Patents

Literature

45results about How to "Lower concentration levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

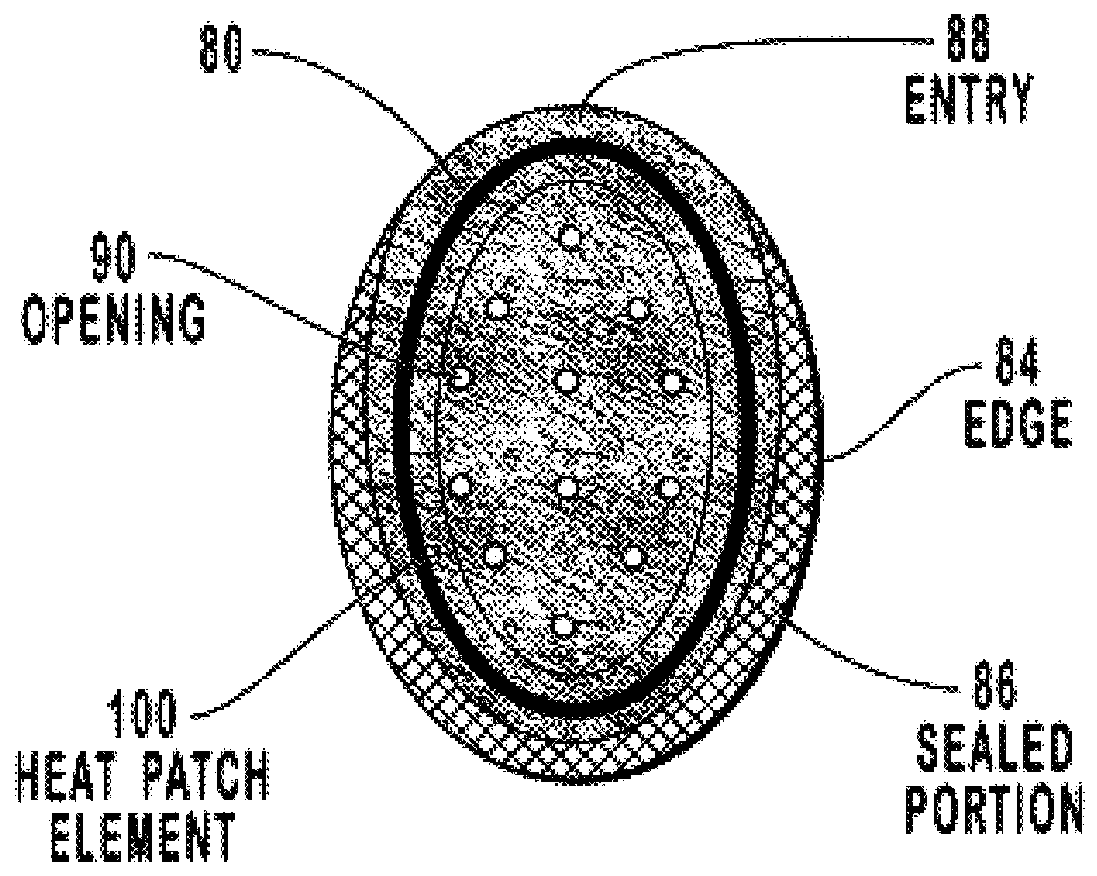

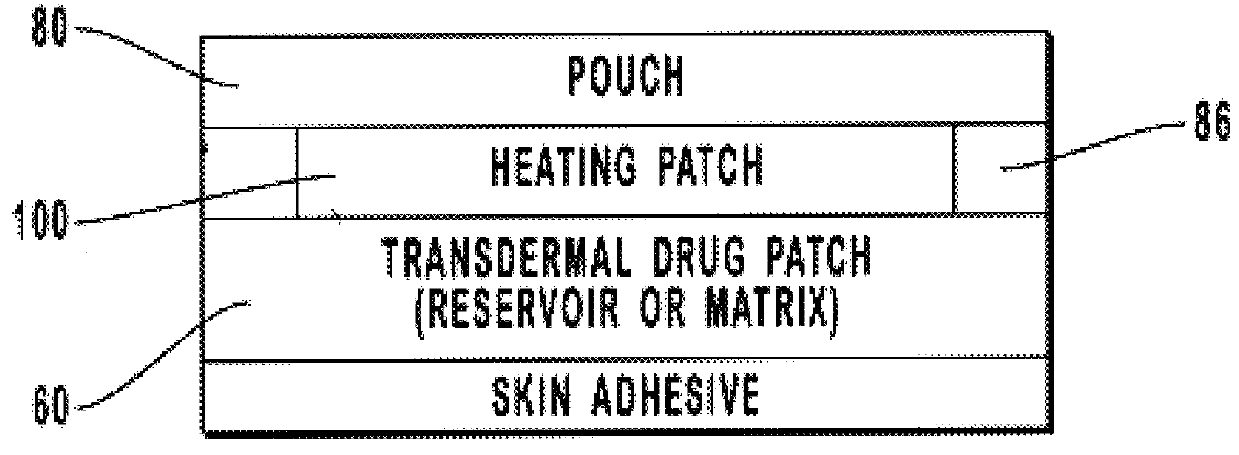

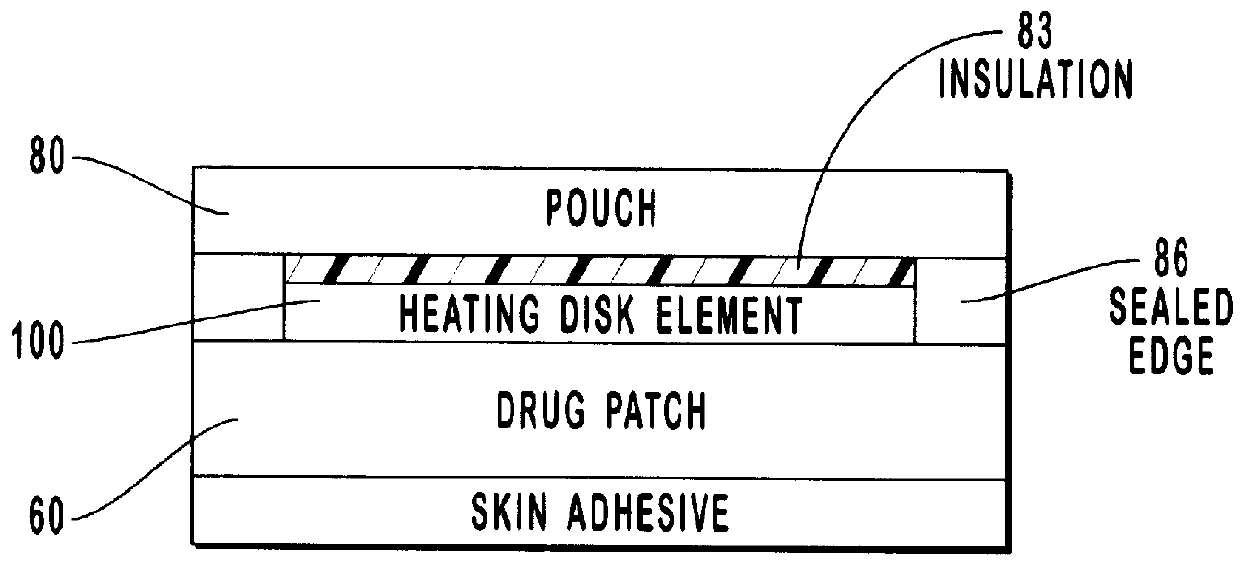

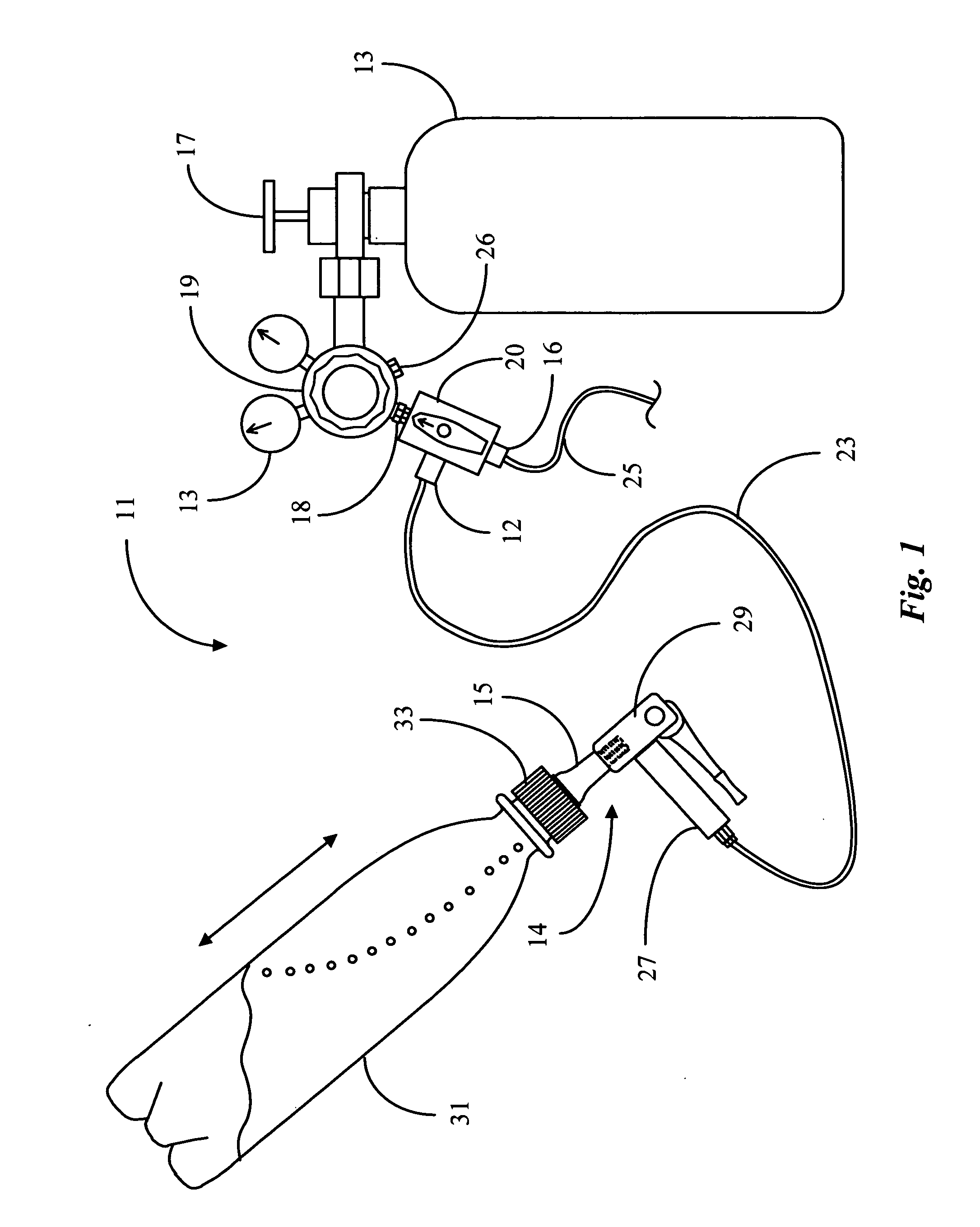

Transdermal drug patch with attached pocket for controlled heating device

InactiveUS6261595B1Shorten the timeEasy to replaceElectrotherapyMedical devicesTransdermal patchDrug administration

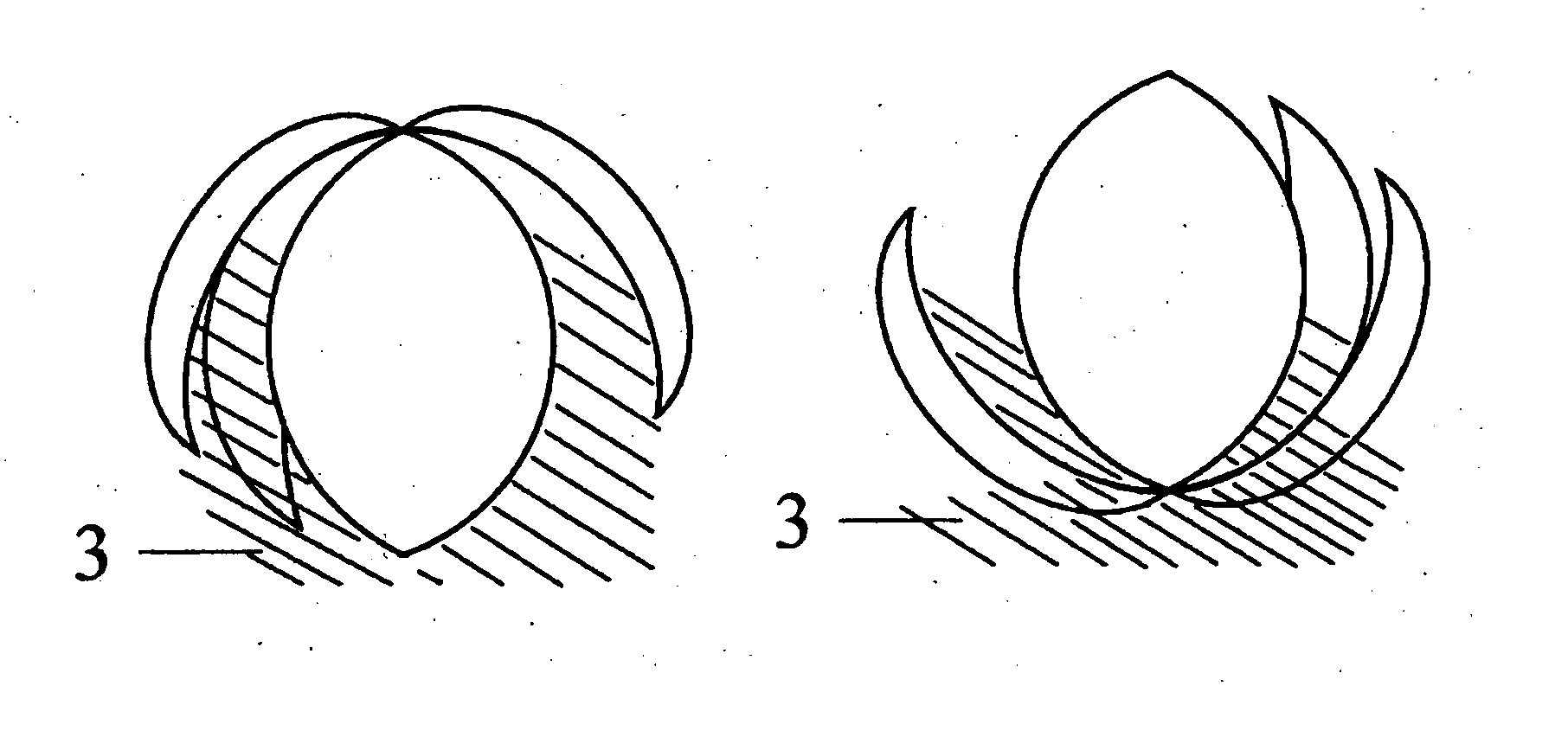

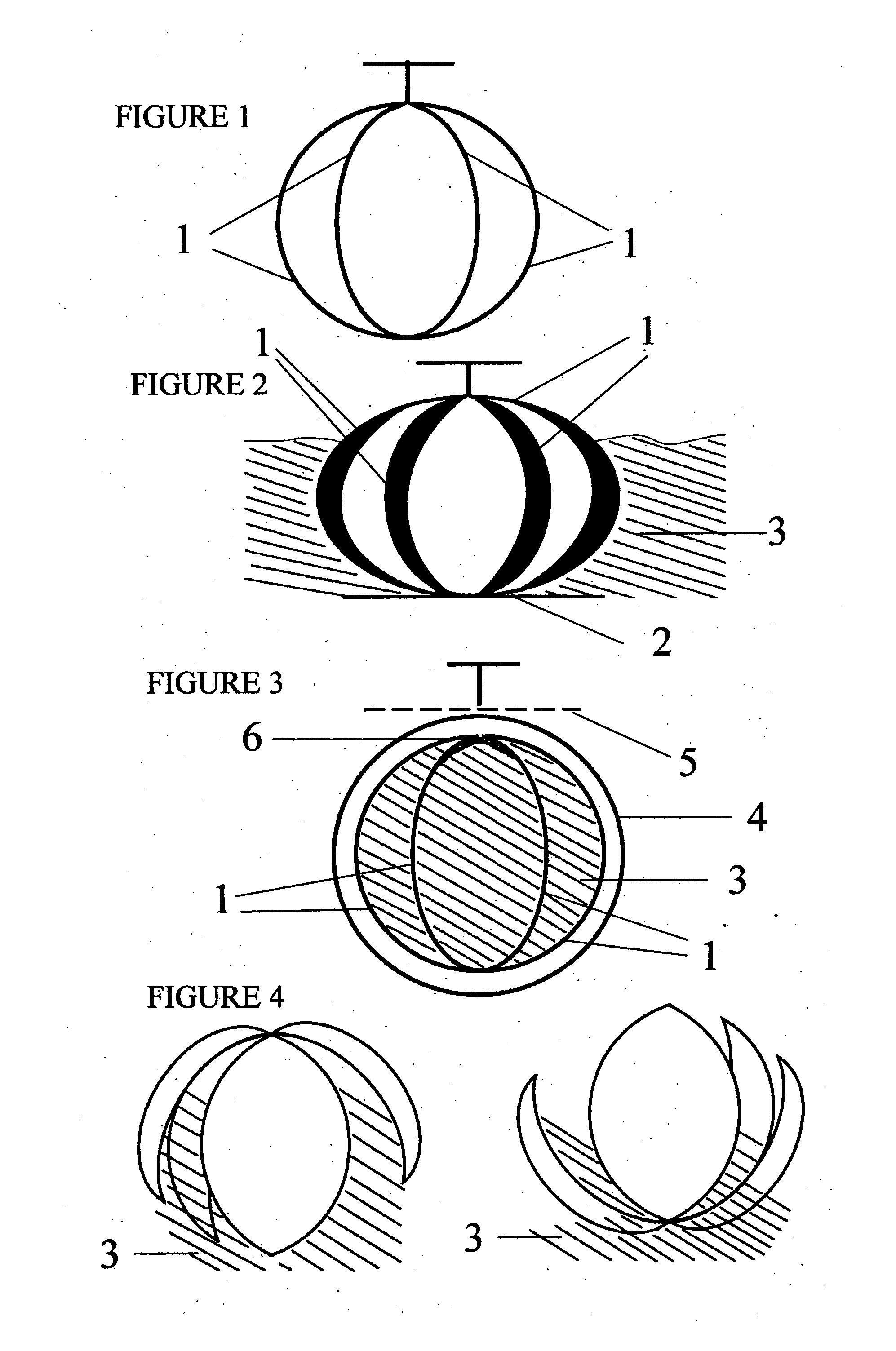

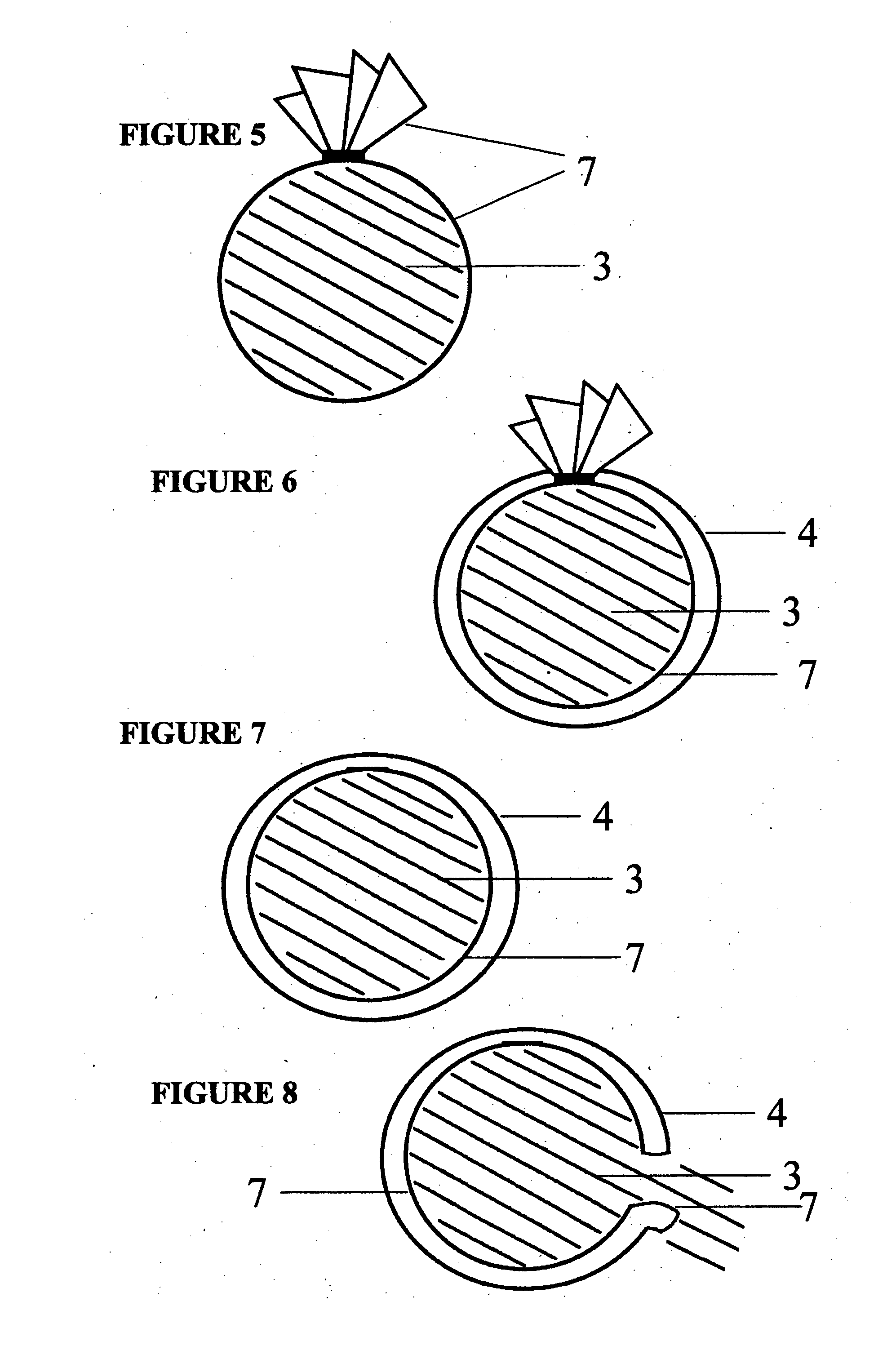

The present invention relates to a transdermal drug delivery system comprising a dermal drug delivery patch and a heating element compartment securable to the dermal drug delivery patch. A freely transferrable heating element is securable within the heating element compartment. A drug can be administered transdermally using the present invention by placing the dermal drug delivery patch upon a patient's skin at an administration site. A heating element compartment is secured to the dermal drug delivery patch and a freely transferrable heating element is placed within the heating element compartment. The heating element provides controlled heat to the dermal drug patch and the patient's skin aid thereby improves dermal drug administration.

