node structure and construction method for pre-embedded insulation boards in lotus root beams of prefabricated buildings

ActiveCN110512727BGood anti-negative bending moment effectImprove the force characteristicsHeat proofingBuilding material handlingPre stressMesh reinforcement

The invention discloses a fabricated building lotus-root-type beam pre-buried heat-preservation plate post-tensioned anchorage joint structure. The fabricated building lotus-root-type beam pre-buriedheat-preservation plate post-tensioned anchorage joint structure comprises a precast column, precast column vertical outward-extending steel bars, a composite lotus-root-type beam column head, lotus-root-type beam outward-extending composite beams, a composite lotus-root-type beam reserved groove, composite lotus-root-type beam edge side outward-extending steel bars, an XPS heat-preservation plate, unbonded prestressed tendons, outward-extending steel bars at composite grooves, composite lotus-root-type beam upper part exposed steel bars and a flat hidden beam steel bar net. The invention further discloses a construction method of the fabricated building lotus-root-type beam pre-buried heat-preservation plate post-tensioned anchorage joint structure, and the construction method comprises the ten construction steps. According to the fabricated building lotus-root-type beam pre-buried heat-preservation plate post-tensioned anchorage joint structure, the force bearing characteristics of abeam-column joint is effectively improved, through an overall post-cast concrete face layer, the overall force bearing requirement of the beam-column joint is well ensured, and the hogging moment resisting effect of the joint is good; and the hoisting cost is low, the hoisting speed and precision are high, building construction is greatly assisted, and the positive effect on promoting industry modernization of prefabricated building hoisting is realized.

Owner:江苏晟功建设集团有限公司

A construction method for vertical section type dismantling of inner support

ActiveCN113463653BThe force characteristics are clearAbsolute duration shortenedArtificial islandsExcavationsSupport removalArchitectural engineering

A vertical section-type dismantling inner support construction method includes designing the starting point for dismantling the upper inner support structure, constructing the lower main structure within the scope of the first new construction section, and erecting a dismantling frame when the concrete strength reaches 80%, Remove the upper inner support structure within the scope of the first new construction section upward, and construct the lower main structure within the scope of the second new construction section. When the concrete strength reaches 80%, erect and dismantle the frame body; dismantle the scope of the second new construction section The inner support structure of the upper layer is completed until the construction of all the lower layer structural plates and the lower layer replacement support structure in the foundation pit is completed, and the upper inner support structure is completely dismantled. The present invention is to dismantle the typical concrete corner brace support, the force characteristics are very clear, and the force of each support block is relatively independent, so as long as the dismantling of the support can satisfy the stability and safety of the force during dismantling, the section-type dismantling construction can be realized. , which can shorten the absolute construction period of support removal.

