Horizontal Anaerobic Digestion Reactor

An anaerobic digestion and reaction device technology, which is applied in biochemical cleaning devices, gas production bioreactors, enzymology/microbiology devices, etc., can solve the problem of substrate utilization gas and heat discharge unevenness, hindering anaerobic reaction, Poor effect and other problems, to achieve maximum practicality and economic benefits, uniform temperature, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

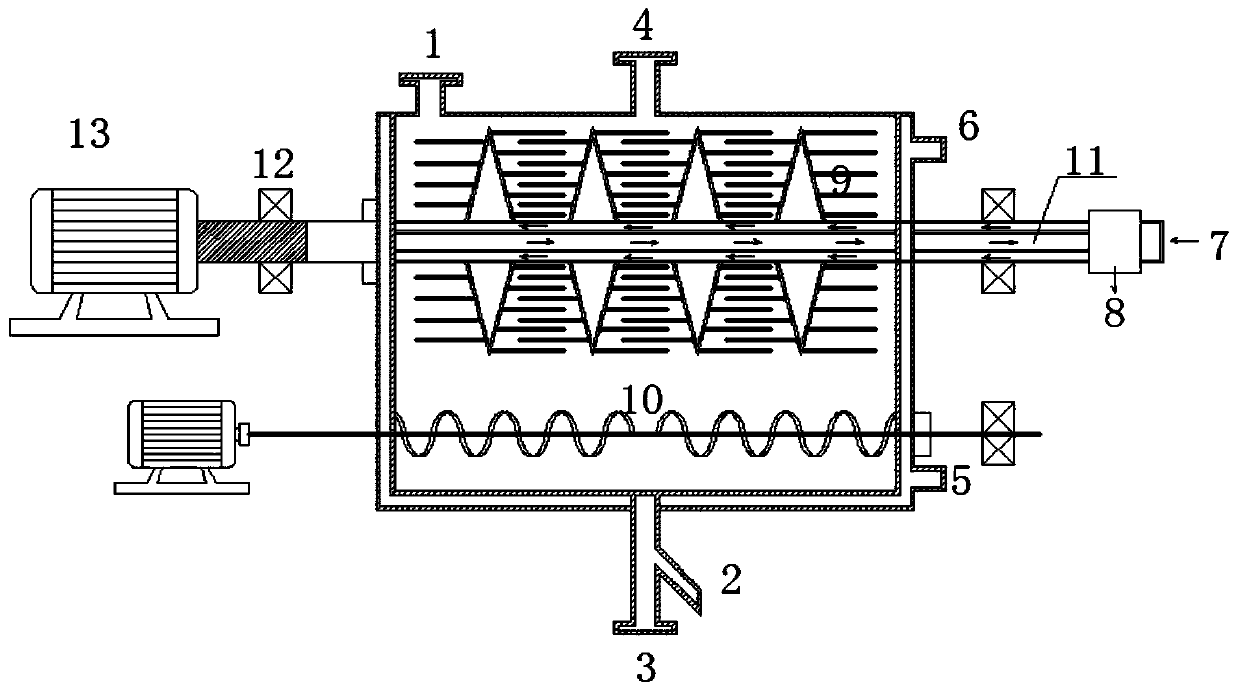

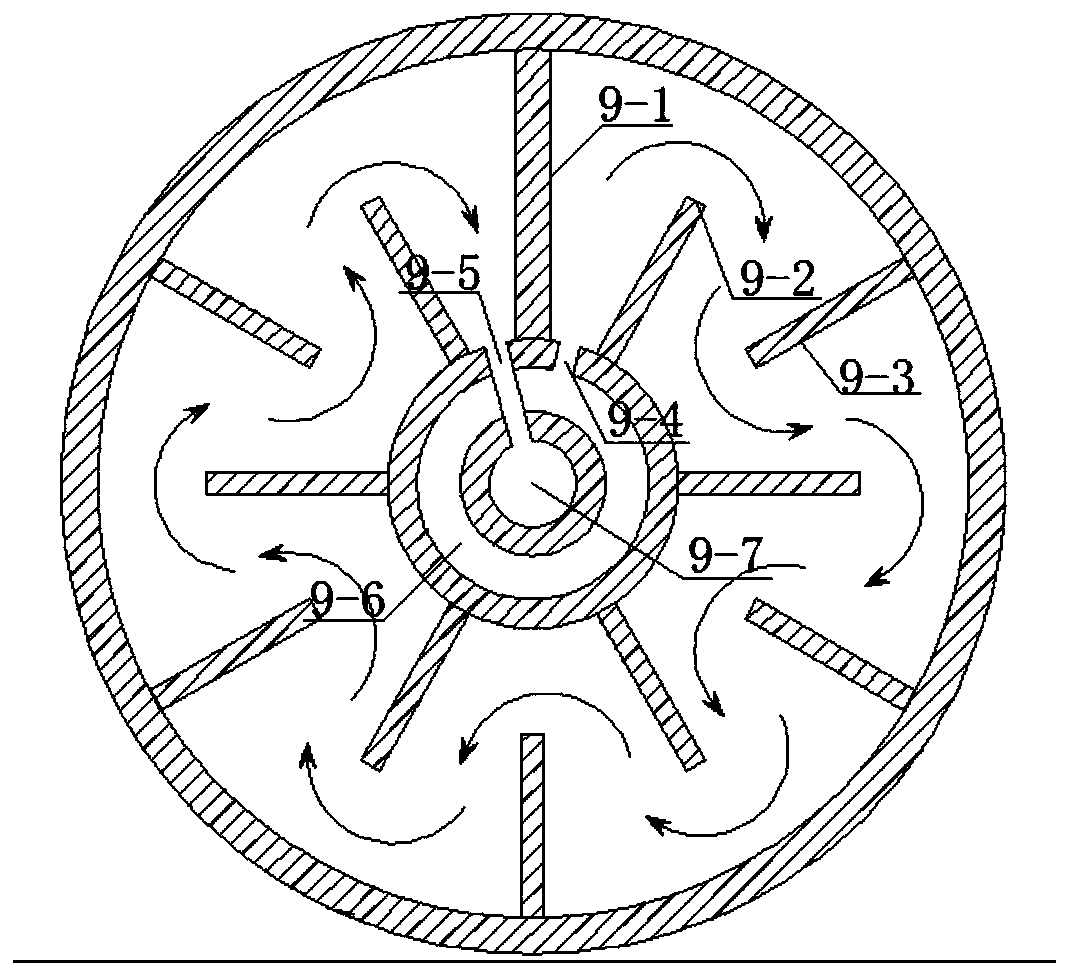

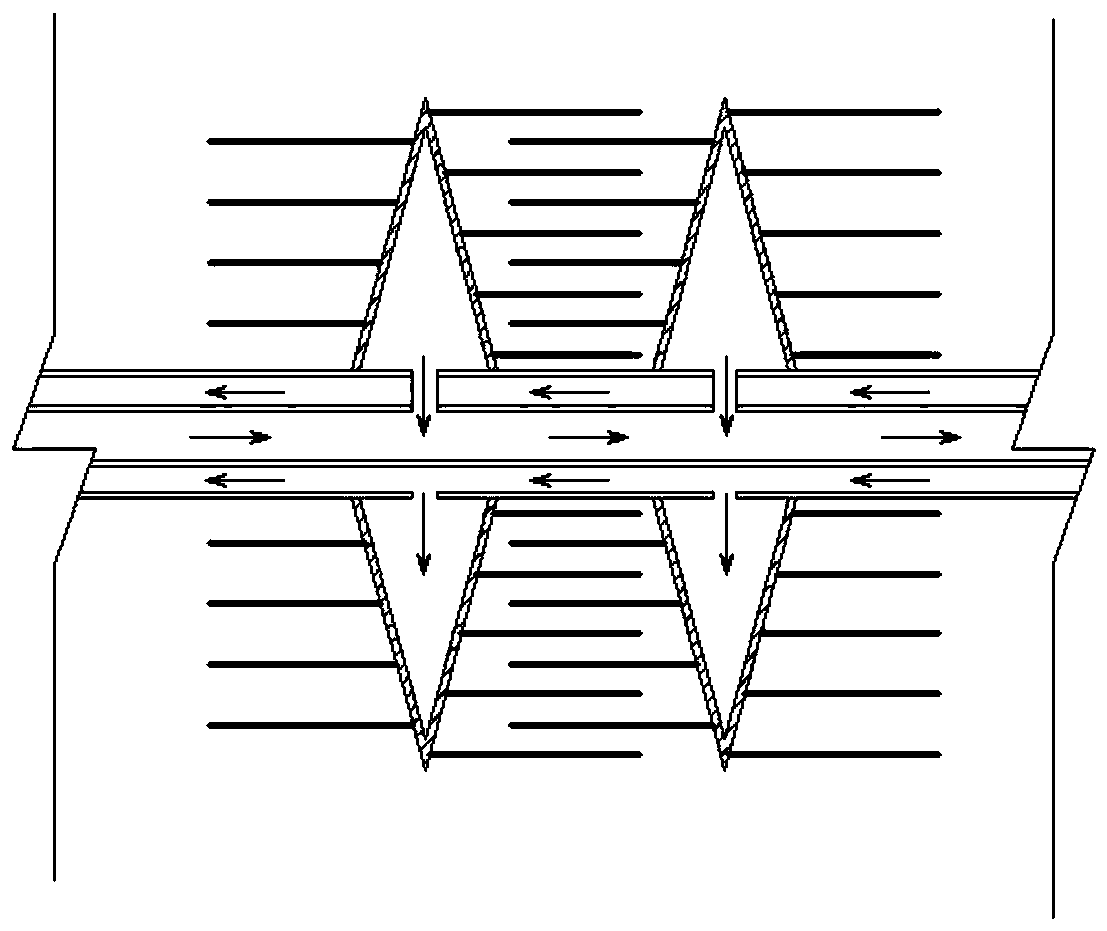

[0031] A horizontal anaerobic digestion reaction device, comprising an inner cylinder, a jacket arranged outside the inner cylinder, blades arranged inside the inner cylinder and a slag discharge auger, the inner cylinder is provided with a The feed port 1 and the feed port 2 are provided, and the reactor water inlet 5 and the reactor water outlet 6 are arranged on the jacket. Blade 9 and slag discharging auger 10 are placed in the inner cylinder.

[0032] Further, the inner cylinder and the jacket of the main body of the reactor are cylindrical, and the material is not limited, and a sight glass can be provided to facilitate the experimenter to observe the state of the material during the reaction. The upper part of the inner cylinder is provided with a material inlet 1 and an air outlet 4, and the lower part of the inner cylinder is provided with a materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com