Patents

Literature

37results about How to "Advanced technical indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano crystallite composite filter material and supplement of manufacture method thereof

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

Manufacturing technology for high-speed and high-temperature precision deep groove ball bearing

The invention discloses a manufacturing technology for a high-speed and high-temperature precision deep groove ball bearing. A complete set of bearing product is manufactured by processing a forge piece blank into a workpiece billet with an outer ring and an inner ring, then respectively performing technical processes of respective technologies of cold rolling, thermal treatment, coarse grinding, thermal stabilization, fine grinding, grinding and the like, performing inspection and then performing cleaning and assembling. In the cold rolling technique, a cold rolling machine tool is used, a main driving forming rolling wheel is used as an outer die of a mold, and a driven forming mandril is used as an inner die of the mold, so that the forming rolling wheel drives the workpiece billet to rotate, and a supporting wheel pushes the forming mandril to forwards feed and extrude the workpiece billet to roll and form a product; in the thermal stabilization technique, the workpiece subjected to coarse grinding is subjected to heat preservation in a tempering furnace at temperature of 400 DEG C for 4 hours and then is taken out for natural cooling. The limit rotating speed of the complete set of bearing is 12,000 r / min, and the limit working temperature is 160 DEG C; the working noise is less than or equal to 45 dB; the rated load is Cr41.2KN and Cor24KN. The manufacturing precision is high, and the matching performance is high.

Owner:山东鑫兴精密轴承科技有限公司

Firing system gradient combustion self-denitration technological method

ActiveCN108167860ALower concentration levelsGood for burnoutFuel supply regulationIndirect carbon-dioxide mitigationFlue gasEngineering

The invention relates to a firing system gradient combustion self-denitration technological method, and belongs to the technical field of cement industry flue gas denitration. According to the firingsystem gradient combustion self-denitration technological method, a gradient combustion environment with an extreme oxygen deficient area-oxygen deficient combustion area-oxygen enrichment burnout area is formed in a decomposing furnace; the gradient combustion environment is realized through classified feeding of decomposing furnace inlet fuel, tertiary air and decomposing furnace inlet materials; a furnace inlet tertiary air hose is divided into an upper branched pipe and a lower branched pipe, the tertiary air lower branched pipe is fed in from the lower portion of a decomposing furnace cylinder, and the upper branched pipe is fed in from the middle of the decomposing furnace cylinder; the decomposing furnace inlet fuel is divided into two layers and is further fed into the furnace, thelower layer of the fuel is fed in from a decomposing furnace cone, and the upper layer of the fuel is fed in from the decomposing furnace cylinder; the extreme oxygen deficient area refers to the decomposing furnace area located below the tertiary air lower branched pipe; the oxygen deficient combustion area refers to the area located between the tertiary air upper branched pipe and the tertiaryair lower branched pipe; and the oxygen enrichment burnout area refers to the decomposing furnace area located above the tertiary air upper branched pipe. The firing system gradient combustion self-denitration technological method has the advantages that the process is optimized, reliability is good and the flow path is reasonable.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

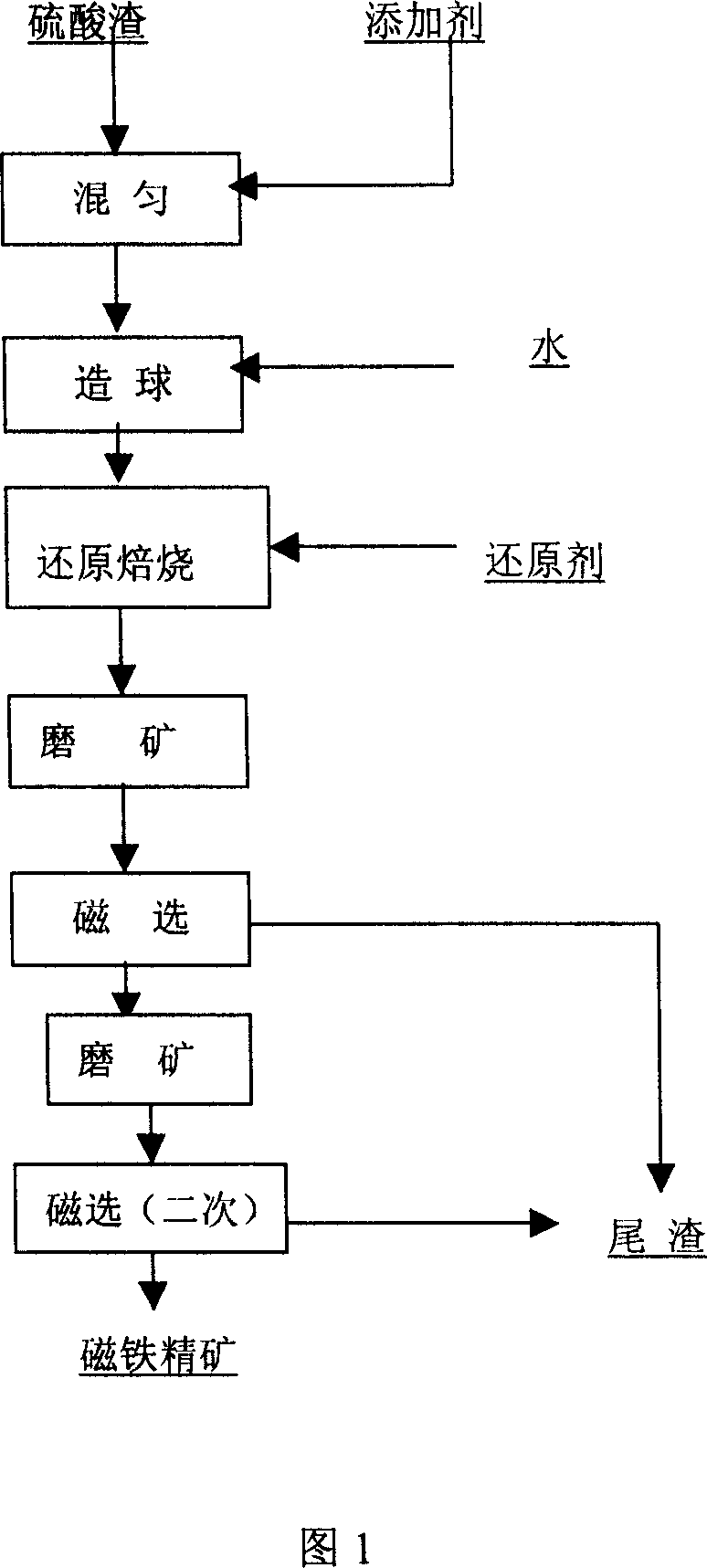

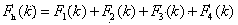

Method of producing high grade magnetic concentrate from sulfuric-acid residue composite pellet

InactiveCN1924034ASimple processAdvanced technical indicatorsProcess efficiency improvementSlagMagnetite

The invention discloses a high-grade magnet concentrate preparing method of sulfuric slag composite ball, which is characterized by the following: adopting reducing sintering method; conversing hematite in the sulfuric slag into magnetic ore; dissolving harmful element (Cu, Zi, S) in the salt; rolling sulfur in the non-magnetic phase or easily soluble sulfate; using wet magnetic cobbing technology to enrich iron; removing the harmful element.

Owner:CENT SOUTH UNIV

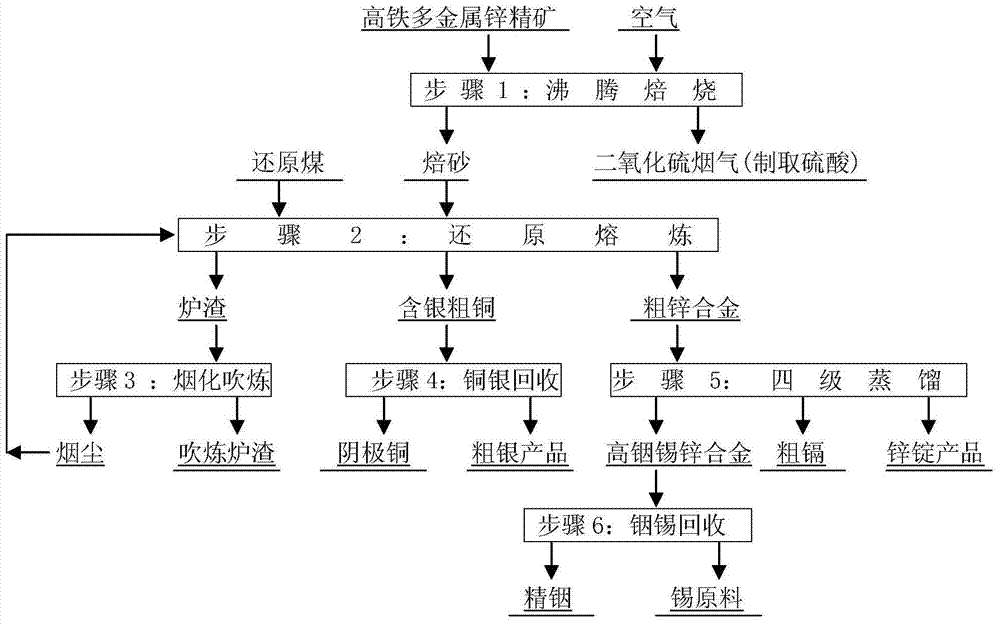

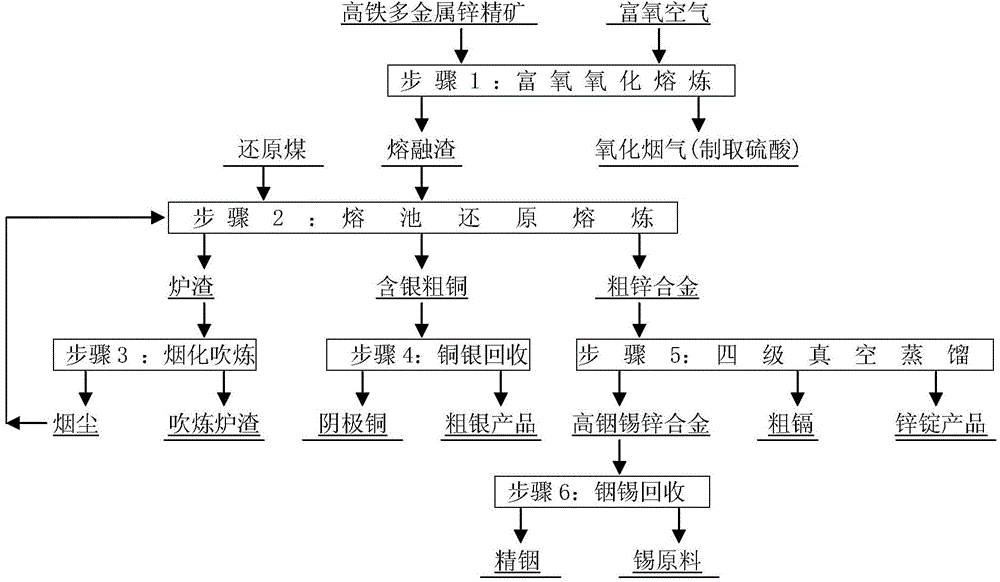

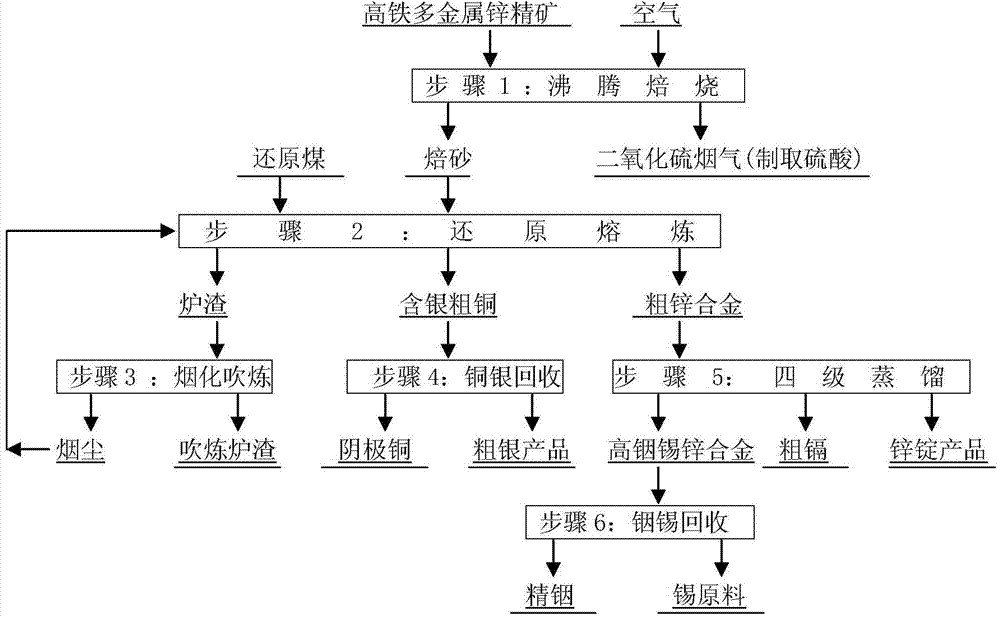

Method for treating high-iron and multi-metal zinc concentrate

ActiveCN103695635AEfficient recyclingAdvanced technical indicatorsPhotography auxillary processesProcess efficiency improvementIndiumSlag

The invention discloses a method for treating high-iron and multi-metal zinc concentrate. The method comprises the following steps of: boiling and roasting zinc concentrate containing 14-20 percent of Fe, 0.03-0.10 percent of In, 0.2-0.6 percent of Cu, 0.2-0.6 percent of Cd, 0.005-0.02 percent of Ag. 0.1-0.2 percent of Sn and 40-50 percent of Zn to produce flue gas and a roasted product; preparing sulfuric acid by using the flue gas; blending the roasted product in a reducing agent to be reduced and smelted to produce a crude zinc alloy, crude silver-containing copper and furnace cinder; blowing the furnace cinder to obtain soot and blown furnace cinder, returning the soot to be reduced and smelted, and selling the blown furnace cinder; extracting copper and silver from crude silver-containing copper; enabling the crude zinc alloy to enter a conventional distillation tower for performing four stages of distillation to produce a pyrogenic process distilled zinc product, a crude cadmium product and a high-indium, tin and zinc alloy; extracting indium and tin from the high-indium, tin and zinc alloy. The method is reasonable in process, good in comprehensive recovery, high in production efficiency, low in product cost, and clean and environment-friendly in production process.

