Method and smelting furnace for processing high-iron multi-metal zinc concentrate

A zinc concentrate and multi-metal technology, applied in the direction of process efficiency improvement, photographic technology, instruments, etc., can solve the problems of large power consumption and reduction coal, large coke consumption, low smelting recovery rate, etc., to achieve reduction of reduction coal Consumption, elimination of interference from impurities, and the effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

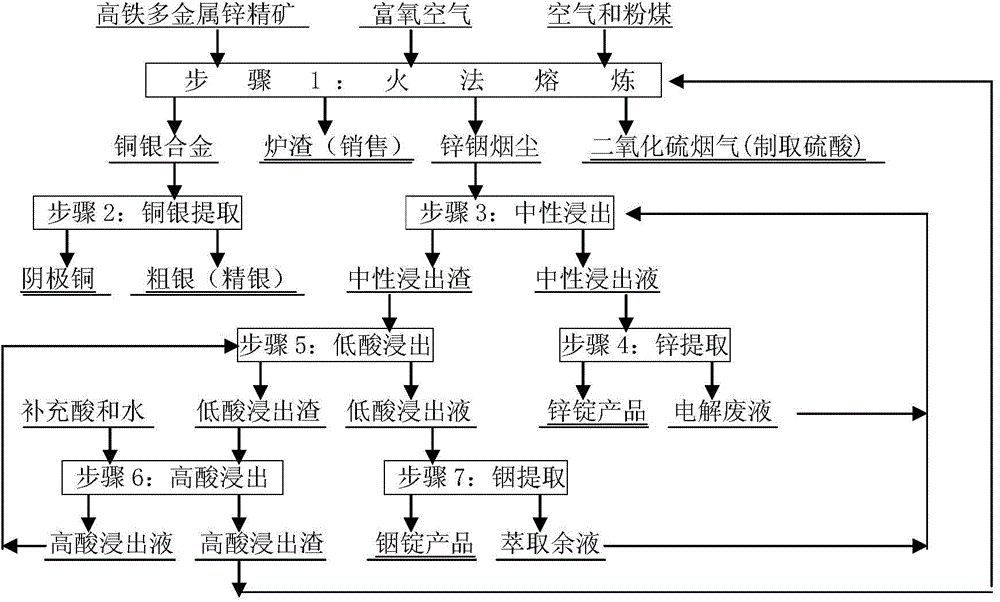

[0028] Present embodiment is the first example of the method for processing high-iron polymetallic zinc concentrate of the present invention, comprises the steps:

