Patents

Literature

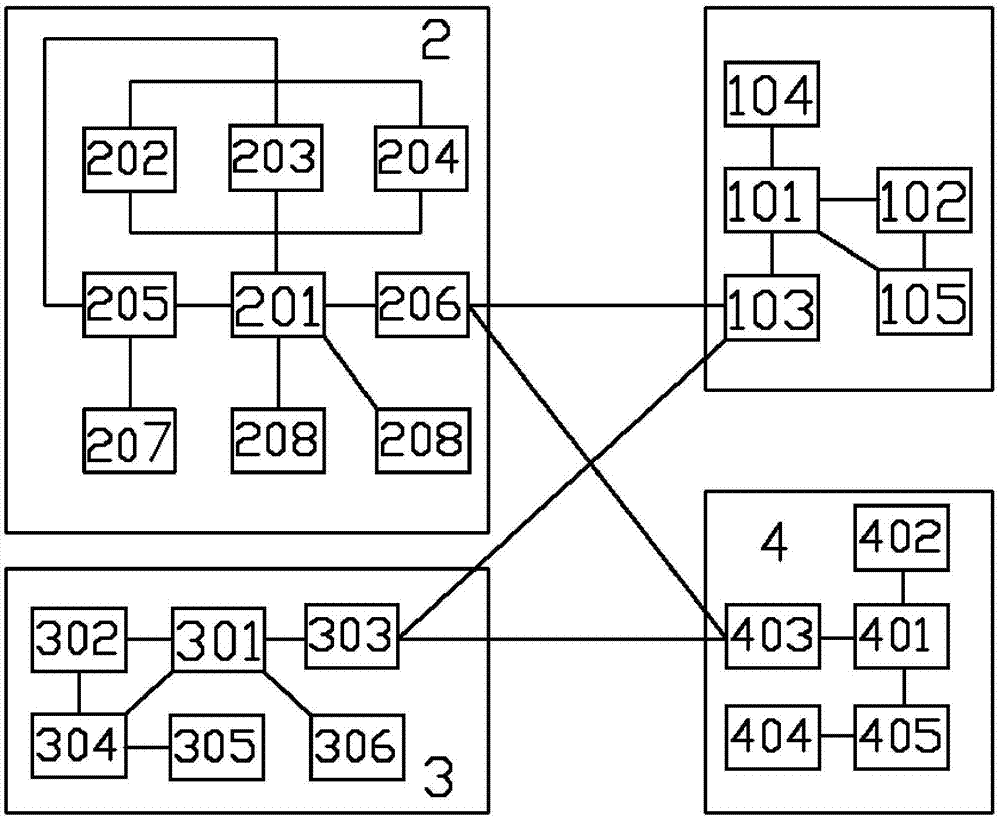

39results about How to "Improve hoisting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

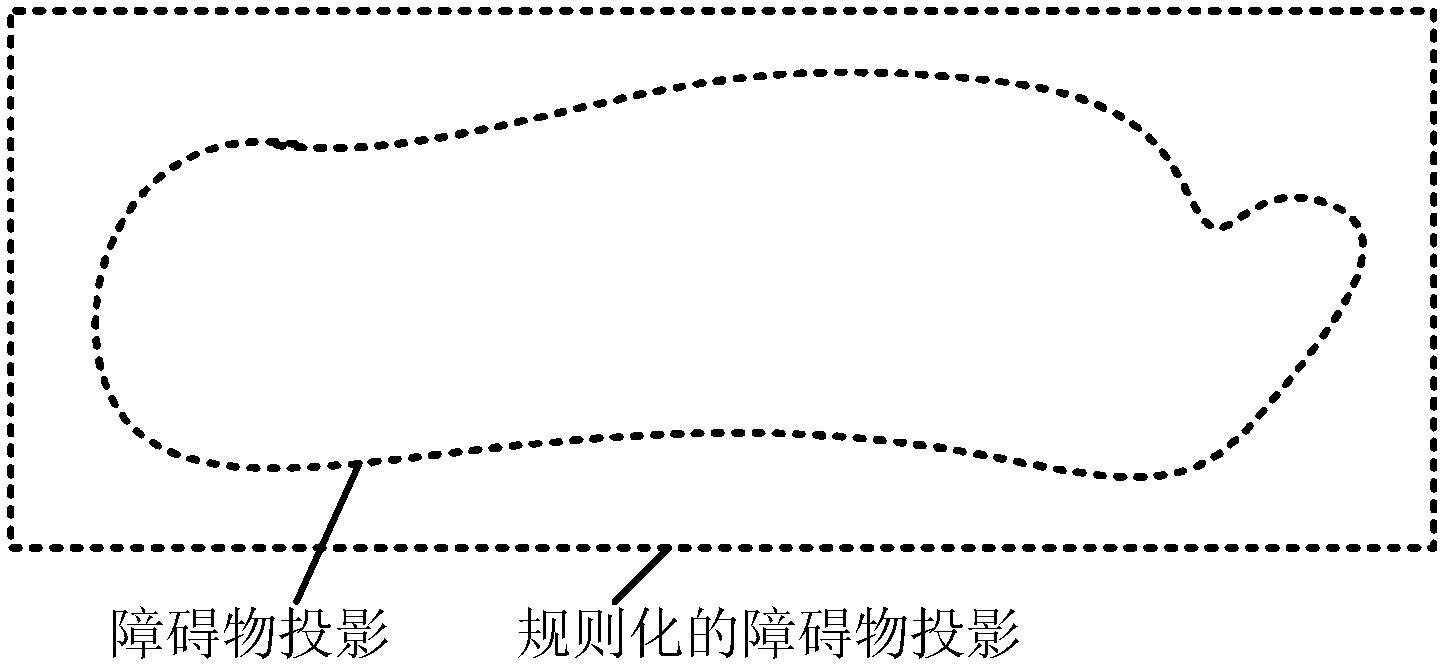

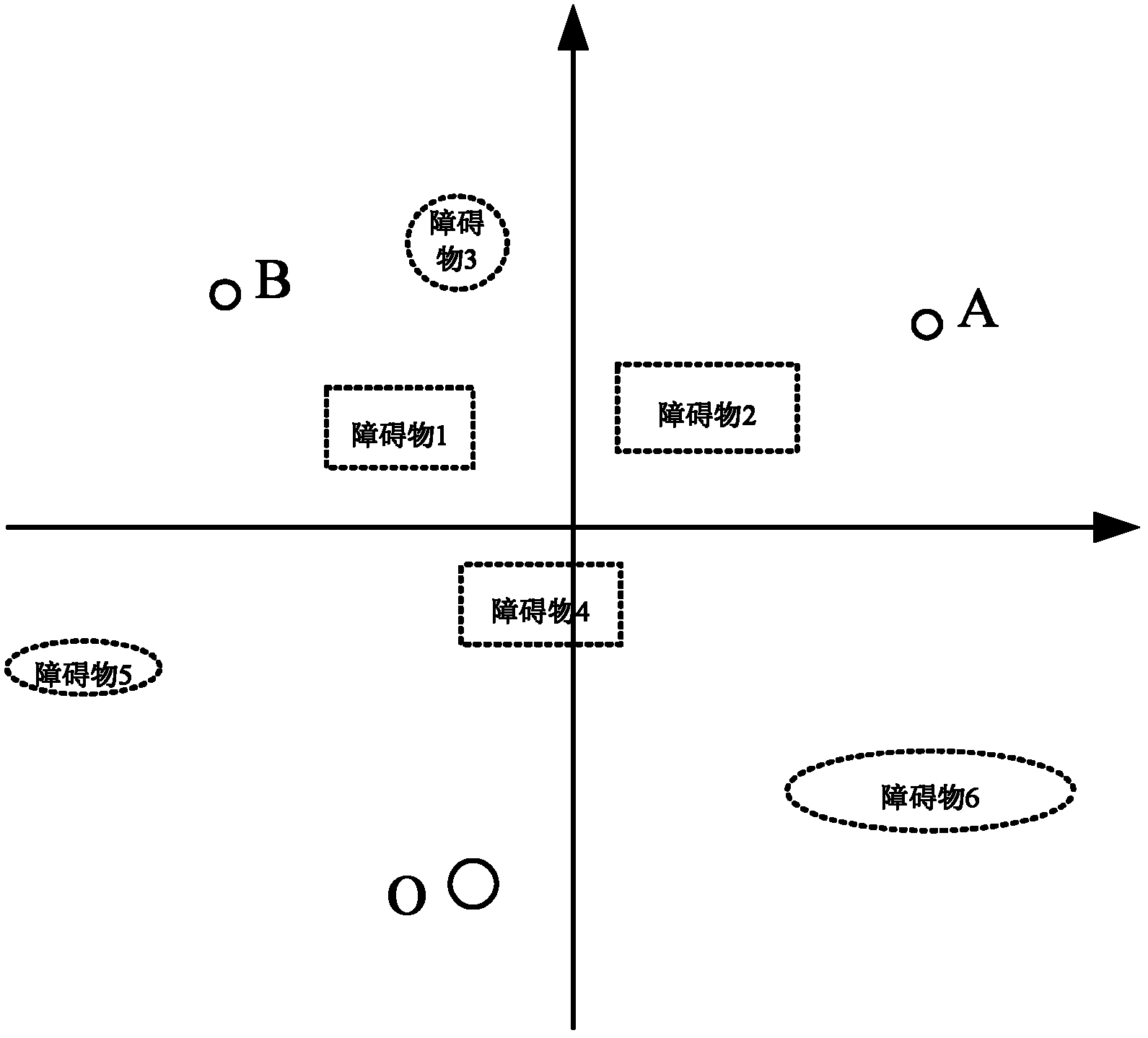

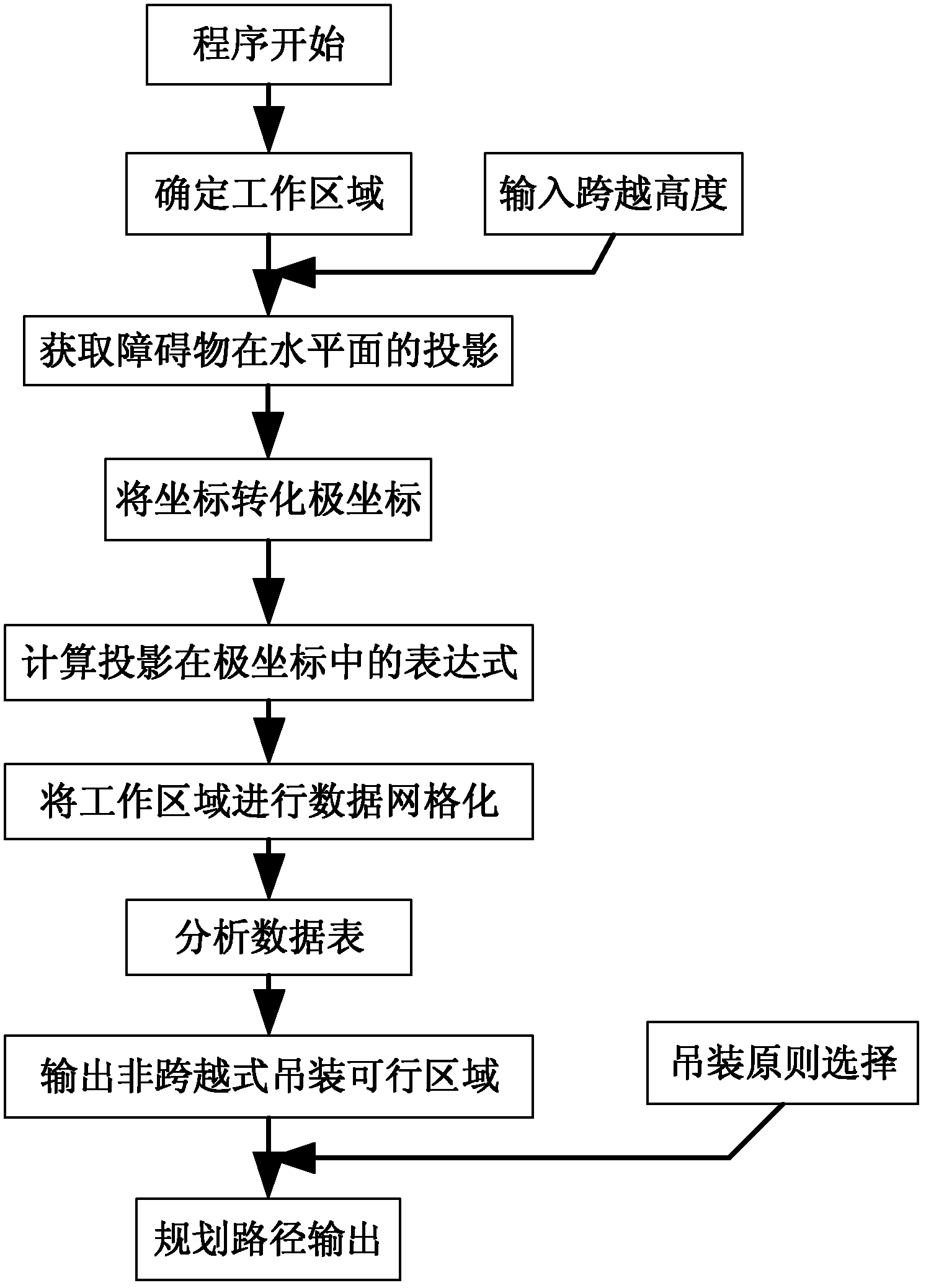

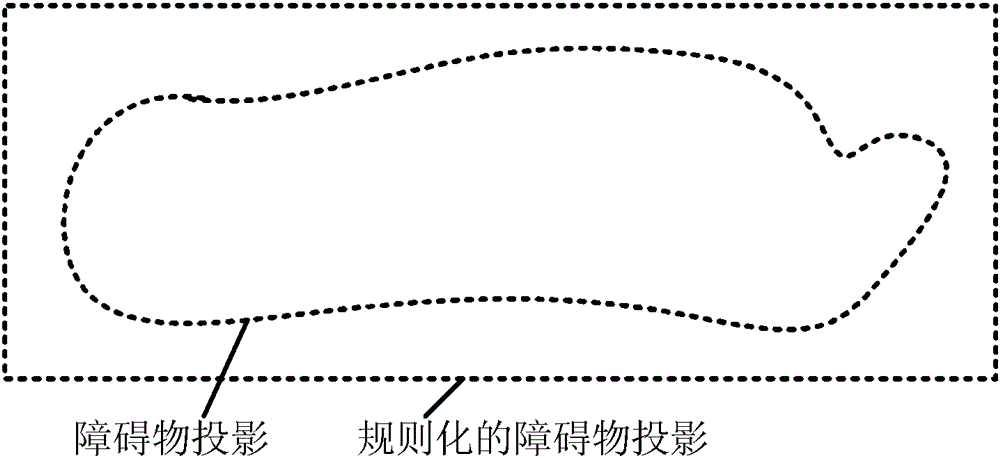

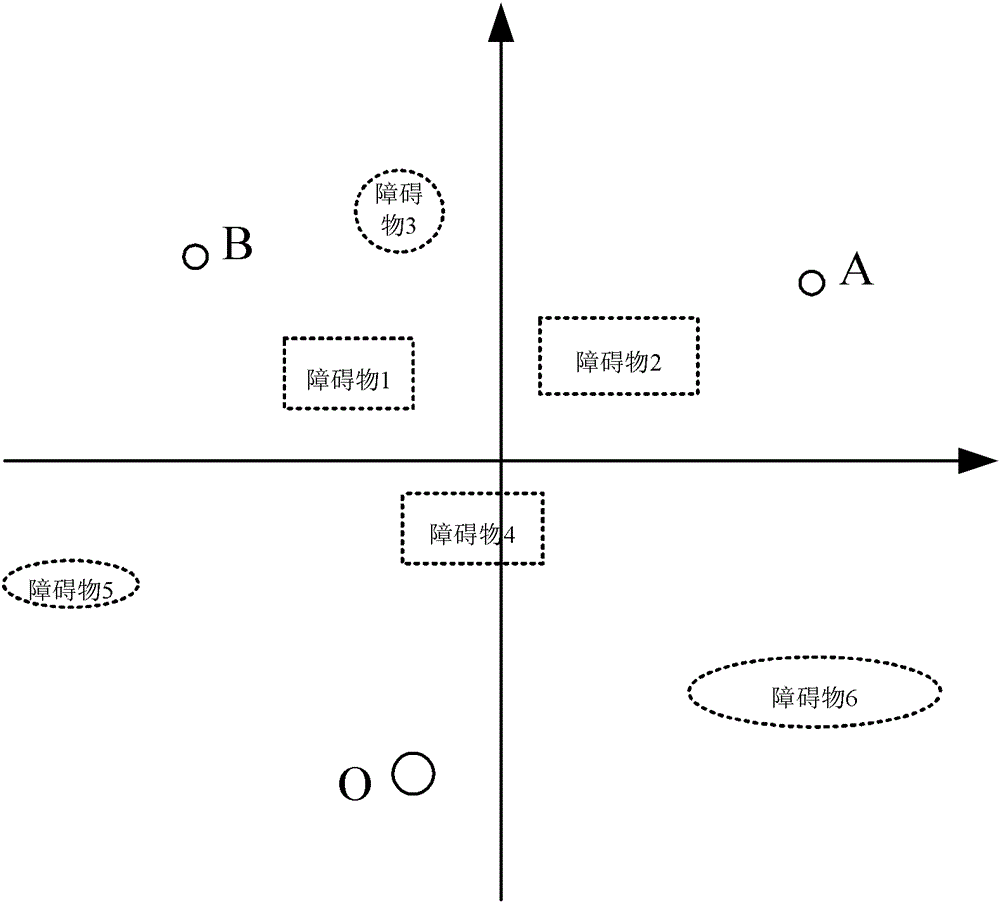

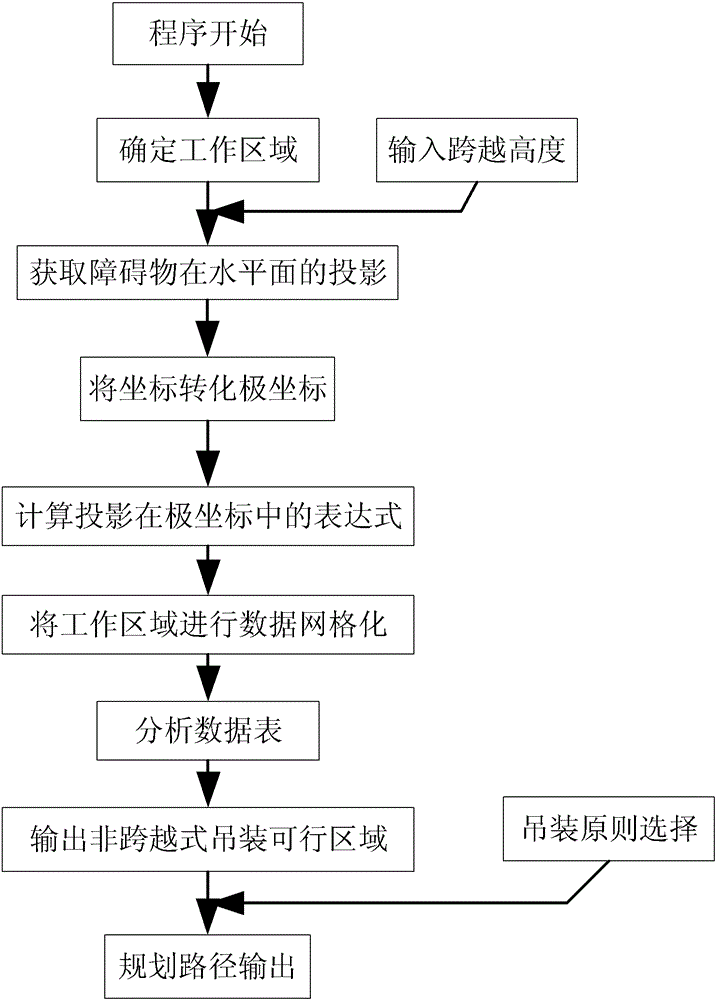

Method for planning path of lift object for crane

The invention provides a method for planning a path of a lift object for a crane. The method comprises the following steps of: projecting an obstacle on a working plane of the crane; performing polar radius-oriented processing on the projection and transforming a coordinate expression form of the obstacle into a polar coordinate expression form; analyzing the obstacle which is positioned on the path of the lift object to ensure that the lift object can pass through the path; and determining a lifting path according to a lifting principle. By the method for planning the path of the lift object for the crane, distances among obstacles can be calculated quickly and efficiently, the planned lifting path can be searched precisely, and the lifting safety and reliability of the lift object can be improved.

