Fuel coal furnace exhaust gas calcium water bath spraying composite desulfurizing process and its special equipment

A desulfurization process and flue gas technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of low desulfurization efficiency, short reaction time between desulfurization medium and flue gas, low utilization rate of desulfurization medium, etc. Achieve the effects of wide application range, advanced technical indicators and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

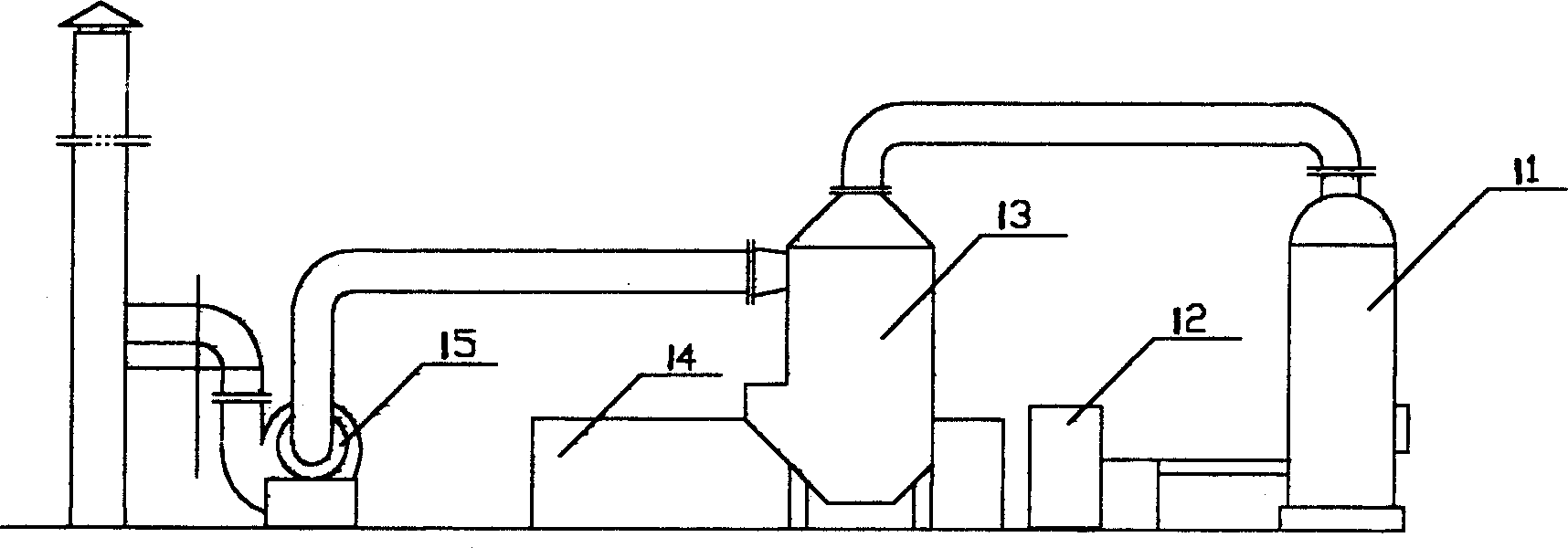

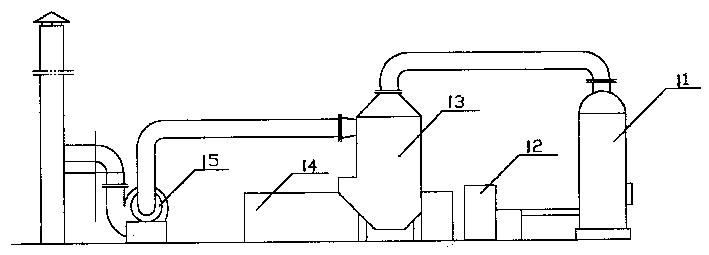

[0030] As shown in the figure is a schematic diagram of LSD-800 single-grate direct-fired domestic boiler flue gas calcium spraying water bath composite desulfurization process system. In the figure, 11 is a coal-fired boiler; 12 is a calcium spraying system; 13 is a water bath purifier; 14 is a circulating water system; 15 is a boiler induced draft fan.

[0031] In the figure, the calcium spraying system is composed of an air compressor (compressed air outlet pressure is 0.7Mpa), a screw conveyor, and a gas-solid mixer. The powdery desulfurization medium (such as calcium carbonate, etc.) is sent into the gas-solid mixer by the screw conveyor and mixed evenly with the high-speed flowing compressed air, and sprayed into the coal-fired furnace through the connecting pipe fixed on the furnace wall for high-temperature combustion. area for decomposition and desulfurization reactions. The reaction product, the undecomposed and reacted desulfurization medium, and the fly ash produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com