Owner:CHINA CONSTR FIRST GROUP THE FIFTH CONSTR +1

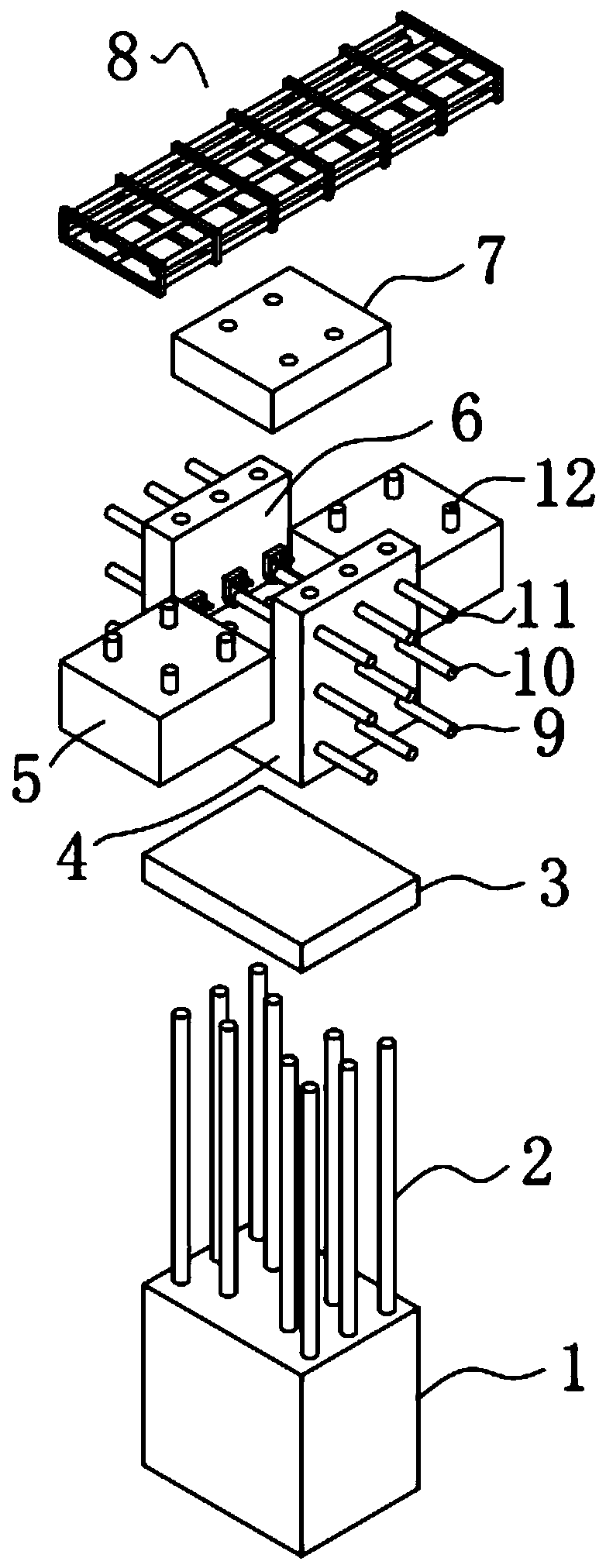

A prefabricated building superimposed lotus root beam-column joint structure and its construction method

ActiveCN110512728BImprove the force characteristicsGuaranteed stress requirementsBuilding material handlingShaped beamMesh reinforcement

The invention discloses an assembly-type building laminated lotus-root-shaped beam-column joint structure. The assembly-type building laminated lotus-root-shaped beam-column joint structure comprisesa prefabricated column, prefabricated column vertical protruding bars, a laminated lotus-root-shaped beam-column head, a lotus-root-shaped beam protruding laminated beam, a lotus-root-shaped beam reserved laminated groove, laminated lotus-root-shaped beam side protruding bars, laminated lotus-root-shaped beam upper exposed bars and a flat hidden beam bar net. The invention further discloses a construction method of the assembly-type building laminated lotus-root-shaped beam-column joint structure, and the construction method comprises ten construction steps. The stress characteristic of a beam-column joint is effectively improved, the overall stress demand of the beam-column joint is well met through a whole post-pouring concrete surface layer, and the hogging moment resisting effect of the joint is good; and the lifting cost is low, the lifting speed and precision are high, great help is brought to building construction, the positive effect is achieved on promoting achievement of industry modernization of prefabricated assembly-type building lifting, and a clear idea is provided for innovative research of detailed structural design such as a lifting method and the connection joint.

