Method for preparing high-performance natural rubber through biological coagulation technology

A technology for natural rubber and biological coagulation, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of reducing the total solid content of coagulation waste liquid, the quality of fresh latex, and the difficulty in operating income of natural rubber processing enterprises. To improve again and other problems, to achieve the effect of high self-adhesion, excellent processing performance, high chemical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

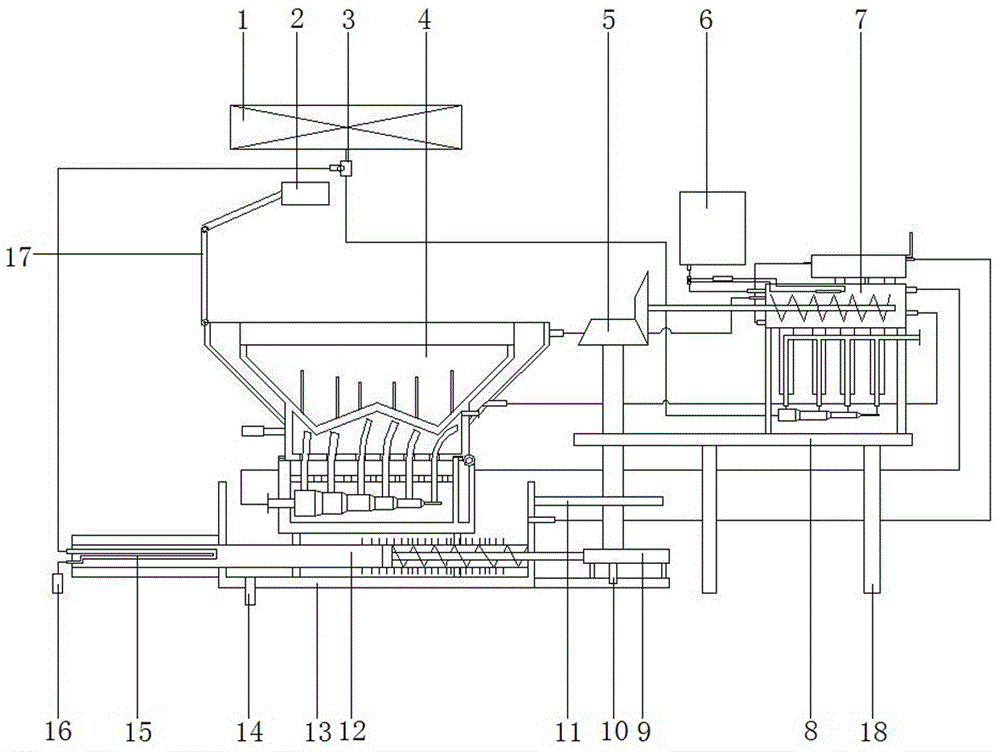

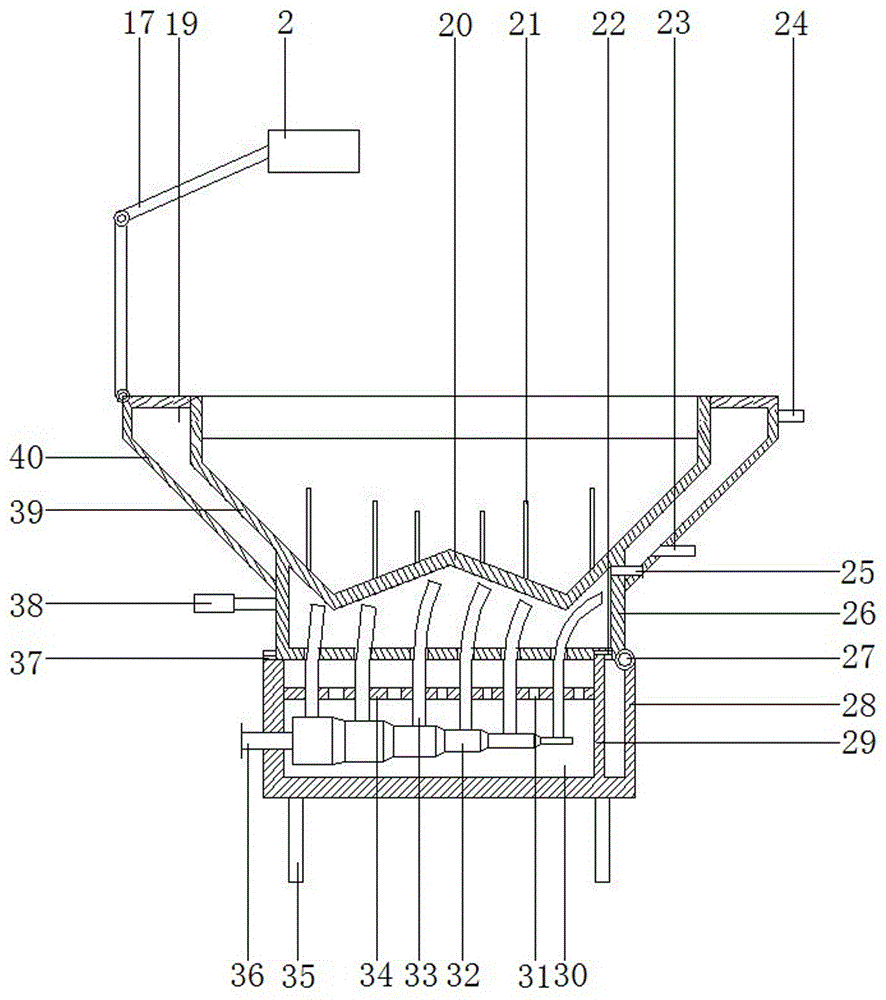

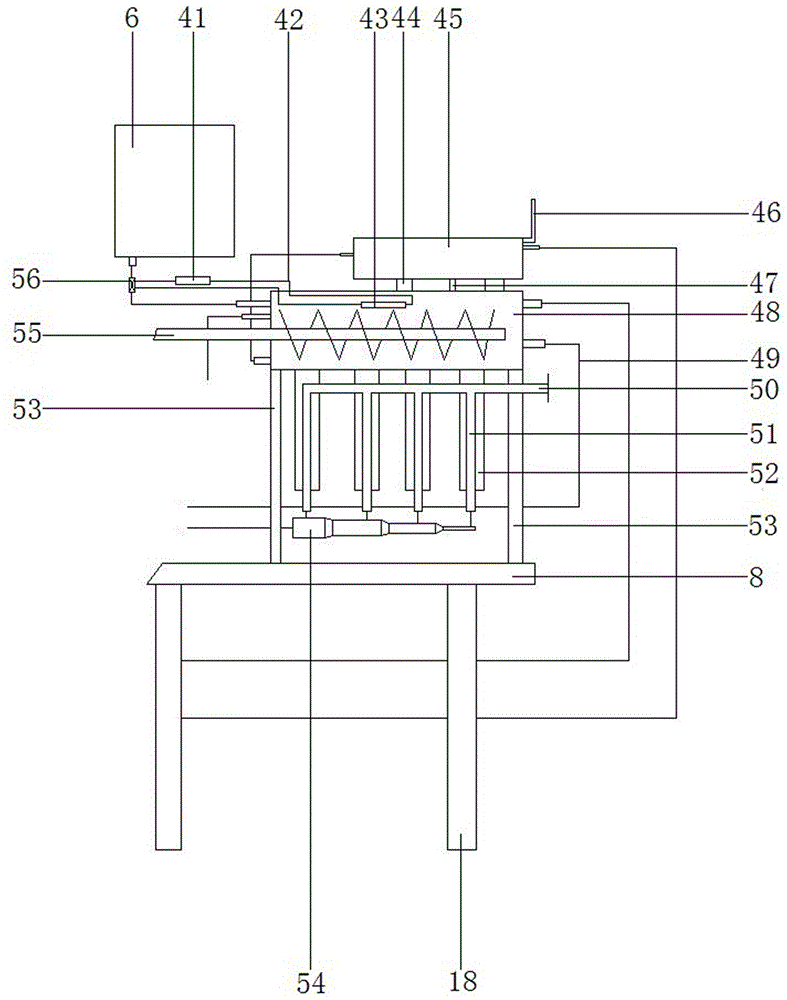

Image

Examples

Embodiment 1

[0050] A method for preparing high-performance natural rubber using biological coagulation technology, including coagulation of fresh latex symbiotic microorganisms, extrusion dehydration, crepe pressing, cleaning, granulation, drying, and packaging, characterized in that the coagulation technology of fresh latex symbiotic microorganisms The good symbiotic flora coagulation solution is mixed with filtered fresh latex and placed in a constant temperature coagulation box for constant temperature coagulation. After the above steps, high-performance natural rubber is finally obtained.

[0051] As a further improvement of the present invention, the symbiotic flora coagulation liquid is composed of self-sufficient symbiotic flora and coagulated flora, wherein the number of bacteria in the self-sufficient symbiotic flora is twice that of the coagulated flora.

[0052] As a further improvement of the present invention, the self-supporting symbiotic flora is composed of photosynthetic b...

Embodiment 2

