Fabricated building prefabricated steel reinforced concrete end column-beam joint prestressing tendon interlaced tension anchoring structure and construction method

A technology of prestressed tendons and construction methods, applied in building structures, building components, buildings, etc., can solve the problems of inability to effectively improve the stress characteristics of beam-column joints, low hoisting speed and precision, and poor negative bending moment resistance of joints, etc. problem, to achieve the effect of improving the mechanical characteristics of beam-column joints, good anti-negative bending moment effect of joints, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

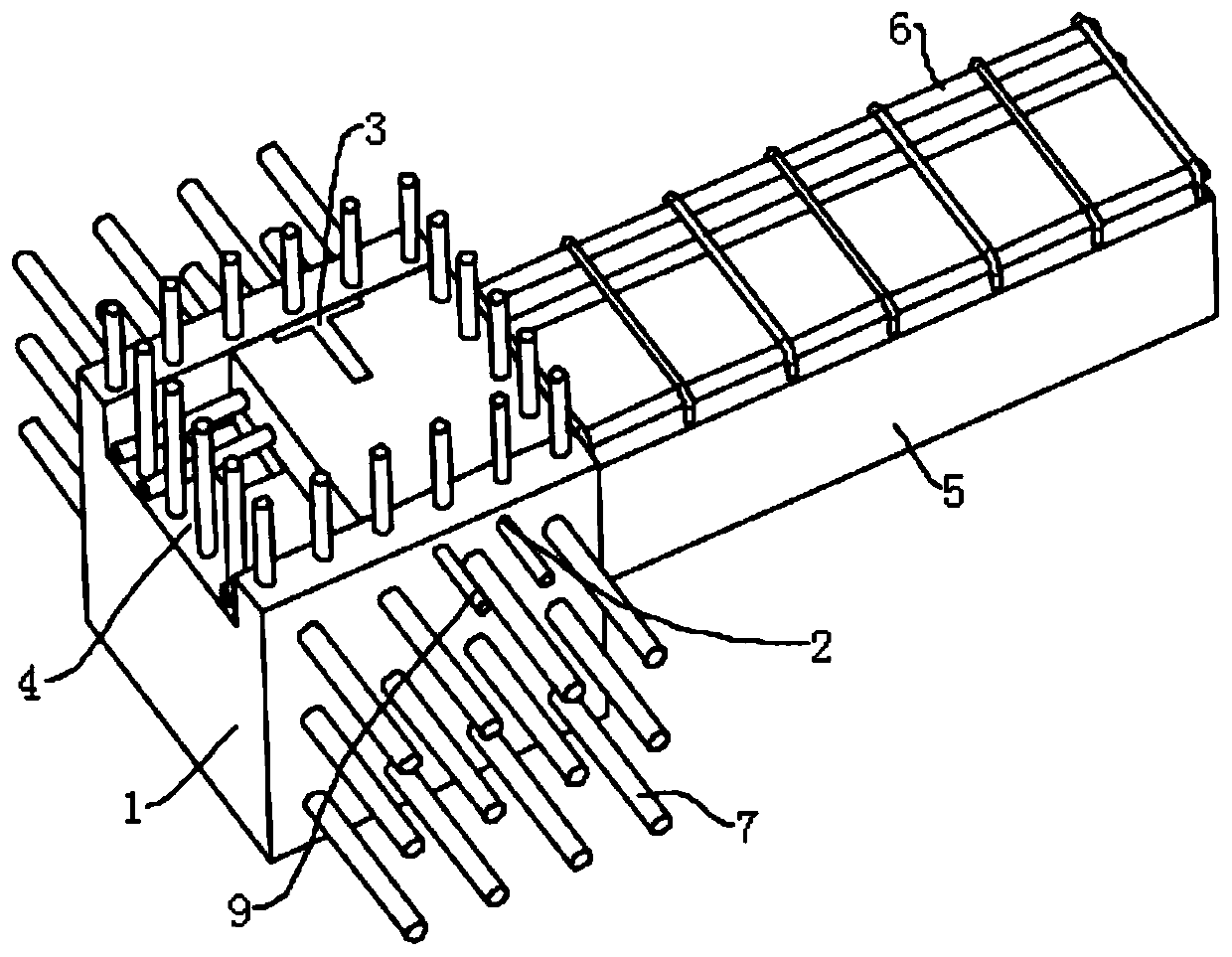

