Patents

Literature

117results about How to "Improve self-adhesiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinyl chloride electrostatic film and preparation method thereof

InactiveCN106046626AHigh static resistanceImprove anti-static effectFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of electrostatic film, and in particular, relates to a polyvinyl chloride electrostatic film and a preparation method thereof, wherein the polyvinyl chloride electrostatic film comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 46-73 parts of a plasticizer, 1-3 parts of a heat stabilizer, 3-7 parts of an anti-electrostatic agent, 0.3-0.7 part of a gelatinizing agent, 0.02-0.03 part of a pigment powder, and 0.1-0.3 part of other auxiliary agents. The polyvinyl chloride electrostatic film has high electrostatic resistance, has high anti-electrostatic effect and protection functions, has high self-adhesive performance, and has excellent stable performance under high temperature conditions; the polyvinyl chloride electrostatic film also has the advantages of being ultra thin, tough, transparent, self-adhesive, good in transparency, small in watermarks and the like, has fewer crystal points and low-temperature resistance, and has excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Asphalt strip and preparation and construction methods thereof

ActiveCN104109399AEasy to carryImprove ductilityPaving detailsBuilding insulationsAntioxidantDust control

The invention discloses an asphalt strip and preparation and construction methods thereof, belonging to the technical field of asphalt pavement construction. The asphalt strip is characterized by comprising the following components in parts by weight: 70-90 parts of asphalt, 2-10 parts of a styrene-butadiene copolymer, 8-15 parts of solvent naphtha, 1-5 parts of a filler, 1-5 parts of a stabilizer and 0.1-0.3 part of an antioxidant, wherein the solvent naphtha is one of aromatic hydrocarbon oil, coal tar, diesel oil or kerosene; and the asphalt is petroleum asphalt or coal tar pitch. The construction method of the asphalt strip comprises the following steps: flushing, dedusting, caulking and welting. The asphalt strip has high viscidity and extensibility, filling of a pavement crack can be finished without heating, the construction method of the asphalt strip is short in used time, and can be finished without an assist of crack sealing equipment, and the construction effect is firm and lasting.

Owner:淄博恒信路面材料有限公司

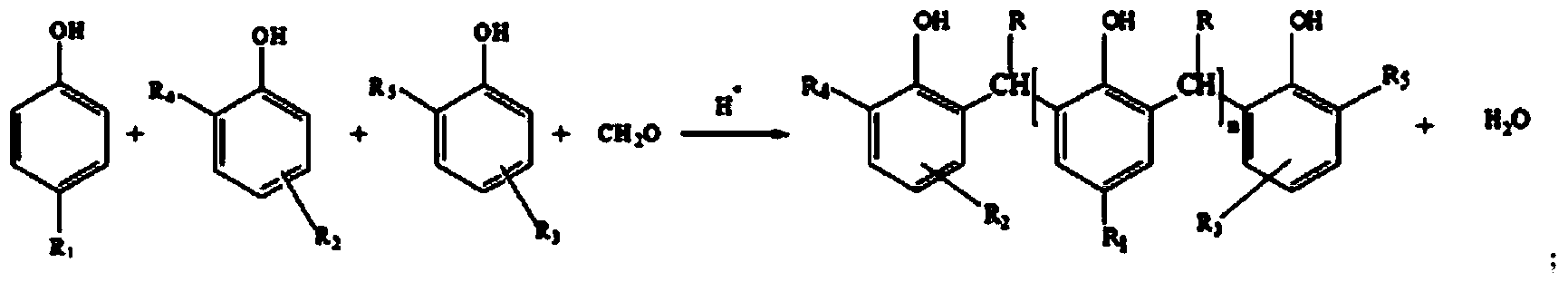

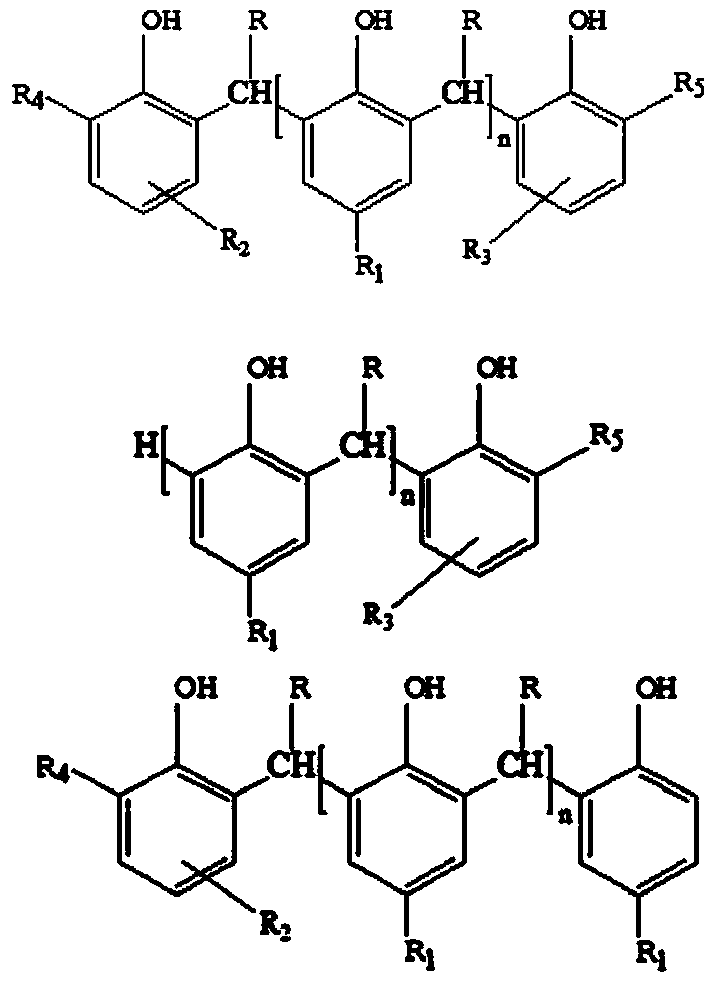

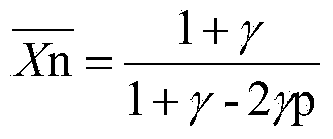

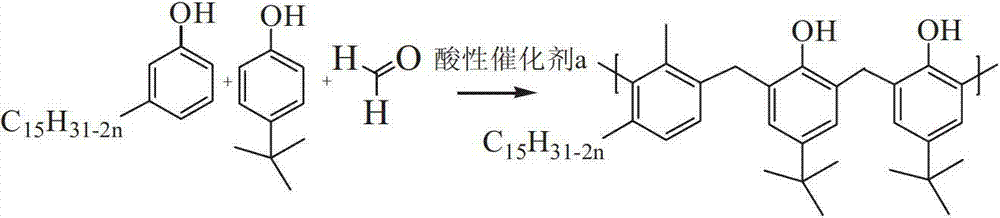

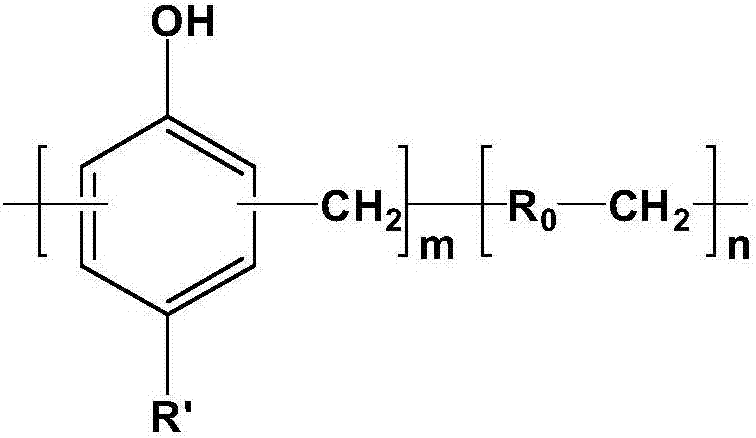

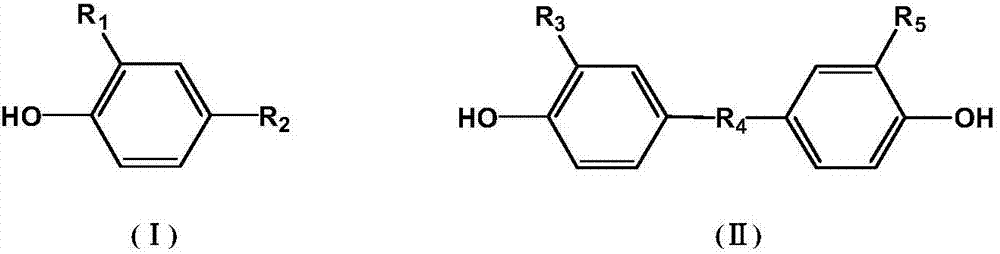

Synthesis method of alkyl phenol aldehyde resin

The invention discloses an alkyl phenol aldehyde resin and a synthesis method thereof. The synthesis method comprises the following steps: adding raw materials mono-substituted alkyl phenol and di-substituted alkyl phenol into a reactor, reacting with aldehyde under the action of an acidic catalyst, heating for dehydration, adding aldehyde, and reacting to obtain the alkyl phenol aldehyde resin. Compared with like alkyl phenol aldehyde resins, the alkyl phenol aldehyde resin disclosed by the invention has obviously higher tackifying effect and lower free phenol content. The invention also discloses application of the alkyl phenol aldehyde resin in production manufacturing of tires and rubber products.

Owner:RACHEM CHINA CO LTD

Ethylene propylene diene monomer self-adhesive waterproof roll

ActiveCN104629659AImprove adhesionImprove self-adhesivenessNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceEthylene-propylene-diene-monomer

The invention discloses an ethylene propylene diene monomer self-adhesive waterproof roll. The roll comprises a non-woven fabric layer, a rubber waterproof layer, a silane coupling agent layer, a grafted ethylene propylene diene monomer self-adhesive layer and an isolating membrane which are sequentially compounded and arranged from top to bottom. The roll is characterized in that the grafted ethylene propylene diene monomer self-adhesive layer comprises the following components in parts by weight: 30-40 parts of grafted ethylene propylene diene monomer, 0.1-1 part of an active agent, 15-20 parts of tackifier, 20-25 parts of tackifying resin, 20-30 parts of filler, 2 parts of a vulcanizing agent, 1 part of zinc oxide, 0.1-0.5 part of an accelerant TMTD, 0.5 part of an antiaging agent and 0.5 part of a coupling agent. The roll disclosed by the invention can be used for improving the bonding force between a base material and an adhesive layer to a great extent and better solves the defect that the self-adhesive and mutual-adhesive performances of the ethylene propylene diene monomer are poor.

Owner:NINGBO HUAGAOKE WATERPROOF TECH

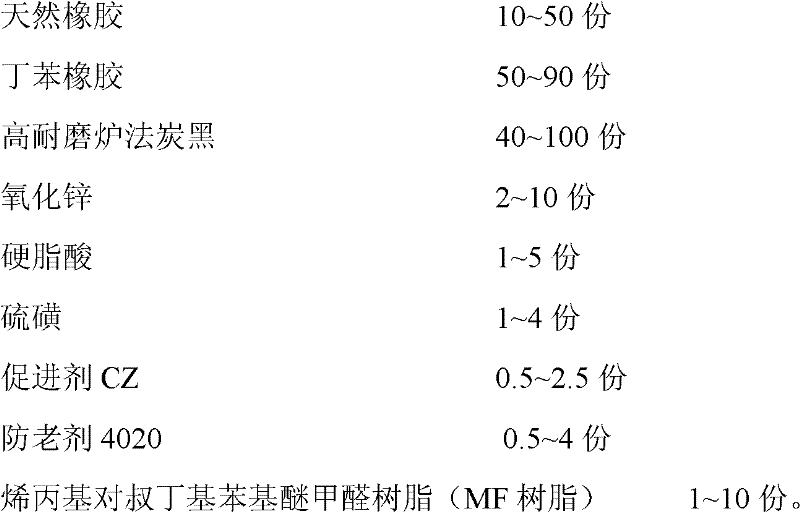

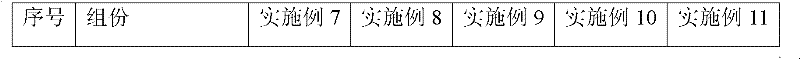

Rubber material containing phenolic tackifying resin

The invention discloses a rubber material containing a phenolic tackifying resin, which comprises from the following formula components in part by mass: 10 to 50 parts of natural rubber, 50 to 90 parts of butadiene styrene rubber, 40 to 100 parts of high-wear-resistance furnace black, 2 to 10 parts of zinc oxide, 1 to 5 parts of stearic acid, 1 to 4 parts of sulfur, 0.5 to 2.5 parts of accelerator CZ, 0.5 to 4 parts of antiaging agent 4020, and 1 to 10 parts of melamine formaldehyde (MF) resin. The MF resin is allyl p-tert-butyl phenyl ether formaldehyde resin. The MF resin contains not only polar phenolichydroxyl but also allyl double bond; therefore, compared with unmodified p-tert-butyl phenolic resin (BF resin), the MF resin can provide high initial self-tackifying strength for rubber materials, has long-lasting tackifying capacity, and improves the crosslinking density and physical and mechanical properties of vulcanized rubber.

