A white cement clinker bleaching process and equipment

A white cement and clinker technology, applied in clinker production, cement production and other directions, can solve the problems affecting the normal operation of the rotary kiln, not having heat recovery, reducing the strength of clinker, etc., to achieve strong operability and practicability, The design concept is environmentally friendly and the effect of reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

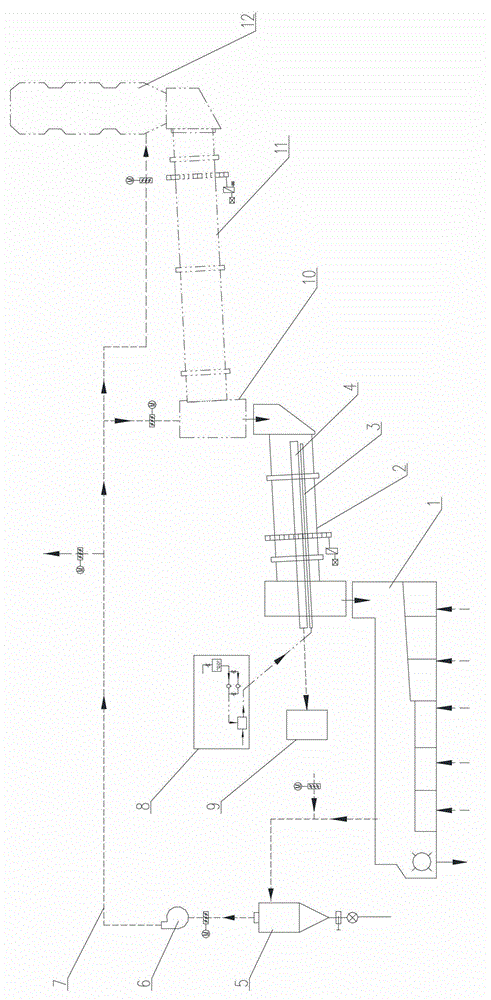

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0019] See figure 1 , a white cement clinker bleaching process, comprising the following steps:

[0020] 1) Use the single cylinder bleaching machine 2 to quench the high-temperature white cement clinker leaving the kiln to 550~600°C by spraying water;

[0021] 2) Use the grate cooler 1 to cool the white cement clinker rapidly cooled to 550-600°C to below 100°C, and at the same time introduce the hot air from the grate cooler 1 into the rotary kiln door cover 10 and the calciner 12, respectively as Secondary air and tertiary air for fuel combustion.

[0022] A device for realizing the white cement clinker bleaching process described above, comprising a single-cylinder bleaching machine 2 and a grate cooler 1 connected in series, the feed po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com