High-hardness thermosetting self-repairing polyurethane and preparation method thereof

A thermosetting, self-healing technology, applied in the field of self-healing polyurethane materials, to achieve high Young's modulus, high self-healing efficiency, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

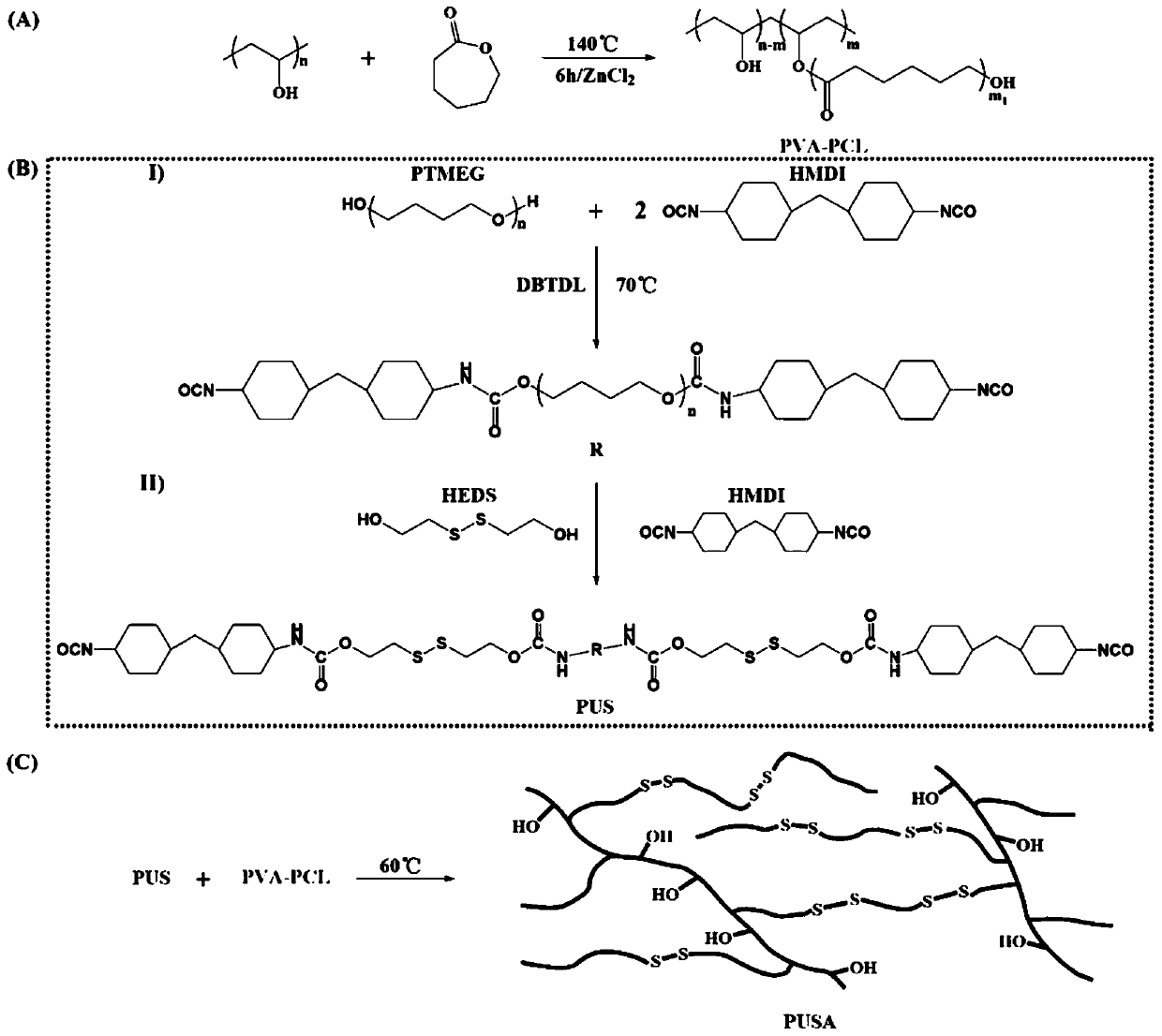

Method used

Image

Examples

Embodiment 1

[0047] Take 4.4g of polyvinyl alcohol with a molecular weight of about 1750g / mol and place it in a reaction kettle, dissolve it in 20g of dimethyl sulfoxide at 90°C, add 11.4g of ε-caprolactone and 0.1 g zinc chloride, the reaction system was under the protection of nitrogen, stirred at 25°C for 4h, so that the solution was fully mixed, heated to 140°C for 5h, and a colorless transparent liquid was obtained, and then the obtained liquid was added to the separatory funnel, and the extraction agent 2 was added. Chloromethane, the obtained product is a white polymer. The obtained product is washed with methanol and dried in a vacuum oven at 25°C for 24 hours to obtain a polyvinyl alcohol-grafted polycaprolactone crosslinking agent.