Owner:ZARS INC

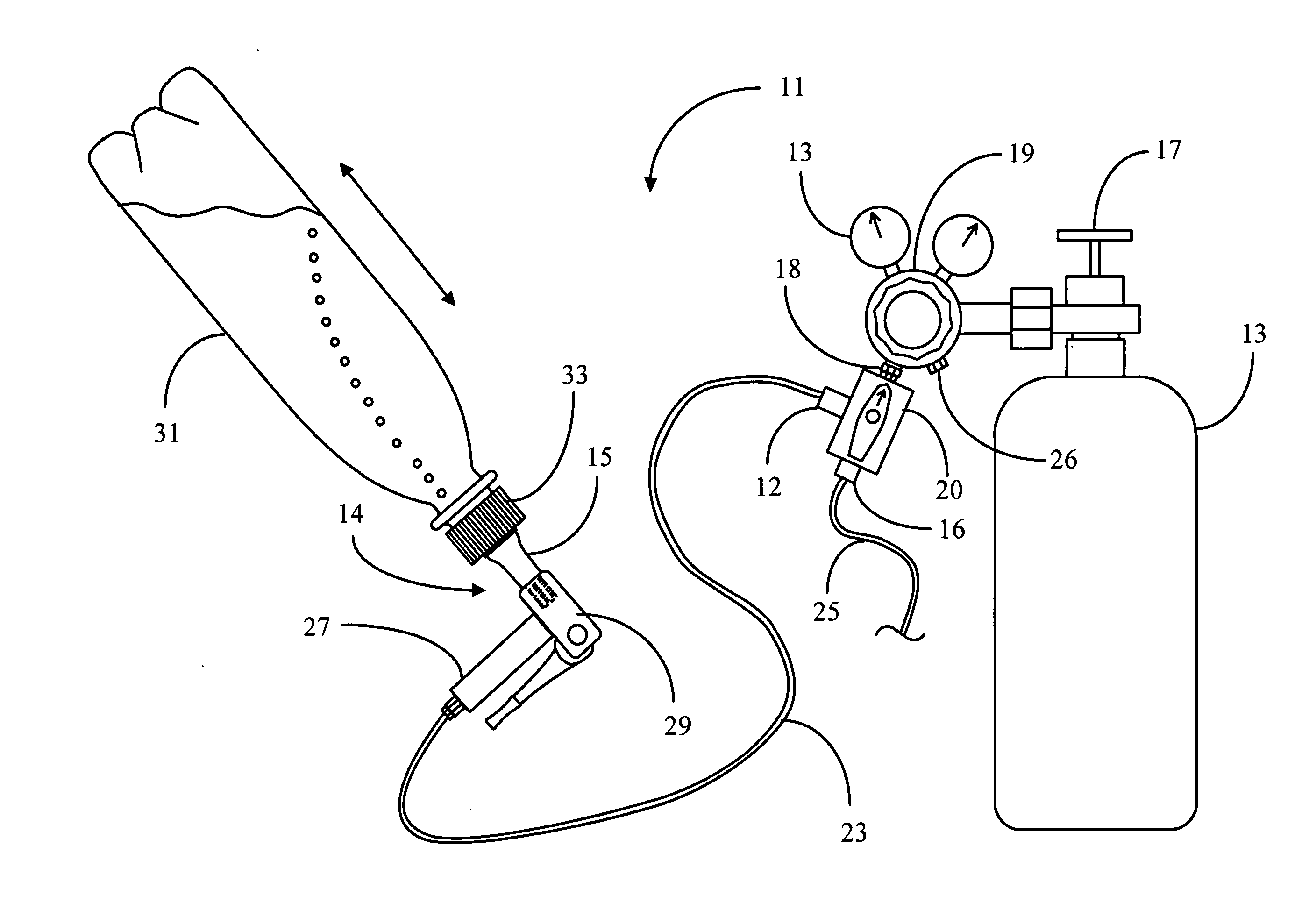

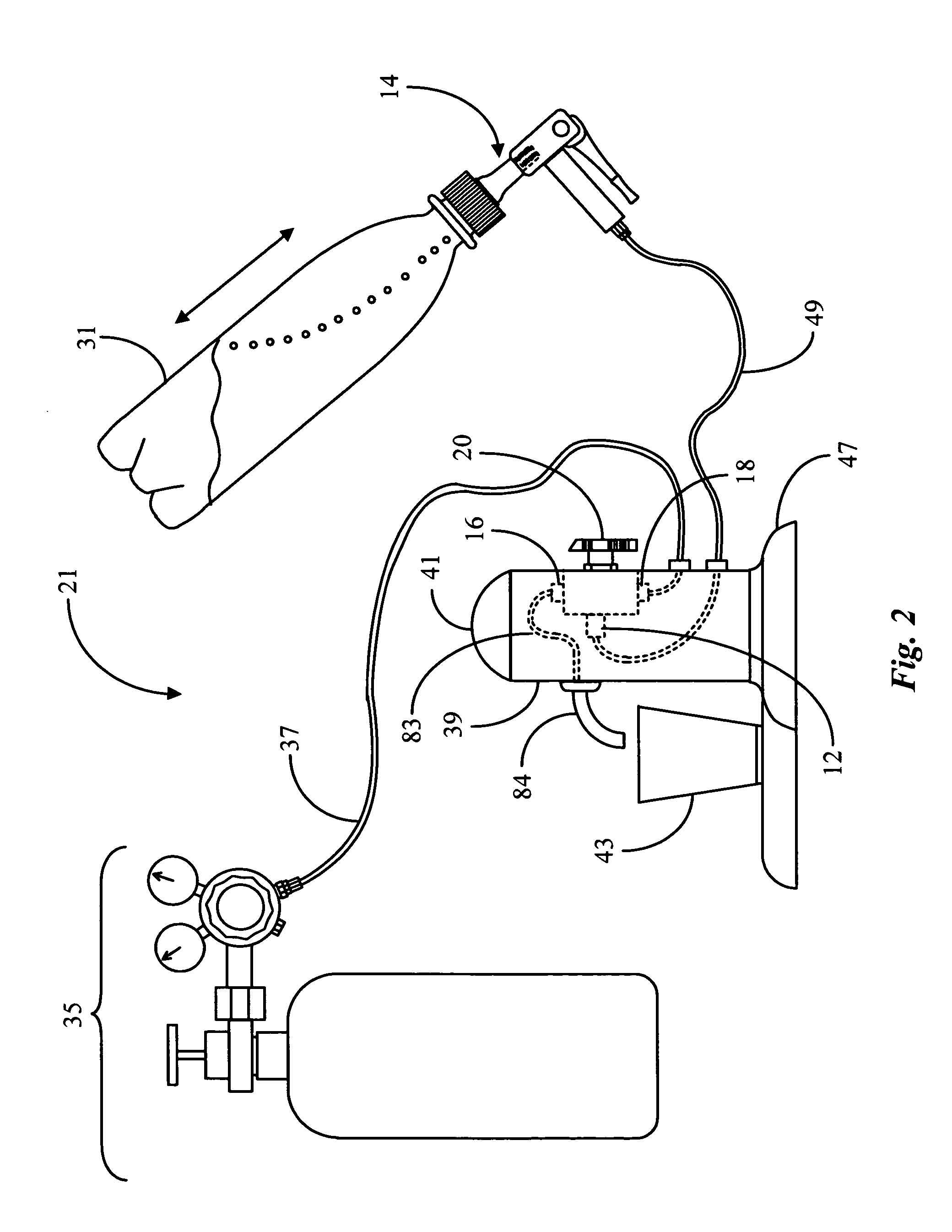

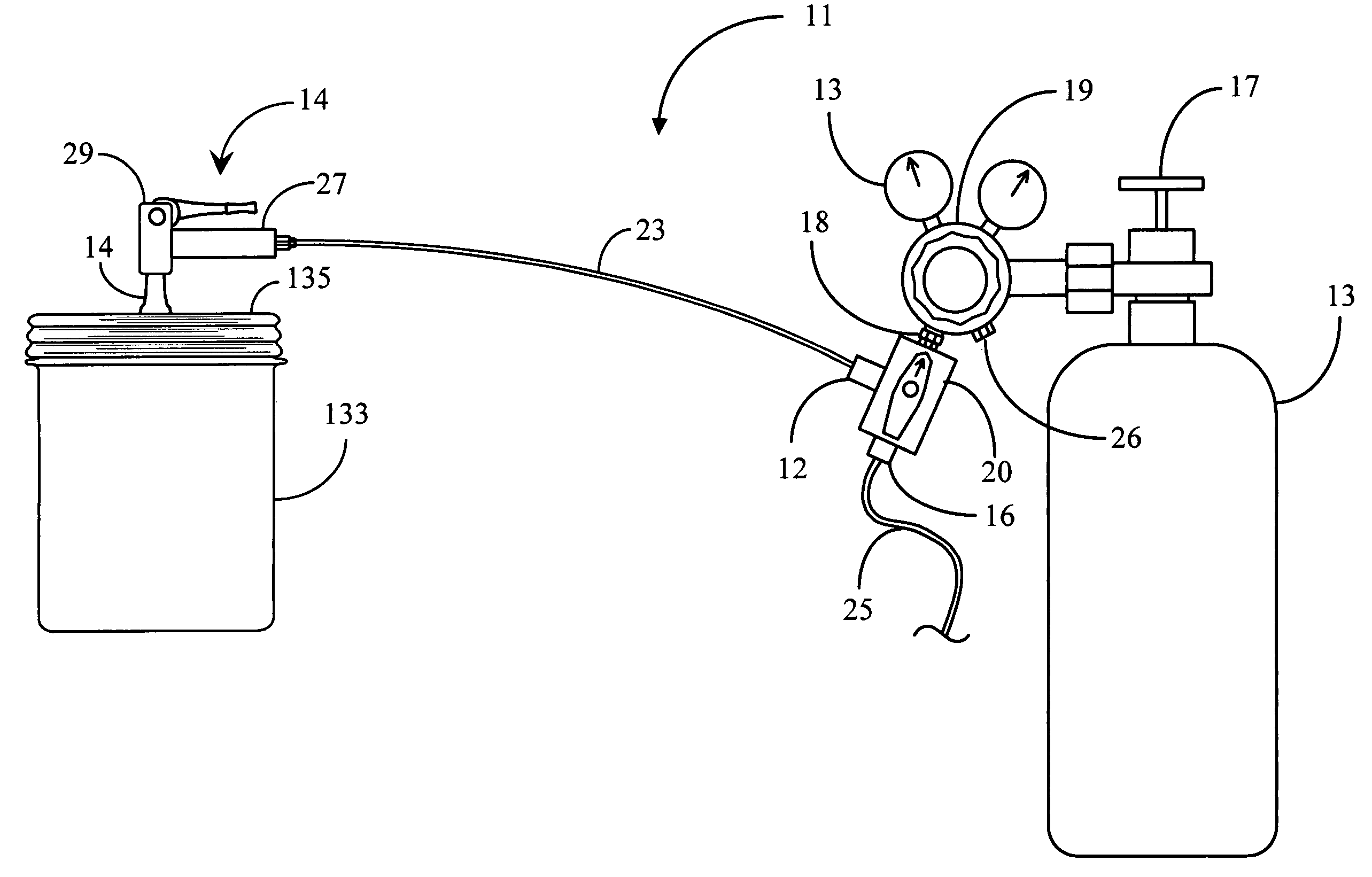

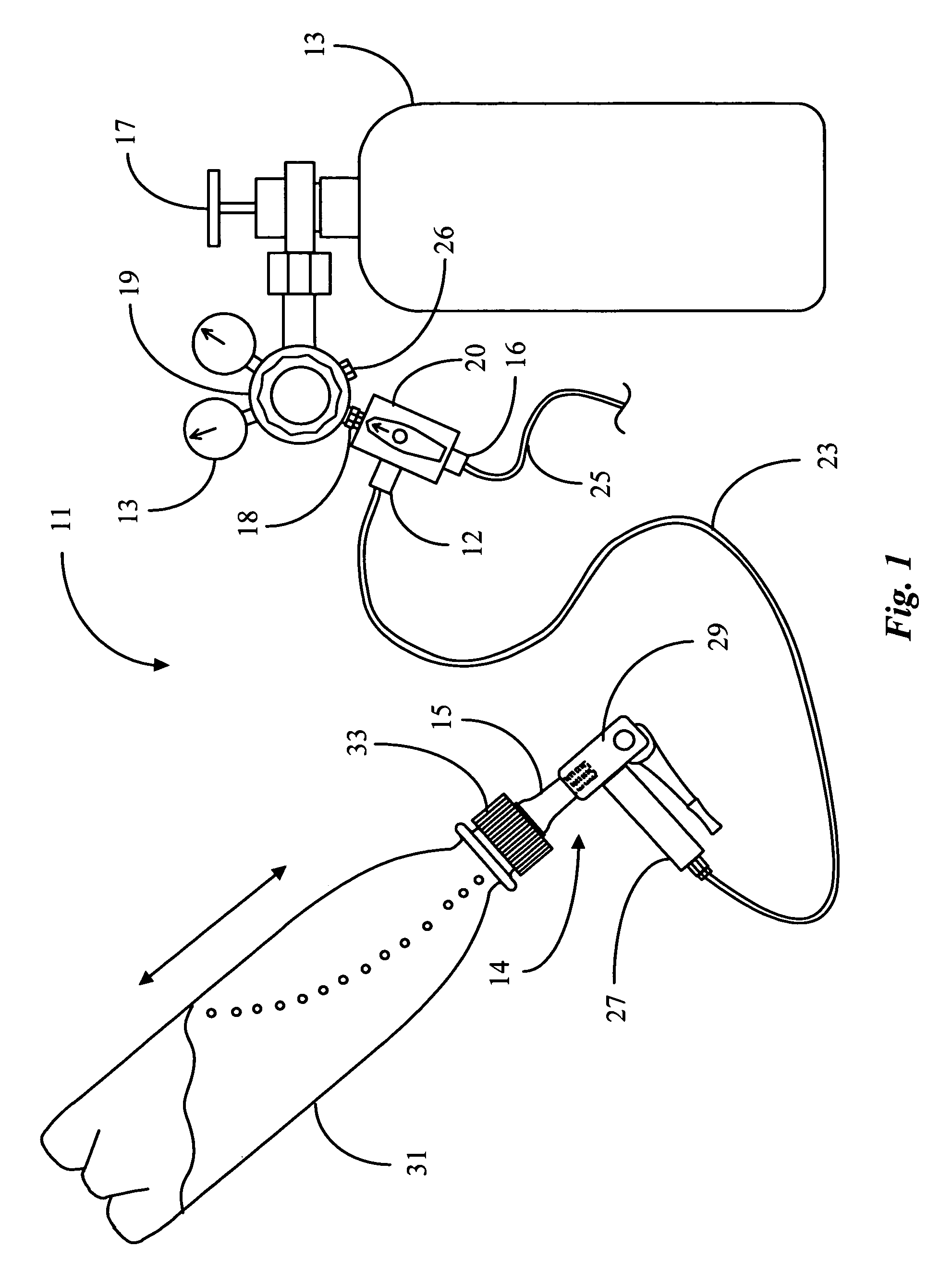

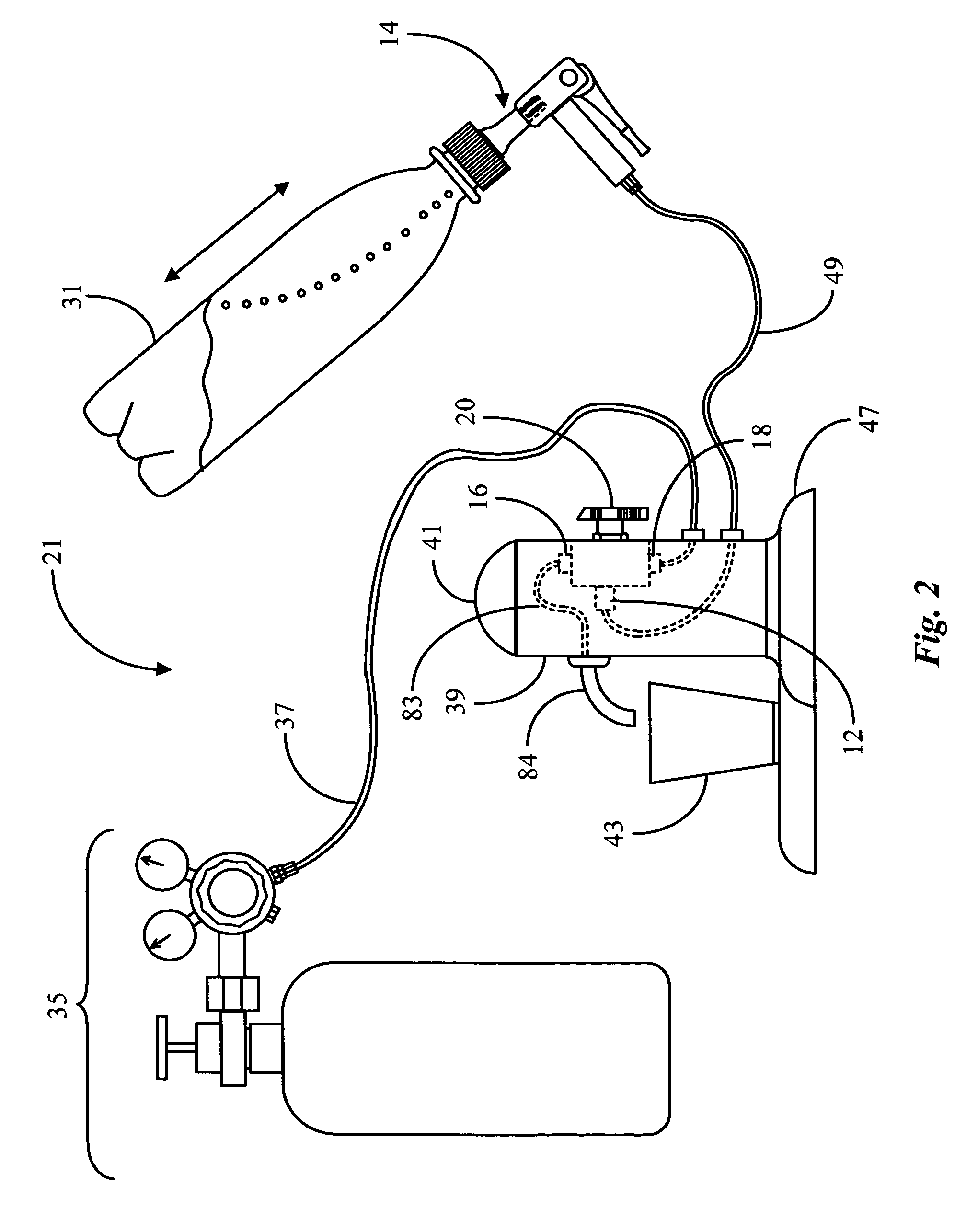

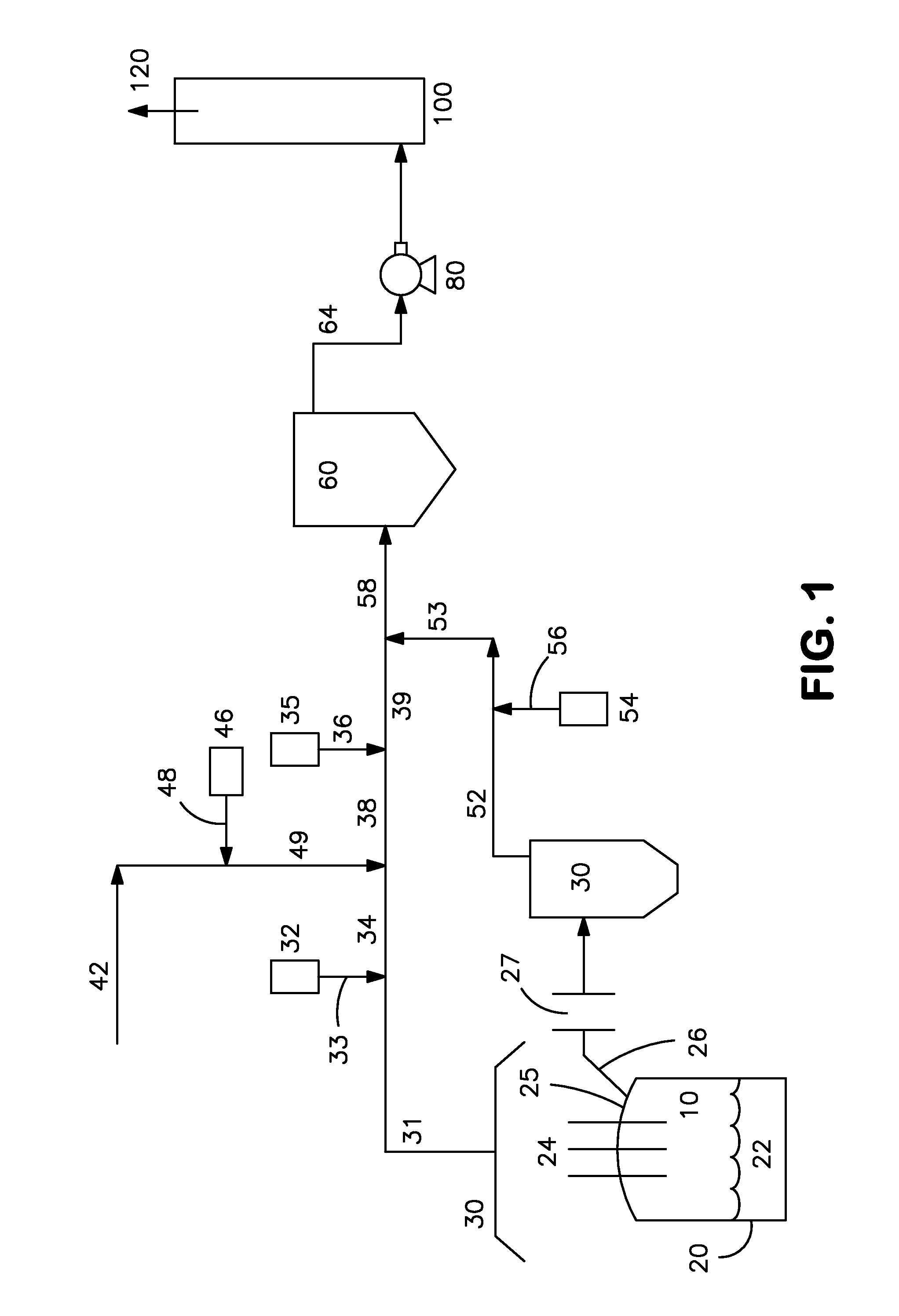

Method and apparatus for preserving beverages and foodstuff

InactiveUS20060016511A1Lower concentration levelsLiquid fillingFood preservationEngineeringOXYGEN EXPOSURE

Systems and methods for preserving a perishable material sensitive to oxygen and bacterial spoilage are taught. The systems in some embodiments comprise a pressurized source of a first gas other than oxygen and a container for the perishable material, the container having a sealable lid, a passage including a one-way valve through the lid connected by a gas conduit to the pressurized source, and a mechanism for venting the container. In various embodiments oxygen exposure to the perishable material in the container is diluted by at least one cycle of pressurizing the container with the first gas other than oxygen, and then venting the container. In some embodiments oxygen dilution is by vacuum.