Owner:ZOOMLION HEAVY IND CO LTD

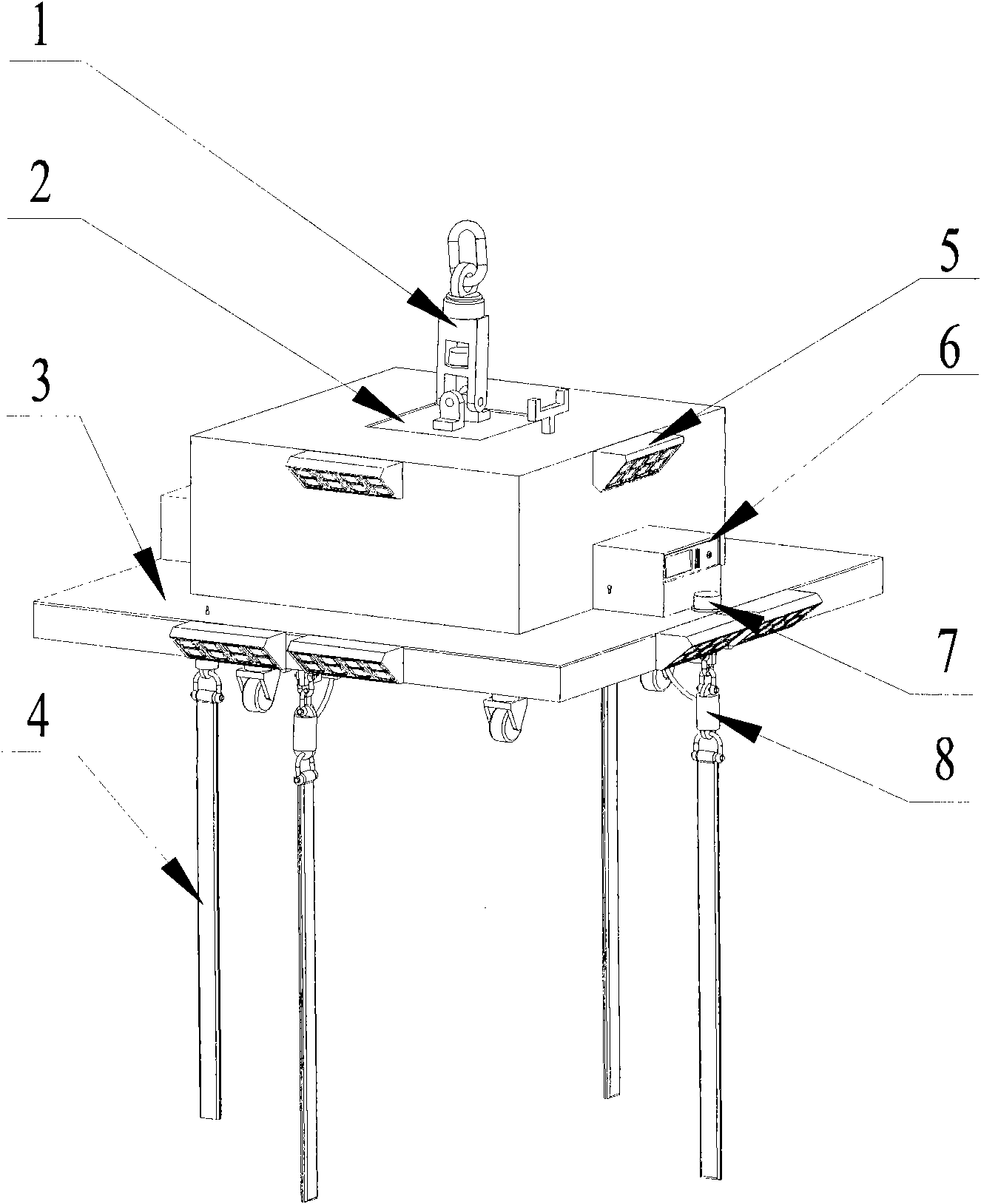

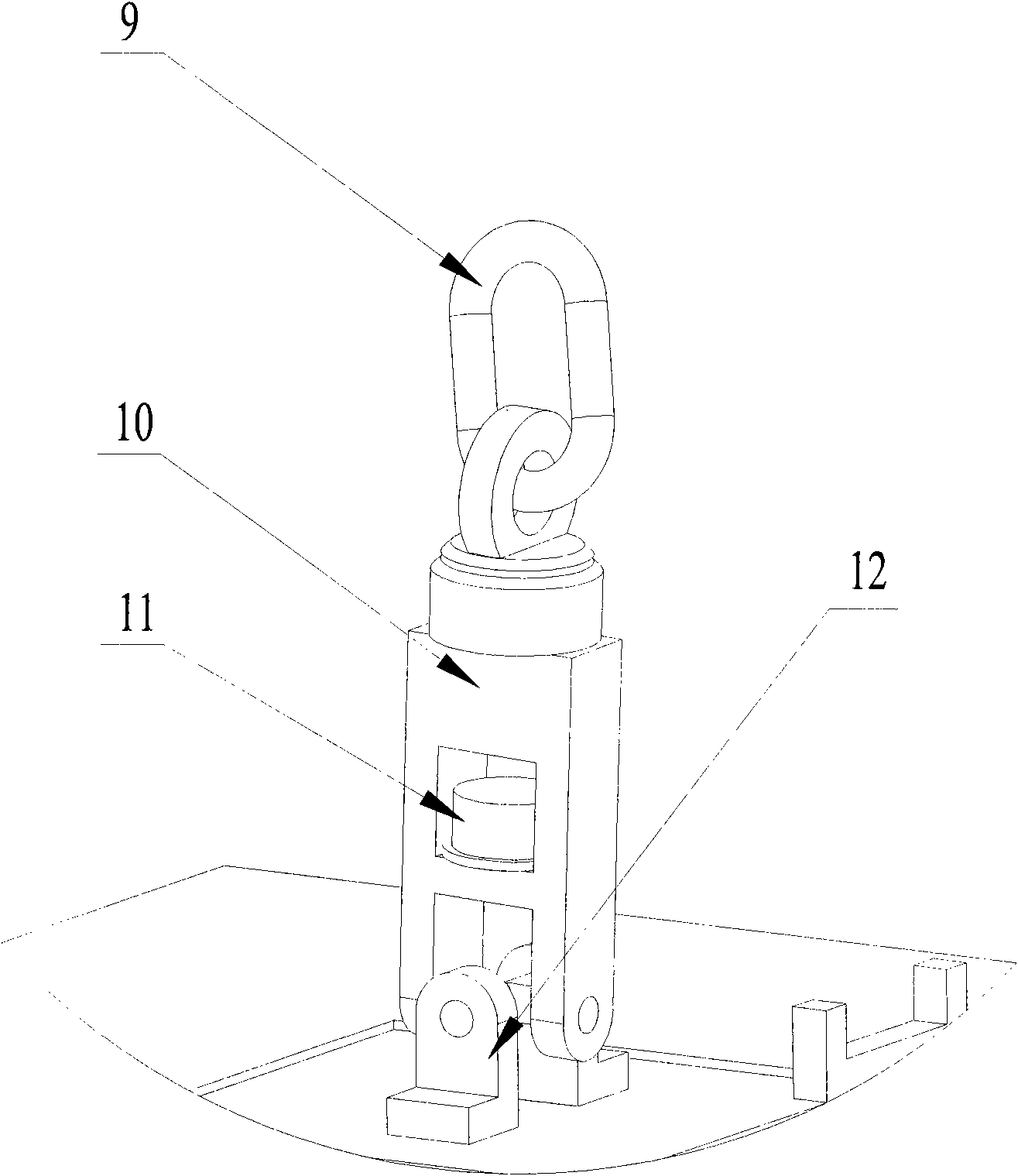

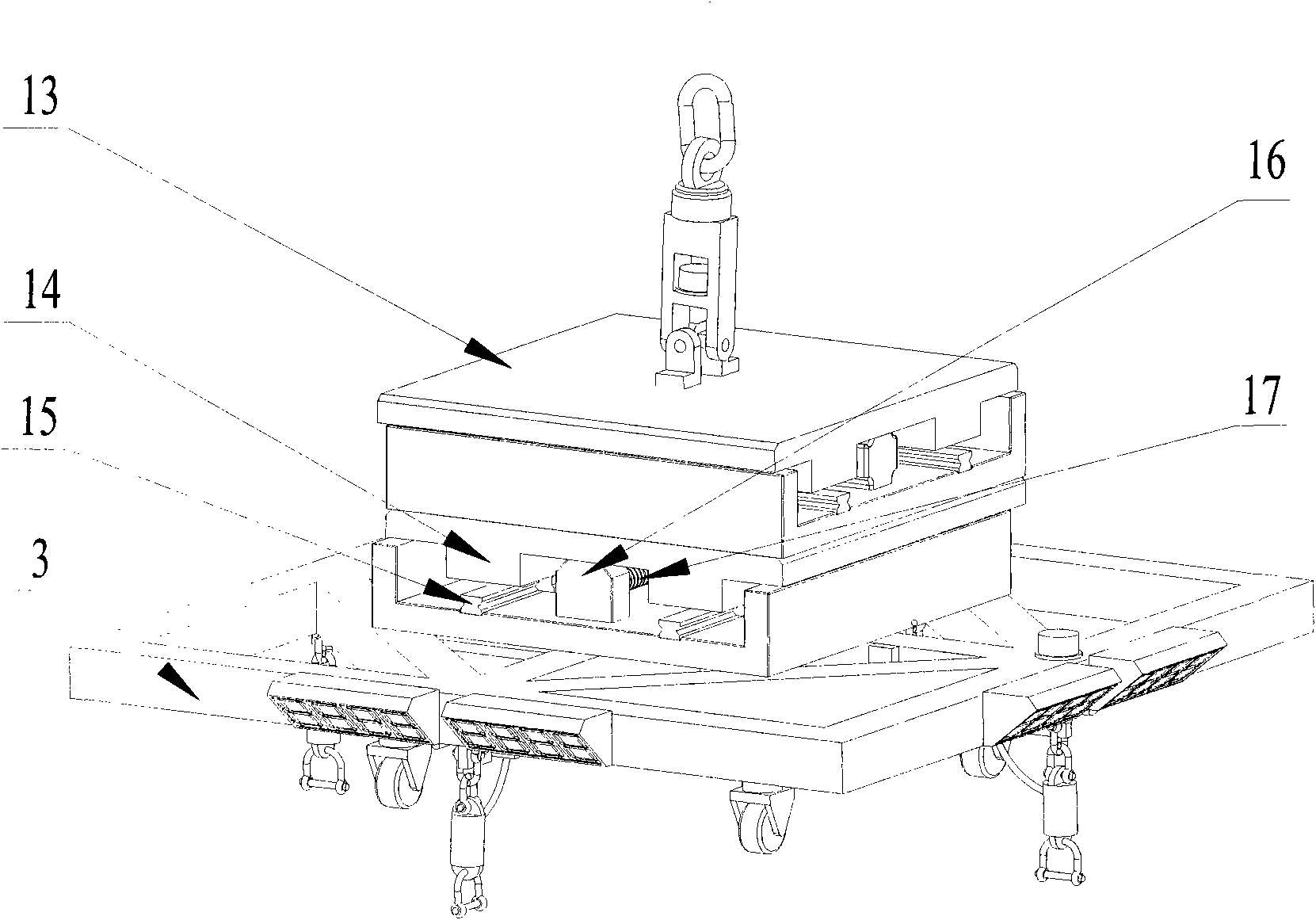

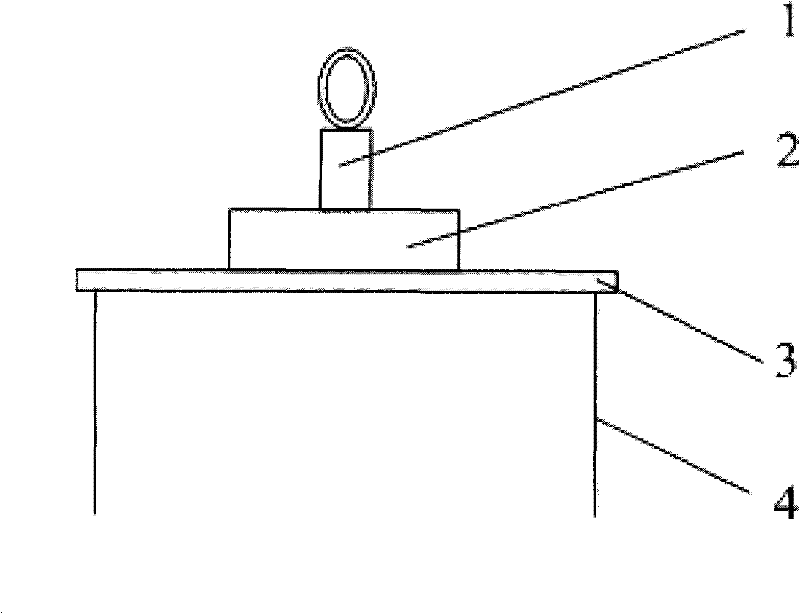

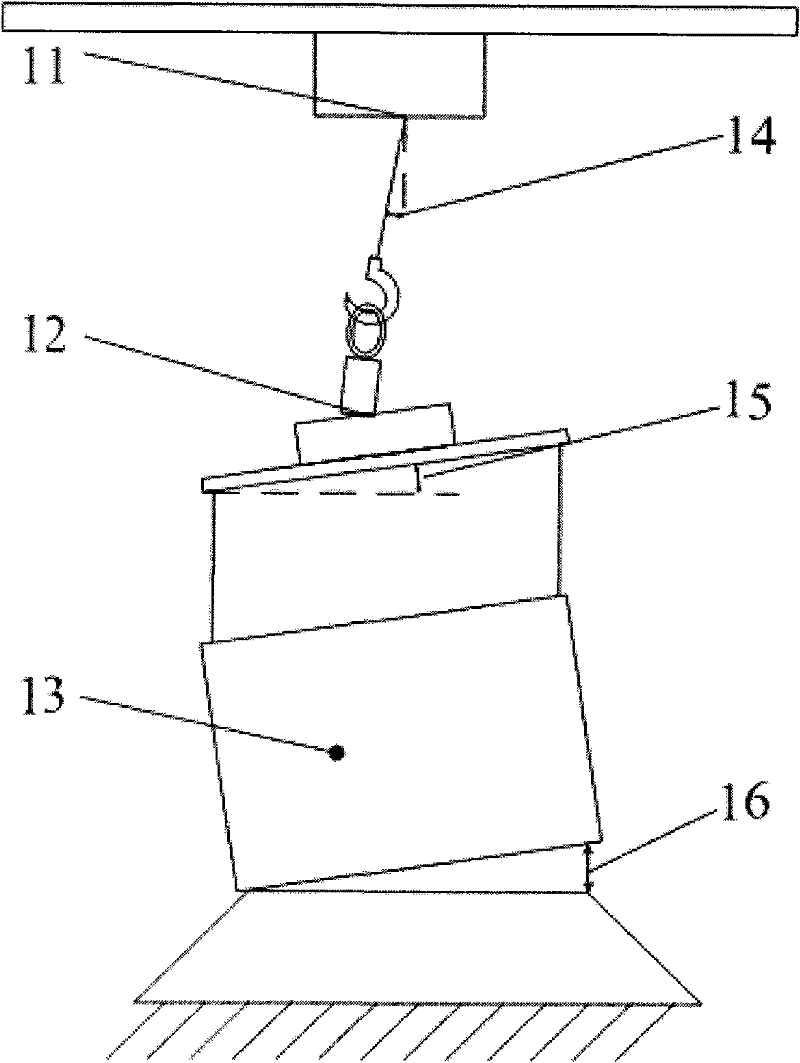

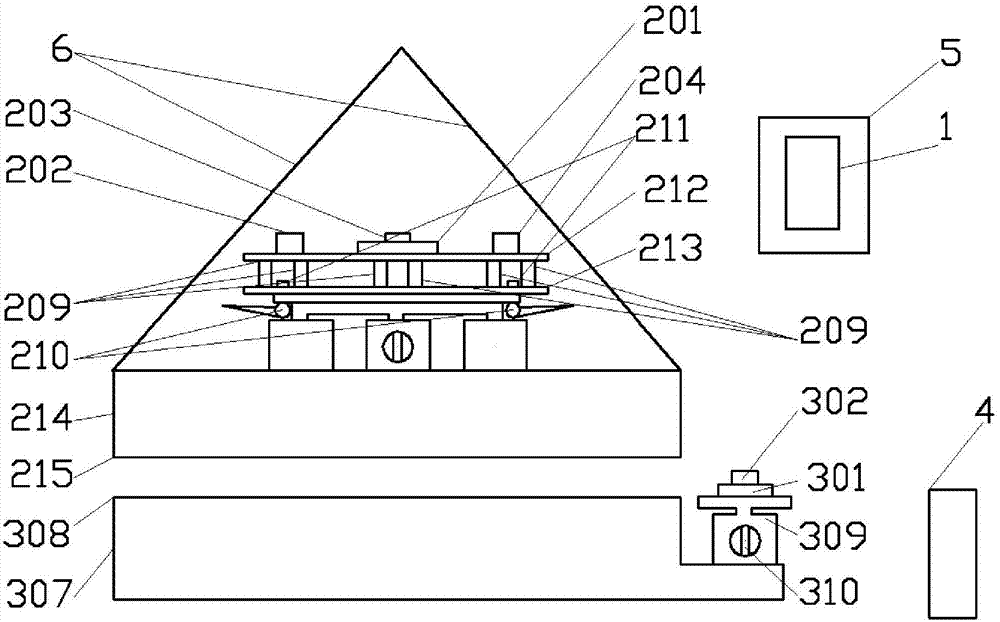

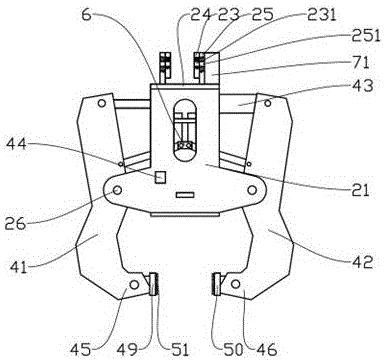

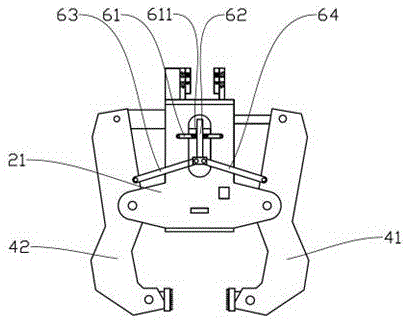

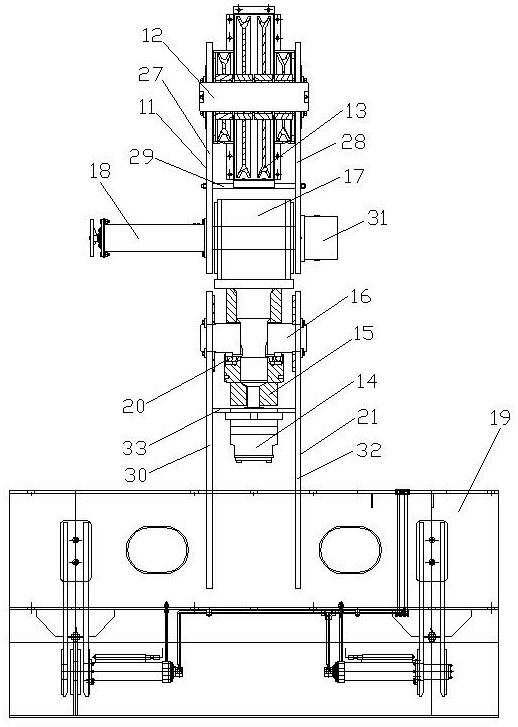

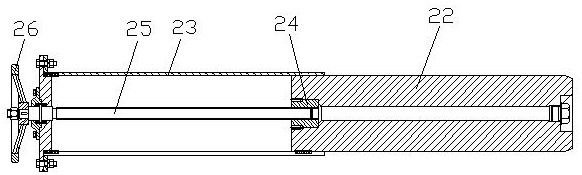

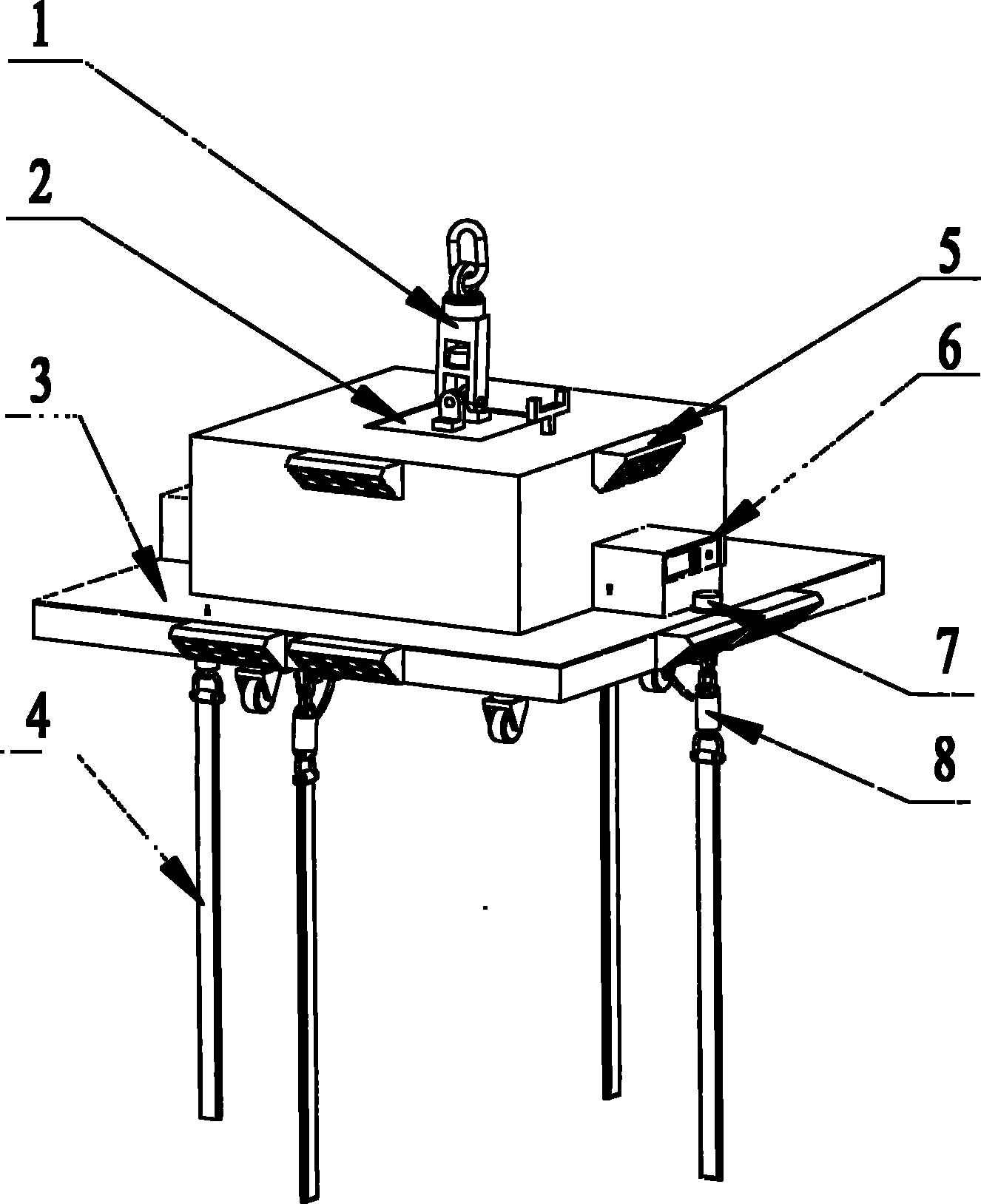

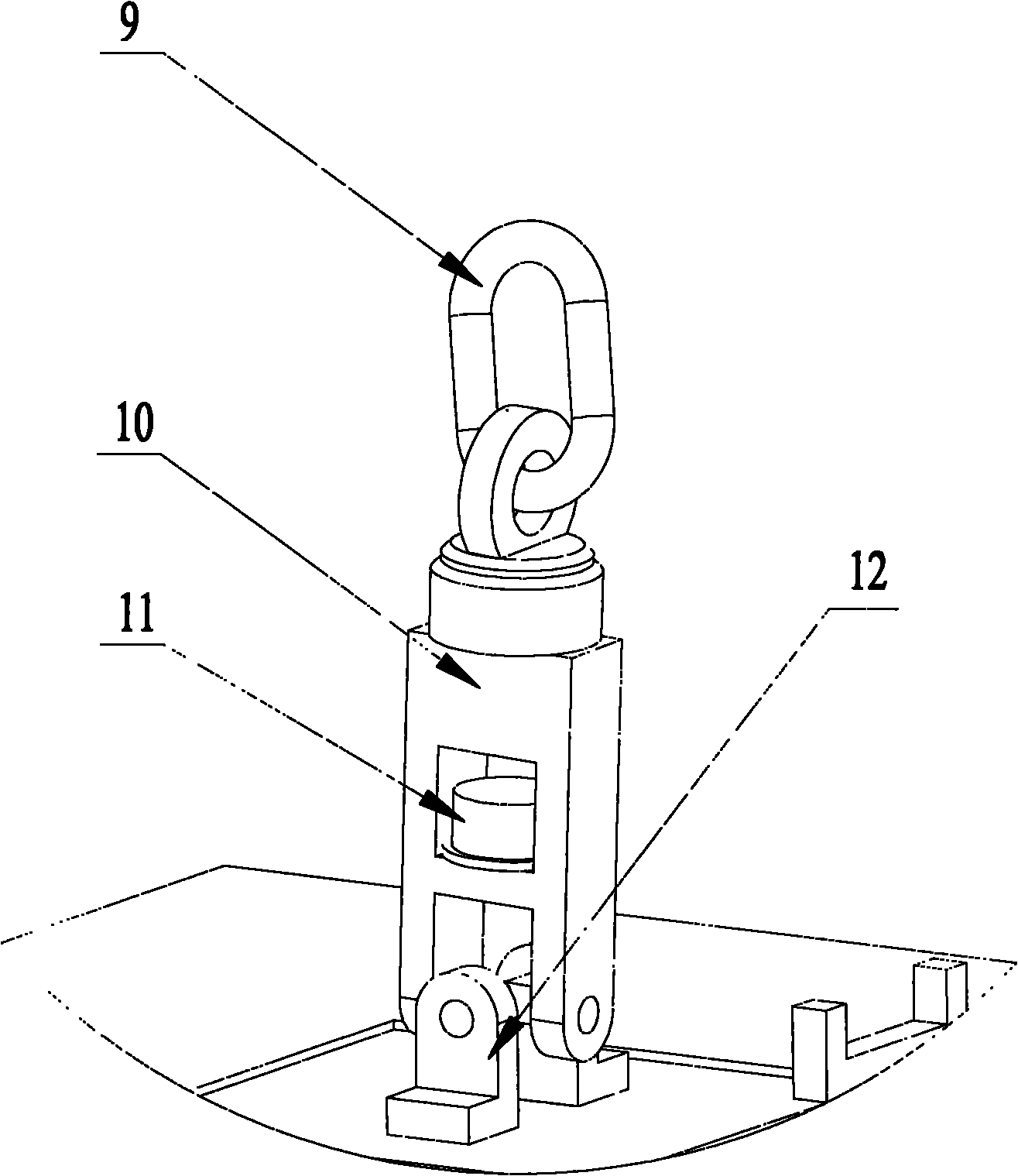

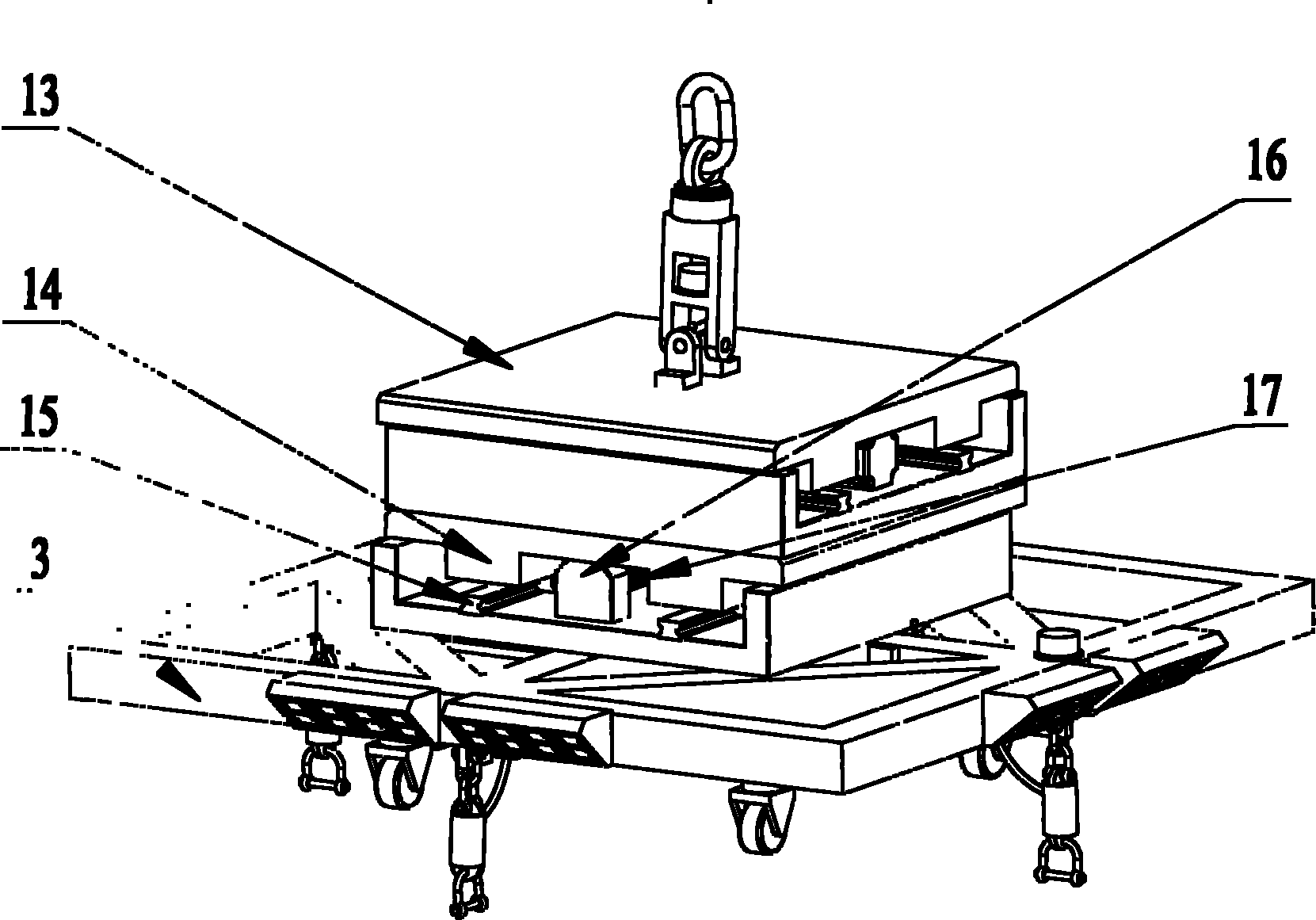

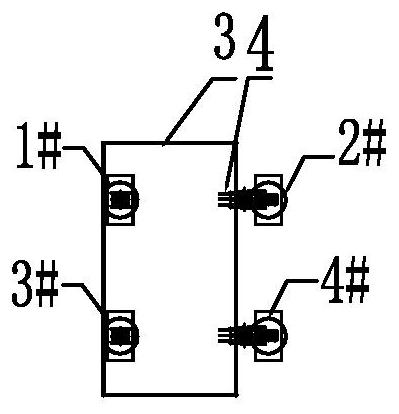

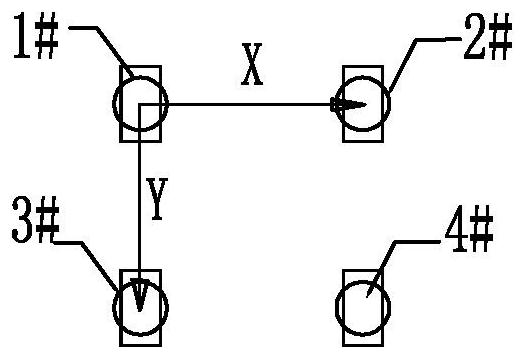

Horizontal adjusting sling for spacecraft

ActiveCN102556831AReduce labor intensityOvercome the problem of automatic level adjustmentLoad-engaging elementsUniversal jointEngineering