Owner:LAIBIN CHINA TIN SMELTING

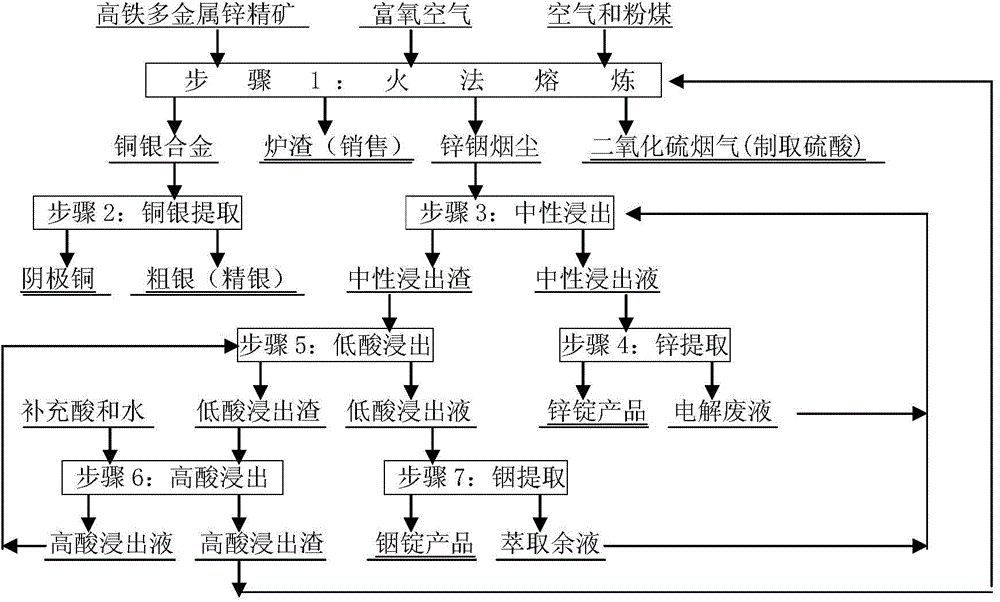

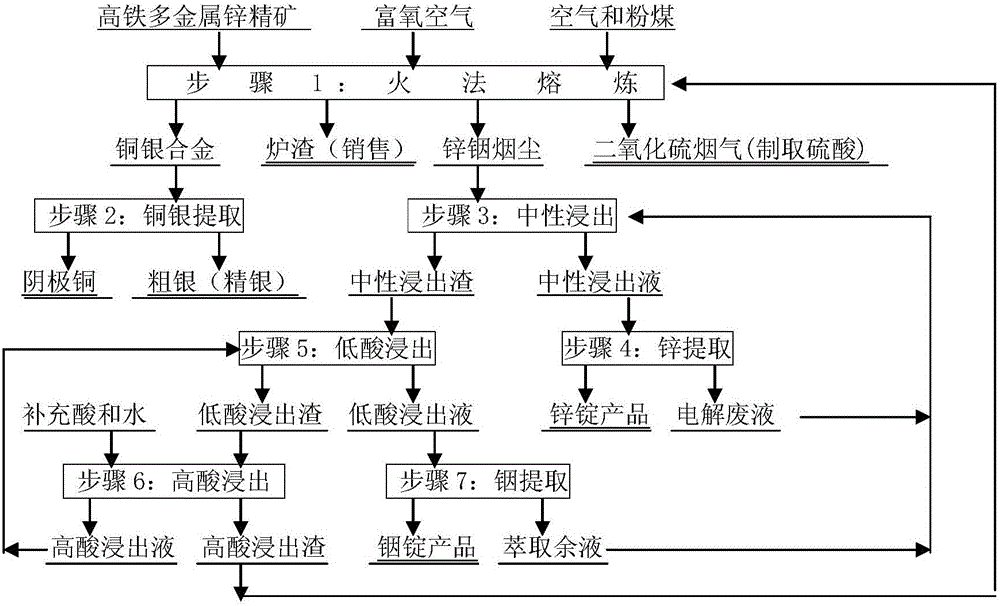

Method and smelting furnace for processing high-iron multi-metal zinc concentrate

ActiveCN104060089AEfficient recyclingAdvanced technical indicatorsPhotography auxillary processesProcess efficiency improvementElectrolysisIndium

The invention relates to a method and a smelting furnace for processing a high-iron multi-metal zinc concentrate. The method comprises the following steps of: adding the zinc concentrate which contains the following components in percentage by weight: 16%-24% of Fe, 0.02-0.40% of In, 0.2%-2.0% of Cu, 0.004%-0.04% of Ag and 36%-48% of Zn to the smelting furnace, successively carrying out three processes including oxygen-enriched oxidation smelting, weak reduction smelting and strong reduction smelting to product sulfur dioxide fume, a copper-silver alloy, smelting slag and zinc-indium smoke dust, wherein the sulfur dioxide fume is used for preparing sulfuric acid, the smelting slag is externally sold, the copper-silver alloy is separated to extract copper and silver, and the zinc-indium smoke dust is subjected to neutral leaching to obtain a neutral leaching solution and neutral leaching residues; producing electrolytic zinc through the neutral leaching solution according to a conventional process; carrying out two-stage acid counter current leaching on the neutral leaching residues to obtain a low-acid leaching solution and high-acid leaching residues; returning the high-acid leaching residues to the smelting furnace for smelting, producing fine indium by using the low-acid leaching solution according to a conventional P204 extraction process, and returning extraction raffinate to neutral leaching. The method disclosed by the invention has the advantages of short process flow, high production efficiency, low production cost, good integrated recovery and clean and environment-friendly production process.

