Solidifying and stabilizing method for toxicity containing organic matter dangerous waste matter

A technology of hazardous waste and organic matter, applied in the direction of solid waste removal, etc., can solve problems such as interference, inability to immobilize organic matter, high immobilization rate of toxic organic matter, etc., and achieve the effect of reducing the concentration level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment, further illustrate the present invention. The content described in the examples does not limit the present invention.

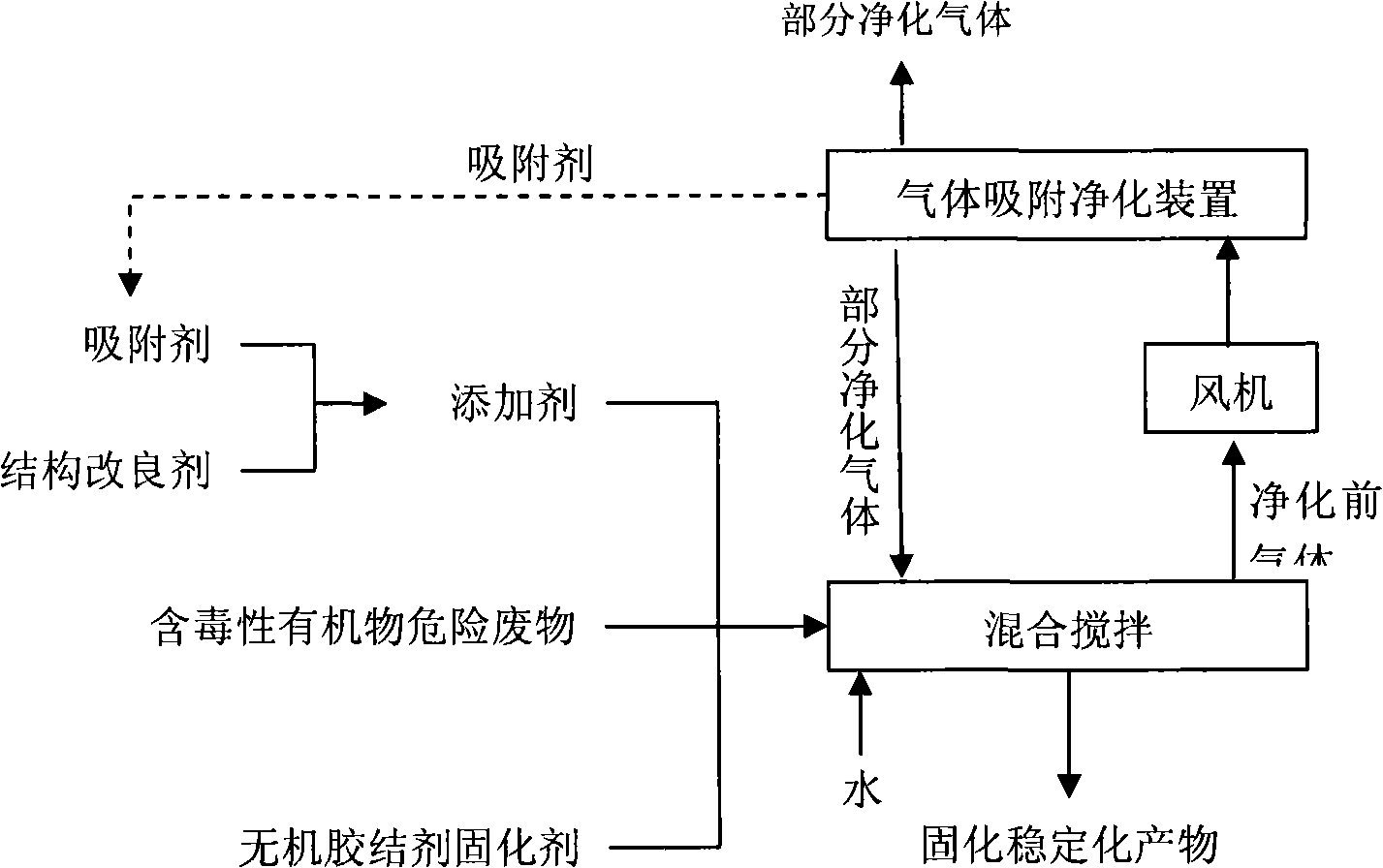

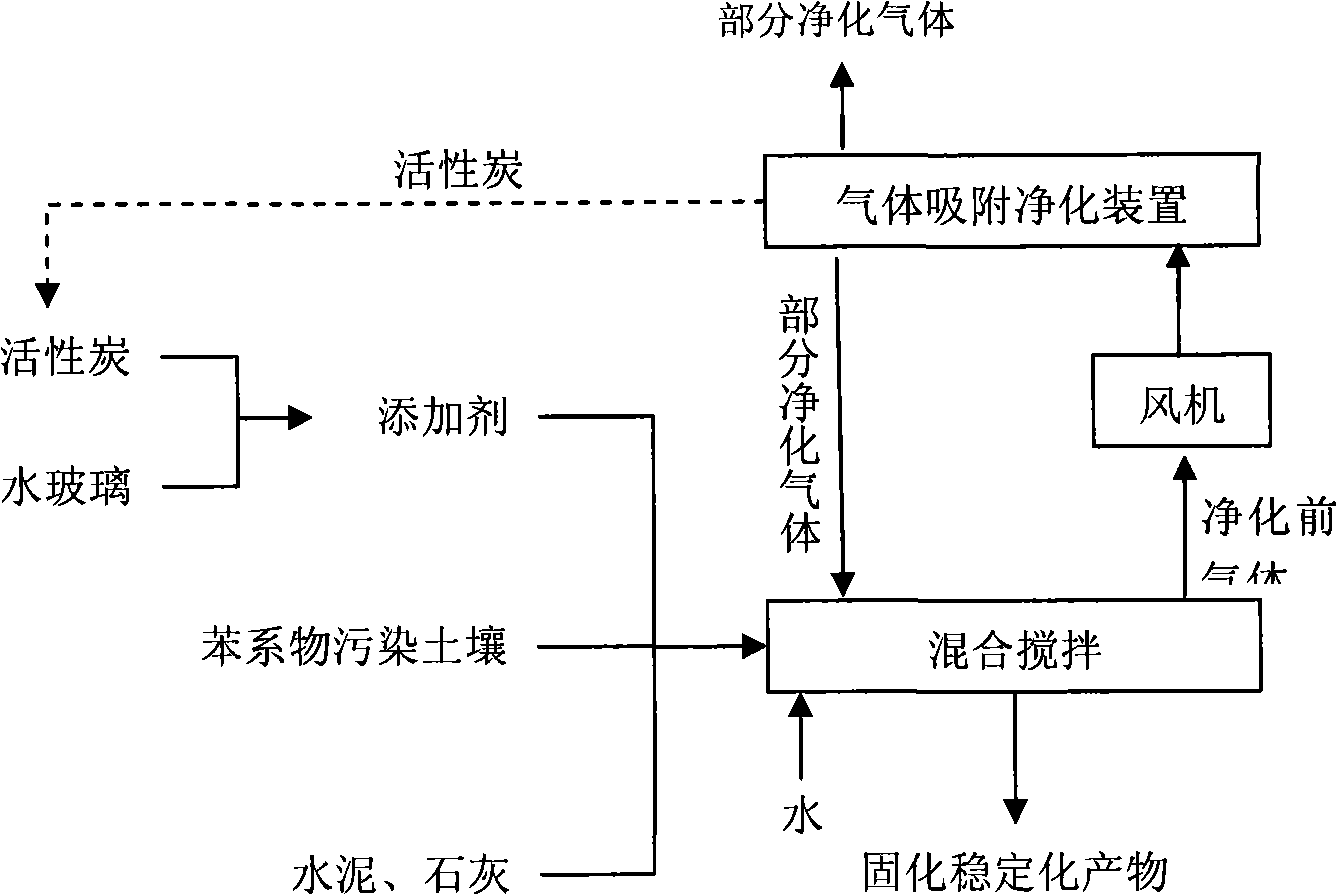

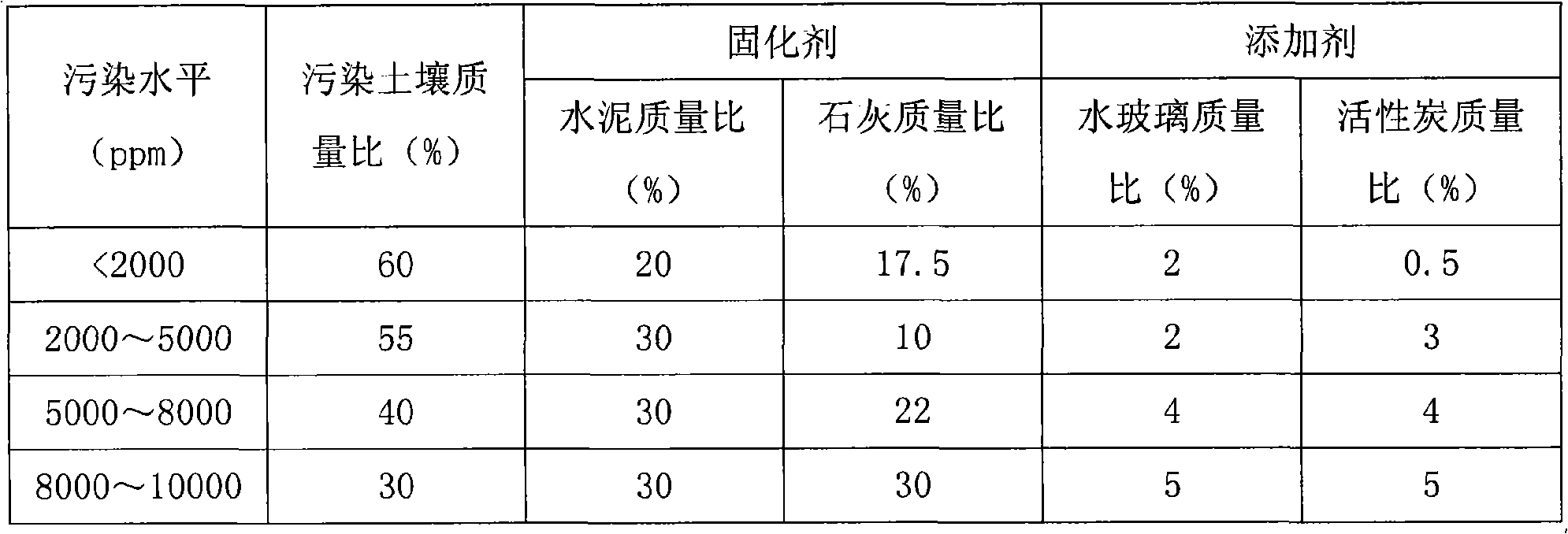

[0027] figure 1 It is a flowchart of the present invention. A method for solidifying and stabilizing hazardous waste containing toxic organic substances, comprising the steps of: 1) adding 30-60% of hazardous waste containing toxic organic substances, 0.5-10% of additives, and 30-60% of inorganic binder and curing agent according to the mass ratio of dry weight; Add to the mixer, and add water so that the water content accounts for 30-50% of the total dry weight of all solids, and the total volume of the mixed material does not exceed two-thirds of the volume of the mixer; 2) Turn on the mixer to stir and mix, and turn on the gas internal circulation at the same time device, the fan of the gas internal circulation device passes the gas in the agitator into the gas adsorption purification device, and after the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com