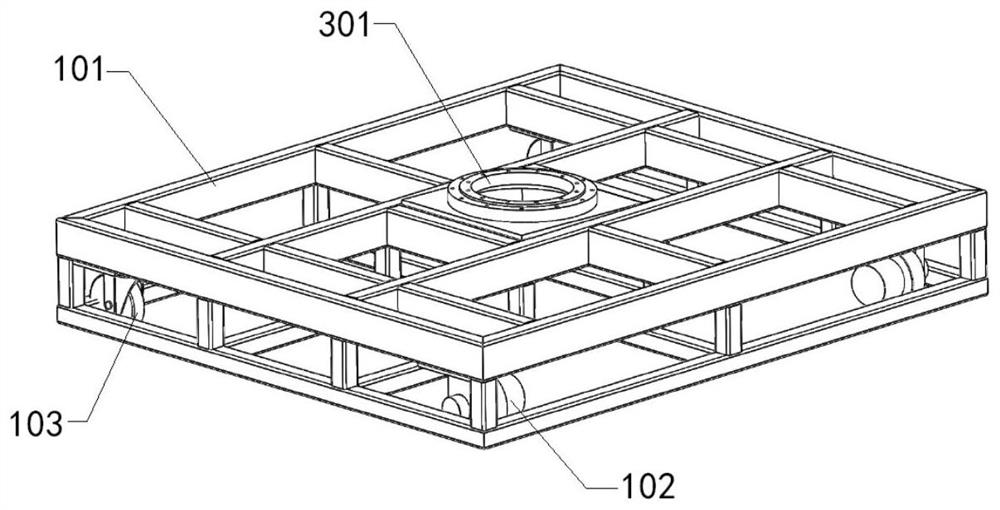

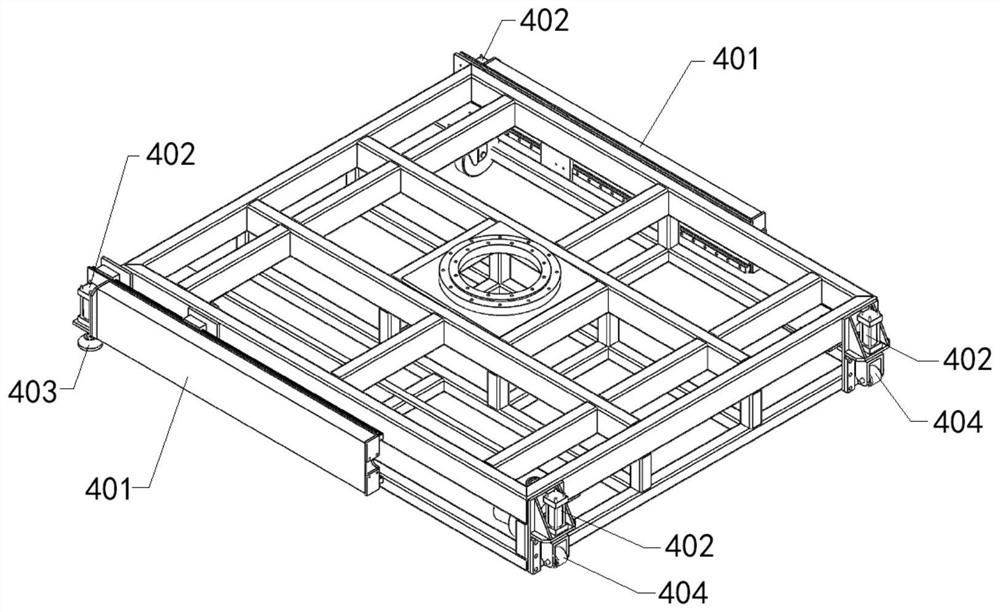

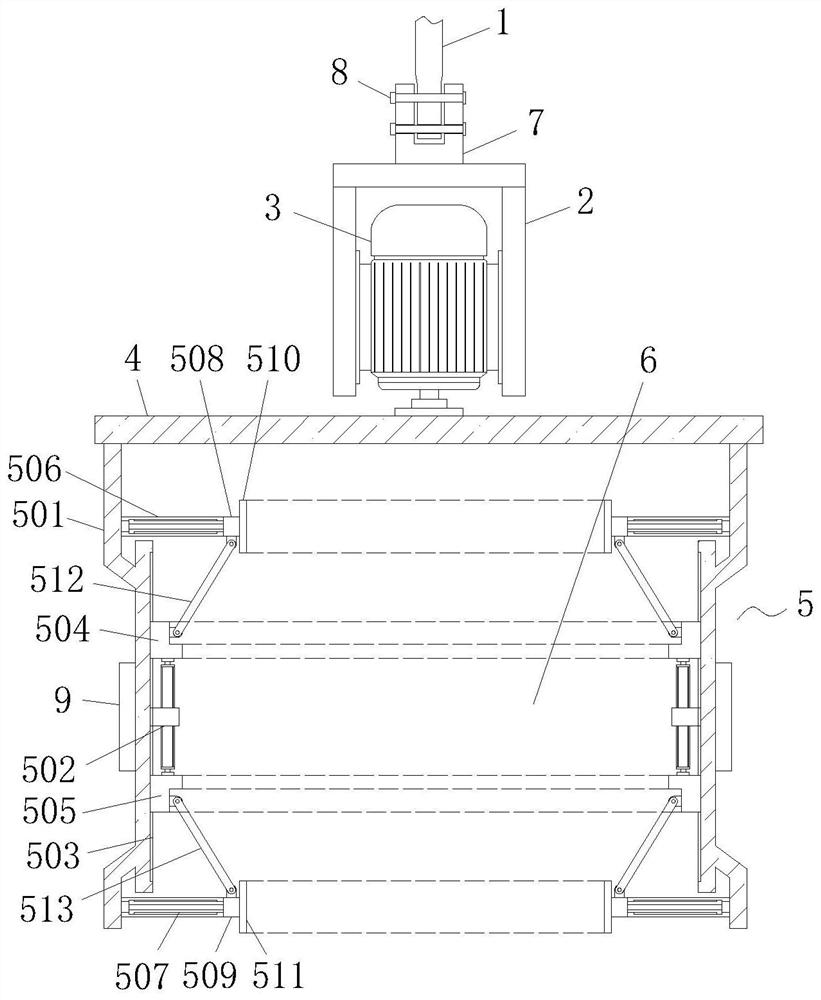

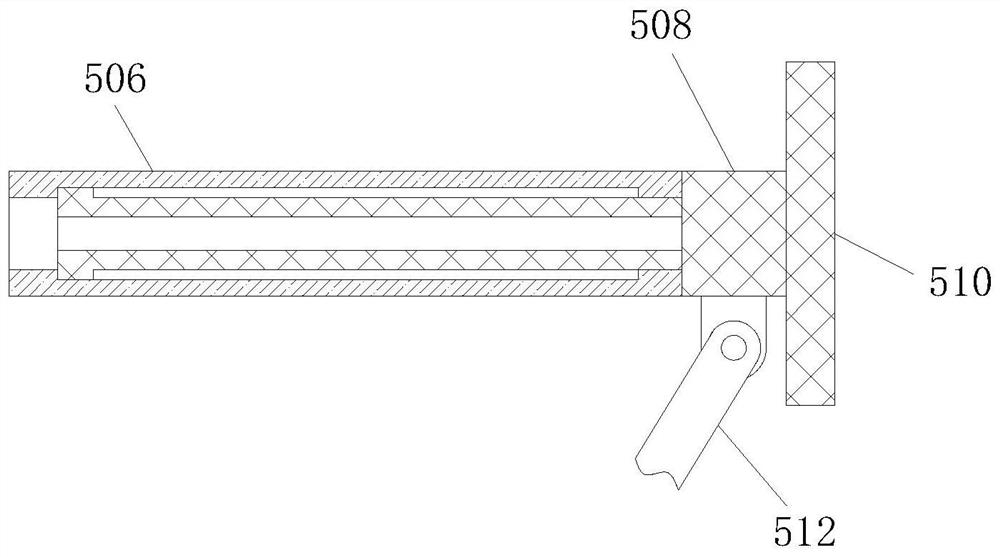

The invention provides a horizontal adjusting sling for a spacecraft, which comprises a hoisting ring component, an XY workbench, a hoisting beam and straps, wherein the XY workbench is arranged on the hoisting beam; the top center of the XY workbench is hinged with the hoisting ring component through a universal joint; four straps are arranged below the hoisting beam; the XY workbench comprises an X workbench and a Y workbench; the X workbench slides on the Y workbench through a slide rail along the X direction; the Y workbench slides on the hoisting beam through a slide rail in the Y direction; and the hoisting ring component comprises a hoisting ring connected with a hook of a crane, a middle bearing structure and a two-dimensional inclination sensor b for measuring the angle of inclination of the hook relative to the crane. Compared with the prior art, the horizontal adjusting sling for hoisting the spacecraft solves the problem that automatic horizontal adjustment cannot be implemented in a two-dimensional plane, the digitization and automation in the measuring and adjusting process are achieved, the hoisting accuracy and hoisting efficiency are improved and the labor intensity of operators is reduced.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

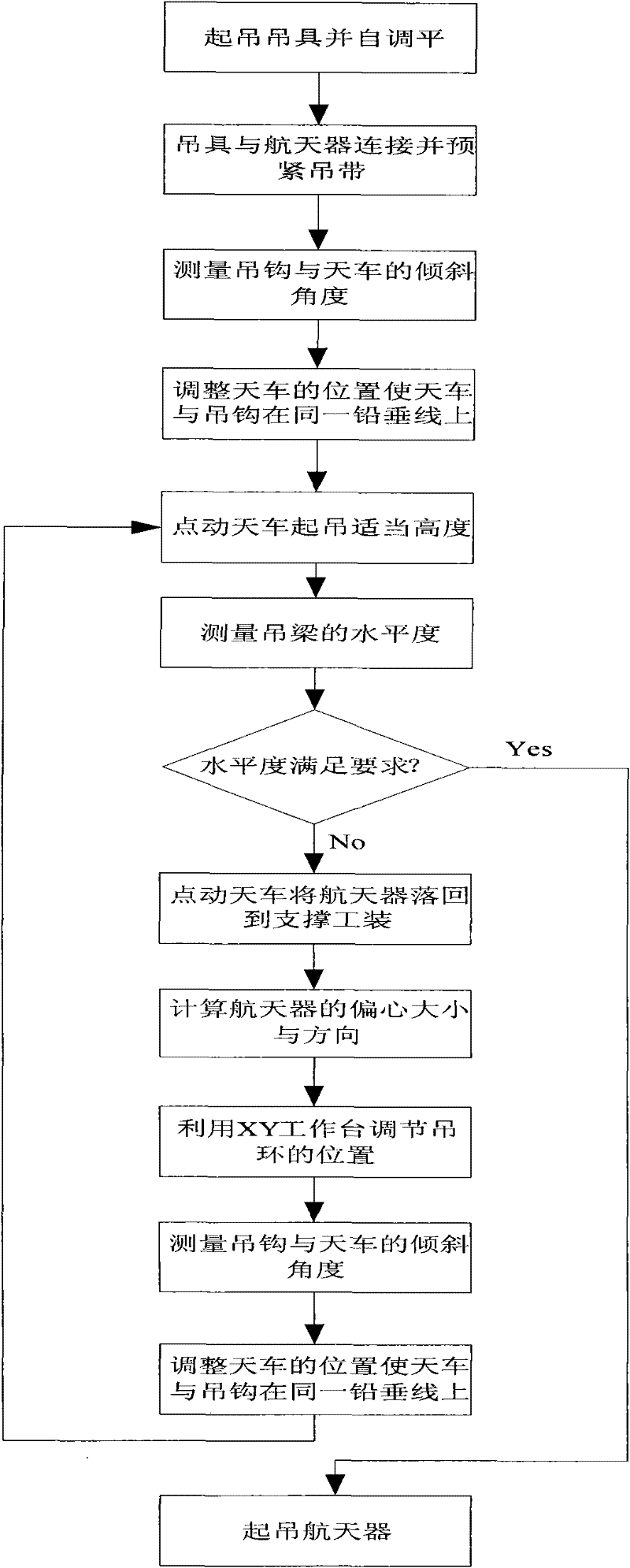

Adjusting method for level adjustment of hanging tool for spacecraft

ActiveCN102530726AReduce labor intensityGo digitalLoad-engaging elementsUltimate tensile strengthIndustrial engineering

The invention discloses an adjusting method for level hanging adjustment for a hanging tool based on hanging point adjustment. The adjusting method mainly comprises the following steps of hanging adjustment processes, such as level adjustment of the hanging tool per se, centering of a hanging hook (or a hanging ring of the hanging tool) with a crown block, levelness measurement and position adjustment, wherein a measurement value of an obliquity sensor on a hanging ring assembly is used as a reference for judging the centering of the crown block with the hanging hook; a measurement value of an obliquity sensor on a hanging beam is used as a criterion for judging the hanging levelness; position adjustment of the hanging points of the hanging tool is realized through the movement of a worktable XY in a plane; and on the premise of ensuring the centering between the crown block and the hanging hook, the hanging points of the hanging tool are adjusted to proper positions, so that two-dimensional levelness adjustment of the spacecraft in the hanging process is realized. According to the adjusting method for high-precision level hanging, disclosed by the invention, the levelness is less than 4.1 mm / m, and the level adjustment process can be completed within 180 s, so that digitalization and automation of measurement and adjustment processes are realized, the hanging precision and hanging efficiency are improved, the labor intensity of operating personnel is lowered, and the application value is remarkable.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