Owner:LIANYUNGANG REBO CHEM CO LTD

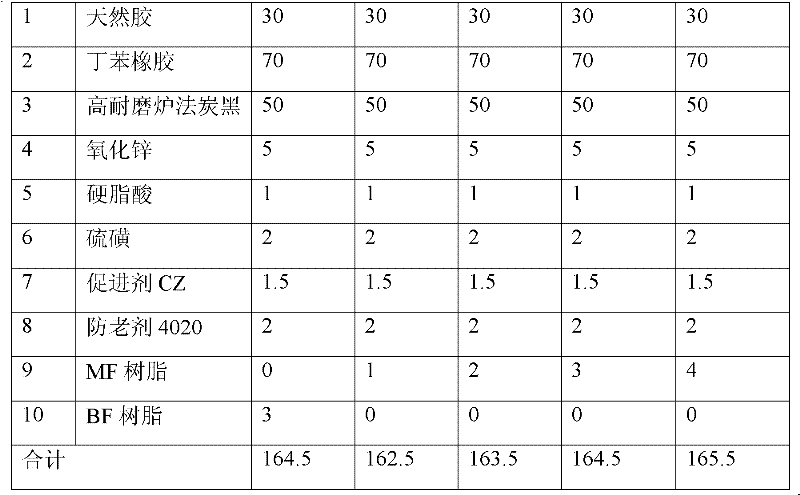

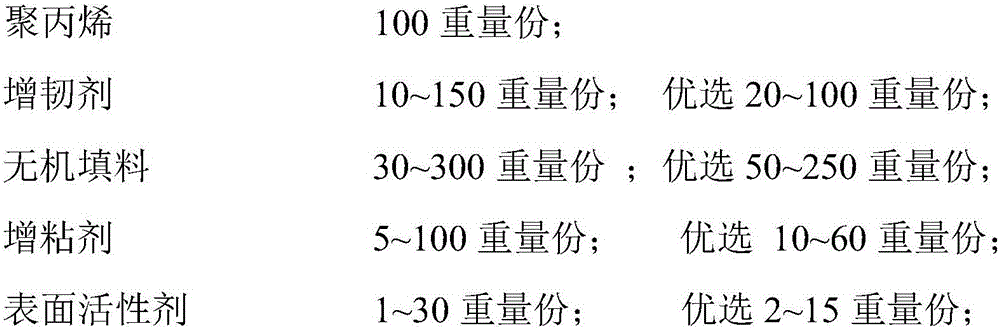

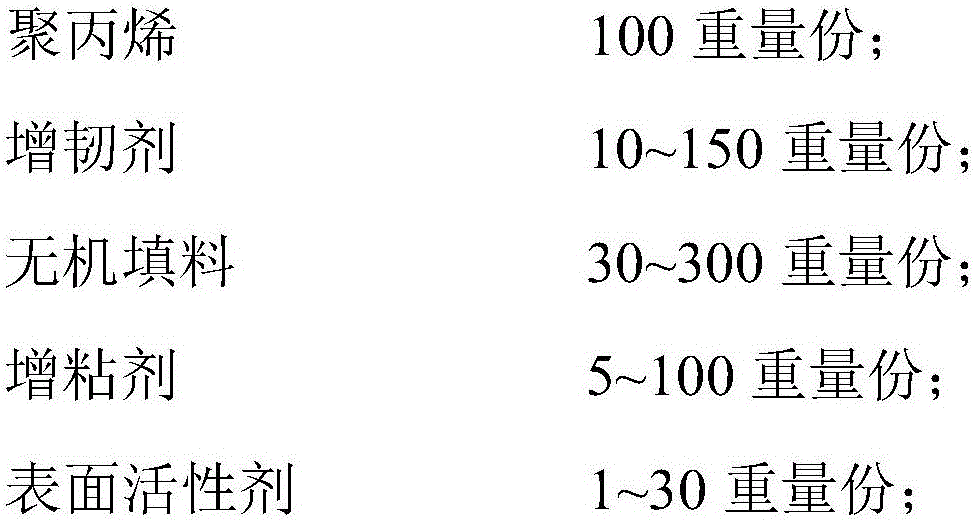

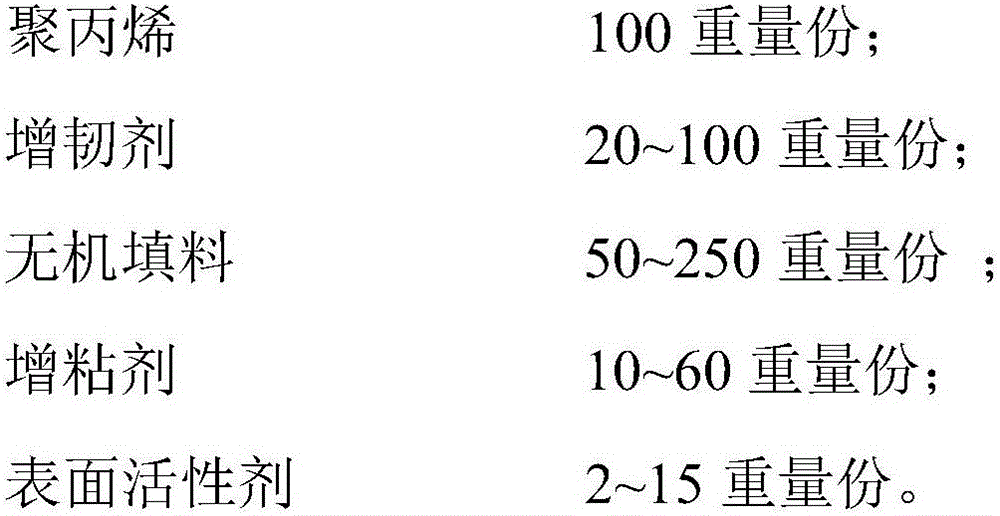

Polypropylene composite material capable of realizing 3D (three-dimensional) printing and preparation method thereof

InactiveCN106633411AImprove surface activityImprove liquidityAdditive manufacturing apparatusPolypropylene compositesPolymer science

The invention discloses a polypropylene composite material capable of realizing 3D (three-dimensional) printing and a preparation method thereof. The polypropylene composite material is prepared by mixing the following raw material ingredients in parts by weight: 100 parts of polypropylene, 10 to 150 parts of toughening agents, 30 to 300 parts of inorganic filler, 5 to 100 parts of thickening agents and 1 to 30 parts of surfactants, wherein the toughening agents are thermoplastic vulcanized rubber; the inorganic filler is calcium carbonate and / or talcum powder; the thickening agents are chlorinated polyethylene; the surfactants are stearic acid and / or titanate. The preparation method comprises the following steps that firstly, the inorganic filler and the surfactants of the quantities are stirred at high speed; then, a mixture and other ingredients of the quantities are subjected to melt blending; the polypropylene composite material capable of realizing the 3D printing is prepared. The polypropylene composite material has high toughness and low shrinkage, and is a good 3D printing material.

Owner:许家萁

Silicon-free heat-conducting gasket and preparation method thereof

InactiveCN103319829AImprove heat resistanceImprove aging resistanceHeat-exchange elementsAcrylic resinPlasticizer

The invention relates to a silicon-free heat-conducting gasket and a preparation method thereof. The silicon-free heat-conducting gasket comprises the following raw materials in parts by weight: 100 parts of acrylics resin, 100-1000 parts of heat conduction powder, 10-40 parts of a plasticizer,1-10 parts of a vulcanizing agent, 0-3 parts of a scorch retarder, and 0-3 parts of pigment, the prepared silicon-free heat-conducting gasket provided by the invention has good insulativity, excellent ageing resistance property, high flexibility and good autohension, is not undergoing oil leakage even though being used for a long time, and is particularly suitable for heat conduction filling gap of a silicone oil sensitive occasion.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

Chlorate oxygen column as ignitor and production thereof

ActiveCN1817824AIncrease oxygen contentMature and stable manufacturing processExplosivesOxygenPotassium perchlorate

An ignition medicine with chlorate oxygen column and its production are disclosed. The ignition medicine consists of sodium chlorate 30~50% with grain size 60~300 meshes, lithium hyperchlorate or sodium perchlorate 10~30% with grain size 60~300 meshes, barium dioxide 0.1~6% with grain size 80~200 meshes, metal oxide ironic oxide or cuprous oxide 5~9% with grain size 20~200 meshes, metal powders 15~25% with grain size 100~300 meshes and cobalt salt 5~15% with grain size 40~200 meshes. It has shorter gas-take time and higher starting success probability of engine.

Owner:中国航天科技集团公司第四研究院第四十二所

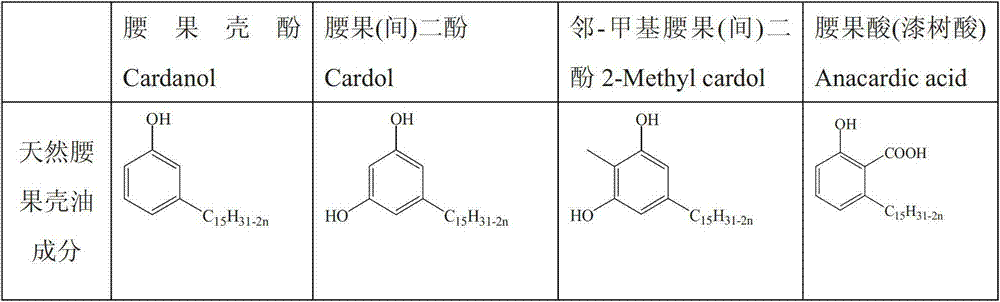

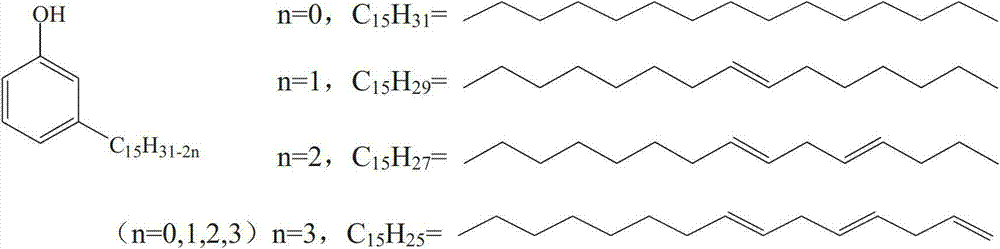

Cashew oil modified alkyl phenol-phenol formaldehyde tackifying resin, preparation method and application thereof

The present invention provides a cashew oil modified alkyl phenol-phenol formaldehyde tackifying resin, which is a cardanol and alkyl phenol formaldehyde copolymerized product, wherein the polymer side chain is a long carbon chain having unsaturated double bonds, and the softening point is 100-140 DEG C. The present invention further discloses a preparation method and an application of the cashew oil modified alkyl phenol-phenol formaldehyde tackifying resin, wherein the cashew oil modified alkyl phenol-phenol formaldehyde tackifying resin can be adopted as a rubber tackifier so as to provide good self-adhesion for the rubber material and reduce dynamic heat production of the rubber, and the rubber tackifier is particularly suitable for tire production.