Owner:LAIBIN CHINA TIN SMELTING

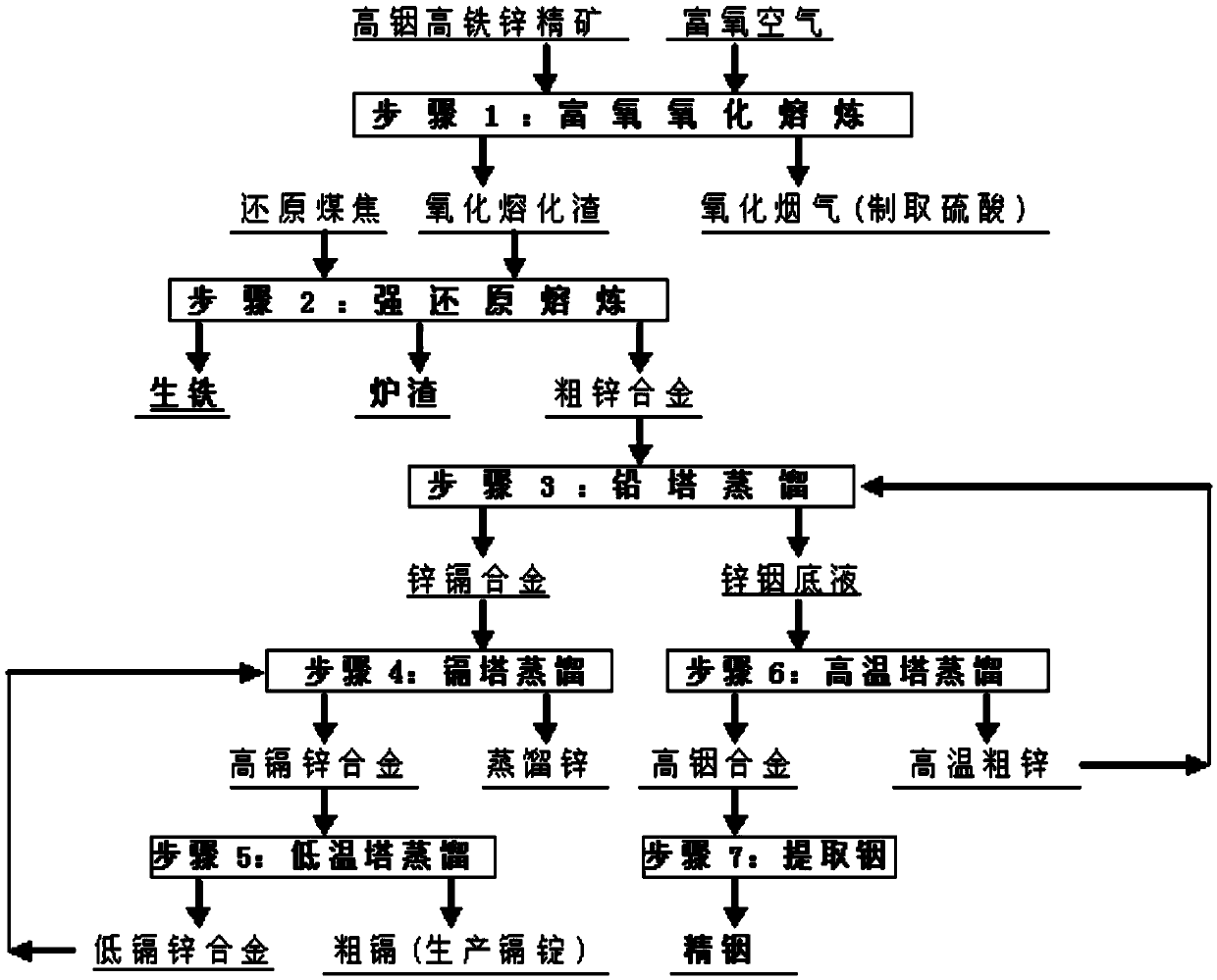

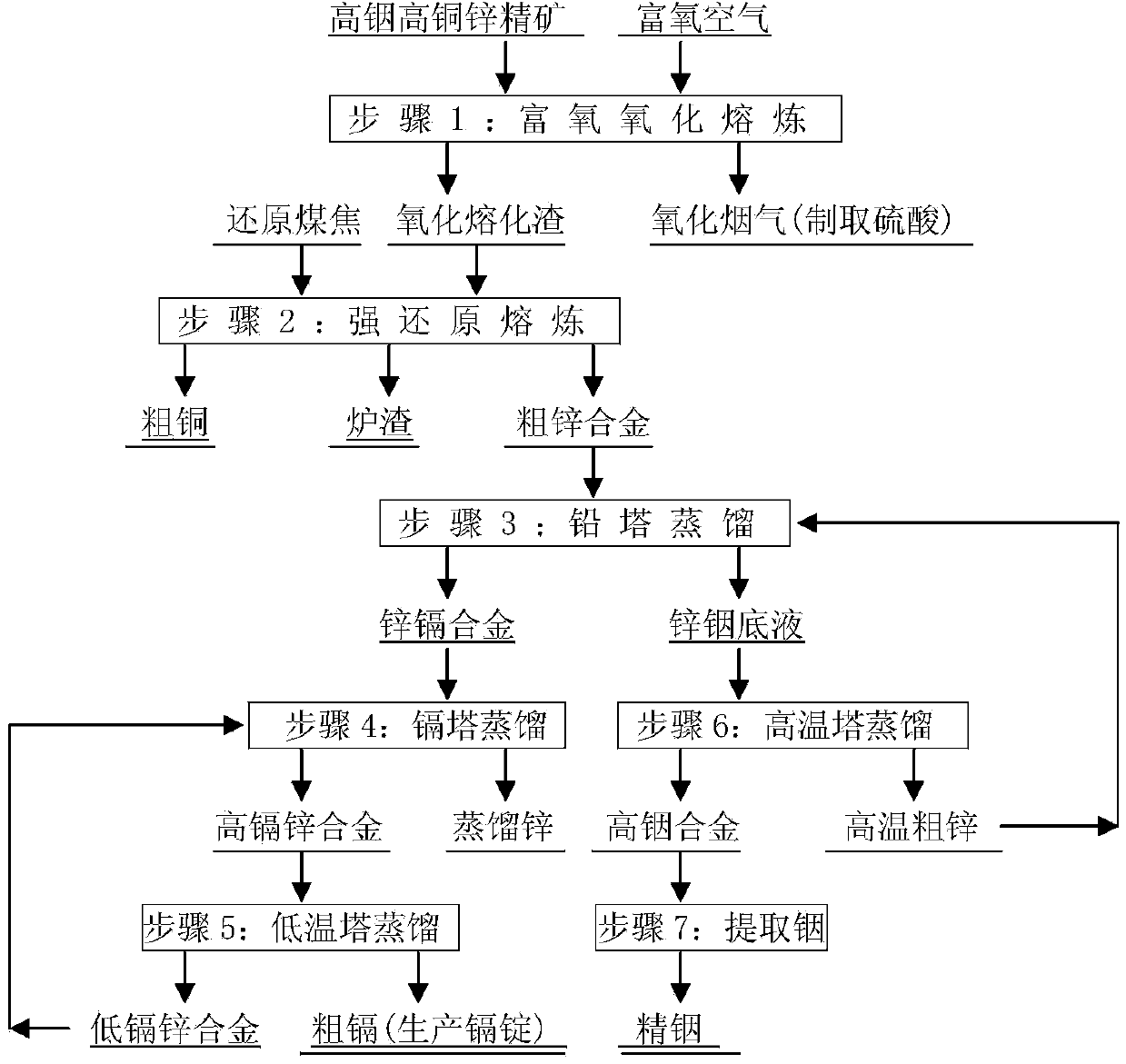

Method for processing zinc concentrate with high content of indium and iron

The invention discloses a method for processing zinc concentrate with high content of indium and iron. The method comprises steps of carrying out oxygen-enriched oxidizing smelting on the zinc concentrate so as to generate oxidized smoke and fused slag, preparing sulfuric acid through the oxidized smoke; allowing the fused slag to enter a reducing smelting furnace with a lead rain condenser for strong reduction smelting so as to generate crude zinc alloy, pig iron and slag; allowing the crude zinc alloy to enter a lead tower for distilling so as to generate a zinc-cadmium alloy and a zinc-indium base solution; allowing the zinc-cadmium alloy to enter a cadmium tower for secondary distilling so as to produce pyrogenic process distilled zinc and high cadmium-zinc alloy; casting and cooling down the pyrogenic process distilled zinc so as to obtain a zinc ingot product, distilling the high cadmium-zinc alloy in a low temperature tower so as to obtain crude cadmium and a low cadmium-zinc alloy, returning the low cadmium-zinc alloy back to the cadmium tower for distilling; distilling the zinc-indium base solution in a high temperature tower so as to generate a high indium alloy and high temperature crude zinc, returning the high temperature crude zinc back to the lead tower for distilling, and extracting indium from the high indium alloy through steps of 'crushing-leaching-extracting-replacing-electrolyzing'. The method has short technological processes and high production efficiency, has clean and environment-friendly production process, and does not discharge three wastes.

Owner:CENT SOUTH UNIV

Moving type hangar

InactiveCN103850510AThe technical scheme of the mobile hangar is scientific and reasonableThe preparation process is simple and reliableParkingsManufacturing technologyPolyvinyl chloride

The invention discloses a moving type hangar, which comprises three parts of end doors, a middle main body and an accessory. The main structure of the moving type hangar disclosed by the invention adopts the modular design; the whole hanger comprises end door modules distributed on two ends of the hangar, and multiple groups of middle main body modules, wherein the end of each group of module is provided with a port; except that the end door position is fixed, the rest modules of the hangar can be subjected to unordered mutual connection. The manufacture material of the main structure of the moving type hangar is selected from one or multiple types of PVC (polyvinyl chloride) membrane material, TPU (thermoplastic urethanes) membrane material, EVA (ethylene vinyl-acetate) membrane material, acrylic ester membrane material, neoprene membrane material, butadiene styrene rubber membrane material, ETFE (ethyl tetra fluoro ethylene) membrane material, PVDF (polyvinylidene fluoride) membrane material, PTFE (polytetrafluoroethylene) membrane material and PVF (polyvinyl fluoride) membrane material. The moving type hangar is erected with an inflation method, each group of modules can be respectively curly packaged after venting, and the moving type hangar has the advantages of strong maneuverability, simple operation process, stable and reliable performance, advanced technical index, scientific structural design, cheap and abundant raw materials and mature manufacture technology and is suitable to popularize and apply within a large range in the industry.