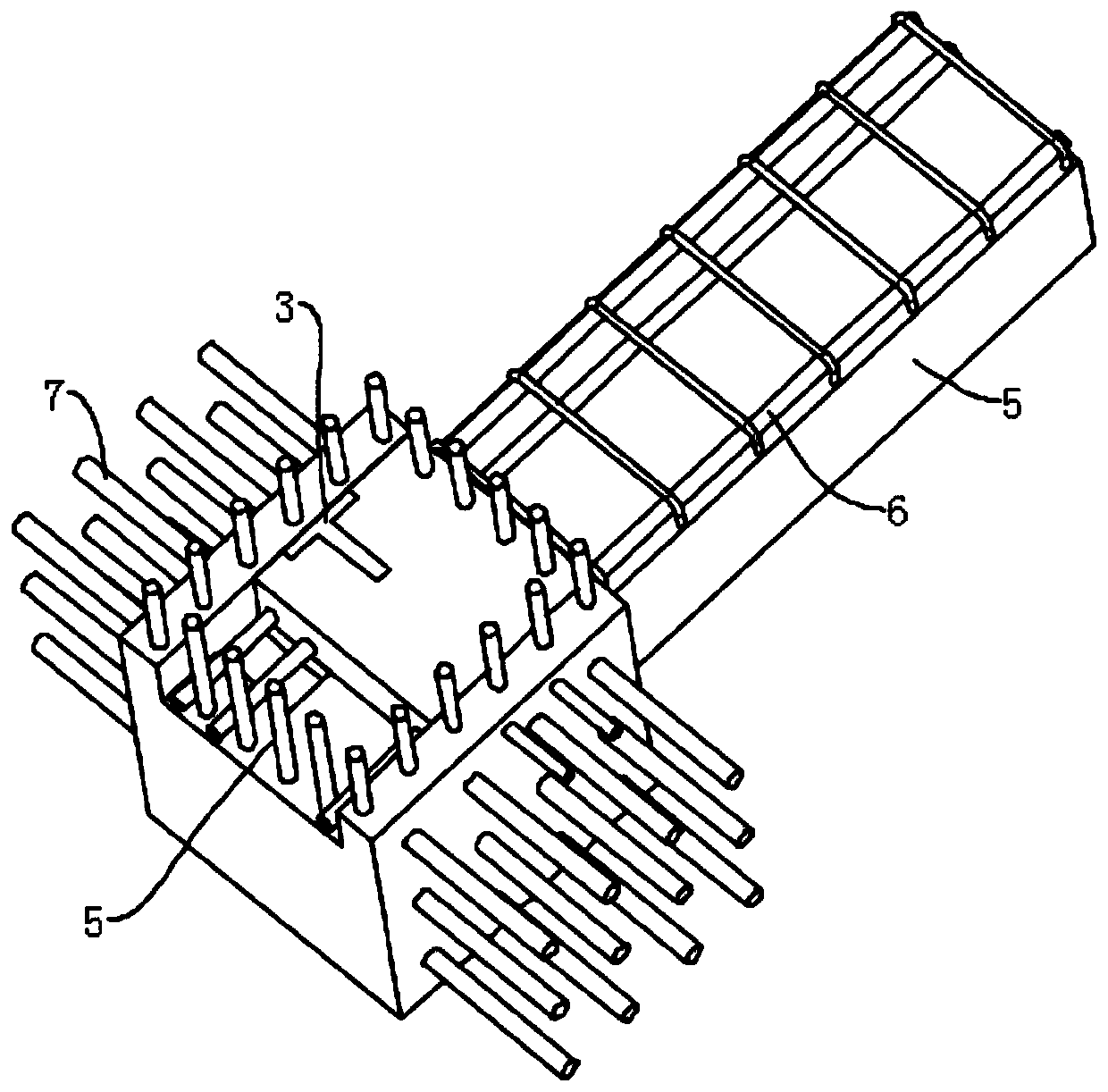

[0050] A prefabricated building prefabricated steel concrete end column-beam joint prestressed tendon interlaced tension anchor structure, including prefabricated column 1, also includes:

[0051] The reserved channel 2 reserved in the prefabricated column 1;

[0052] T-shaped steel column 3 integrally formed with prefabricated column 1;

[0053] The prefabricated column laminated layer 4 arranged on the upper part of the prefabricated column 1;

[0054] A composite beam 5 arranged at one end of the prefabricated column 1;

[0055] The top steel bar 6 exposed on the upper part of the composite beam 5;

[0056] The outstretched steel bar 7 extending from the side of the prefabricated column 1;