Owner:SINO LEGEND CHINA CHEM +1

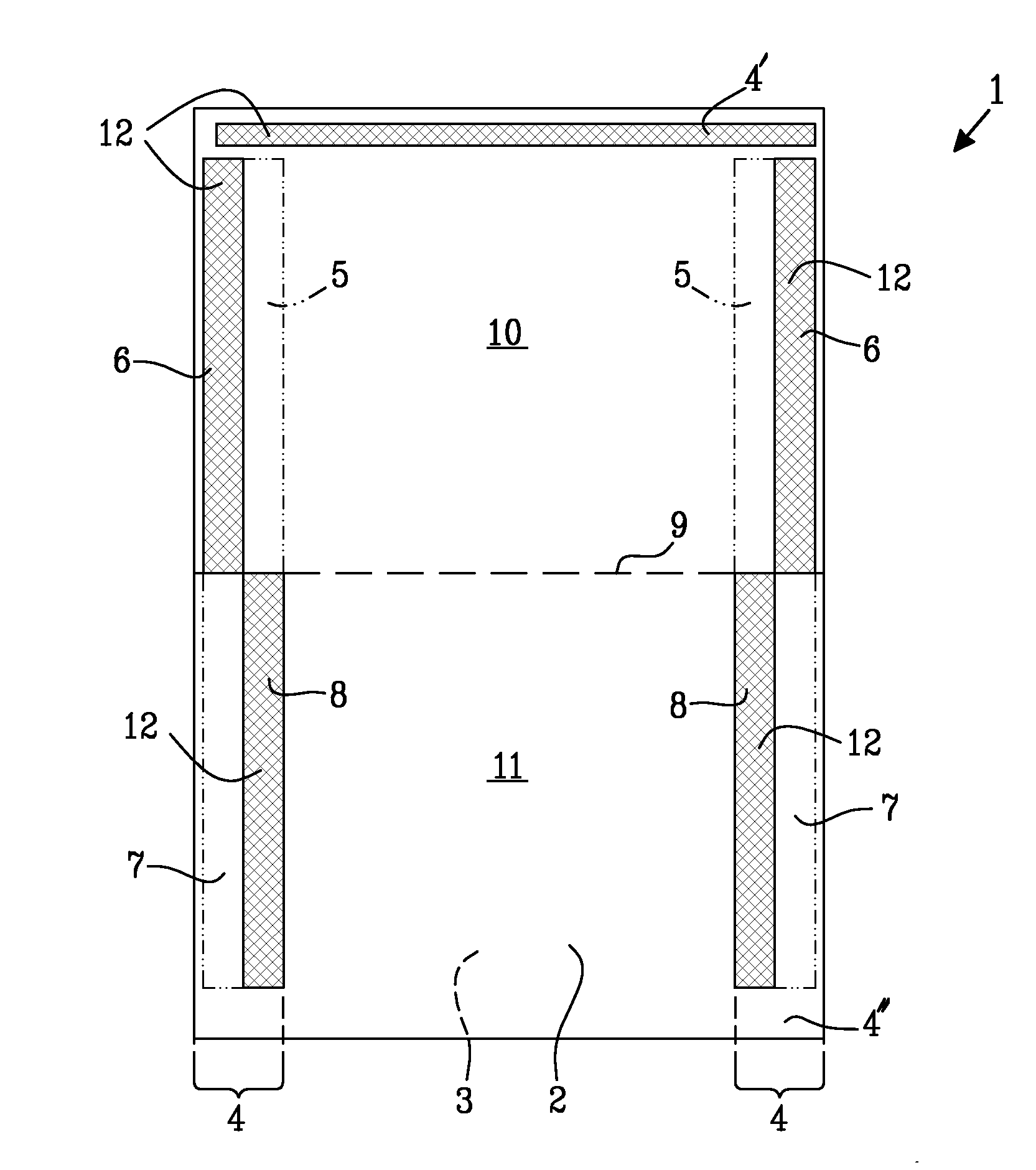

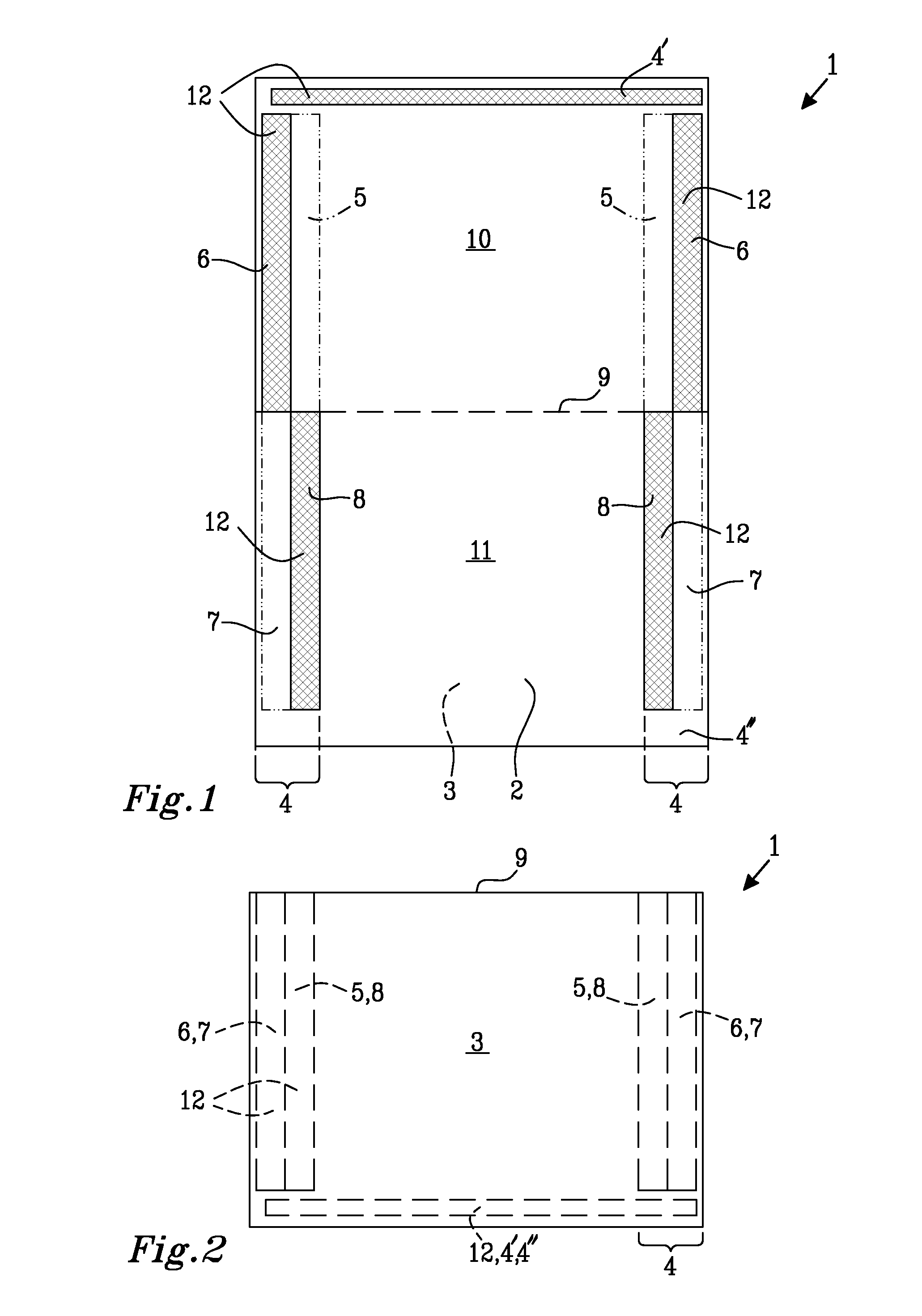

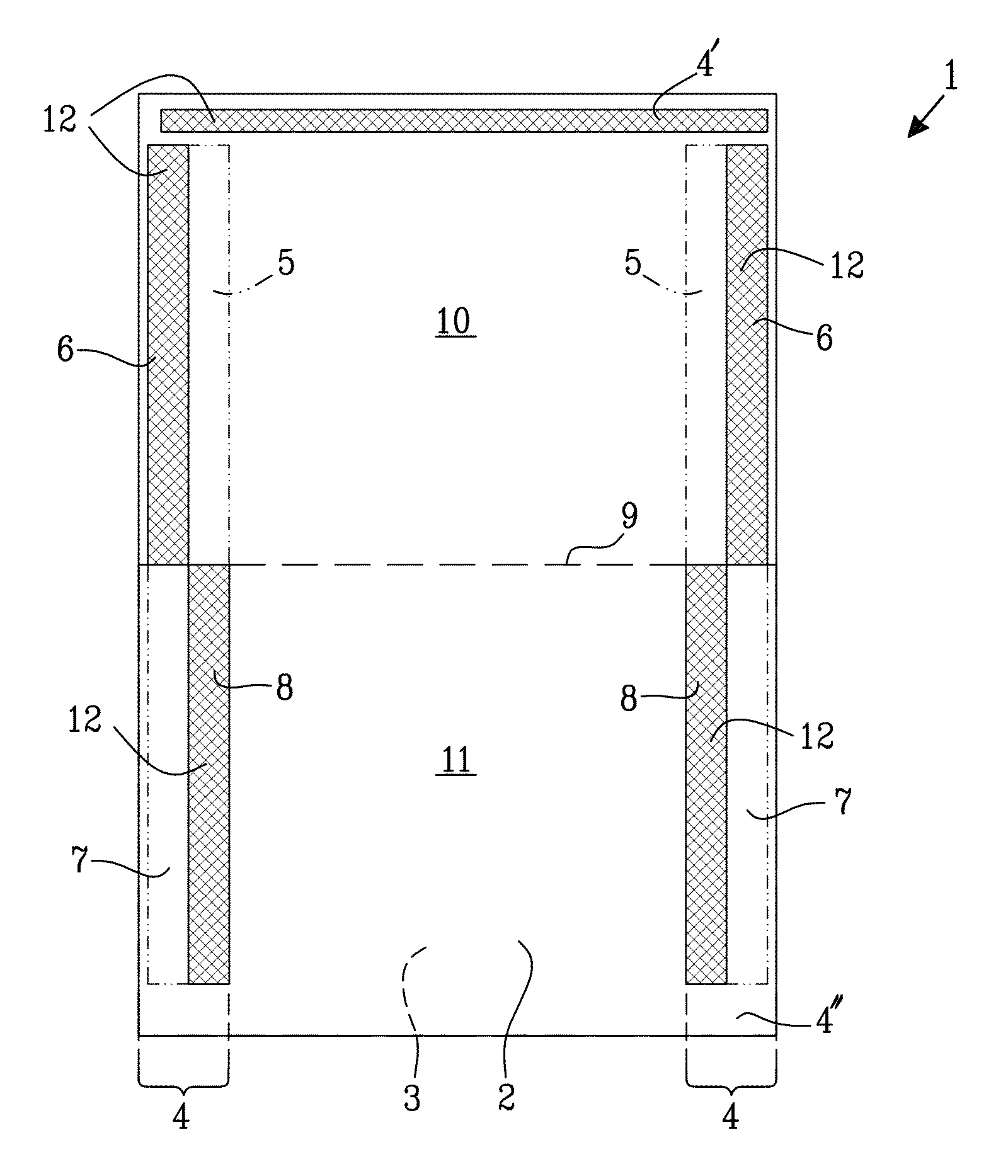

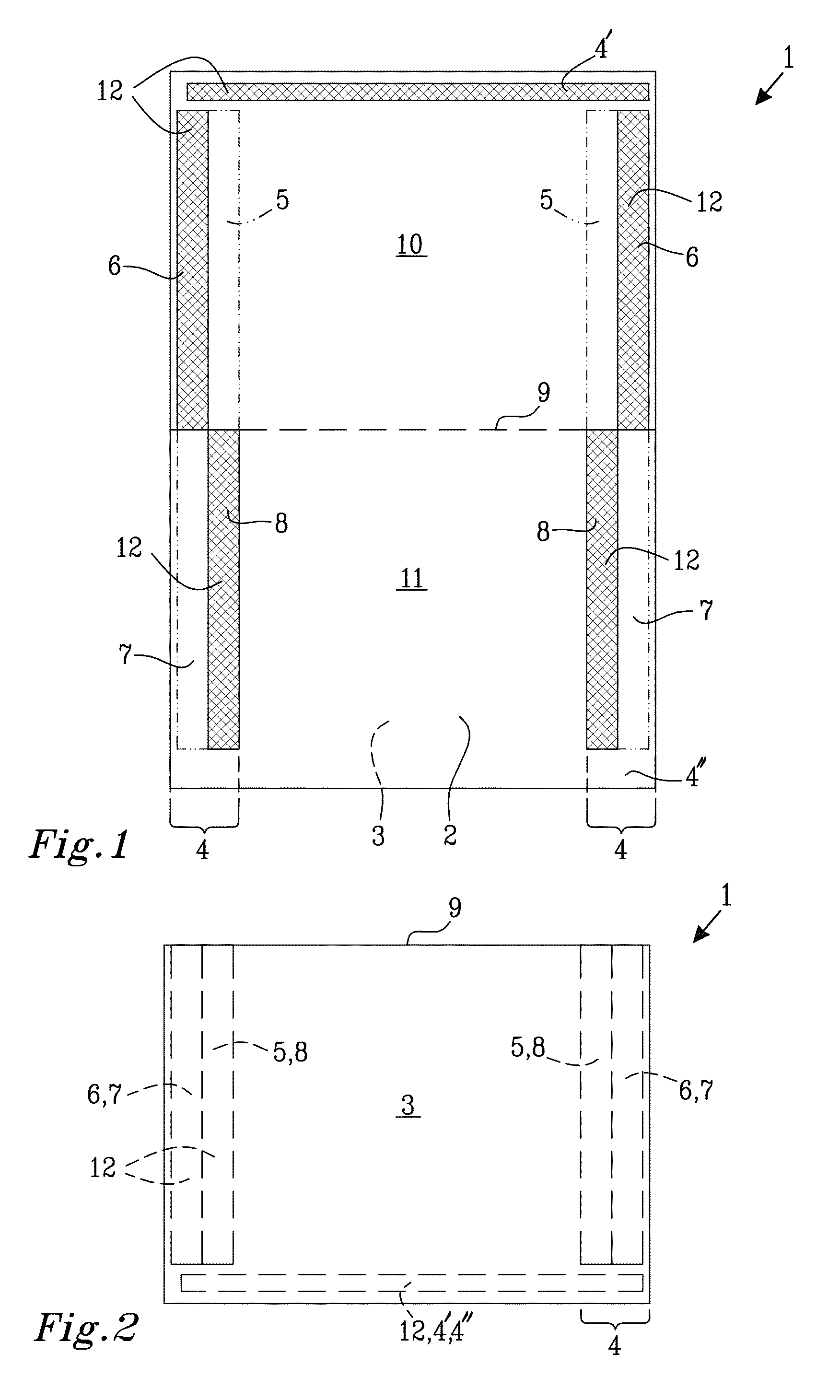

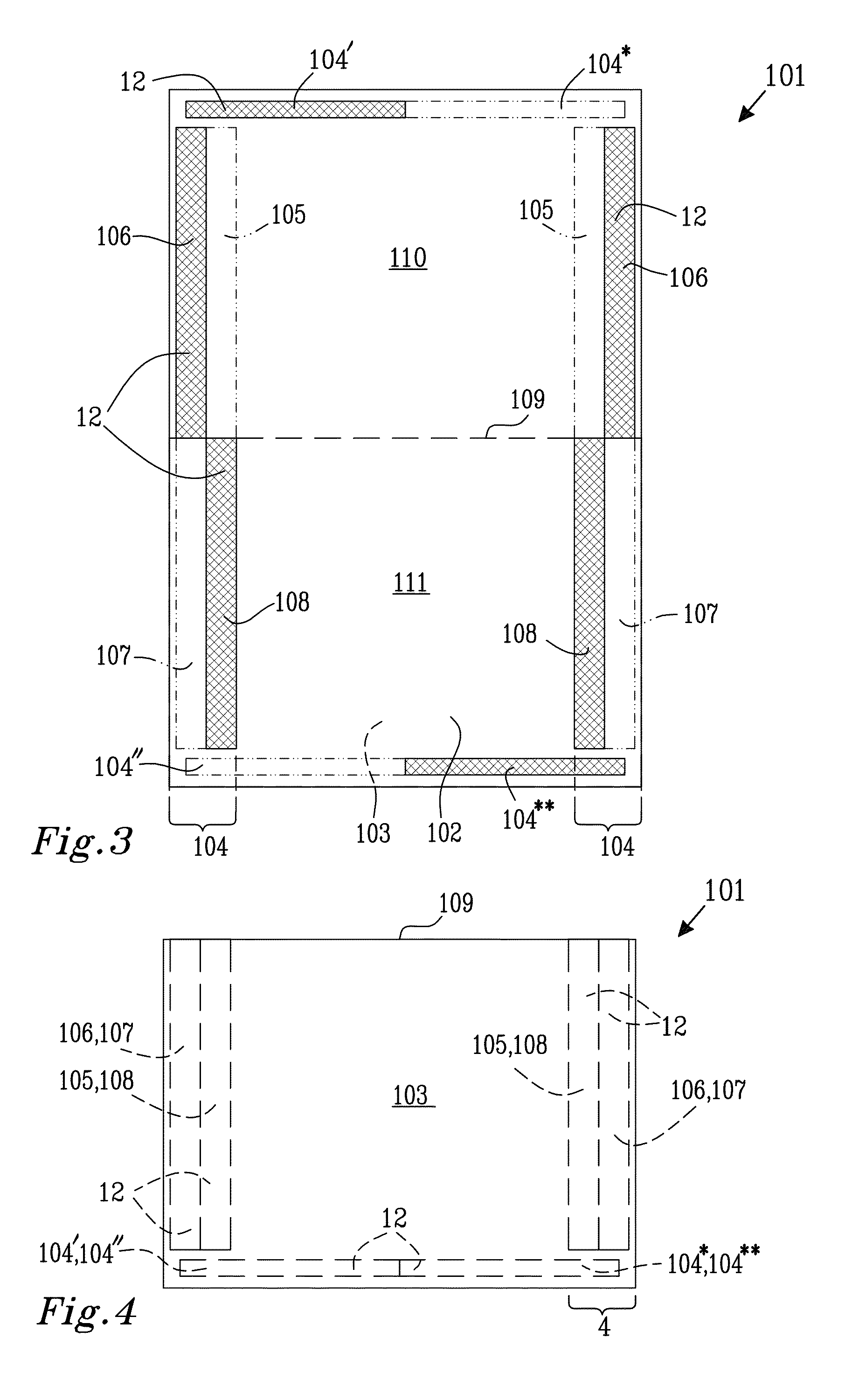

Packaging unit having improved sealing properties

A packaging unit formed from a sheet of material having an inner surface, an outer surface and one folding axis dividing the sheet into a first region and a second region. The inner surface includes an inner edge portion and an outer edge portion, wherein one of the inner edge portion and the outer edge portion of the edge zone of the first region is provided with adhesive, and the other of the inner edge portion and the outer edge portion of the edge zone of the first region is adhesive-free. One of the inner edge portion and the outer edge portion of the edge zone of the second region is provided with adhesive, and the other of the inner edge portion and the outer edge portion of the edge zone of the second region is adhesive-free in a complementary manner to the edge zone of the first region.