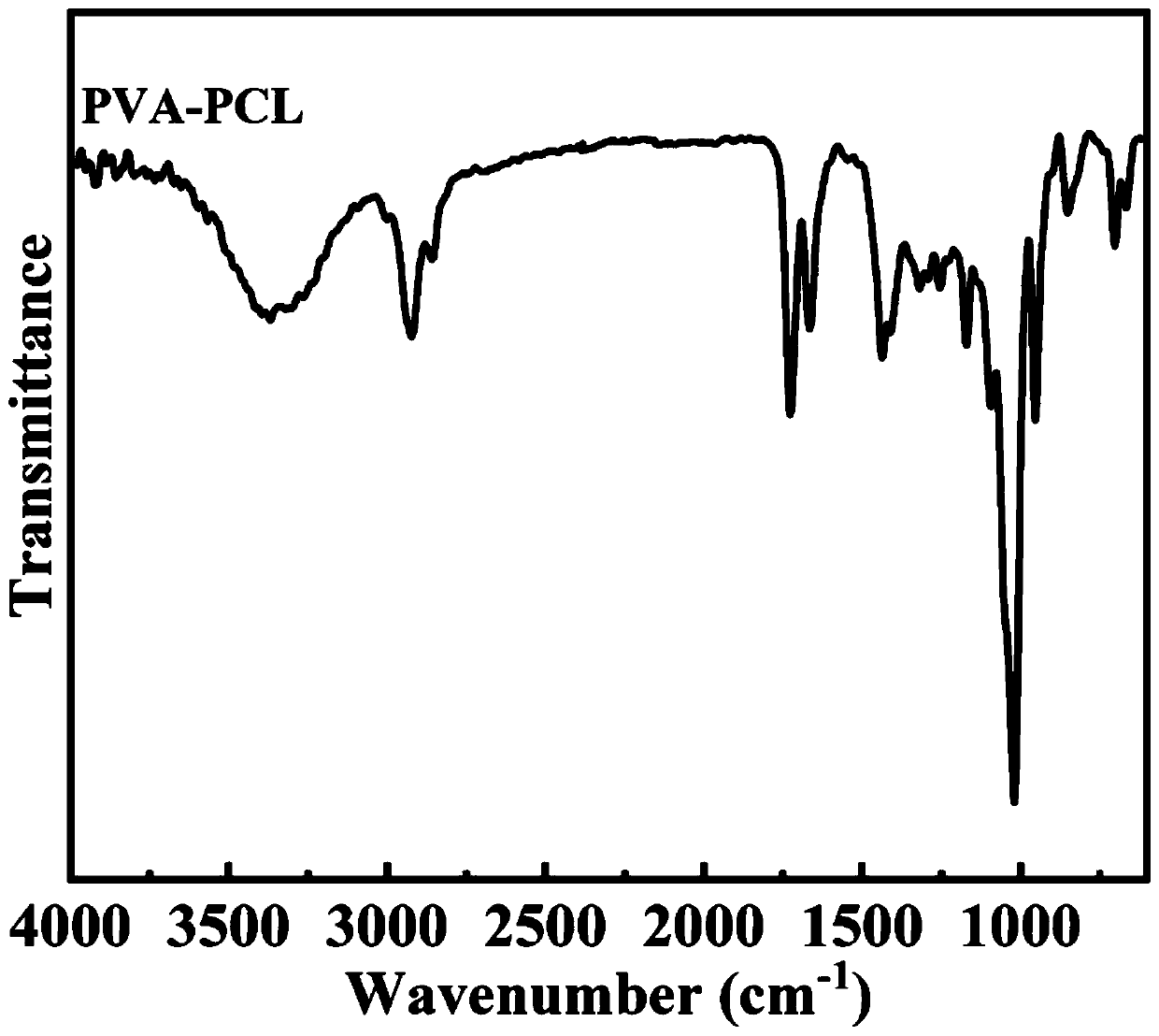

[0048] See attached figure 2 , which is the infrared spectrum of the polyvinyl alcohol grafted polycaprolactone crosslinking agent prepared in Example 1 of the present invention. It can be seen from the figure that the characteristic peak of -C-O-C...

Embodiment 2

[0050] (1) Take 20g of polytetrahydrofuran with a molecular weight of about 1000 in the reaction kettle, pass nitrogen into the reaction kettle for 10 minutes, place the reaction kettle at 120°C for 2 hours in vacuum, completely remove the moisture in the reaction kettle, and put it under the protection of nitrogen , add 10.49g dicyclohexylmethane 4,4'-diisocyanate, 40g solvent N,N-dimethylformamide, 0.04g catalyst dibutyltin dilaurate into the reaction system, react the reaction system at 70°C for 1h, An isocyanate-terminated prepolymer is obtained.

[0051] (2) Add 8.48g of chain extender 2,2'-dithiodiethanol and 15.74g of dicyclohexyl 4,4'-diisocyanate into the reaction system, and react at 70°C for 1.5h under the protection of nitrogen to obtain isocyanate-blocked terminal linear polymer.

