A prefabricated beam slab and its construction method

A construction method and prefabricated technology, applied in the processing of building materials, construction, building components, etc., can solve the problems affecting construction quality and construction progress, the impact of structural stability at joints, and low work efficiency, so as to eliminate concrete The effect of slurry leakage, improving project economic benefits and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

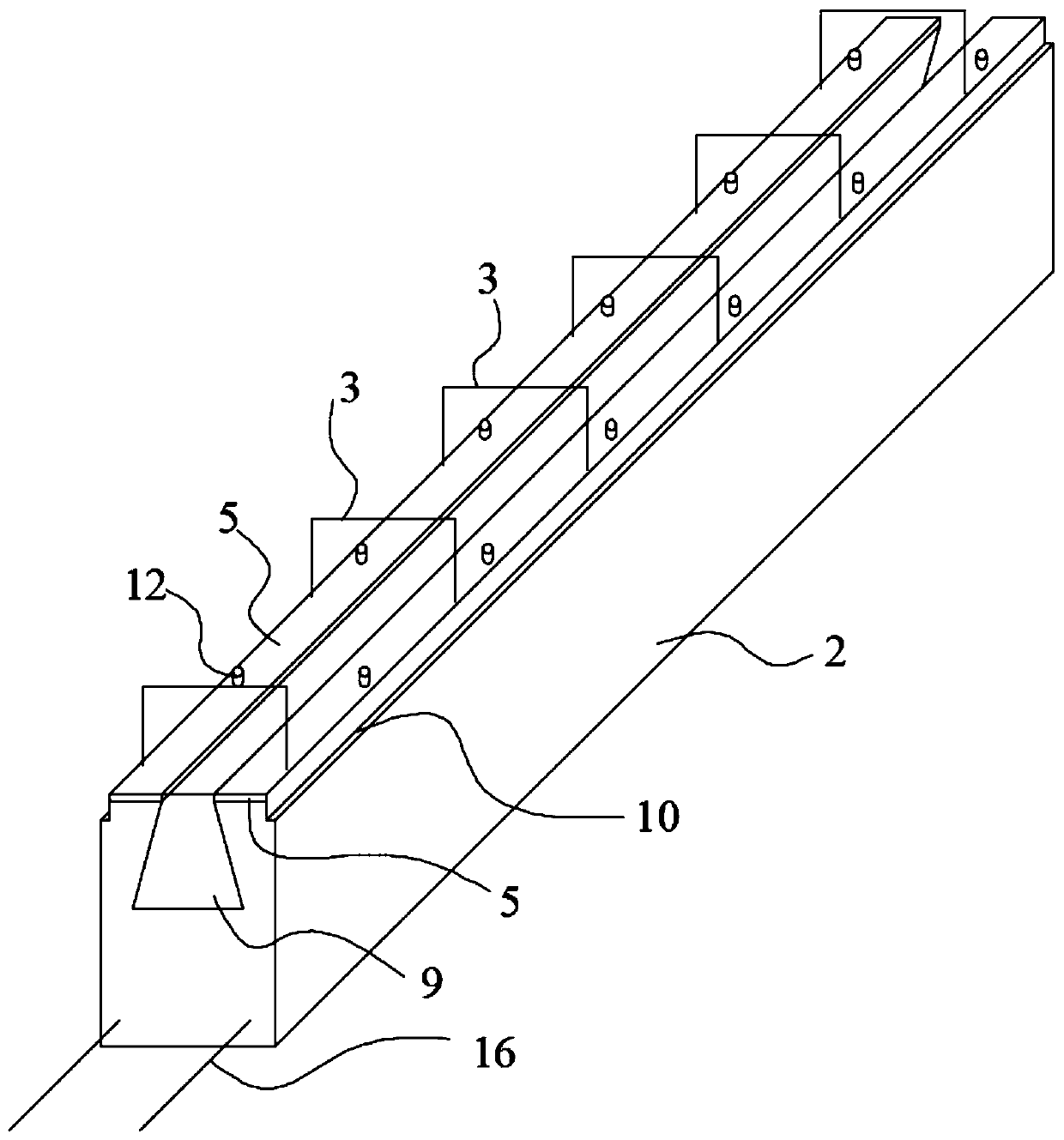

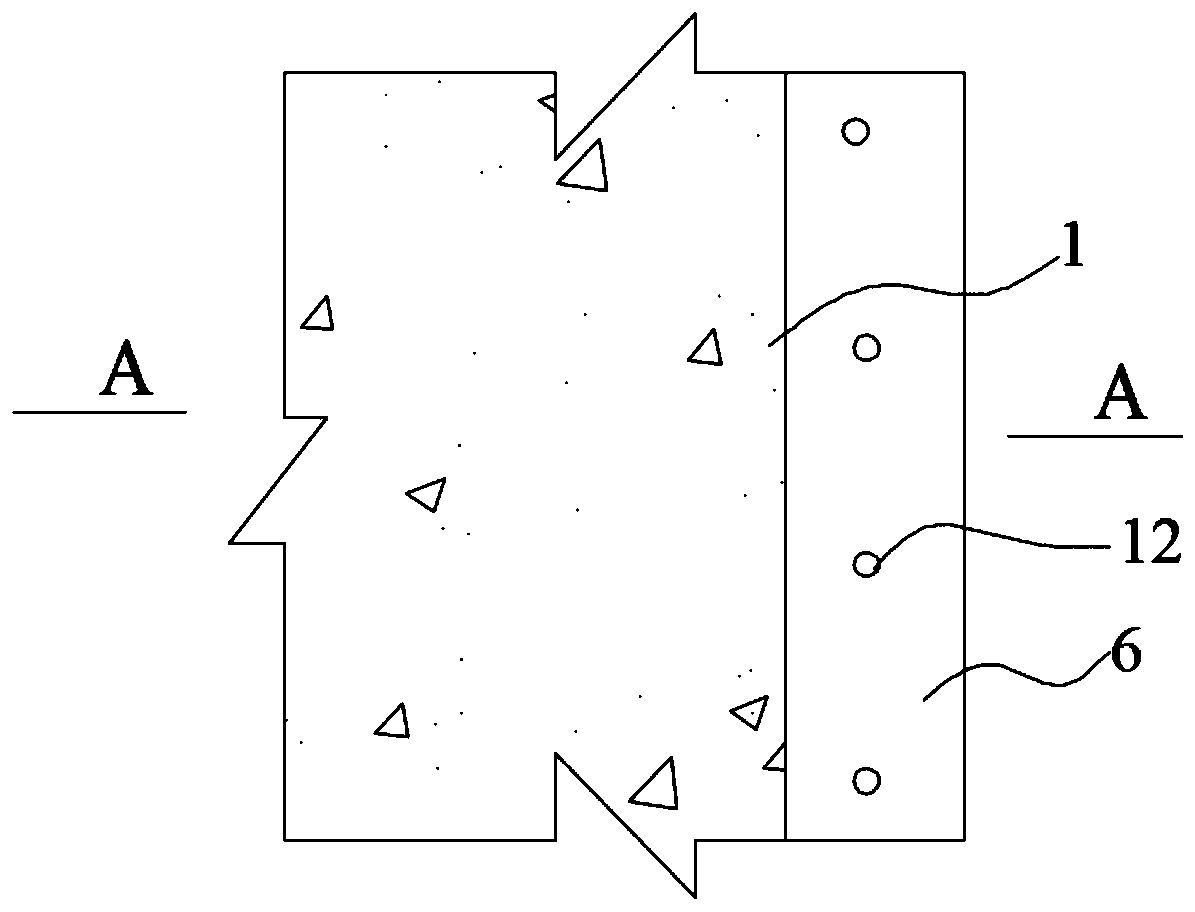

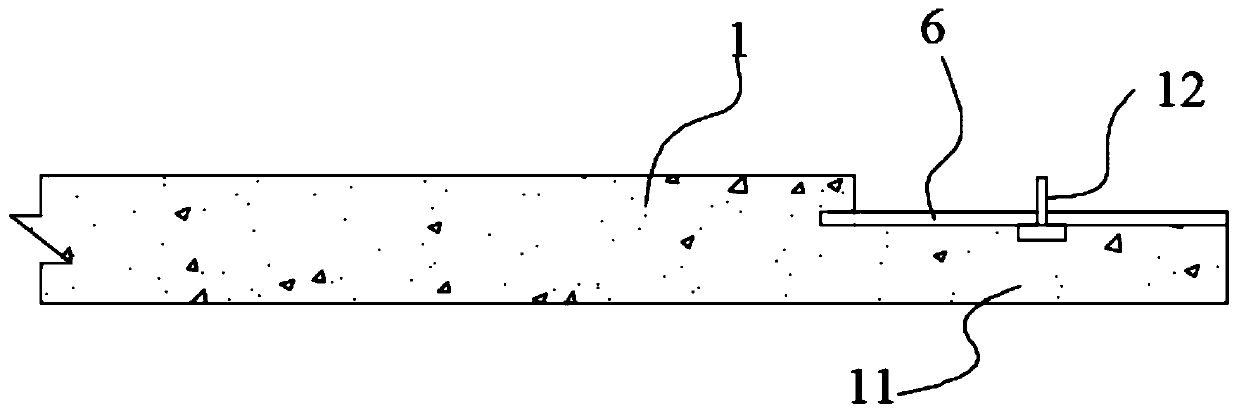

[0033] The present invention is illustrated below in conjunction with the accompanying drawings.

[0034] like Figure 1-6 As shown, an assembled beam slab includes a laminated beam 2 and a laminated plate 1 connected to both sides of the laminated beam 2. The middle part of the top surface of the laminated beam 2 is provided with a groove 9 along the length direction, and the groove 9 The top surfaces of the laminated beams 2 on both sides are respectively provided with pre-embedded first connecting steel plates 5, and the edges of both sides of the laminated beam 2 are provided with recesses 10 for connecting the laminated plates 1, and one end of the laminated plates 1 is provided with a The flange 11 extending in the plane direction, the second connecting steel plate 6 is embedded in the upper part of the flange 11, and the second connecting steel plate 6 extends into the interior of the main body of the laminated plate 1 by 10 mm, and the other sides are flat with the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com