Hoisting rigging and hoisting method thereof

A hoisting method and rigging technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of difficult to guarantee accuracy, complicated operation, and large labor consumption, and achieve the effect of improving the overall hoisting accuracy and high adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

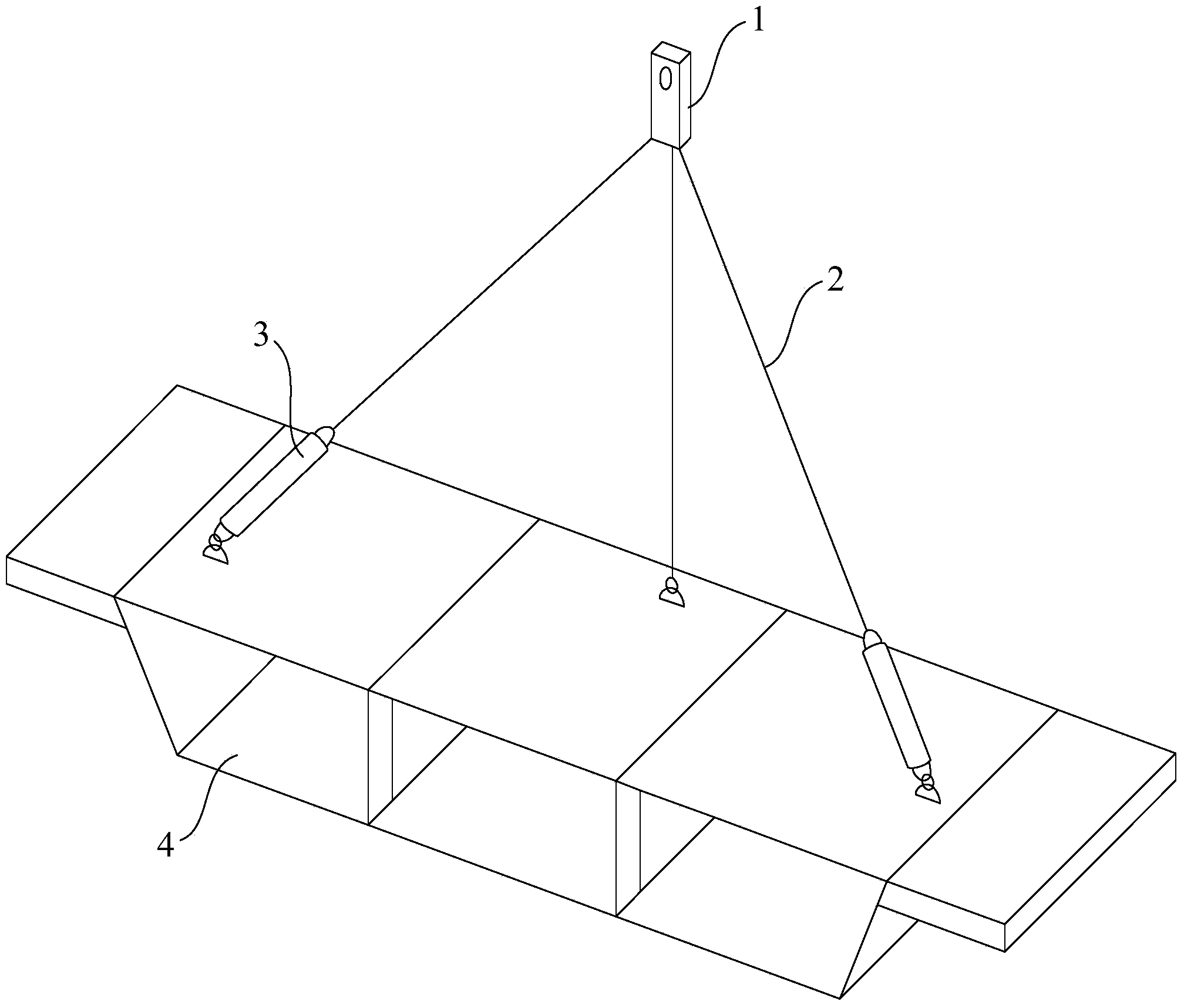

[0029] Such as figure 1 As shown, in this embodiment, the number of the steel wire ropes 2 is three, the number of the hydraulic pull pumps 3 is two, and one end of the three steel wire ropes 2 is connected with the hook device 1, two of which The other end of the wire rope 2 is respectively connected to one end of the two hydraulic pull pumps 3, the other end of the other wire rope 2 is fixed to one side of the member 4, and the other ends of the two hydraulic pull pumps 3 are respectively fixed at both ends of the member 4.