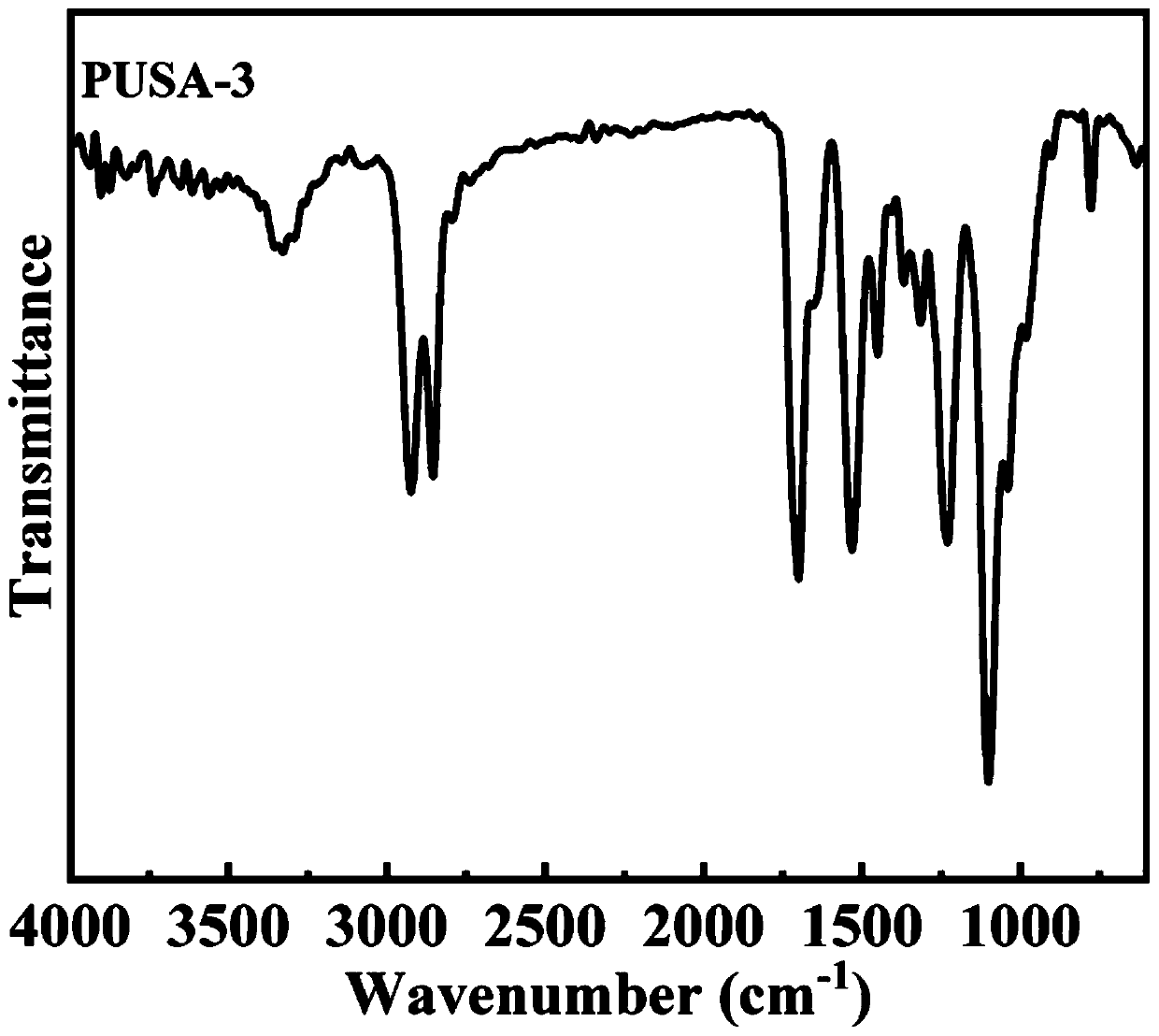

[0052] (3) Dissolve 4.74g of polyvinyl alcohol-grafted polycaprolactone in 30g of N,N-dimethylformamide, add the resulting solution into the system, and mix and react at 60°C for 20min...

Embodiment 3

[0061] (1) Take 30g of polytetrahydrofuran with a molecular weight of about 1000 in the reactor, pass nitrogen into the reactor for 10 minutes, place the reactor at 120°C for 2 hours in vacuum, completely remove the moisture in the reactor, and put it under the protection of nitrogen , add 15.74g dicyclohexyl methane 4,4'-diisocyanate, 40g solvent N,N-dimethylformamide, 0.04g catalyst dibutyltin dilaurate to the reaction system, react the reaction system at 70°C for 1h, An isocyanate-terminated prepolymer is obtained.

[0062] (2) Add 8.48g of chain extender 2,2'-dithiodiethanol and 10.49g of dicyclohexyl methane 4,4'-diisocyanate into the reaction system, and react at 70°C for 1.5h under the protection of nitrogen to obtain isocyanate-blocked terminal linear polymer.

[0063] (3) Dissolve 1.58g of polyvinyl alcohol-grafted polycaprolactone in 30g of N,N-dimethylformamide, add the resulting solution into the system, and mix and react at 60°C for 20min under the protection of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com