Owner:北京云创太和科技有限公司

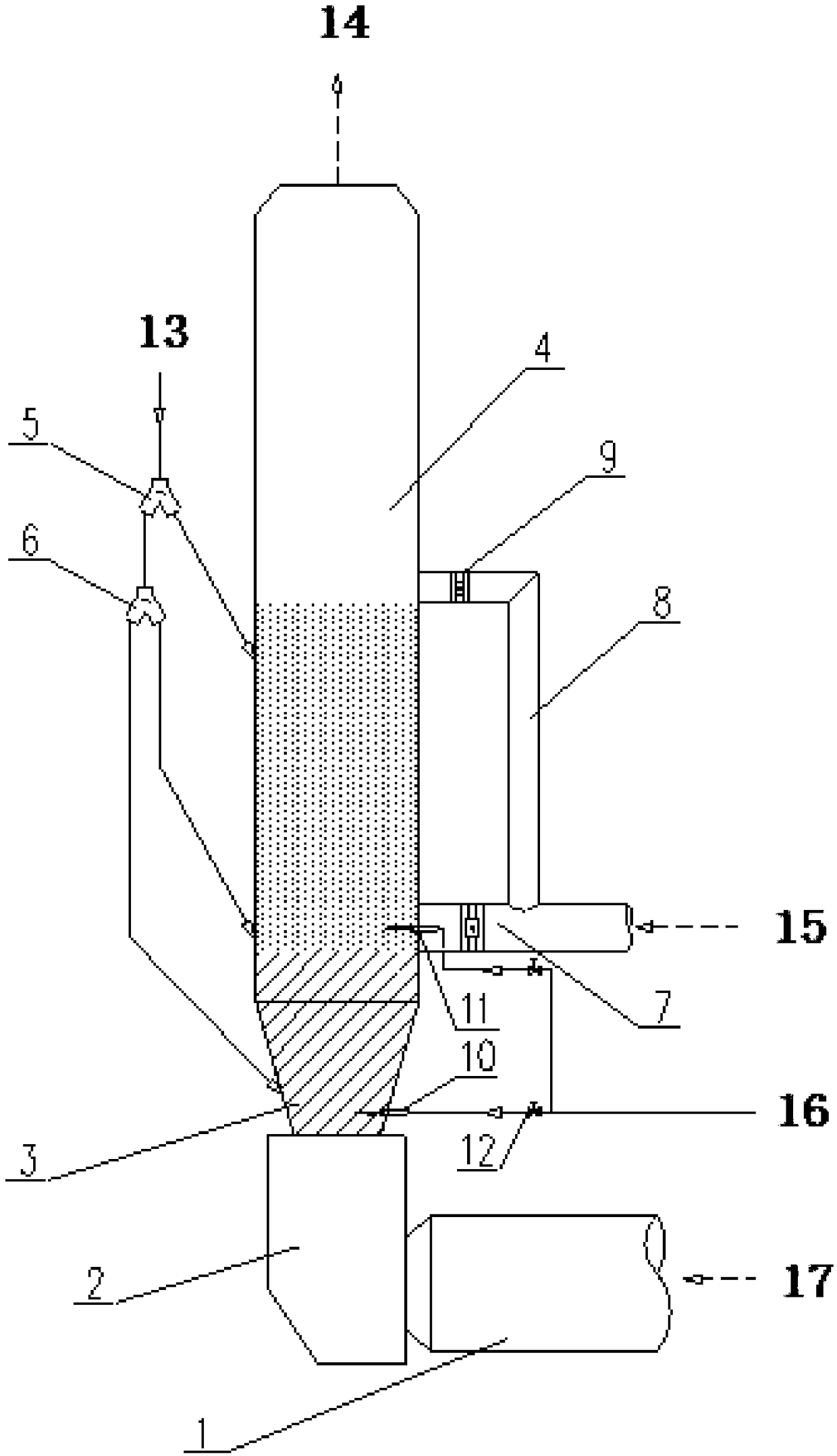

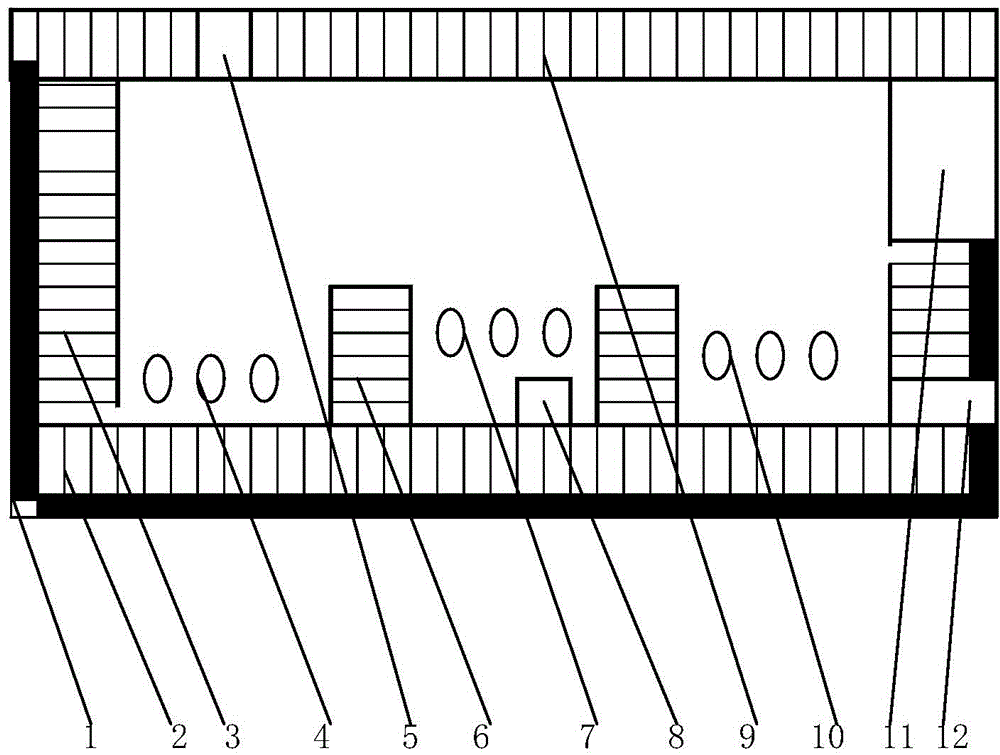

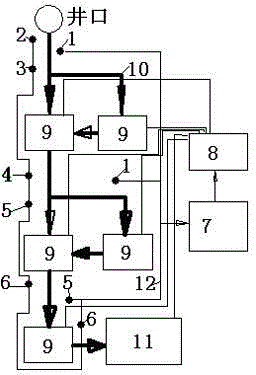

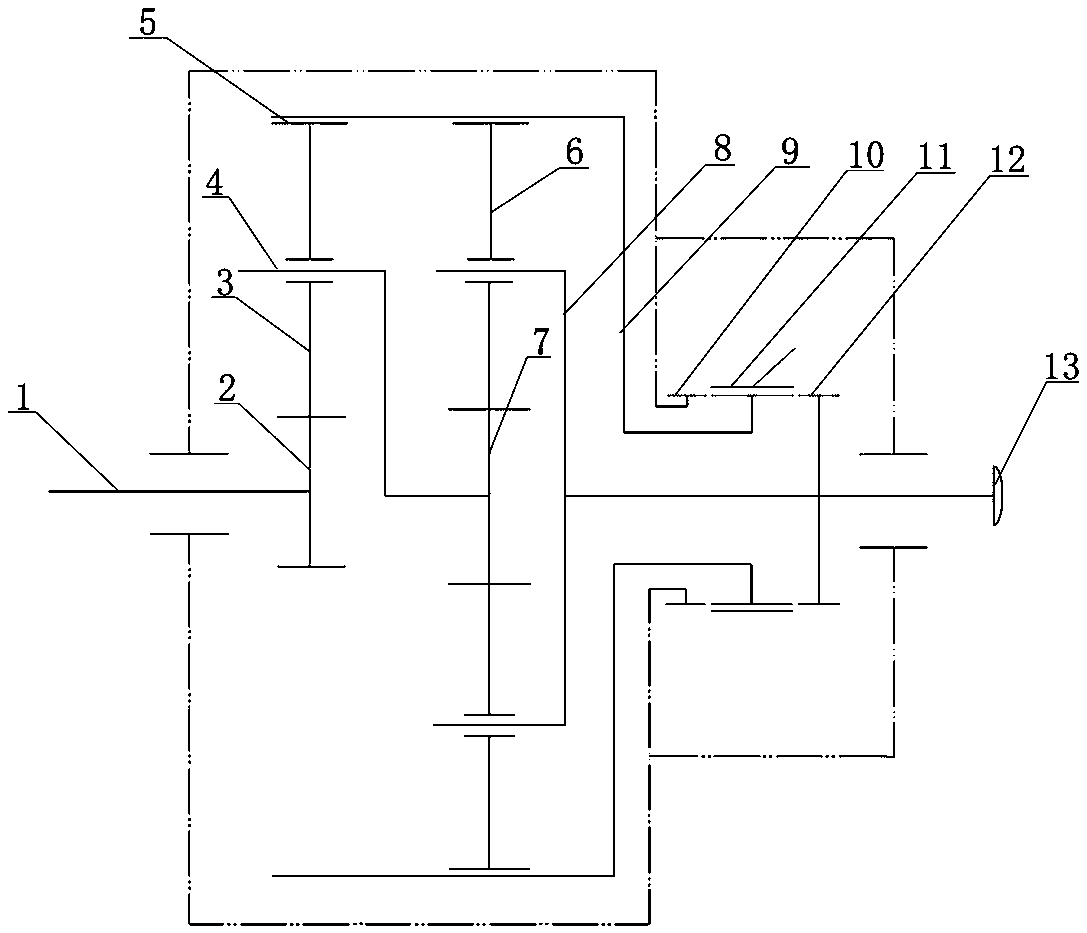

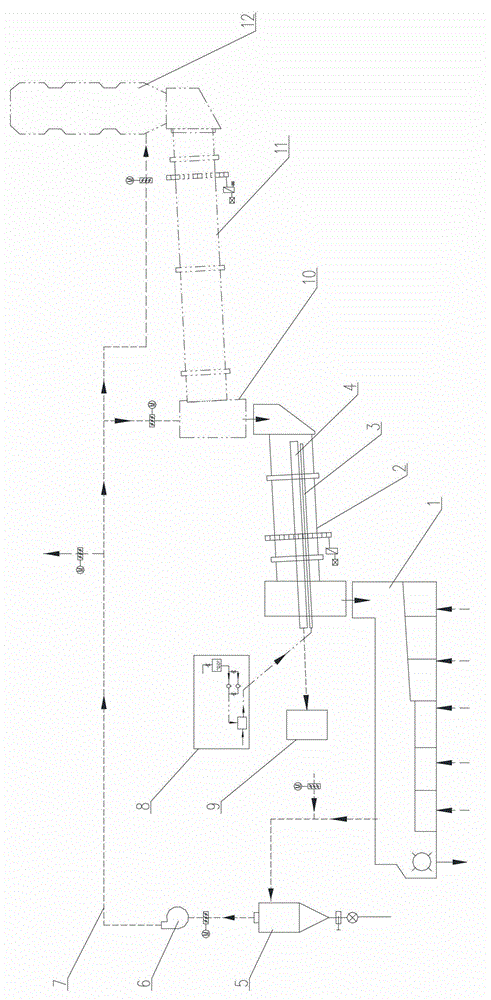

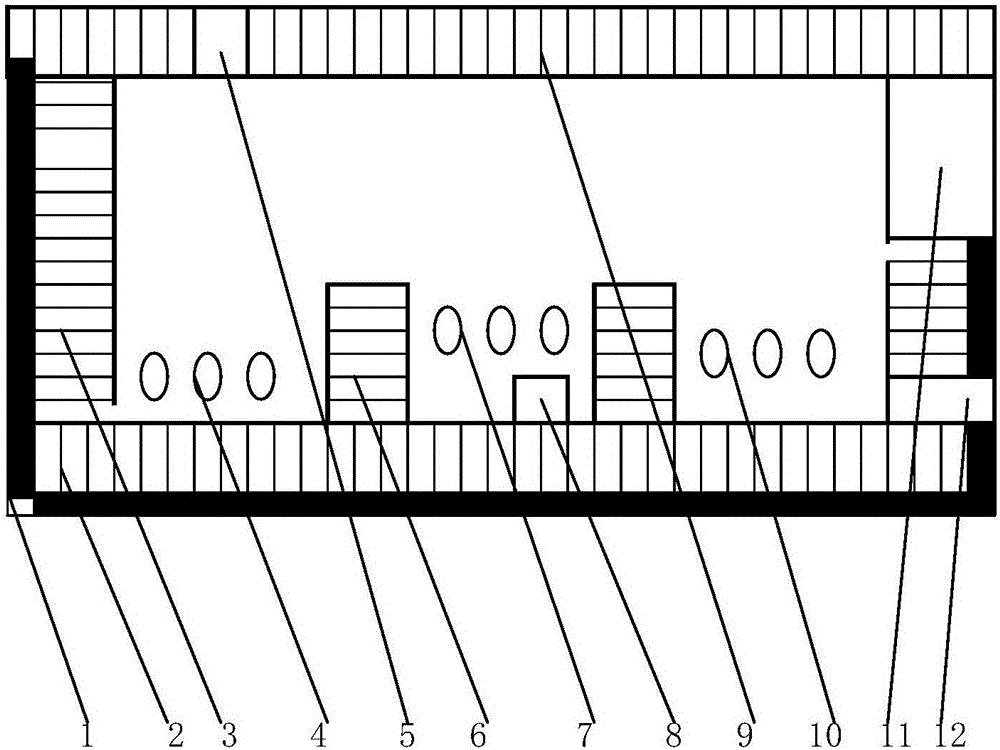

Intelligent drill rig solid control system

The invention discloses an intelligent drill rig solid control system. The intelligent drill rig solid control system comprises a visual camera (1), an air sensor (2), a temperature sensor (3), a pressure sensor (4), a slurry granularity sensor (5), a slurry viscosity sensor (6), a PLC (7), an electronic switch (8), a solid control device (9), a conveyor belt (10), a storing tank (11), a connecting cable (12) and other devices. According to the intelligent drill rig solid control system, intelligent automatic and unmanned mining is the development direction of a drill rig well site solid control system and is also an effective way to ensuring the working safety of a working surface.

Owner:HUANGSHI KEXING ELECTROMECHANICAL SCI & TECH

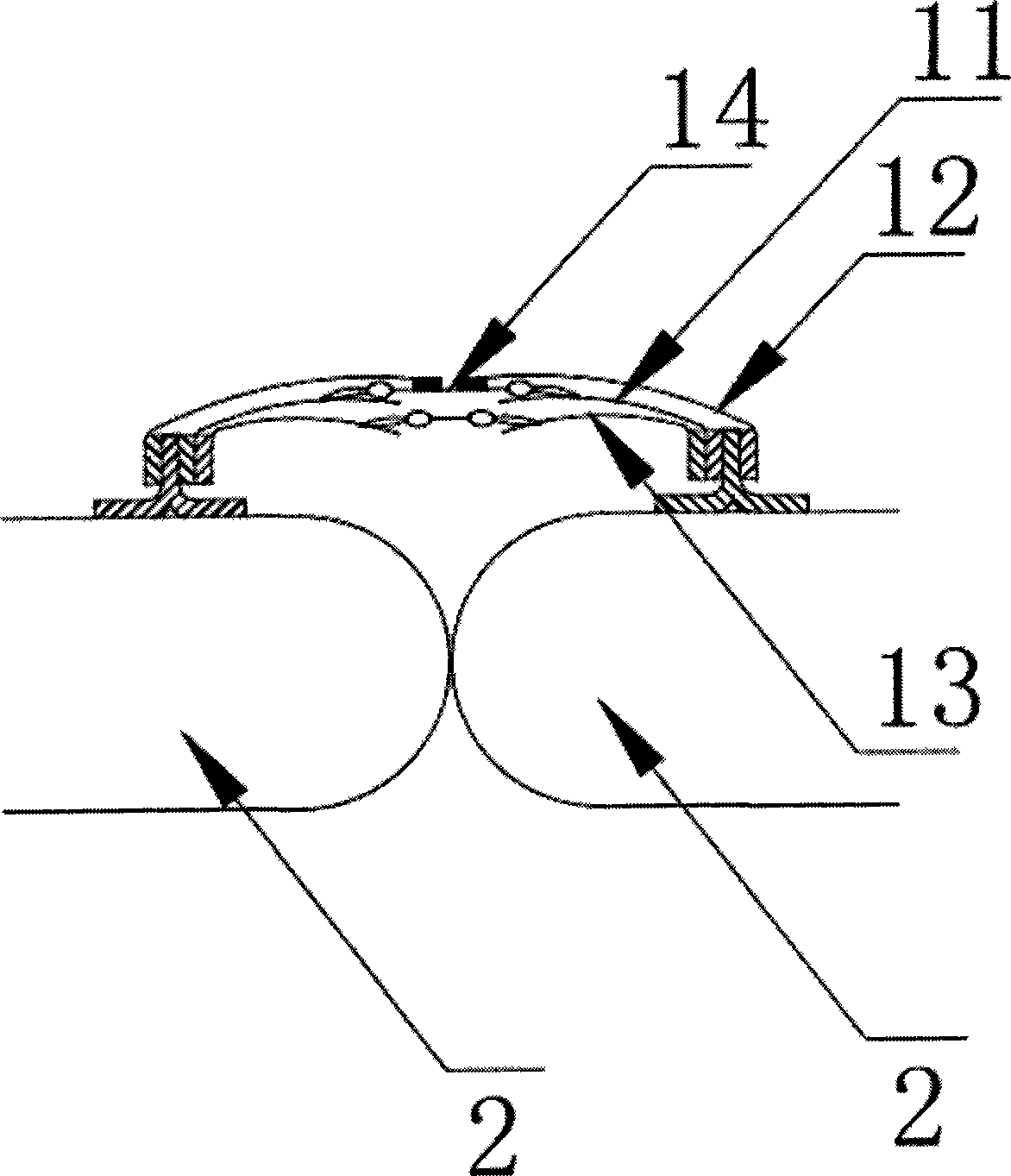

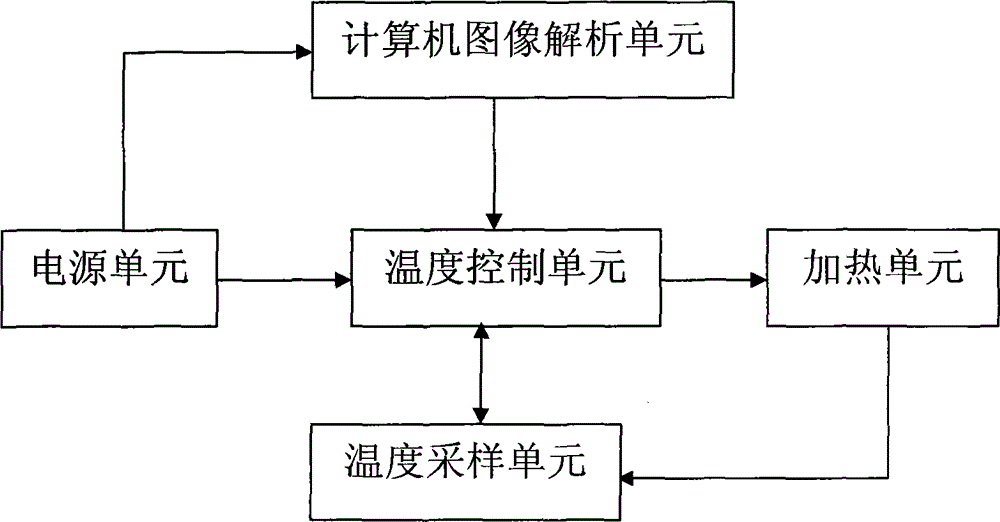

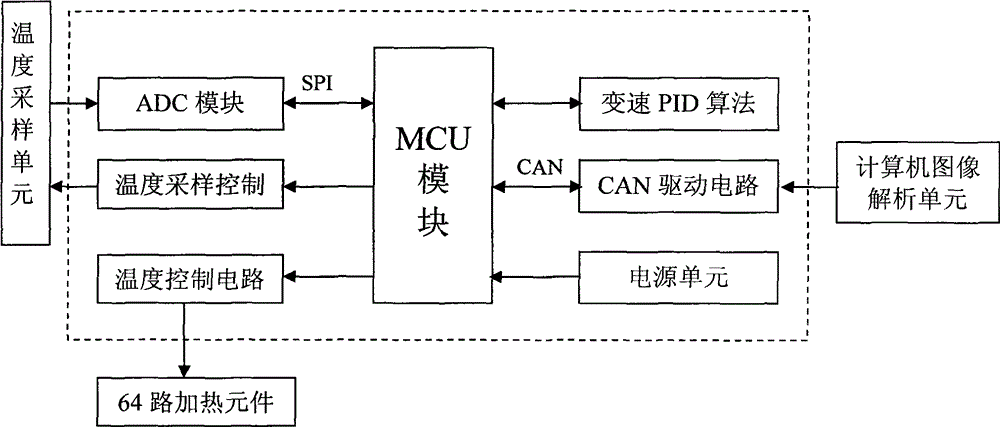

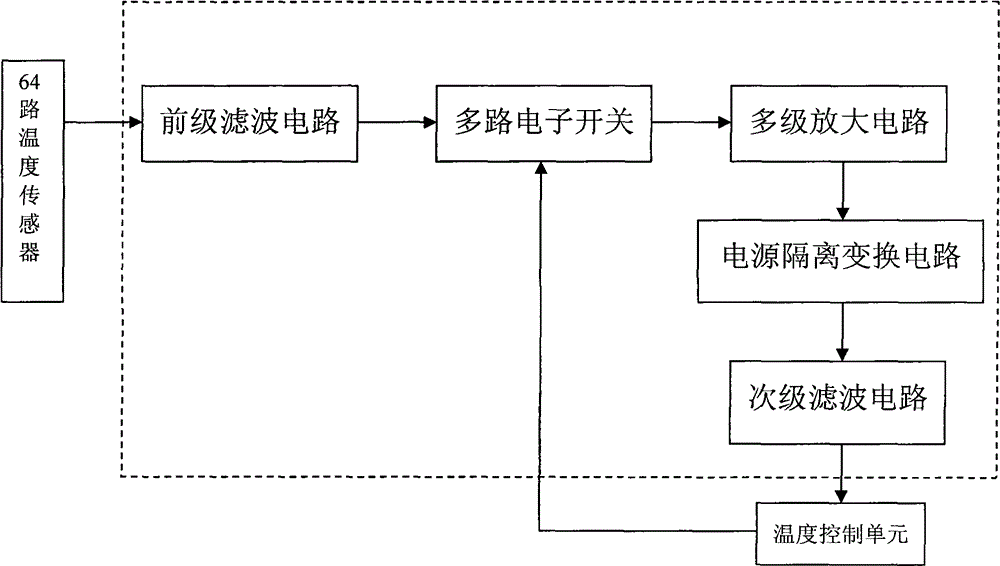

Middle-far-infrared image simulation device

InactiveCN104952057AAdvanced technical indicatorsSimulation is accurate and effectiveImage analysisSimulator controlTemperature controlData information

The invention relates to a middle-far-infrared image simulation device. The device comprises a power unit, a heating unit, a temperature control unit, a temperature sampling unit, and a computer image analysis unit. The heating unit is disposed in a rubber slab provided with a circular iron sheet in an inset manner. The above units are connected with each other through wires. The computer image analysis unit is used for the analysis of an infrared image led into a system, and enables the analyzed data information to be transmitted to the temperature control unit. The temperature control unit carries out the heating control of the heating unit according to the obtained data information, and determines the turning-on of one electronic switch in the temperature sampling unit to carry out temperature detection. Afterwards, the temperature sampling unit can enable the induced miniature signal to be transmitted to the temperature control unit, thereby finally achieving a purpose that the temperature control unit achieves the control of the heating unit according to the data information analyzed by the computer image analysis unit, and completing the projection of the infrared image. The device is reasonable in design, is advanced in idea, and is adapted to wide application.

