Method for treating high-iron and multi-metal zinc concentrate

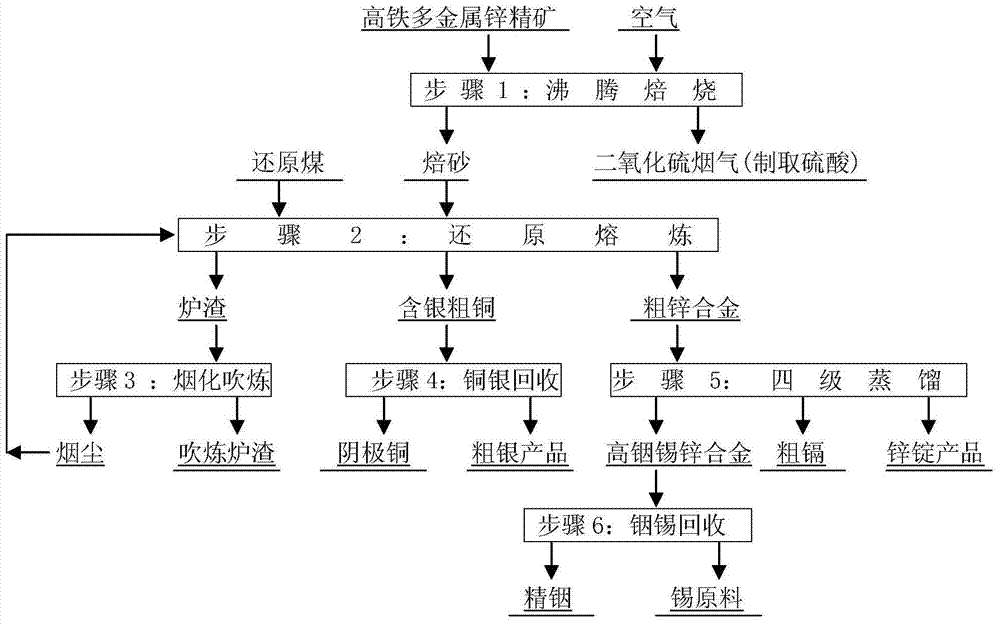

A treatment method, zinc concentrate technology, applied in the field of high-iron polymetallic zinc concentrate treatment, can solve the problems of large volatilization kiln processing capacity, low smelting recovery rate, and low recovery rate of valuable metals, so as to reduce the consumption of reduced coal , advanced technical indicators, and the effect of thorough metal separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0021] Present embodiment is the first example of the processing method of high-iron polymetallic zinc concentrate of the present invention, comprises the steps:

[0022] (1) Boiling roasting: Zinc concentrate containing Fe14%, In0.03%, Cu0.2%, Cd0.2%, Ag0.01%, Sn0.1%, Zn40%, S28% is heated at 11t / h The speed of adding 48m 2 Roasting desulfurization is carried out in the fluidized fluidized furnace, the roasting temperature is 880°C, and the air input volume is 27000Nm 3 / h, and at 26000Nm 3 / h speed output containing SO 2 8%, O 2 9% flue gas and calcine produced at a rate of 10t / h, sulfur dioxide flue gas to produce sulfuric acid;

[0023] (2) Reduction smelting: After adding reducing agent according to 20% of the calcined sand weight, the calcined mixed material with reduced coal enters three 4000kVA electric furnaces with lead rain condensers at a rate of 4t / (h.unit) respectively. Reduction smelting, smelting temperature is 1300 ℃, each furnace puts slag twice a day, p...

no. 2 example

[0030] (1) Boiling roasting: Zinc concentrate containing Fe17%, In0.07%, Cu0.4%, Cd0.4%, Ag0.015%, Sn0.15%, Zn45%, S30%, 10t / h The speed of adding 43m 2 Roasting and desulfurization are carried out in the fluidized fluidized furnace, the roasting temperature is 910°C, and the air input volume is 26000Nm 3 / h, and at 25000Nm 3 / h speed output containing SO 2 8.2%, O 2 8.7% flue gas and calcine produced at a rate of 9t / h, sulfur dioxide flue gas to produce sulfuric acid;

[0031] (2) Reduction smelting: After adding reducing agent according to 22.5% of the calcined sand weight, the calcined mixed material with reduced coal enters three 4000kVA electric furnaces with lead rain condensers at a rate of 3.675t / (h*unit) Carry out reduction smelting, the smelting temperature is 1350 ℃, each furnace puts slag twice a day, puts zinc twice, puts blister copper once a day, and produces a total of Zn98.5%, In0.14%, Cu0.03%, Cd0. 97%, Sn0.19% crude zinc alloy 95t, containing Cu83.1%, F...

no. 3 example

[0038] (1) Boiling roasting: Zinc concentrate containing Fe20%, In0.10%, Cu0.6%, Cd0.6%, Ag0.02%, Sn0.2%, Zn50%, S32% is heated at 25t / h The speed is added to 109m 2 Roasting desulfurization is carried out in the fluidized furnace, the roasting temperature is 940°C, and the air input volume is 72000Nm 3 / h, and at 70000Nm 3 / h speed output containing SO 2 8.2%, O 2 8.7% flue gas and calcine produced at a rate of 22t / h, sulfur dioxide flue gas to produce sulfuric acid;

[0039] (2) Reduction smelting: After adding reducing agent according to 25% of the calcined sand weight, the calcined mixed material with reduced coal enters five 6000kVA electric furnaces with lead rain condensers at a rate of 5.5t / (h*unit) Carry out reduction smelting, the smelting temperature is 1400 ℃, each furnace puts slag twice a day, puts zinc twice, puts blister copper once a day, and produces a total of Zn98.1%, In0.19%, Cu0.02%, Cd1. 28%, Sn0.22% crude zinc alloy 269t, containing Cu84.2%, Fe2.9%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com