Owner:CHANTALAT VINIT

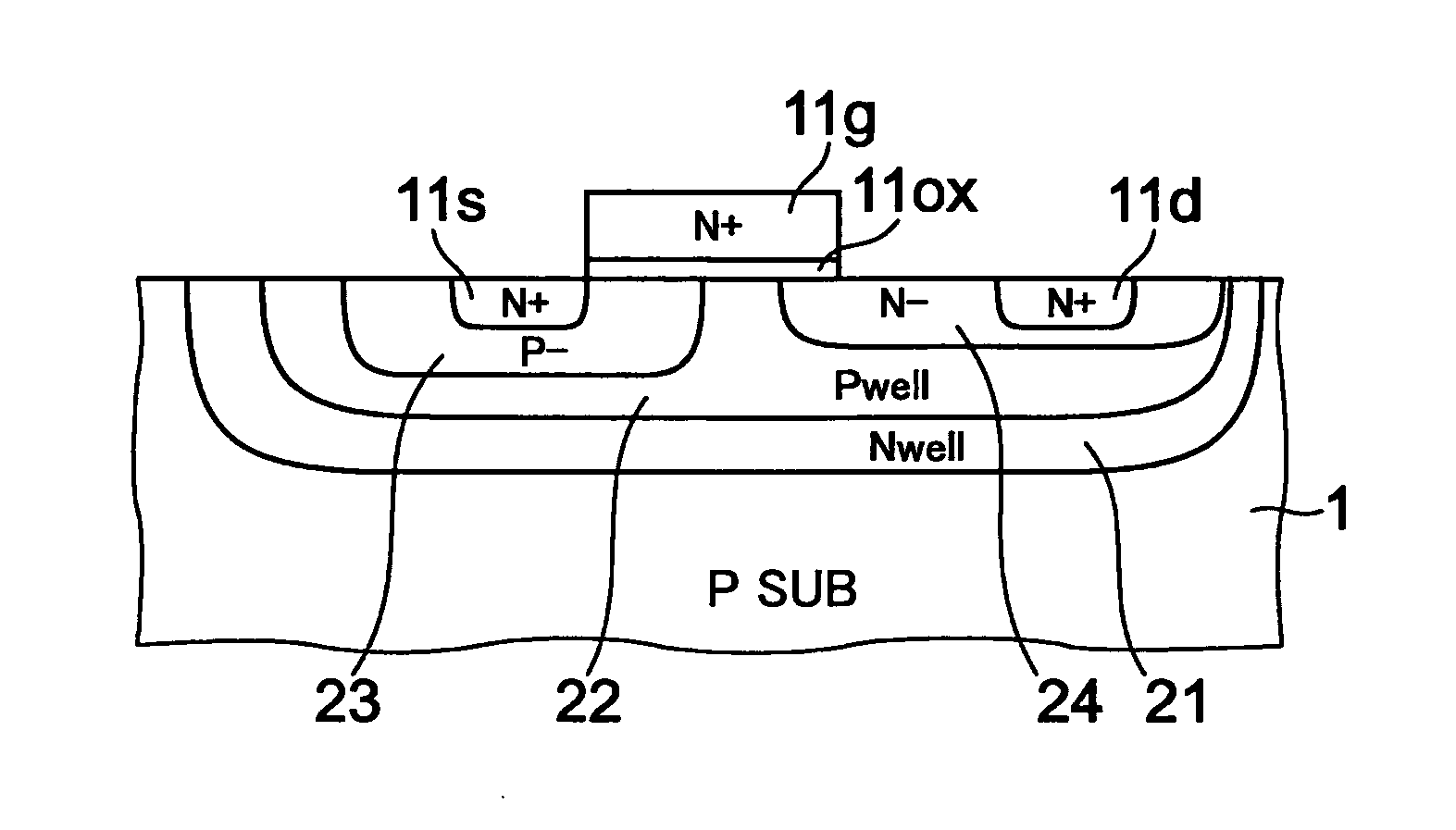

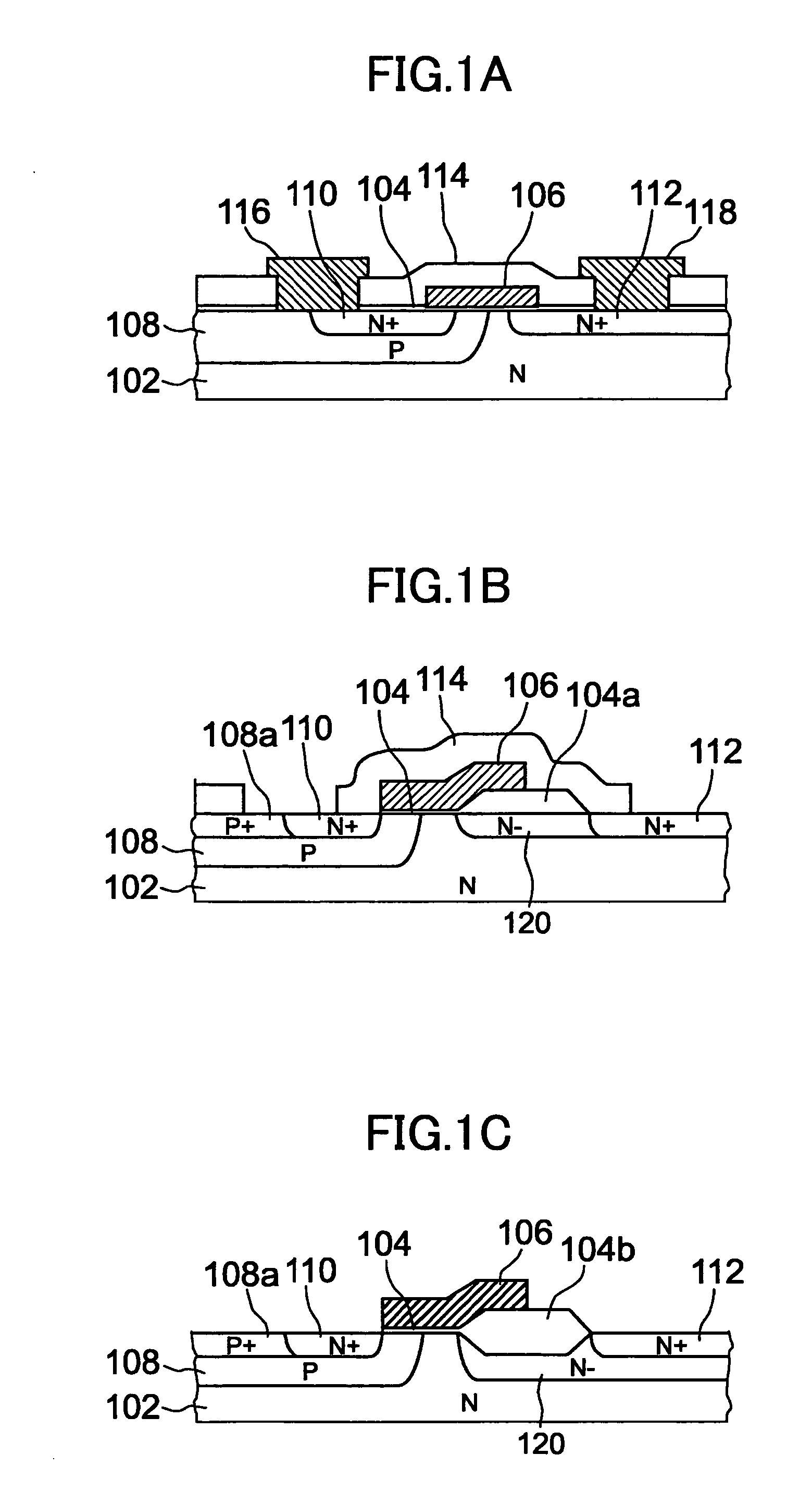

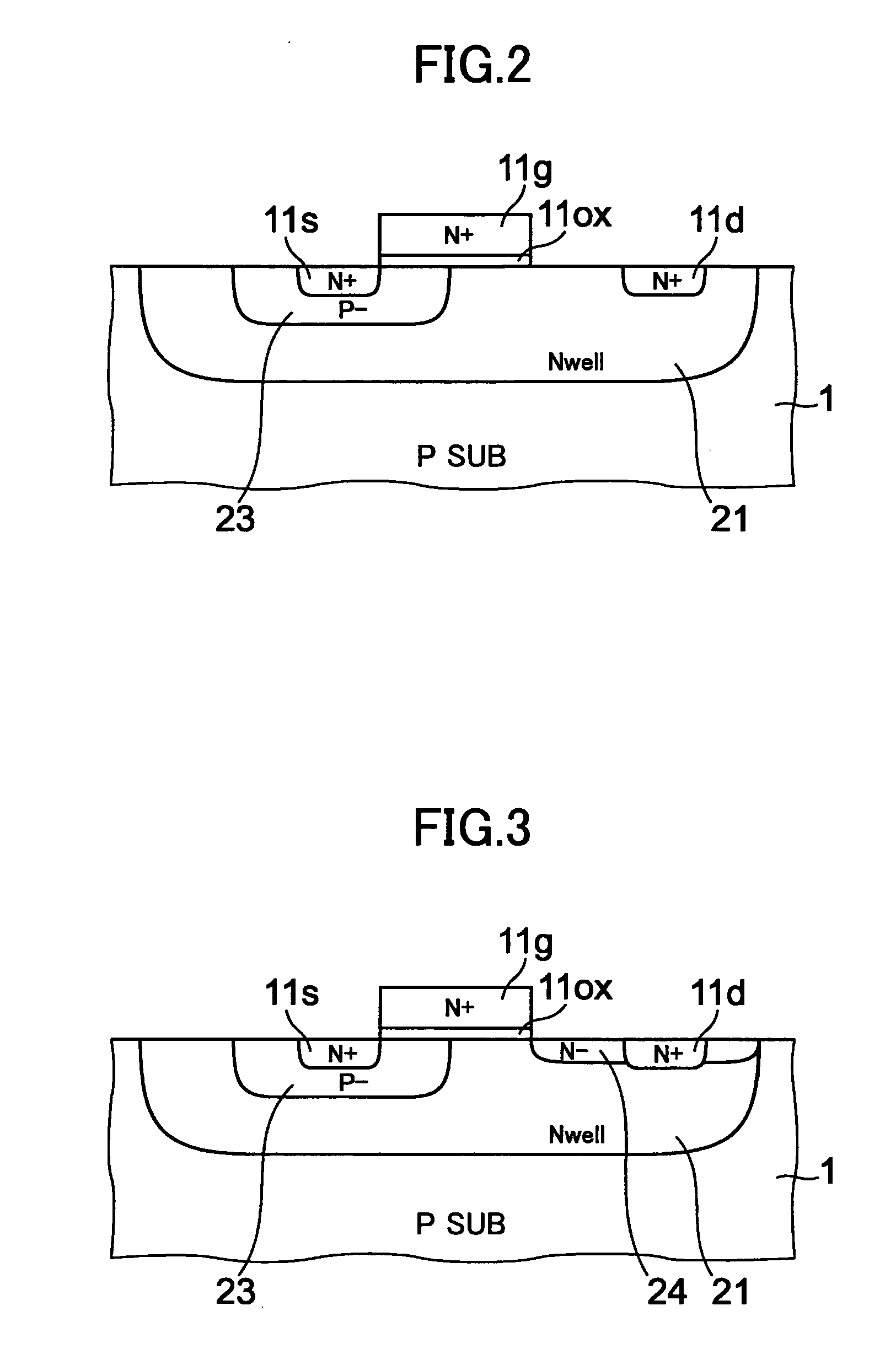

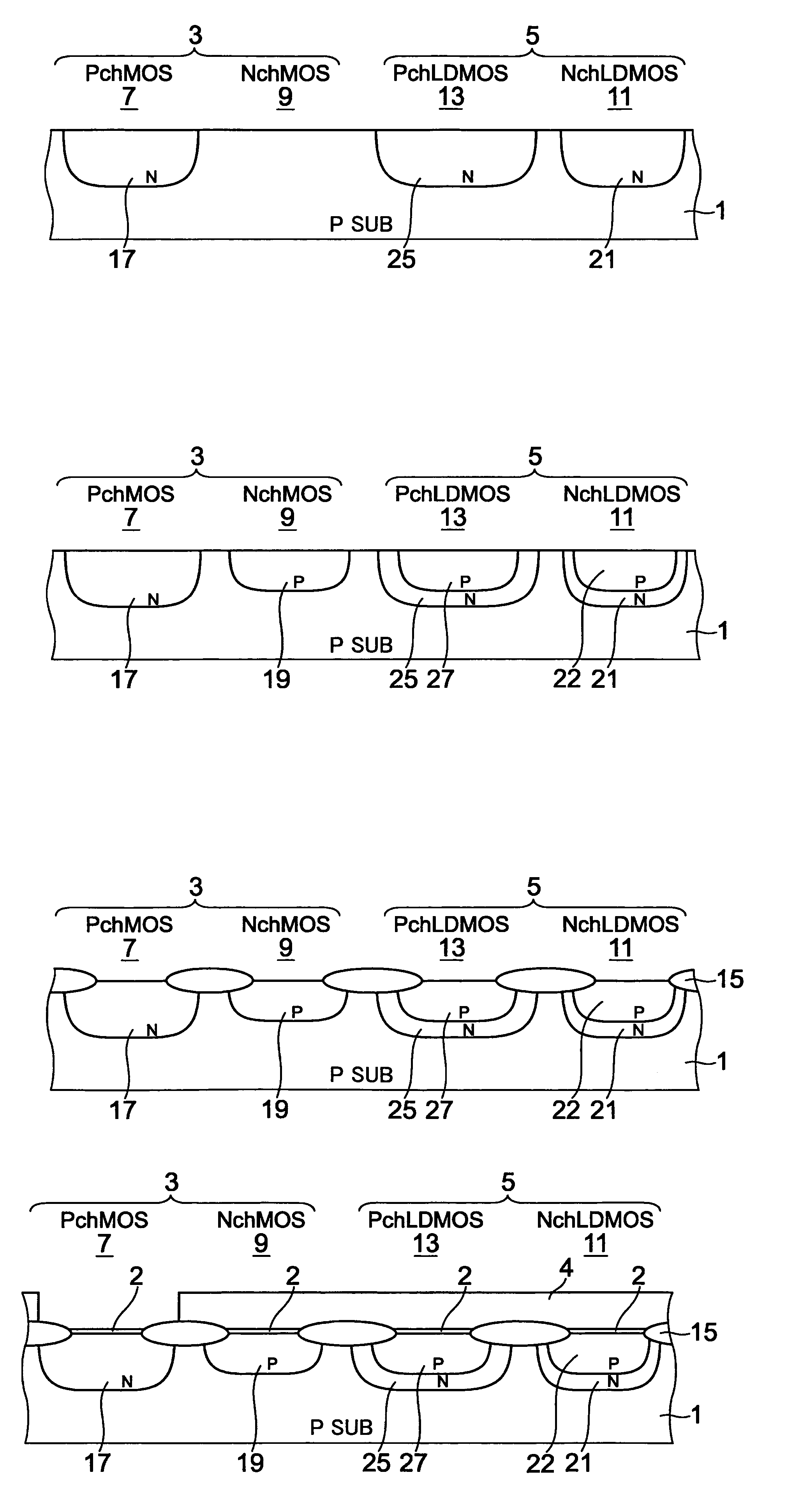

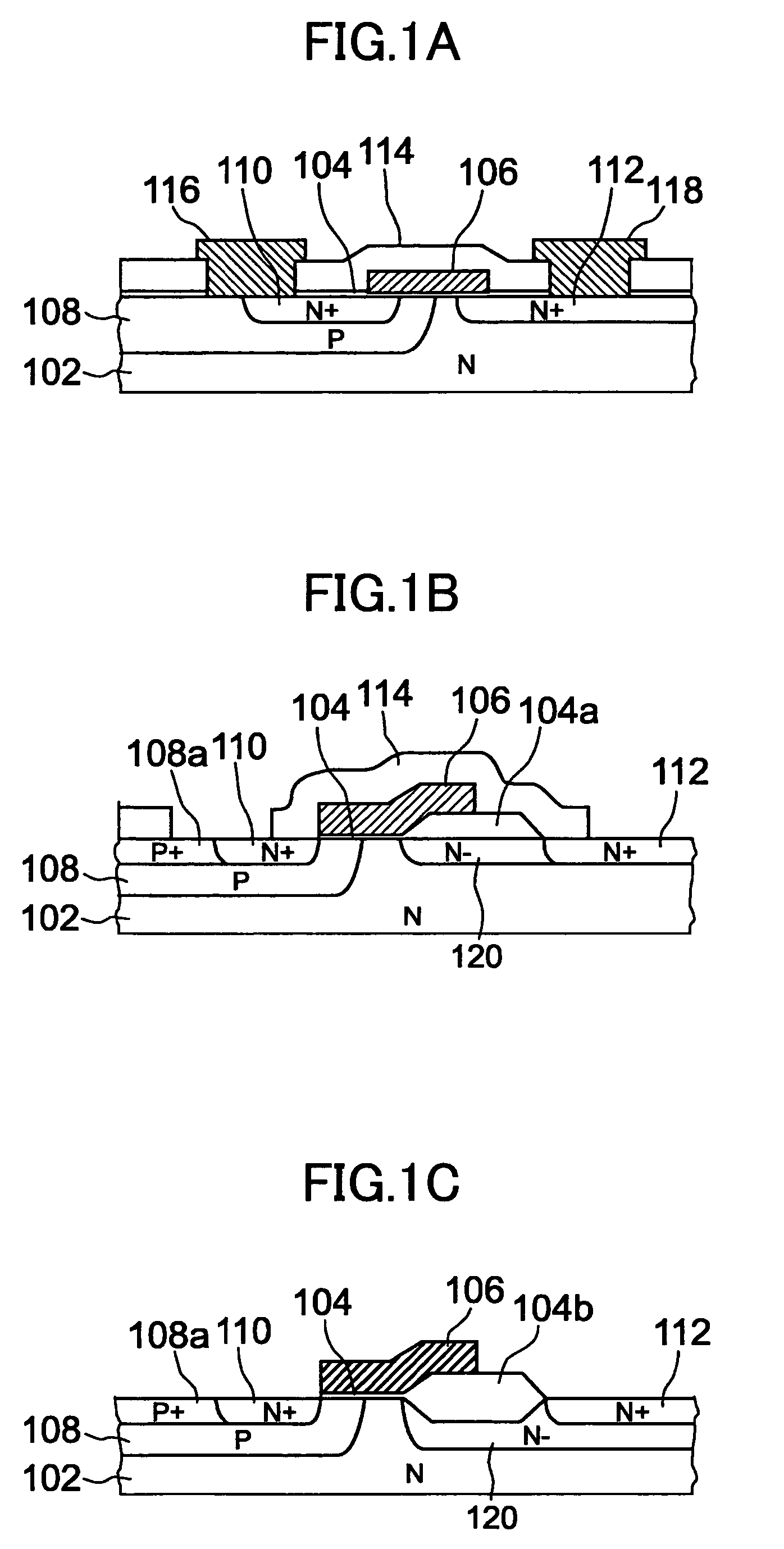

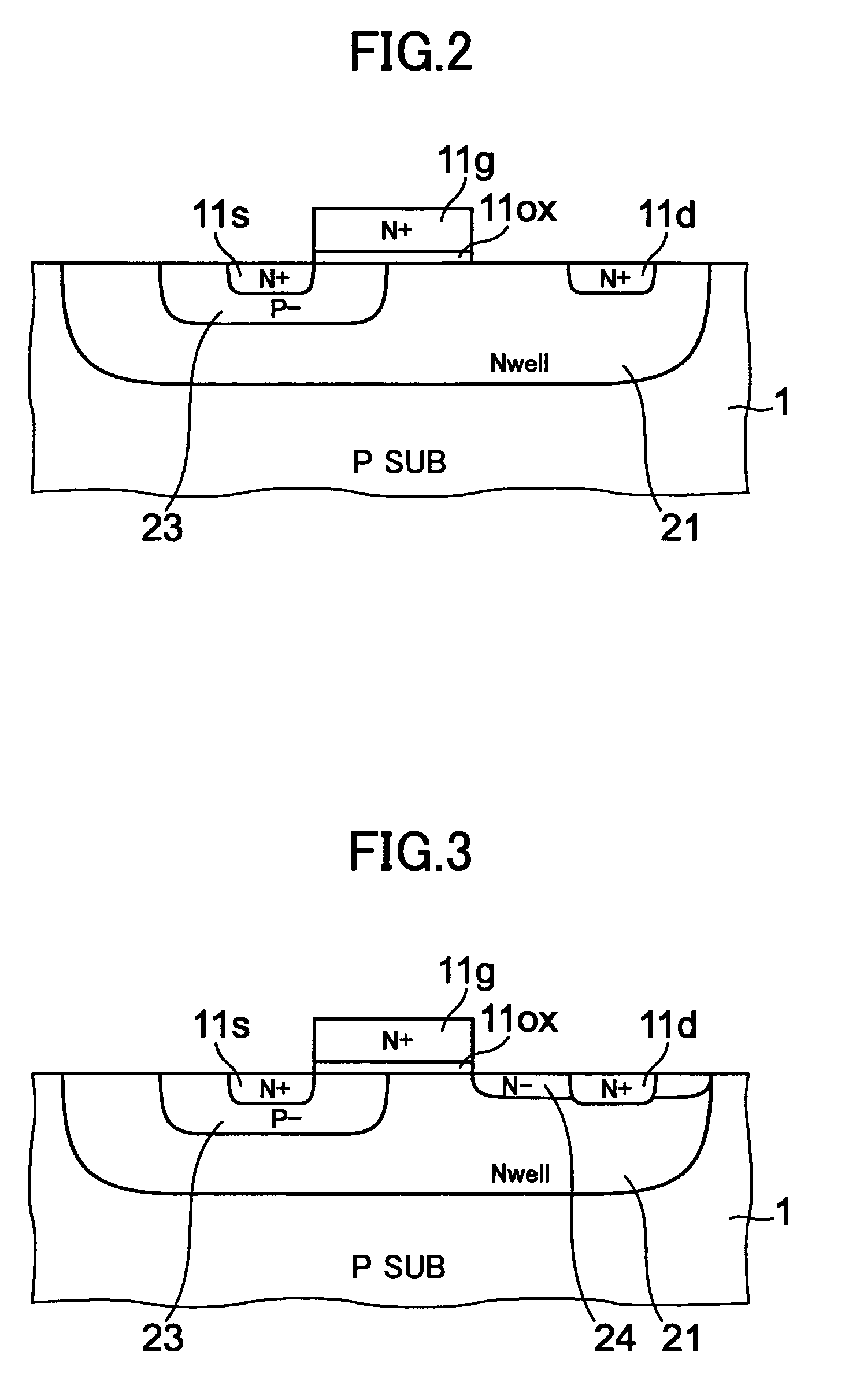

Semiconductor device and fabrication process thereof, and application thereof

InactiveUS20060197149A1Improve breakdown voltageLower concentration levelsSolid-state devicesSemiconductor/solid-state device manufacturingLDMOSManufacturing technology

An LDMOS transistor includes a gate insulation film formed on a semiconductor substrate, a gate electrode formed on the gate insulation film, a drain well of a first conductivity type formed in the substrate so as to include a gate region covered with the gate electrode, a channel well of a second conductivity type formed in the drain well in a partially overlapped relationship with the gate region, a source region of the first conductivity type formed in the channel well in an overlapping manner or adjacent with a side surface of the gate electrode, a medium-concentration drain region of the first conductivity type having an intermediate concentration level and formed in the drain well at a side opposing to the source region in a manner partially overlapping with the gate region, the medium-concentration drain region being formed with a separation from the channel well, a drain region of the first conductivity type formed in the medium-concentration drain region with a separation from the gate region, a low concentration well of the second conductivity type formed inside the drain well so as to include at least a part between said channel well and the medium-concentration drain region.

Owner:RICOH KK

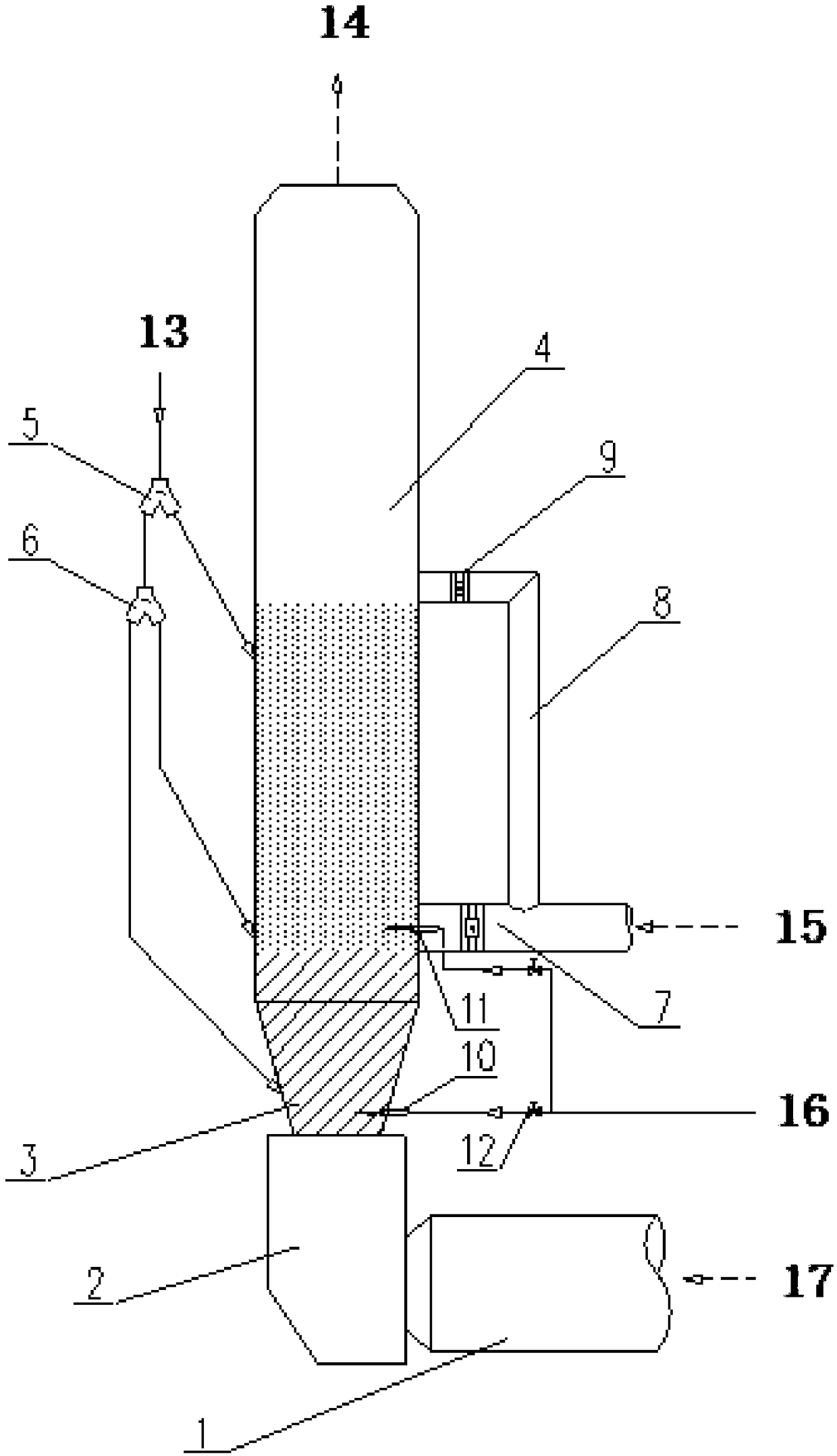

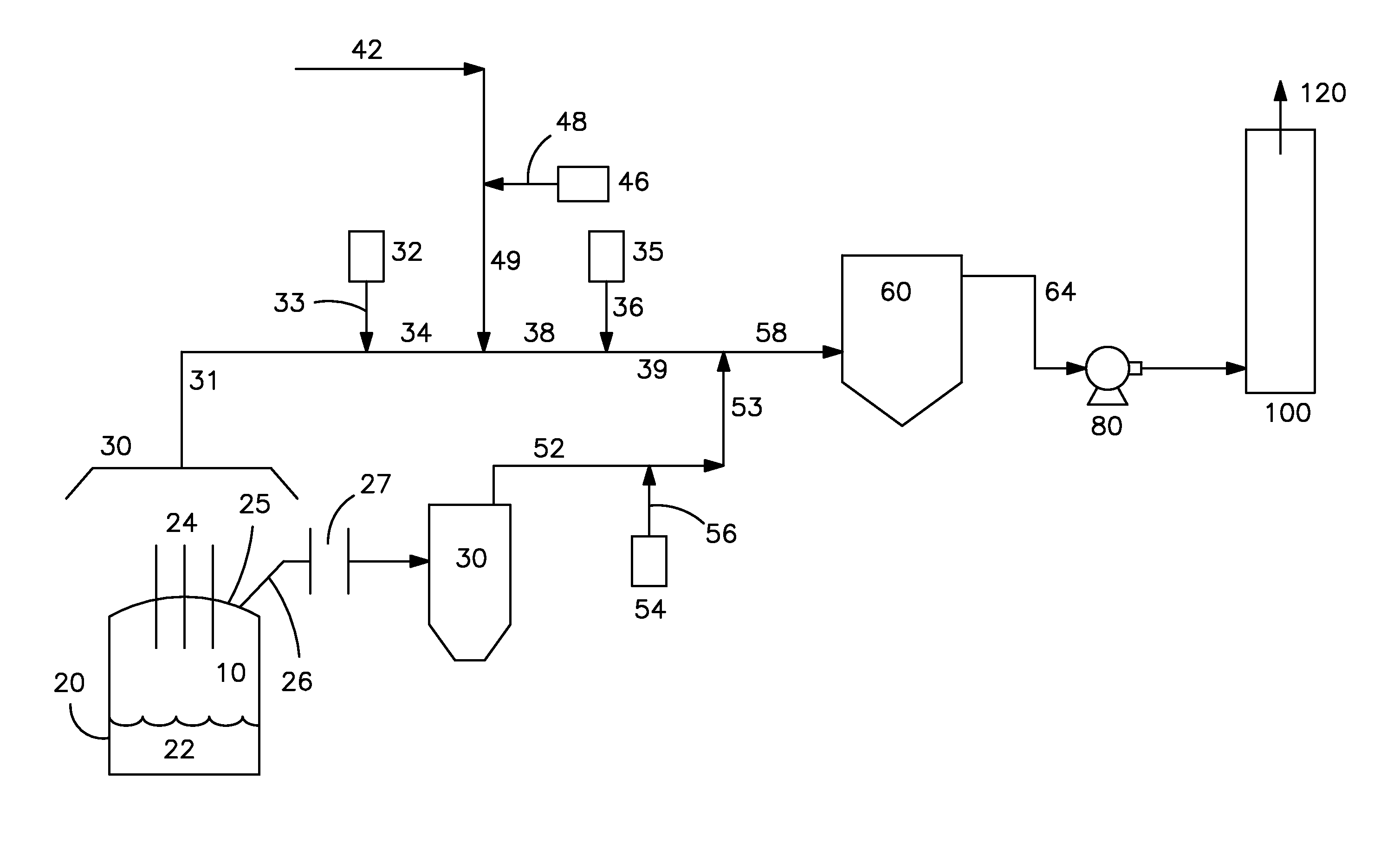

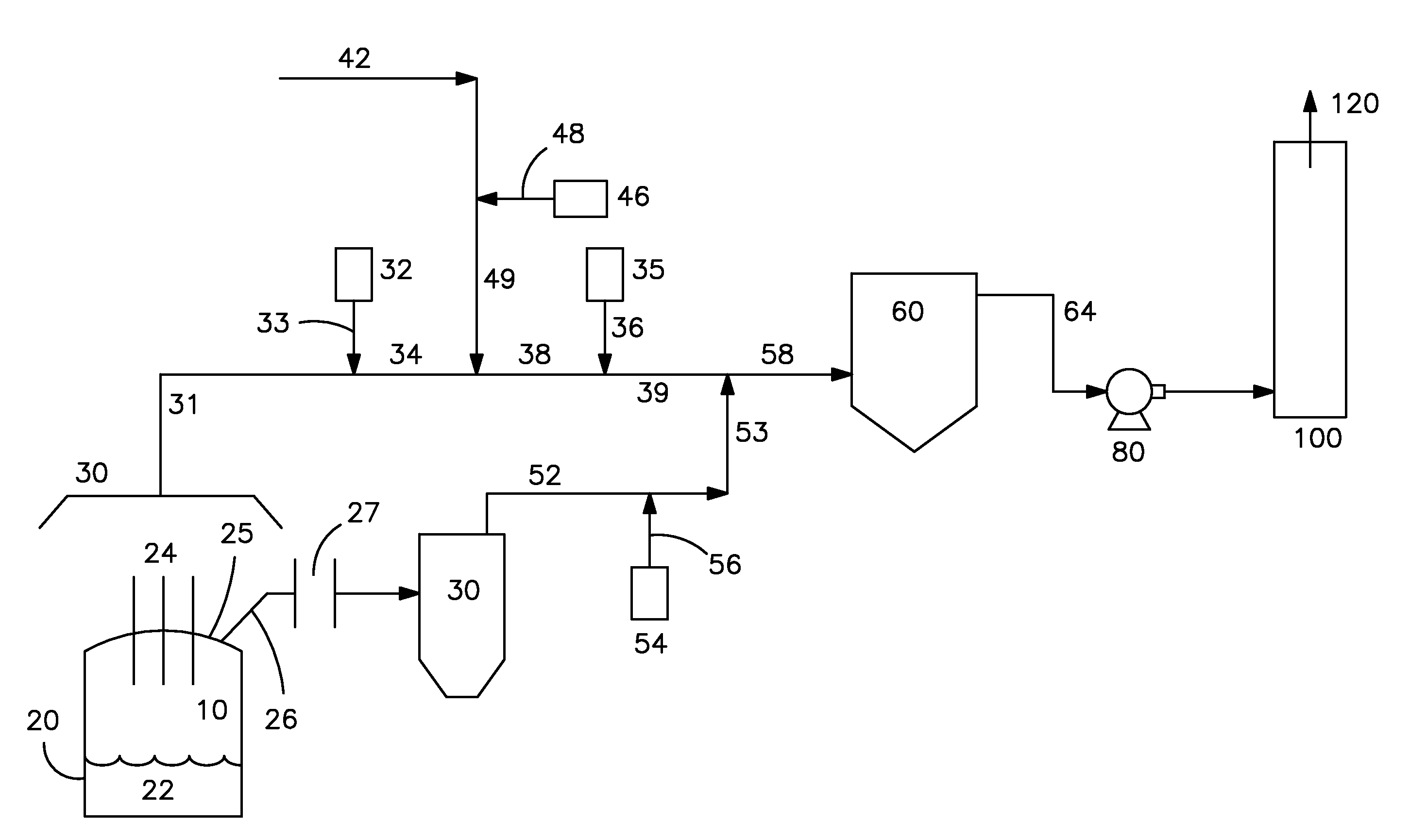

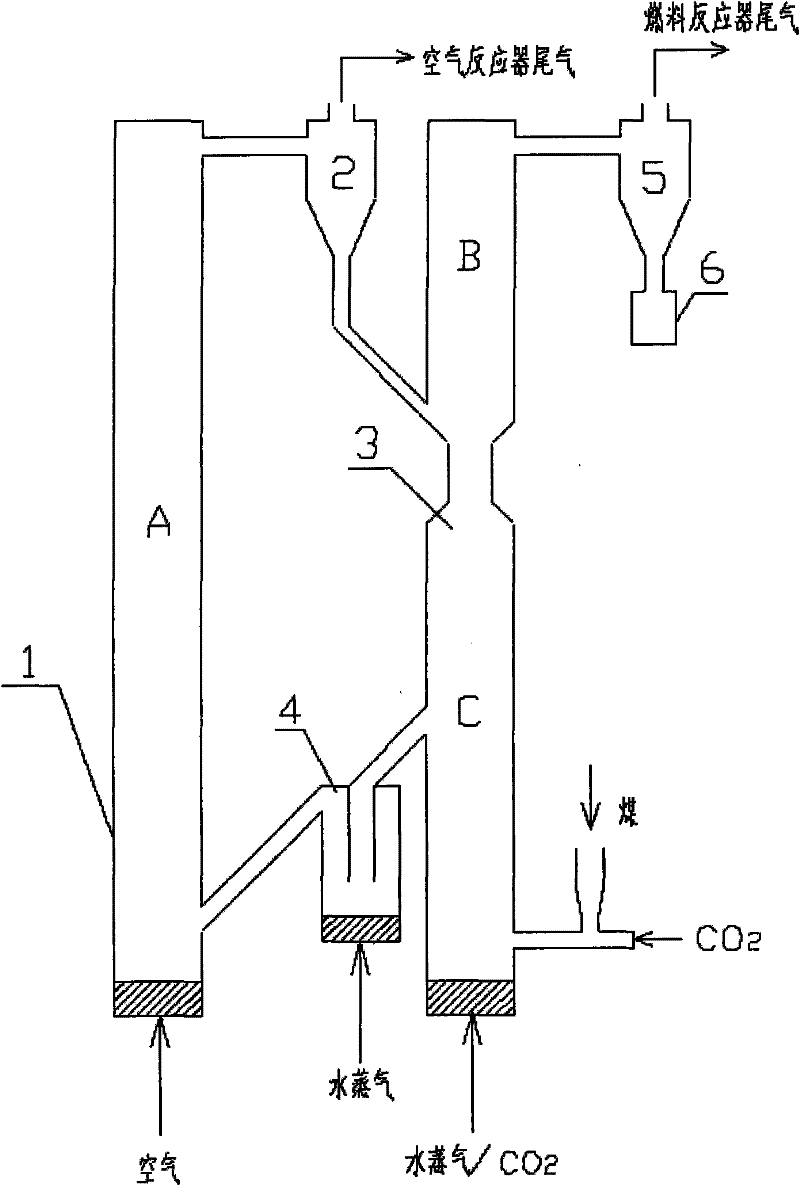

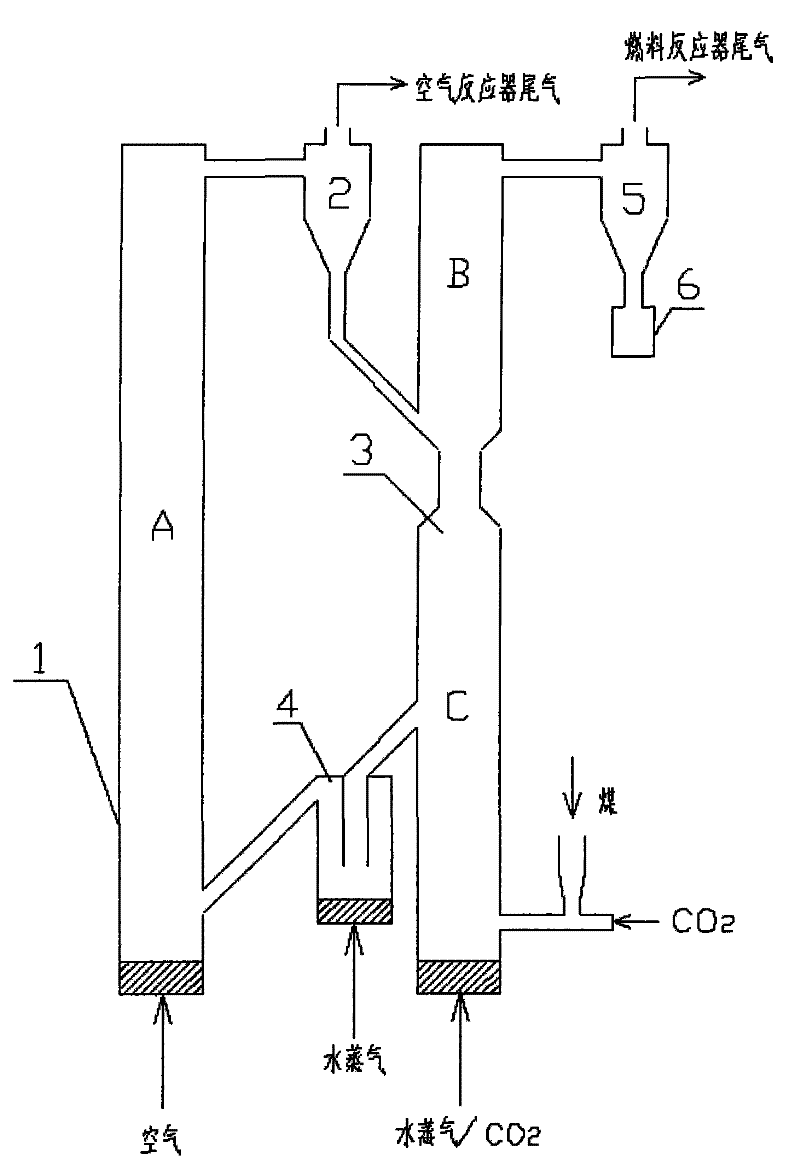

Firing system gradient combustion self-denitration technological method

ActiveCN108167860ALower concentration levelsGood for burnoutFuel supply regulationIndirect carbon-dioxide mitigationFlue gasEngineering

The invention relates to a firing system gradient combustion self-denitration technological method, and belongs to the technical field of cement industry flue gas denitration. According to the firingsystem gradient combustion self-denitration technological method, a gradient combustion environment with an extreme oxygen deficient area-oxygen deficient combustion area-oxygen enrichment burnout area is formed in a decomposing furnace; the gradient combustion environment is realized through classified feeding of decomposing furnace inlet fuel, tertiary air and decomposing furnace inlet materials; a furnace inlet tertiary air hose is divided into an upper branched pipe and a lower branched pipe, the tertiary air lower branched pipe is fed in from the lower portion of a decomposing furnace cylinder, and the upper branched pipe is fed in from the middle of the decomposing furnace cylinder; the decomposing furnace inlet fuel is divided into two layers and is further fed into the furnace, thelower layer of the fuel is fed in from a decomposing furnace cone, and the upper layer of the fuel is fed in from the decomposing furnace cylinder; the extreme oxygen deficient area refers to the decomposing furnace area located below the tertiary air lower branched pipe; the oxygen deficient combustion area refers to the area located between the tertiary air upper branched pipe and the tertiaryair lower branched pipe; and the oxygen enrichment burnout area refers to the decomposing furnace area located above the tertiary air upper branched pipe. The firing system gradient combustion self-denitration technological method has the advantages that the process is optimized, reliability is good and the flow path is reasonable.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

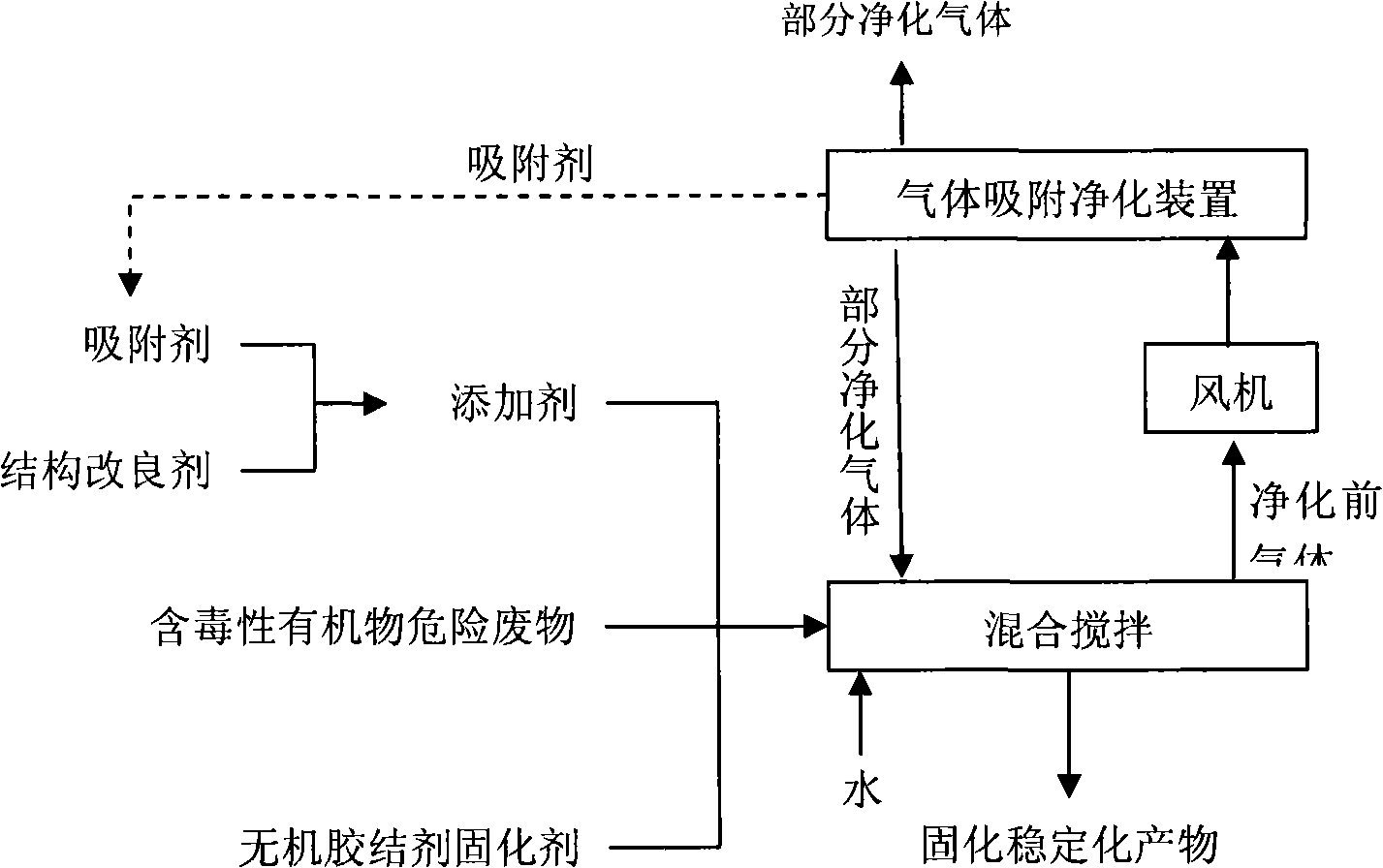

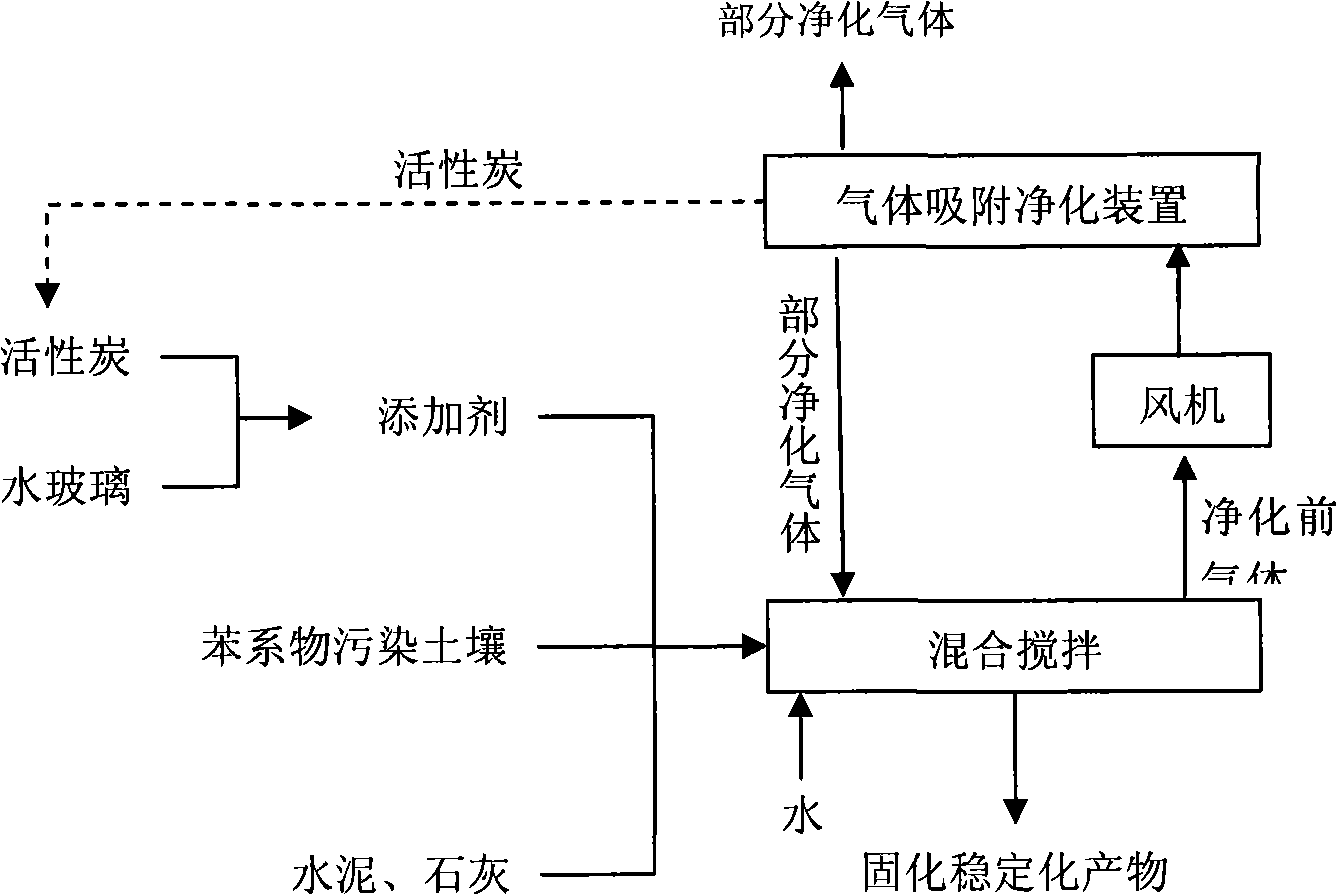

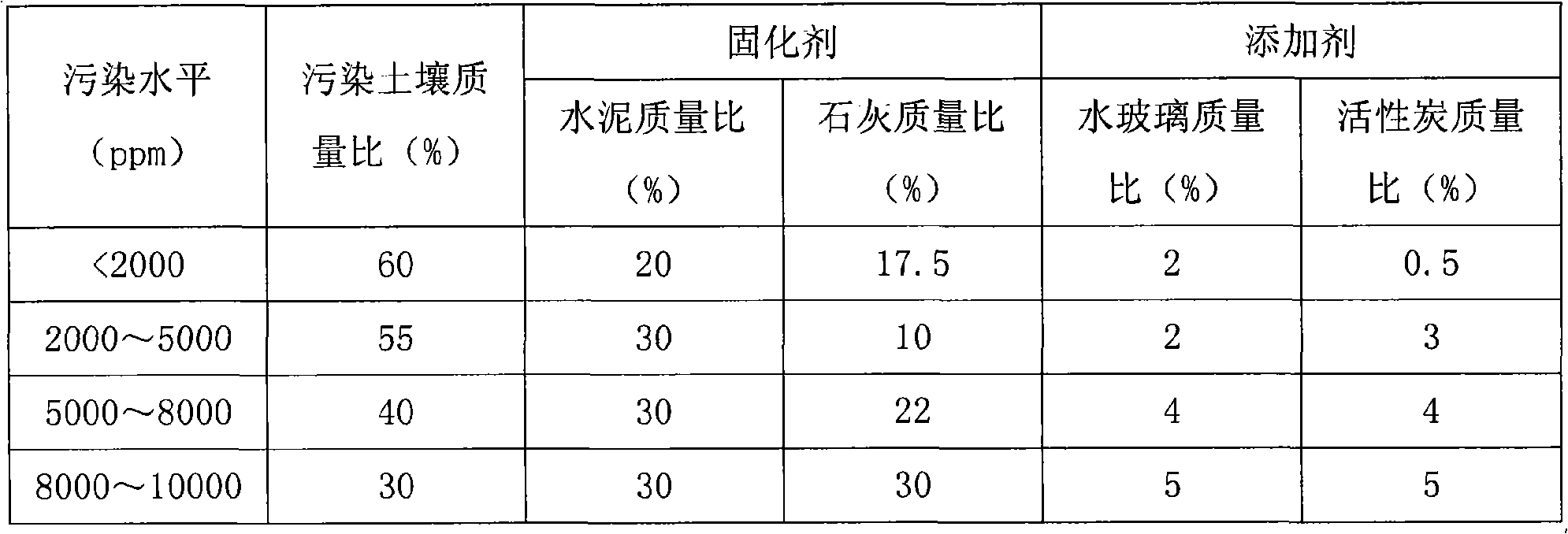

Solidifying and stabilizing method for toxicity containing organic matter dangerous waste matter

The invention discloses a solidification and stabilization method for a hazardous waste containing toxic organic compounds, which belongs to the hazardous waste treatment technical field of environment protection. According to a dry weight ratio, 30 to 60 percent of the hazardous waste containing toxic organic compounds, 0.5 to 10 percent of an additive, 30 to 60 percent of inorganic cementing agent and curing agent are added into an agitator and are stirred by adding water, meanwhile, a gas internal circulation device is started, the gas in the agitator is adsorbed and purified by a gas adsorbing and purifying device, and then part of the gas is fed back into the agitator; after being evenly mixed and stirred materials are discharged, solidified and fed into a maintenance house, and the solidification and stabilization of the hazardous waste containing toxic organic compounds is finished. The additive comprises an adsorbent with adsorbing effect and a structural modifier which can improve the structural performance of a product, such as activated carbon, water glass, calcium chloride, etc. The inorganic cementing agent and curing agent refers to hydraulicity cementing material. The solidification rate of the invention can reach more than 90 percent; and gas circulation can reduce polluted gas discharging, thus being capable of effectively reducing the occurrence of secondary pollution.