[0030] Further, when using the hoisting rigging provided in this embodiment, in step five, when adjusting the height above the ground of multiple positions on the member 4, when the member 4 needs to rotate along the X-axis direction , the two hydraulic pull pumps 3 extend and shrink respectively at the same time, and the amount of expansion and contraction is the same; when the member 4 needs to rotate along the Y-axis direction, the two hydraulic pul...

Embodiment 2

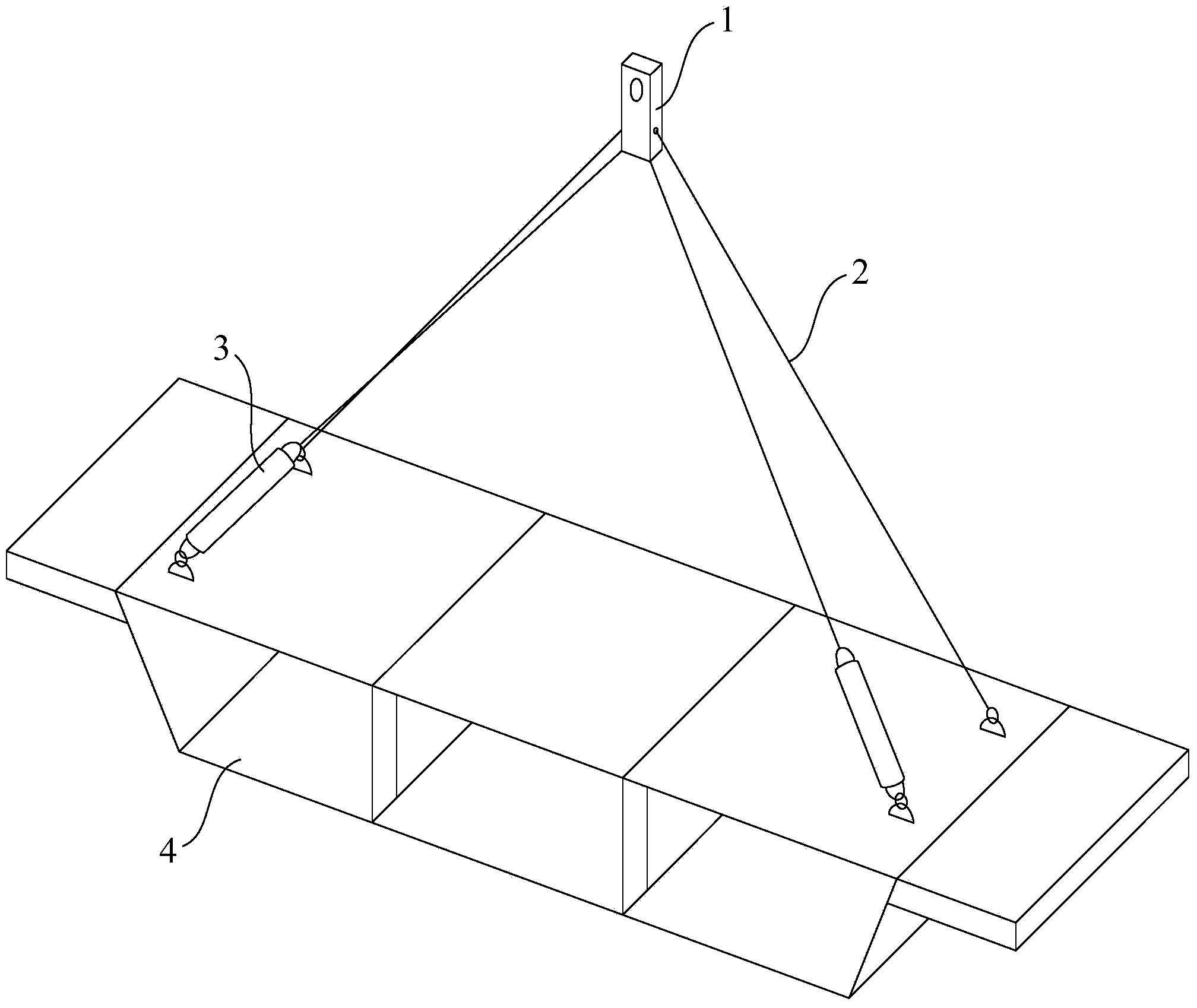

[0032] Such as figure 2 As shown, in this embodiment, the number of the steel wire ropes 2 is three, the number of the hydraulic pull pumps 3 is two, and one end of two steel wire ropes 2 in the three steel wire ropes 2 is connected with the hook device 1 , the other end of which is respectively connected to one end of the two hydraulic pull pumps 3, and the other steel wire rope 2 is passed through the hook device 1, and its two ends and the other ends of the two hydraulic pull pumps 3 are respectively Fixed on the four corners of the member 4 , the other ends of the two hydraulic pull pumps 3 are located on the same side of the member 4 .

