Wet joint connection structure for fully prefabricated bridges

A technology of prefabricated assembling and connecting structures, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of increasing construction costs, increasing the configuration of bridge deck reinforcement, and reducing the effective height of bridge deck structures, so as to save costs and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The wet joint section mentioned in the present invention refers to the part that is arranged between the prefabricated beams that are prefabricated in blocks and uses cast-in-place concrete to connect the prefabricated beams as a whole.

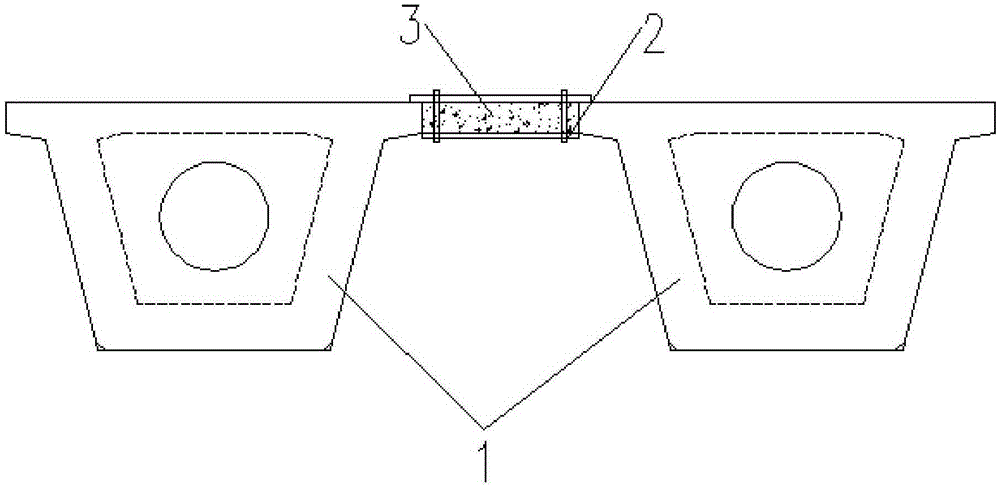

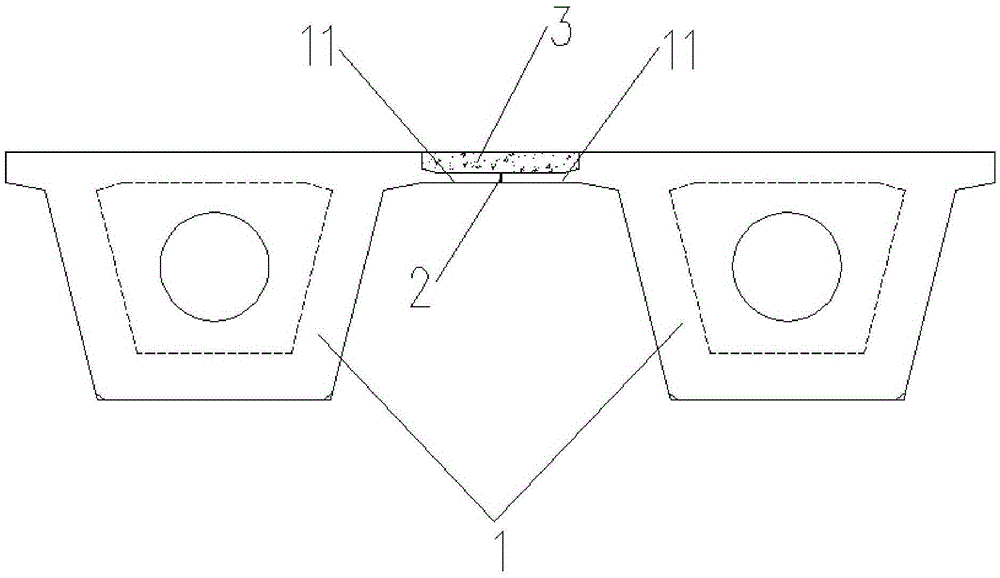

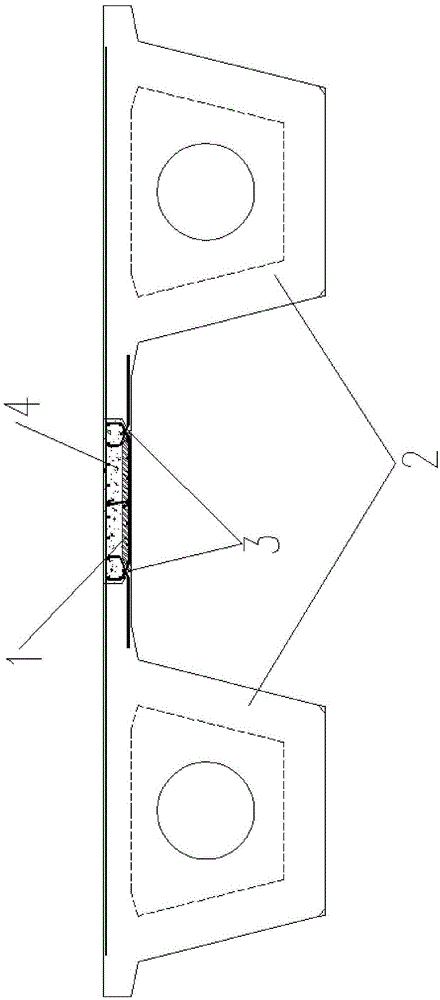

[0020] The invention provides a wet joint connection structure used for fully prefabricated assembled bridges. In the first embodiment, if Figure 3 to Figure 5 As shown, it includes a prefabricated lower bridge deck 1 with a certain thickness. In order to ensure that the prefabricated lower bridge deck 1 has a certain strength, its thickness should be greater than 5 cm. In this embodiment, the selected thickness is 7 cm.

[0021] The prefabricated lower bridge deck 1 is arranged at the wet joint between two prefabricated girders 2 . Since there is a certain gap 3 between the prefabricated lower bridge deck 1 and the prefabricated beams on both sides, before the concrete 4 is poured later, the gap is firstly sealed.

[0022] In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com