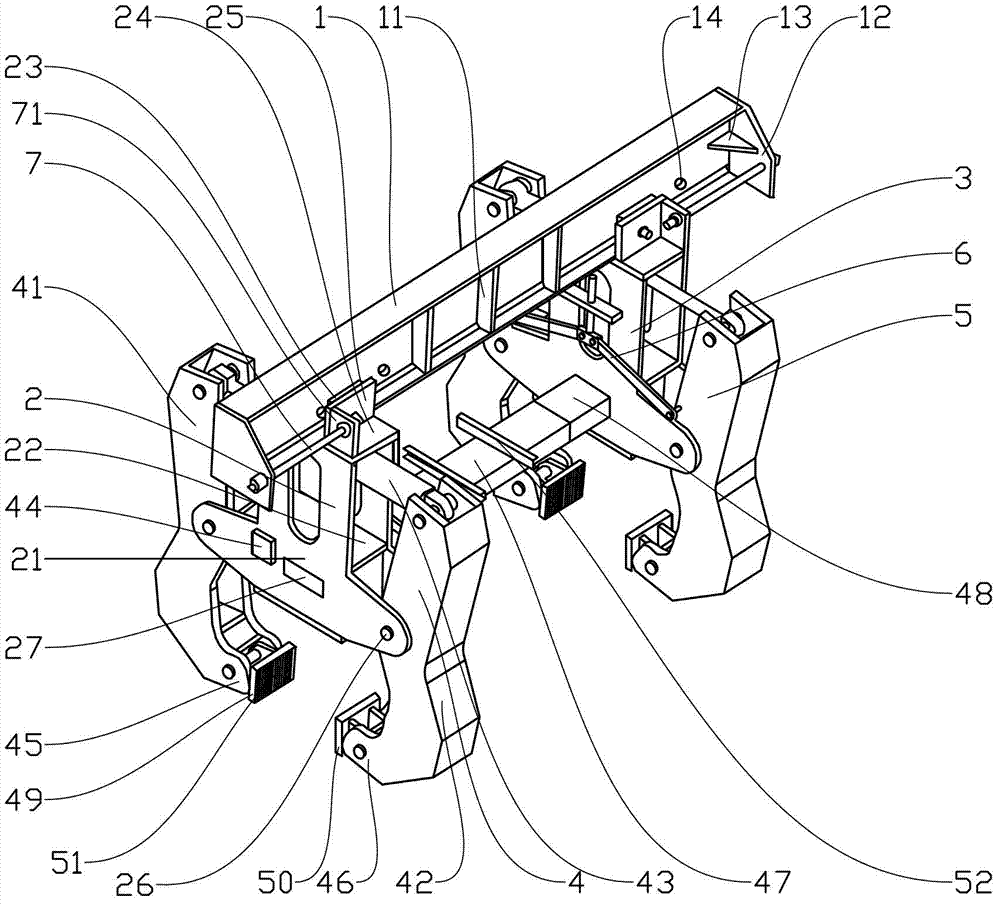

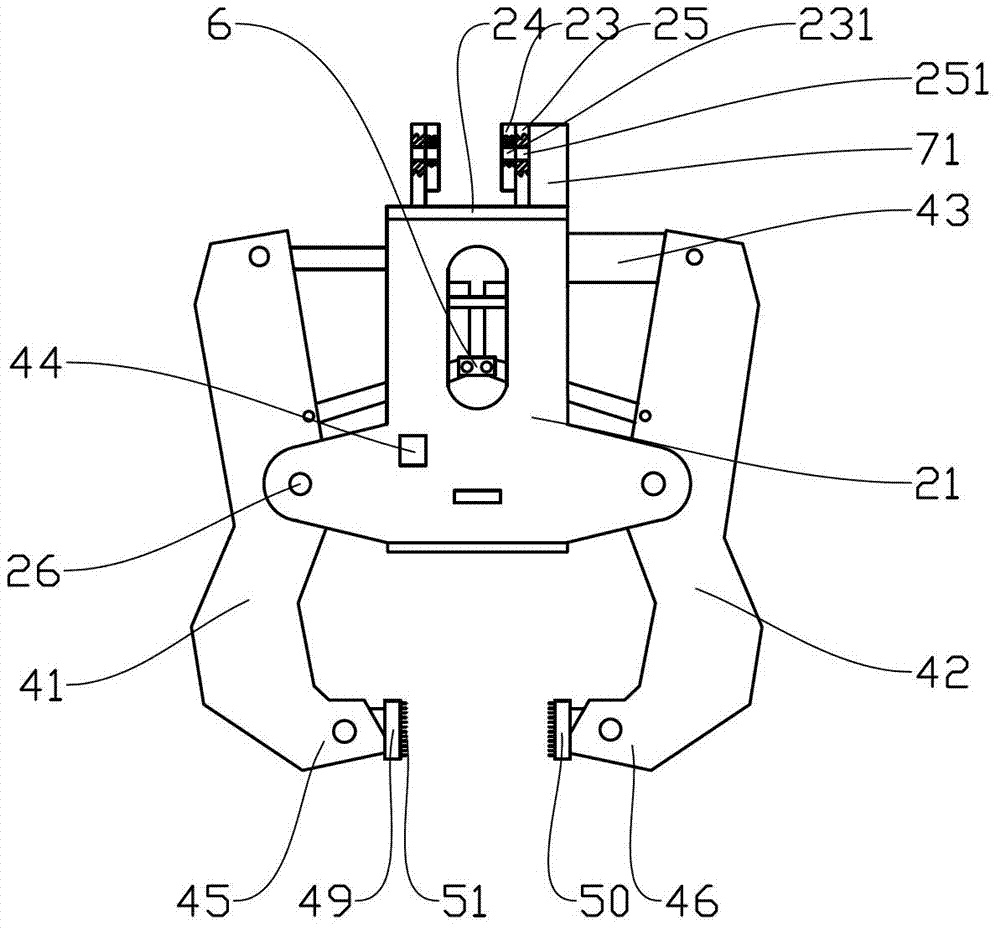

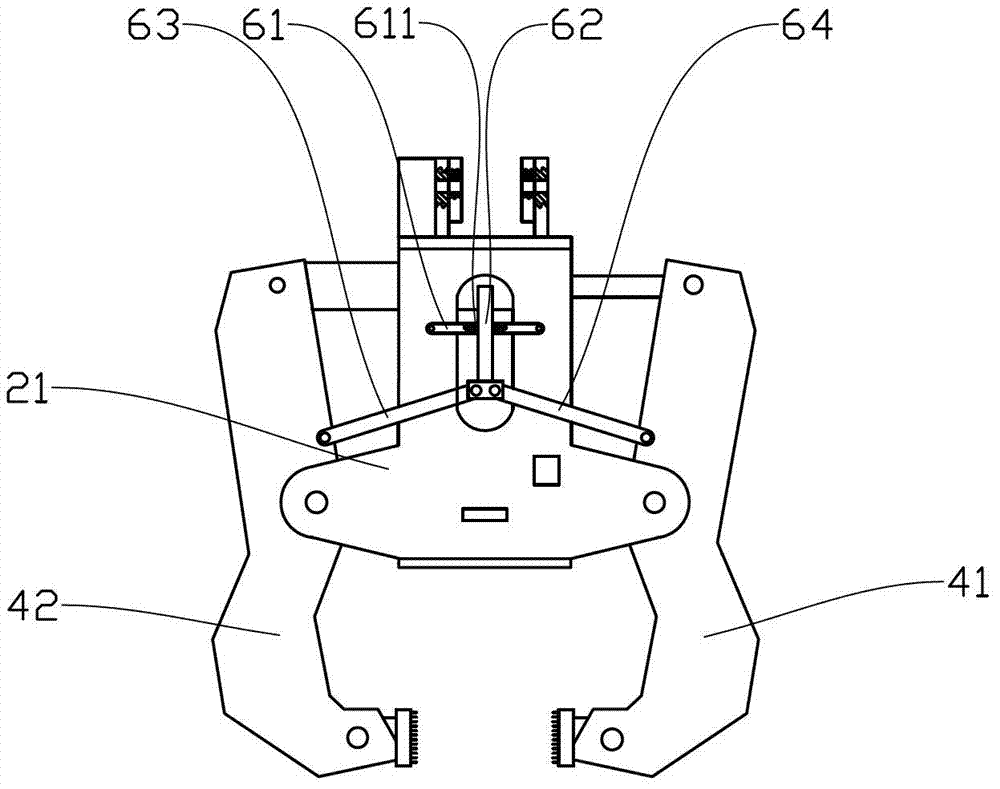

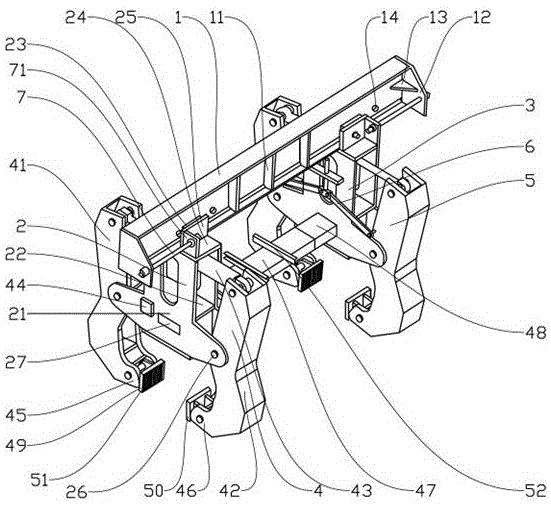

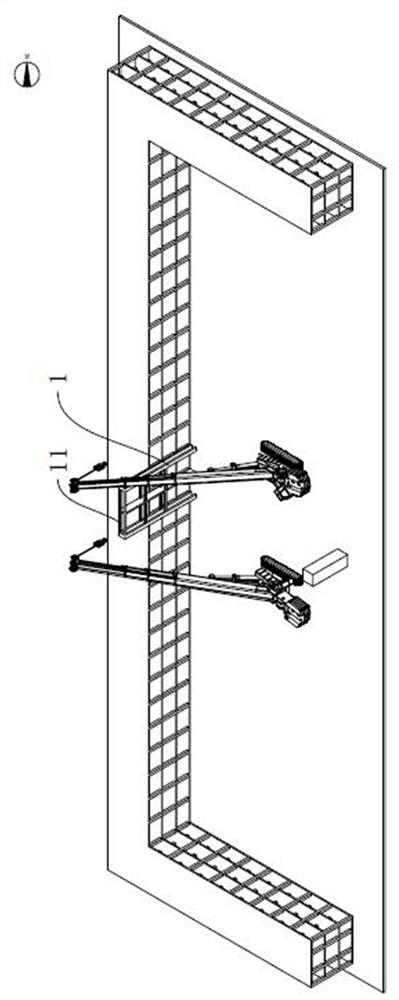

Heavy manipulator

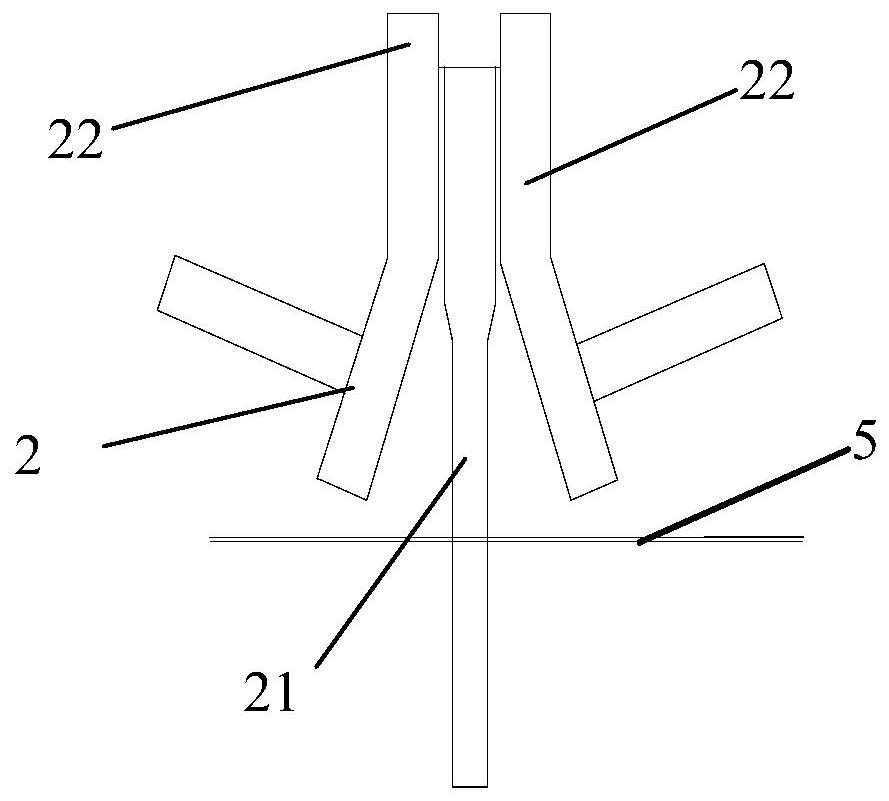

InactiveCN102730548ASave manpower and material resourcesImprove hoisting accuracyLoad-engaging elementsManipulatorEngineering

The present invention discloses a heavy manipulator, and belongs to the field of mechanical lifting. The purpose of the present invention is mainly to solve problems of time consuming, labor consuming, low efficiency, and low accuracy during hoisting of large machinery equipment. The heavy manipulator comprises a lifting beam, a first main frame, a first set of manipulators, a second main frame, and a second set of manipulators. The top end of the main frame is provided with a slide block. The top end of the manipulator is provided with a hydraulic cylinder connected with a pressure sensing alarm device. Both ends of the hydraulic cylinder respectively control a left clamp arm and a right clamp arm of the manipulator. A hydraulic station is arranged on a hydraulic station fixation assembly arranged between the two sets of the manipulators. During use of the heavy manipulator of the present invention, the left clamp foot and the right clamp foot move on the machinery equipment, the power is turned on, and the pressure sensing alarm device receives the signal and sends an audible alarm, such that the lifting work can be completed, wherein the signal is that the left clamp foot and the right clamp foot are tightly pressed and the lifting equipment is required. The heavy manipulator of the present invention has characteristics of simple structure, time saving, labor saving, high efficiency, and high lifting precision.

Owner:田利新

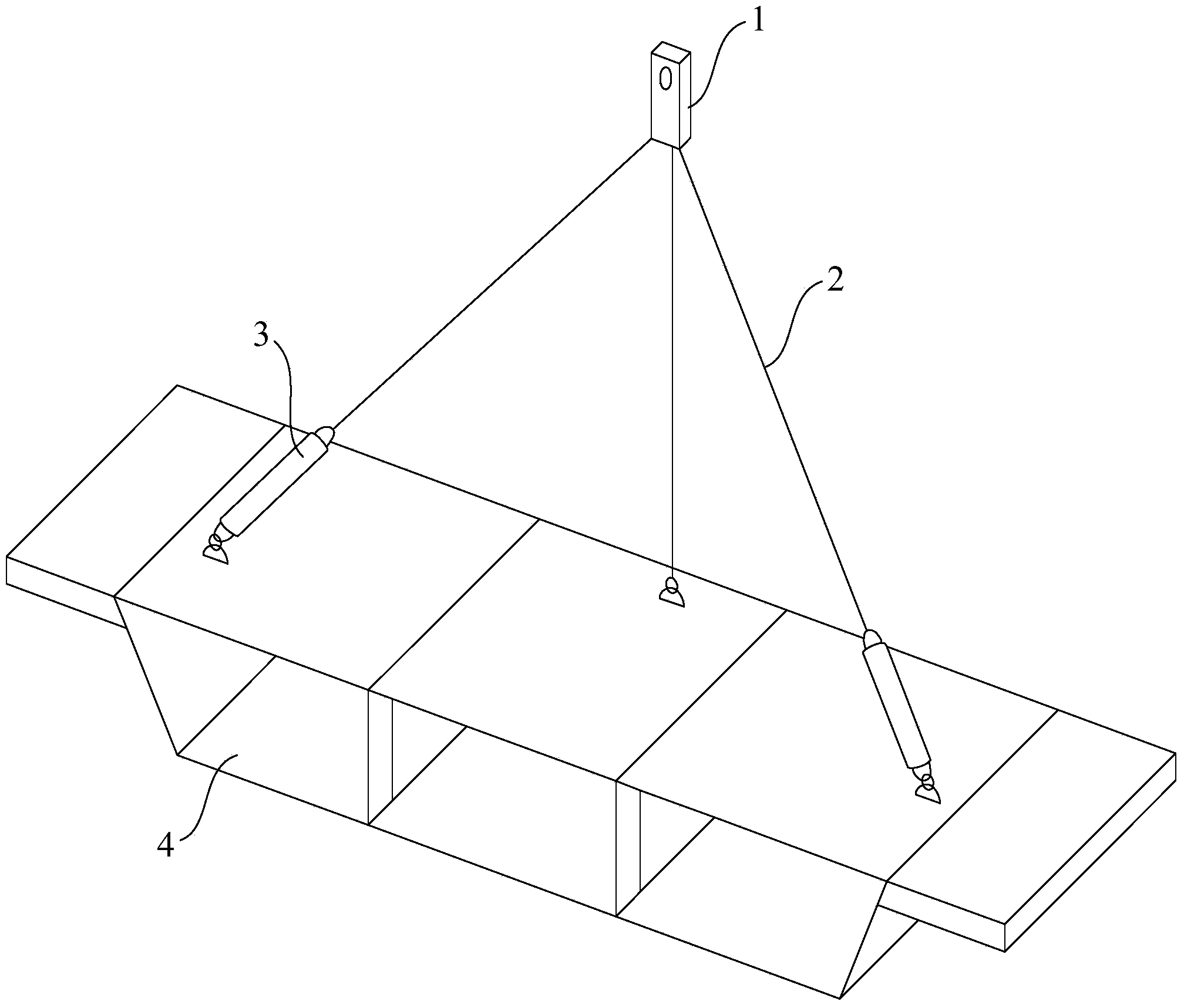

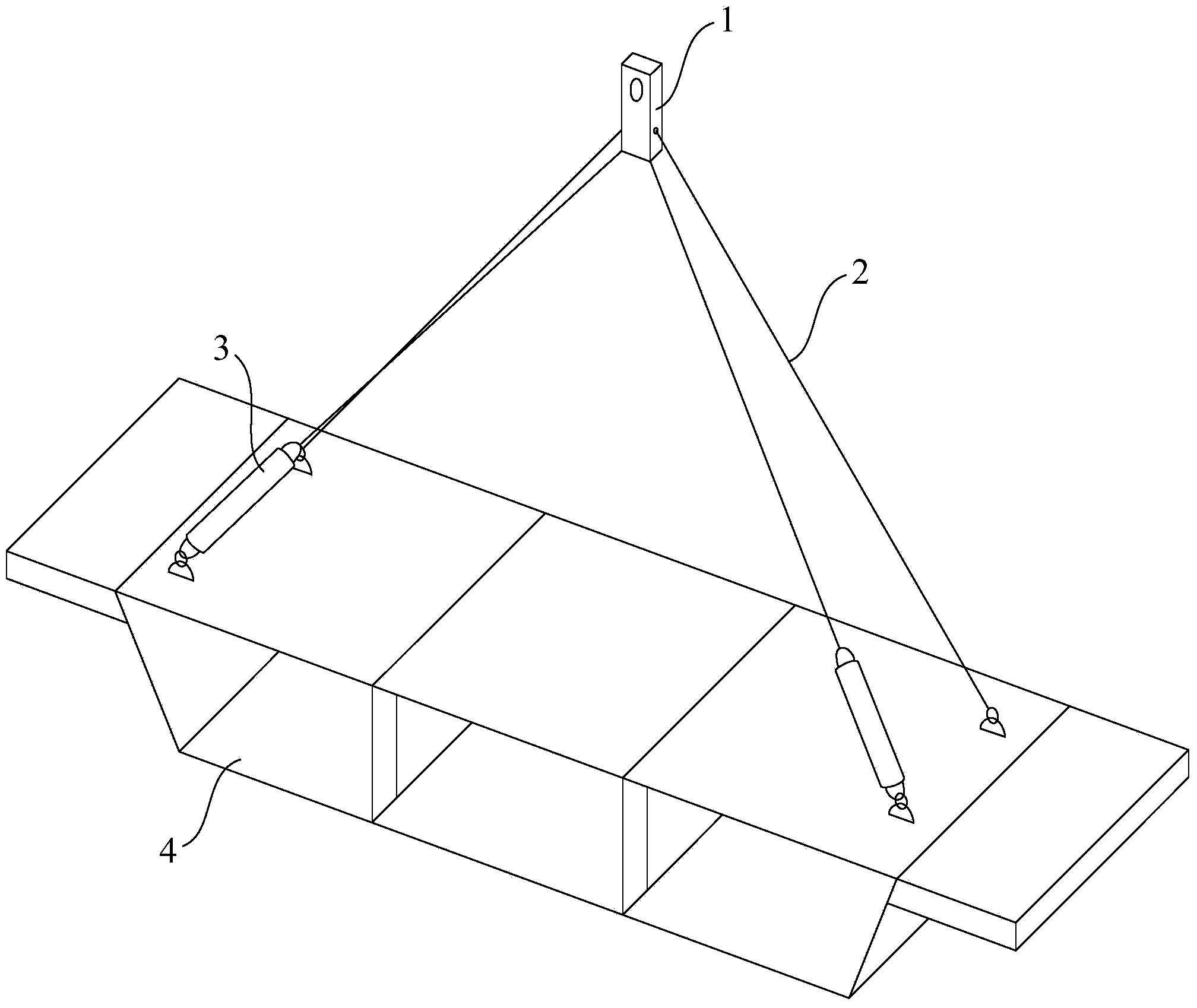

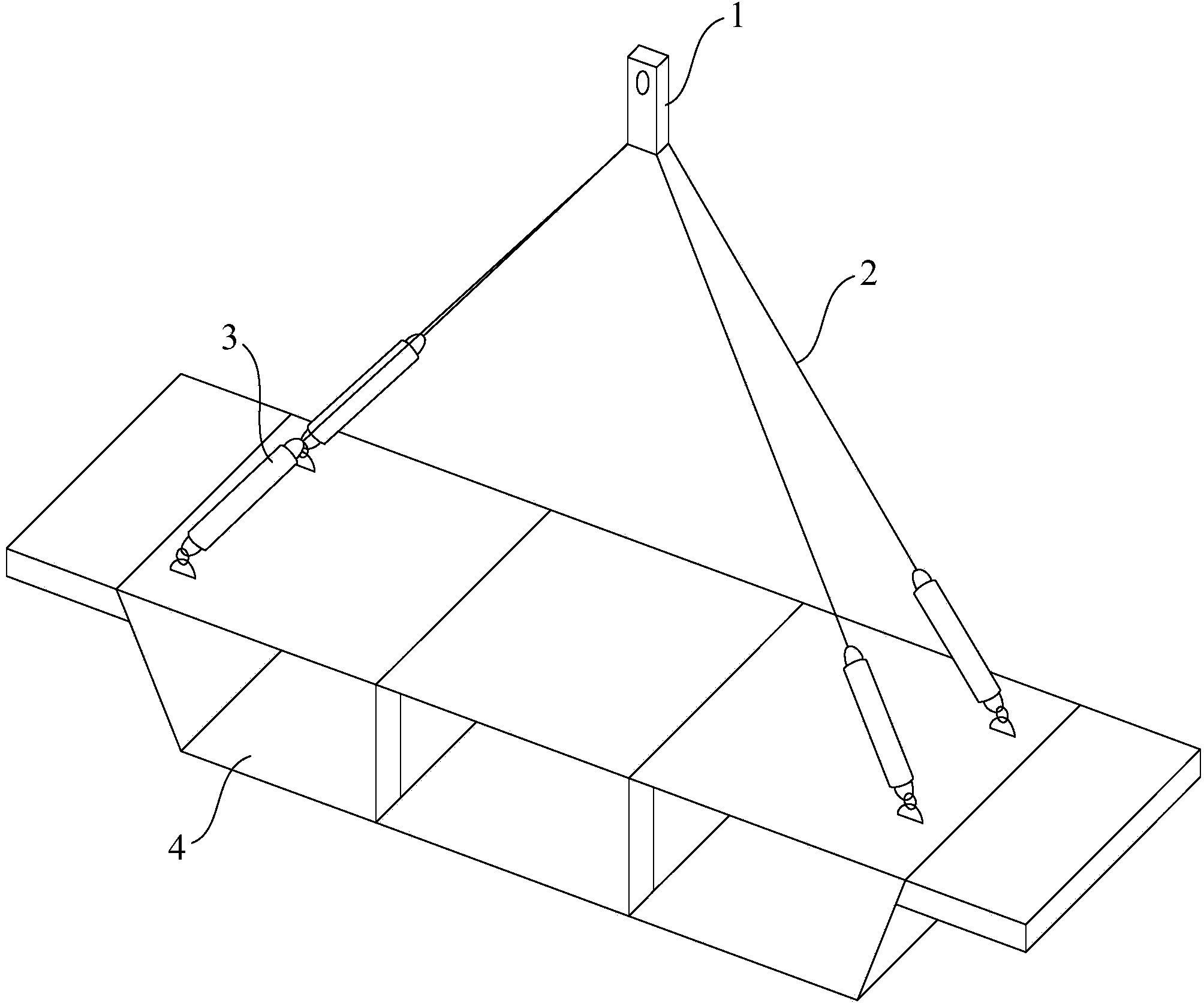

Hoisting rigging and hoisting method thereof

InactiveCN103910280AHigh adjustment accuracyImprove overall hoisting accuracyLoad-engaging elementsHydraulic pumpIndustrial engineering

The invention provides a hoisting rigging and a hoisting method thereof. On the basis of the prior art, a hydraulic pull pump is additionally arranged; the main effect of the hydraulic pull pump is used for adjusting the length of a steel wire rope by virtue of self retraction, so that a three-dimensional space state of a member meets the hoisting requirements. According to the hoisting rigging and the hoisting method thereof, the single set of the rigging is used so as to realize the adjustment of the three-dimensional space state of the member; the adjusting precision is high and the whole hoisting precision of the member is improved.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Gesture monitoring and positioning device in large workpiece lifting process

ActiveCN107986161AImprove hoisting accuracySave Auxiliary CommandLoad-engaging elementsEngineeringMechanical engineering

The invention discloses a gesture monitoring and positioning device in a large workpiece lifting process. A slave machine A with a GPS module and a gesture detecting module is mounted on a plane of alarge workpiece to be lifted; a slave machine B with a GPS receiving module and a gesture detector is mounted on a mounting base; a main machine module with a display screen is mounted on a lifting console; and a base station is mounted in an open high place without a shielding object in a construction environment. A main machine is respectively in wireless communication with the slave machine A and the slave machine B. The slave machine A is in wireless communication with the base station. The slave machine A and the slave machine B calculate an absolute position and gesture information of lifted workpieces; meanwhile, the slave machine A improves the positioning precision through the base station; and the slave machine A and the slave machine B send information to the main machine through a wireless communication module. The main machine displays the workpiece speed, the acceleration, the distance and the workpiece lifting schematic diaphragm on the screen. The system can greatly improve the workpiece installation positioning and gesture detecting precision through unique layout and solution algorithm to effectively improve the large workpiece lifting installation efficiency.

Owner:DALIAN UNIV OF TECH

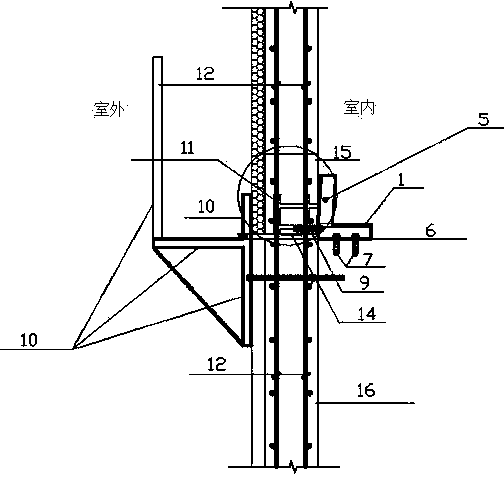

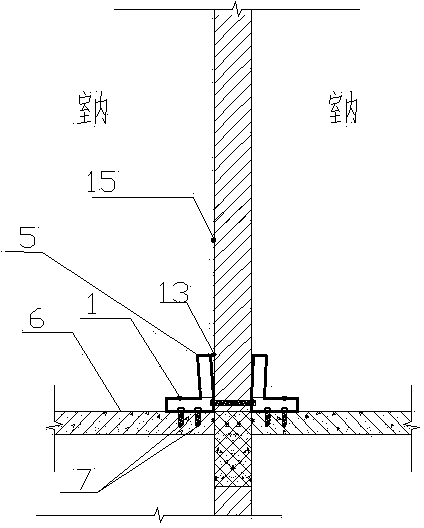

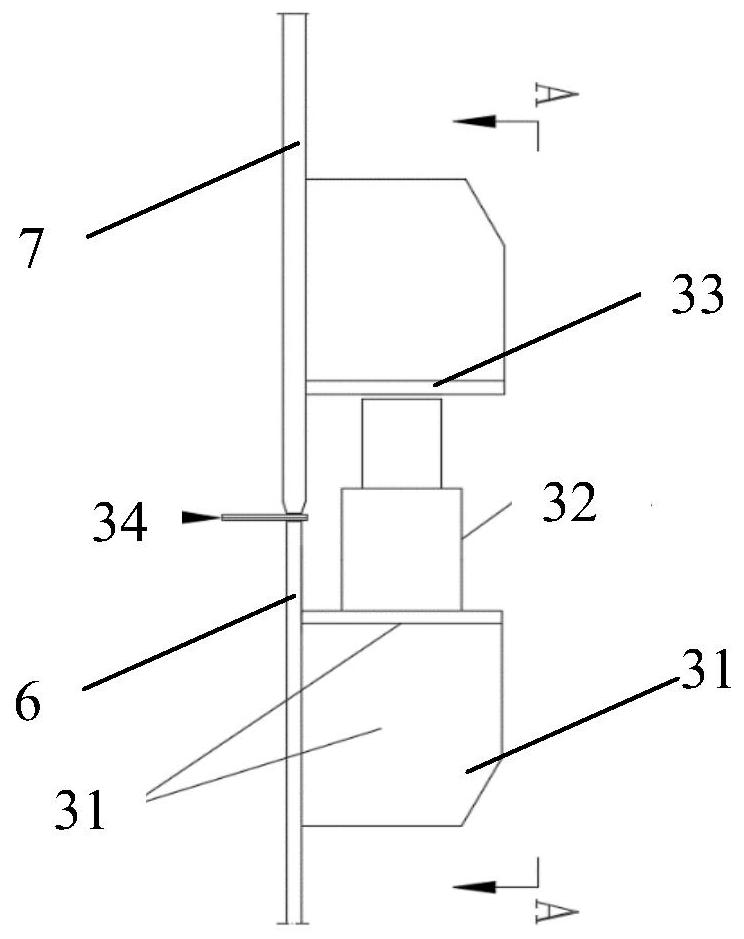

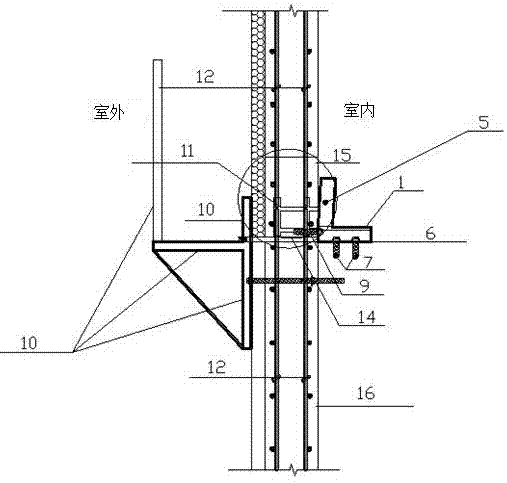

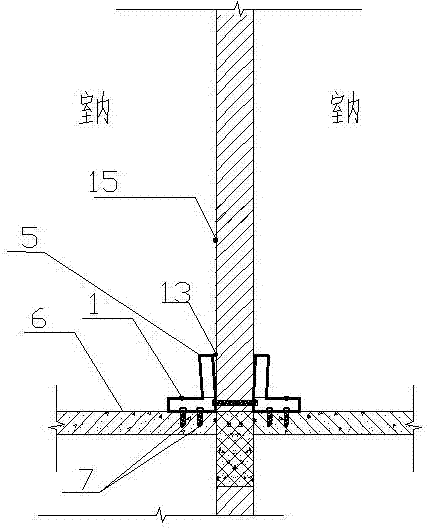

High-precision positioning guide device and use method thereof

The invention relates to a high-precision positioning guide device and a use method thereof. The device comprises an outer side device and an inner side device which are combined, wherein the inner side device comprises first channel steel; the bottom of the first channel steel is provided with a fixing bolt hole; the side face of the first channel steel is provided with a Y-shaped guide groove. The problem of constraint on engineering progress and construction quality and safety can be solved, and meanwhile the problems such as poor environmental protection performance, complexness in disassembly and assembly, adverseness to recovery and recycling, poor stiffness performance, looseness in fixation, poor mechanical property and poor safety and reliability are solved; thus members such as prefabricated walls are quickly arranged in place and corrected, and the utilization rate and the hanging precision of a tower crane are improved.