Owner:ESSITY HYGIENE & HEALTH AB

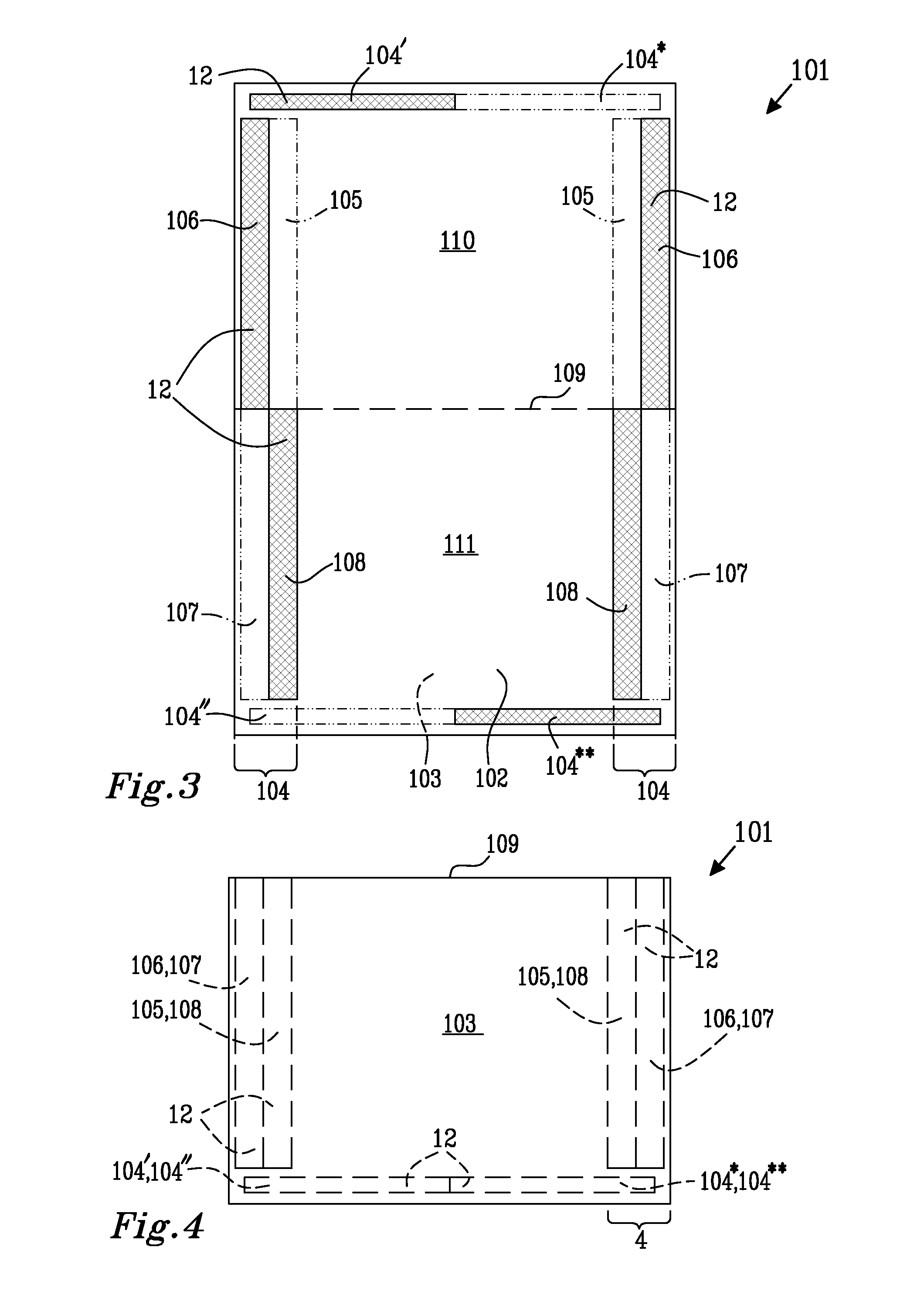

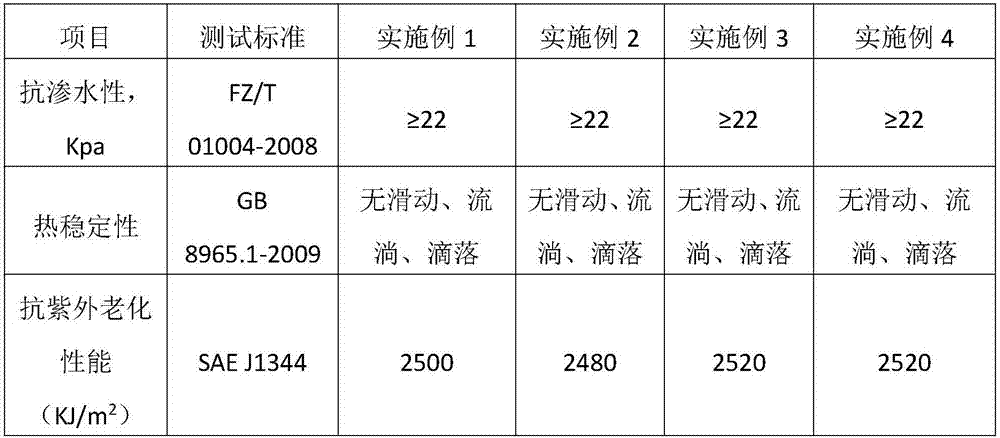

High-temperature-resistant self-adhesive waterproofing coiled material and preparation method thereof

InactiveCN107216823ASimple preparation processRaw materials are easy to getNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolymer science

The invention discloses a high-temperature-resistant self-adhesive waterproofing coiled material and a preparation method thereof. The high-temperature-resistant self-adhesive waterproofing coiled material is formed by sequentially compounding five layers of an isolating membrane layer, a high-temperature-resistant self-adhesive waterproofing glue layer, a carrier film layer, the high-temperature-resistant self-adhesive waterproofing glue layer and the isolating membrane layer from top to bottom, wherein the high-temperature-resistant self-adhesive waterproofing glue is prepared from the following raw materials of epichlorohydrin rubber, a softening agent, benzotriazole-modified zinc oxide, polyformaldehyde, organic silicon elastomers for daily use, petroleum asphalt and natural asphalt; the benzotriazole-modified zinc oxide is prepared by adopting a special preparation method; the total thickness of the waterproofing coiled material is 1.5 to 5.0mm; the thickness of the carrier film layer is 1.0 to 3.5mm. The waterproofing coiled material disclosed by the invention has the advantages of excellent waterproofing property, excellent high temperature resistance and excellent ageing resistance.

Owner:ZHEJIANG DIHENG IND CO LTD

Synthesis and applications of long-acting tackifying phenol formaldehyde resin

The present invention relates to a long-acting tackifying phenol formaldehyde resin and applications of the long-acting tackifying phenol formaldehyde resin in rubbers, wherein the long-acting tackifying phenol formaldehyde resin is prepared by carrying out a co-condensation reaction on a phenol compound containing a carbon-carbon double bond, an alkylphenol compound and an aldehyde compound. According to the present invention, the long-acting tackifying phenol formaldehyde resin contains the unsaturated double bond structure, such that the long-acting tackifying phenol formaldehyde resin can provide good initial self-adhesion and long-acting tackifying for rubbers when the long-acting tackifying phenol formaldehyde resin is adopted as the rubber tackifier, and the dynamical heat generation of the rubber can be reduced; and the long-acting tackifying phenol formaldehyde resin is particularly suitable for the manufacture and production of tires.

Owner:SINO LEGEND CHINA CHEM +1

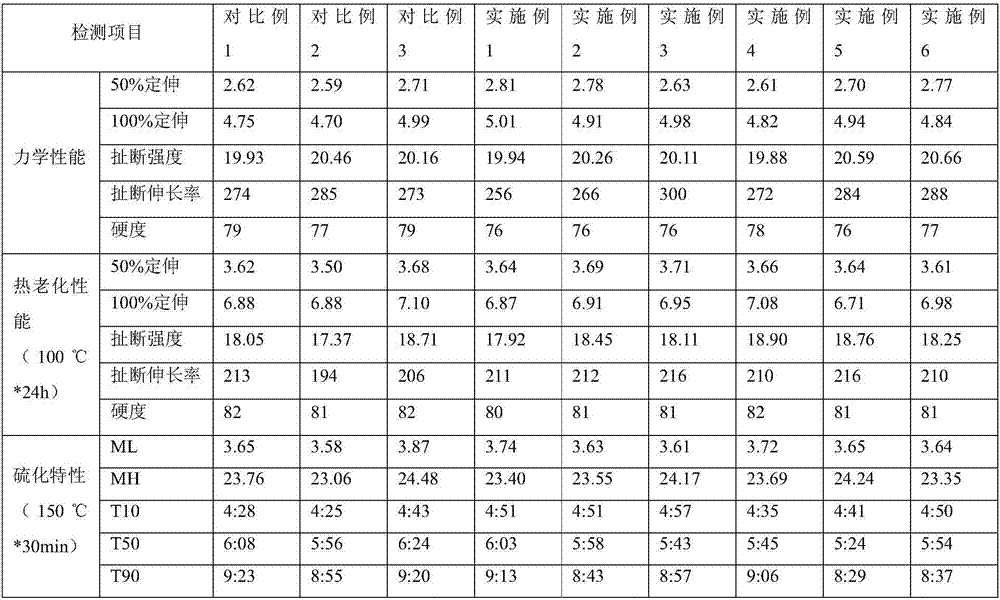

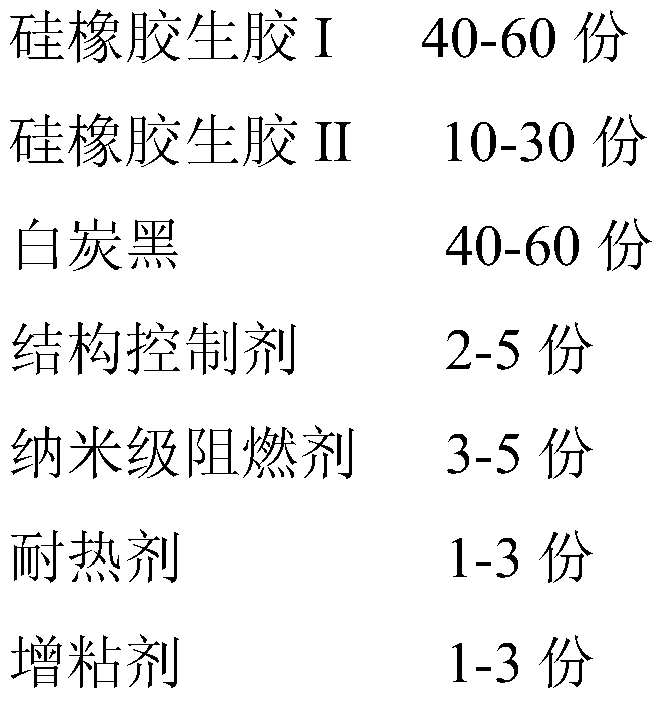

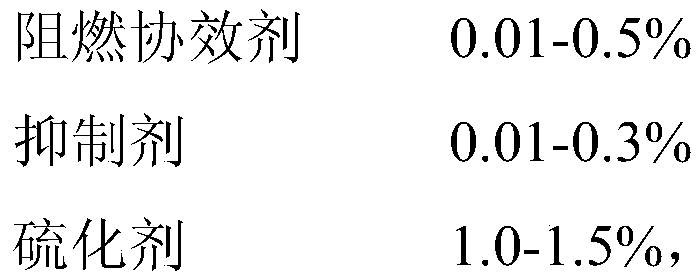

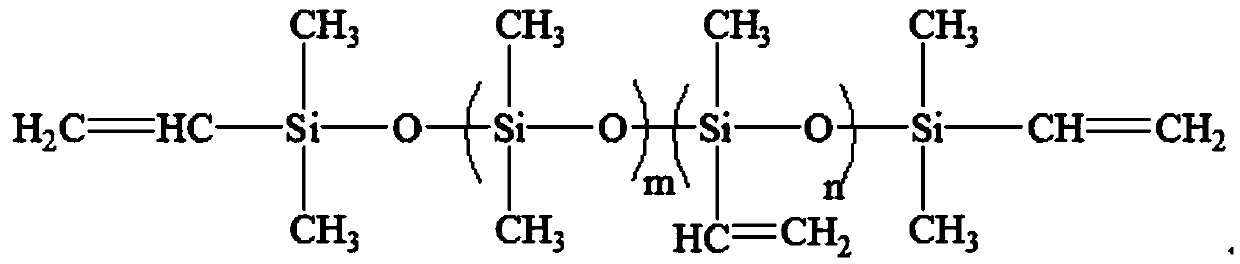

High-performance flame-retardant silicone rubber self-adhesive tape and preparation process therefor

PendingCN109705766AImprove flame retardant performanceLight weightNon-macromolecular adhesive additivesFilm/foil adhesivesOrganic solventPolymer science

The invention discloses a high-performance flame-retardant silicone rubber self-adhesive tape and a preparation process therefor. The high-performance flame-retardant silicone rubber self-adhesive tape comprises the following raw materials in parts by weight: 40-60 parts of silicone rubber crude rubber I, 10-30 parts of silicone rubber crude rubber II, 40-60 parts of white carbon black, 2-5 partsof structure controller, 3-5 parts of nano-scale flame retardant, 1-3 parts of heat resisting agent, 1-3 parts of tackifier, 0.01% to 0.5% of flame-retardant synergist, 0.01% to 0.3% of inhibitor and1.0% to 1.5% of vulcanizer, wherein the silicone rubber crude rubber I is methylvinyl silicone rubber and has the molecular weight of 450,000 to 600,000 and the vinyl content of 0.05% to 0.15%, and the silicone rubber crude rubber II is methylphenylvinyl silicone rubber and has the molecular weight of 350,000 to 400,000, the vinyl content of 0.1% to 0.2% and the phenyl content of 30% to 50%. The flame-retardant silicone rubber self-adhesive tape prepared by the preparation process has no need of adding a large amount of flame retardant and has the characteristics of good flame retardance, light specific weight, good fluidity, high tensile strength, good resilience, high self-adhesion, excellent electrical properties, organic solvent resistance and long shelf life and service life.

Owner:昆山诺泰普复合新材料有限公司

Method for preparing high-performance natural rubber through biological coagulation technology

The invention discloses a method for preparing high-performance natural rubber through a biological coagulation technology. The method comprises the steps of fresh latex symbiotic microorganism solidification, extruding dehydration, crepe pressing, cleaning, granulation, drying and packaging. According to the fresh latex symbiotic microorganism solidification technology, cultured symbiotic bacteria solidification liquid and fresh latex are mixed and placed into a constant-temperature solidification box for constant-temperature solidification, and steps are executed, and finally the high-performance natural rubber is obtained. Mass industrial production can be achieved, and rapid odorless solidification of latex is achieved; due to rapid biological solidification, little non-rubber matter of natural rubber latex is decomposed, it is ensured that the chemical and physical properties of a solidified white gelatinous lump are quite high, strain induced crystallization can easily occur on the obtained high-performance rubber, and therefore the high-performance rubber has quite high autohension, good green strength and excellent processing performance.

