A two-speed large-speed differential transmission

A technology of transmission and speed difference, which is applied in the direction of transmission device, gear transmission device, belt/chain/gear, etc., to achieve the effect of reliable use, low cost, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

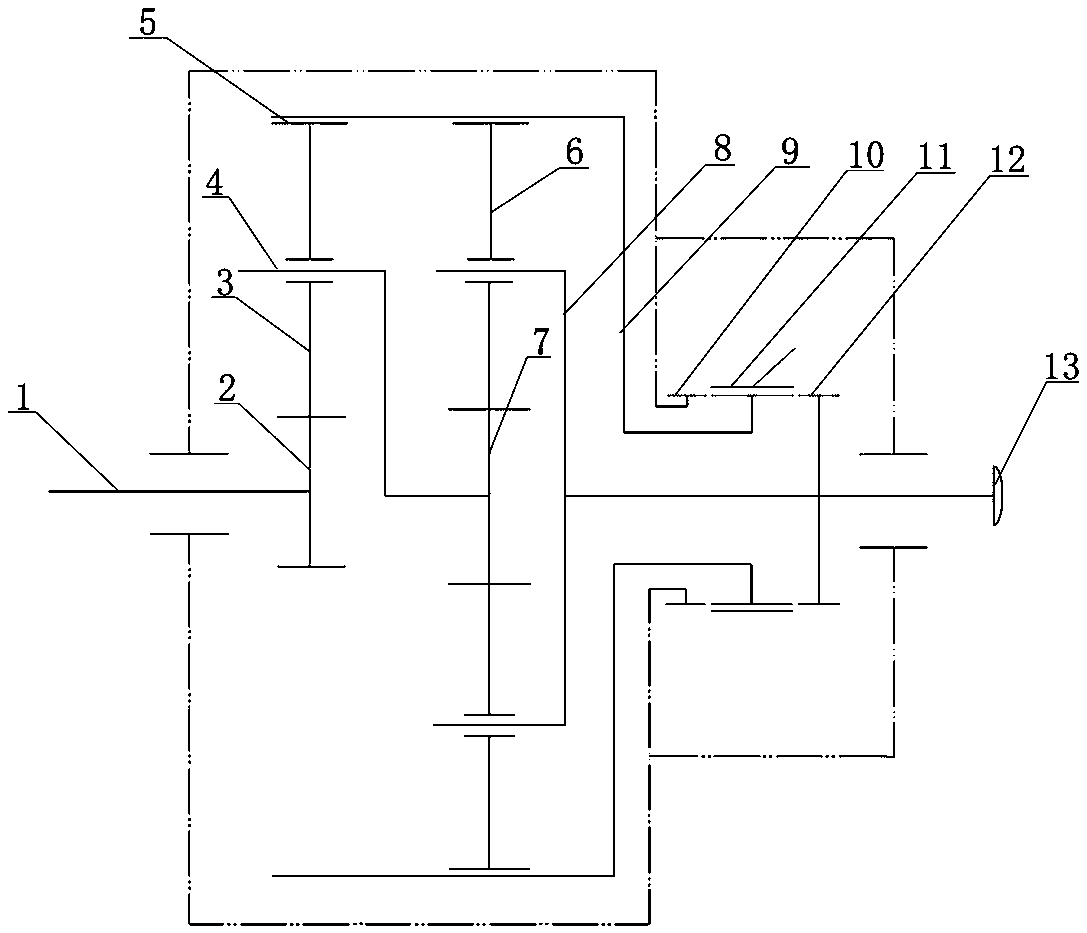

[0013] Embodiment: The two-speed large-speed differential transmission described in the present invention includes an input shaft connected with an electric motor or a hydraulic motor, a two-stage planetary transmission, a gear shifting mechanism, and an output shaft connected with a second-stage planet carrier and output flange;

[0014] The shifting operating mechanism of the second-speed large-speed differential transmission may be a shift fork tooth sleeve structure or a hydraulic friction clutch fluid structure according to different application occasions. Only through the operating mechanism can there be power output.

[0015] The input shaft of the second-speed large-speed differential transmission is connected to the sun gear of the first-stage planetary transmission, the planet carrier of the first-stage planetary transmission is connected to the sun gear of the second-stage planetary transmission, and the first-stage planetary transmission and the second-stage planeta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com