Owner:SHANDONG SANJIAN CONSTR ENG +1

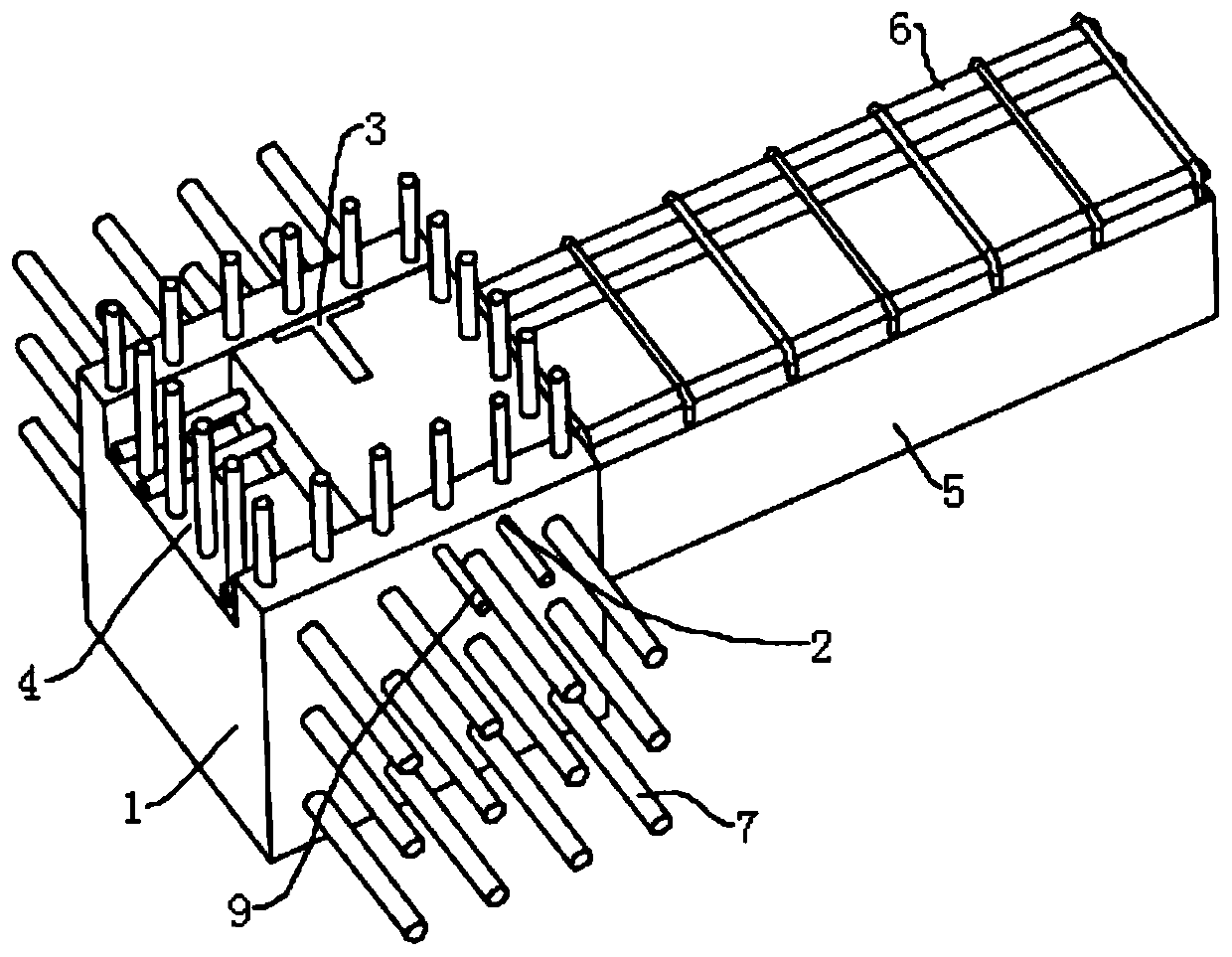

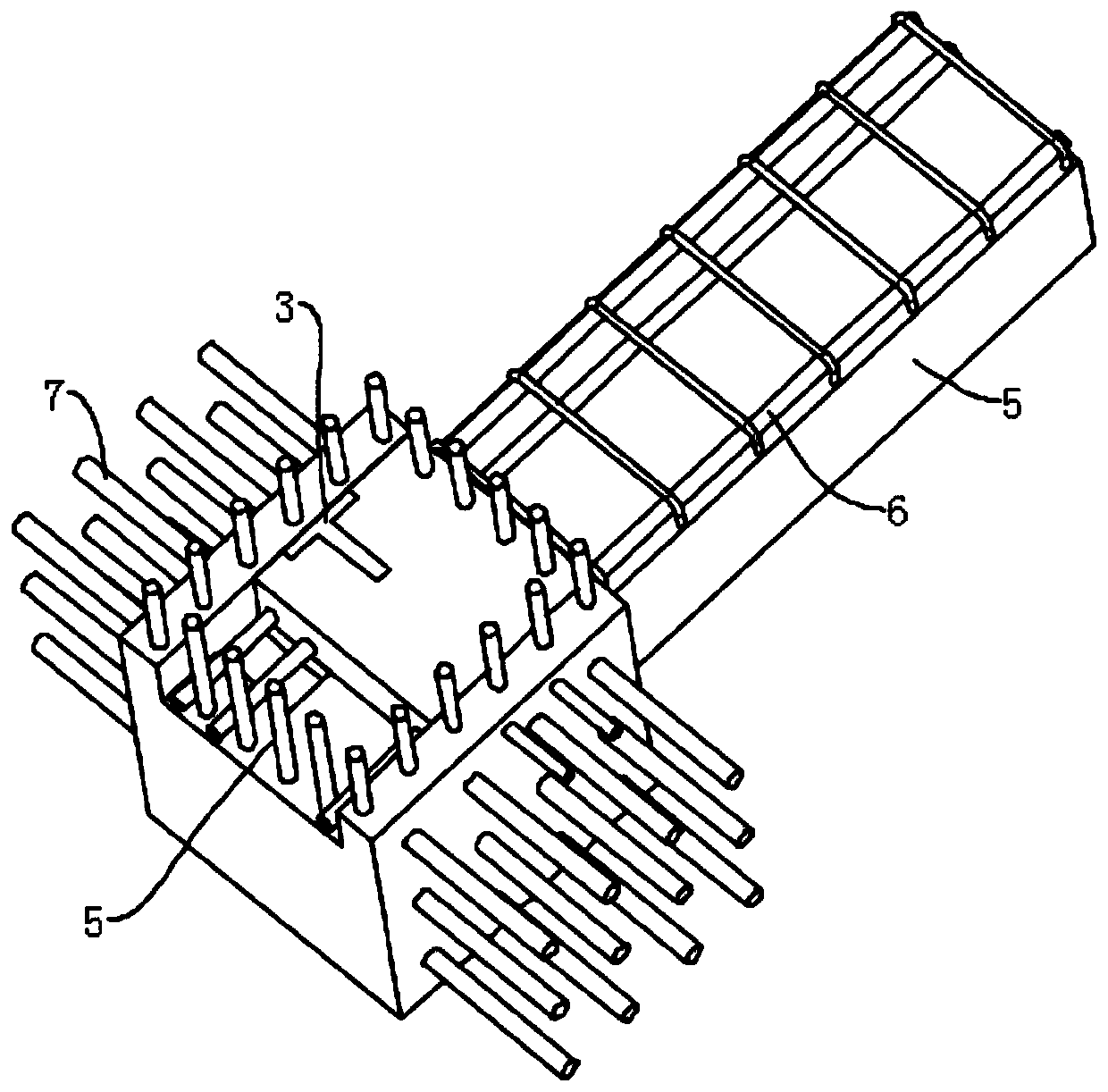

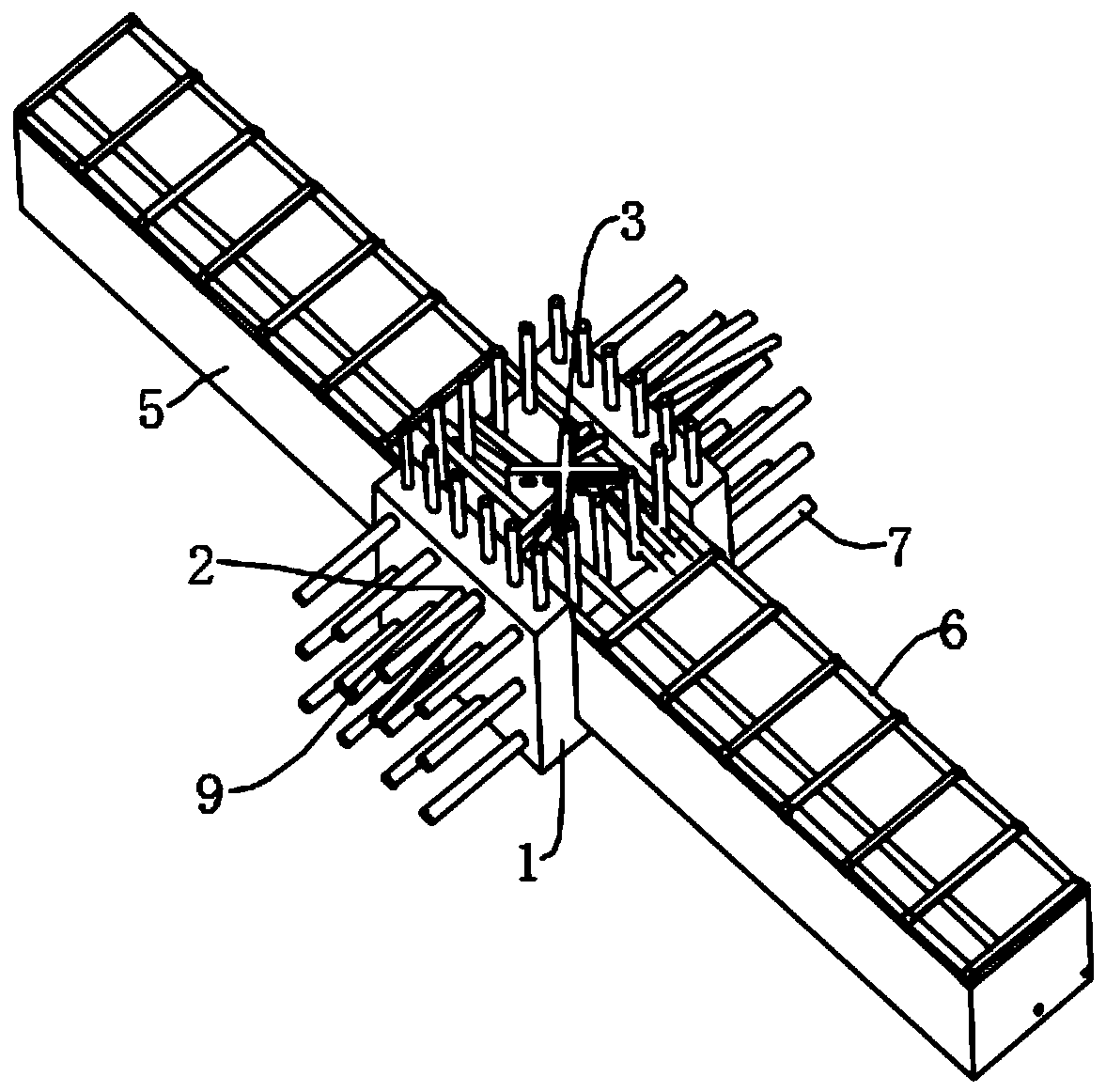

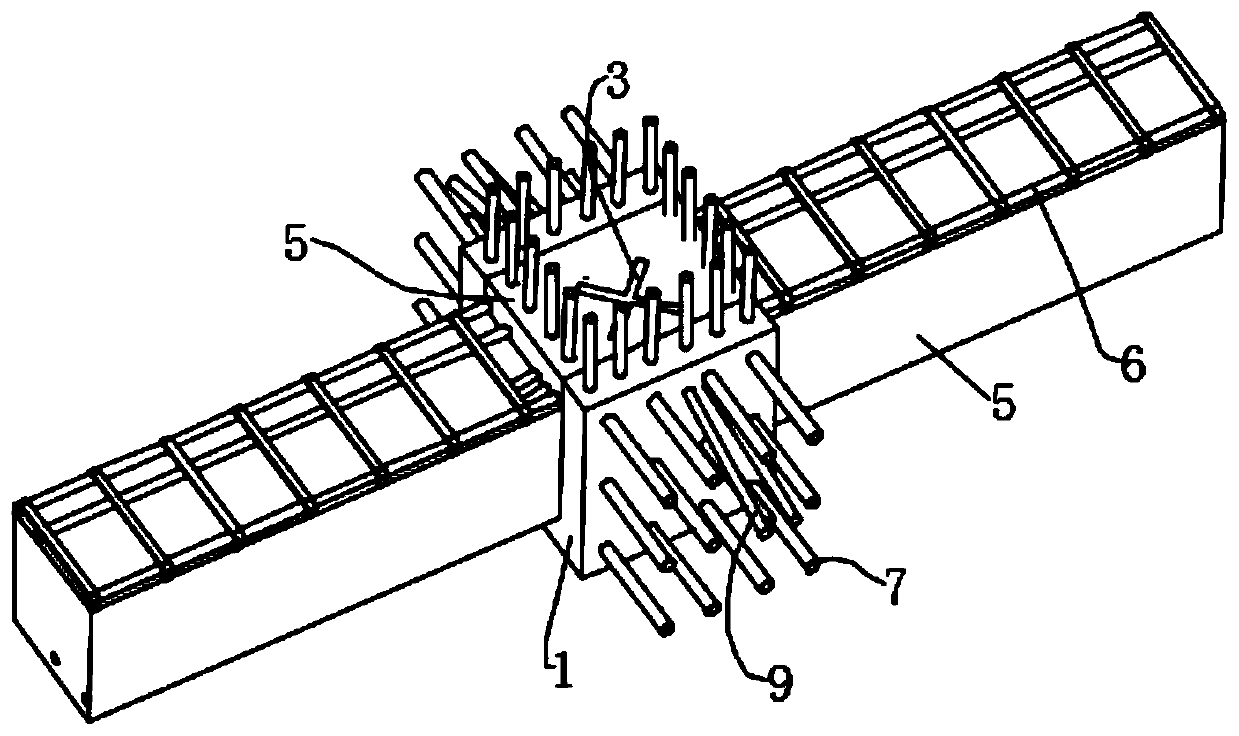

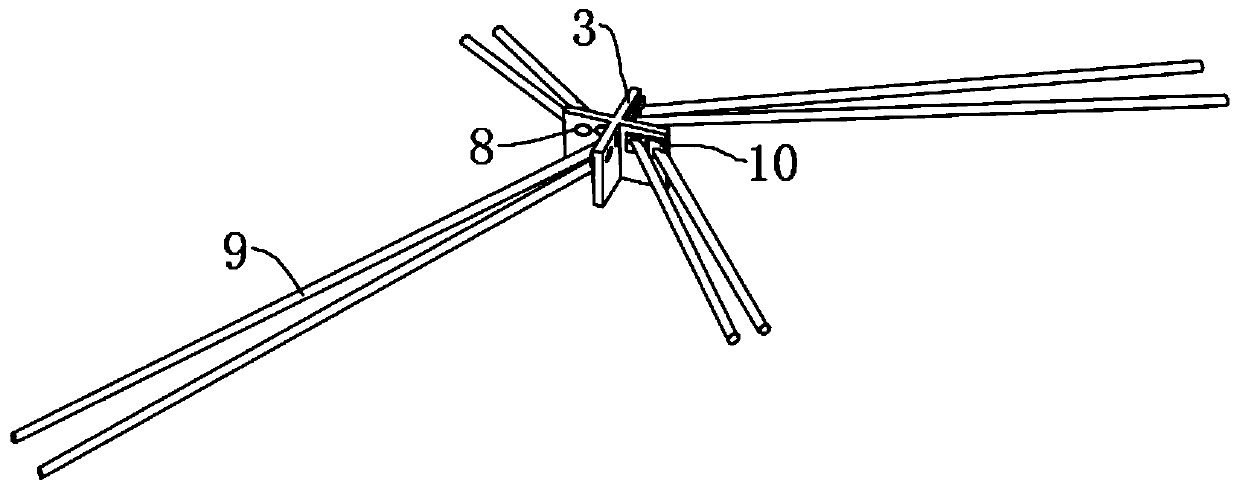

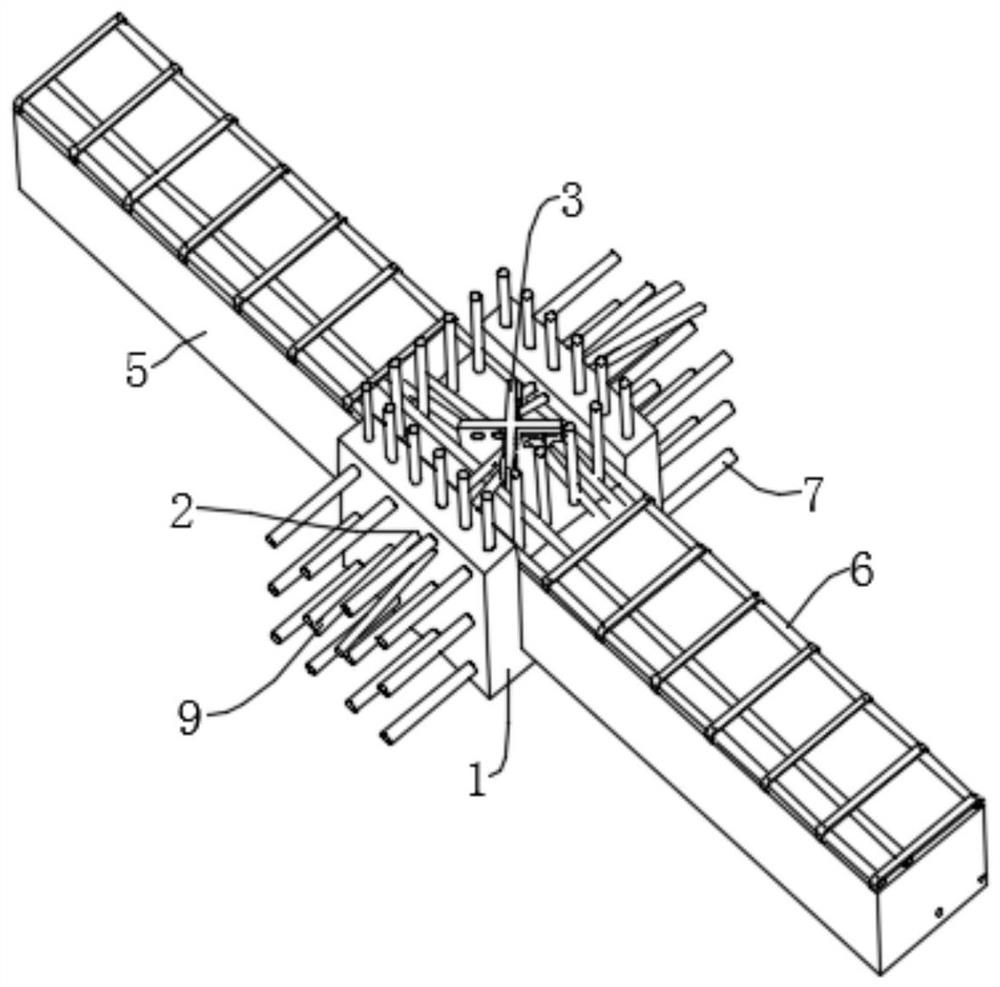

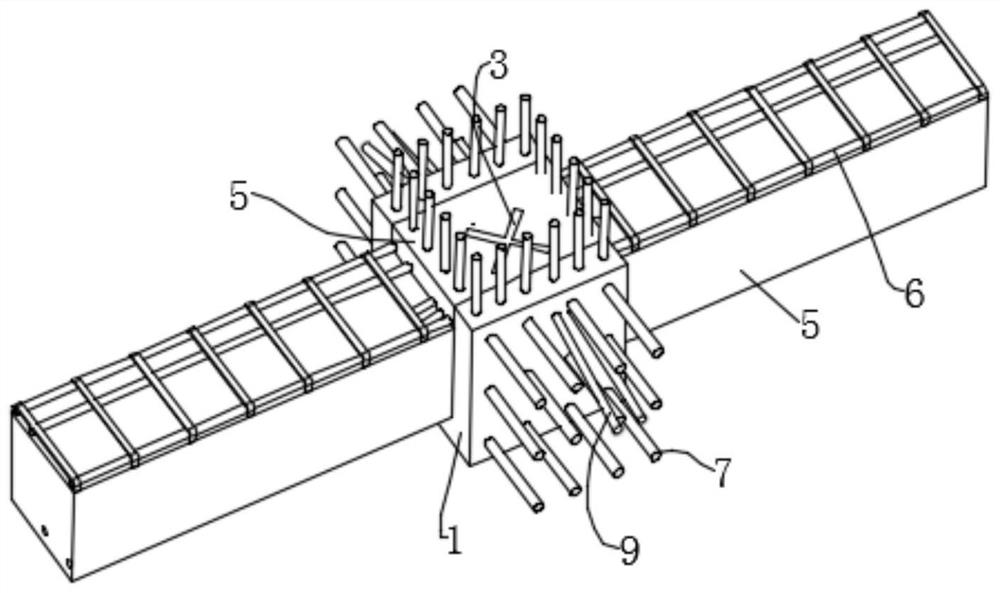

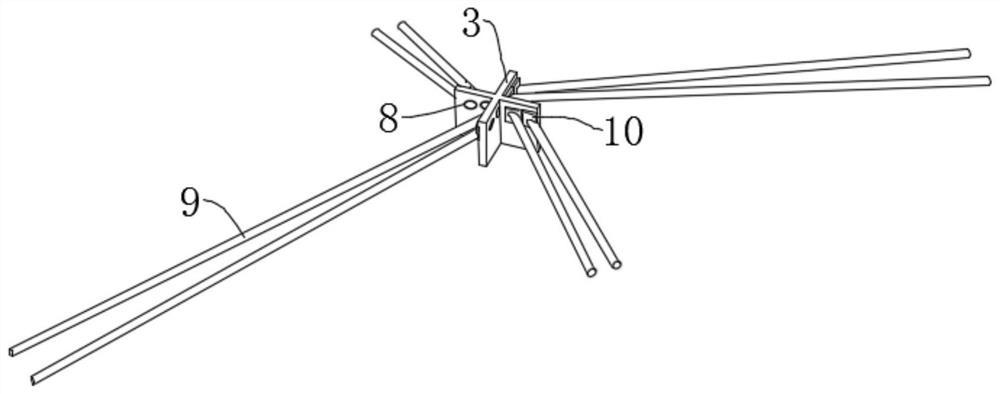

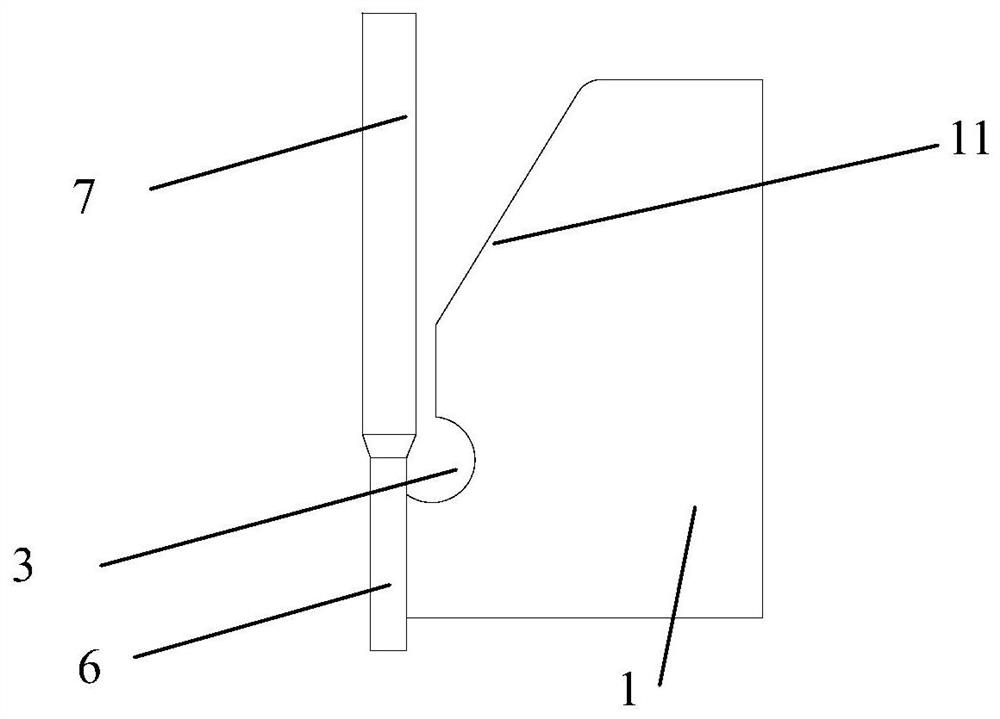

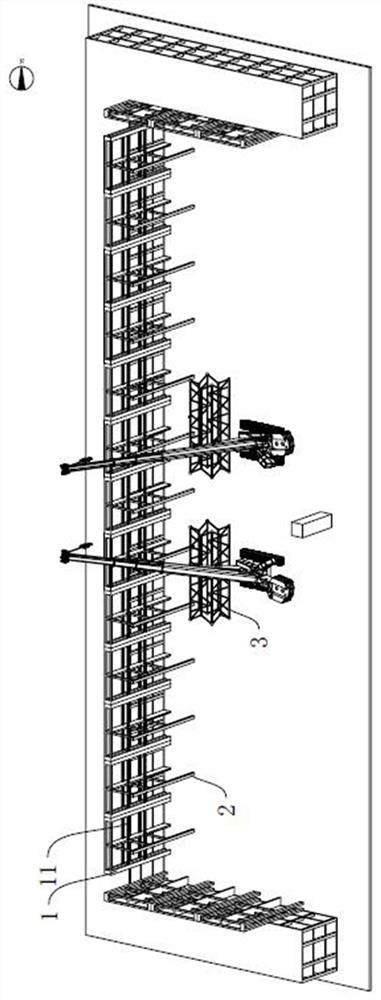

Fabricated building prefabricated steel reinforced concrete end column-beam joint prestressing tendon interlaced tension anchoring structure and construction method

ActiveCN111364681AHigh strengthImprove the force characteristicsBuilding reinforcementsReinforced concretePre stress

The invention discloses a fabricated building prefabricated steel reinforced concrete end column-beam joint prestressing tendon interlaced tension anchoring structure. The fabricated building prefabricated steel reinforced concrete end column-beam joint prestressing tendon interlaced tension anchoring structure comprises prefabricated columns, and further comprises reserved hole channels reservedin the prefabricated columns, T-shaped steel columns integrated with the prefabricated columns, prefabricated column laminated layers arranged on the upper parts of the prefabricated columns, superimposed beams arranged at one ends of the prefabricated columns, top steel bars exposed to the upper parts of the superimposed beams, external extension steel bars extending outside the sides of the prefabricated columns, a plurality of reserved penetrating holes formed in the T-shaped steel columns, prestressing tendons penetrating through the multiple reserved penetrating holes, and prestressing tendon anchoring devices fixed to the T-shaped steel columns, and the prestressing tendons are fixed to the T-shaped steel columns through the prestressing tendon anchoring devices. The structure ensures the overall stress requirements of beam-column joints and enables the joints to have a good hogging moment resisting effect.

