Gesture monitoring and positioning device in large workpiece lifting process

A technology of large workpieces and positioning devices, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve some problems such as the difficulty of adjusting small offsets, and achieve the effects of shortening adjustment time, saving auxiliary command, and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

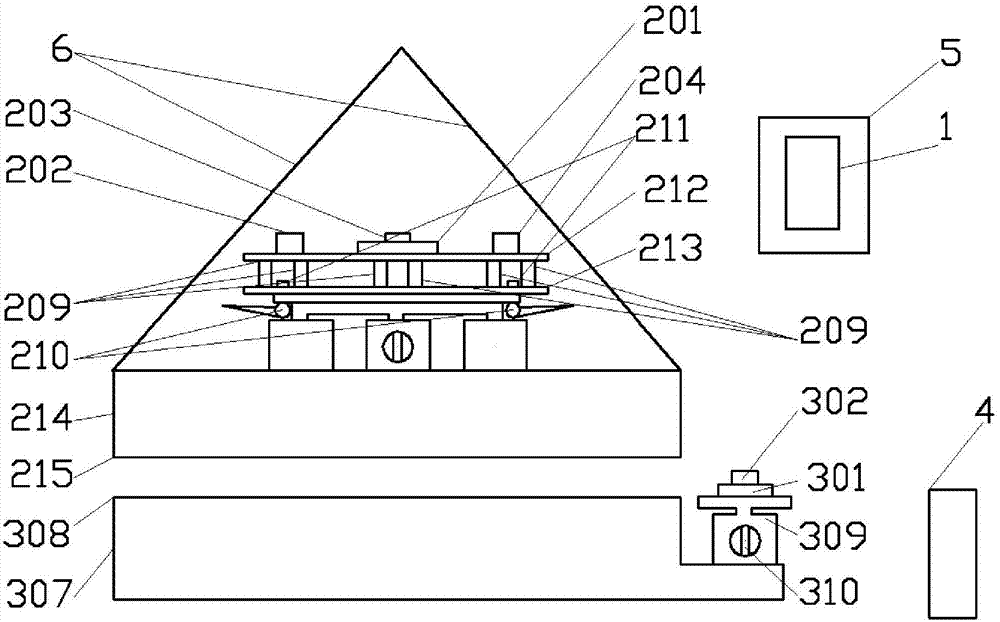

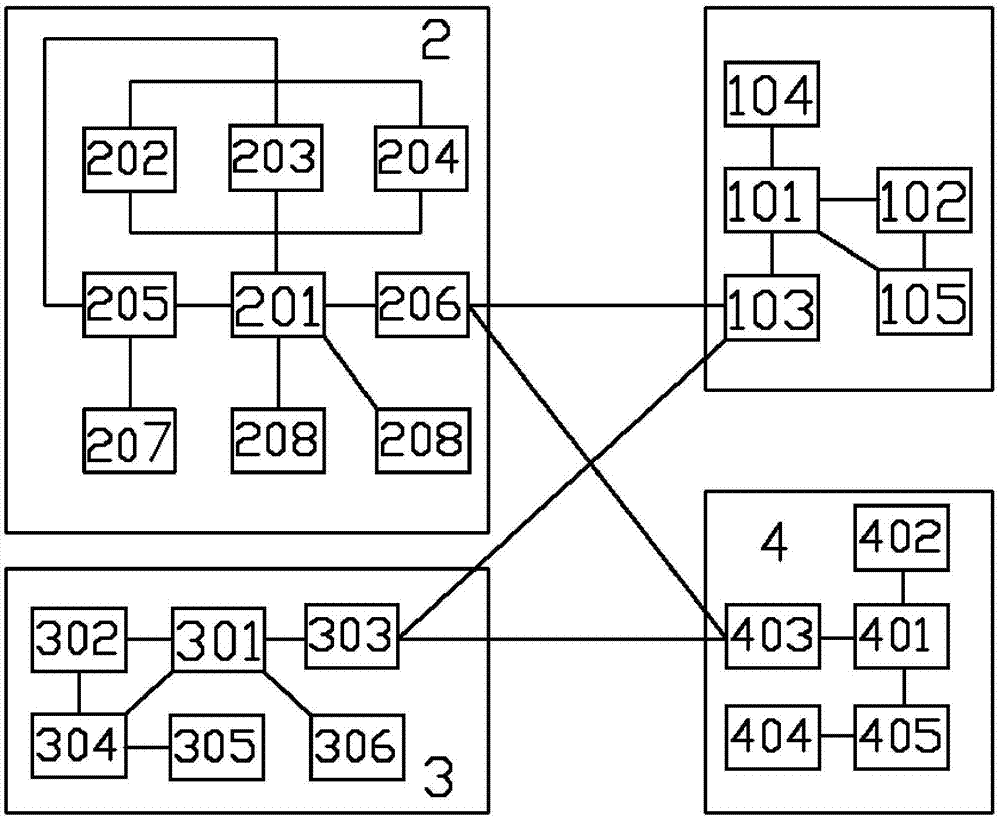

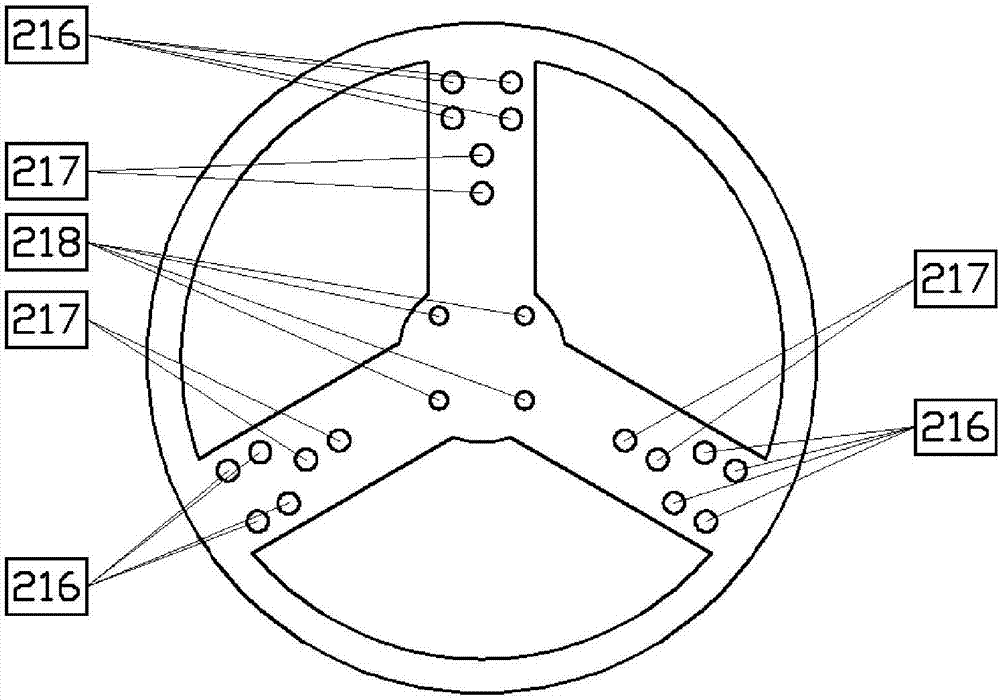

[0029]The invention not only invents a set of attitude monitoring and positioning device in the hoisting process of the workpiece, but also provides a matching method. A device for attitude monitoring and positioning during workpiece hoisting includes a master machine, a slave machine A and a slave machine B. The host 1 includes a microprocessor A, the display module is connected to the SPI interface of the microprocessor A through the SPI bus data line port, and the wireless data transmission module A is connected to the host microprocessor through the UART serial port line, and the host controls the keyboard and GPIO connection for Microprocessor A. The DC stabilized power supply input terminal cab is connected to the power supply pin of the microprocessor A at the vehicle 24V power supply connection output terminal. Main engine 1 is installed in the suitable position of cockpit 5. Microprocessor B is connected with three GPS modules (GPS-A, GPS-B, GPS-C) respectively thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com