Novel concrete terrace protective material and preparation method thereof

A technology for floor materials and concrete, applied in the field of floor coatings, can solve the problems of poor environmental protection, few engineering applications, cumbersome construction process, etc., and achieve the effect of improving surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

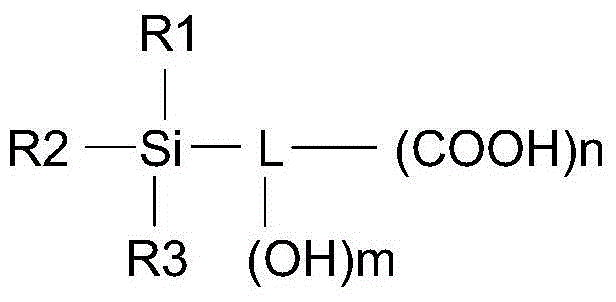

[0070] The preparation method of organic modified silicate of the present invention is:

[0071] 3) Add organosilane to water to form a stable suspension, and slowly raise the temperature to 55°C;

[0072] 2) Turn on the stirring, control the rotation speed to 500r / min, and add the acidified tetraethyl orthosilicate to the above suspended matter for constant temperature reaction for 24h;

[0073] 3) filtering the obtained sedimentation product, washing with water for several times, and vacuum drying;

[0074] 4) Sintering the dried product at 220° C. for 4 hours to obtain an organically modified silicate product.

[0075] A kind of preparation method of novel concrete protection floor material, it comprises the following steps:

[0076] (1) Inject water, pH adjusting agent in batching tank (A), open disperser (i.e. stirring equipment), (for example or preferably adjust the rotating speed of stirring equipment to be 800-2000r / min, such as 1200r / min), Add silicate, stirring c...

Embodiment 1

[0088] Embodiment 1 (preparation example):

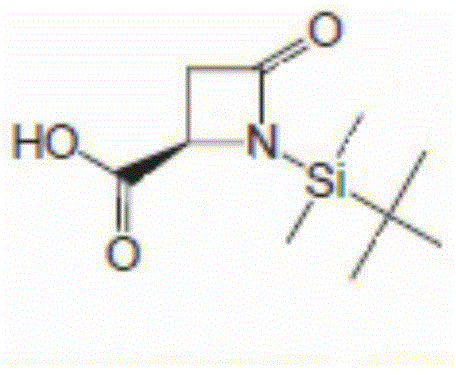

[0089] 1) Add 240kg of TQ-4 organosilane (structure shown in the following formula) from Changsha Institute of Chemical Industry to 800kg of deionized water, and slowly raise the temperature to 55°C;

[0090]

[0091] 2) Turn on the stirring, control the rotational speed to 200r / min, and add 180kg of tetraethyl orthosilicate from Changsha Research Institute of Chemical Industry after acidification treatment (500ml concentration of 35% hydrochloric acid added), and react at constant temperature for 24h;

[0092] 3) Reduce to normal temperature, filter the reaction solution, take the sediment and wash it with water for 3 times;

[0093] 4) Transfer the sediment into a crucible, put it into a constant temperature oven at 220° C. for sintering for 4 hours, and obtain an organically modified silicate product.

[0094] Infrared (IR) spectrum of organomodified silicate products: at 1458cm -1 There is a C-H absorption peak at 3438cm -...

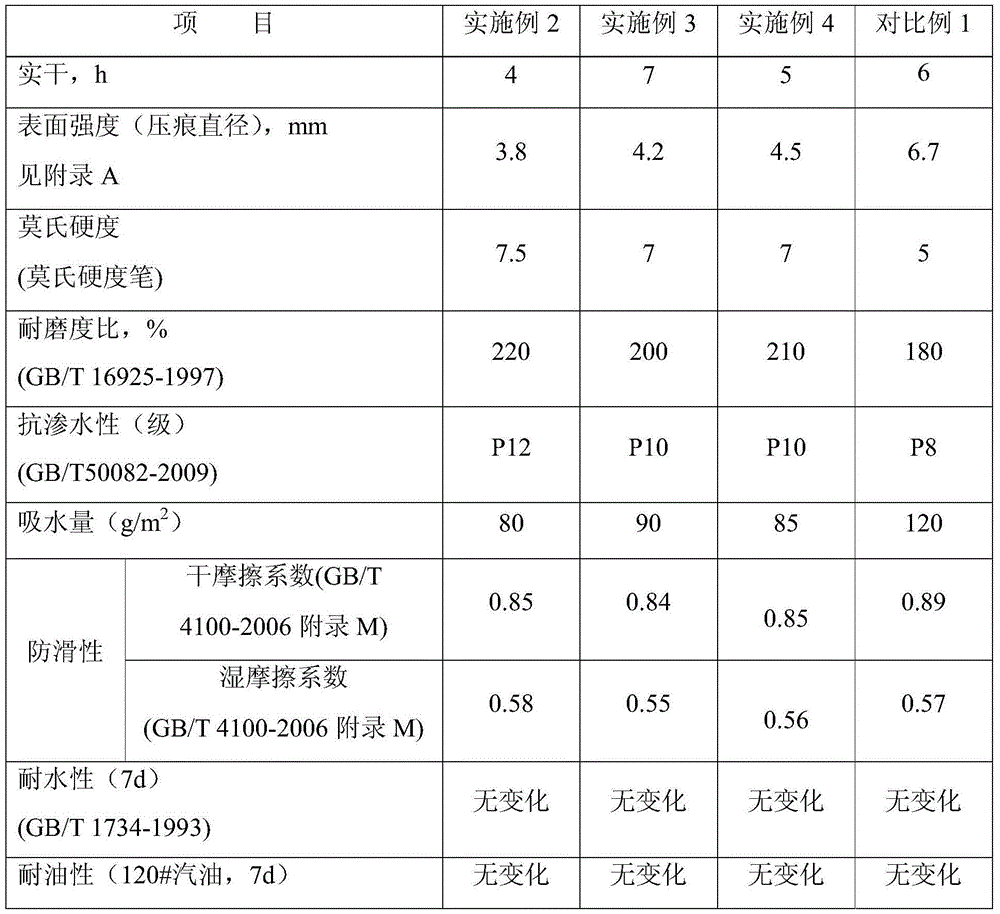

Embodiment 2

[0096] 1) Weigh 400kg of deionized water, 2kg of sodium hydroxide from Guangzhou Hewei Chemical Industry Co., Ltd., and 5kg of lithium hydroxide monohydrate from Shanghai Zhongli Industrial Co., Ltd., and mix and stir evenly at a speed of 1200r / min. Add 45kg of sodium silicate from Qingdao Dewang Chemical Co., Ltd. and 80kg of lithium silicate from Shanghai Zhongli Industrial Co., Ltd., and continue stirring until completely dissolved;

[0097] 2) Add 210 kg of organic modified silicate prepared in 1) in three equal parts, and ensure that the previous feeding is completely dissolved before feeding each time, and continue to stir after feeding, and reduce the speed to 400r / min for use;

[0098] 3) Weigh 200kg of deionized water, 1kg of sodium hydroxide from Guangzhou Hewei Chemical Industry Co., Ltd., and 2kg of lithium hydroxide monohydrate from Shanghai Zhongli Industrial Co., Ltd., stir and dissolve, increase the speed to 1200r / min, and add Degussa’s 715W1kg, 12kg of modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com