Owner:北京云创太和科技有限公司

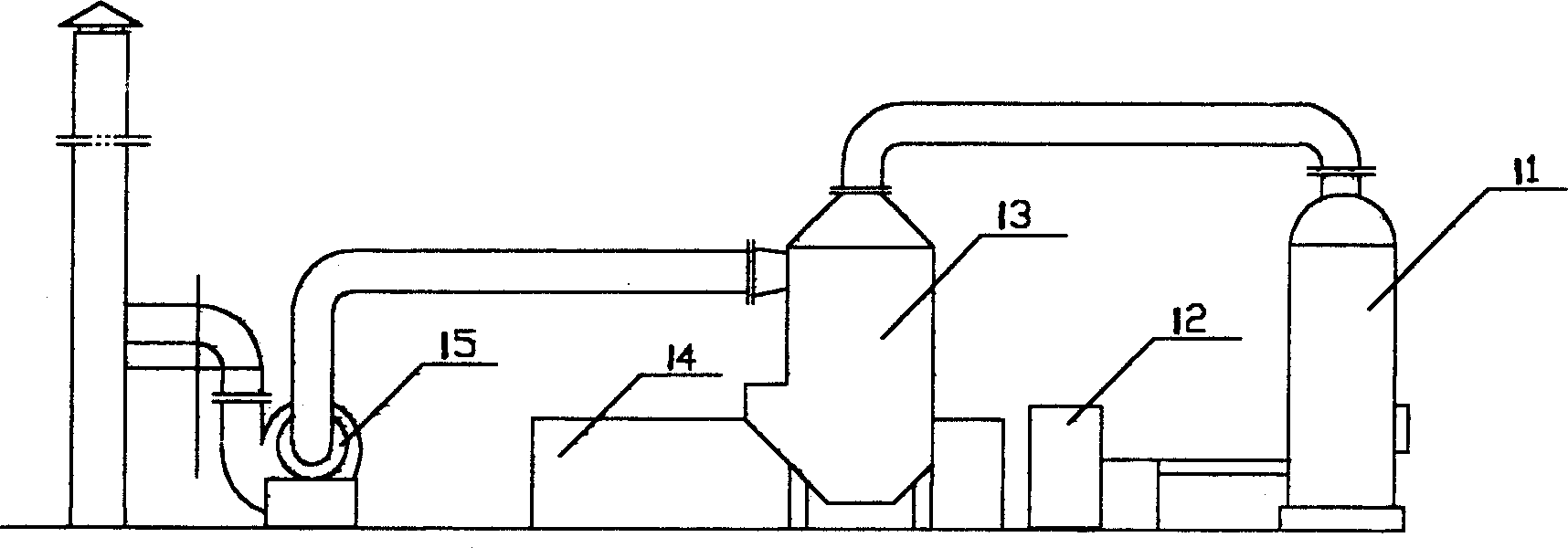

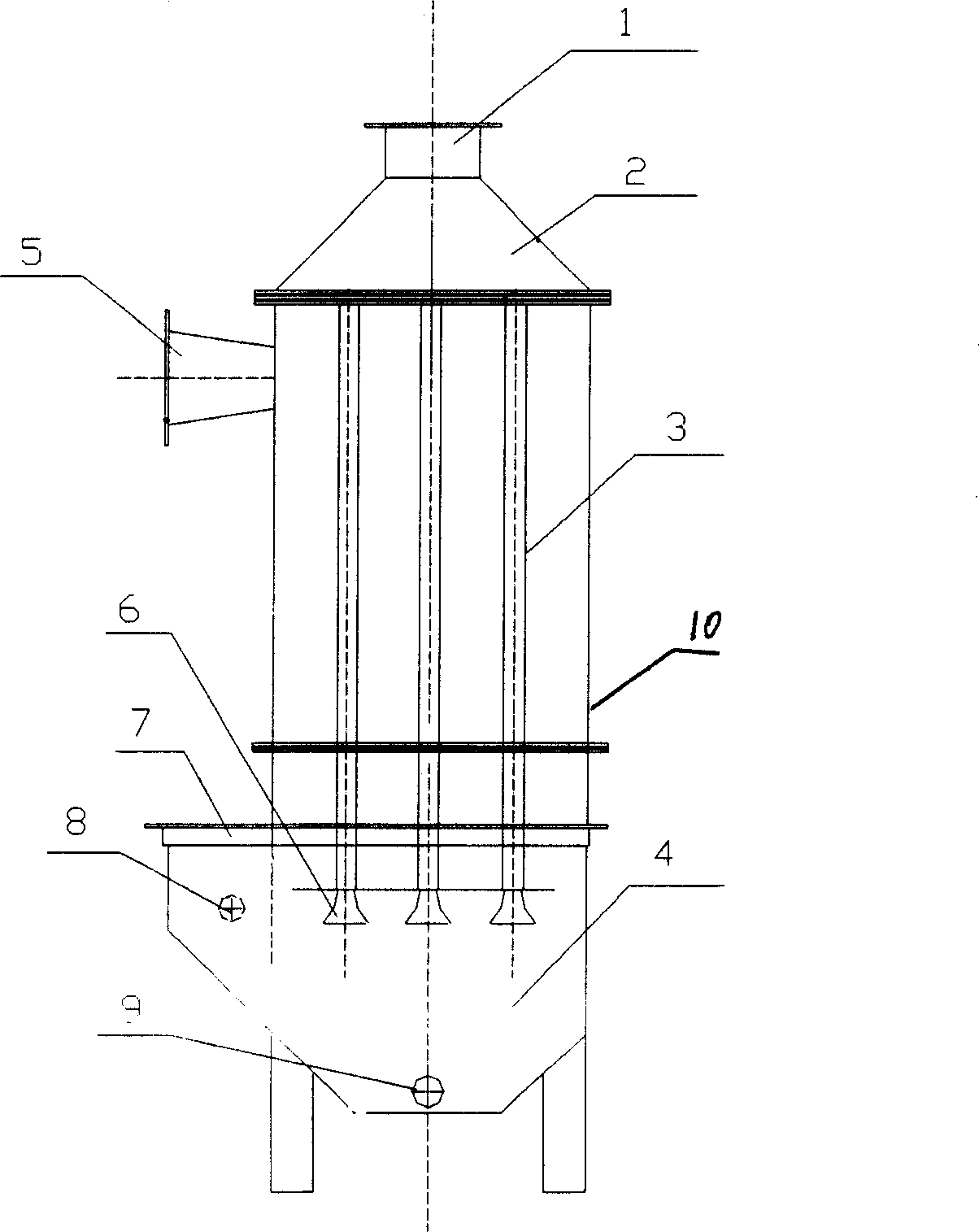

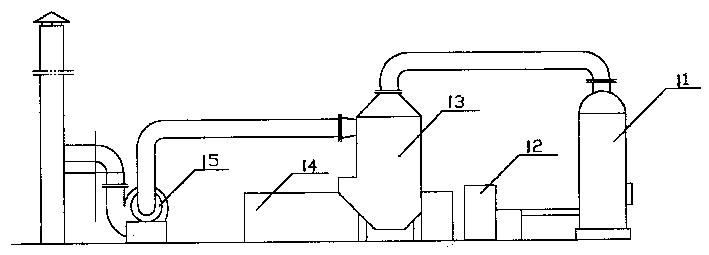

Fuel coal furnace exhaust gas calcium water bath spraying composite desulfurizing process and its special equipment

InactiveCN1493390AEasy to operateAdvanced technical indicatorsDispersed particle separationWater bathsCombustion

A process for desulfurizing the fume of coal-burning furnace by spraying calcium and water bath features that the desulfurizing medium is sprayed into high-temp region in combustion box, where it is burning and takes part in desulfurizing reaction, the resultant along with unreacted lime stone, calcium oxide and flyash, and the fume come in water bath to generate alkaline slurry for absorbing SO2, and the resultant, flyash and deposit in water pool are discharged. Its apparatus is composed of boiler, Ca spraying system, water bath cleaner, circulating water system, and draught fan.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Manufacturing technology of high-speed high-temperature precise deep-groove ball bearing

InactiveCN108044310AHigh precisionQuality improvementBearing componentsManufacturing technologyBall bearing

The invention discloses a manufacturing technology of a high-speed high-temperature precise deep-groove ball bearing. The manufacturing technology comprises the steps that a forging blank is machinedinto a workpiece blank with an outer ring and an inner ring, the workpiece blank is subjected to the technological process of technologies such as cold rolling and expanding, heat treating, rough grinding, heat stabilizing, fine grinding and grinding, checked and then subjected to the technological process of a cleaning and assembling technology, and a whole-set bearing product is manufactured; the cold rolling and expanding technology comprises the steps that a cold rolling and expanding machine tool is adopted, a driving molding rolling wheel serves as a mold outer mold, a driven molding core rod serves as a mold inner mold, the molding rolling wheel drives the workpiece blank to rotate, a supporting wheel pushes the molding core rod to move forwards to feed and extrude the workpiece blank, and rolling and expanding molding is achieved; the heat stabilizing technology comprises the steps that heat preservation is conducted on a workpiece obtained after rough grinding for 4 hours at 400 DEG C in a tempering furnace, and the workpiece is taken out of the furnace and naturally cooled; and for the whole-set bearing, the limit rotation speed is 12,000 r / min, the limit working temperature is 160 DEG C, the working noise is lower than or equal to 45 dB, and the rated load is Cr 41.2 KN and Cor 24 KN. According to the manufacturing technology of the high-speed high-temperature precise deep-groove ball bearing, the manufacturing precision is high, and the matching performance is good.

Owner:余姚市奥祥轴承有限公司

Production process of white cement

The invention discloses a white cement clinker bleaching process. The white cement clinker bleaching process comprises the following steps: breaking raw materials, then preparing raw material, mixingthe raw material, then firing, immersing and bleaching in water, drying clinker, milling cement to obtain white cement. The raw meal used for roasting are prepared by mixing the broken raw materials,then carrying out closed-loop raw meal milling with cooperation of a high-chromium vanadium titanium ball mill and a powder concentrator. Compared with the existing cement process, the heat consumption of unit of clinker of a roasting system can be reduced 80-120kcal in per kg of clinker. The white cement clinker bleaching process is taken as a process with latest white cement clinker bleaching technology, optimal process and lowest energy consumption at home and abroad at present; the white cement clinker bleaching process is reasonable in processes, environment-friendly in design concept andadvanced in technical indexes, meets the national energy economization and environment protection trend, can reduce the production costs of enterprises, and has extremely high operability and practicability.

Owner:江苏兆佳建材科技有限公司

Smelting method of high-iron multi-metal zinc concentrate

ActiveCN103695663BReduce lossesEfficient recyclingPhotography auxillary processesProcess efficiency improvementIndiumDistillation

The invention relates to a smelting method of a high-iron multi-metal zinc concentrate. The method comprises the following steps: performing oxygen-enrichment oxidation melting on a zinc concentrate containing 14% to 20% of Fe, 0.03% to 0.10% of In, 0.2% to 0.6% of Cu, 0.2% to 0.6% of Cd, 0.005% to 0.02% of Ag, 0.1% to 0.2% of Sn and 40% to 50% of Zn so as to generate an oxidized flue gas and molten slags; preparing the oxidized flue gas into sulfuric acid; performing reduction smelting on the molten slags in a smelting pool so as to generate a crude zinc alloy, crude copper containing silver and slags; blowing the slags so as to obtain smoke dust and blown slags; returning the smoke dust to be subjected to reduction smelting; selling the blown slags in a market; extracting the copper and the silver from the crude copper containing silver; and performing four-stage distillation on the crude zinc alloy entering an electric-heating graphite vacuum furnace so as to generate a pyrogenic distilled zinc product, a crude cadmium product and a high-indium-tin zinc alloy which is used for extracting indium and tin. The method is reasonable in process, good in comprehensive recovery, high in production efficiency, low in production cost and clean and environmentally friendly in production process.