[0033] Further, when using the hoisting rigging provided in this embodiment, in step five, when adjusting the height above the ground of multiple positions on the member 4, when the member 4 needs to rotate along the X-axis direction , the two hydraulic pull pumps 3 extend and shrink respectively at the same time, and the amount of expa...

Embodiment 3

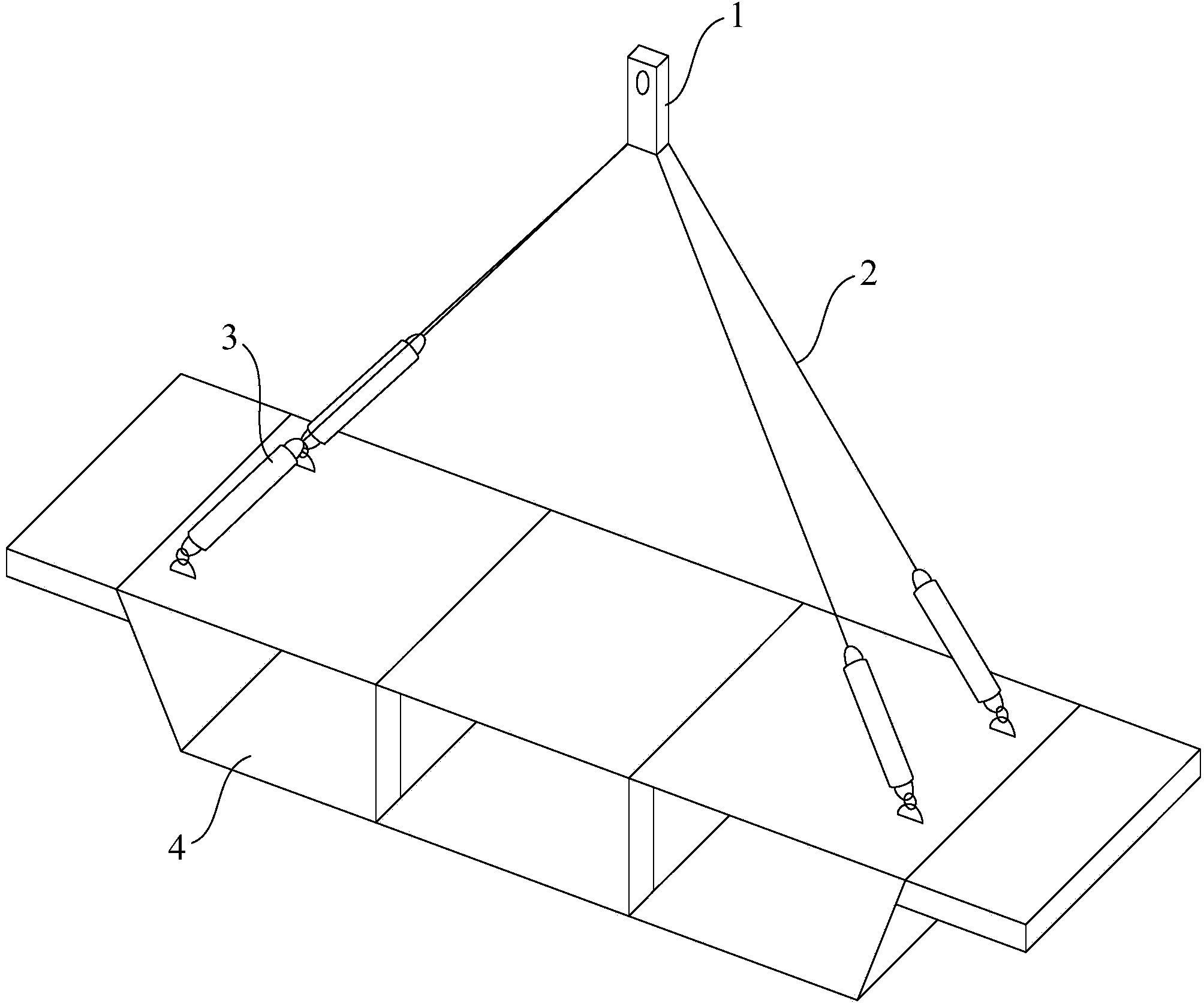

[0035] Such as image 3 As shown, in this embodiment, the number of the steel wire ropes 2 is four, the number of the hydraulic pull pumps 3 is four, and one end of the four steel wire ropes 2 is connected to the hook device 1, and its The other ends are respectively connected to one ends of the four hydraulic pull pumps 3 , and the other ends of the four hydraulic pull pumps 3 are respectively fixed on the four corners of the member 4 .

[0036] Further, when using the hoisting sling provided in this embodiment, in the fifth step, when adjusting the height above the ground of multiple positions on the member 4, it is only necessary to adjust the expansion and contraction of each hydraulic pump 3 one by one , to complete the three-dimensional state adjustment of the component 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com