Universal member pre-buried node and installing method thereof

A universal rod, pre-embedded technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of low positioning accuracy of pre-embedded nodes, difficulty in ensuring safety and reliability, and inability to meet construction requirements. The method is simple and easy to implement, reduces construction costs, and ensures the effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with accompanying drawing, the present invention is described in further detail:

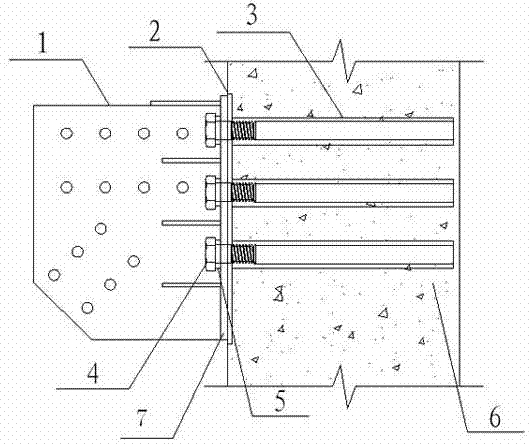

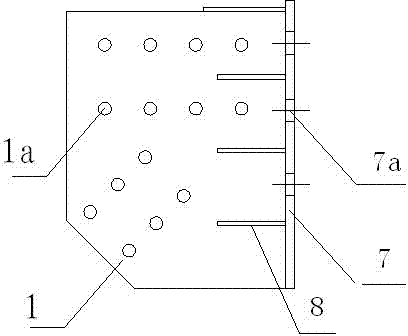

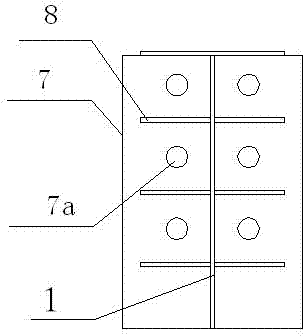

[0025] Such as figure 1 , figure 2 , image 3 with Figure 4 The pre-embedded joints of universal rods shown include gusset plates, six screws 3 (the number of screws is determined according to the actual situation on site), six locking bolts 4 that are respectively connected with the six screws 3, and one end of the six screws 3 is connected. is provided with an internal thread;

[0026] A positioning steel plate 2 is provided with six through holes, and six screw rods 3 pass through the through holes on the positioning steel plate 2 respectively, and are welded together with the positioning steel plate 2 and embedded in the concrete 6 together;

[0027] The gusset plate is T-shaped and consists of a vertical plate 1 and a straight plate 7. A reinforcing rib 8 is provided at the joint between the vertical plate 1 and the straight plate 7 of the gusset plate. The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com