Owner:LAIBIN CHINA TIN SMELTING

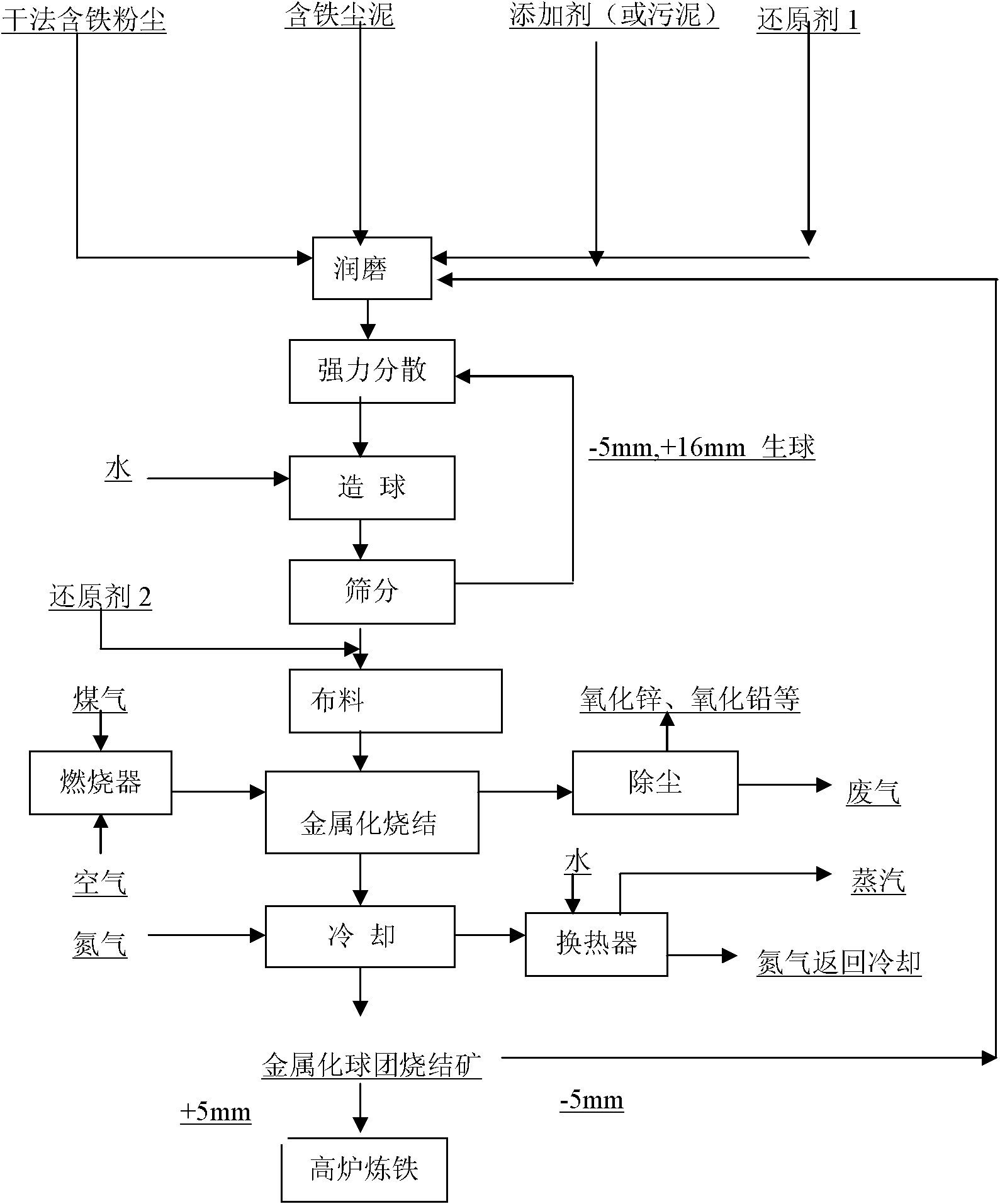

Comprehensive utilization process of zinc-containing iron dust

ActiveCN102534199BSimple processAdvanced technical indicatorsProcess efficiency improvementSludgeNitrogen gas

The invention relates to a comprehensive utilization process of zinc-containing iron dust. The process comprises the steps of: uniformly mixing iron-containing dust mud, iron-containing dust, carbon-containing sludge, pyrite residue, first reducing coal and an additive, and carrying out moist grinding, pelletizing and screening to obtain qualified raw pellets; and then uniformly mixing the raw pellets with second reducing coal, carrying out downdraught drying and reduction roasting on a pellet sinter roasting machine to finish sintering of metallized pellets, carrying out nitrogen cooling to room temperature, and discharging to obtain the metallized pellet sintered ore. According to the invention, the process method is simple and convenient for operation; aiming at the characteristics of the zinc-containing iron dust in steel mill, high-efficiency utilization of iron, zinc, carbon and other valuable elements is realized by pelletizing and metallized roasting, and at the same time, harmful elements are removed and secondary pollution is eliminated; at the same time of removing the harmful elements, the zinc-containing iron dust is prepared into metallized pellet sintered blocks, and iron has high grade and low content of zinc, sulfur and other harmful elements, and can be used as a high-quality raw material to be directly entered into a blast furnace for smelting, therefore, the comprehensive utilization process plays an effect of reducing coke and increasing yield on the blast furnace and has significant economic benefits.

Owner:CENT SOUTH UNIV +1

Waterproof coating

InactiveCN107201091AQuality improvementAdvanced technical indicatorsChloropene polymer coatingsAnti-corrosive paintsAdhesiveNeoprene

A waterproof paint, including adhesive, reflective material, additives, etc., the adhesive is selected from neoprene, and the reflective material is selected from silver powder paste. The waterproof paint of the invention has excellent waterproof function and obvious effect of high and low temperature resistance. The invention is mainly used for the surfaces of buildings and various objects, and the construction is simple, time-saving and labor-saving, without curing and without gasification pollution.

Owner:高仁丽

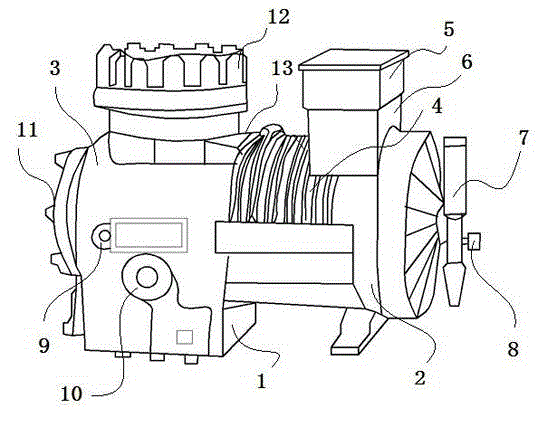

Semi-hermetic refrigeration compressor

InactiveCN105604877AHigh degree of generalizationImprove performancePositive displacement pump componentsPump controlRefrigeration compressorLow noise

The invention relates to a semi-hermetic refrigeration compressor, which comprises a shell, a motor, a cylinder, a piston, control equipment and a cooling system, wherein the control equipment comprises a starter and a thermal protector, and a suction line valve is arranged at one end of the shell; a low-pressure screw plug is arranged on the suction line valve, and an oil filling port is formed in the cylinder; an oil level lens is arranged at the lower end of the oil filling port, and an oil heater jointis arranged at one side of the oil level lens; a high-pressure screw plug is also arranged on the cylinder, and a discharge line valve is arranged at one side of the high-pressure screw plug. After the whole equipment assembly is finished, the compressor has the advantages of high performance, advanced technical indicators, reasonable structure, small size, light weight, low noise, high degree of universality of parts, and smooth operation; the motor adopts inhaled steam cooling, the overload capacity is large, and the durability is high; the service life of the compressor is 50,000 hours, the mean running time without failures is 12,000 hours, and the reliability is high. The product can be widely matched with various climatic environment equipment, refrigeration and freezing equipment, ice cream machines and other cold drink food machinery equipment.