Owner:昆明珩森科技有限公司

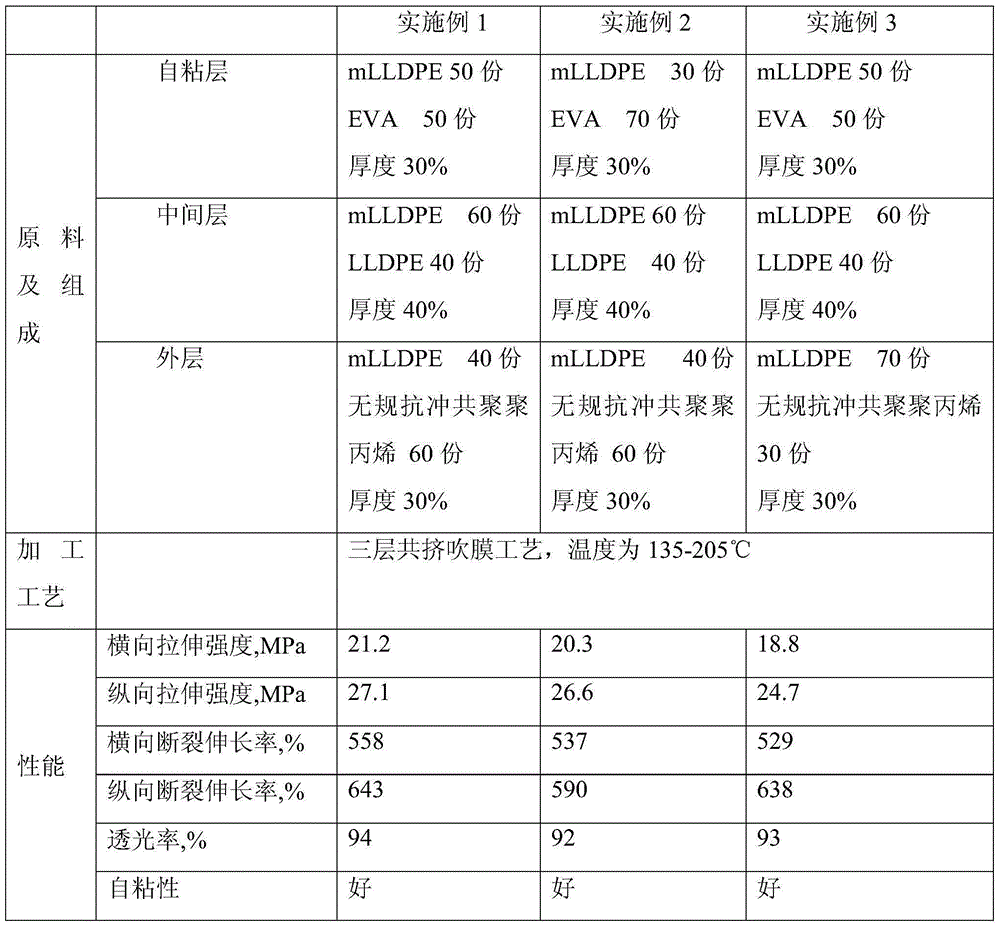

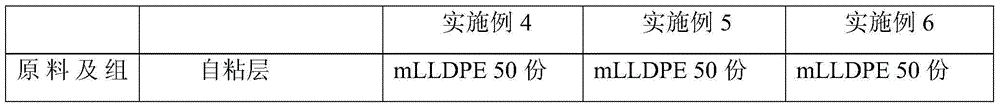

High-strength puncture-resistant auto-adhesive protective film

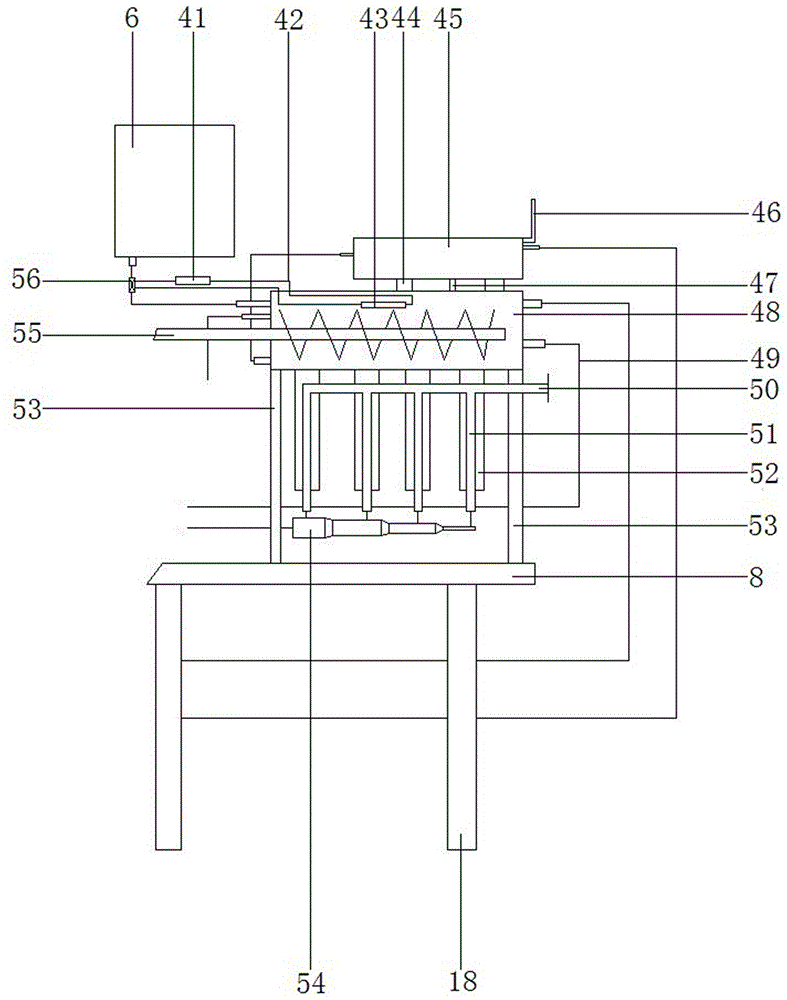

ActiveCN106553417AHigh strengthImprove self-adhesivenessSynthetic resin layered productsBlow moldingPlastic packaging

The invention belongs to the technical field of plastic package, in particular to a high-strength puncture-resistant auto-adhesive protective film. The high-strength puncture-resistant auto-adhesive protective film is prepared through three layers of coextrusion blow molds , the inner layer is obtained by mixing mLLDPE and EVA, the middle layer is obtained by mixing the mLLDPE and LLDPE, and the outer layer is obtained by mixing random anti-shock co-polypropylene and the LLDPE. The high-strength puncture-resistant auto-adhesive protective film is obtained by screening, preparing and coextrusion blow molding of three layers of raw materials, all layers have good consistency and a high caking property, and the obtained thin film is high in auto-adhesive performance, strength and puncture resistant and has excellent optical transparence. The high-strength puncture-resistant auto-adhesive protective film meets the packaging requirements of frozen fishes and shrimps, spike ices, sharp objects and the like owing to high strength and puncture resistance, the high-strength puncture-resistant auto-adhesive protective film can be widely used in the fields of normal temperature foods, frozen foods, electric equipment products, home furnishing, building materials, medicine, chemical engineering and the like.

Owner:CHINA PETROLEUM & CHEM CORP

Packaging unit having improved sealing properties

A packaging unit formed from a sheet of material having an inner surface, an outer surface and one folding axis dividing the sheet into a first region and a second region. The inner surface includes an inner edge portion and an outer edge portion, wherein one of the inner edge portion and the outer edge portion of the edge zone of the first region is provided with adhesive, and the other of the inner edge portion and the outer edge portion of the edge zone of the first region is adhesive-free. One of the inner edge portion and the outer edge portion of the edge zone of the second region is provided with adhesive, and the other of the inner edge portion and the outer edge portion of the edge zone of the second region is adhesive-free in a complementary manner to the edge zone of the first region.

Owner:ESSITY HYGIENE & HEALTH AB

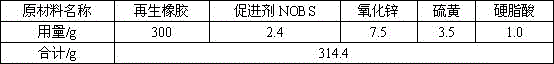

Agricultural tire crown compound of high filling tire reclaimed rubber

The invention discloses an agricultural tire crown compound of high filling tire reclaimed rubber. The agricultural tire crown compound is prepared from the following raw materials in parts by mass: 25 to 35 parts of standard rubber No.20; 15 to 25 parts of cis-butadiene rubber 9000; 10 to 50 parts of butadiene-styrene rubber 1502; 70 to 30 parts of tire reclaimed rubber; 3.0 to 5.0 parts of zinc oxide; 2.0 to 4.0 parts of stearic acid; 0.5 to 0.7 part of anti-aging agent BLE; 0.8 to 1.0 part of anti-aging agent RD; 1.5 to 2.5 parts of anti-aging agent 4020; 2.0 to 3.0 parts of protective wax; 55 to 65 parts of intermediate super carbon black N220; 9.0 to 12 parts of aromatic hydrocarbon oil; 1.5 to 2.5 parts of sulfur; 1.1 to 1.3 parts of accelerant NOBS; 1.0 to 2.0 parts of thermal oxidation resistant agent RF; 1.0 to 2.0 parts of homogenizing dispersant MS. The agricultural tire crown compound has the advantages that the processability of low-temperature emulsion aggregation of SBR (styrene butadiene rubber) is improved, resource recycling is realized, pollution is reduced, the environment is protected, and the production cost is reduced, etc.

Owner:江苏华冠橡塑制品有限公司

Environment-friendly type multifunctional self-adhesive and preparing method thereof

InactiveCN101012359AImprove adhesionImprove self-adhesivenessMonocarboxylic acid ester polymer adhesivesNatural rubber adhesivesEmulsionPressure sensitive

The invention discloses an environment-protective multifunctional self-viscose and making method, which comprises the following parts: natural aqueous latex, VAE emulsion, pressure-sensitive emulsion of acrylic acid, phthalandione dioctyl, phthalandione dibutyl ester, aqueous defoamer RE-3921, antiager DNP.

Owner:周广灿

Electromagnetic wire and processing method thereof

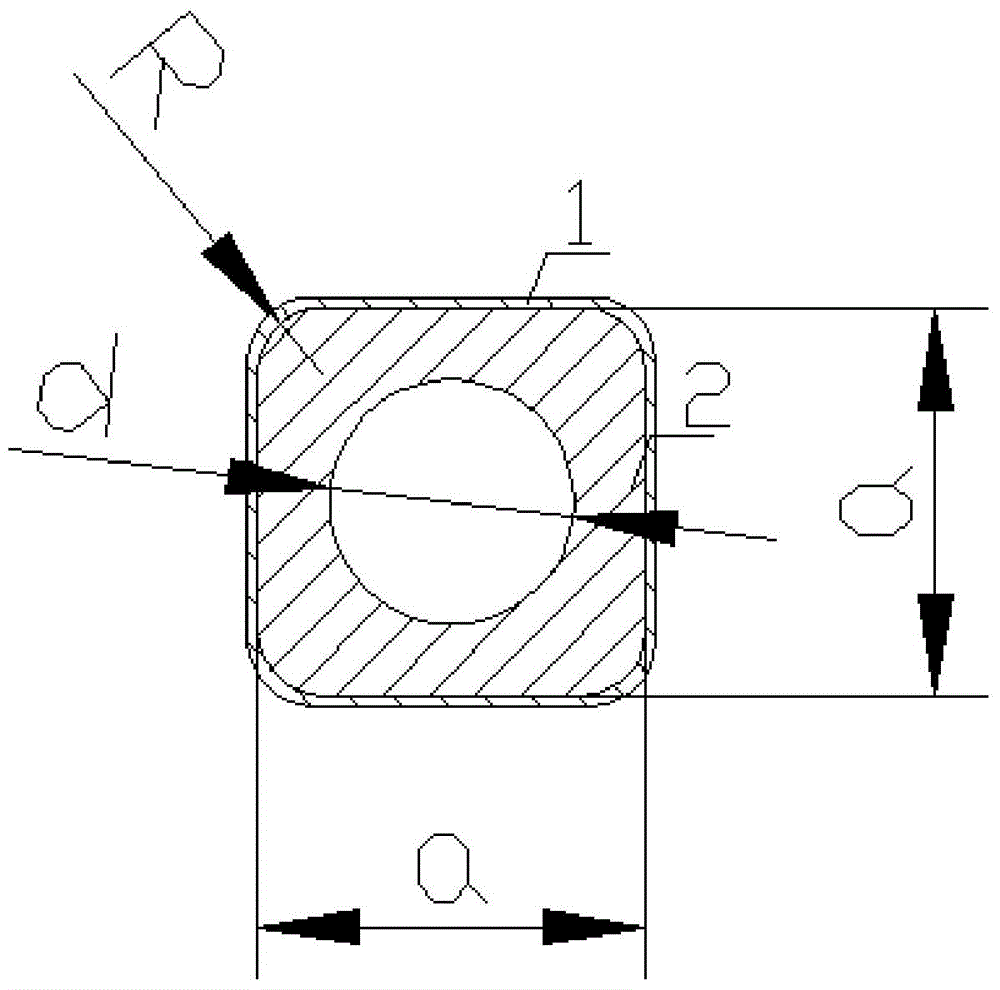

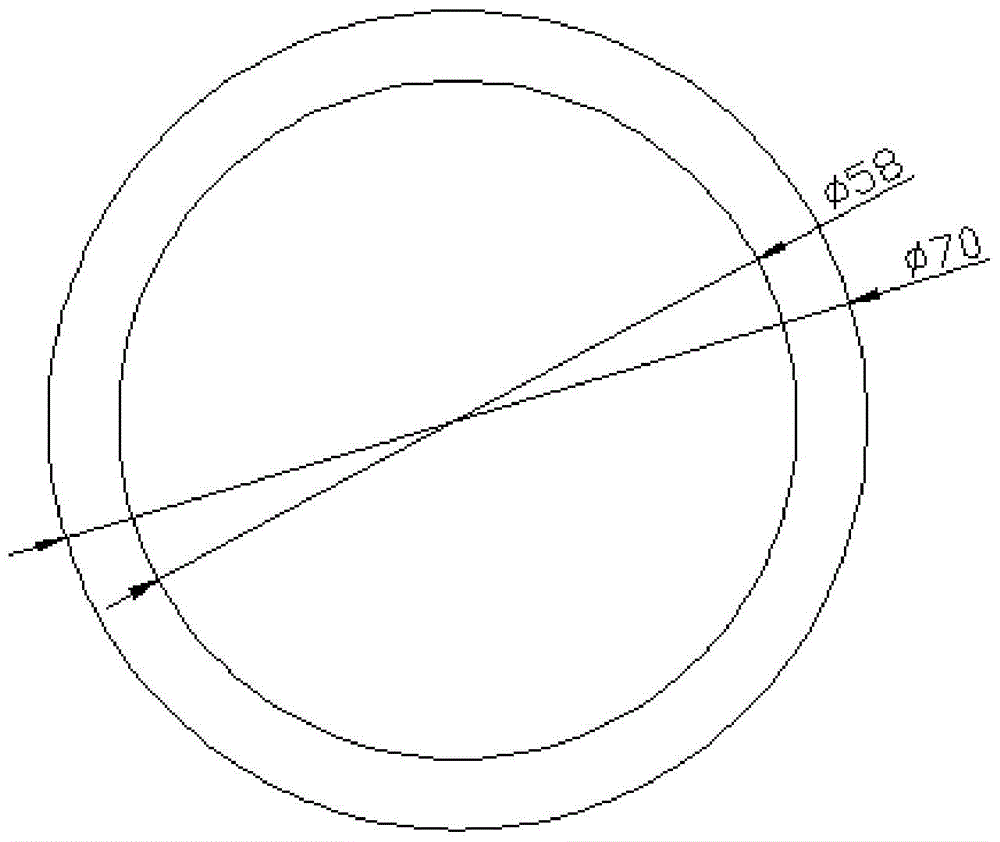

InactiveCN104409157AIncrease the conductive areaIncrease the drawing sizeInsulated cablesPower cablesComposite filmSurface roughness

The invention discloses an electromagnetic wire and a processing method thereof. The electromagnetic wire comprises a body and an insulated body wrapping the body, wherein the inner contour line of the cross section of the body is square, and the outer contour line is round. In the processing, a moving core mark is matched with a moving outer mold to draw, so that the electromagnetic wire high in size precision, low in inner surface roughness, small in grain size and high in corrosion resistance is obtained. By continuously drawing a core ball on a coiling and pulling machine, a required long product is obtained, and the maximum length is at least up to 300m. A polyimide F46 composite film is adopted, and the advantages of high pressure resistance, high temperature resistance, high corrosion resistance and the like are achieved.

