Modular hoisting and two-stage overall synchronous hoisting method for super-long-span steel roof

A technology of synchronous lifting and steel roofing, which is applied in the direction of construction and building construction, can solve the problems of limited height and achieve the effect of improving the hoisting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

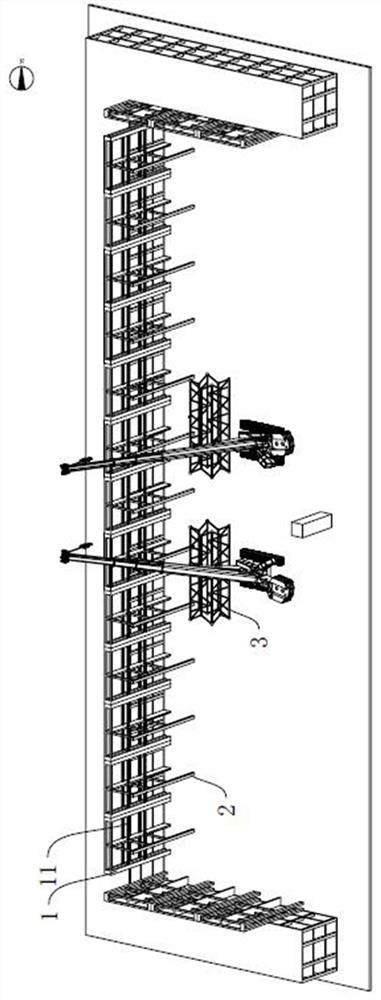

[0064] The following is attached Figure 1-14 The application is described in further detail.

[0065] The embodiment of the present application discloses a method for modular hoisting and two-stage overall synchronous lifting of a super-large-span steel roof.

[0066] A method for modular hoisting and two-stage overall synchronous hoisting of a super-large-span steel roof includes:

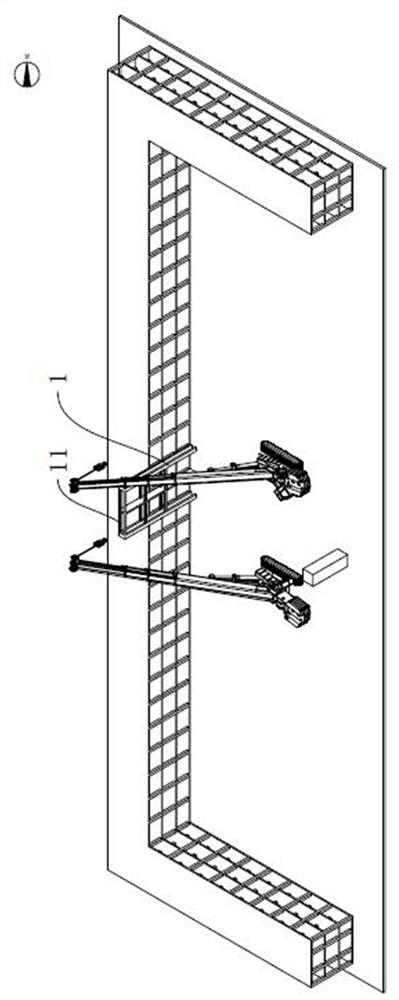

[0067] refer to figure 1 , S1, install steel column 1 and inter-column support 11 in sections, the installation sequence starts from the middle of the west side of the hangar to the north and south sides at the same time; in this embodiment, a 50t crawler crane is used to install steel column 1 and inter-column support 11 in sections .

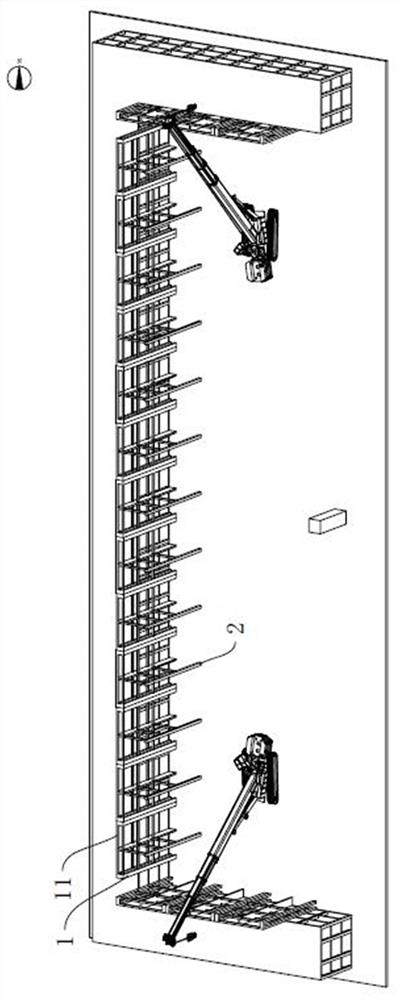

[0068] refer to figure 2 , S2, 50t crawler cranes continue to hoist the steel column 1 and inter-column support 11 in the next section, while the steel column 1 and inter-column support 11 are installed, the temporary support 2 is constructed; the temporary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com