Owner:TSINGHUA UNIV

Method and apparatus for preserving beverages and foodstuff

Owner:CHANTALAT VINIT

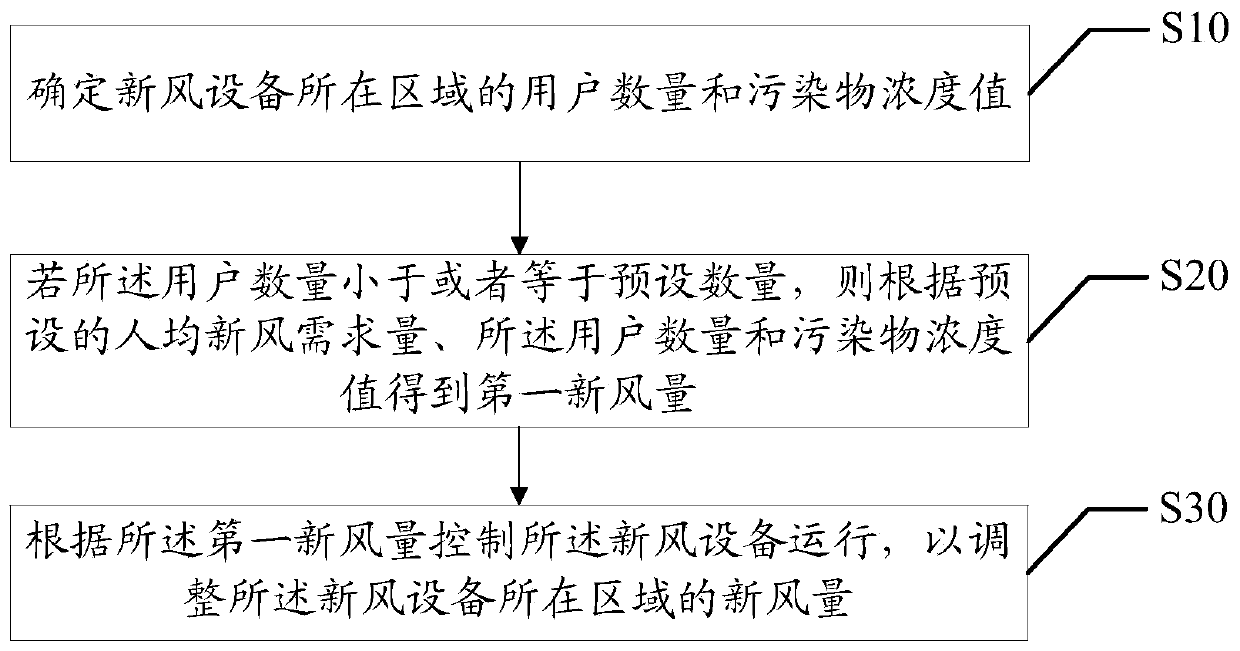

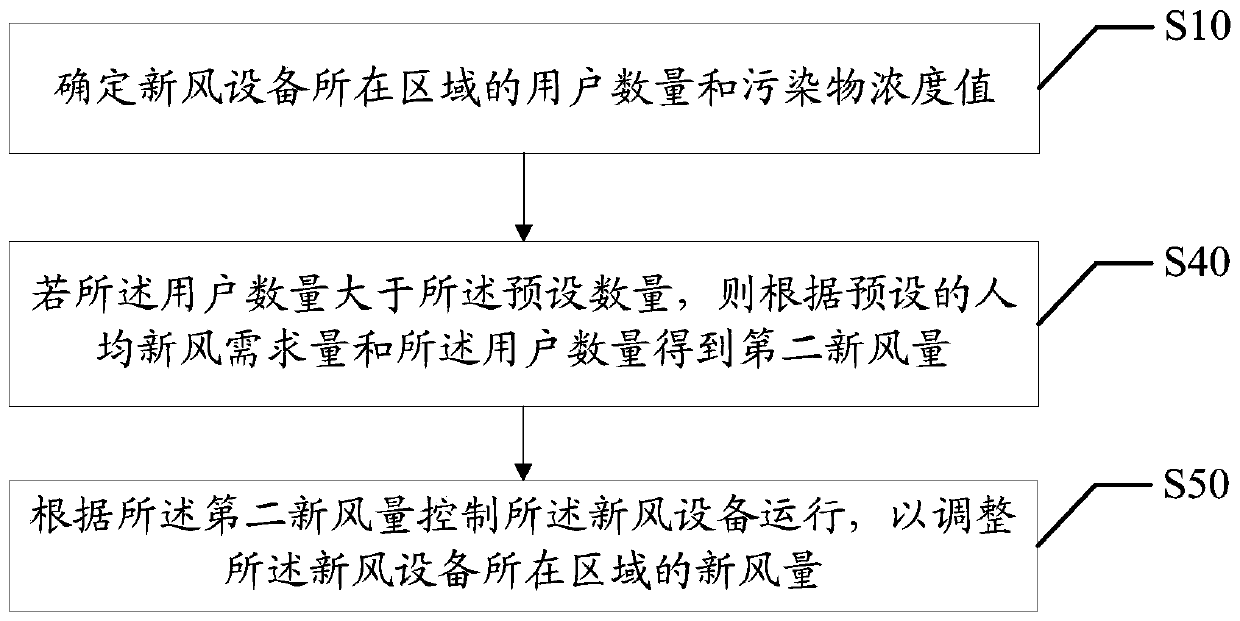

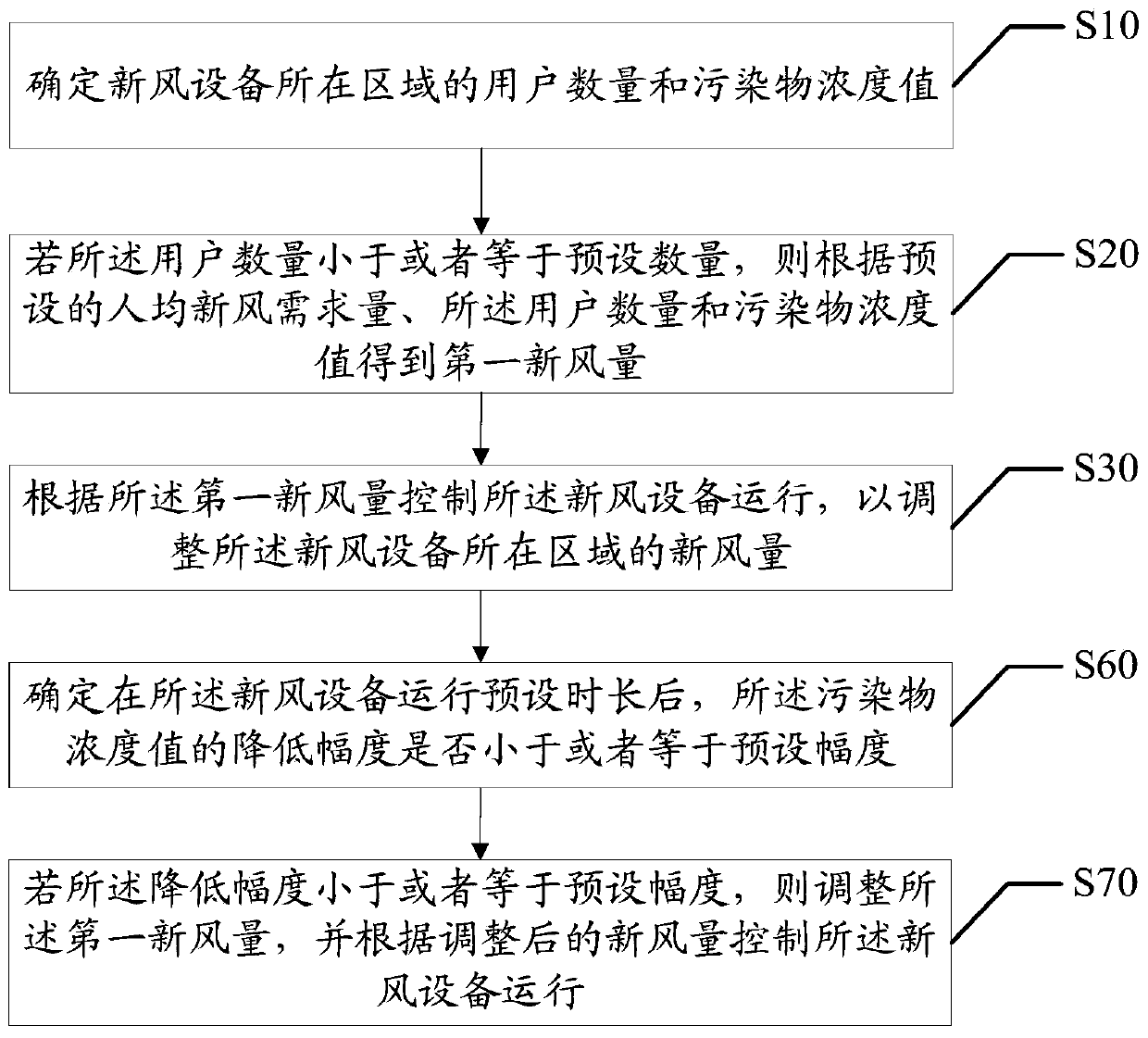

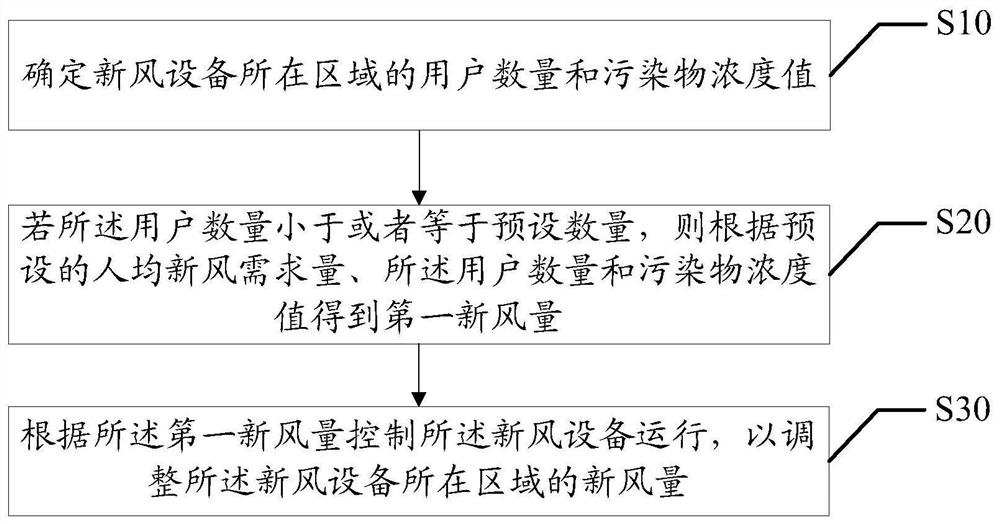

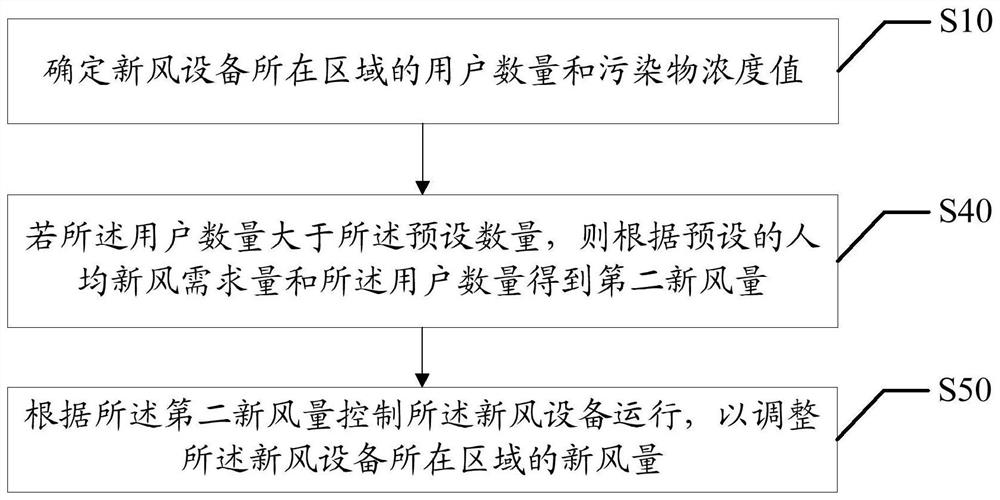

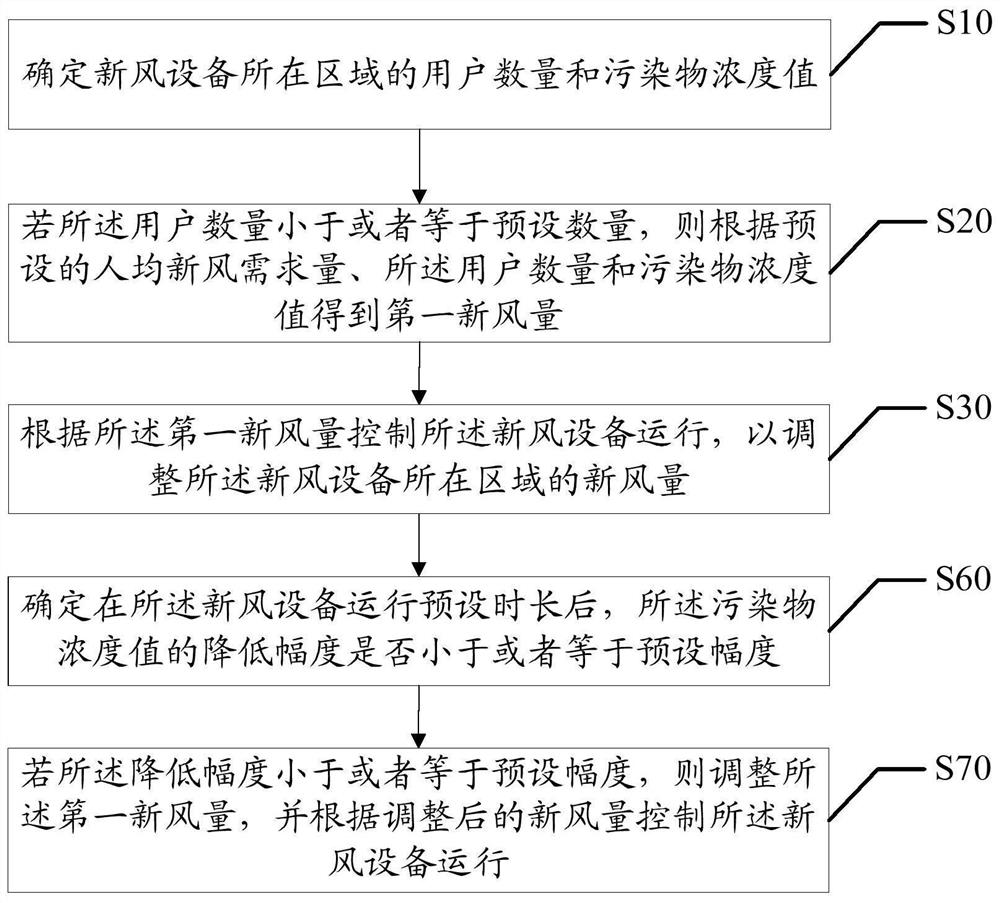

Control method of fresh air equipment, fresh air equipment and readable storage medium

ActiveCN110848909AGuarantee air qualityQuality assuranceMechanical apparatusSpace heating and ventilation safety systemsFresh airEnvironmental engineering

The invention discloses a control method of fresh air equipment, the fresh air equipment and a readable storage medium. The method comprises the steps that the user number and the pollutant concentration value of the area where the fresh air equipment is located are confirmed; if the user number is smaller than or equal to the preset number, the first fresh air quantity is obtained according to the preset per capita fresh air demand quantity, the user number and the pollutant concentration value; and the fresh air equipment is controlled to run according to the first fresh air quantity, so that the fresh air quantity of the area where the fresh air equipment is located is adjusted. The accuracy of adjusting the fresh air quantity of the fresh air equipment is improved, and the air qualityof area where the fresh air equipment is located is guaranteed.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

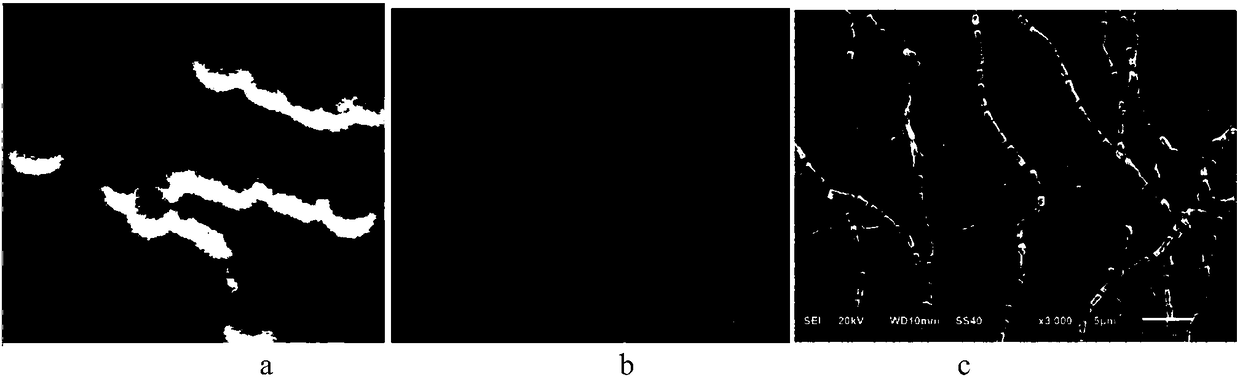

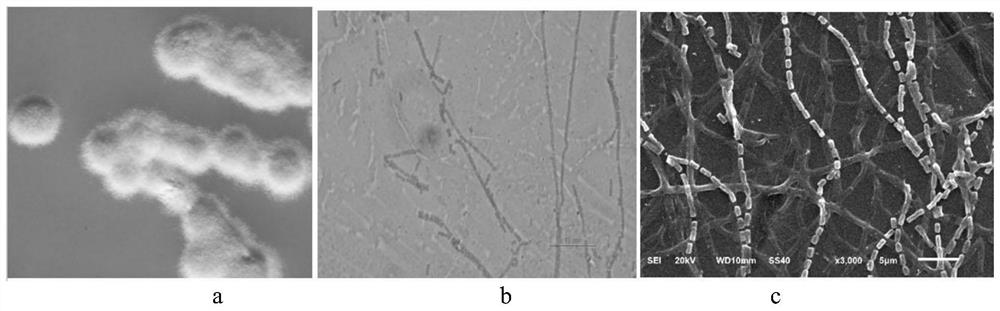

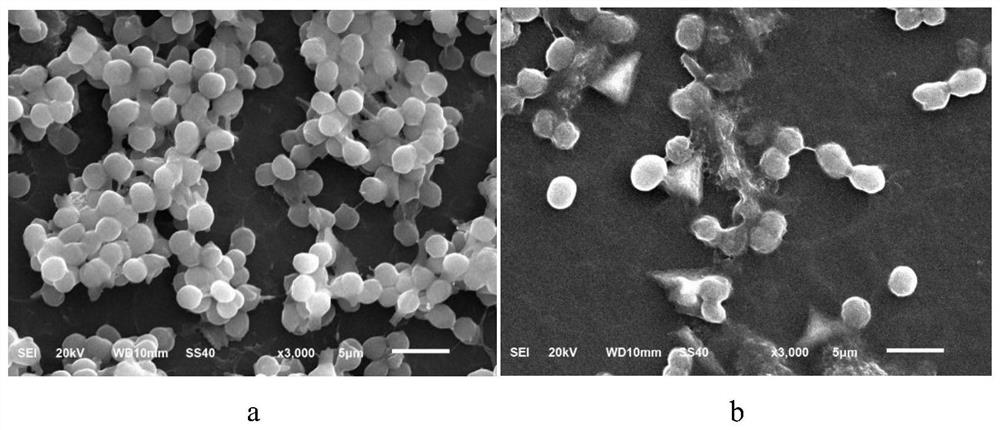

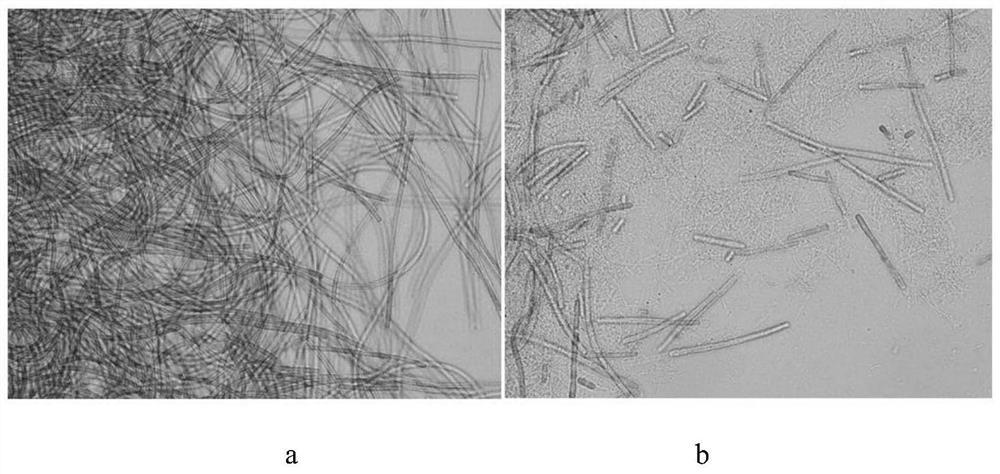

Multi-functional Streptomyces amritsarensis and application thereof

The invention relates to the field of micro-organisms, and particularly relates to a multifunctional Streptomyces amritsarensis and application thereof. Streptomyces amritsarensis HG-16, with a preservation number of CCTCC-M-2018237. The streptomycin cannot only kill the microcystin, but also antagonize the fusarium graminearum. The fermentation liquid and the active secretion can effectively inhibit the production of the microcystin in a short time, can inhibit the expression of the synthetic gene of 90% microcystin within 9 hours, and can completely inhibit the expression of the microcystingene after 36 hours. Three days after the addition of the Streptomyces, the inhibition rate of the algae toxin is 93%; while for the algicidal bacteria which has been reported to have the effect of inhibiting the production of the microcystin needs more than 3 days to inhibit the synthesis of the microcystin.

Owner:SOUTHWEST UNIV

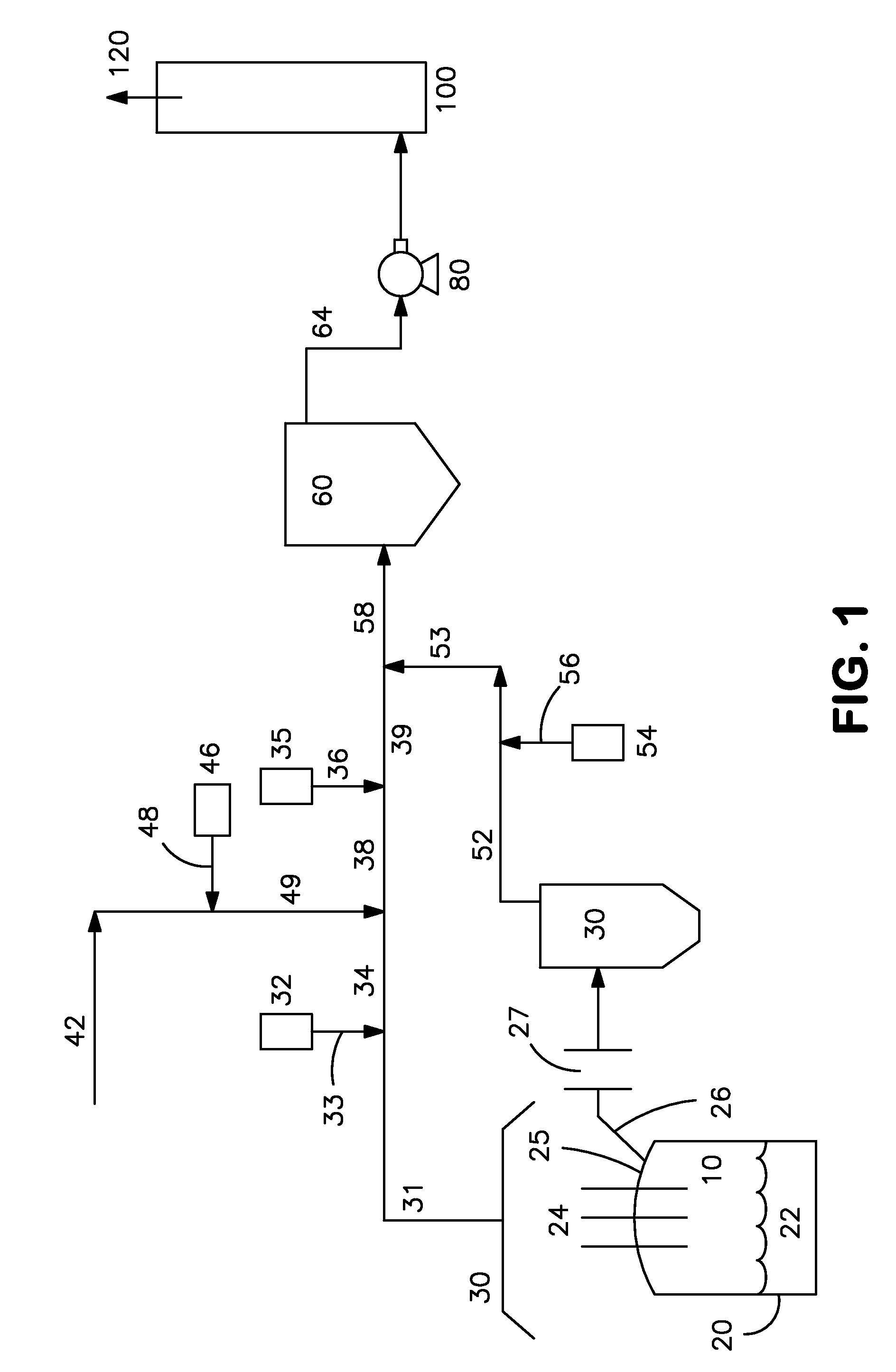

Combustion of co and combustibles in steel furnace offgases

InactiveUS20120213684A1Reduce contentJet momentumGas treatmentDispersed particle separationSteelmakingCombustion