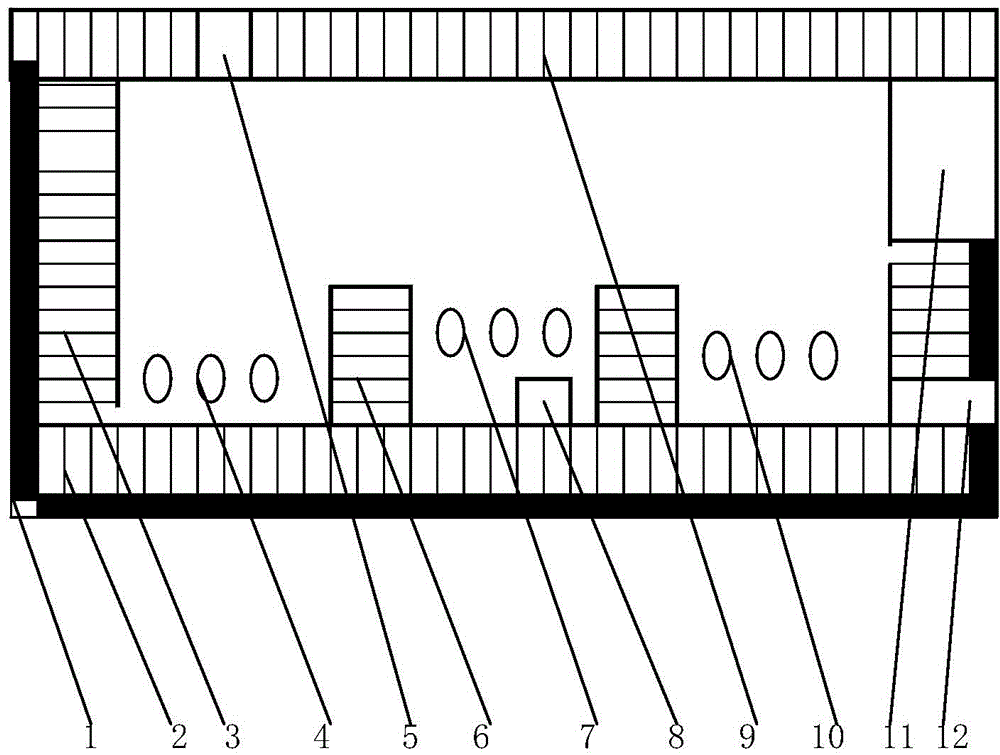

[0029] (1) pyromelting: the zinc concentrate containing Fe16%, In0.02%, Cu0.2%, Ag0.004%, Zn48%, is added in the smelting furnace of the present invention with the speed of 20t / h Oxygen-enriched oxidation smelting pool, the hearth area of the oxidation smelting pool is 16m 2 , the depth of the oxidation smelting pool is 3.5m, and at the same time, the oxygen-enriched tuyere is 0.4m away from the bottom of the furnace with 16000Nm 3 Inject oxygen-enriched air with an oxygen concentration of 48% at a speed of 1200°C for oxygen-enriched oxidative smelting. Zinc concentrate is oxidized and desulfurized to form self-slag; self-slag passes through the first furnace The upper part of a partition wall overflows to the weak reduction smelting pool, and the hearth area of the weak reduction smelting pool is 20m 2 , the...

no. 2 example

[0037] This embodiment is a second example of a method for processing high-iron polymetallic zinc concentrate according to the present invention, comprising the following steps:

[0038] (1) pyromelting: the zinc concentrate containing Fe20%, In0.20%, Cu1.1%, Ag0.02%, Zn42%, is added in the smelting furnace of the present invention with the speed of 20t / h Oxygen-enriched oxidation smelting pool, the hearth area of the oxidation smelting pool is 16m 2 , the depth of the oxidation smelting pool is 3.5m, and at the same time from the oxygen-enriched tuyere 0.5m away from the bottom of the furnace with 12000Nm 3 Inject oxygen-enriched air with an oxygen concentration of 64% at a speed of 1250°C for oxygen-enriched oxidative smelting. Zinc concentrate is oxidized and desulfurized to form self-slag; self-slag passes through the first stage in the furnace The upper part of a partition wall overflows to the weak reduction smelting pool, and the hearth area of the weak reduction s...

no. 3 example

[0046] This embodiment is a third example of a method for processing high-iron polymetallic zinc concentrate according to the present invention, comprising the following steps:

[0047] (1) pyromelting: the zinc concentrate containing Fe24%, In0.40%, Cu2.0%, Ag0.04%, Zn36%, is added in the smelting furnace of the present invention with the speed of 20t / h Oxygen-enriched oxidation smelting pool, the hearth area of the oxidation smelting pool is 16m 2 , the depth of the oxidation smelting pool is 3.5m, and at the same time, the oxygen-enriched tuyere is 0.6m away from the bottom of the furnace with 8200Nm 3 Oxygen-enriched air with an oxygen concentration of 93% is injected at a speed of 1 / h, and the oxygen-enriched oxidation smelting is carried out at an oxidation melting temperature of 1300°C. The zinc concentrate is oxidized and desulfurized to form self-slag; the self-slag passes through the first furnace in the furnace. The upper part of a partition wall overflows to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com