[0075] A method for preparing high-performance natural rubber using biological coagulation technology, including coagulation of fresh latex symbiotic microorganisms, extrusion dehydration, crepe pressing, cleaning, granulation, drying, and packaging, characterized in that the coagulation technology of fresh latex symbiotic microorganisms The good symbiotic flora coagulation solution is mixed with filtered fresh latex and placed in a constant temperature coagulation box for constant temperature coagulation. After the above steps, high-performance natural rubber is finally obtained.

[0076] As a further improvement of the present invention, the specific processing technology of described high-performance natural rubber is as follows:

[0077] a. Coagulation of fresh latex with symbiotic microorganisms: the coagulation solution of symbiotic flora and the filtered fresh latex are mixed at a ratio of 1:50 and placed in a constant temperature coagulation box for constant temperature...

Embodiment 3

[0093] A method for preparing high-performance natural rubber using biological coagulation technology, including coagulation of fresh latex symbiotic microorganisms, extrusion dehydration, crepe pressing, cleaning, granulation, drying, and packaging, characterized in that the coagulation technology of fresh latex symbiotic microorganisms The good symbiotic flora coagulation solution is mixed with filtered fresh latex and placed in a constant temperature coagulation box for constant temperature coagulation. After the above steps, high-performance natural rubber is finally obtained.

[0094] As a further improvement of the present invention, the specific processing technology of described high-performance natural rubber is as follows:

[0095] a. Coagulation of fresh latex with symbiotic microorganisms: the coagulation solution of symbiotic flora and the filtered fresh latex are mixed at a ratio of 1:100 and placed in a constant temperature coagulation box for constant temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com