Owner:WU KUANG TSAI +1

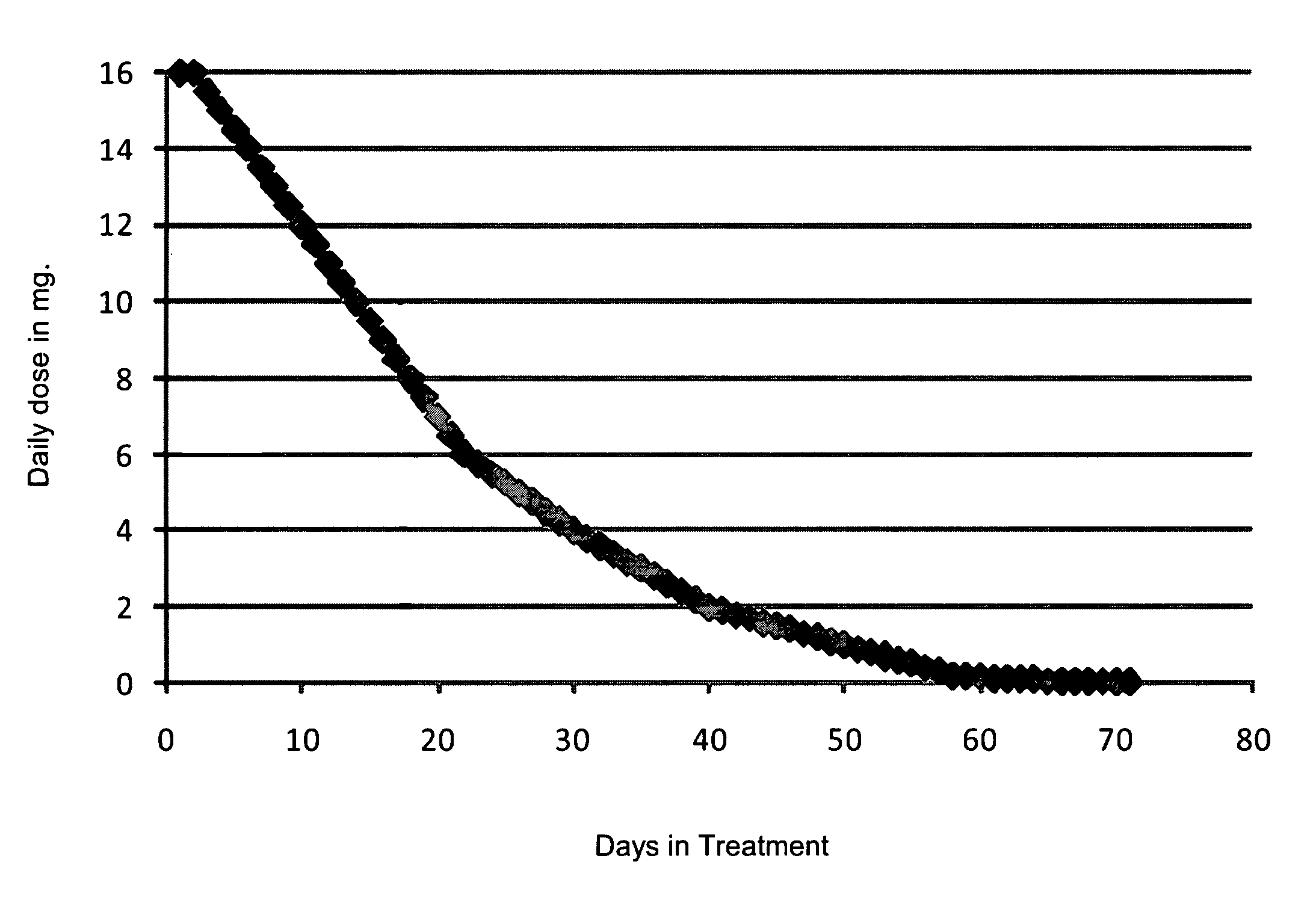

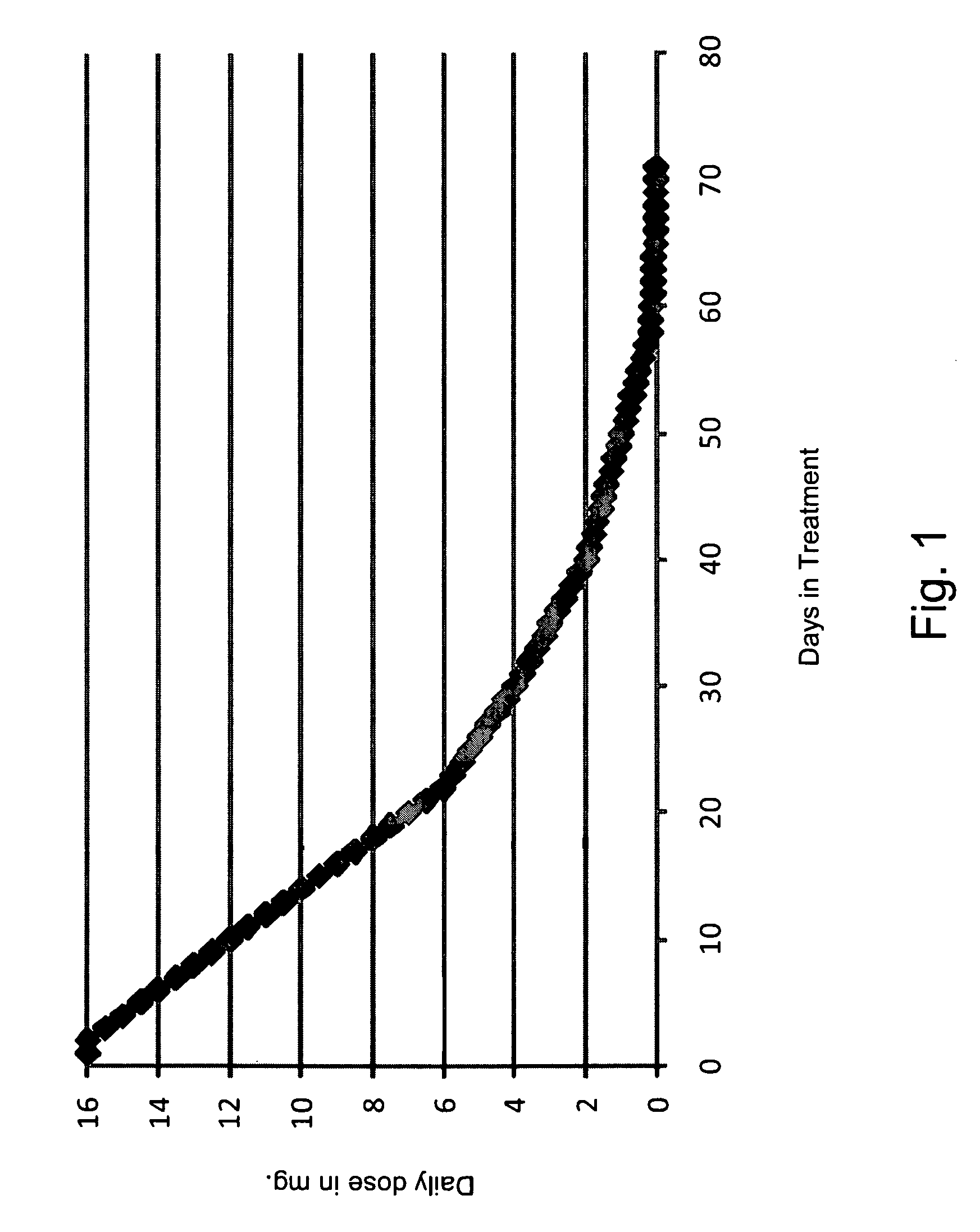

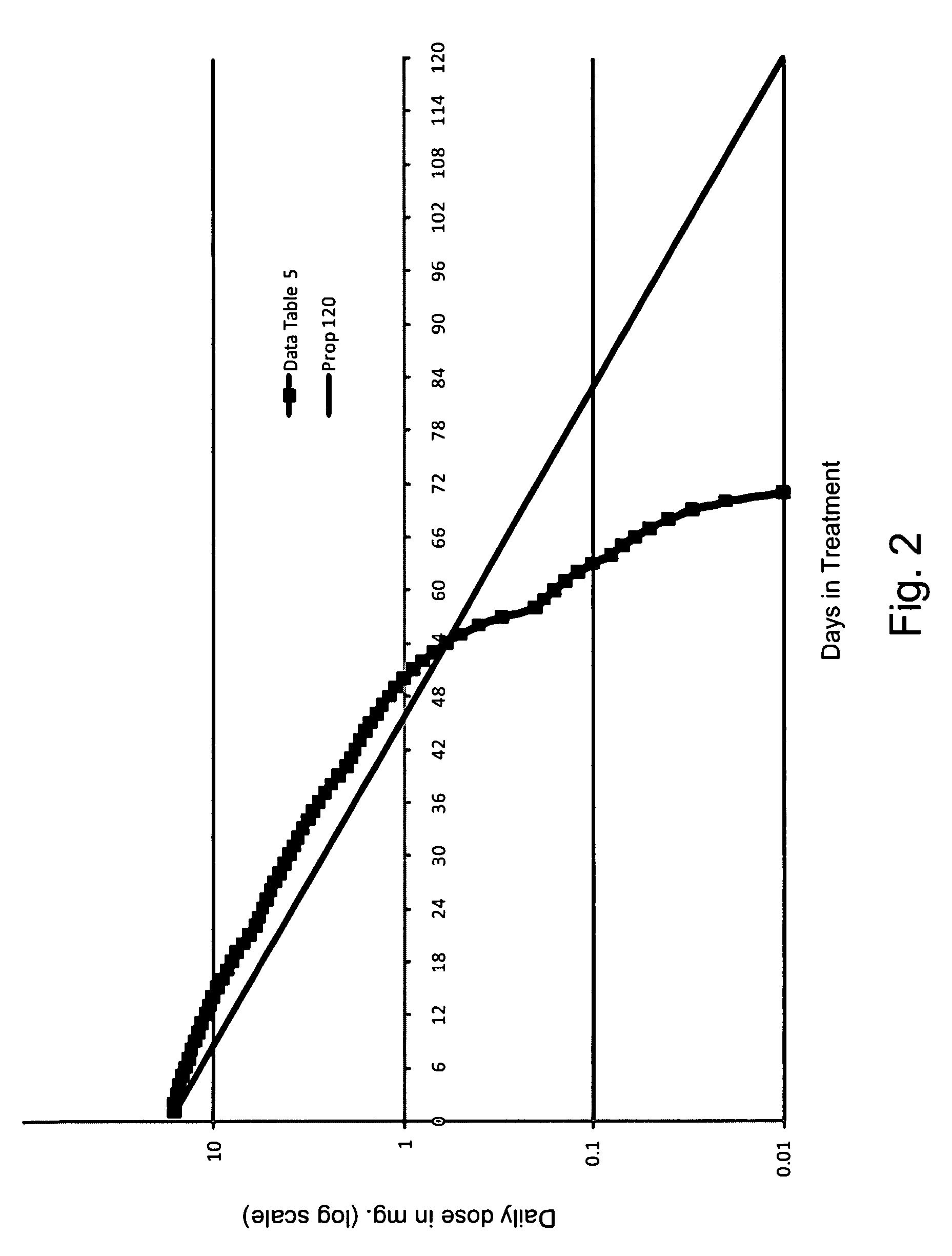

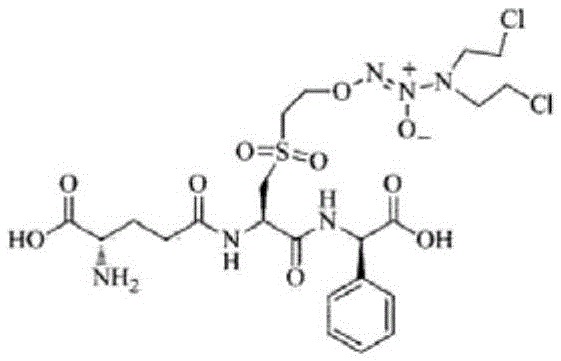

Method and dosage regimens for eliminating a chemical substance in blood

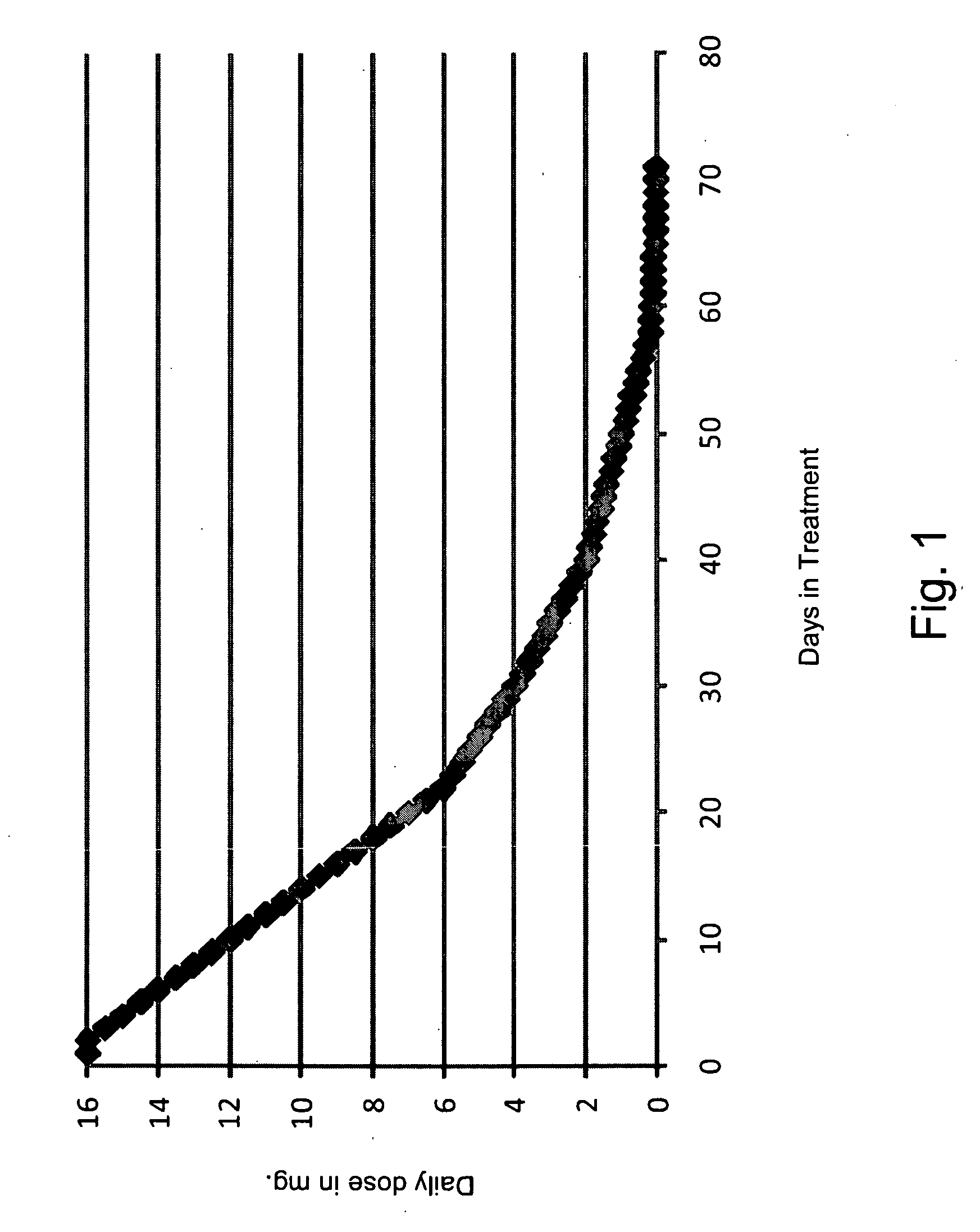

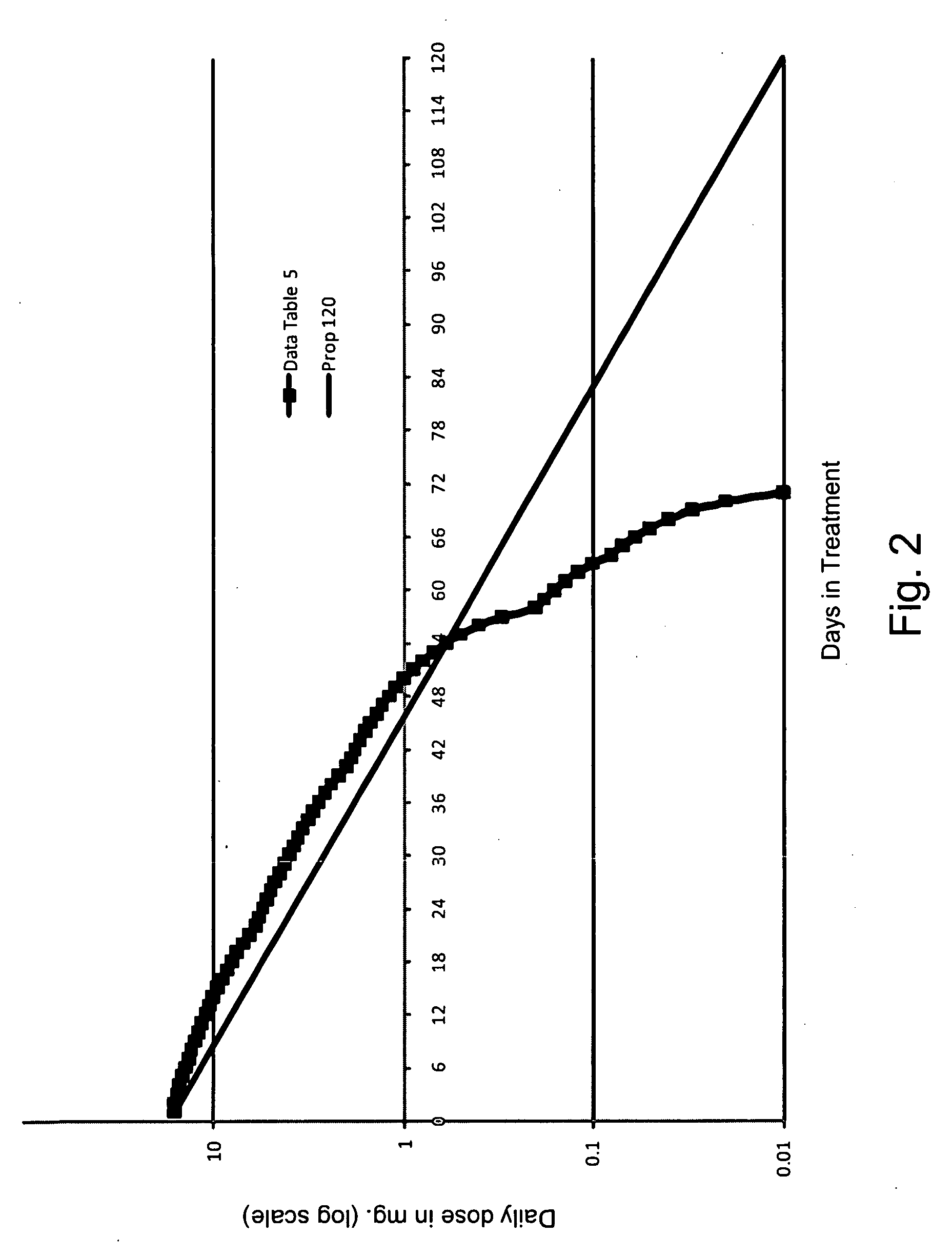

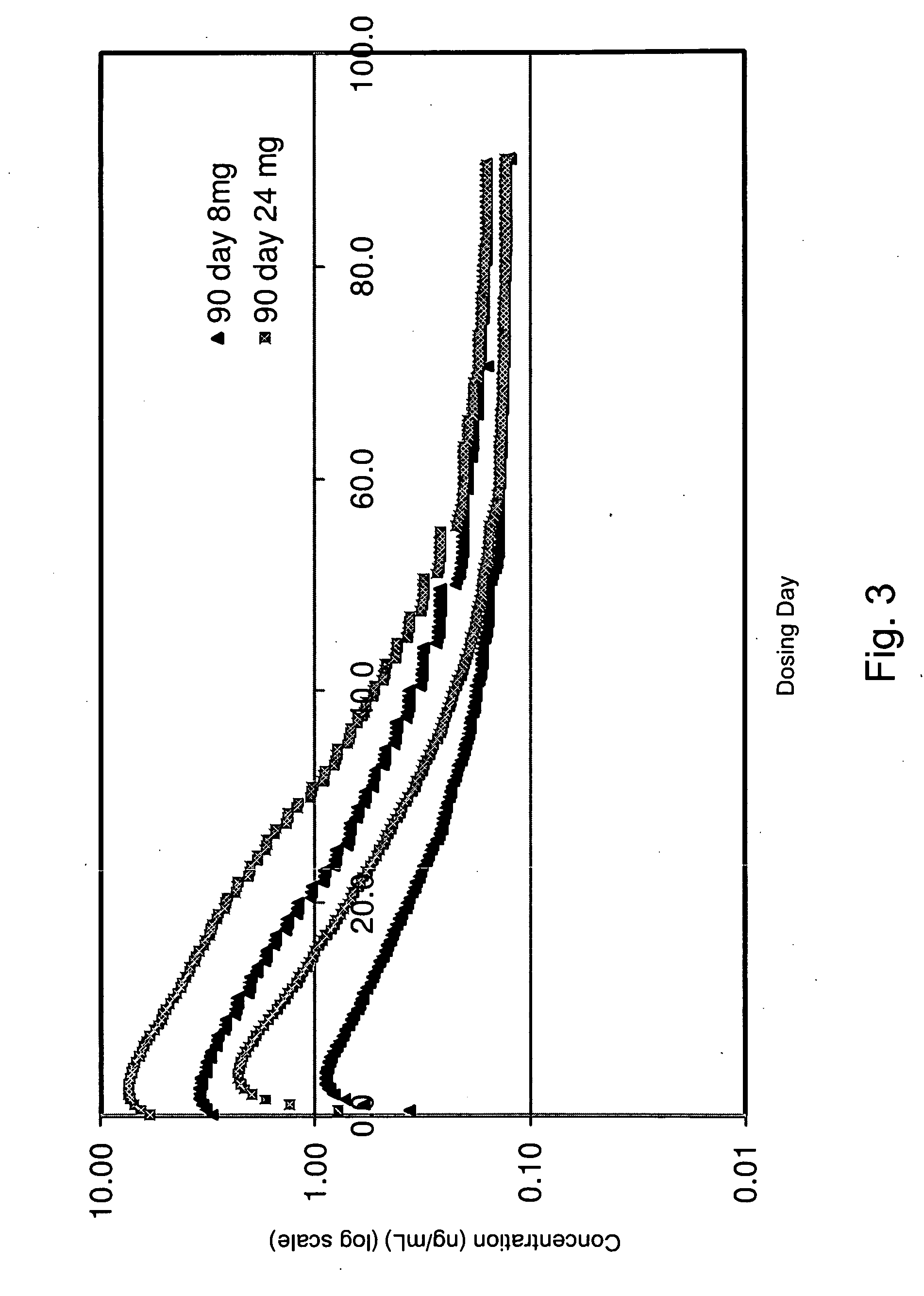

ActiveUS20100048535A1Cease completelyReduce concentrationBiocideNervous disorderNervous systemPeak value

A method of reducing the concentration of a chemical or drug substance in the blood plasma that targets the same or similar receptors as the normal neurotransmitters in the central or peripheral nervous system includes titrating an initial peak concentration of the chemical or drug substance in the blood for a predefined dosing period, titrating a lowest concentration level of the chemical or drug substance in the blood immediately before the end of the dosing period, and providing a plurality of subsequent dosing periods where each subsequent dosing period requires administration of a dosing amount of the chemical or drug substance and titrating of the peak concentration and the lowest concentration level to ensure that the lowest concentration level of the chemical or drug substance in the blood plasma for the subsequent dosing period is decreased by not more than five percent of the lowest concentration level of the previous dosing period and where the plurality of dosing periods added together extends the method for seventy days or more.

Owner:SLATER KENNETH +3

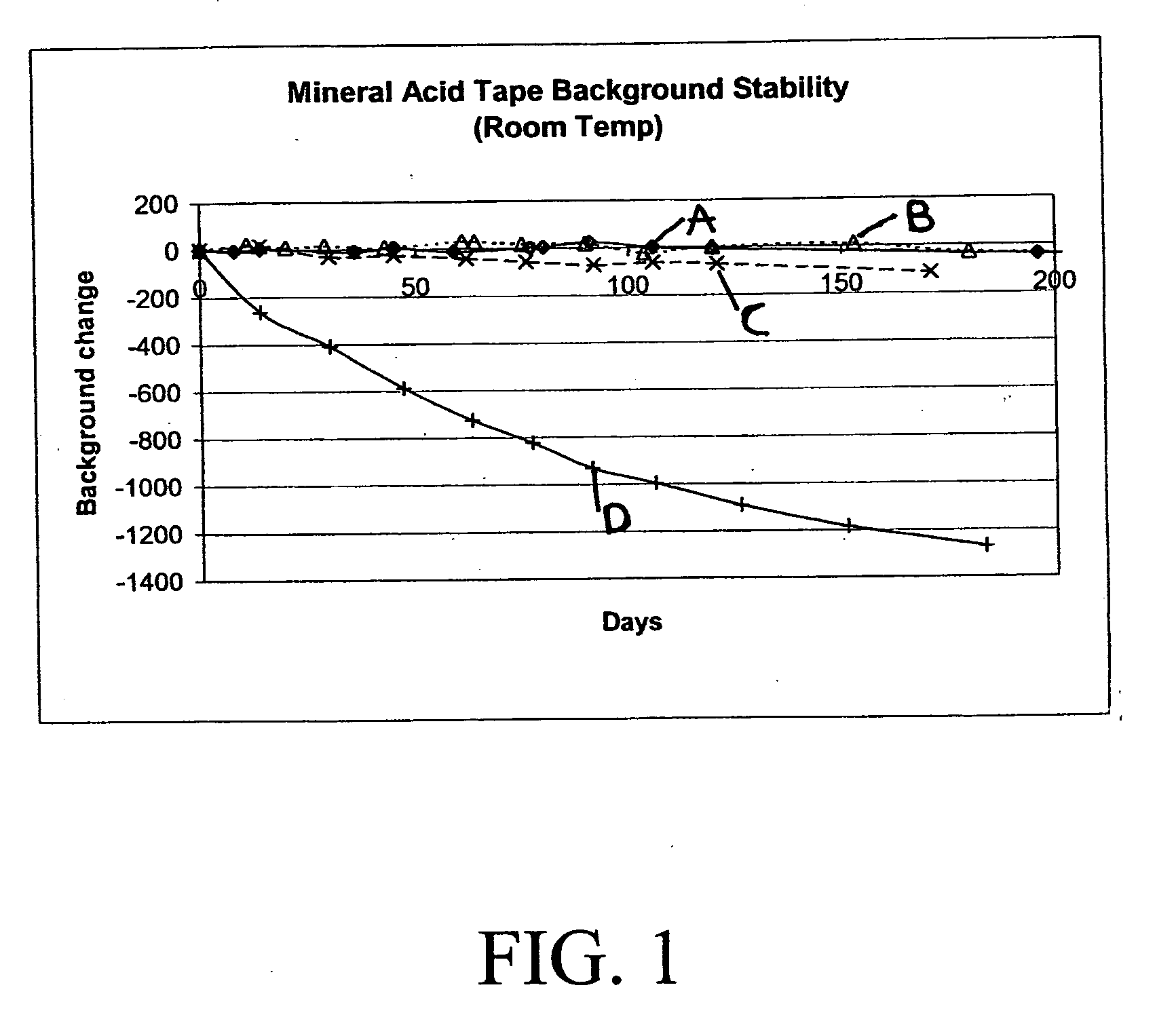

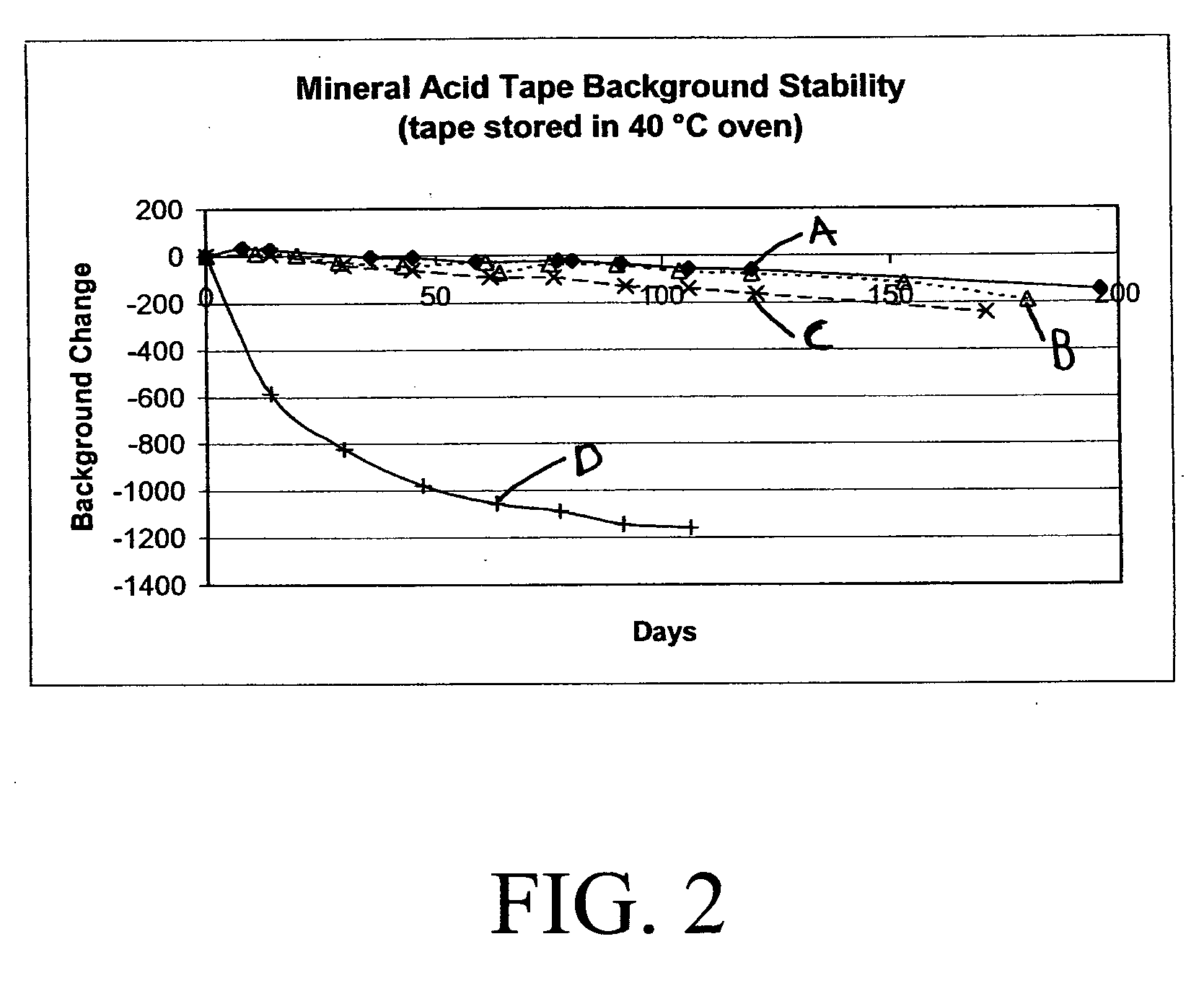

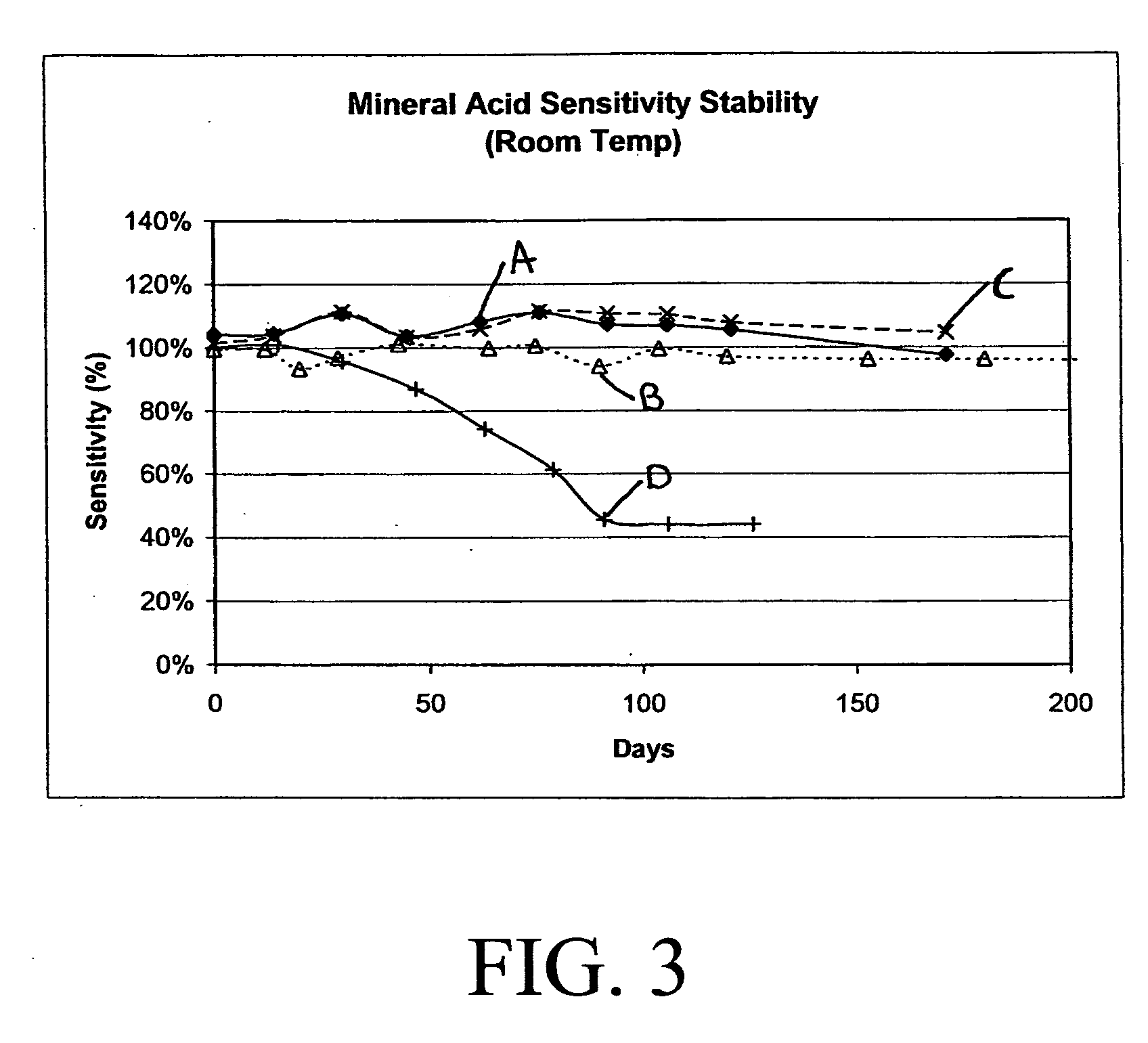

Extended life mineral acid detection tape

ActiveUS20060073071A1Low toxicityReduced dependency temperatureMaterial analysis by observing effect on chemical indicatorAnalysing gaseous mixturesTime extensionCellulose

A mineral acid detection tape includes a cellulose paper substrate saturated with a formula solution and provides an extended life detection tape of at least a three-month period of time when place in service.

