Cast-in-place prestressed concrete pavement structure and construction method thereof

A technology for concrete pavement and pavement structure, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve problems such as difficulty in widespread promotion and popularization, high economic cost, etc., and achieve small prestress loss and prolong service life The effect of life, good deformation and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

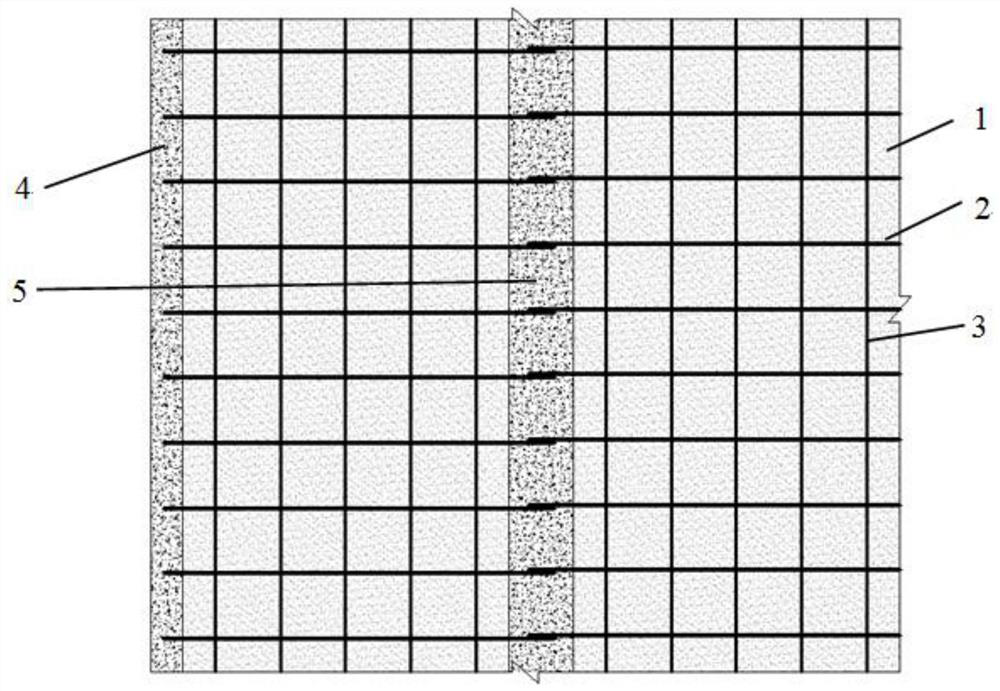

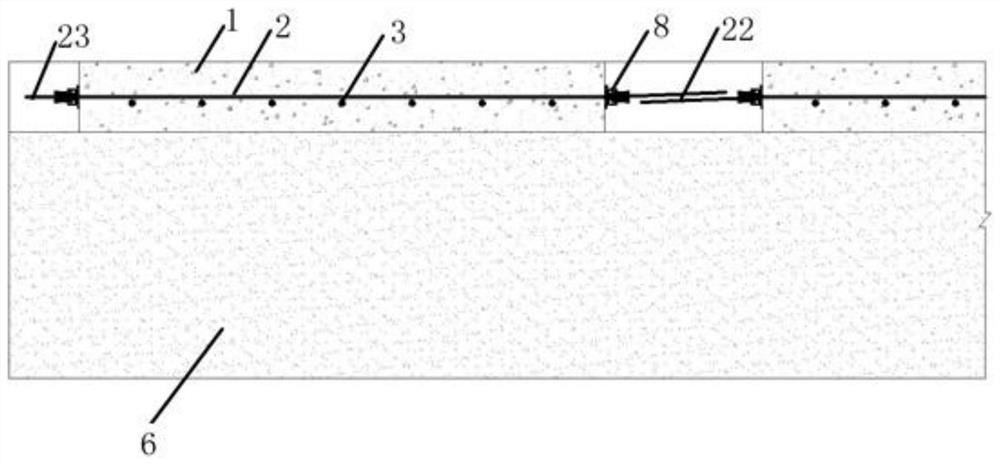

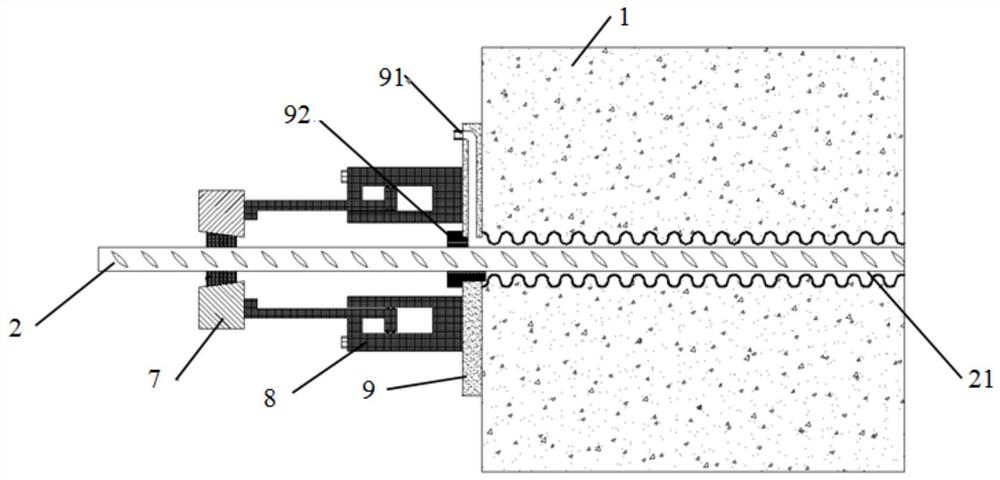

[0042] Such as figure 1 The shown cast-in-place prestressed concrete pavement structure includes a driveway pre-cast belt 1, a curb post-cast belt 4 and a driveway post-cast belt 5 respectively laid on the roadbed 6, and the curb post-cast belt 4 is located at The side part of the first pouring belt 1 in the lane, the post-casting belt 5 between the lanes is located on the lane divider line of the overall pavement structure, and both sides of the back-casting belt 5 between the lanes are the first pouring belts 1 for the lane; The pouring strip 1 includes transverse steel bars 2 and longitudinal steel bars arranged at intervals along the pavement structure, and a concrete slab that connects each steel bar by pouring; the ends of the transverse steel bars 2 are inserted into the curb post-cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com