Owner:江苏晟功建设集团有限公司

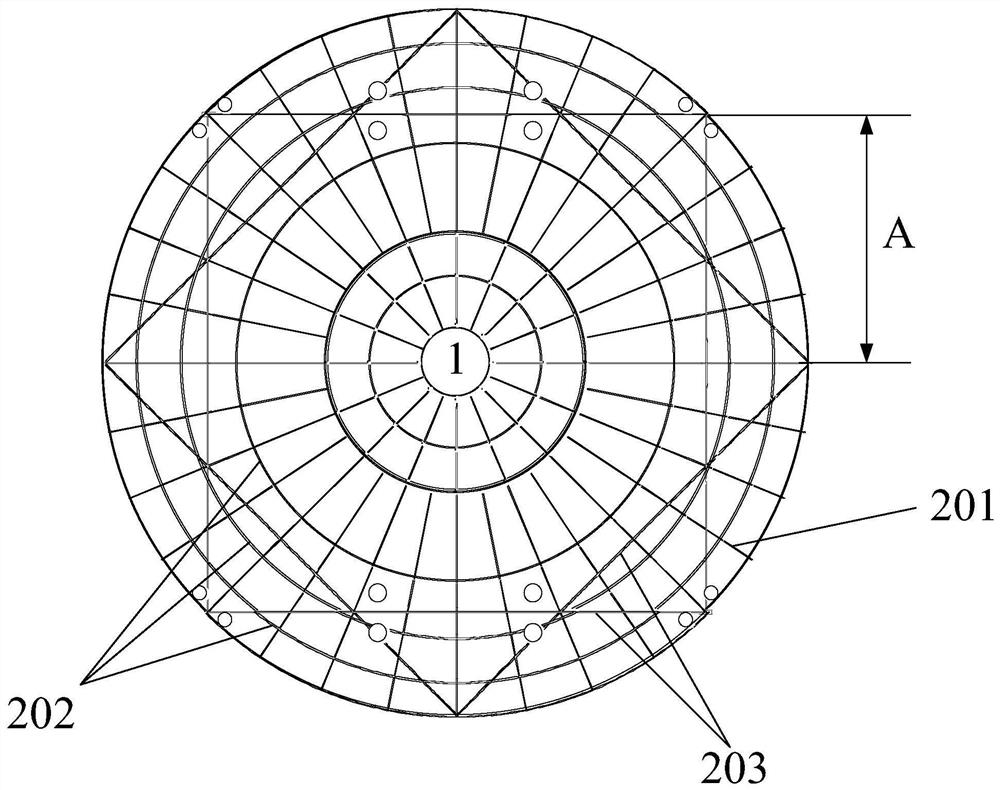

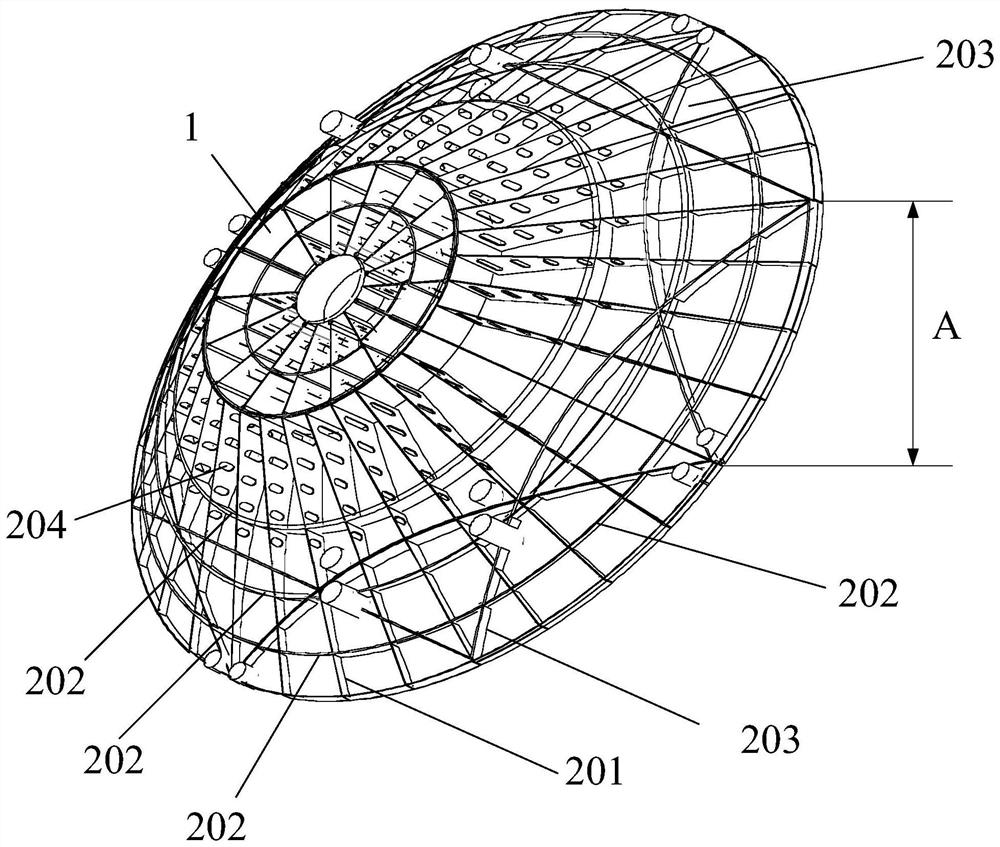

A magnesium alloy satellite antenna reflector

The invention provides a magnesium alloy satellite antenna reflection surface, which belongs to the technical field of satellite antennas. The reflective surface of the satellite antenna adopts an integrated molding structure, and the overall antenna is a box structure; the reflective surface of the satellite antenna includes an intermediate body and a plurality of sectors, and the intermediate body is located in the center and has a cylindrical box structure; The fan is distributed in the circumferential direction of the intermediate body, forming a circular reflection surface; the front surface of the fan is a smooth arc surface, and the rear surface is a support structure; the support structure includes radial ribs, axial Ribs and square ribs. The invention has the advantages of high precision, stable signal reception, light weight, good anti-aging performance and not easily deformed.