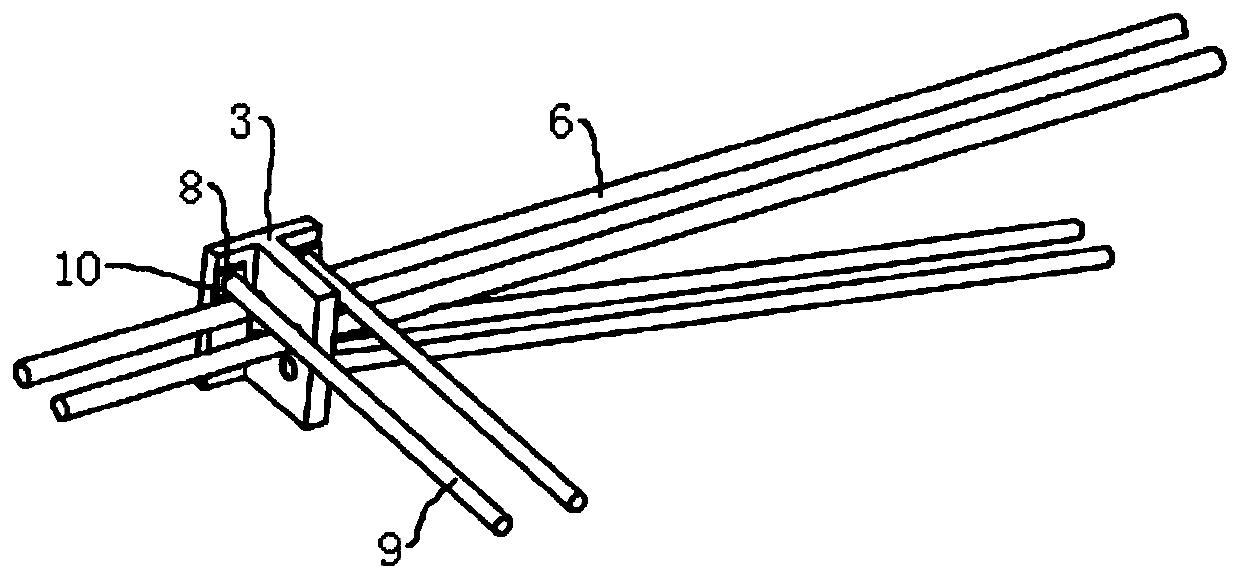

[0057] A plurality of reserved perforations 8 provided on the T-shaped steel column 3;

[0058] Prestressed tendons 9 passing through a plurality of reserved perforations 8;

[0059] The prestressed tendon 9 anchoring device fixed on the T-shaped steel column 3, the prestressed ten...

Embodiment 2

[0063] The difference from Embodiment 1 is that it also provides a construction method for assembling prefabricated steel concrete end column-beam joint prestressed tendon cross-tensioned anchorage structure, which specifically includes the following steps:

[0064] a. The factory makes prefabricated columns 1;

[0065] b. Prefabricated column 1 hoisting construction;

[0066] c. Hoisting of composite beam 5 and installation of support system;

[0067] d. Sleeve grouting connection of prefabricated column 1 side extension steel bar 7 at the post-casting section of beam-column joint;

[0068] e. Installation of formwork and support system at the post-casting section of beam-column joints;

[0069] f. The three-direction prestressed tendon 9 is perforated and temporarily fixed;

[0070] g. Concrete pouring at the post-cast section of beam-column joints;

[0071] h. Tensioning and anchoring of prestressed steel bars in three directions;

[0072] j. Install and fix the flat d...

Embodiment 3

[0088] The difference from Example 2 lies in the construction method for assembling the prefabricated steel concrete end column beam joint prestressed tendon interlaced tension anchorage structure, which specifically includes the following steps:

[0089] a. The factory makes prefabricated columns 1;

[0090] b. Prefabricated column 1 hoisting construction;

[0091] c. Hoisting of composite beam 5 and installation of support system;

[0092] d. Sleeve grouting connection of prefabricated column 1 side extension steel bar 7 at the post-casting section of beam-column joint;

[0093] e. Installation of formwork and support system at the post-casting section of beam-column joints;

[0094] f. The three-direction prestressed tendon 9 is perforated and temporarily fixed;

[0095] g. Concrete pouring at the post-cast section of beam-column joints;

[0096] h. Tensioning and anchoring of prestressed steel bars in three directions;

[0097] j. Install and fix the flat dark beam st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com