Owner:刘荣春

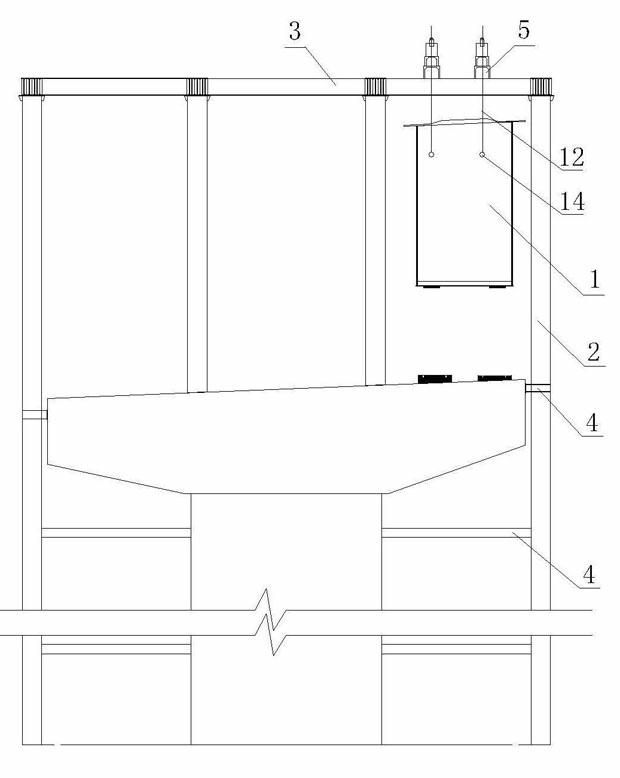

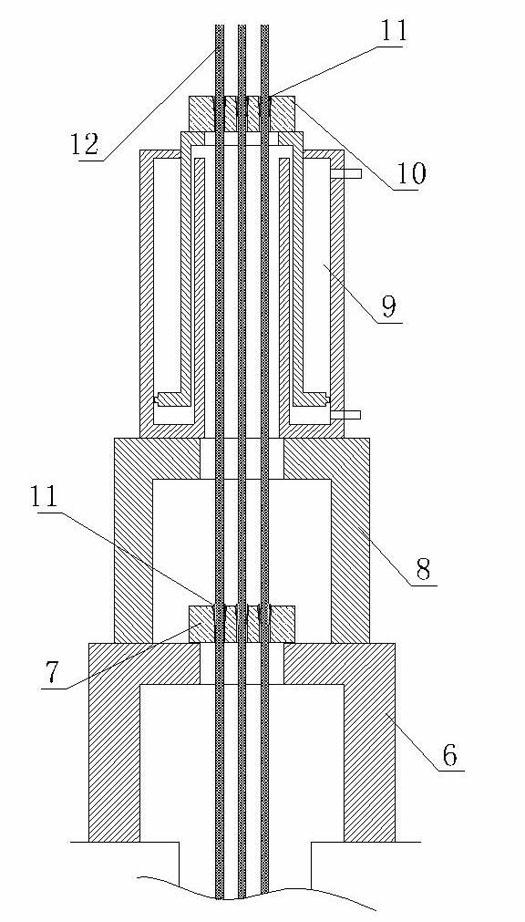

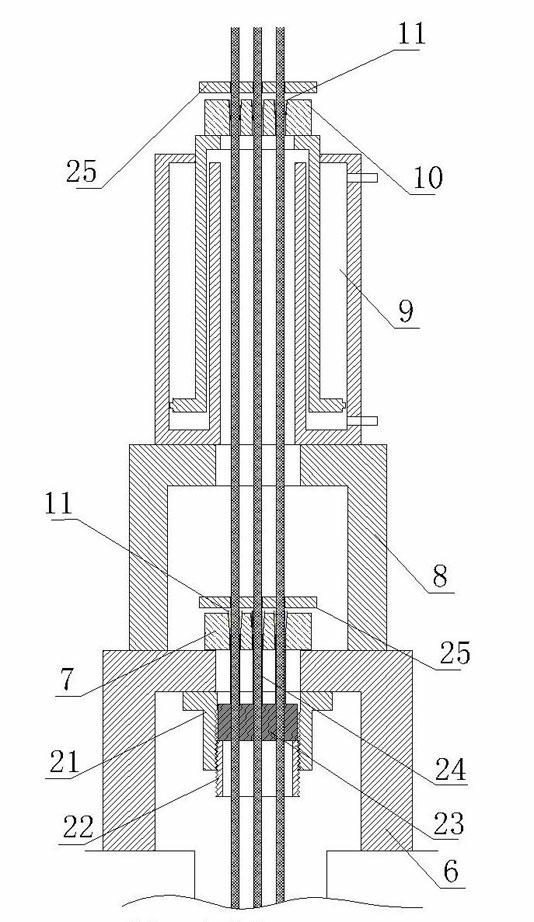

Continuous beam falling system and continuous beam falling method

ActiveCN102535347AThe drop beam method is simple and fastReduce occupancyBridge erection/assemblyClassical mechanicsContinuous beam

The invention relates to a continuous beam falling system and a continuous beam falling method, and belongs to the technical field of construction equipment and methods. The continuous beam falling system comprises a gantry bracket and a continuous beam falling mechanism arranged on the top of the gantry bracket, wherein the continuous beam falling mechanism comprises a lower supporting foot connected with the top of the gantry bracket, a lower tool anchor and an upper supporting foot which are fixedly connected to the top of the lower supporting foot, and a continuous jack fixedly connected to the top of the upper supporting foot; an upper tool anchor is fixedly connected to the top of the continuous jack; clamping sheets are arranged in through holes of the upper tool anchor and the lower tool anchor; and steel stranded wires penetrate through the clamping sheets. The continuous beam falling method comprises the following steps of: anchoring the steel stranded wires in turn by using the upper tool anchor and the lower tool anchor, withdrawing the anchors, and descending and ascending the continuous jack. A hoisted beam can continuously fall stably. The invention has the advantages that: the system and the method are safe and reliable, and time and labor are saved.

Owner:THE SECOND CONSTR OF CTCE GROUP

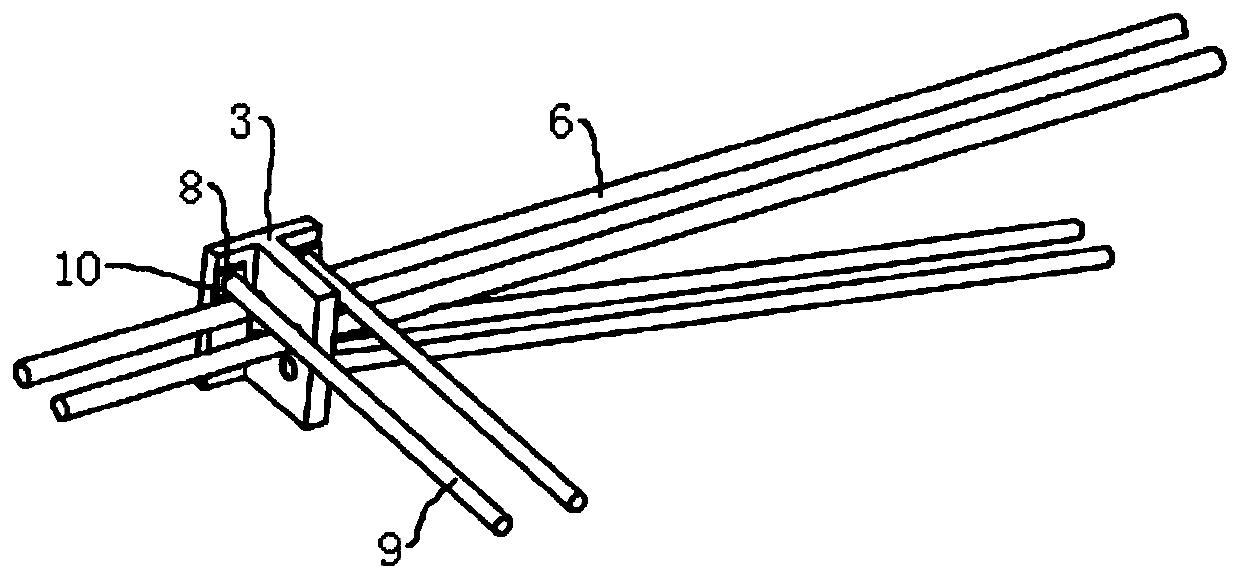

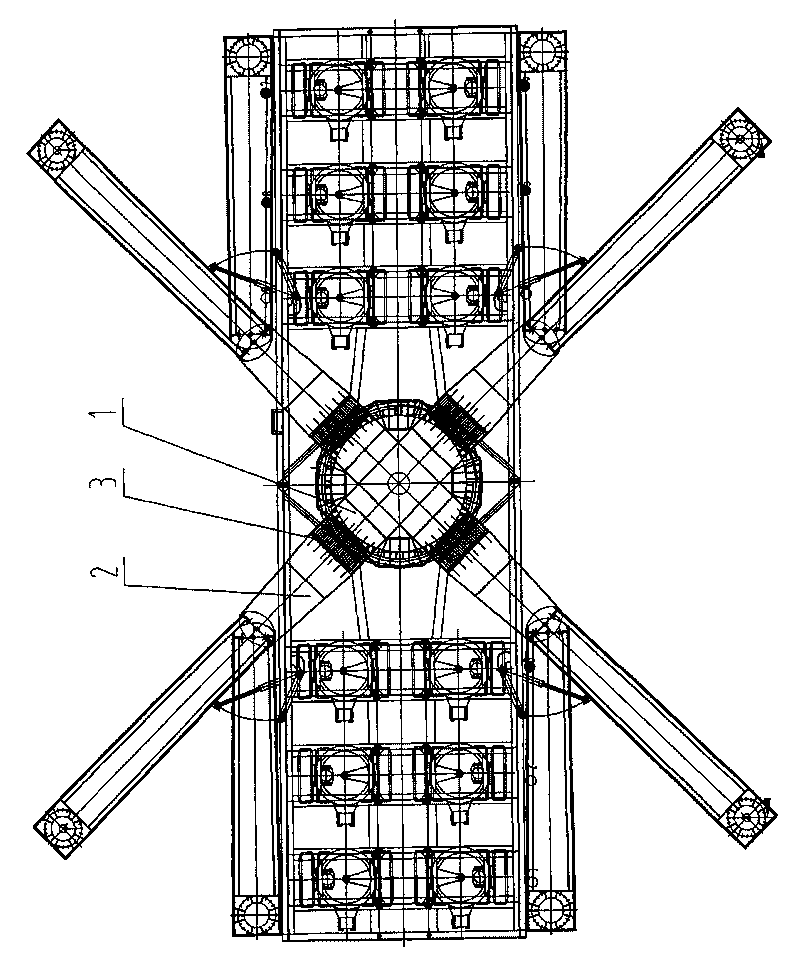

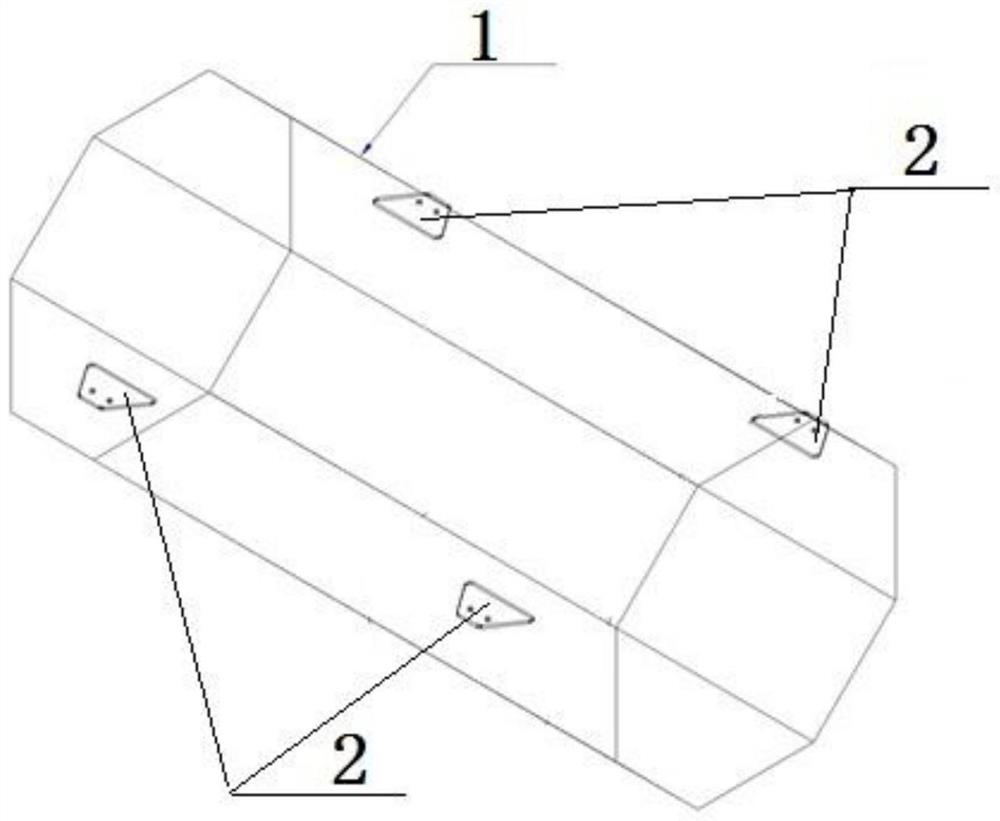

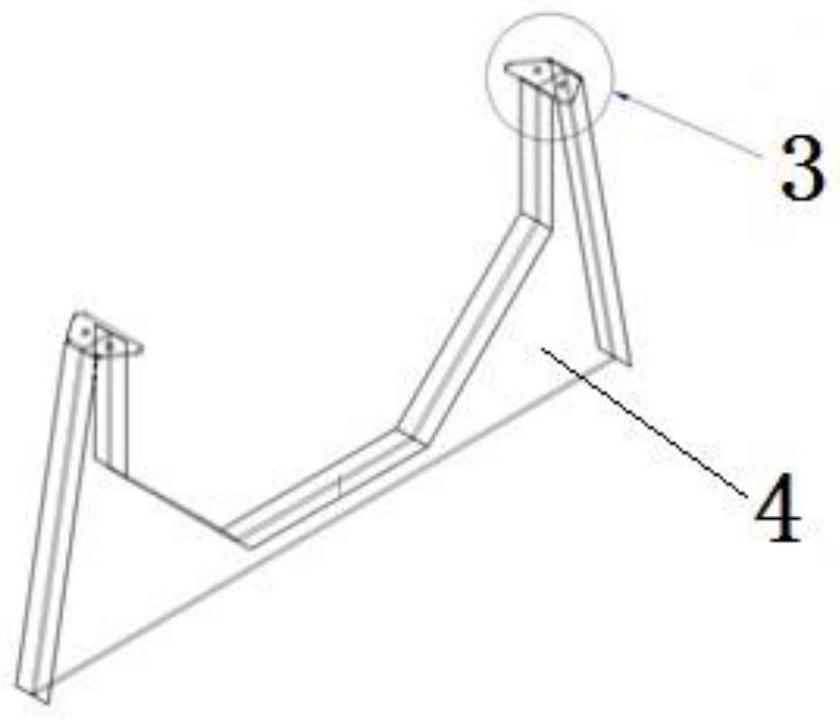

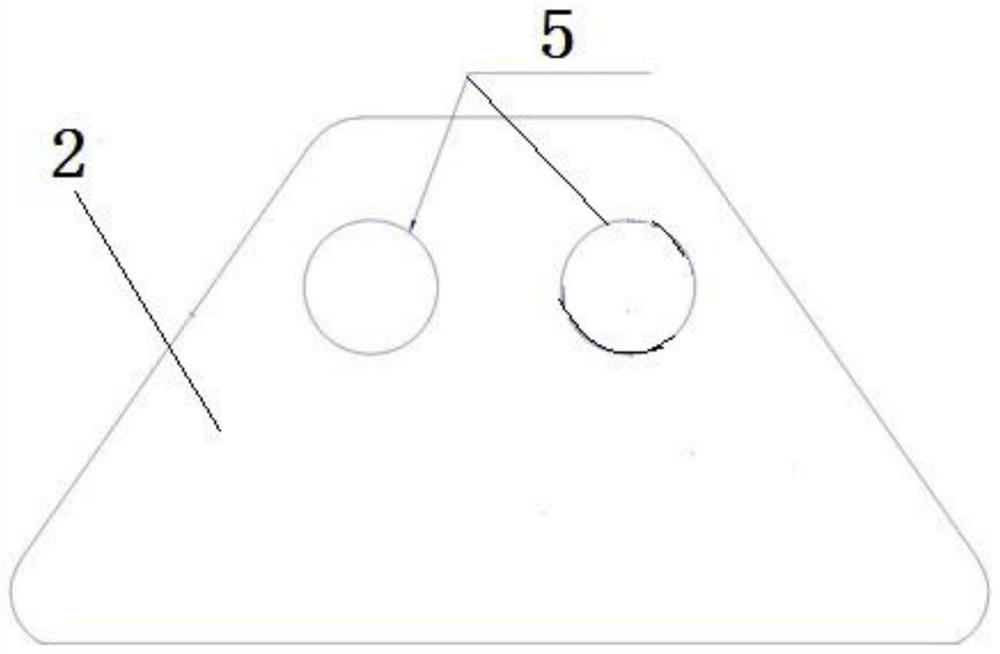

Quick coupling for connecting box-beam steel structure module

The invention provides a quick assembling coupling for connecting box-beam steel structure modules, which is characterized by comprising a plurality of segments or pieces of box-beam steel structure modules for forming a box-beam component, wherein, quick assembling couplings (3) are symmetrically arranged at abutting ends of every two adjacent box-beam steel structure modules. Each quick assembling coupling comprises up and down enclosed flange connection boxes (12, 13), a plurality of shear-resistant positioning pin holes (10) and a plurality of stud hole tubes (9), wherein, the up and down enclosed flange connection boxes (12, 13) are arranged at the abutting ends of the box-beam steel structure modules; the shear-resistant positioning pin holes (10) are used for penetrating shear-resistant positioning pins (15); and the stud hole tubes (9) are arranged side by side in each enclosed flange connection box and used for penetrating double end studs (14).

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

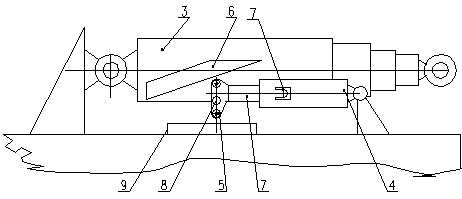

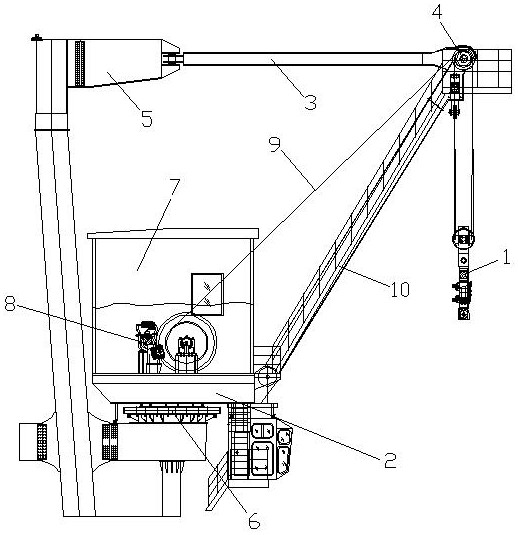

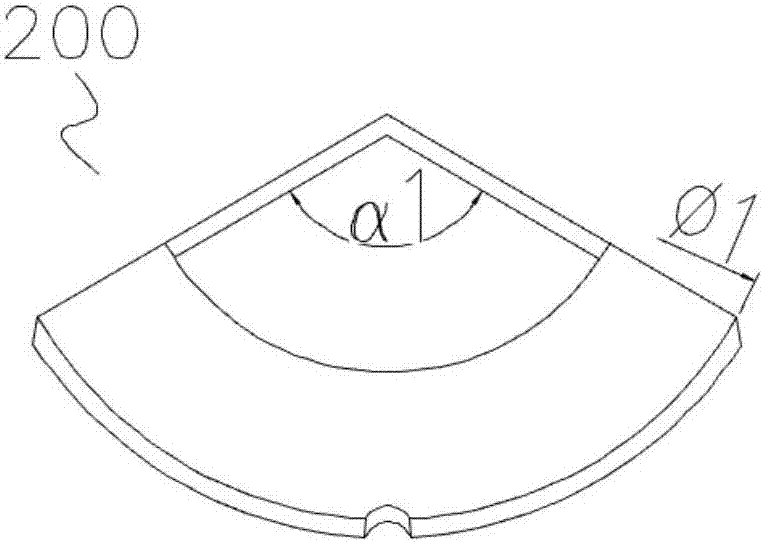

Self-mounting three-cylinder combined multistage variable amplitude device

ActiveCN109516392ARealize large-angle automatic rotationIncrease the stick out lengthCranesEngineeringControl theory

The invention discloses a self-mounting three-cylinder combined multistage variable amplitude device, and belongs to the technical field of engineering hoisting machinery. The self-mounting three-cylinder combined multistage variable amplitude device comprises a boom, an auxiliary jib, a variable amplitude main cylinder and auxiliary displacement cylinders, wherein one end of the variable amplitude main cylinder is hinged to the boom; the other end of the variable amplitude main cylinder is detachably hinged to the auxiliary jib; one ends of the auxiliary displacement cylinders are hinged to the boom; rollers are mounted at the other ends of the auxiliary displacement cylinders; wedge-shaped guide rails and roller clamping grooves are fixed on the variable amplitude main cylinder; when theauxiliary displacement cylinders stretch out, the rollers are propped against the wedge-shaped guide rollers; and when the auxiliary displacement cylinders retreat, free ends of the auxiliary displacement cylinders enter the roller clamping grooves. According to the self-mounting three-cylinder combined multistage variable amplitude device, requirements of small mounting interval and large span are met, 0-90-degree large-angle automatic rotation of the auxiliary jib is achieved, the auxiliary jib is automatically mounted without external hoisting equipment, an automatic locking fixing function of the variable amplitude main cylinder is achieved, the variable amplitude device is prevented from swinging / shaking in high air, stability and safety of the auxiliary jib are improved, and hoisting precision is improved.

Owner:XCMG HYDRAULICS CO LTD

Heavy manipulator

InactiveCN106553961AAchieve mechanical propertiesFully automatedLoad-engaging elementsControl engineeringManipulator

The invention belongs to the field of mechanical hoisting and discloses a heavy manipulator to mainly solve the problems that when large machinery equipment is hoisted, time and labor are wasted, the efficiency is low, and the precision is low are mainly solved. The heavy manipulator comprises a hoisting cross beam, a first main frame, a first set of manipulator bodies, a second main frame and a second set of manipulator bodies. A sliding block is arranged at the top end of the main frame. The top end of the manipulator is provided with a hydraulic oil cylinder connected with a pressure sensor alarm. The two ends of the hydraulic oil cylinder control left tong arms and right tong arms of the manipulator. A hydraulic station is arranged on a hydraulic station fixing set between the two sets of manipulator bodies. When the heavy manipulator is used, left tong feet and right tong feet are moved to the machinery equipment, a power source is turned on, the pressure sensor alarm gives an alarm after receiving a signal that the left tong feet and the right tong feet press the machinery equipment needing to be hoisted, and in this way, the hoisting work can be completed. The heavy manipulator has the beneficial effects of being simple in structure, capable of saving time and labor and high in efficiency and hoisting precision.