Owner:HONEYWELL ANALYTICS AG

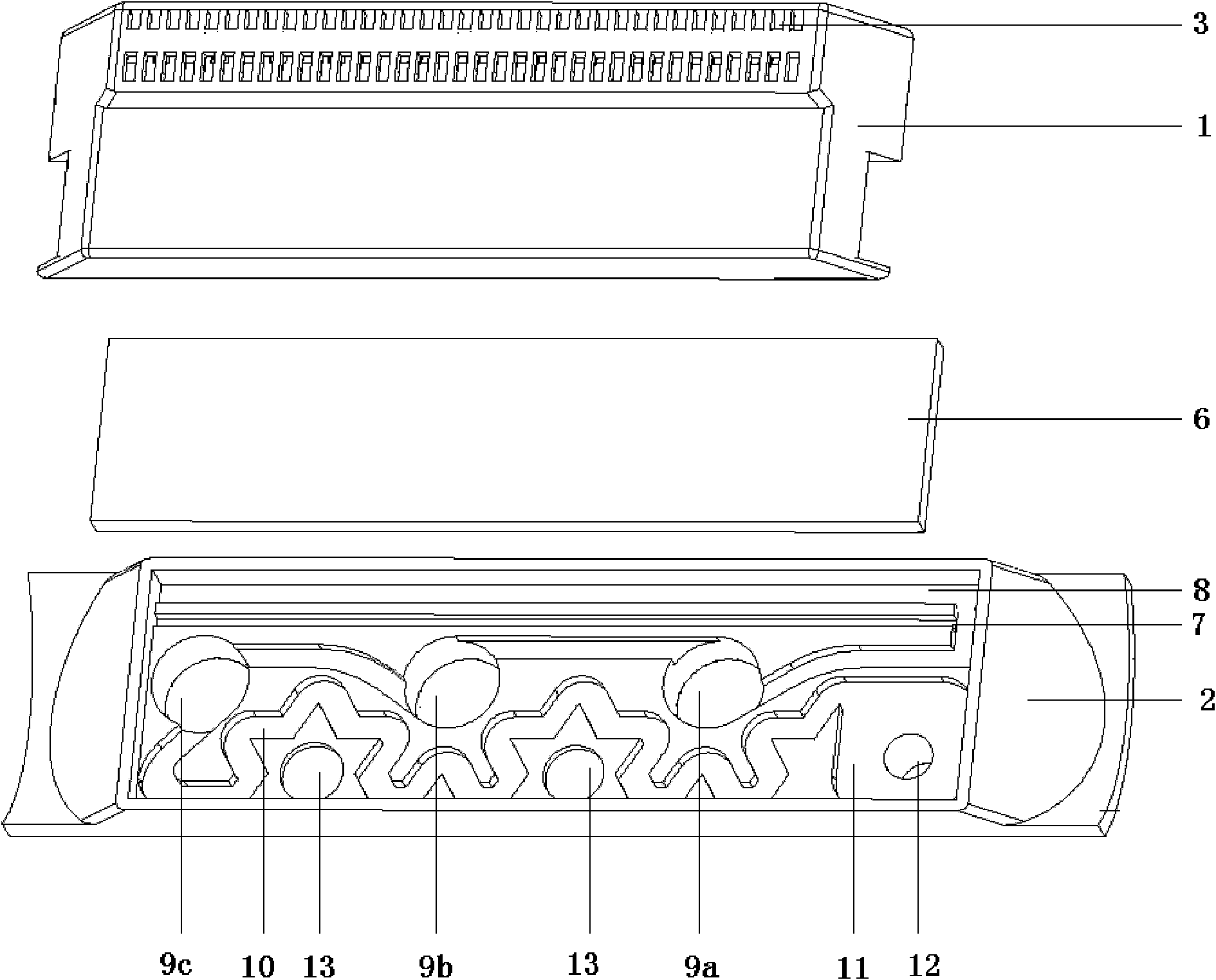

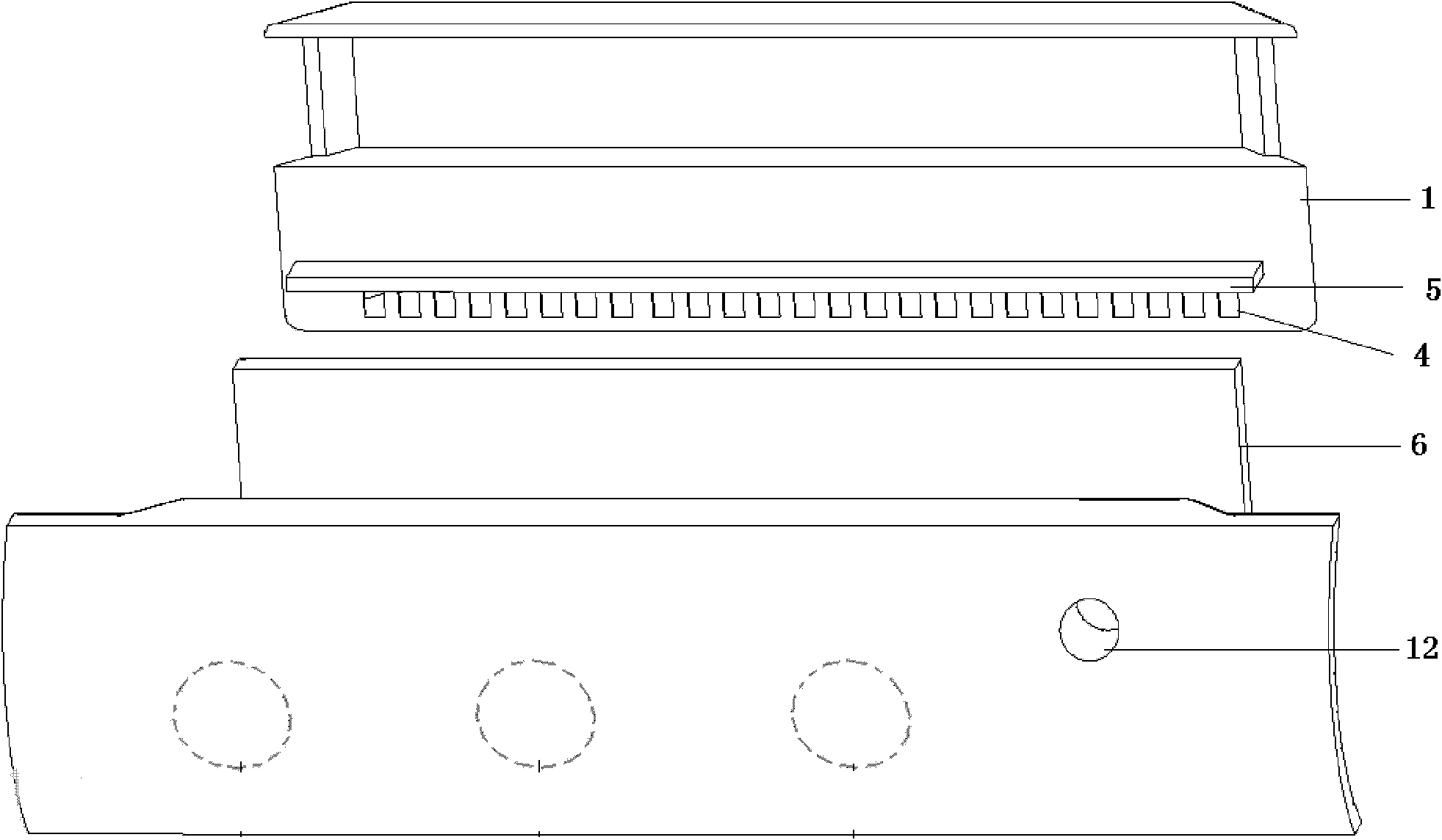

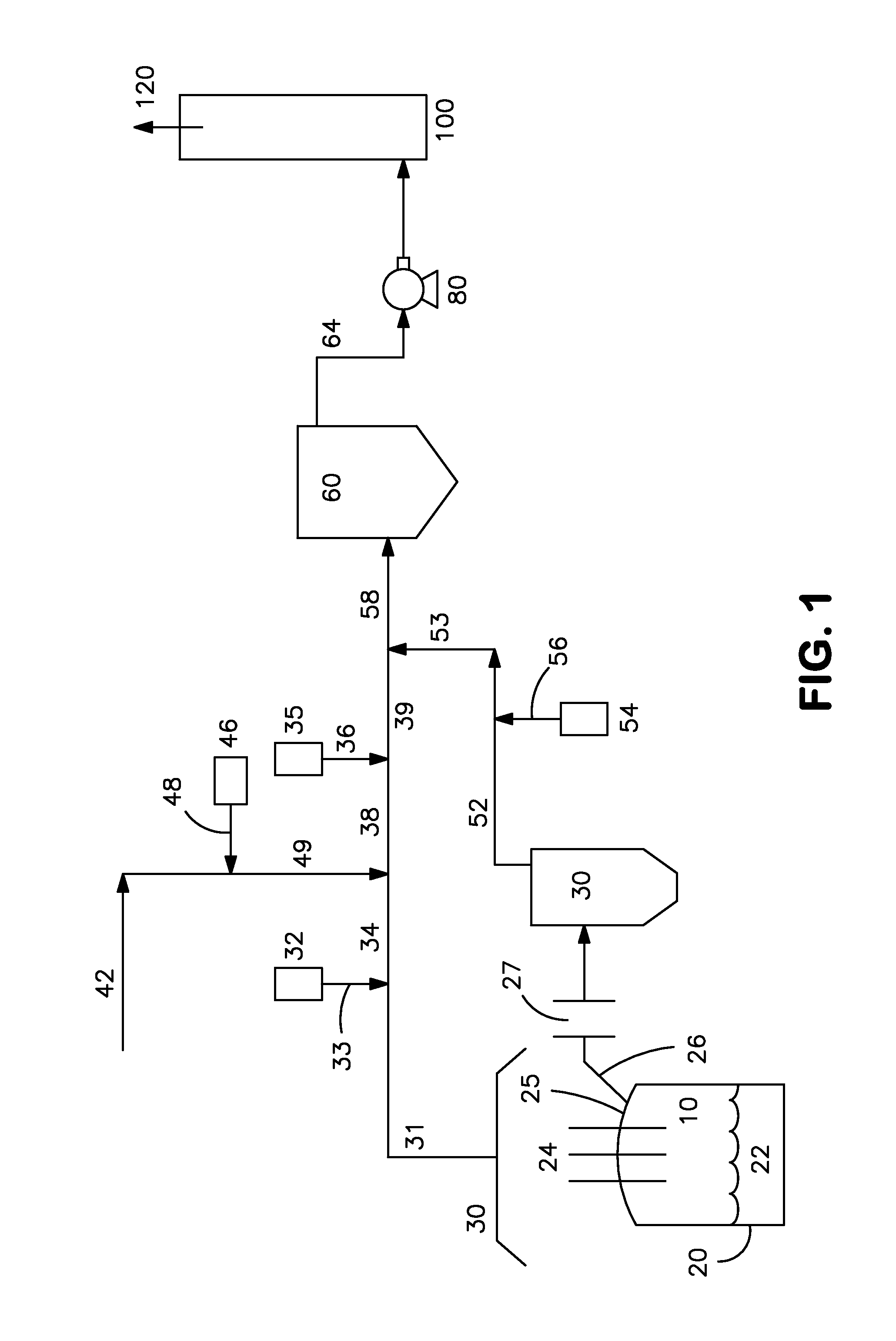

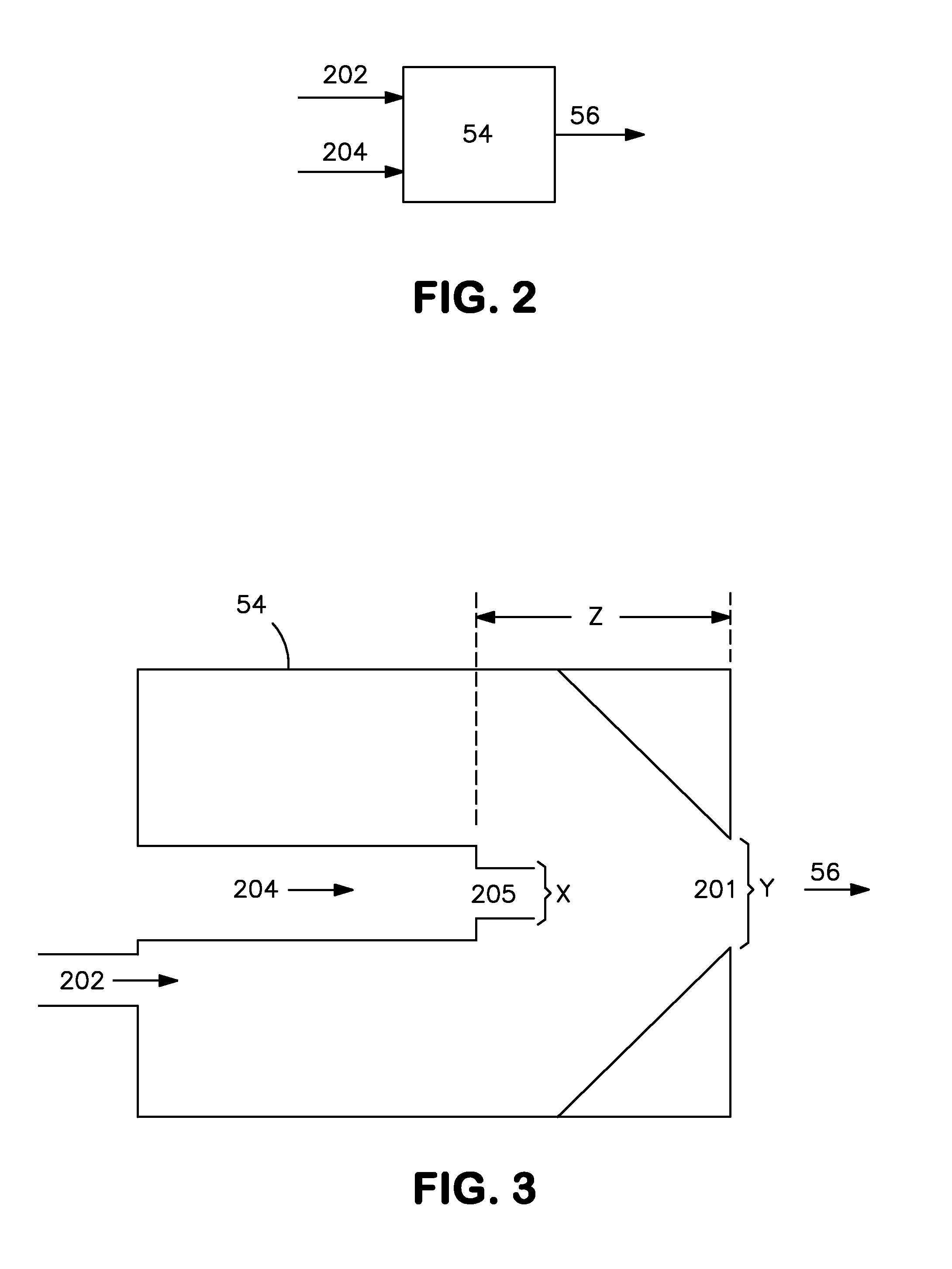

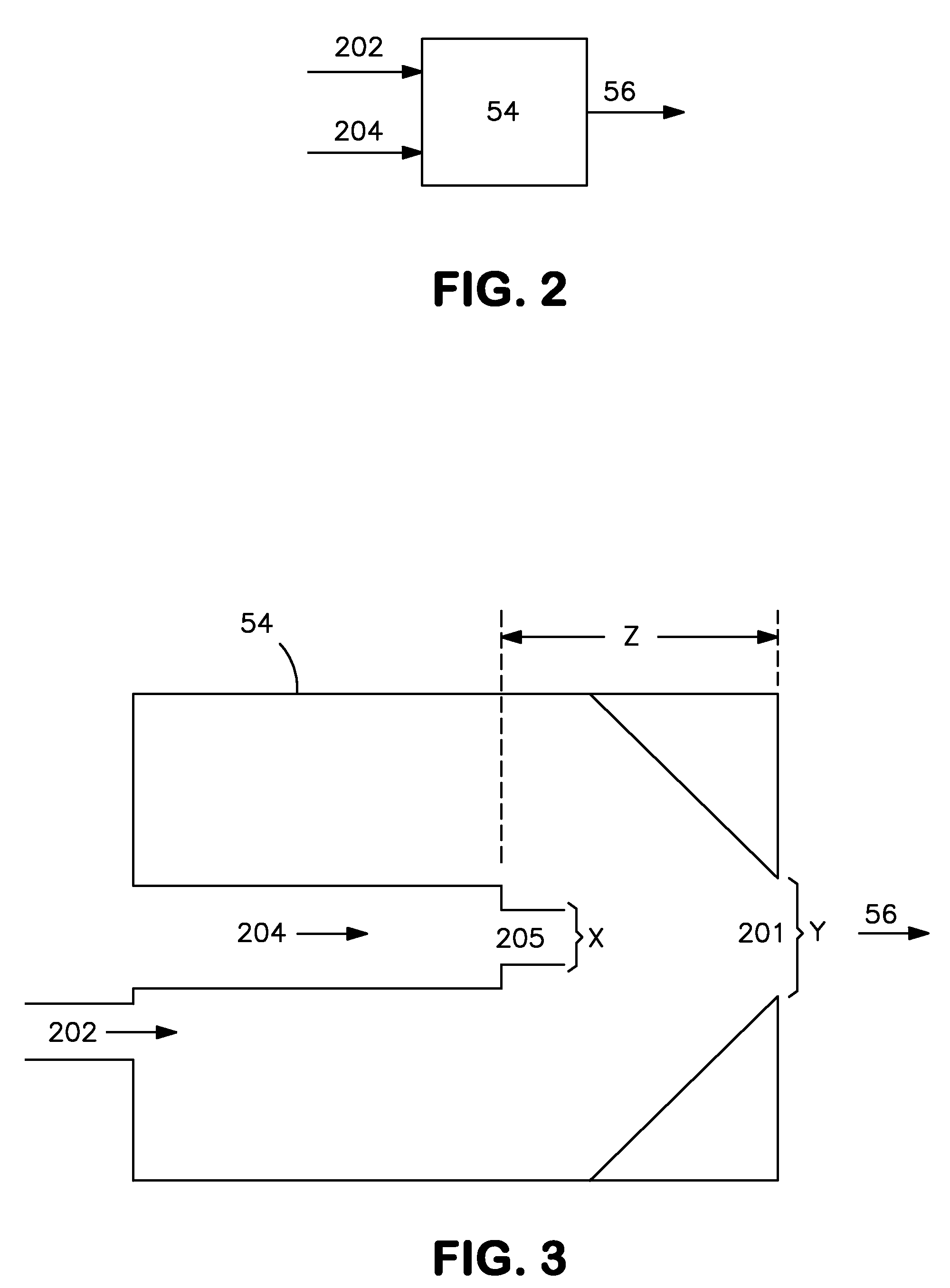

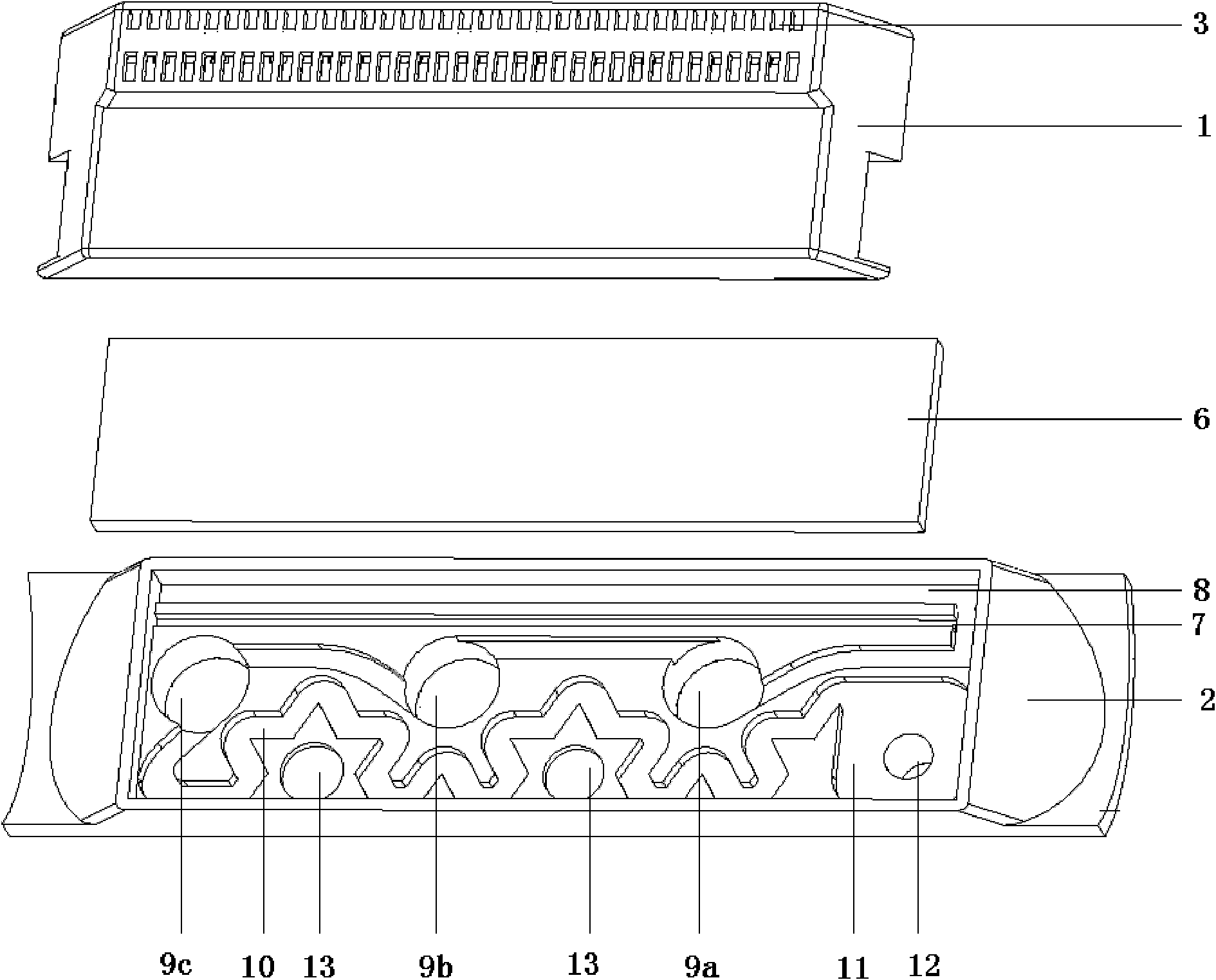

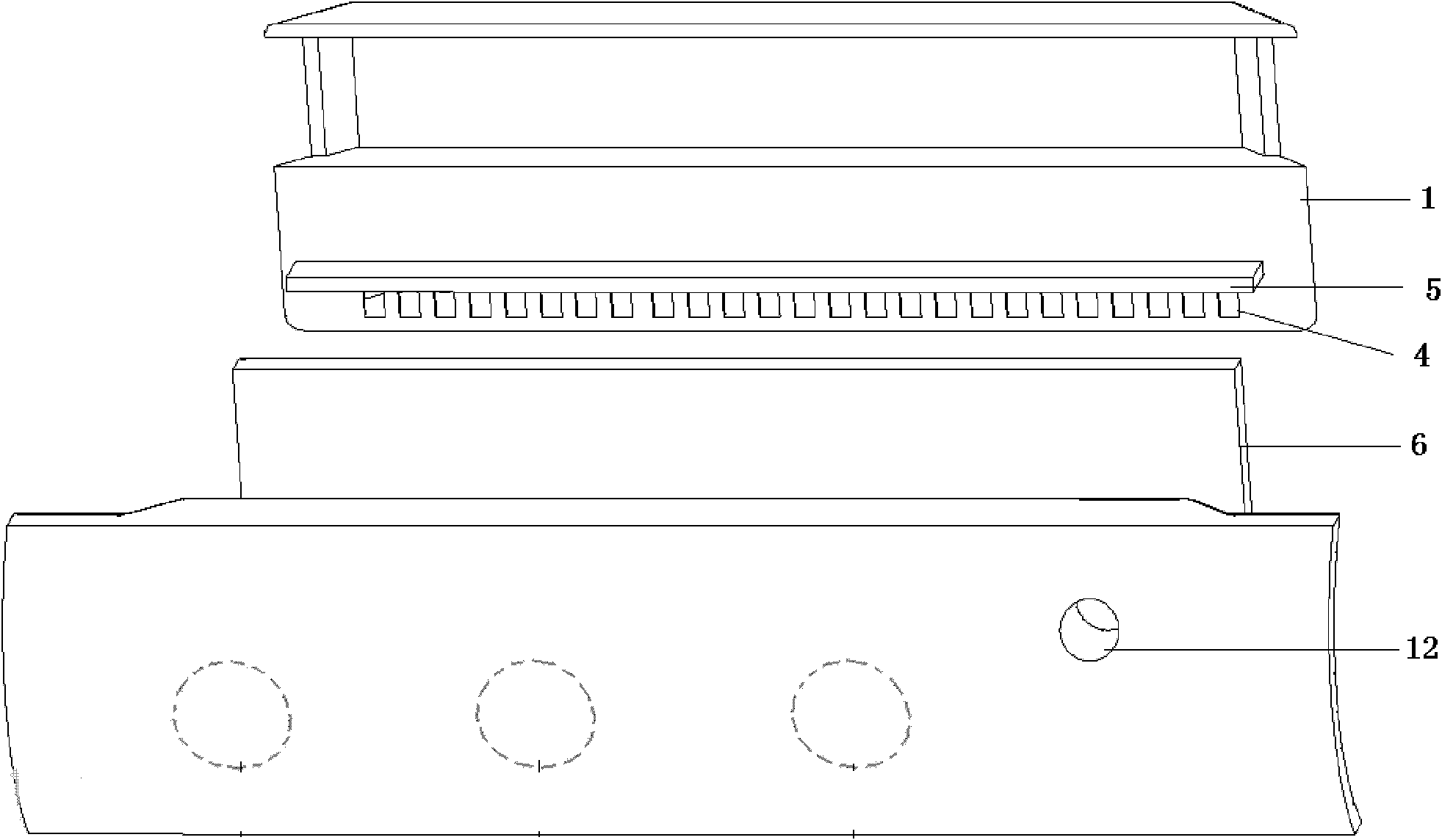

Sheet irrigator for flood diversion and drip irrigation

ActiveCN102430488ALower concentration levelsImprove hydraulic performanceSpray nozzlesDrip irrigationEngineering

The invention discloses a sheet irrigator for flood diversion and drip irrigation. The irrigator comprises an upper shell body and a lower shell body, wherein the lower shell body is matched with the upper shell body, the upper shell body is a closed shell body, a plurality of water inlet grids are arranged at the top of the upper shell body, at least a row of water outlet grids are arranged at the bottom of the upper shell body, an inserting plate is arranged on the bottom of the upper shell body, which is close to the water outlet grids, and extends towards a direction away from the upper shell body; the lower shell body is provided with an opening at the top, a groove body is arranged in the lower shell body at a position corresponding to the inserting plate, and is matched with the inserting plate, a space is arranged between the groove body and one end of the lower shell body; a water inlet flow passage is arranged in the lower shell body at a position corresponding to the water outlet grids, and extends towards the other side of the groove body through the space; a water outlet of the water inlet flow passage is communicated with at least one silt presedimentation tank, the water outlet of the silt presedimentation tank is communicated with an energy dissipation flow passage; and a water outlet hole is arranged on the bottom of the lower shell body, which is close to thewater outlet of the energy dissipation flow passage. The sheet irrigator can be used for effectively solving the problem of synchronous improvement on hydraulic performance and anti-clogging performance of the irrigator, and is applicable to a flood diversion and drip irrigation system with self-adaptive regulation and control capacity.