Owner:济南宝世达实业发展有限公司

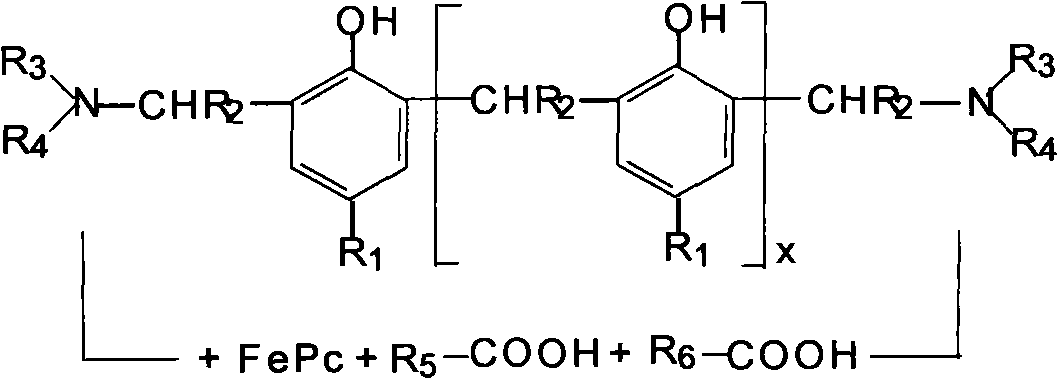

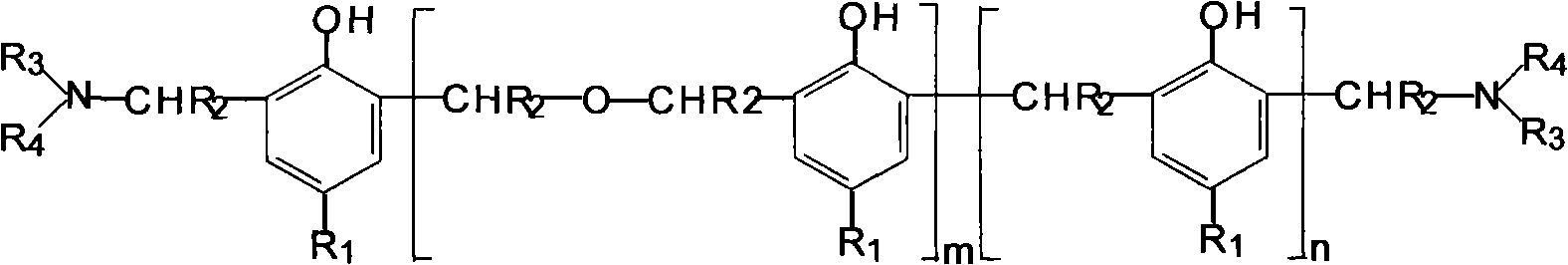

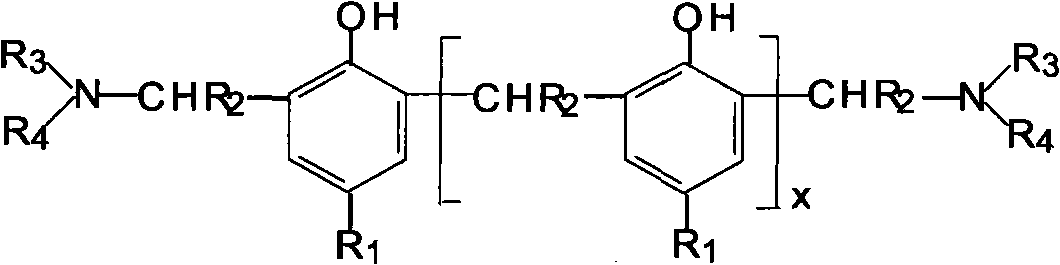

Multifunctional phenolic resin for rubber industry and manufacture method thereof

The invention provides a multifunctional phenolic resin for a rubber industry and a manufacture method thereof. Nitrogen-containing compound is introduced to a condensation resin structure of alkylphenol and aldehyde. Phthalocyanine iron (II), abietic acid, and fatty acid which have chemical peptized activity and contained in rubber are improved so that rubber peptization is improved and the rubber has the best self-adhesive property and retainability.

Owner:RACHEM CHINA CO LTD

Self-adhered rubber tape

InactiveCN104845541AImprove self-adhesivenessHigh bonding strengthNon-macromolecular adhesive additivesFilm/foil adhesivesEngineeringUltimate tensile strength

The invention discloses a self-adhered rubber tape that is prepared from the following components in parts by mass: 100 parts of basic rubber, 30-50 parts of a tackifier, 20-40 parts of tackifying rubber, 50-200 parts of reinforcer, 10-20 parts of reinforced resin, 0.5-1.5 part of vulcanizing agent, 4-6 parts of an accelerant and 3-50 parts of carbon black. By adopting different types of rubber, the self-adhered rubber tape disclosed by the invention solves the problems of behavior of electricity, waterproofness, alkali resistance and acid resistance. By adopting a method of combining the tackifying resin with a tackifier, the self-adhering of a rubber strip is effectively improved. By adopting the terpene reinforced resin, the bonding strength is improved. By using a special formula, the self-adhered rubber tape disclosed by the invention can be used for self-adhered lapped electric wires in stress control of conductive and semi-conductive fields as well as insulative, waterproof, hermetic and insulative occasions.

Owner:WUXI LONGSHUN IND

Hot melting pressure-sensitive glue as well as preparation method and application thereof

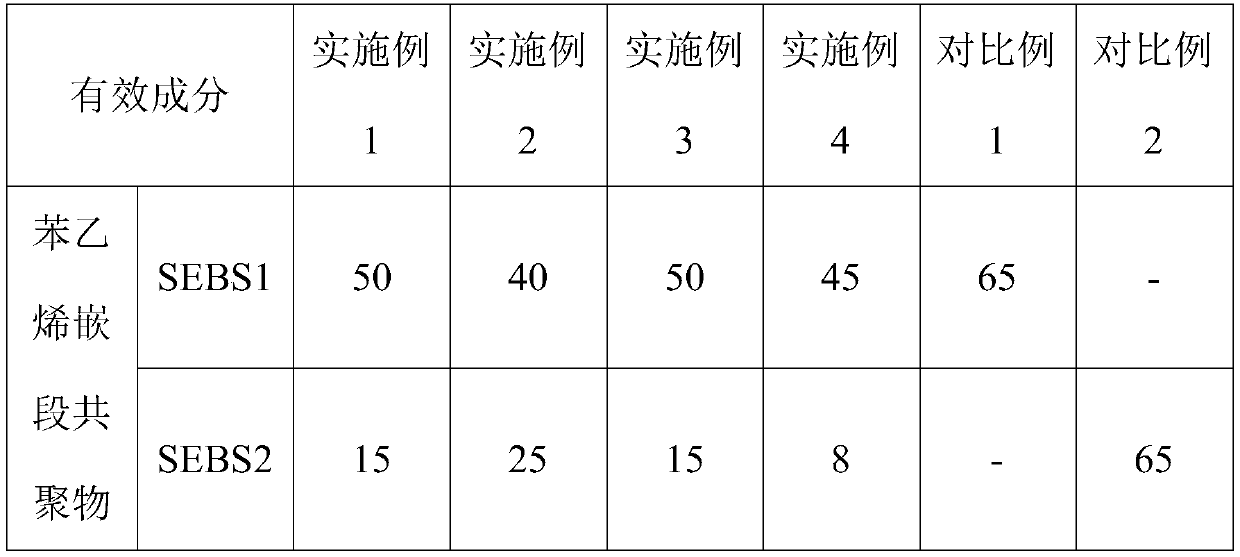

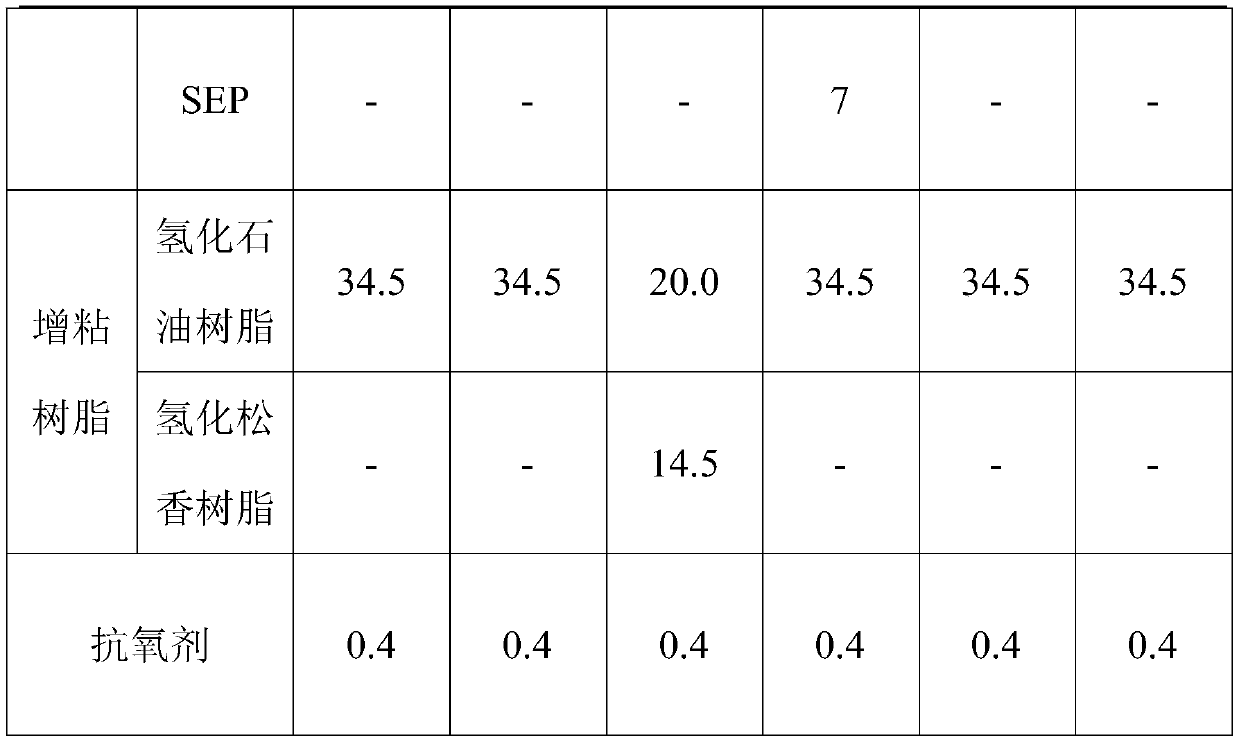

ActiveCN109777331ANo pollutionImprove stabilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesTectorial membranePlasticizer

The invention discloses a hot melting pressure-sensitive glue as well as a preparation method and application thereof. The hot melting pressure-sensitive glue comprises the following effective components in parts by weight: 55-70 parts of styrene segmented copolymer, 30-45 parts of tackifying resin, and 0.1-0.5 part of an antioxidant. The preparation method comprises the following steps: mixing styrene segmented copolymer, tackifying resin and antioxidant to obtain a mixture; pelletizing the mixture in water; drying. The hot melting pressure-sensitive glue is used for preparing a protection film; the hot melting pressure-sensitive glue is free from plasticizer such as mineral oil and polybutene oil; the problems of oil separating out and smoking in processing are avoided; a die head is notinfluenced; the production can be continuously carried out; generation of three wastes in production is avoided; the environmental pollution is avoided.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

High wear resistant automobile foot pad material

The invention relates to a high wear resistant automobile foot pad material prepared from the following raw materials by weight: 35-40 parts of ethylene-propylene-diene monomer, 30-35 parts of polyurethane, 15-22 parts of a nano-filler, 8-10 parts of carbon black, 3-4 parts of glass fibers, 3-4 parts of dioctyl phthalate, and 2-3 parts of paraffin oil. An automobile foot pad provided by the invention adopts the ethylene-propylene-diene monomer and polyurethane as base rubber; by addition of the nano-filler and the glass fibers for compositing, a traditional reinforcing method using a large amount of carbon black is changed; the novel nano-filler is used for increasing the crosslinking points of rubber; meanwhile, the bonding points of carbon black, the nano-filler and rubber are significantly increased due to good dispersity of the filler, a space network structure is formed, and the strength, wear resistance and aging resistance of the rubber are effectively enhanced.

Owner:合肥凯大新型材料科技有限公司

Fireproof furniture protective film not changing color easily and preparation method thereof

The invention discloses a fireproof furniture protective film not changing a color easily and a preparation method thereof. The furniture protective film comprises, by mass parts, 100 parts of polyvinylidene fluoride, 20-30 parts of maleic anhydride grafted polyethylene, 13-19 parts of polyisobutylene, 1-2 parts of ultraviolet absorber, 2-4 parts of nanocrystalline fiber, 5-6 parts of straw fibers, 12-15 parts of chitosan and 2-3 parts of phosphonitrilic chloride trimer. The furniture protective film has good fireproof performance, is long in service life and still does not change the color after use for a long time.

Owner:UVAT TECH

High-viscosity self-adhesion protective film and preparation method thereof

InactiveCN105860200AHigh transparencyImprove aestheticsNon-macromolecular adhesive additivesFilm/foil adhesivesLow-density polyethyleneMolten state

The invention discloses a high-viscosity self-adhesion protective film and a preparation method thereof. The high-viscosity self-adhesion protective film comprises four layers, i.e. an A outer layer, a B middle layer, a C middle layer and a D inner layer; raw materials of four layers mainly comprise linear low density polyethylene, metallocene and SEBS; in the preparation method, a high-speed running pressure box is adopted, a mode of multiple groups of extrusion screws is adopted, and after raw materials are in a high-temperature molten state, repeated multilayer filtration is adopted by a candle-type screen changer. The protective film disclosed by the invention has high self-adhesion, high stability and a wide application range, is more transparent in film appearance, has fewer film surface fish eye phenomena, has a mush higher physical property than a conventional self-adhesion protective film, is easy to adhere and easy to tear, has a more prominent protective effect, is low in cost, is simple in process, and is energy-saving and environmental-friendly.