Owner:HUBEI QIXIANG TECH DEV CO LTD

Rotary crane device

PendingCN114735605AImprove hoisting accuracyImprove hoisting efficiencyHydro energy generationWinding mechanismsSlewing bearingBlock and tackle

The invention discloses a rotary lifting device, which belongs to the technical field of lifting opening and closing equipment, comprises a lifting appliance, and is characterized in that the lifting appliance comprises an upper lifting frame, a pulley shaft, a movable pulley block, a pin penetrating piece, a lifting head, a lower lifting frame, a lifting hook cross beam, a lifting hook nut, a rotary driving piece and a grabbing beam, the lifting head is fixed on the upper lifting frame through a pin penetrating piece, the lifting hook cross beam penetrates through the lifting hook nut and is arranged on the lower lifting frame, the lifting hook nut is connected with the lifting head, the rotary bearing is arranged between the lifting hook cross beam and the lifting hook nut, the rotary driving piece is arranged on the lower lifting frame, and the grabbing beam is connected with the lower lifting frame. The lifting appliance can synchronously and reversely rotate to ensure that the axis of a gate is always parallel to the axis of a gate groove, and the lifting appliance and the gate are prevented from shaking in the rotation process, so that the gate can be automatically and accurately positioned into the groove, the lifting precision and the lifting efficiency are improved, and the whole rotation lifting appliance is convenient to mount.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

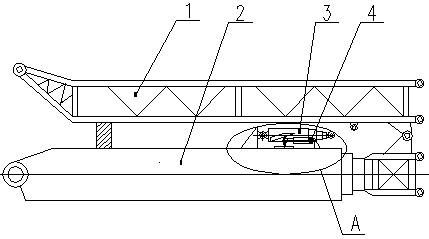

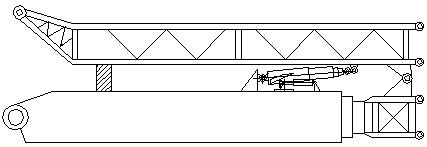

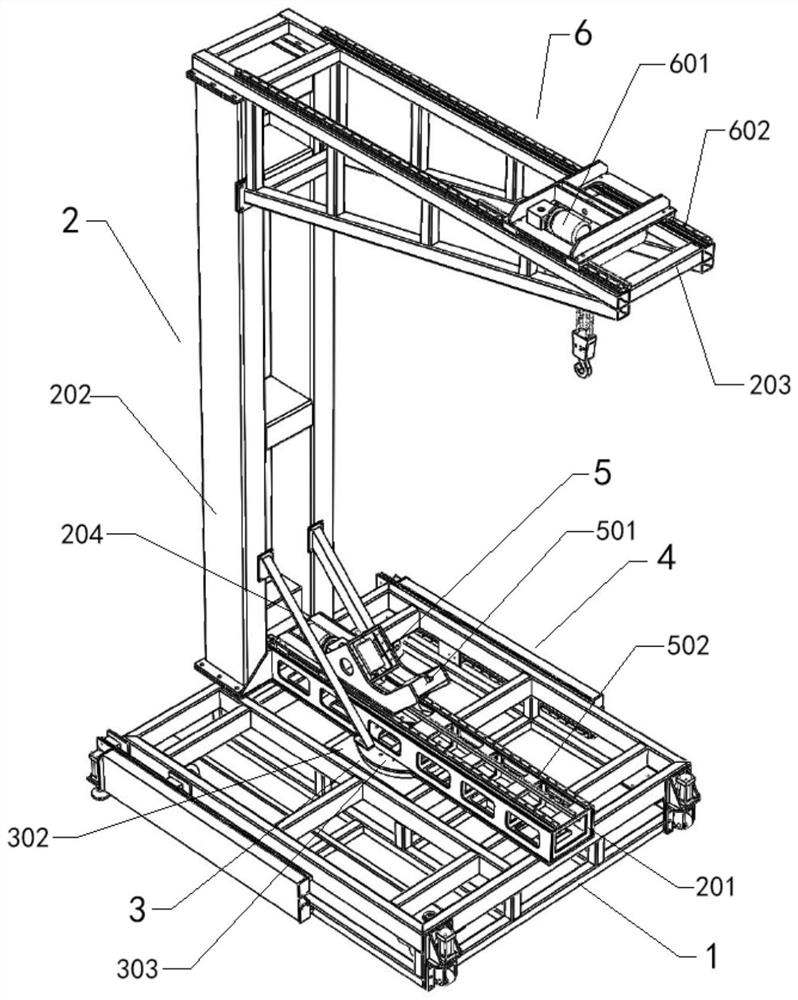

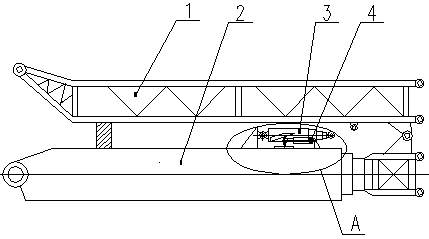

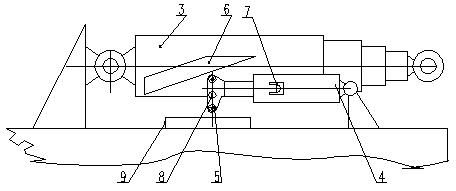

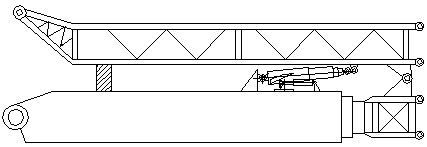

Tool trolley for hoisting GIL (Gas Insulated Line) through pipe

The invention relates to a tool trolley for hoisting a GIL (Gas Insulated Line) through pipe. The tool trolley comprises a walking flatcar, a hoisting truss, a rotating mechanism, a supporting leg mechanism, a through pipe supporting mechanism and a through pipe hoisting mechanism, wherein one end of the rotating mechanism is connected with the walking flatcar, the other end of the rotating mechanism is connected with the hoisting truss, the supporting leg mechanism is fixed on the walking flatcar, the through pipe supporting mechanism is installed at the bottom of the hoisting truss, the through pipe hoisting mechanism is installed at the top of the hoisting truss, and the position of the through pipe supporting mechanism corresponds to the position of the through pipe hoisting mechanism. Compared with the prior art, the tool trolley has the advantages of being high in safety, capable of effectively improving GIL installation efficiency and hoisting precision, good in practicability and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

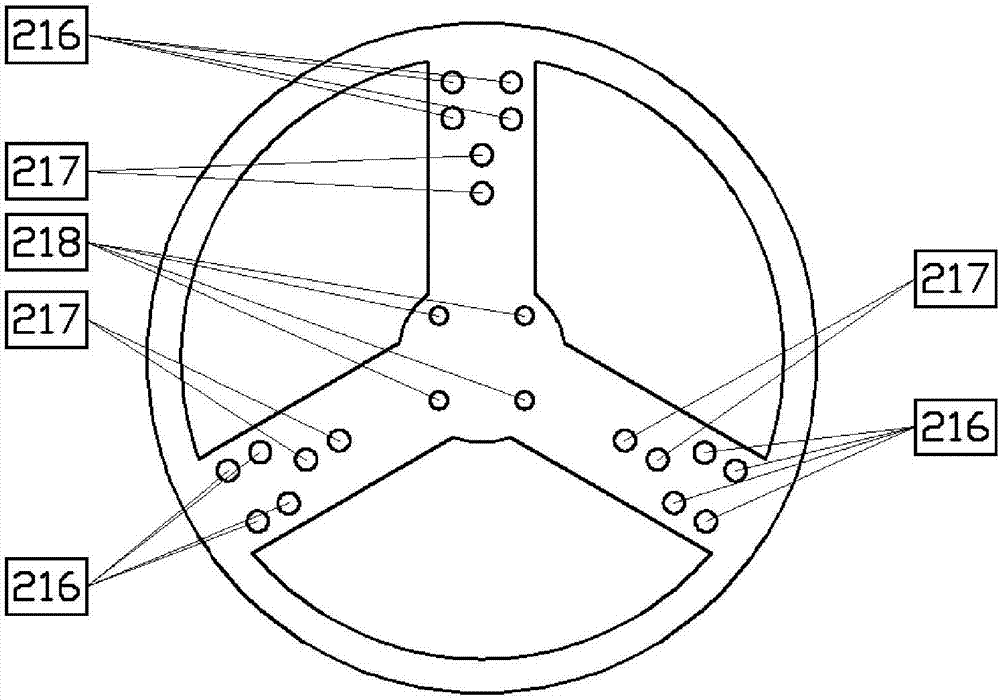

Lifting device for logistics supply chain

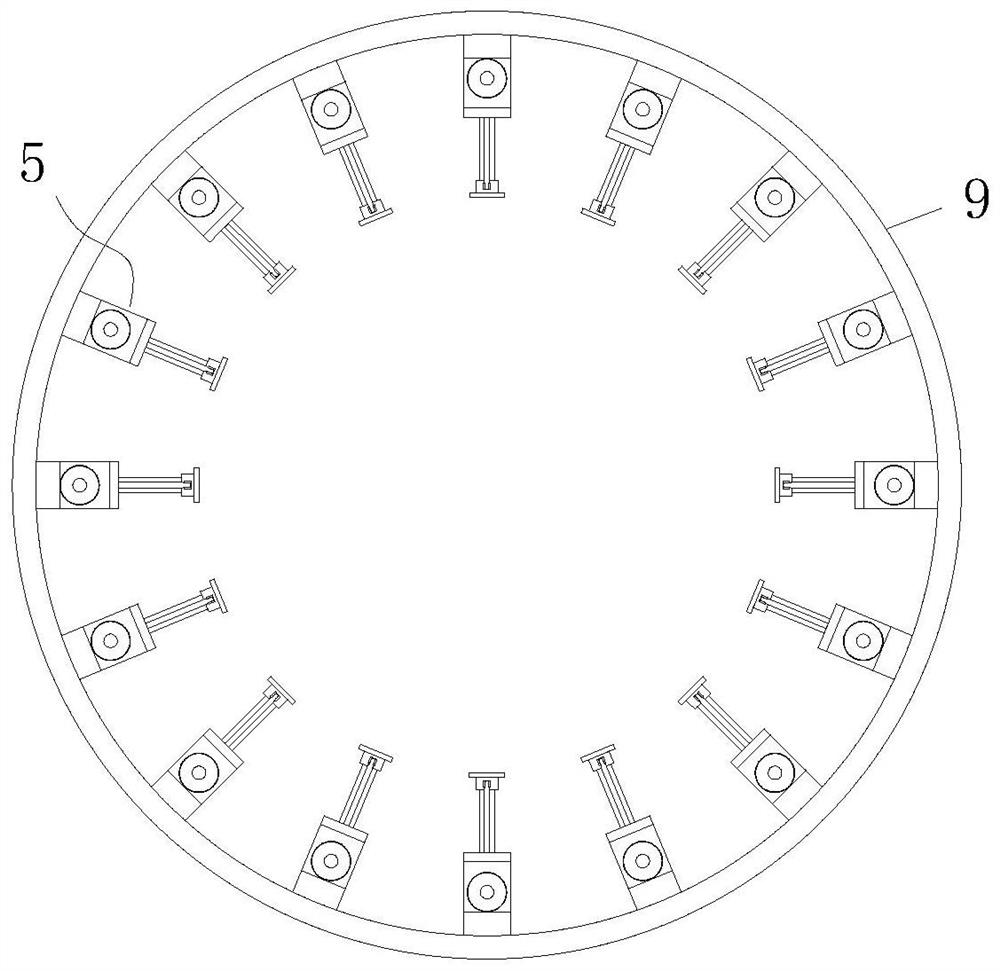

PendingCN112811306AAvoid shakingGuaranteed stabilityLoad-engaging elementsLogistics managementElectric machinery

The invention belongs to the technical field of logistics equipment, and particularly relates to a lifting device for a logistics supply chain. The lifting device comprises a lifting rod, a connecting frame, a motor, an assembling plate and a plurality of lifting and clamping units arranged in a circular array along the bottom edge of the assembling plate, the connecting frame is connected to the bottom of the lifting rod, the lifting rod is connected with a logistics supply chain transfer mechanism, the motor is fixedly mounted on the connecting frame, the assembling plate is transversely connected to the bottom of an output shaft of the motor, and a lifting and clamping cavity is formed among the multiple lifting and clamping units. A traditional combined lifting structure of a hook and a lifting rope is abandoned, the multiple lifting and clamping units are adopted for clamping an object, then the lifting rod and the transfer mechanism are matched to complete lifting operation, shaking of the object in the lifting process is effectively avoided, the stability and safety in the lifting process are guaranteed, the lifting precision is improved, lifting operation can be carried out in cooperation with a conveyor belt conveying mode, and the lifting efficiency is greatly improved.

Owner:SUZHOU INDAL PARK INST OF SERVICES OUTSOURCING

Horizontal adjusting sling for spacecraft

ActiveCN102556831BReduce labor intensityOvercome the problem of automatic level adjustmentLoad-engaging elementsUniversal jointEngineering

The invention provides a horizontal adjusting sling for a spacecraft, which comprises a hoisting ring component, an XY workbench, a hoisting beam and straps, wherein the XY workbench is arranged on the hoisting beam; the top center of the XY workbench is hinged with the hoisting ring component through a universal joint; four straps are arranged below the hoisting beam; the XY workbench comprises an X workbench and a Y workbench; the X workbench slides on the Y workbench through a slide rail along the X direction; the Y workbench slides on the hoisting beam through a slide rail in the Y direction; and the hoisting ring component comprises a hoisting ring connected with a hook of a crane, a middle bearing structure and a two-dimensional inclination sensor b for measuring the angle of inclination of the hook relative to the crane. Compared with the prior art, the horizontal adjusting sling for hoisting the spacecraft solves the problem that automatic horizontal adjustment cannot be implemented in a two-dimensional plane, the digitization and automation in the measuring and adjusting process are achieved, the hoisting accuracy and hoisting efficiency are improved and the labor intensity of operators is reduced.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Hoisting clamp and hoisting method for wheel of circular cooler

ActiveCN112919310AReduce installation difficultyEasy alignmentHandling discharged materialLoad-engaging elementsStructural engineeringControl theory

Owner:SGIS SONGSHAN CO LTD

Staggered tensioning anchoring structure and construction method for assembling building prefabricated steel reinforced concrete middle column beam joint prestressed tendons

ActiveCN111335485AHigh strengthImprove the force characteristicsBuilding constructionsRebarReinforced concrete

The invention discloses a staggered tensioning anchoring structure for assembling building prefabricated steel reinforced concrete middle column beam joint prestressed tendons. The structure comprisesa prefabricated column, and further comprises a preserved duct preserved inside the prefabricated column, a crossed steel column integrally formed with the prefabricated column, a prefabricated column stacking layer arranged at the upper portion of the prefabricated column, a stacking beam arranged at one end of the prefabricated column, a top steel bar exposed out of the upper portion of the stacking beam, an outer stretching steel bar stretching out of the side of the prefabricated column, a plurality of preserved through holes formed in the crossed steel column, prestressed tendons penetrating through the preserved through holes, and a prestressed tendon anchoring device fixed to the crossed steel column. The prestressed tendons are fixed to the crossed steel column through the prestressed tendon anchoring device. The structure ensures the integrated stress requirement of the beam column joint, and the joint is good in hogging moment resisting effect.

Owner:钱野

Path Planning Method for Hoisting Objects of Cranes

ActiveCN102542361BHigh precisionImprove securitySpecial data processing applicationsSimulationPlanning method

Owner:ZOOMLION HEAVY IND CO LTD

A self-installing three-cylinder combined multi-stage luffing device

ActiveCN109516392BRealize large-angle automatic rotationIncrease the stick out lengthCranesControl theoryMechanical engineering

The invention discloses a self-mounting three-cylinder combined multistage variable amplitude device, and belongs to the technical field of engineering hoisting machinery. The self-mounting three-cylinder combined multistage variable amplitude device comprises a boom, an auxiliary jib, a variable amplitude main cylinder and auxiliary displacement cylinders, wherein one end of the variable amplitude main cylinder is hinged to the boom; the other end of the variable amplitude main cylinder is detachably hinged to the auxiliary jib; one ends of the auxiliary displacement cylinders are hinged to the boom; rollers are mounted at the other ends of the auxiliary displacement cylinders; wedge-shaped guide rails and roller clamping grooves are fixed on the variable amplitude main cylinder; when theauxiliary displacement cylinders stretch out, the rollers are propped against the wedge-shaped guide rollers; and when the auxiliary displacement cylinders retreat, free ends of the auxiliary displacement cylinders enter the roller clamping grooves. According to the self-mounting three-cylinder combined multistage variable amplitude device, requirements of small mounting interval and large span are met, 0-90-degree large-angle automatic rotation of the auxiliary jib is achieved, the auxiliary jib is automatically mounted without external hoisting equipment, an automatic locking fixing function of the variable amplitude main cylinder is achieved, the variable amplitude device is prevented from swinging / shaking in high air, stability and safety of the auxiliary jib are improved, and hoisting precision is improved.

Owner:XCMG HYDRAULICS CO LTD

Prefabricated building prefabricated steel concrete intermediate column-beam joint prestressed tendon interlaced tension anchorage structure and construction method

ActiveCN111335485BHigh strengthImprove the force characteristicsBuilding constructionsPre stressSteel columns

The invention discloses a prefabricated steel-concrete intermediate column-beam node interlaced tension anchoring structure for prefabricated buildings. Formed cross-shaped steel column; prefabricated column laminate layer arranged on the upper part of the prefabricated column; laminated beam arranged at one end of the prefabricated column; top steel bars exposed on the upper part of the The outstretched reinforcement on the side of the prefabricated column; the multiple reserved perforations on the cross-shaped steel column; the prestressed tendons passing through the multiple reserved perforations; the prestressed steel bars fixed on the cross-shaped steel column A tendon anchoring device, the prestressed tendons are fixed on the cross-shaped steel column through the prestressed tendon anchoring device; this structure ensures the integral stress requirements of the beam-column joints, and makes the joints have a good anti-negative bending moment effect.

Owner:钱野

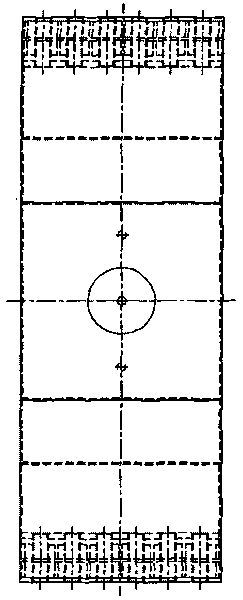

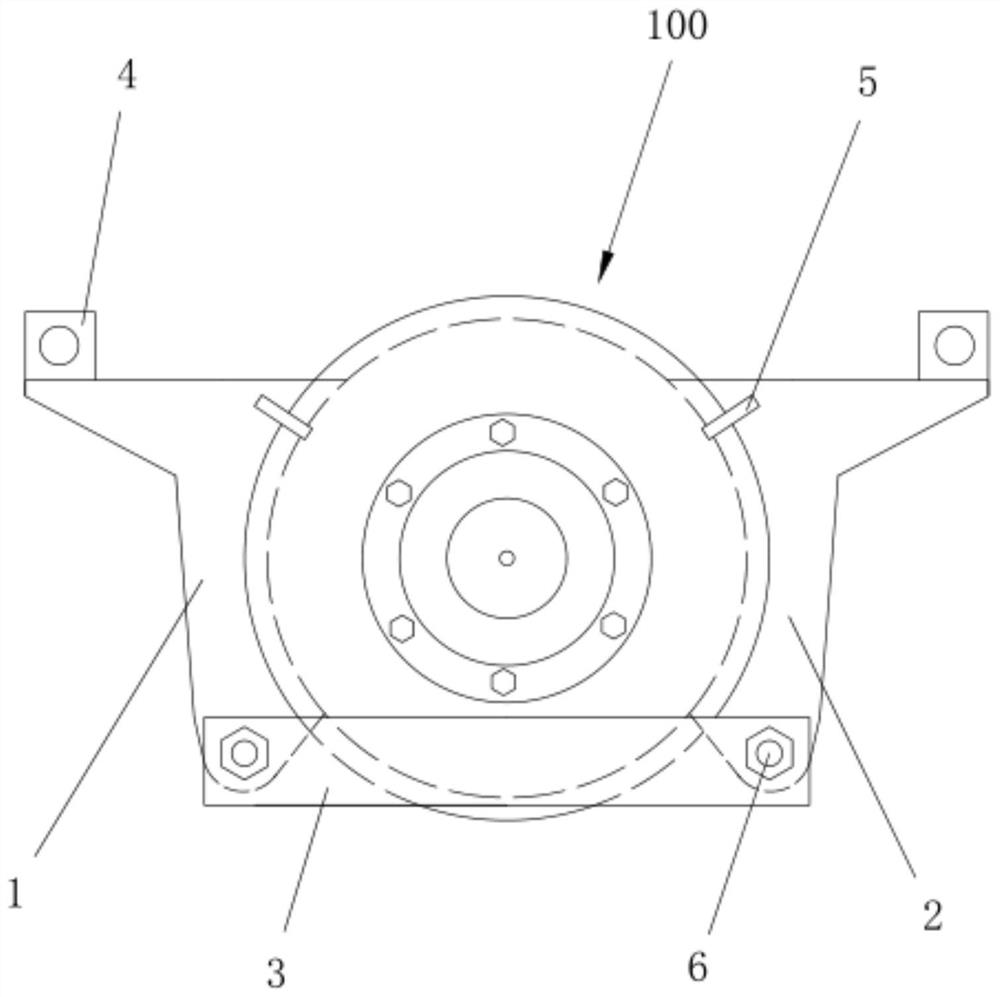

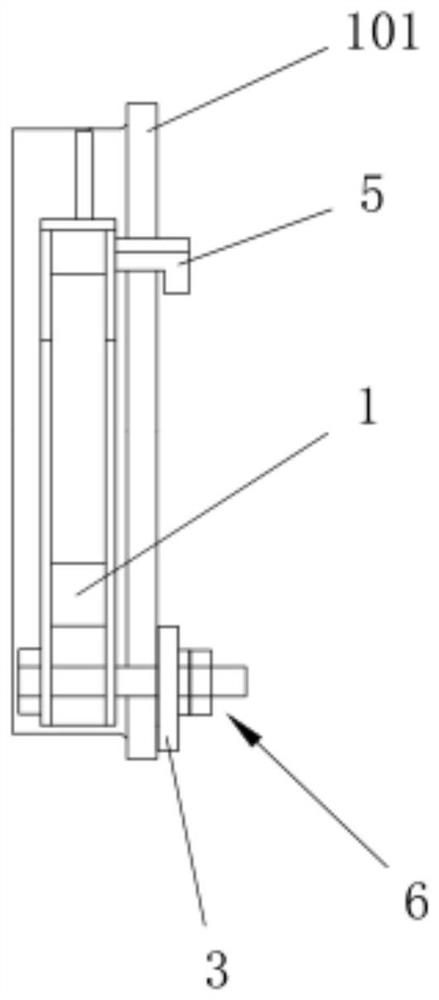

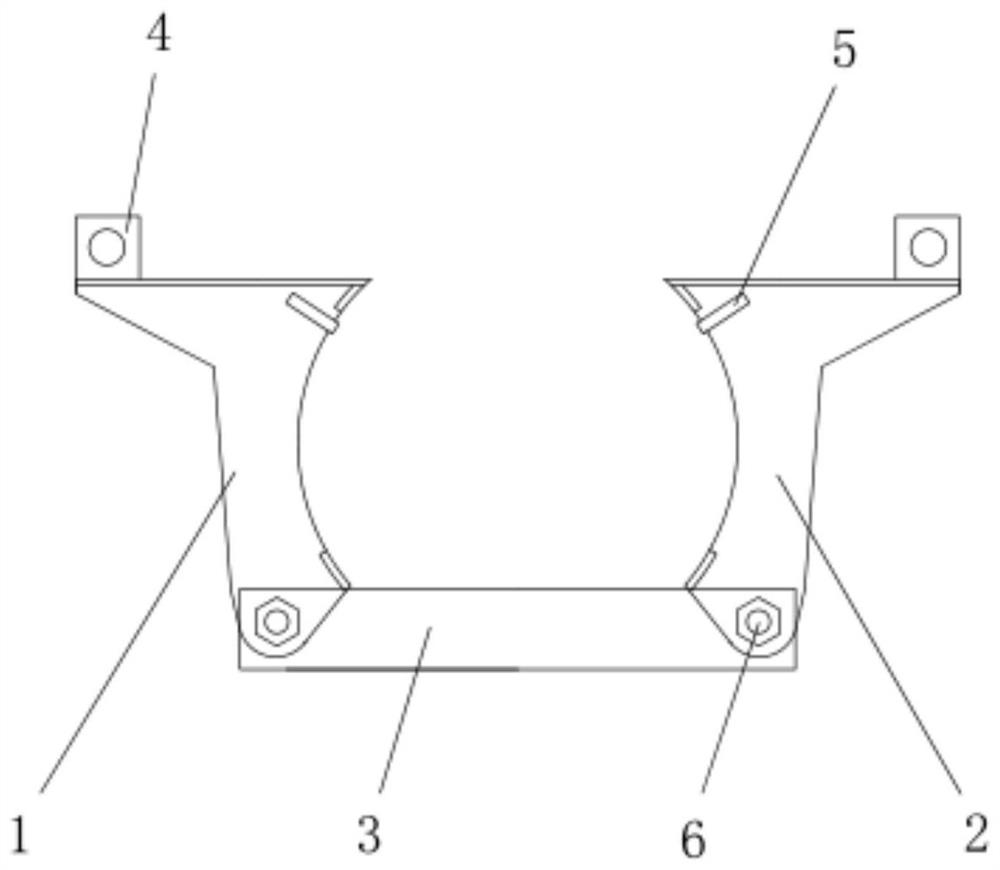

Auxiliary device suitable for accurate hoisting and butt joint of large-diameter thin-wall cylindrical structure

PendingCN113818416AImprove hoisting accuracyImprove hoisting efficiencyArtificial islandsUnderwater structuresButt jointThin walled

The invention discloses an auxiliary device suitable for accurate hoisting and butt joint of a large-diameter thin-wall cylindrical structure. The auxiliary device comprises a plurality of position guiding pieces and an angle guiding structure, the multiple position guiding pieces are fixed to the outer wall of the tail end of a first cylinder in a surrounding mode, and a circular-truncated-cone-shaped sliding channel is defined by the guiding faces of the multiple position guiding pieces; the angle guiding structure comprises a guiding rib and a guiding plate, the guiding plate is fixed to the outer wall of a second cylinder and is integrally in a herringbone shape, a guiding channel distributed in the axial direction of the first cylinder is formed in the middle of the guiding plate, the fixed end of the guiding rib is fixed to the first cylinder, and the guiding end of the guiding rib corresponds to the guiding channel. According to the auxiliary device suitable for accurate hoisting and butt joint of the large-diameter thin-wall cylindrical structure, when butt joint is achieved, the guiding end is inserted into the guiding channel; the auxiliary device further comprises a gap adjusting structure and a butt joint dislocation adjusting structure, hoisting butt joint of the large-diameter thin-wall cylindrical structure can be assisted, and the hoisting precision and efficiency are improved.

