Intelligent drill rig solid control system

A solid control system and drilling rig technology, applied in construction and other fields, can solve problems such as unsuitable personnel for construction, high risk, and large site noise, and achieve the effect of avoiding blindness and arbitrariness and advanced technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

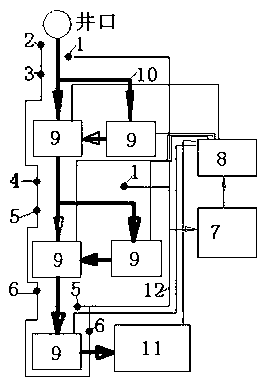

[0014] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings. At present, everyone has recognized that mud is one of the key factors related to the success or failure of drilling. The role and status of mud are more prominent, and it is also more widely valued. The volume or mass percentage of mud is what we usually call the solid phase content of drilling fluid. Generally, drilling fluid is called mud, and the solid phase control of mud is referred to as solid control. The solid phase of drilling fluid is divided into three types according to their functions. Two types: useful solid phase and harmful solid phase. The process of solid phase control is a process of removing harmful solid phase and retaining useful solid phase.

[0015] The main functions of mud are:

[0016] (1) Carrying and suspending cuttings. It is to take the cuttings broken by the drill bit out of the wellbore from the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com