Owner:夏振宇

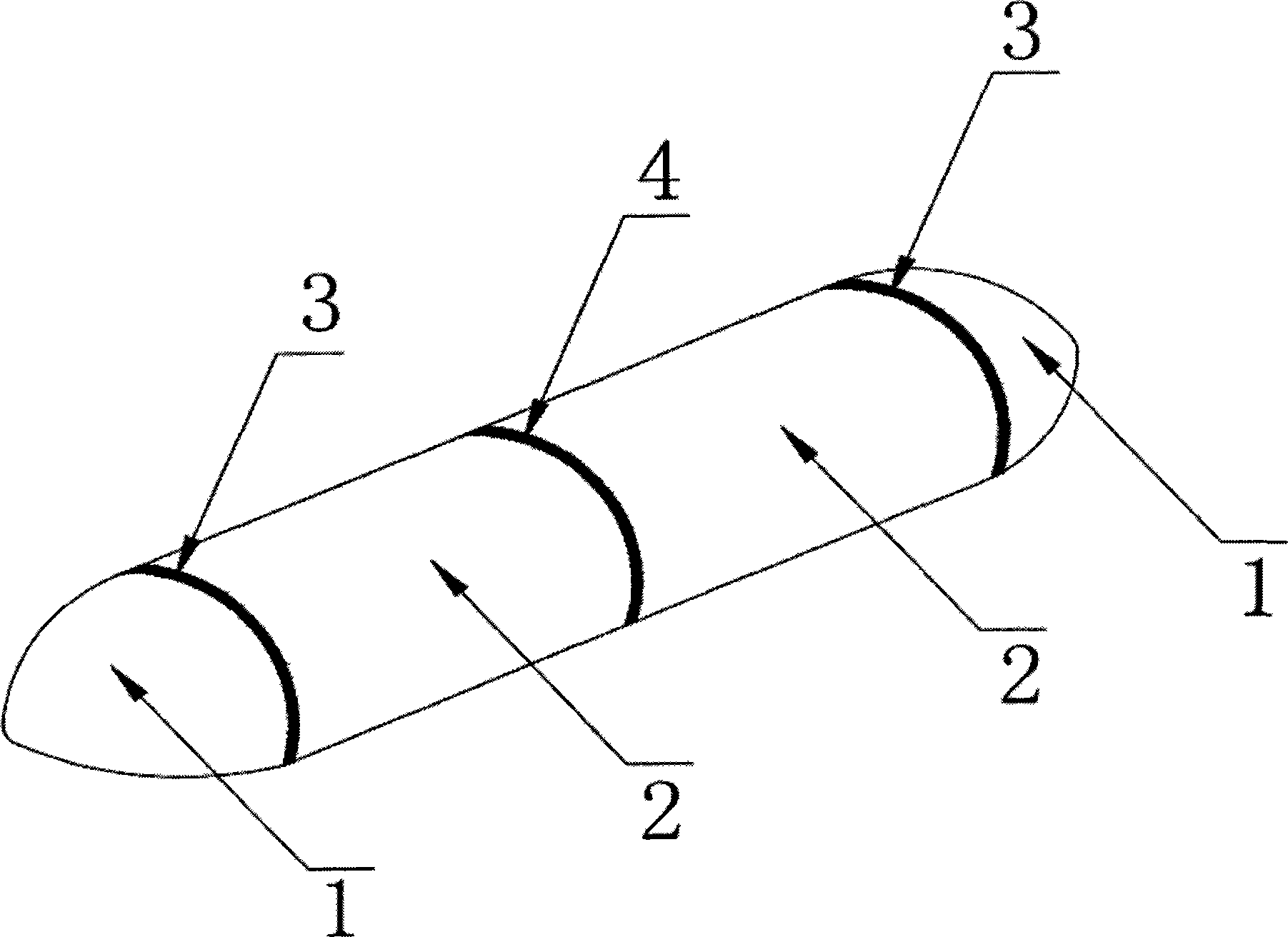

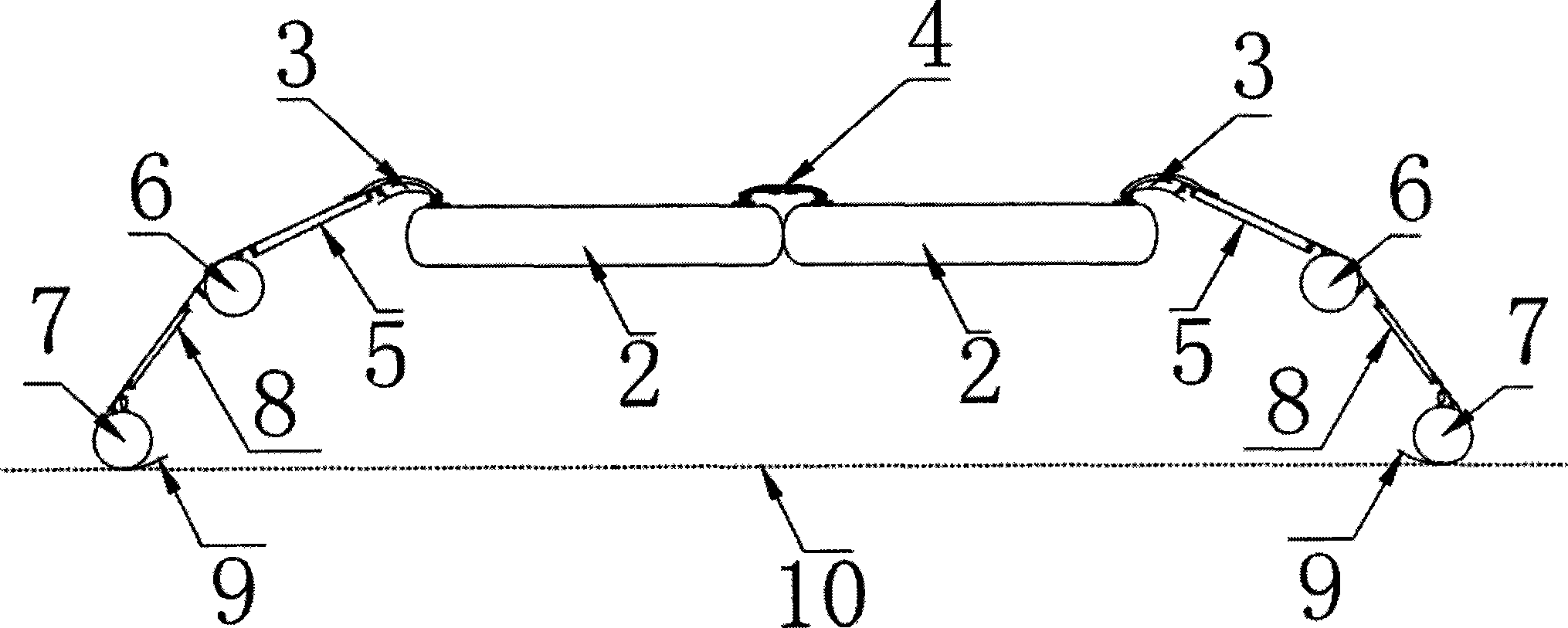

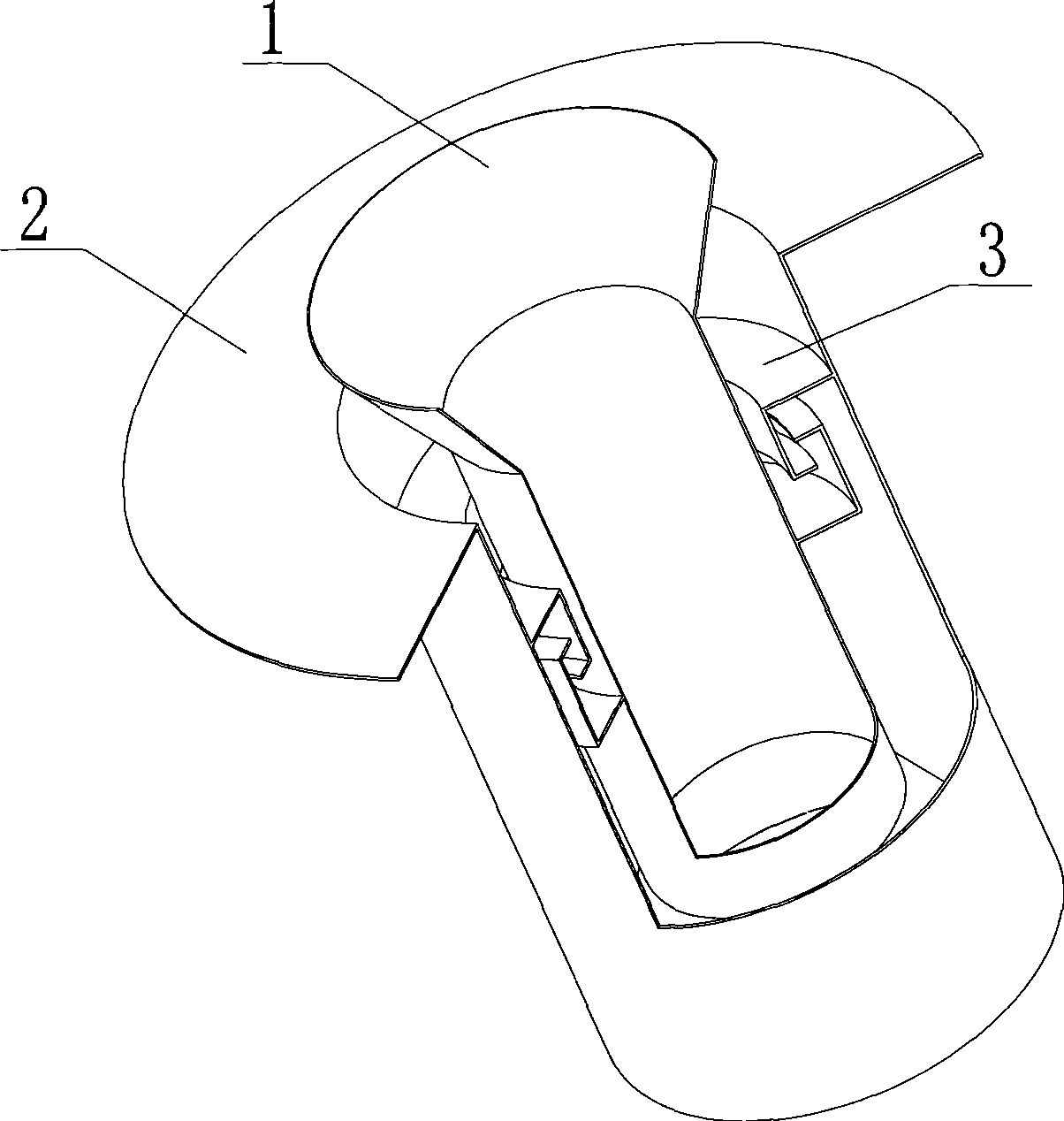

Liquid surface sealing of clip-shaped slot structure

InactiveCN101520113AUnique designNovel structureFluid pressure sealed jointsEngineeringMechanical engineering

The invention relates to a liquid surface sealing device of a clip-shaped slot structure and belongs to the field of environmental protection. Gap connection in the form of the clip-shaped slot structure is adopted between an inverted funnel pipe opening of a fixed element and a pipe opening of a rotating element, and a certain amount of working solutions are added into the clip-shaped slot structure, thus achieving the goal of flexible connection between mobile and static elements as well as the sealing without mechanical friction.

Owner:方建升 +1

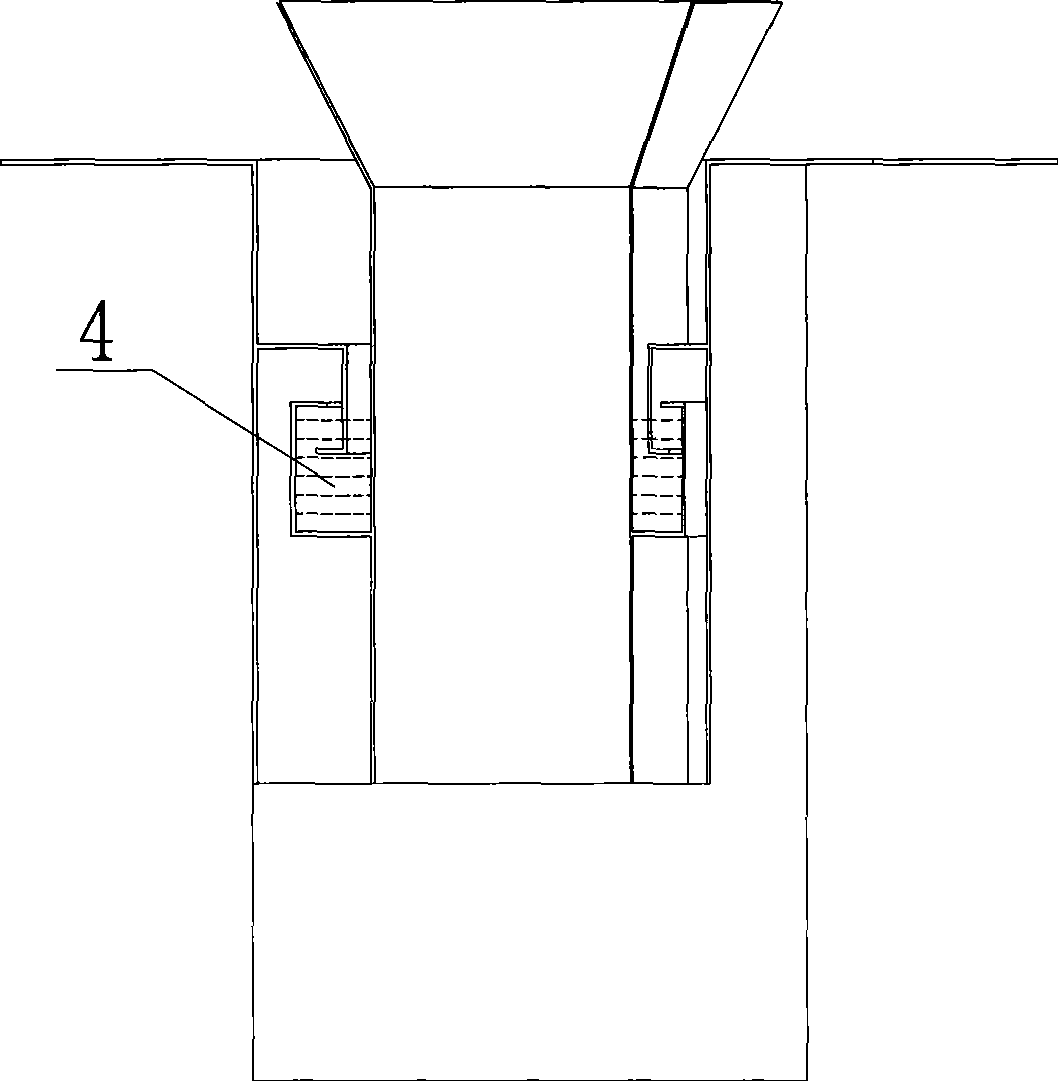

Treatment method of high-indium and high-copper zinc ore concentrate

ActiveCN103725884AEfficient recyclingAdvanced technical indicatorsRotary drum furnacesCrucible furnacesIndiumDistillation

The invention discloses a treatment method of a high-indium and high-copper zinc ore concentrate, which comprises the following steps: performing oxygen enrichment oxidizing smelting on the zinc ore concentrate containing 0.03-0.10% of In, 2-5% of Cu and 40-50% of Zn, performing strong reduction smelting on fusion slag to produce spelter alloy, crude copper and slag, and selling the crude copper and slag externally; distilling the spelter alloy to produce zinc cadmium alloy and a zinc indium base solution; performing secondary distillation on the zinc cadmium alloy to produce distilled zinc and high cadmium zinc alloy; casting and cooling the distilled zinc to obtain a zinc ingot product, distilling the high cadmium zinc alloy in a low-temperature tower to obtain crude cadmium and low cadmium zinc alloy, and distilling the low cadmium zinc alloy in a cadmium tower; distilling the zinc indium base solution in a high-temperature tower to produce high indium alloy and high-temperature crude zinc, distilling the high-temperature crude zinc in a lead tower, and extracting indium from high indium alloy. The adopted treatment method has the following advantages: the technological process is short, the invested occupied area is small, the production efficiency is high, the production cost is low, the production process is clean and environmentally friendly, and the three wastes (waste gas, waste water and industrial residue) are not emitted.

Owner:LAIBIN CHINA TIN SMELTING

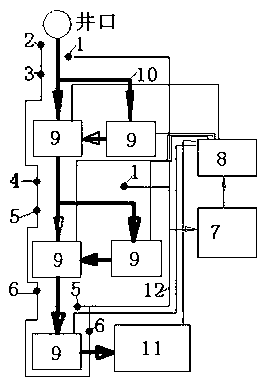

Intelligent drill rig solid control system

InactiveCN103015925AAvoid blindnessAvoid randomnessConstructionsProgrammable logic controllerControl system

The invention discloses an intelligent drill rig solid control system which comprises a visual camera (1), a gas sensor (2), a temperature sensor (3), a pressure sensor (4), a slurry granularity sensor (5), a slurry viscosity sensor (6), a PLC (programmable logic controller) (7), an electronic switch (8), solid control equipment (9), a conveying belt (10), a storage tank (11), a cable jumper (12) and the like. Intelligent automation and unmanned exploitation are the development trend of the drill rig well field solid control system and also effective ways for guaranteeing safe operation of working faces.

Owner:四川首富曼石油装备有限公司

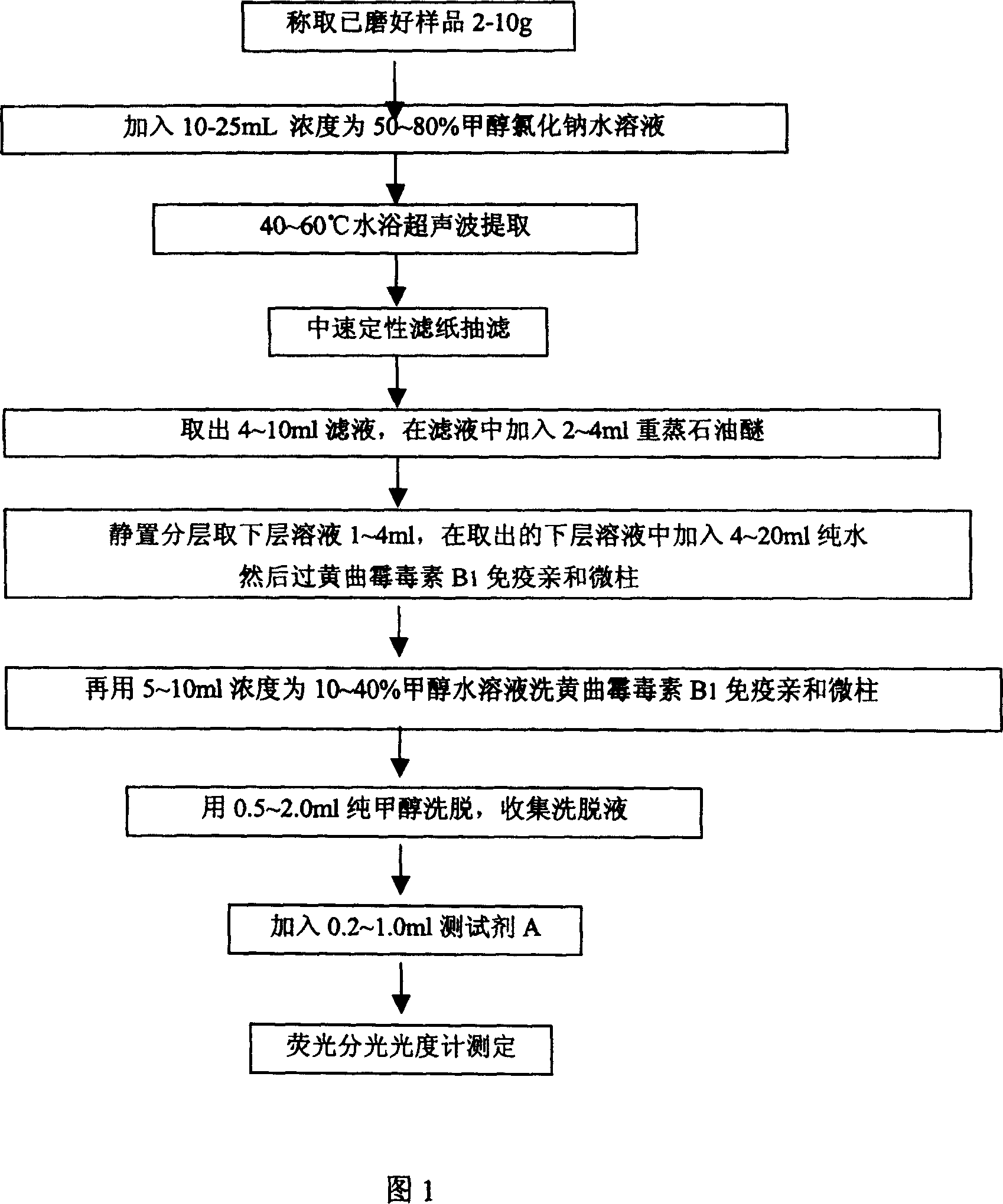

Fast detecting method for aftatoxin B*

InactiveCN1322327CEasy to handleEasy to operateFluorescence/phosphorescenceWater bathsSpectrofluorometer