Owner:OFFSHORE OIL ENG CO LTD

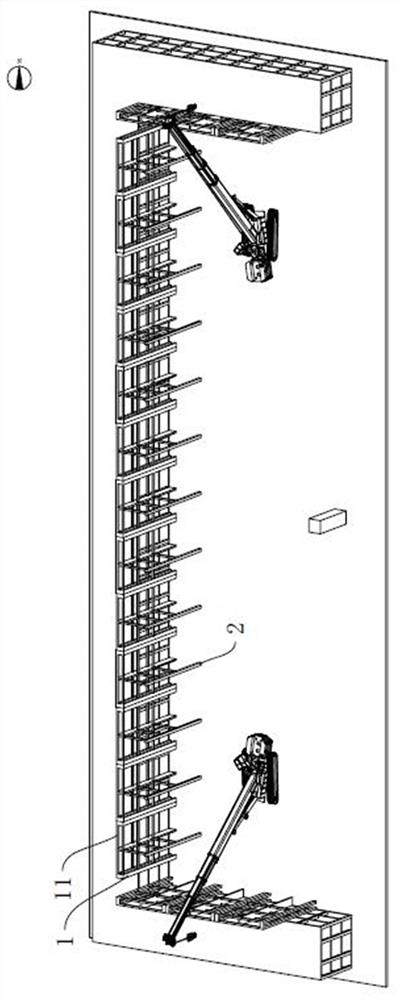

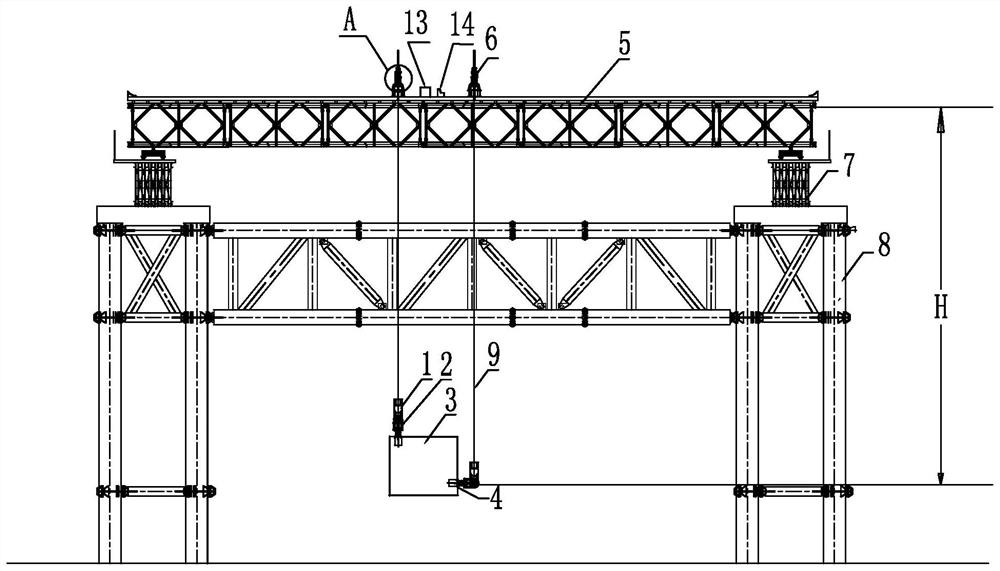

Modular hoisting and two-stage overall synchronous hoisting method for super-long-span steel roof

ActiveCN114215191BGuaranteed installation accuracyReduce the area of high-altitude embedding areaBuilding constructionsArchitectural engineeringSteel columns

This application involves the modular hoisting of super-large-span steel roofs, and a two-stage overall synchronous lifting method. The trusses on the west side of the steel roofs are used for assembly on the ground, and 250t crawler cranes are used to hoist them in place separately; the gate trusses, hall grids and The W-shaped oblique trusses are assembled on the ground at the same time, and the hoisting towers and temporary towers are erected. After the assembled hall grid is raised by 3m, it is docked with the gate truss, and then the rods are embedded, and then the welded roof The roof structure is raised again to the design position and docked with the side truss, and the corresponding position is embedded and repaired. After the welding is completed, the whole is unloaded, and the lifting tower is removed. This application is aimed at large-span steel roofs, two lifting processes, temporary towers and lifting towers The existence of the trusses plays a role in adjusting the posture during the hoisting of the steel roof, which improves the hoisting accuracy. The trusses on the west side are hoisted in sections, which reduces the area where the steel columns are embedded in the high-altitude rods, ensuring that the steel columns and support The installation accuracy of the seat node.

Owner:BEIJING CONSTR ENG GRP CO LTD

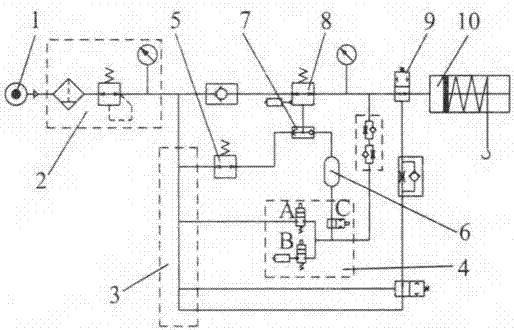

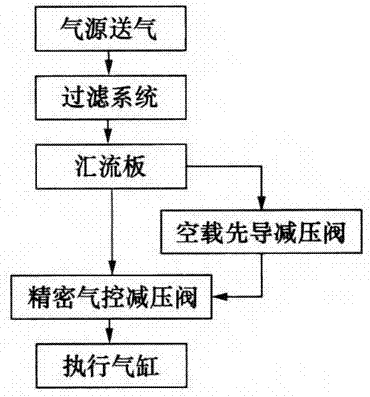

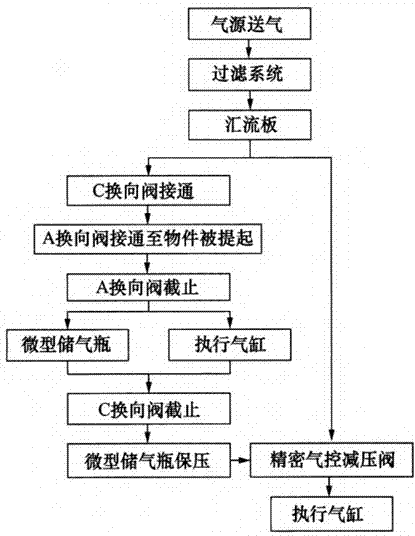

Full-process suspension pneumatic balancer control system

InactiveCN106865442AReduce labor intensityReduce manufacturing costPortable liftingWinding mechanismsProduction lineControl system

Provided is a full-process suspension pneumatic balancer control system. The pneumatic control system achieves the non-load full-process suspension function and the heavy-load full-process suspension function, and objects can be subjected to non-gravity operation including horizontal movement and vertical floating. By applying the pneumatic control system to the industrial production and manufacturing process, the labor intensity of operators can be relieved, the operation cycle time can be shortened, besides, the object hoisting precision is greatly improved, reliable conditions are provided for high-precision assembly operation of a production line, and the production cost of enterprises is reduced. Meanwhile, reference bases are further provided for researches on a pneumatic balance system.

Owner:魏莹

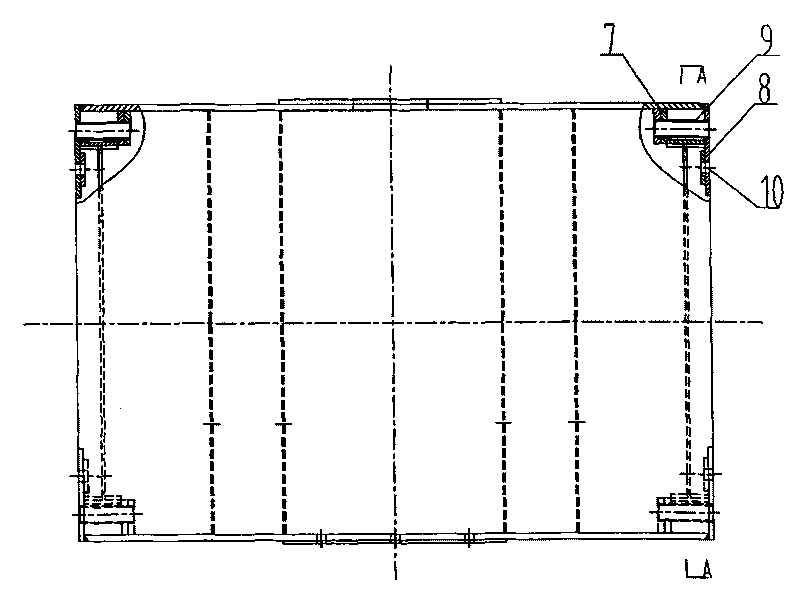

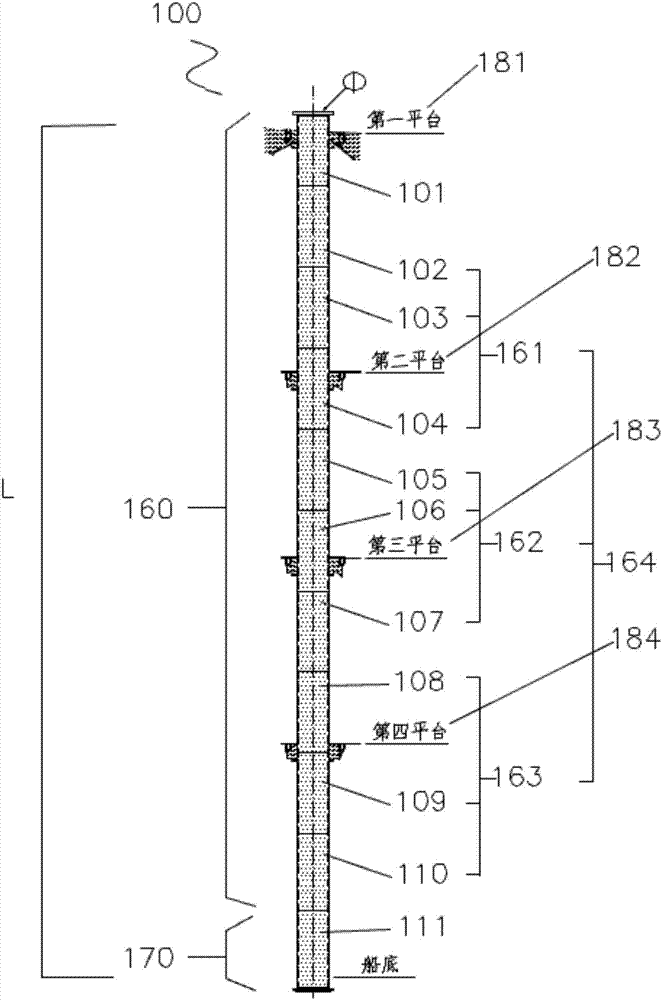

Duplex stainless steel chemical tanker deck cabin hoisting precision control method

PendingCN114394209AEasy to installImprove hoisting accuracyVessel designingMarine engineeringMechanical engineering

The invention discloses a duplex stainless steel chemical tanker deck cabin hoisting precision control method which comprises the following steps: measuring the three-dimensional size of a bolt hole in a deck cabin segmented connecting plate by using a total station, and adjusting the mounting position of a deck cabin base according to the three-dimensional size of the bolt hole in the deck cabin segmented connecting plate. The positions of the bolt holes in the deck cabin base connecting plate and the positions of the bolt holes in the deck cabin subsection connecting plate can coincide during installation, and after the position of the deck cabin base is adjusted and the deck cabin base is installed, the deck cabin is installed on the deck cabin base. The deck cabin hoisting control method is easy to operate, the deck cabin is accurately installed in place in the hoisting process, the deck cabin hoisting precision and working efficiency are improved, and the hoisting time is shortened.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Hoisting device for realizing integral continuous large-amplitude space angle rotation of heavy object and hoisting method thereof

PendingCN114590714ASimple structureEasy to operateBase supporting structuresBraking devices for hoisting equipmentsSupporting systemControl system

The invention discloses a hoisting device for realizing integral continuous large-amplitude space angle rotation of a heavy object. The hoisting device comprises a hoisting steering mechanism, a steel structure supporting system, a lifting jack group and a control system, the hoisting steering mechanism comprises an upper-end lifting appliance, a steering lifting appliance, a steel strand and a fixed-end anchorage device; the steel structure supporting system comprises a hoisting cross beam, a longitudinal beam and a portal frame; an even number of lifting jacks of the lifting jack group are divided into two groups and are respectively mounted on the two lifting cross beams; the upper ends of the steel strands penetrate through the lifting jacks and are anchored on the fixed end anchorage devices through the tensioning end anchorage devices; the upper-end lifting appliance is connected with the steering lifting appliance in a pin shaft manner; the steering lifting appliance is in pin joint with a lifting lug on a heavy object; according to the hoisting method for achieving integral continuous large-amplitude space angle rotation of the heavy object, the lifting lugs are arranged on the outer side of the gravity center of the heavy object structure, integral continuous large-amplitude space angle rotation of the heavy object is achieved by changing the horizontal projection distance between the lifting lugs of the heavy object and the height of a sling between the lifting lugs and a lifting point, and the method is easy and convenient to operate and good in technical effect.

Owner:LIUZHOU OVM ENG

A high-precision positioning and guiding device and a method of using the same

The invention relates to a high-precision positioning guide device and its use method, comprising an outer device and an inner device combined, the inner device includes a first channel steel, the bottom of the first channel steel is provided with fixing bolt holes, and the first channel steel There is a Y-shaped guide groove on the side. It can solve the problems that restrict the progress of the project and the quality and safety of construction, and at the same time solve the problems of poor environmental performance, cumbersome disassembly and assembly, unfavorable recycling and turnover, poor rigidity performance, insufficient fixation, poor mechanical properties and poor safety and reliability performance, etc. problems; thereby realizing the rapid positioning and correction of components such as prefabricated walls, and improving the utilization rate of the tower crane and the hoisting accuracy.

Owner:SHANDONG SANJIAN CONSTR ENG +1

Suspension centre automatic adjusting method of leveling spreader for spacecraft

InactiveCN102976207BReduce labor intensityAdvanced technical indicatorsLoad-engaging elementsEngineeringUltimate tensile strength

The invention discloses a suspension centre automatic adjusting method of a leveling spreader for a spacecraft; according to the method, measured values of a tension sensor and a dip angle sensor and intrinsic parameter of the spreader are used as input, displacements respectively in the X and the Y directions of an XY worktable are calculated by using different formulae, and then iteration is carried out repeatedly until the measured values of the sensors meet the levelness lifting requirement. Compared with the prior art, the accurate adjusting method disclosed by the invention solves the difficulty of fast and automatic leveling of the suspension center of the spreader in a two-dimensional plane, has advanced technical index, achieves digitization and automation of the adjusting process, improves suspension precision and suspension efficiency, reduces labor intensity of operators, can reach the levelness within the range of 5mm / m by only three times of adjustments, and has significant value in application.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

The construction process of the protective pipe of the fpso seawater lift pump

ActiveCN106184611BReduce precision control requirementsMeet the precision control requirementsVessel designingFloating buildingsSeawaterBuilding process

The invention discloses a building process of a protection tube of a FPSO (floating product storage and offloading) seawater lift pump. The building process includes: S1, respectively building an upper structure and a lower structure of the protection tube of the seawater lift pump; S2, locating the lower structure of the protection tube of the seawater lift pump at a reserved position of a hull, and hoisting the upper structure to be docked with the lower structure; S3, docking a platform on the upper structure with a hull platform. In addition, the invention further discloses a hoisting process of the protection tube of the FPSO seawater lift pump. The hoisting process includes: T1, hoisting the hull on an eleventh foundation section, mounting and positioning; T2, manufacturing a locating adjustment device; T3, manufacturing a guide plate; T4, docking the upper structure of the protection tube with the eleventh foundation section, welding and fixing. The protection tube of the seawater lift pump is divided into the long upper structure and the short lower structure which are built separately, so that paint wear during hoisting after the structures of the protection tube are integrally coated is avoided, repeated coating period is shortened, hoisting accuracy is easy to control, and difficulty in local paint make-up after the structures of the protection tube are mounted is lowered.

Owner:广州文冲船舶修造有限公司

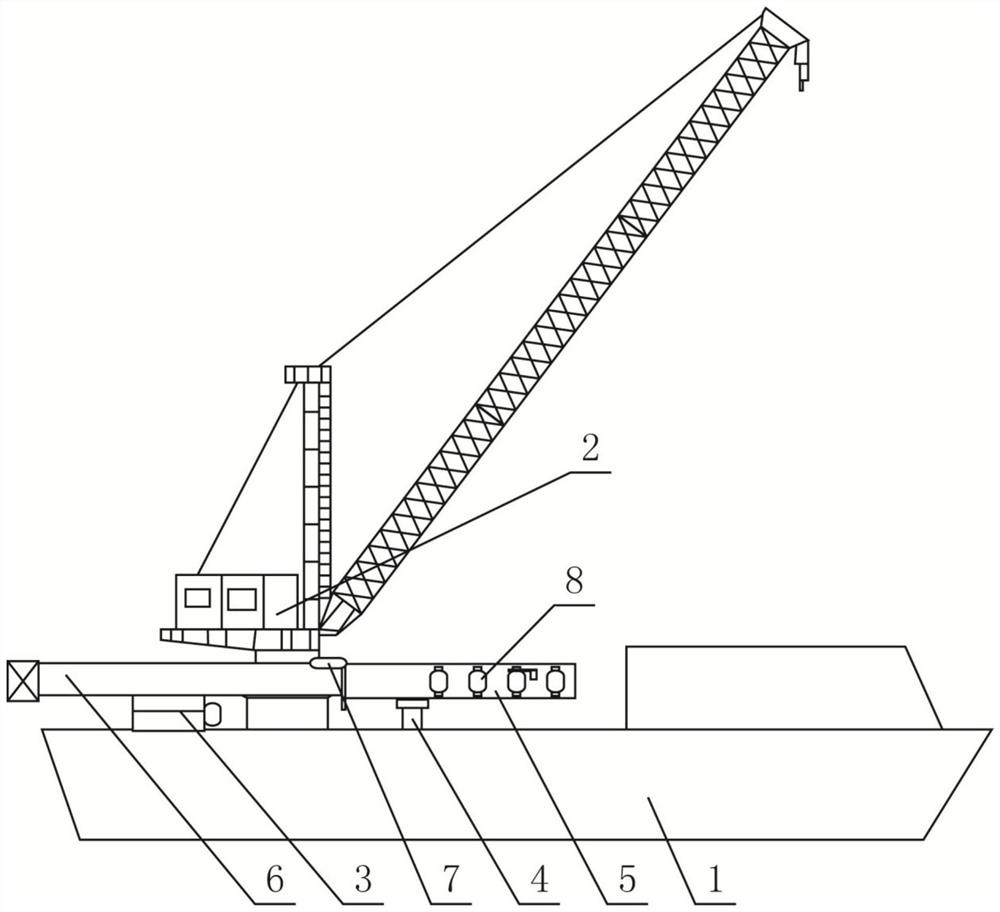

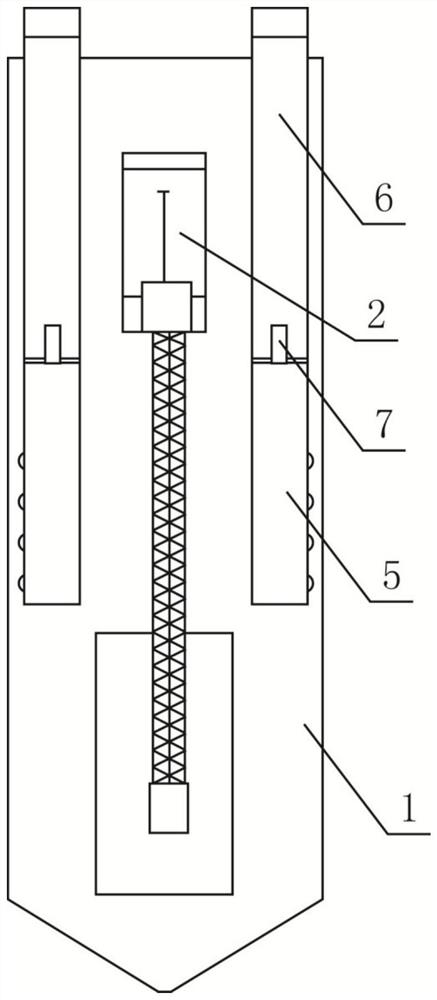

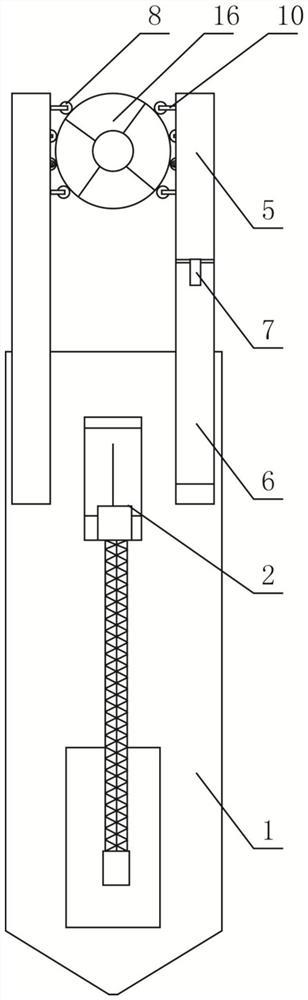

Installation equipment of offshore wind turbine generator

PendingCN114483462AHeight adjustableAdjustable angleWind motor assemblyWind motor supports/mountsEngineeringOffshore wind power

The invention provides an offshore wind turbine generator installation device which comprises a ship body, a full-rotation crane, rotation arms and a rotation mechanism, the full-rotation crane is fixed to the ship body, the two sides of a stern of the ship body are each provided with one rotation arm, the rotation arms are connected with the ship body through the rotation mechanism, and the rotation mechanism is fixed to the ship body. A plurality of floating foundation pressing mechanisms are arranged on the opposite sides of the two rotary arms respectively, and at least one floating foundation pressing mechanism is provided with a rotation driving mechanism. By capturing the floating foundation of the offshore wind turbine generator, the installation positions of equipment such as a tower drum and blades are accurately positioned, the influence of factors such as waves and wind power is reduced, the installation difficulty of the offshore wind turbine generator is reduced, and the installation efficiency is improved.

Owner:SINOHYDRO HARBOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com