Method for preparing high strength green pellets from steel plant iron-containing dust

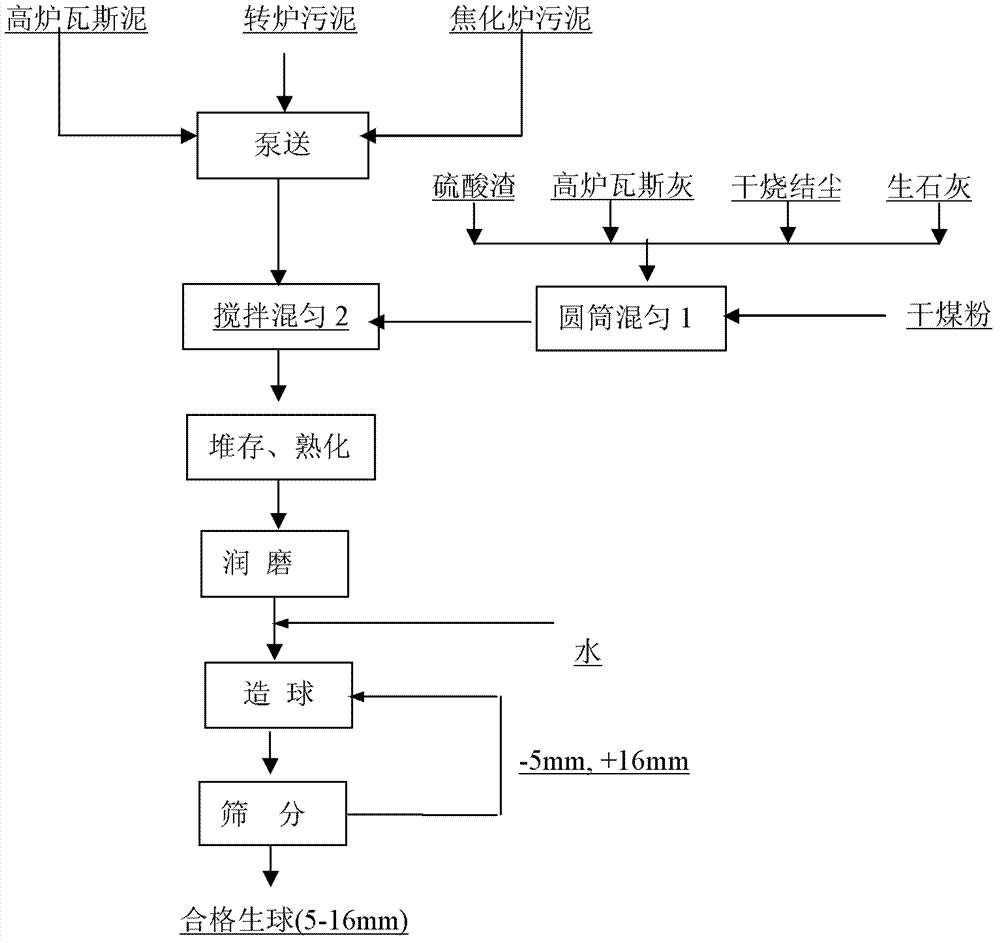

A high-strength, dusty technology, applied in the field of iron and steel metallurgy, can solve the problems of poor spheroidization, large differences in surface hydrophilicity, difficulty in spheroidization, etc., and achieve the effects of low production cost, advanced technical indicators and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Raw material ratio (by weight on a dry basis): converter sludge 20%, gas sludge 5%, coking furnace sludge 10%, dry dust 15%, gas ash 10%, sulfuric acid slag 20%, quicklime 10%, Coal powder 10%. The mixture was mixed three times according to the process, and after being stored for 8 hours, it was added to a moistening mill for moistening. The moisture content of the moistening material was 8%, the time for moistening was 3 minutes, the time for pelletizing was 12 minutes, and the moisture content for pelletizing was 15%. Green balls: The water content of green balls is 13.3%, the drop strength of green balls is 4.2 times / 0.5m, the compressive strength of green balls is 11.0Newton / piece, and the particle size of green balls is 5-16mm.

Embodiment 2

[0025] Raw material ratio (by weight on a dry basis): converter sludge 25%, gas sludge 5%, dry dust 8%, gas ash 17%, sulfuric acid slag 20%, quicklime 10%, coal powder 15%. The mixture was mixed three times according to the process, and after being stored for 8 hours, it was added to a moistening mill for moistening. The moisture content of the moistening material was 7.3%, the moistening time was 3 minutes, the pelletizing time was 12 minutes, and the pelletizing moisture was 15%. Green balls: The water content of green balls is 12.3%, the drop strength of green balls is 4.2 times / 0.5m, the compressive strength of green balls is 11.0Newton / piece, and the particle size of green balls is 5-16mm.

Embodiment 3

[0027] Raw material ratio (by weight on a dry basis): converter sludge 20%, gas sludge 5%, dry dust 10%, gas ash 15%, sulfuric acid slag 25%, quicklime 10%, coal powder 15%. The mixture was mixed three times according to the process, and after being stored for 8 hours, it was added to a moistening mill for moistening and grinding. The moisture content of the moistening material was 8.8%, the moistening time was 3 minutes, the pelletizing time was 12 minutes, and the pelletizing moisture was 14%. Green balls: The water content of green balls is 15.3%, the drop strength of green balls is 6.3 times / 0.5m, the compressive strength of green balls is 12.0 Newton / piece, and the particle size of green balls is 5-16mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com