Owner:CHINA AGRI UNIV

Method and dosage regimens for eliminating a chemical substance in blood

ActiveUS8163731B2Cease completelyReduce concentrationBiocideNervous disorderBlood plasmaPeak concentration

Owner:SLATER KENNETH +3

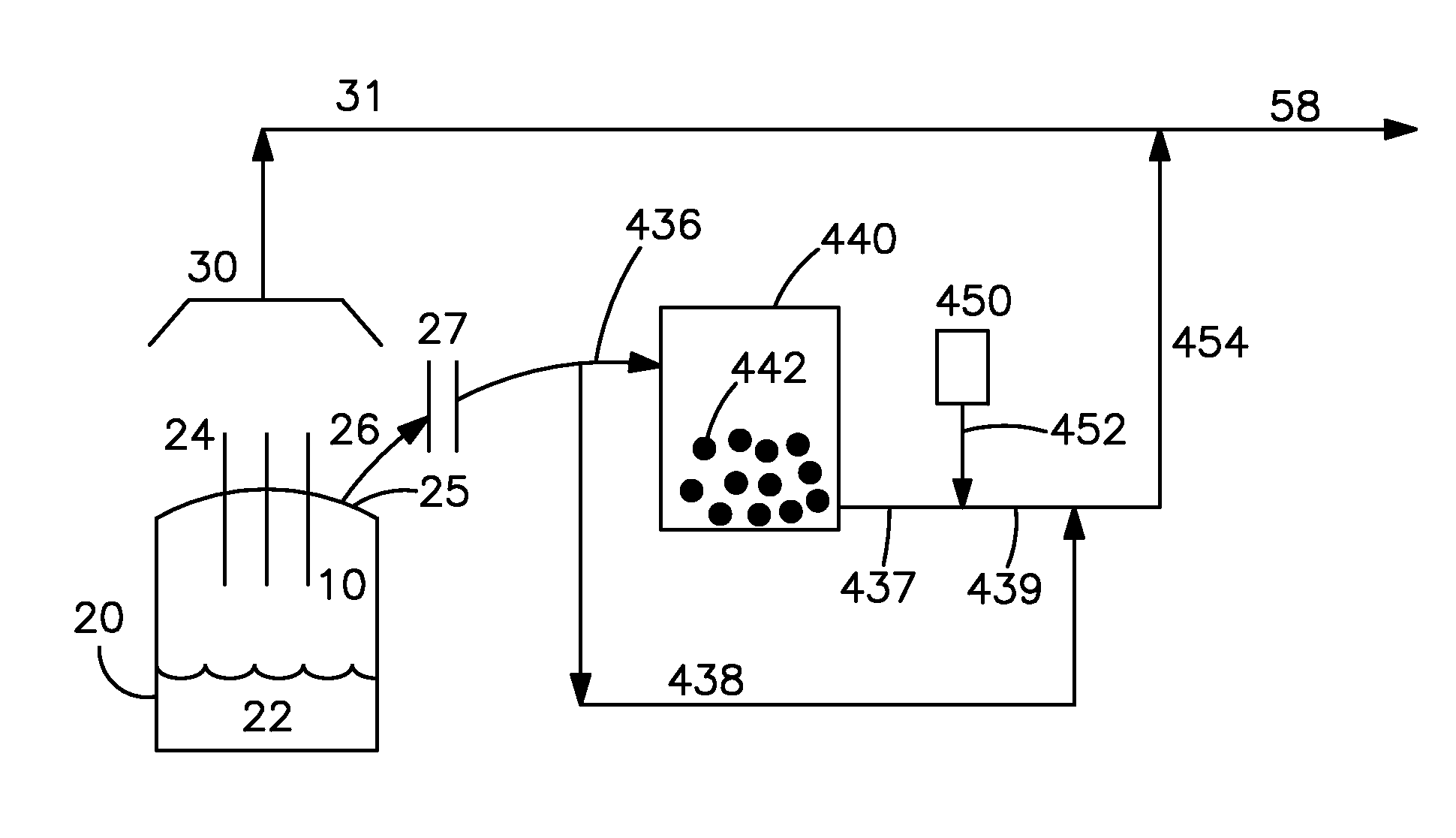

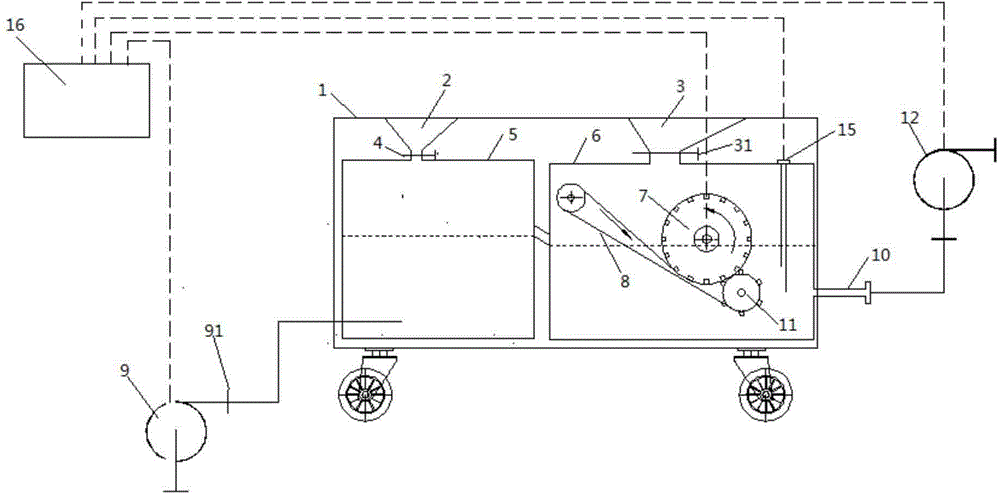

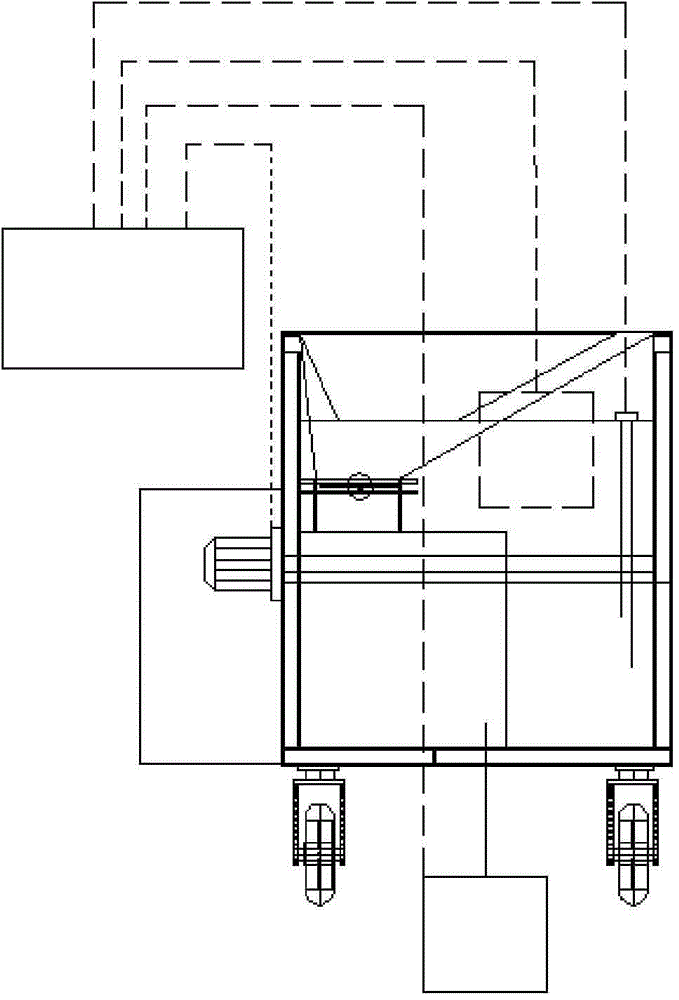

Equipment for adding agents through carrier and method for adding agents

InactiveCN103599862AGuaranteed continuityReduce manual operationsWater/sewage treatmentLiquid spraying apparatusBiomedical engineeringMixing chamber

The invention provides equipment for adding agents through a carrier and a method for adding the agents. The equipment comprises an immersible pump, an agent mixing chamber, a carrier absorption agent chamber, a carrier compression belt, a carrier compression roller, a water output pump, a liquidometer, a driving device and a control device. The immersible pump pumps water in water bodies to be treated into the agent mixing chamber, and the agents and the water are mixed in the agent mixing chamber. Then, the agents and the water overflow to enter the carrier absorption agent chamber through an overflowing channel. After the carrier is added, the carrier is compressed through the carrier compression roller and the carrier compression belt, air is removed, it is guaranteed that the carrier absorbs solutions to the maximum extent, the carrier absorbing the solutions is conveyed into a target water body through the water output pump, and the agents are slowly released. The equipment is provided with a carrier absorption agent part, the agents are slowly released to the water body through the carrier released to the water body as time grows, and the effect is better. The equipment comprises the control device, the whole equipment can achieve continuous work, and efficiency is higher.

Owner:天津臻熙科技发展有限公司

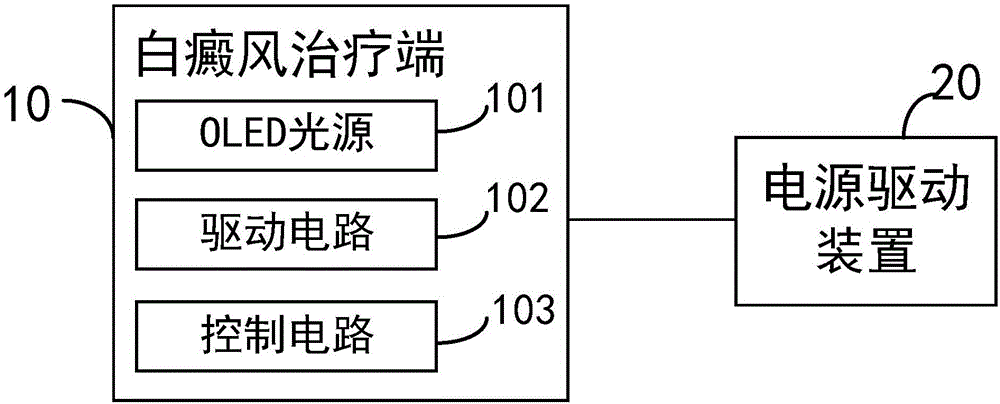

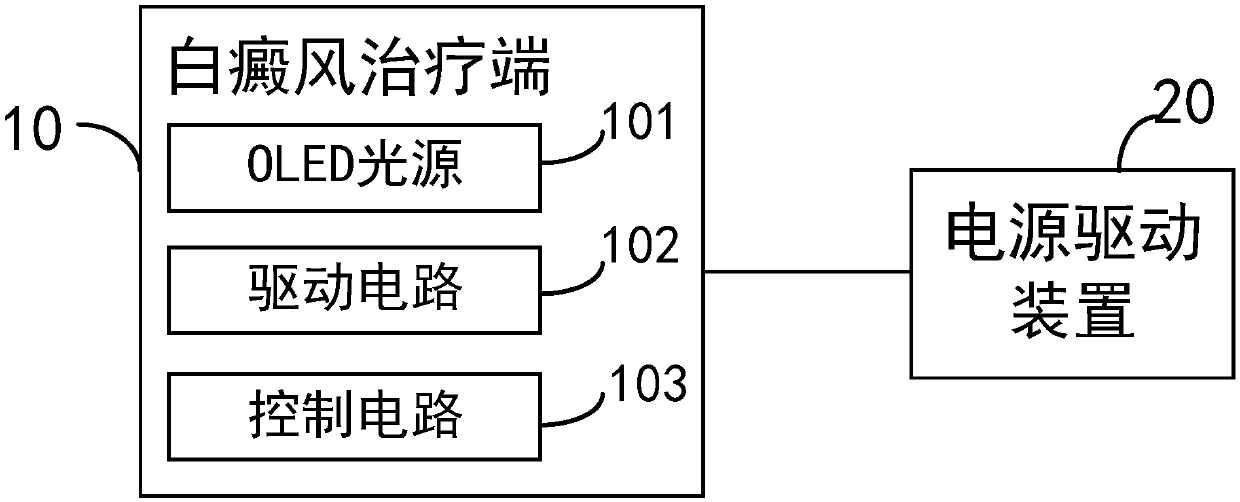

OLED leucoderma therapeutic instrument

The invention discloses an OLED leucoderma therapeutic instrument. The OLED leucoderma therapeutic instrument comprises a leucoderma therapeutic end and a power source driving device, wherein the leucoderma therapeutic end comprises an OLED light source used for emitting a red light source. The OLED leucoderma therapeutic instrument is advantaged in that an OLED is taken as a therapeutic light source, red light emitted by a red light emission unit is employed, repair cream is further cooperatively utilized to effectively stimulate melanin cells to secrete melanin, a concentration level of hydrogen peroxide of leucoderma skin is reduced, and thereby leucoderma therapeutic operation is carried out.

Owner:长春若水科技发展有限公司

Combustion of co and combustibles in steel furnace offgases

InactiveUS20140076106A1Reduce contentJet momentumGas treatmentDispersed particle separationSteelmakingCombustion

A hot oxygen stream containing radicals is fed into an offgas stream from a steelmaking vessel to convert carbon monoxide in the offgas to carbon dioxide.

Owner:PRAXAIR TECH INC

Insect bait

InactiveUS20130091758A1Importance of particular attractants can be reducedLower concentration levelsBiocideAnimal repellantsToxicantDecoy

An insect bait that can be carried by the insect, that includes a toxicant capable of killing insects in a nest, and that includes attractants, having at least one non-toxic layer that delays contact with the toxicant, wherein the size, shape and attractants attract the insect to take the whole of the bait to a nest situation where further manipulation of the bait by the insect will release the toxicant.

Owner:HILEY CARINA

Auxiliary material used for injection or oral administration

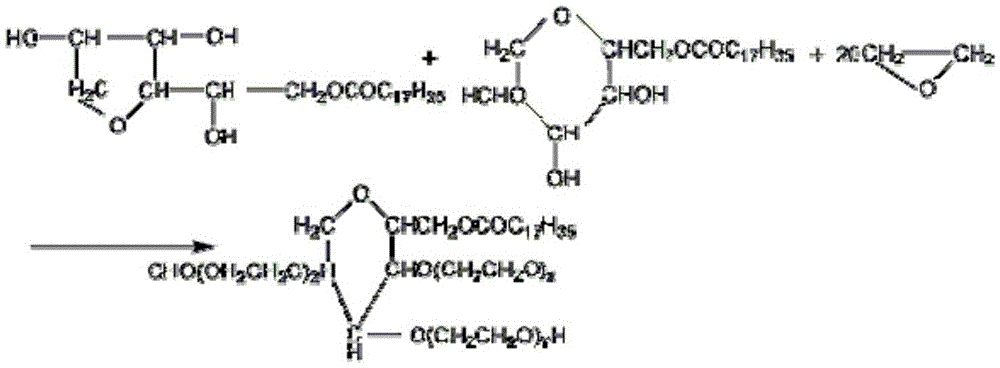

PendingCN105534885ALower concentration levelsImprove securityPowder deliverySolution deliveryAlkaneSurface-active agents

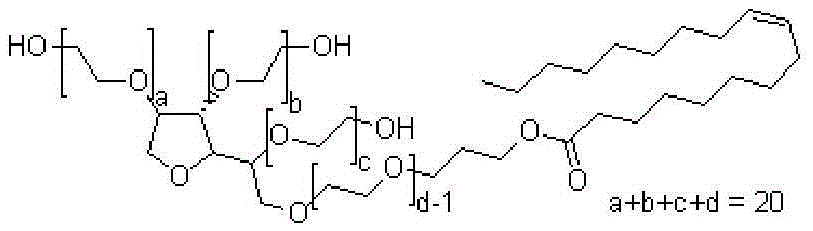

The invention relates to an auxiliary material used for injection or oral administration. Basic component of the surface active agent is polyoxyethylene sorbitan (mono)oleate, wherein total content of carbonyls contained in aldehyde compounds and one compounds is not more than 20meq / kg, or / and total content of epoxy groups is not more than 10meq / kg, or / and total content of alkane compounds and olefin compounds is not more than 10meq / kg, and total content of peroxyl groups contained in peroxides is not more than 20meq / kg. The auxiliary material has relatively high safety and is used for improving safety and / or stability of a preparation used for injection or oral administration. In addition, the invention also relates to a preparation method and quality standard of the auxiliary material.

Owner:钟术光

Semiconductor device and fabrication process thereof, and application thereof

InactiveUS7339234B2Improve breakdown voltageLower concentration levelsSolid-state devicesSemiconductor/solid-state device manufacturingLDMOSSemiconductor

An LDMOS transistor includes a gate insulation film formed on a semiconductor substrate, a gate electrode formed on the gate insulation film, a drain well of a first conductivity type formed in the substrate so as to include a gate region covered with the gate electrode, a channel well of a second conductivity type formed in the drain well in a partially overlapped relationship with the gate region, a source region of the first conductivity type formed in the channel well in an overlapping manner or adjacent with a side surface of the gate electrode, a medium-concentration drain region of the first conductivity type having an intermediate concentration level and formed in the drain well at a side opposing to the source region in a manner partially overlapping with the gate region, the medium-concentration drain region being formed with a separation from the channel well, a drain region of the first conductivity type formed in the medium-concentration drain region with a separation from the gate region, a low concentration well of the second conductivity type formed inside the drain well so as to include at least a part between said channel well and the medium-concentration drain region.

Owner:RICOH KK

Combustion of co and combustibles in steel furnace offgases

InactiveUS20110094340A1Destroy low concentration levelImprove abilitiesGas treatmentDispersed particle separationSteelmakingCombustion

A hot oxygen stream containing radicals is fed into an offgas stream from a steelmaking vessel to convert carbon monoxide in the offgas to carbon dioxide.

Owner:PRAXAIR TECH INC

Pulverized coal combustion method and device with CO2 capture function

InactiveCN101666546BOvercoming many disadvantages such as low utilization efficiencyRealize clean utilizationExothermal chemical reaction heat productionExothermal chemical reactions for heatingHigh concentrationCyclone

The invention provides a pulverized coal combustion method with the function of capturing CO2, comprising the steps: CuFe2O4 is decomposed to generate O2 and oxygen vacancy ferrite CuFe2O4-delta (delta is no less than 0 but no more than 2); oxidation reaction is generated between the pulverized coal and the oxygen vacancy ferrite so as to generate CO2, H2O and non-condensed gas, wherein the oxidation reaction is generated between the non-condensed gas and O2 which is obtained by decomposition so as to generate CO2 and steam. The device for achieving the method comprises a loop which is formedby the communication of a fast fluidized bed, a first cyclone separator, a two-stage type bubbling fluidized bed, a U-type flow seal valve and the fast fluidized bed in sequence; and the bubbling fluidized bed is also communicated with a second cyclone separator which is communicated with an ash catching device. The pulverized coal combustion method with the function of capturing CO2 effectively combines a pure oxygen combustion technology of coal with a chemical chain combustion technology, not only lowers the preparation cost of the pure CO2, but also fully realizes the separation of the high-concentration CO2 after the coal reaction.

Owner:HUAZHONG UNIV OF SCI & TECH

In-situ remediation method for underground water and soil of polluted site

ActiveCN113371773AAvoid secondary pollutionReduce dosageContaminated soil reclamationTreatment with anaerobic digestion processesSoil scienceElectron donor

The invention relates to an in-situ remediation method for underground water and soil of a polluted site. The method comprises the following steps: injecting first composite slurry into a water layer or a soil layer located at the pollution plume boundary, and enabling the pollution plume boundary to be covered with the first composite slurry; and injecting second composite slurry into a water-containing layer or a soil layer of the pollution source area, and enabling the second composite slurry and the first composite slurry to cover the polluted site, wherein the first composite slurry and the second composite slurry both contain montmorillonite, zero-valent iron and a trace electron donor composition, and the content of the montmorillonite in the first composite slurry is greater than that of the second composite slurry. According to the method, a flexible in-situ barrier reaction zone is formed at the boundary of the pollution plume boundary , the pollution area is blocked while remediation is carried out, and secondary pollution caused by further diffusion of the pollution plume is prevented; meanwhile, the second composite slurry is injected into the pollution source area, the underground environment is improved, salt pollution in soil and underground water is rapidly eliminated, and efficient remediation in the original pollution source area is achieved.

Owner:ENVIRONMENTAL PROTECTION RES INST OF LIGHT IND

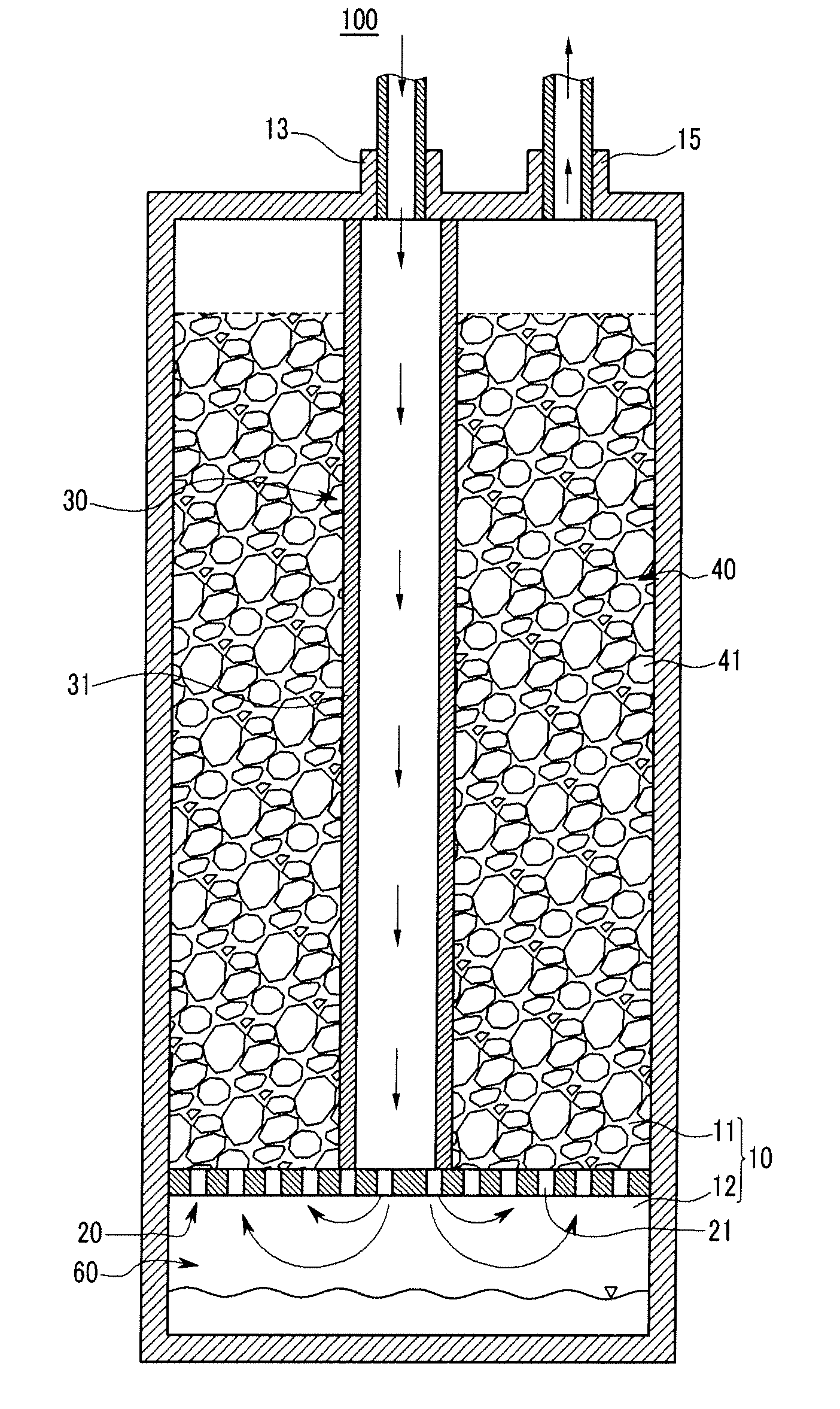

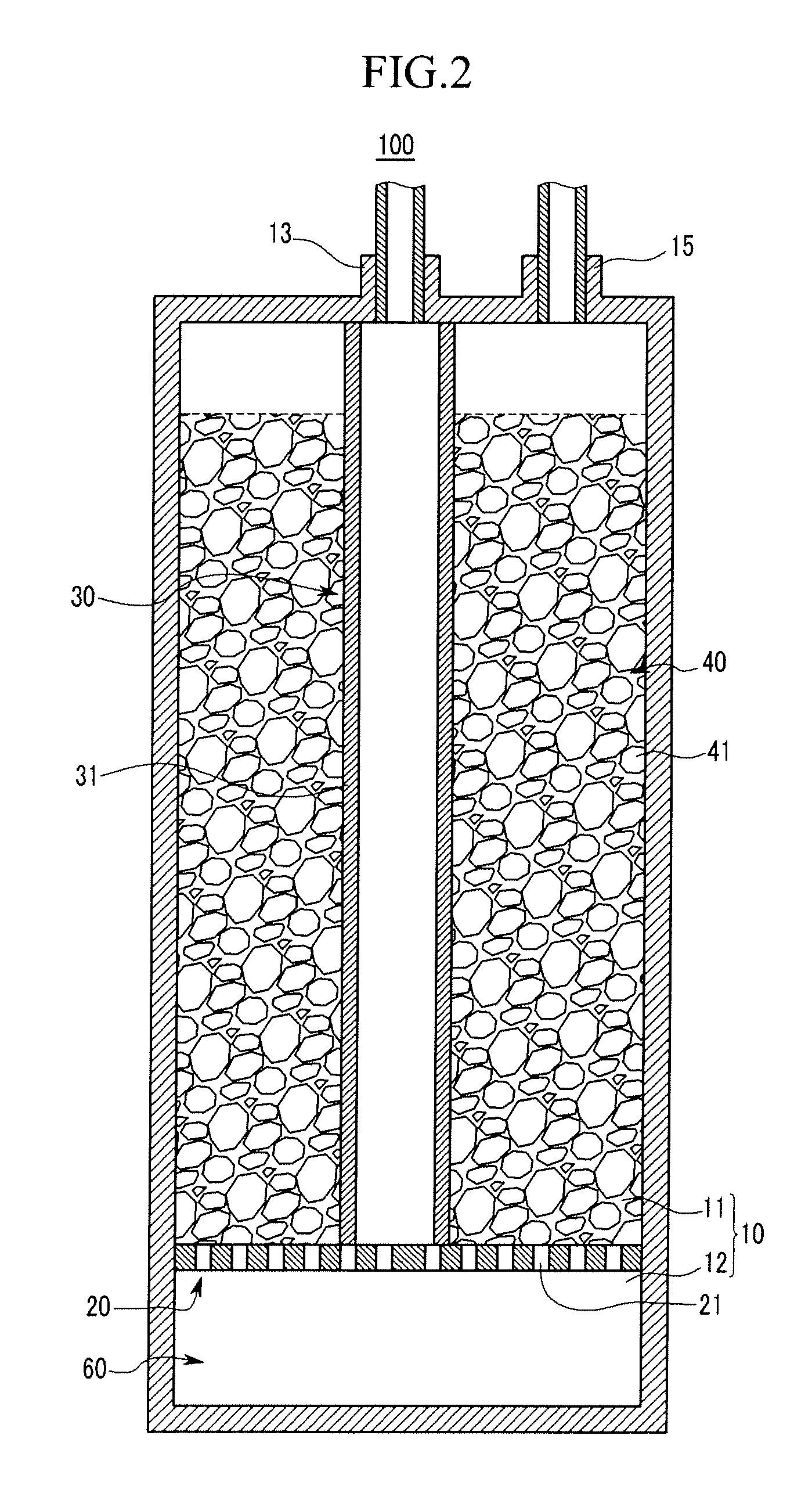

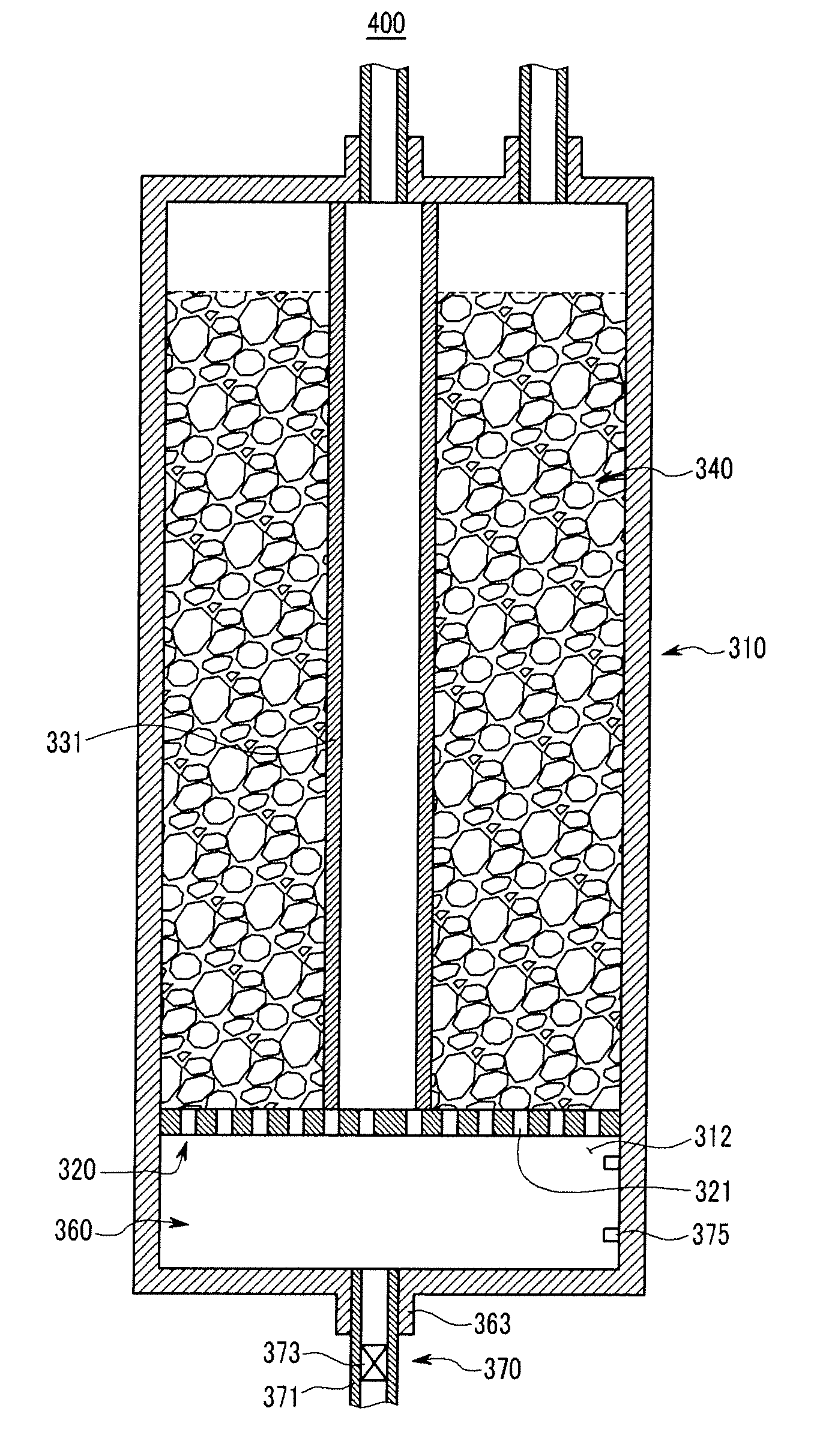

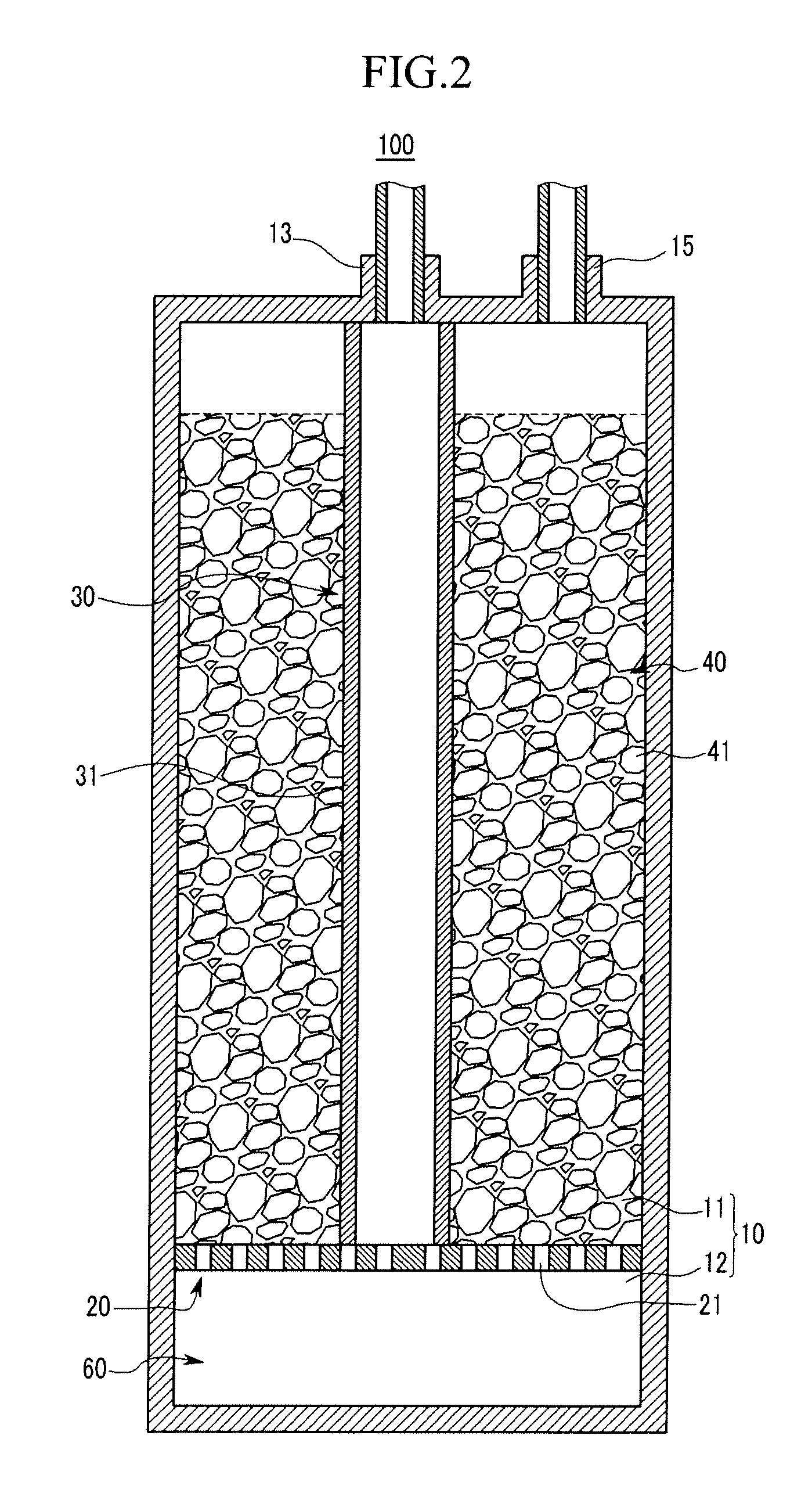

Carbon monoxide treatment apparatus for fuel cell

InactiveUS20080253940A1Reduce and minimize absorptionSimple structureCombination devicesCombustible gas catalytic treatmentFuel cellsEngineering

