Wind Turbine Prestressed Foundation Structure

A technology for wind turbines and infrastructure, applied in infrastructure engineering, construction, etc., can solve problems such as affecting the safety of structural concrete, increasing the reinforcement ratio of main beams, and unfavorable construction operations, so as to reduce the type of structural steel bars and reduce the cost of steel bars. , Solve the effect of over-dense reinforcement of the main beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

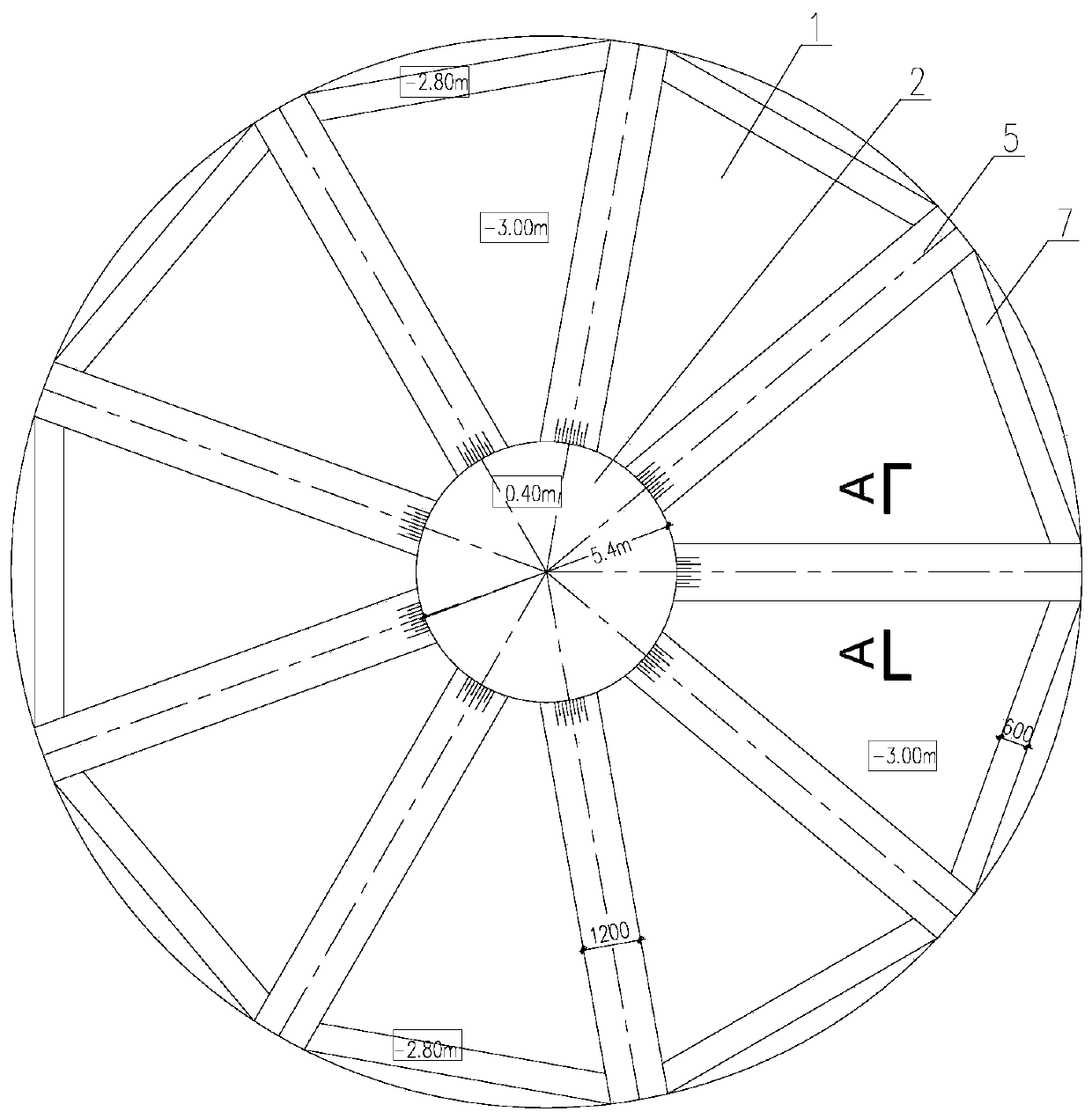

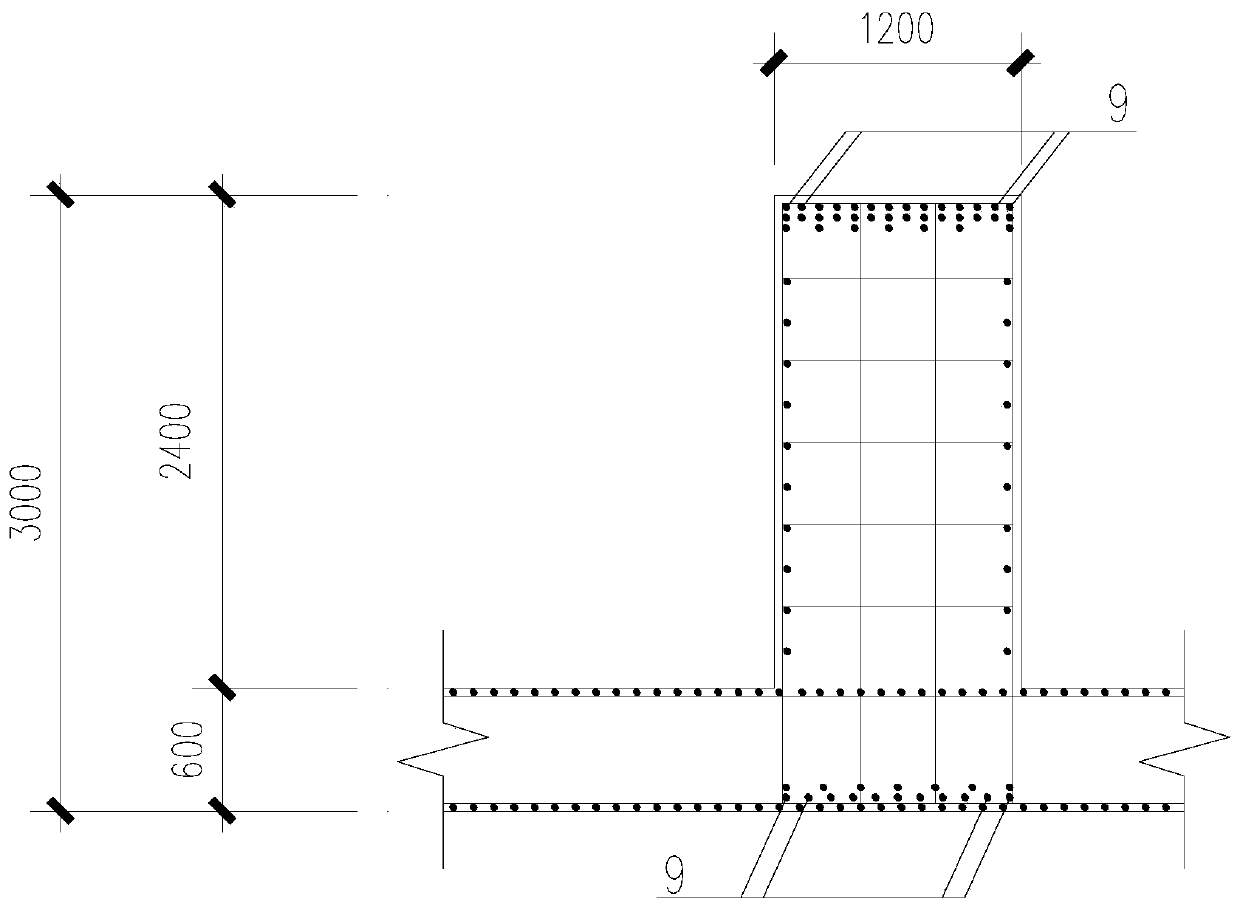

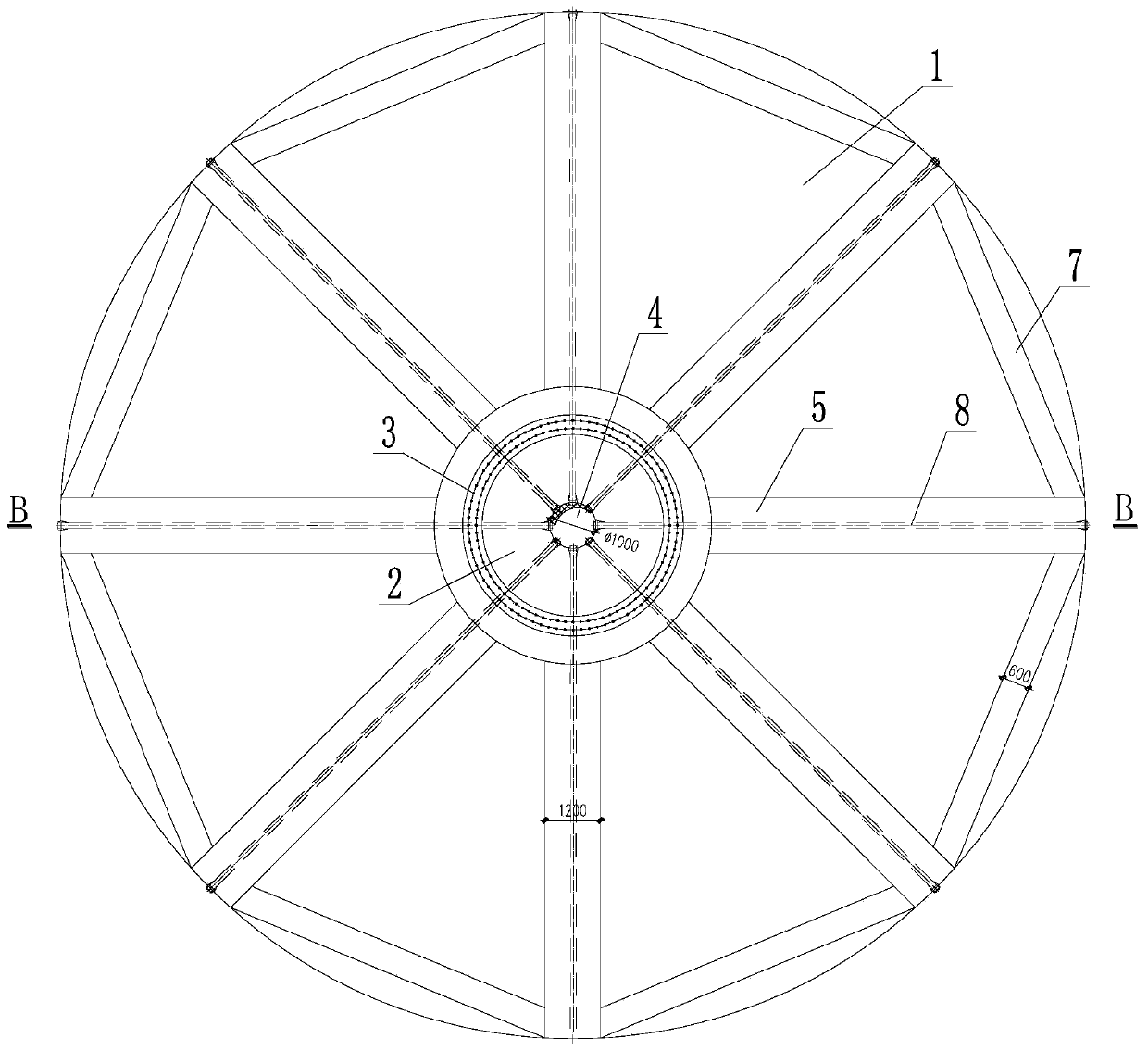

[0019] Such as Figure 3-5 As shown, the prestressed foundation structure of the wind turbine in the present invention is a beam-slab type, including a base plate 1, the base plate 1 is circular, the outer edge of the base plate 1 is the contour line of the basic body structure, and the middle part of the base plate 1 is cylindrical. The pillar 2, the anchor bolt cage 3 used to connect the first section of the wind turbine tower is arranged in the pillar 2, the inspection hole 4 is arranged in the pillar 2, the diameter of the inspection hole 4 is suitable for people to enter, for example, the diameter is 1 meter, which is convenient for the later stage Workers can enter the hollow structure of the platform column 2 to carry out maintenance work. Divergent main beams 5 are evenly distributed around the platform column 2, and the outer sides of two adjacent main beams 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com