Owner:李富贵

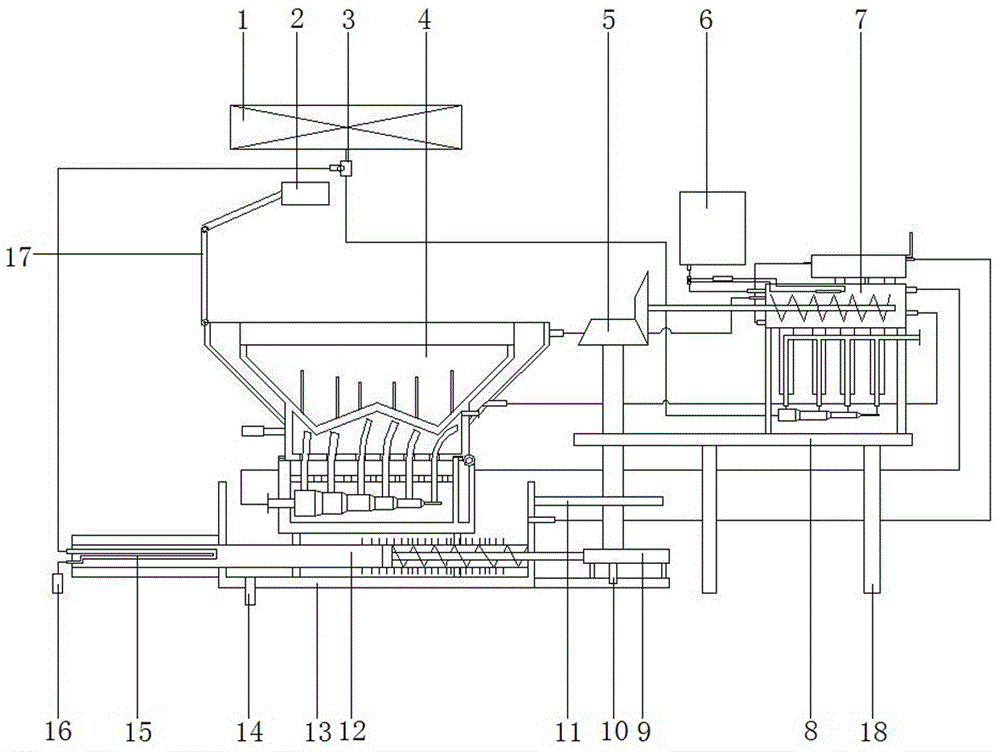

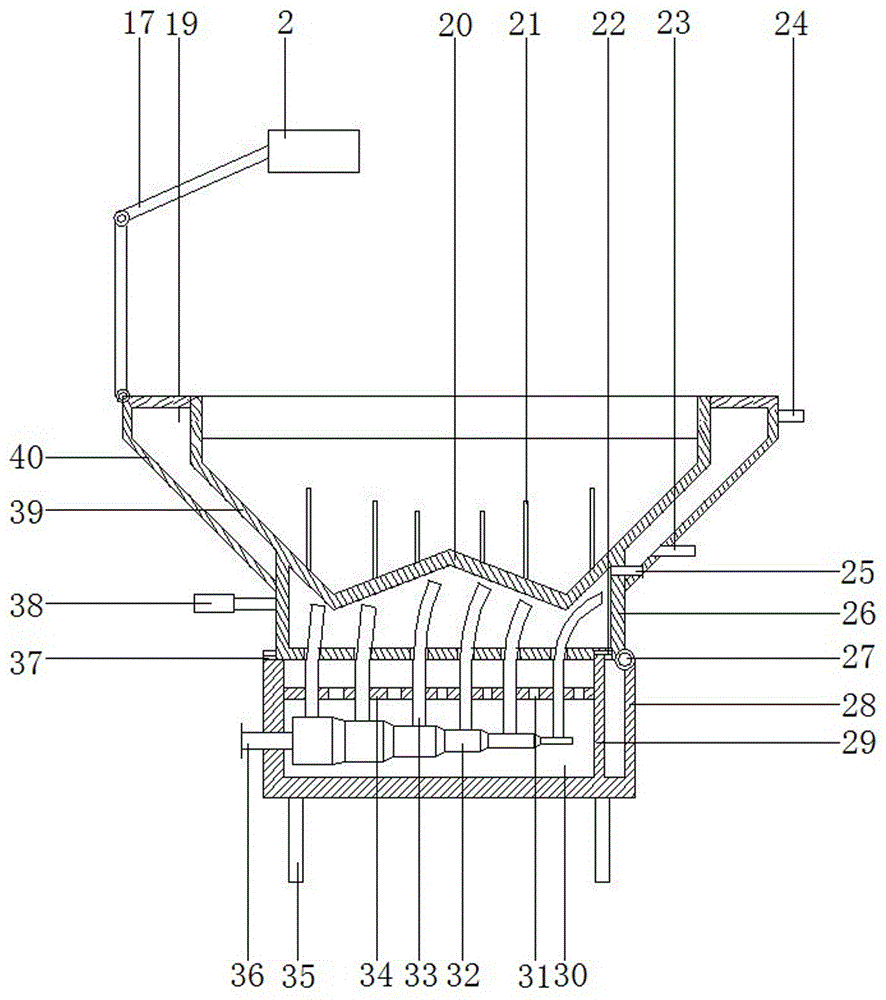

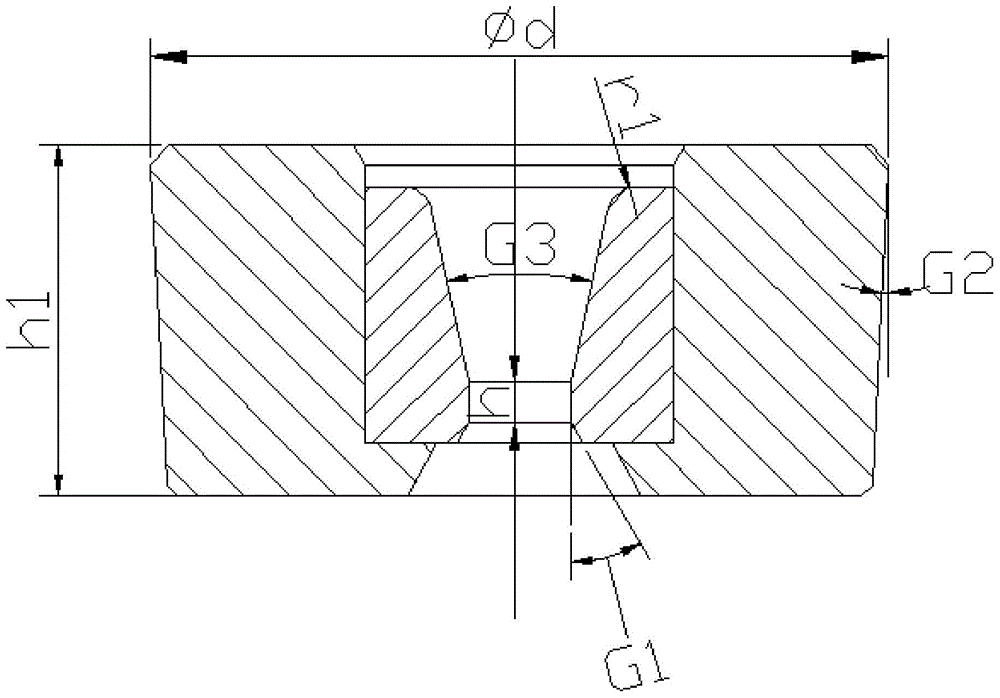

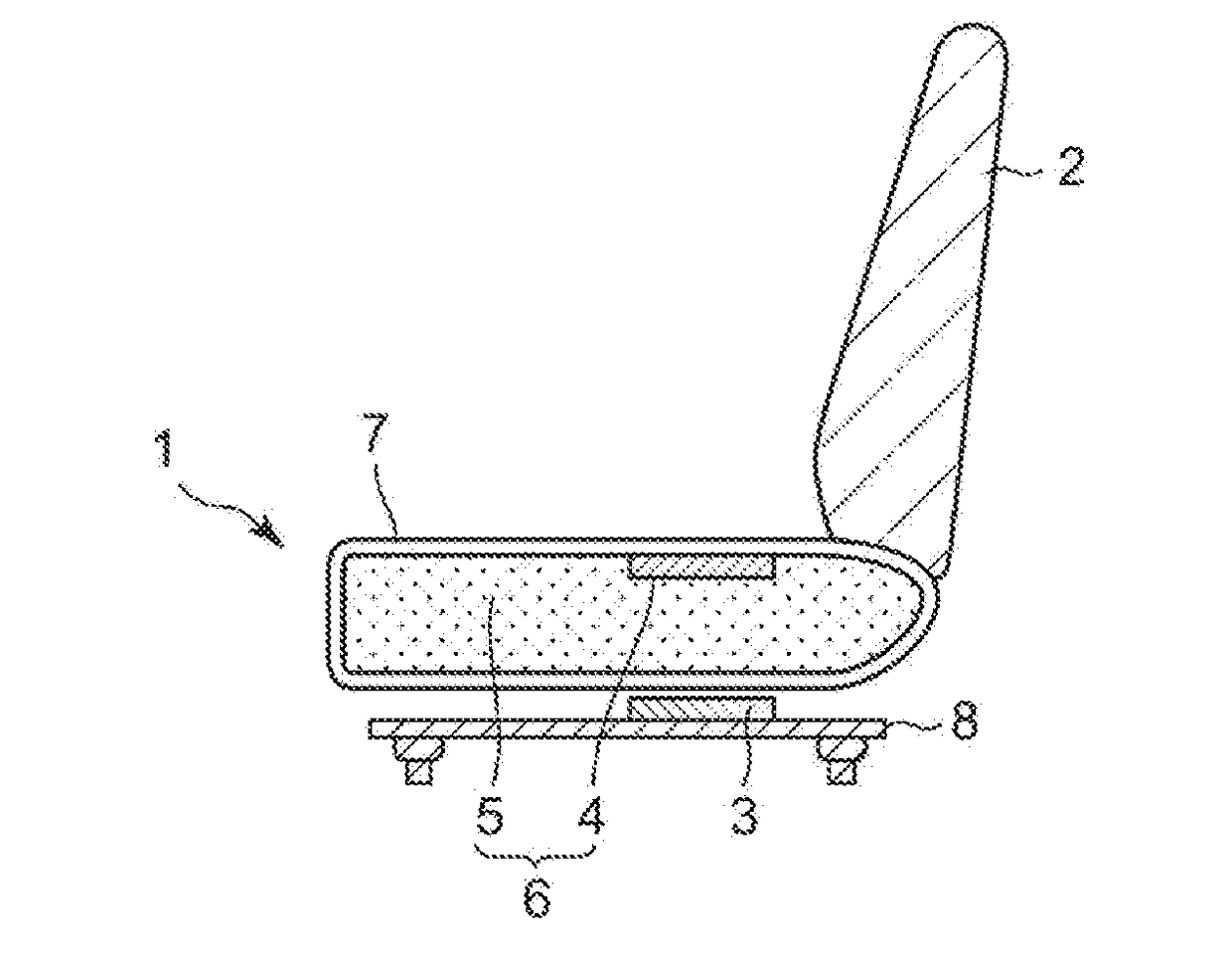

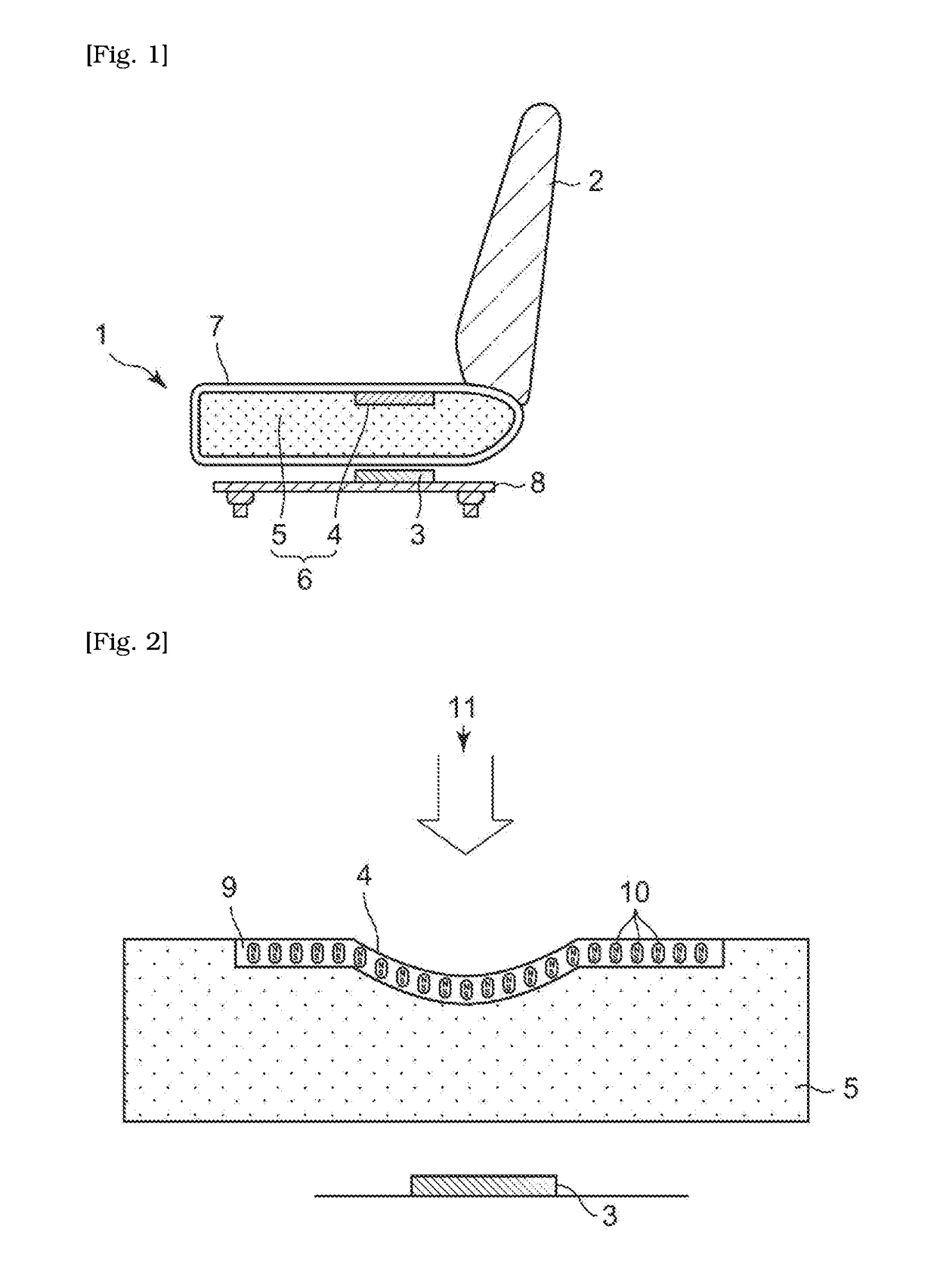

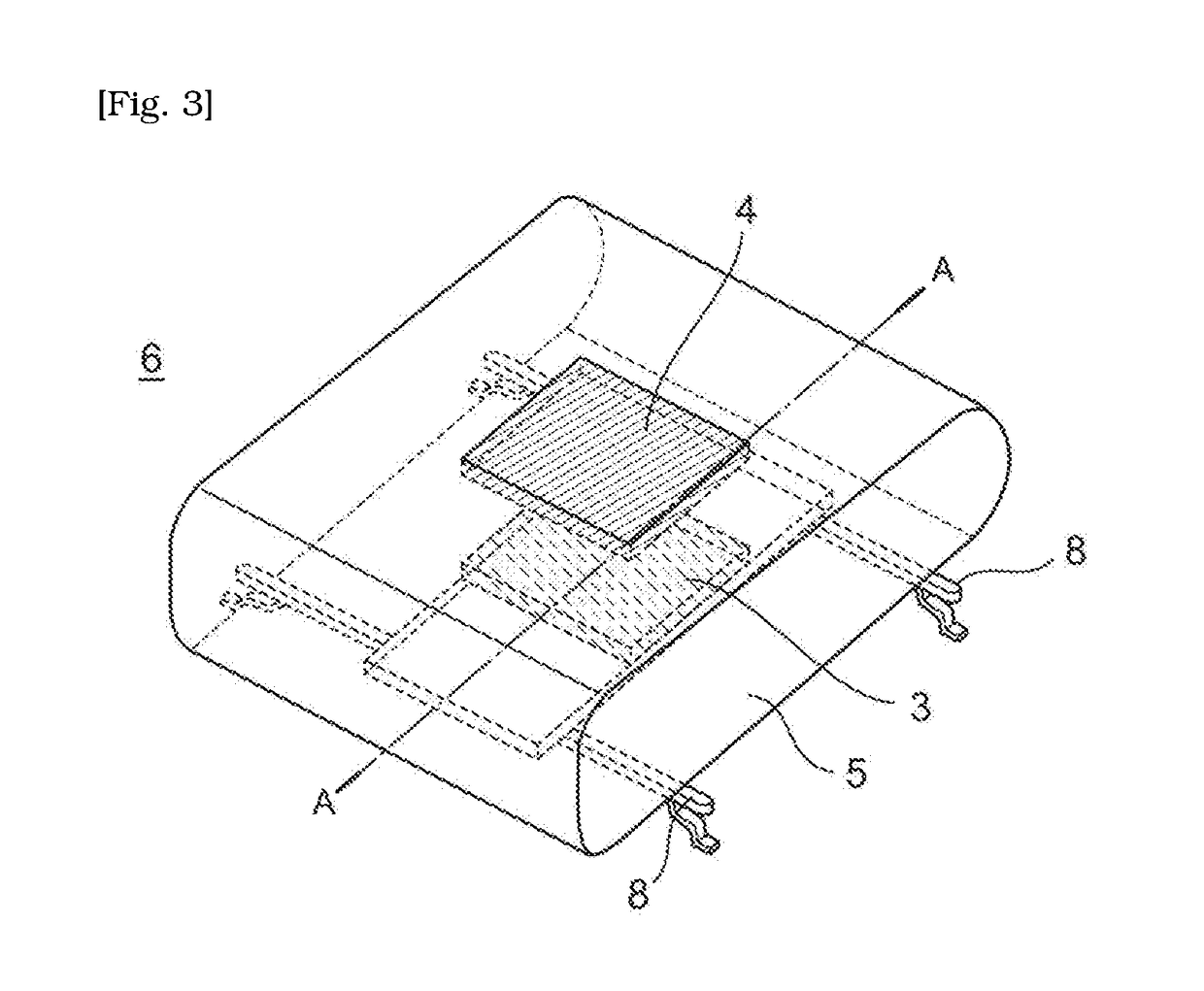

System for detecting deformation of cushion pad and production thereof

InactiveUS20170122719A1Poor durabilityEasy to produceVehicle seatsBelt control systemsElastomerEngineering

The present invention provides a cushion pad with improved durability without feeling of a foreign object.The present invention thus provides a system for detecting a deformation of a cushion pad, comprising;the cushion pad comprising a magnetic elastomer in which magnetic filler is dispersed in an elastomer and an arithmetic average roughness (Ra) is 0.5 to 10.0 μm, and a soft polyurethane foam which is integrated with the magnetic elastomer by adhesion, anda magnetic sensor that detects a magnetic change caused by a deformation of the cushion pad. The present invention also provides a production method thereof.

Owner:TOYO TIRE & RUBBER CO LTD

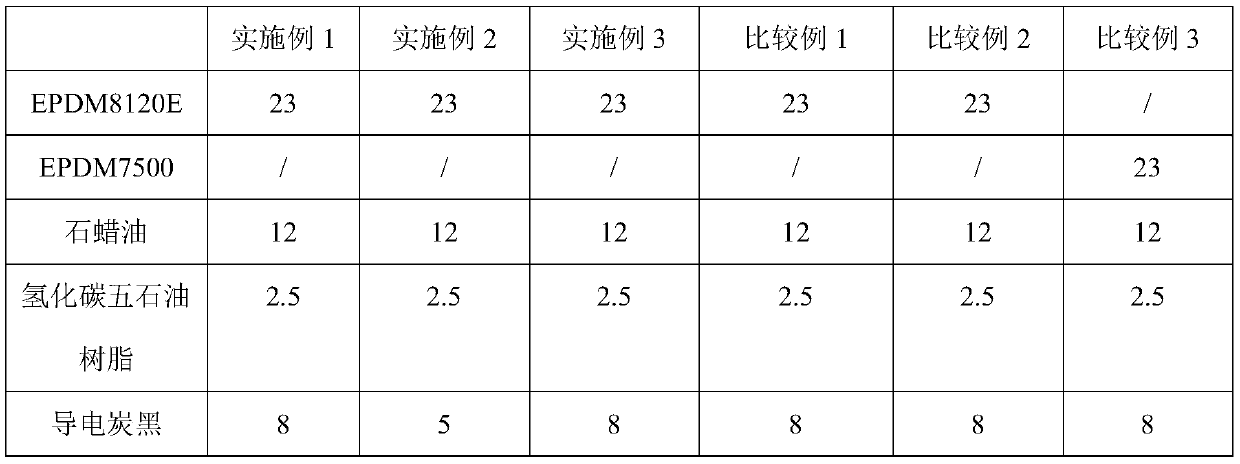

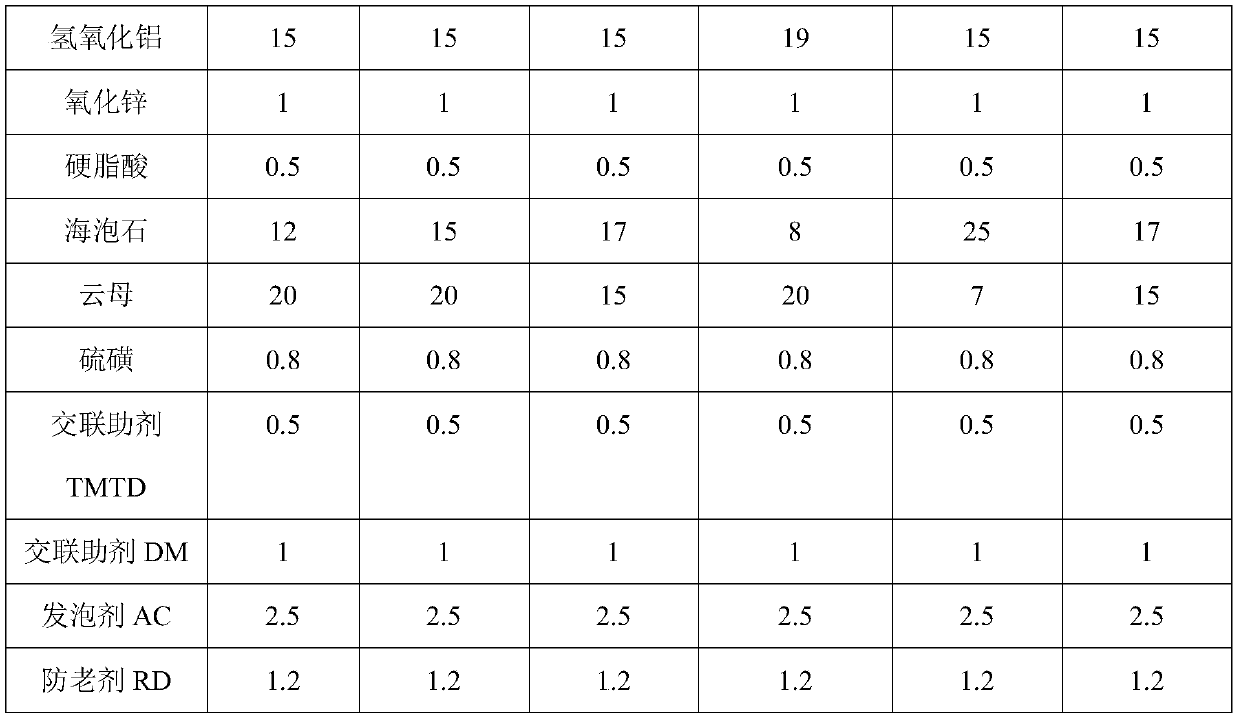

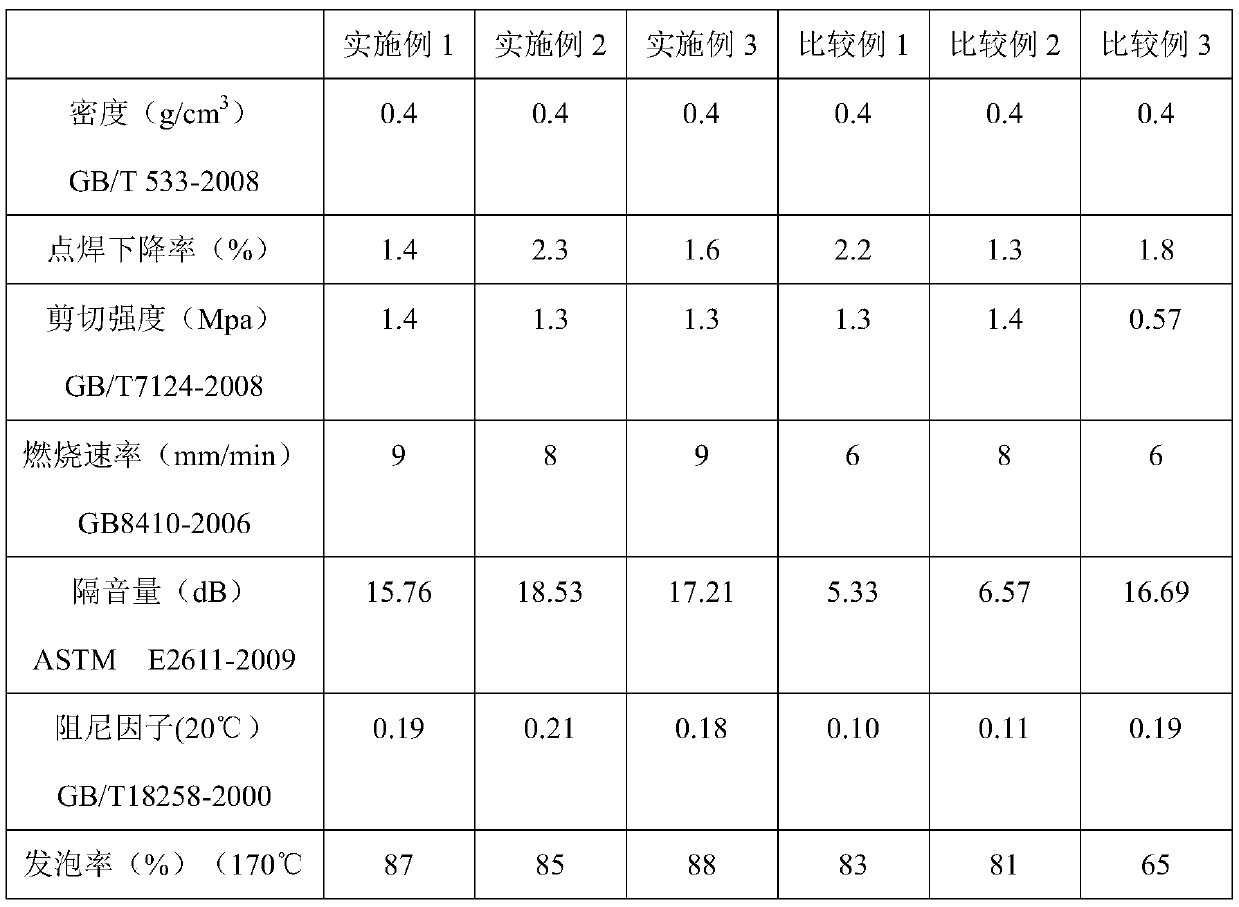

Vehicle flame-retardant sound-insulation noise-reduction rubber pad and preparation method thereof

The invention discloses a vehicle flame-retardant sound-insulation noise-reduction rubber pad and a preparation method of the flame-retardant sound-insulation noise-reduction rubber pad. The sound-insulation noise-reduction flame-retardant rubber pad is prepared from the following raw materials in percentage by weight: 20-30% of ethylene propylene