Treatment method of high-indium and high-copper zinc ore concentrate

A processing method and technology for zinc concentrate, which are applied in the field of processing high indium and high copper zinc concentrate, can solve the problems of large coal coke consumption, large coke consumption, low copper recovery rate, etc., and achieve reduced energy consumption and efficient recovery Utilize and reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

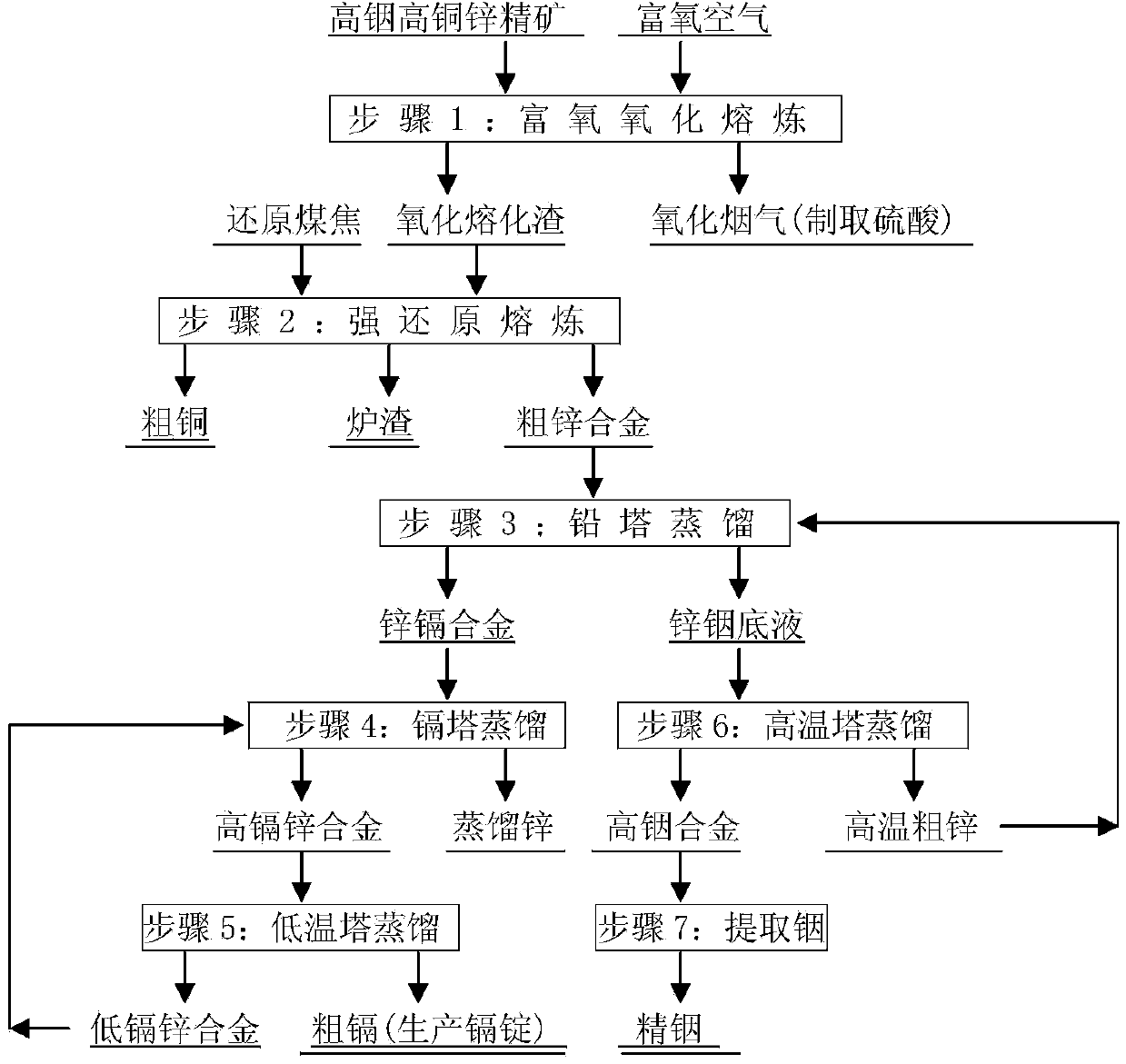

[0022] This embodiment is the first example of the processing method of the high-indium and high-copper-zinc concentrate of the present invention, comprising the following steps:

[0023] (1) Oxygen-enriched oxidative smelting: Zinc concentrate containing 0.03% In, 2% Cu, and 40% Zn is continuously fed into an Ausmelt furnace with an inner diameter of 6000mm at a speed of 35t / h, and at the same time, 49000Nm 3 / h speed into the oxygen concentration of 32% oxygen-enriched air and 14500Nm 3 / h speed into the sleeve air, at a temperature of 1200 ° C, oxygen-enriched oxidation melting, and the output of 61000Nm 3 / h oxidation flue gas and 31t / h molten slag, oxidation flue gas contains SO 2 11%, containing O 2 14%, using the traditional two-turn-two-absorption process to produce sulfuric acid;

[0024] (2) Strong reduction smelting: Molten slag is added to an Ausmelt furnace with an inner diameter of 6500mm and a lead rain condenser at a rate of 31t / h for strong reduction smelti...

no. 2 example

[0031] This embodiment is the second example of the processing method of a high-indium and high-copper-zinc concentrate described in the present invention, comprising the following steps:

[0032] (1) Oxygen-enriched oxidation smelting: Zinc concentrate containing 0.07% In, 4% Cu, and 45% Zn is continuously fed into an Ausmelt furnace with an inner diameter of 6000mm at a speed of 30t / h, and at the same time, it is 3 / h speed into the oxygen concentration of 40% oxygen-enriched air and 15000Nm 3 / h speed into the sleeve air, at a temperature of 1250 ° C, oxygen-enriched oxidation melting, and the output of 45000Nm 3 / h oxidation flue gas and 26t / h molten slag, oxidation flue gas contains SO 2 14%, containing O 2 13%, using the traditional two-turn-two-absorption process to produce sulfuric acid;

[0033] (2) Strong reduction smelting: Molten slag is added to an Ausmelt furnace with an inner diameter of 6500mm and a lead rain condenser at a rate of 26t / h for strong reduction...

no. 3 example

[0040] This embodiment is the third example of the processing method of a high-indium and high-copper-zinc concentrate described in the present invention, comprising the following steps:

[0041] (1) Oxygen-enriched oxidation smelting: Zinc concentrate containing 0.10% In, 5% Cu, and 50% Zn is continuously fed into the Ausmelt furnace with an inner diameter of 6000mm at a speed of 27t / h, and at the same time, it is 3 / h speed into the oxygen concentration of 48% oxygen-enriched air and 15000Nm 3 / h speed into the sleeve air, at a temperature of 1300 ℃, carry out oxygen-enriched oxidation melting, and output 41000Nm 3 / h oxidation flue gas and 23t / h molten slag, oxidation flue gas contains SO 2 15%, containing O 2 16%, using the traditional two-to-two-absorption process to produce sulfuric acid;

[0042] (2) Strong reduction smelting: Molten slag is added to an Ausmelt furnace with an inner diameter of 6500mm and a lead rain condenser at a rate of 23t / h for strong reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com