Adjusting method for level adjustment of hanging tool for spacecraft

A technology for a spacecraft and a spreader is applied in the field of realizing the level adjustment of the spacecraft, which can solve the problems of large working space, difficult to achieve automatic adjustment, difficult to obtain accuracy, etc. The effect of hoisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

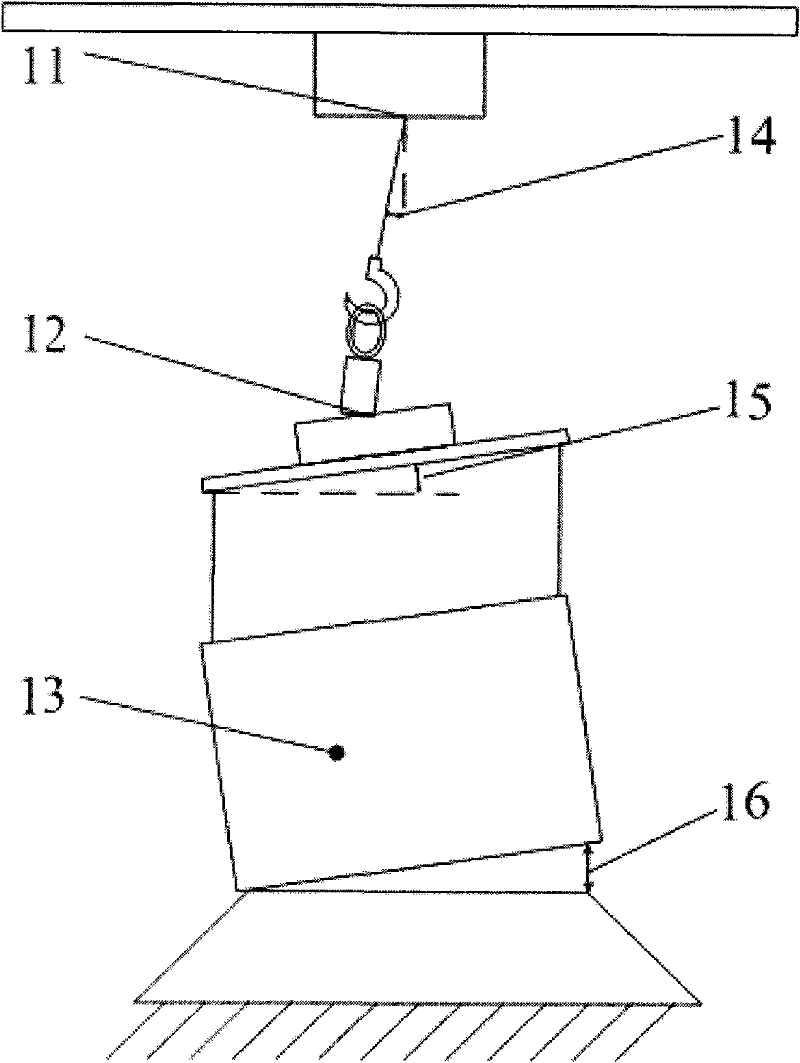

[0024] The horizontal hoisting adjustment method of the spreader based on the hoisting point adjustment of the present invention will be further described below in conjunction with the accompanying drawings.