The present invention is fast detection method of aflatoxin B1 in food and feed. The fast detection method includes the following steps: adding ground sample to be tested in 2-10 g in test tube, adding methanol-sodium chloride aqua of 50-80 % concentration in 10-25 ml, ultrasonic extraction in water bath at 40-60 deg.c, and suction filtering to obtain filtrate in 4-10 ml; adding re-distilled petroleum ether in 2-4 ml into the filtrate, shaking, letting stand to laminate, taking the lower layer of solution in 1-4 ml and adding pure water in 4-20 ml; adding to micro immunoaffinity column of aflatoxin B1, washing with methanol aqua of 10-40 % concentration in 5-10 ml, eluting with methanol in 0.5-2.0 ml, collecting the eluted liquid, adding test agent A in 0.2-1.0 ml; and detecting in fluorescent spectrophotometry or similar instrument. The present invention has the features of simple process, high detection precision and stability, fast detection speed and high safety.

Owner:BEIJING CHINAINVENT INSTR TECH +1

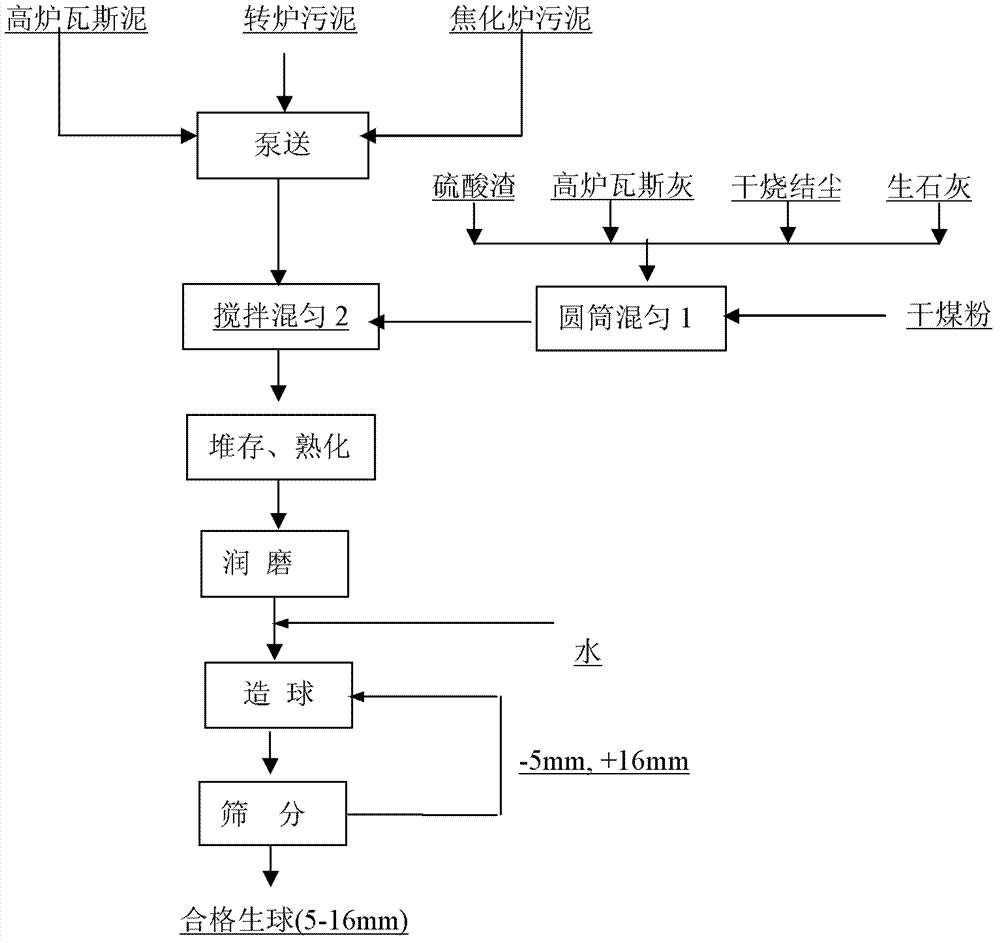

Method for preparing high strength green pellets from steel plant iron-containing dust

ActiveCN102618718BSimple processReduce manufacturing costProcess efficiency improvementGranularitySludge

The present invention relates to a method for preparing high strength green pellets from steel plant iron-containing dust. The method comprises the following steps: taking sludge, dry dust, sulfuric acid residue, dry coal fines, and quick lime to prepare the materials; uniformly stirring the sludge, mixing the sludge with the dry dust, the sulfuric acid residue, the dry coal fines, and the quick lime, stirring and uniformly dispersing, and carrying out piling-ripening for 8-24 hours to obtain a mixed clinker; and carrying out damp milling and balling on the mixed clinker. The method of the present invention has the following advantages that: the process is simple, the production cost is low, and the technical indicators are advanced. The prepared green pellets have characteristics of water content of 10-15%, falling strength of 4-8 times / 0.5 m, compressive strength of 10-15 Newton / per pellet, and granularity of 5-16 mm, and provide high-quality raw materials for the subsequent successful metal pellets sintered roasting dezincification. In addition, the method is suitable for industrial application.

Owner:CENT SOUTH UNIV

Nano crystallite composite filter material

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

Suspension centre automatic adjusting method of leveling spreader for spacecraft

InactiveCN102976207BReduce labor intensityAdvanced technical indicatorsLoad-engaging elementsEngineeringUltimate tensile strength

The invention discloses a suspension centre automatic adjusting method of a leveling spreader for a spacecraft; according to the method, measured values of a tension sensor and a dip angle sensor and intrinsic parameter of the spreader are used as input, displacements respectively in the X and the Y directions of an XY worktable are calculated by using different formulae, and then iteration is carried out repeatedly until the measured values of the sensors meet the levelness lifting requirement. Compared with the prior art, the accurate adjusting method disclosed by the invention solves the difficulty of fast and automatic leveling of the suspension center of the spreader in a two-dimensional plane, has advanced technical index, achieves digitization and automation of the adjusting process, improves suspension precision and suspension efficiency, reduces labor intensity of operators, can reach the levelness within the range of 5mm / m by only three times of adjustments, and has significant value in application.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

A high-speed high-temperature precision deep groove ball bearing manufacturing process

The invention discloses a manufacturing technology for a high-speed and high-temperature precision deep groove ball bearing. A complete set of bearing product is manufactured by processing a forge piece blank into a workpiece billet with an outer ring and an inner ring, then respectively performing technical processes of respective technologies of cold rolling, thermal treatment, coarse grinding, thermal stabilization, fine grinding, grinding and the like, performing inspection and then performing cleaning and assembling. In the cold rolling technique, a cold rolling machine tool is used, a main driving forming rolling wheel is used as an outer die of a mold, and a driven forming mandril is used as an inner die of the mold, so that the forming rolling wheel drives the workpiece billet to rotate, and a supporting wheel pushes the forming mandril to forwards feed and extrude the workpiece billet to roll and form a product; in the thermal stabilization technique, the workpiece subjected to coarse grinding is subjected to heat preservation in a tempering furnace at temperature of 400 DEG C for 4 hours and then is taken out for natural cooling. The limit rotating speed of the complete set of bearing is 12,000 r / min, and the limit working temperature is 160 DEG C; the working noise is less than or equal to 45 dB; the rated load is Cr41.2KN and Cor24KN. The manufacturing precision is high, and the matching performance is high.

Owner:山东鑫兴精密轴承科技有限公司

Method of producing high grade magnetic concentrate from sulfuric-acid residue composite pellet

InactiveCN100371470CSimple processAdvanced technical indicatorsProcess efficiency improvementSlagMagnetite

Owner:CENT SOUTH UNIV

A two-speed large-speed differential transmission

ActiveCN107448561BSimple structureCompact structureToothed gearingsGearing detailsHydraulic motorDifferential transmission

The invention discloses a two-gear big-speed-difference speed changer which mainly consists of an input shaft, a primary sun wheel, a primary planet wheel, a primary planet carrier, an inner toothed ring, a secondary planet wheel, a secondary sun wheel, a secondary planet carrier and a gear shifting control mechanism; the input shaft is connected with a motor or a hydraulic motor; the input shaft is engaged with the primary planet wheel arranged on the primary planet carrier through the fixedly connected primary sun wheel; the primary planet wheel is connected with the secondary planet wheel by sharing the inner toothed ring; the primary planet carrier is fixedly connected with the secondary sun wheel; the secondary sun wheel is engaged with the secondary planet wheel sleeving the secondary planet carrier; the secondary planet carrier is in flange connection with an output shaft; the gear shifting control mechanism comprises a control toothed shaft connected with the inner toothed ring, a toothed seat connected with a housing, a sliding toothed sleeve, a toothed seat connected with the output shaft, and an output flange; the inner toothed ring is connected with a control toothed seat; the control toothed seat is connected with the sliding toothed sleeve; and through the sliding toothed sleeve, one side of the control toothed seat is placed on the toothed seat connected with the housing, and the other side of the control toothed seat is placed on the toothed seat connected with the secondary planet carrier.

Owner:HANGZHOU ADVANCE GEARBOX GRP

Method for treating high-iron and multi-metal zinc concentrate

ActiveCN103695635BEfficient recyclingAdvanced technical indicatorsPhotography auxillary processesProcess efficiency improvementIndiumFractionating column

Owner:LAIBIN CHINA TIN SMELTING

A white cement clinker bleaching process and equipment

The invention discloses a white cement clinker bleaching process which comprises the following steps: 1) performing water spray quenching on high-temperature white cement clinker discharged from a kiln to 550-600 DEG C through a single-drum bleaching machine; 2) performing air cooling on the white cement clinker quenched to 550-600 DEG C to 100 DEG C or below through a grate cooler, and simultaneously introducing hot air discharged from the grate cooler into a kiln entrance cover of the rotary kiln and a decomposition furnace to respectively serve as secondary air and tertiary air for supporting the combustion of fuel. The invention also discloses equipment for realizing the white cement clinker bleaching process. According to the invention, the functions of cement clinker bleaching, cooling and heat recycling are combined; the heat of the white cement clinker can be recycled under the condition of ensuring the bleaching and cooling of the white cement clinker; and the heat loss of a firing system can be greatly reduced.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +2

Method and smelting furnace for processing high-speed iron polymetallic zinc concentrate

ActiveCN104060089BEfficient recyclingAdvanced technical indicatorsPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention relates to a method and a smelting furnace for processing a high-iron multi-metal zinc concentrate. The method comprises the following steps of: adding the zinc concentrate which contains the following components in percentage by weight: 16%-24% of Fe, 0.02-0.40% of In, 0.2%-2.0% of Cu, 0.004%-0.04% of Ag and 36%-48% of Zn to the smelting furnace, successively carrying out three processes including oxygen-enriched oxidation smelting, weak reduction smelting and strong reduction smelting to product sulfur dioxide fume, a copper-silver alloy, smelting slag and zinc-indium smoke dust, wherein the sulfur dioxide fume is used for preparing sulfuric acid, the smelting slag is externally sold, the copper-silver alloy is separated to extract copper and silver, and the zinc-indium smoke dust is subjected to neutral leaching to obtain a neutral leaching solution and neutral leaching residues; producing electrolytic zinc through the neutral leaching solution according to a conventional process; carrying out two-stage acid counter current leaching on the neutral leaching residues to obtain a low-acid leaching solution and high-acid leaching residues; returning the high-acid leaching residues to the smelting furnace for smelting, producing fine indium by using the low-acid leaching solution according to a conventional P204 extraction process, and returning extraction raffinate to neutral leaching. The method disclosed by the invention has the advantages of short process flow, high production efficiency, low production cost, good integrated recovery and clean and environment-friendly production process.

Owner:LAIBIN CHINA TIN SMELTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com