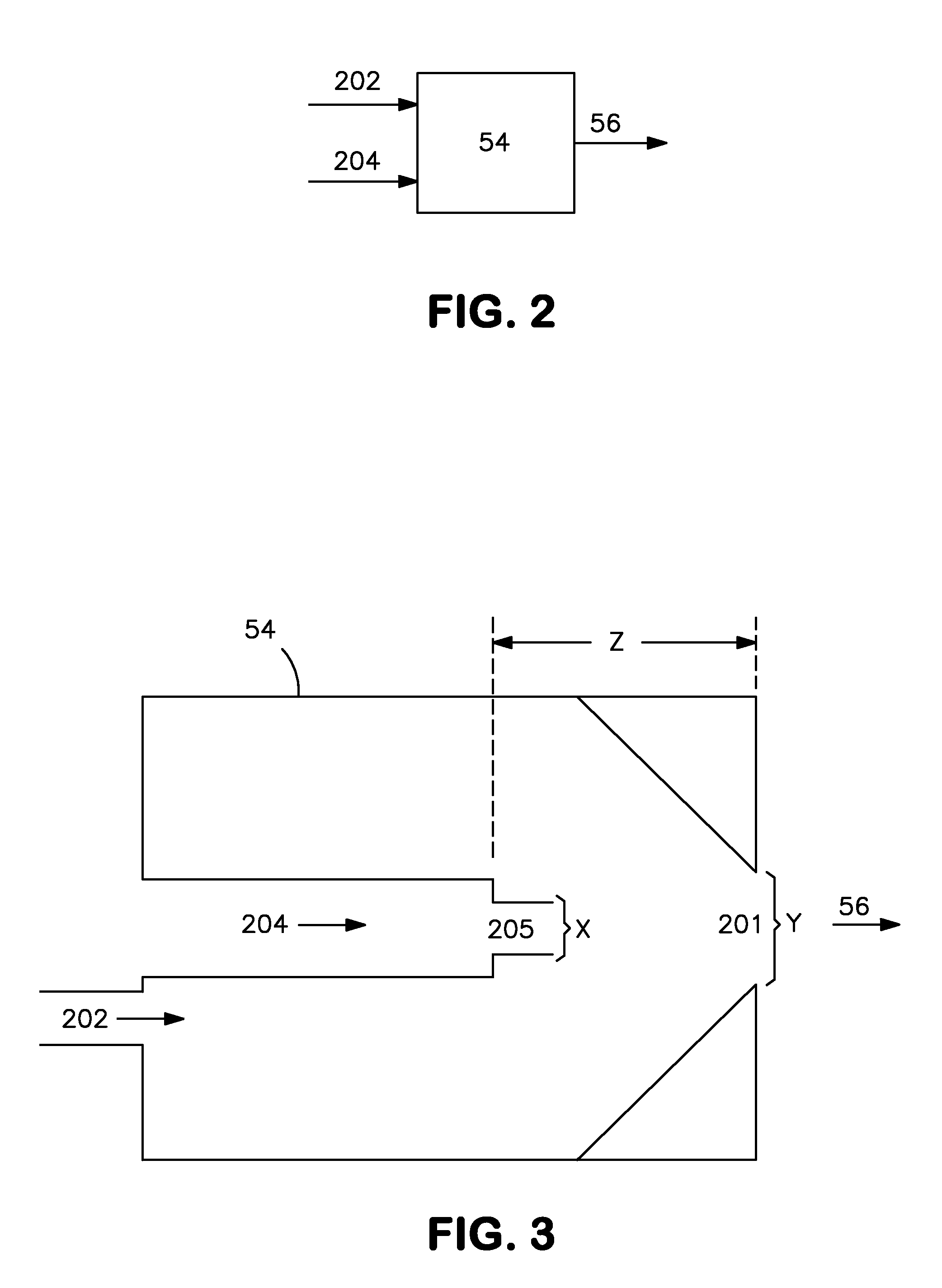

A carbon monoxide treatment apparatus according to an exemplary embodiment of the present invention includes: a reactor body; a partitioning plate located inside the reactor body for partitioning an internal space of the reactor body into a first section and a second section; a channel member in the first section for transporting an introduced gas including a reformed gas and an oxidant gas to the second section; and a reaction unit around the channel member of the first section for reducing a concentration level of carbon monoxide in the introduced gas moving through the first section by utilizing a preferential oxidation reaction of the carbon monoxide and the oxidant gas of the introduced gas, wherein moisture of the introduced gas that has been partially condensed when passing through the channel member is stored in the second section.

Owner:SAMSUNG SDI CO LTD

Carbon monoxide treatment apparatus for fuel cell

InactiveUS8182750B2Lower concentration levelsReduce and minimize absorptionCombination devicesCombustible gas catalytic treatmentFuel cellsEngineering

A carbon monoxide treatment apparatus according to an exemplary embodiment of the present invention includes: a reactor body; a partitioning plate located inside the reactor body for partitioning an internal space of the reactor body into a first section and a second section; a channel member in the first section for transporting an introduced gas including a reformed gas and an oxidant gas to the second section; and a reaction unit around the channel member of the first section for reducing a concentration level of carbon monoxide in the introduced gas moving through the first section by utilizing a preferential oxidation reaction of the carbon monoxide and the oxidant gas of the introduced gas, wherein moisture of the introduced gas that has been partially condensed when passing through the channel member is stored in the second section.

Owner:SAMSUNG SDI CO LTD

Method for removing chlorate in electrolytic circulation light salt brine

The invention relates to the technical field of water treatment, particularly to a method for removing chlorate in electrolytic circulating light salt brine. The method comprises the following step: adding acetaldehyde into electrolytic circulating light salt brine without adding sulfite. The process provided by the invention has the advantages of high decomposition efficiency, low consumption andsimple process.

Owner:鄂尔多斯市瀚博科技有限公司

oled vitiligo treatment instrument

The invention discloses an OLED leucoderma therapeutic instrument. The OLED leucoderma therapeutic instrument comprises a leucoderma therapeutic end and a power source driving device, wherein the leucoderma therapeutic end comprises an OLED light source used for emitting a red light source. The OLED leucoderma therapeutic instrument is advantaged in that an OLED is taken as a therapeutic light source, red light emitted by a red light emission unit is employed, repair cream is further cooperatively utilized to effectively stimulate melanin cells to secrete melanin, a concentration level of hydrogen peroxide of leucoderma skin is reduced, and thereby leucoderma therapeutic operation is carried out.

Owner:长春若水科技发展有限公司

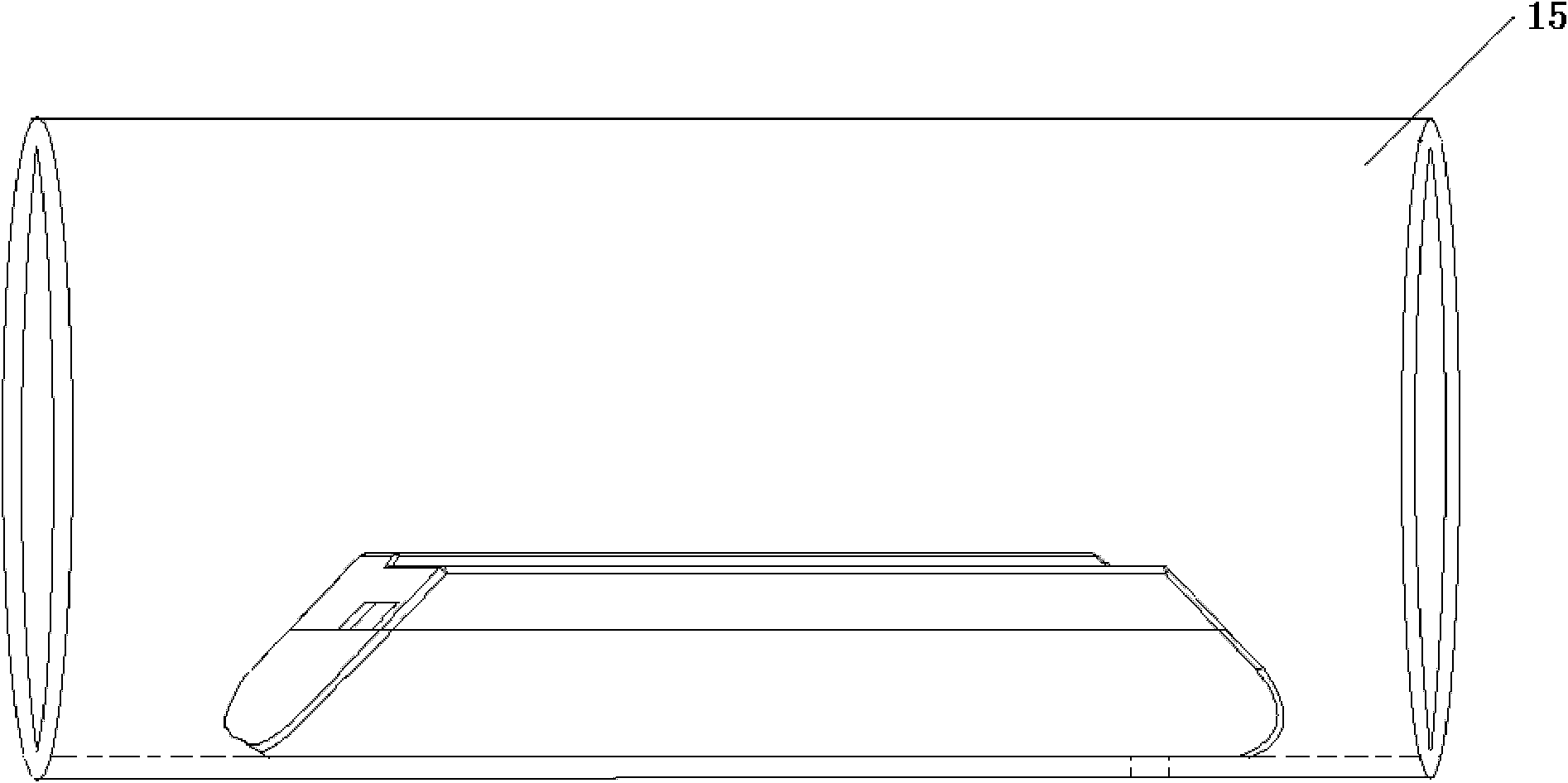

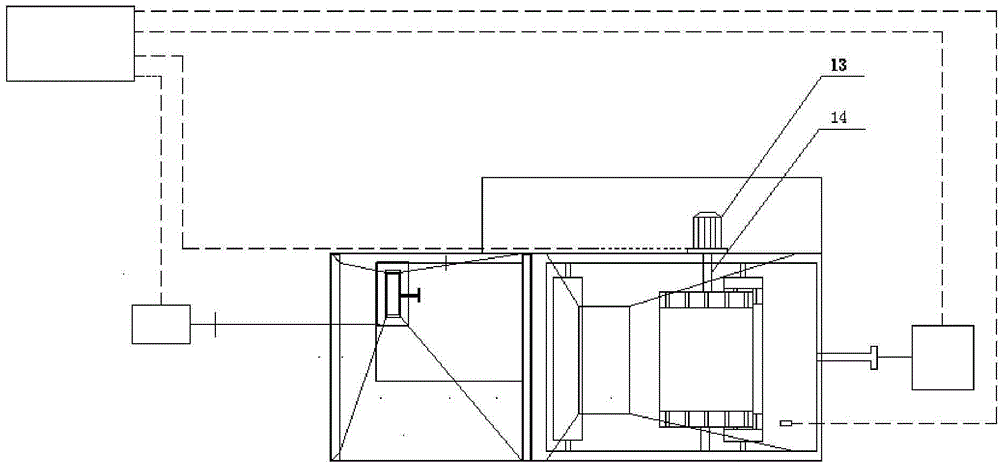

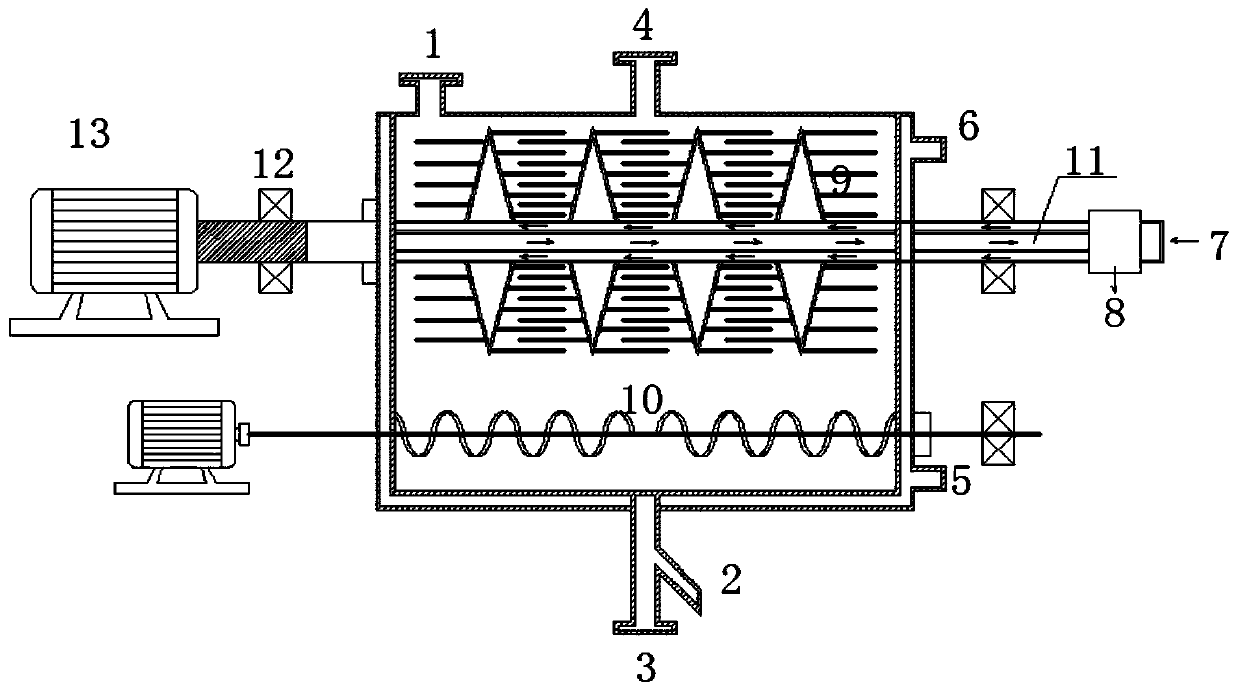

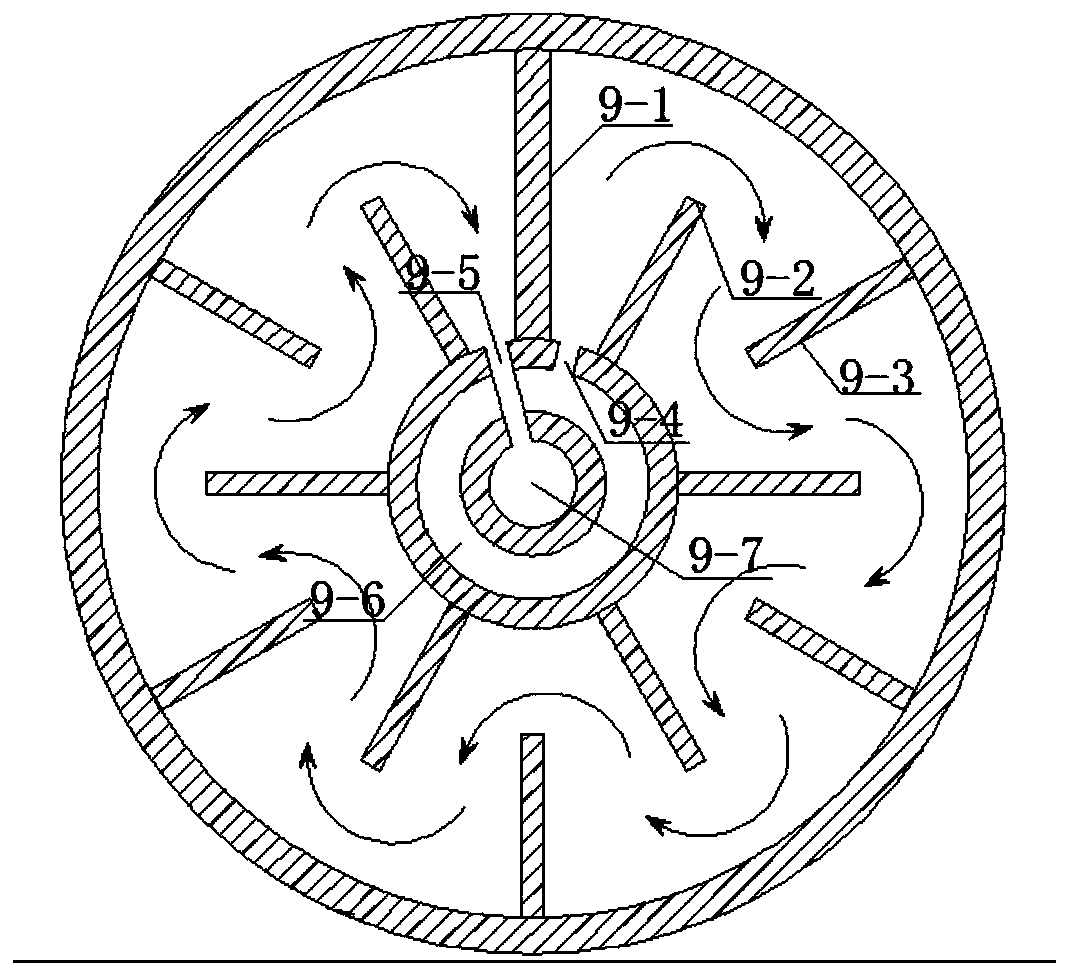

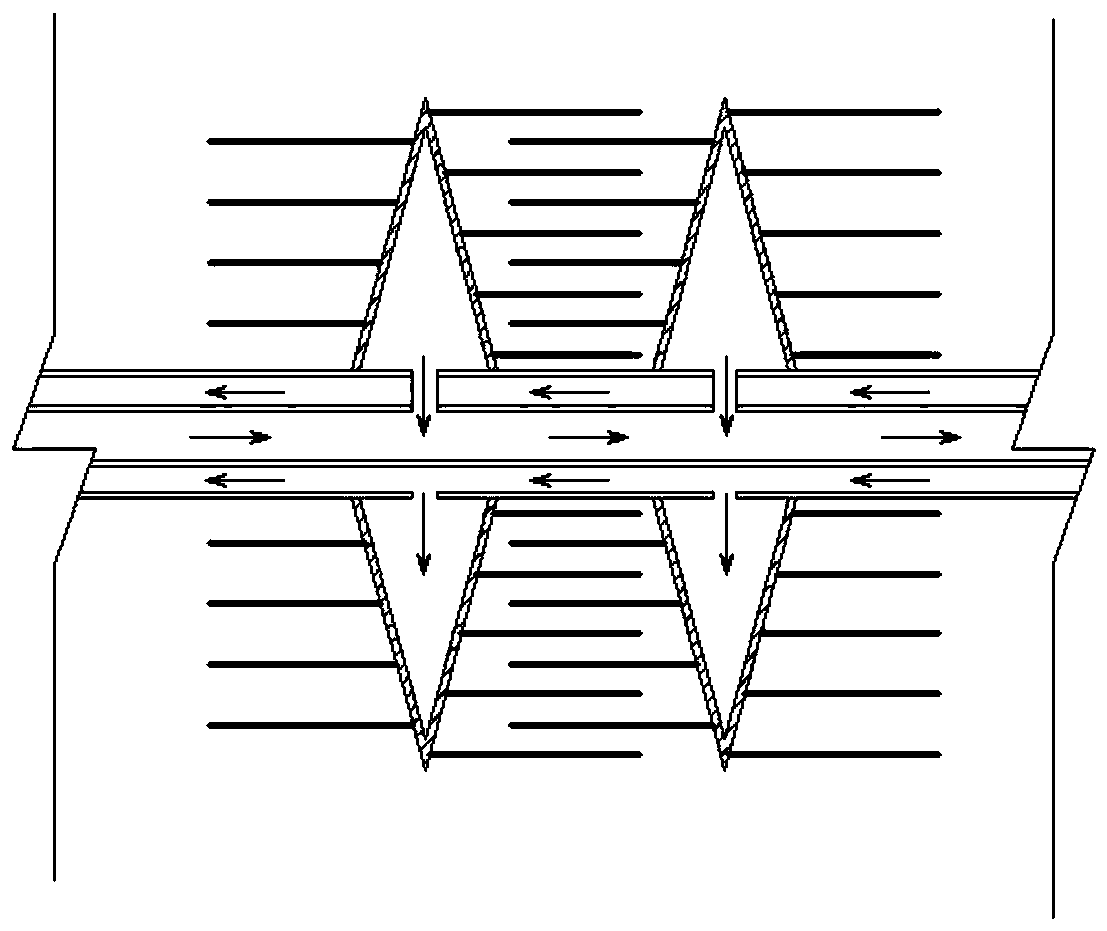

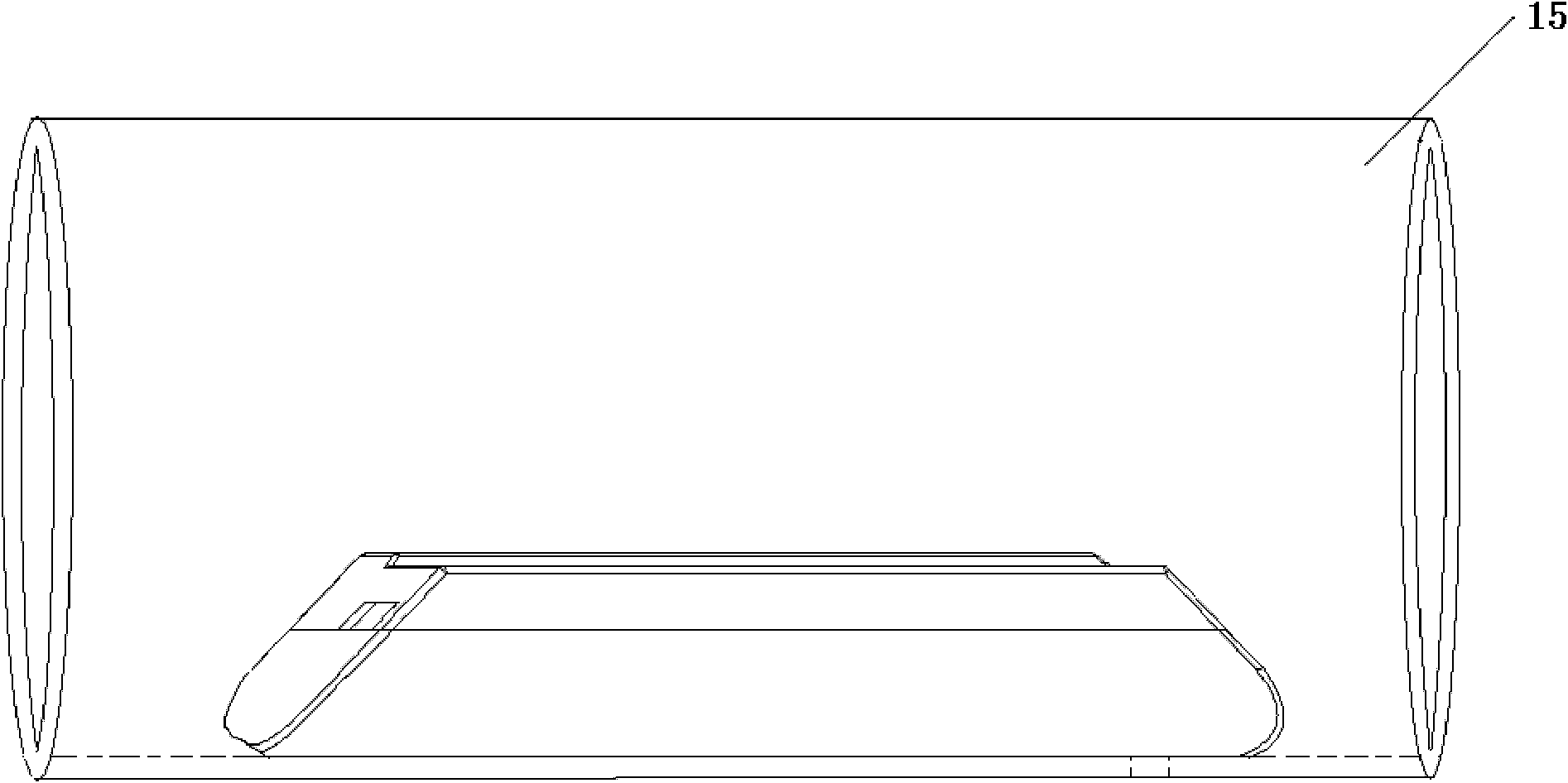

Horizontal Anaerobic Digestion Reactor

ActiveCN106957793BStir wellEvenly distributedBioreactor/fermenter combinationsBiological substance pretreatmentsNutritionDrive shaft

The invention provides a horizontal anaerobic digestion reaction device, and belongs to the field of solid waste treatment. The system device is used for artificially creating nutrition and condition essential to anaerobes, so that anaerobes having high concentration are accumulated in a reactor, and complete an organic anaerobic metabolizing process through the living activities of the anaerobes. The device comprises a reactor main body having a horizontal structure, wherein the reactor main body is provided with an inner tank and an outer jacket; the inner tank has a feed opening and a discharge opening; screw propellers with forward and reverse augers are arranged at the lower part of the reactor main body; a stirrer is arranged at the upper part of the reactor main body and is provided with a concentric transmission shaft and multiple groups of hollow blades connected to the transmission shaft; rake teeth are arranged on two sides of each blade, and rake teeth of adjacent blades are staggered; a baffle and a deflector are arranged in each blade; and the inner cavity and the outer cavity of the concentric transmission shaft are respectively connected with water inlet and outlet pipes of each blade.

Owner:SOUTHEAST UNIV

Sheet irrigator for flood diversion and drip irrigation

ActiveCN102430488BLower concentration levelsImprove hydraulic performanceSpray nozzlesDrip irrigationEngineering

The invention discloses a sheet irrigator for flood diversion and drip irrigation. The irrigator comprises an upper shell body and a lower shell body, wherein the lower shell body is matched with the upper shell body, the upper shell body is a closed shell body, a plurality of water inlet grids are arranged at the top of the upper shell body, at least a row of water outlet grids are arranged at the bottom of the upper shell body, an inserting plate is arranged on the bottom of the upper shell body, which is close to the water outlet grids, and extends towards a direction away from the upper shell body; the lower shell body is provided with an opening at the top, a groove body is arranged in the lower shell body at a position corresponding to the inserting plate, and is matched with the inserting plate, a space is arranged between the groove body and one end of the lower shell body; a water inlet flow passage is arranged in the lower shell body at a position corresponding to the water outlet grids, and extends towards the other side of the groove body through the space; a water outlet of the water inlet flow passage is communicated with at least one silt presedimentation tank, the water outlet of the silt presedimentation tank is communicated with an energy dissipation flow passage; and a water outlet hole is arranged on the bottom of the lower shell body, which is close to thewater outlet of the energy dissipation flow passage. The sheet irrigator can be used for effectively solving the problem of synchronous improvement on hydraulic performance and anti-clogging performance of the irrigator, and is applicable to a flood diversion and drip irrigation system with self-adaptive regulation and control capacity.

Owner:CHINA AGRI UNIV

Streptomyces amritsarensis and its application

The invention relates to the field of microorganisms, in particular to multifunctional Streptomyces amritsarensis alginolytic streptomyces and applications thereof. Streotomyces amritsarensis HG‑16, the preservation number of which is CCTCC M 2018237. The alginolytic streptomyces can not only kill Microcystis, but also antagonize Fusarium graminearum. Streptomyces alginolyticus, its fermentation broth and active secretions can effectively inhibit the production of microcystins in a short period of time. Adding the Streptomyces can inhibit the expression of 90% of the synthetic genes of microcystins within 9 hours, and within 36 hours After that, the expression of microcystin gene can be completely inhibited. After adding the Streptomyces for 3 days, the synthesis inhibition rate of algae toxin is 93%, while the alginolytic bacteria that have been reported to inhibit the synthesis of microcystin need more than 3 days to be able to inhibit production of microcystins.

Owner:SOUTHWEST UNIV

Control method of fresh air equipment, fresh air equipment and readable storage medium

ActiveCN110848909BGuaranteed concentration levelLower concentration levelsMechanical apparatusSpace heating and ventilation safety systemsAir volumeFresh air

The invention discloses a control method of fresh air equipment, fresh air equipment and a readable storage medium. The method includes the steps of: determining the number of users and the concentration value of pollutants in the area where the fresh air equipment is located; if the number of users is less than or equal to the preset number , then the first fresh air volume is obtained according to the preset per capita fresh air demand, the number of users, and the pollutant concentration value; the operation of the fresh air equipment is controlled according to the first fresh air volume, so as to adjust the fresh air in the area where the fresh air equipment is located. Air volume. The invention improves the accuracy rate of adjusting the fresh air volume of the fresh air equipment, and ensures the air quality in the area where the fresh air equipment is located.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com