Owner:LINYI HIGH TECH ZONE SHUANGHANG NEW MATERIAL TECH CO LTD

A steel guide rail structure under the condition of wide temperature range and high precision

ActiveCN105889318BGuaranteed accuracy requirementsGuaranteed stress requirementsLinear bearingsShaftsEngineeringExpansion joint

Owner:苏州腾超机电设备有限公司

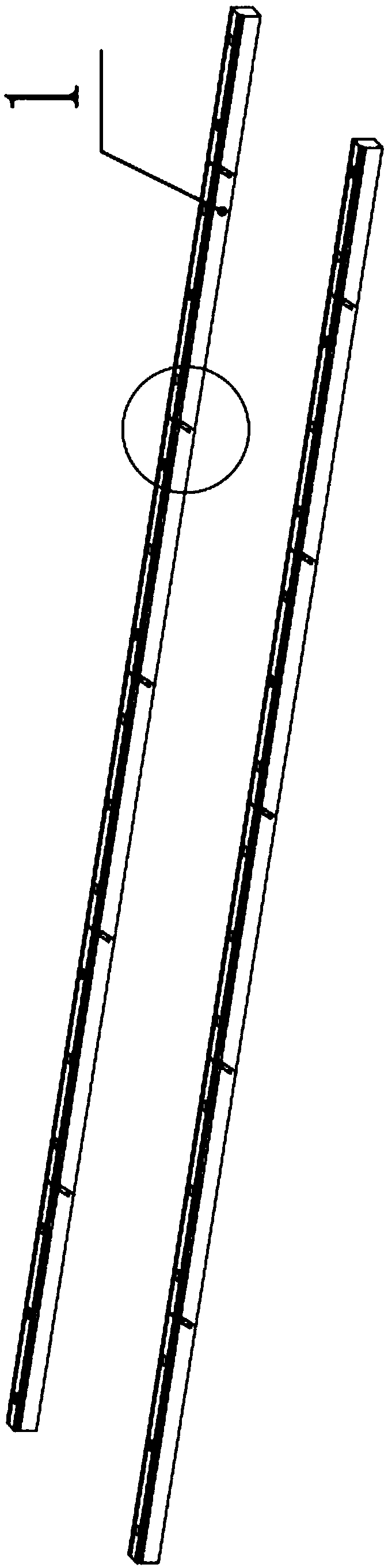

Steel guide rail structure used within wide temperature range and at high precision

ActiveCN105889318AGuaranteed accuracy requirementsGuaranteed stress requirementsLinear bearingsShaftsEngineeringExpansion joint

The invention discloses a steel guide rail structure used within a wide temperature range and at a high precision. The steel guide rail structure comprises a non-steel base and a steel guide rail which is arranged on the non-steel base; the steel guide rail is provided with a plurality of screw fixing holes which are arranged at uniform intervals; the steel guide rail is also provided with a plurality of groups of expansion joint structures; each expansion joint structure group comprises an upper expansion joint and a lower expansion joint which are parallel to each other; each upper expansion joint extends downwards from the upper surface of the steel guide rail; each lower expansion joint extends upwards from the lower surface of the steel guide rail. According to the steel guide rail structure used within wide temperature range and at high precision, the upper expansion joints and the lower expansion joints are respectively arranged on the upper and lower surfaces of the steel guide rail, so the deformation quantity of the steel guide rail, generated when temperature is changed, can be counteracted by the expansion joints in order to guarantee the linear precision requirement of the guide rail; the upper expansion joints and the lower expansion joints are obliquely arranged in parallel and are positioned between two adjacent mounting holes so that the force bearing requirement of the steel guide rail under a working state can be satisfied.

Owner:苏州腾超机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com