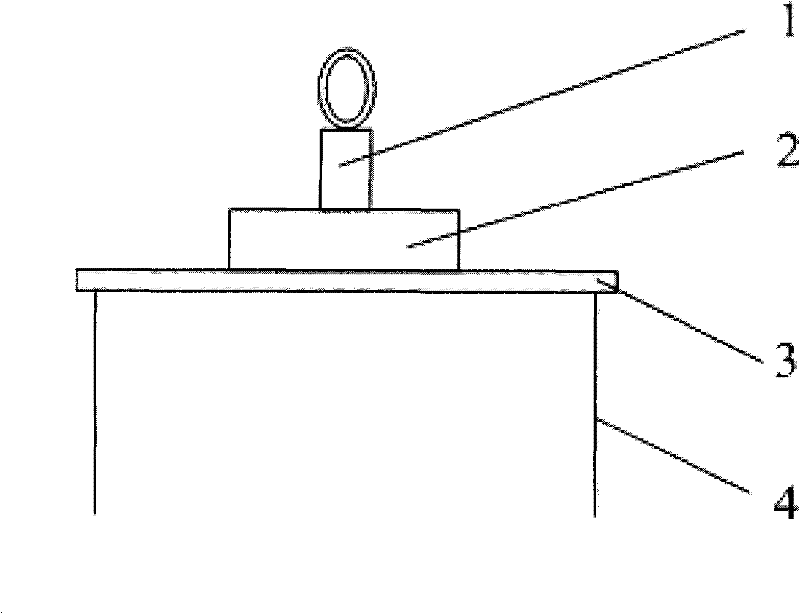

[0025] see figure 1 , figure 1 A schematic structural diagram of the hanger in the horizontal hoisting adjustment method of the present invention is given. Wherein, the hanger in the horizontal hoisting adjustment method of the present invention includes a suspension ring assembly 1 for connecting the crane hook; an XY workbench 2 whose upper part is fixedly connected with the suspension ring assembly 1; The suspension beam 3 of load and the suspension belt 4 that hangs under the suspension beam. The hoisted spacecraft is mounted under the sling.

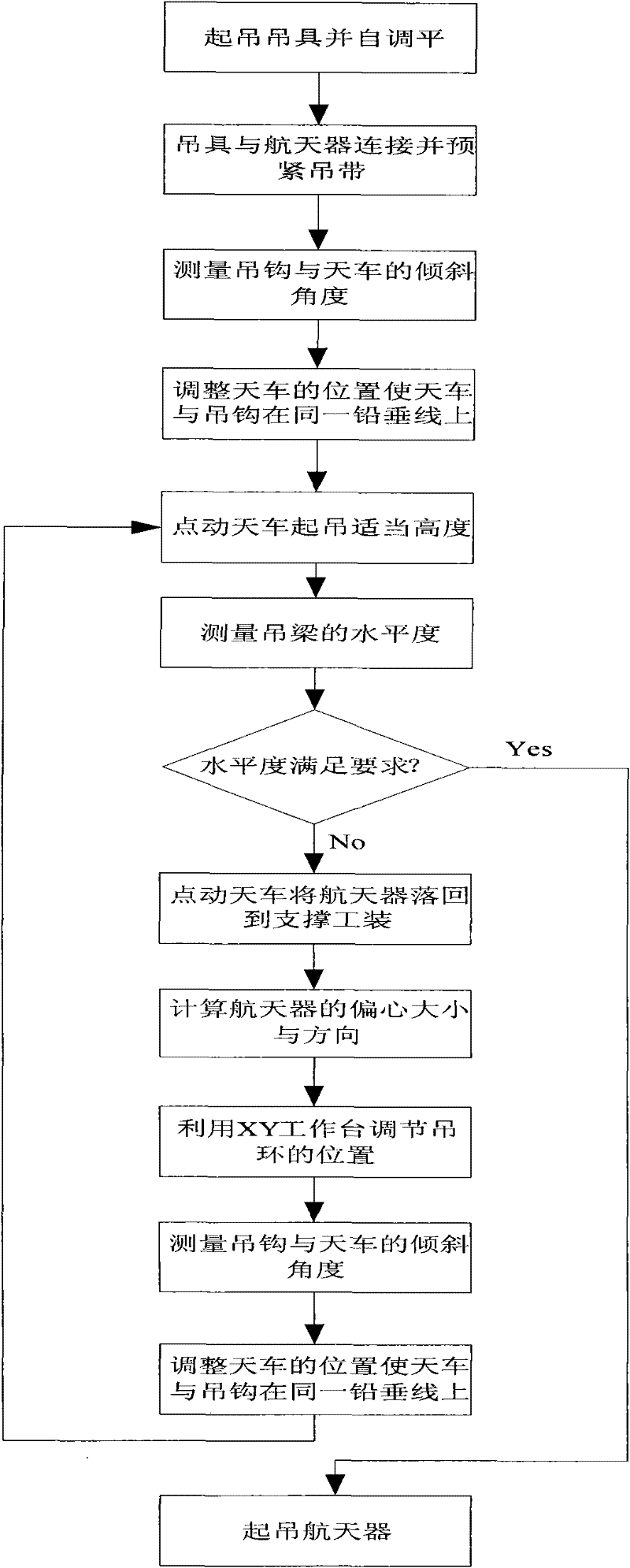

[0026] For the flow chart of the horizontal hoisting adjustment method of the spreader based on the hoisting point adjustment of the present invention, see figure 2 . Among them, the horizontal hoisting adjustment method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com