diene monomer rubber; 10-20% of paraffin oil, 3-5%of hydrogenated C5 petroleum resin, 5-10% of conductive carbon black, 10-20% of a flame retardant, 10-30% of sepiolite, 10-30% of mica, 1-2% of zinc oxide, 0.5-1% of stearic acid, 0.5-1% of sulfur, 1.0-3.0% of a crosslinking aid, 1-3% of a foaming agent and 1-1.8% of an anti-aging agent. Compared with the prior art, the preparation method of the vehicle flame-retardant, sound-insulation noise-reduction rubber pad is simple; all the raw materials are matched for use and the dosage is controlled; the prepared rubber pad product can be foamed under the condition of 140 to 200 DEG C; in this way,when a vehicle passes through a coating workshop, foaming and filling of the rubber pad in a metal plate can be synchronously achieved on a coating line, then the effects of damping, noise reduction,sound insulation and flame retardance are achieved, and the rubber pad can be widely applied to filling and sealing of the metal plate of a vehicle engine compartment and other metal plate parts of the vehicle.

Owner:WUHU HAICHENG RUBBER & PLASTIC

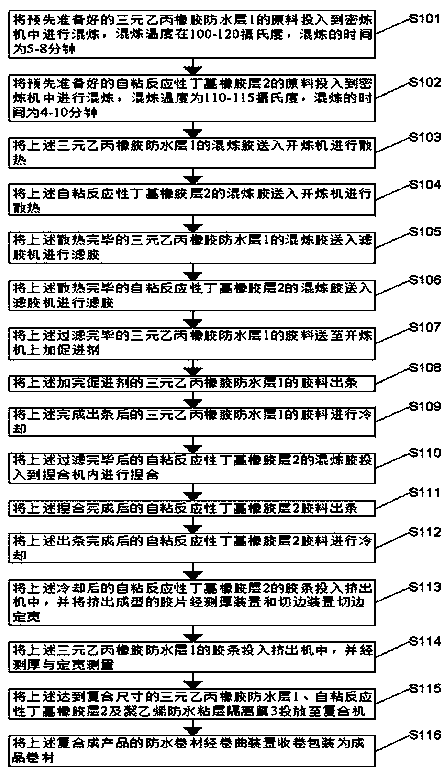

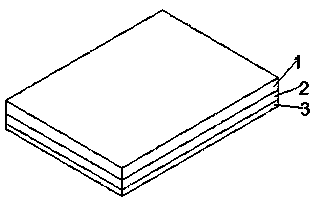

Reaction ethylene-propylene-diene monomer butyl self-adhesive waterproof coiled material and preparation method thereof

ActiveCN110964448AImprove toughnessAvoid breakageNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive

The invention discloses a reaction ethylene-propylene-diene monomer butyl self-adhesive waterproof coiled material and a preparation method thereof. The reaction ethylene-propylene-diene monomer butylself-adhesive waterproof coiled material comprises an ethylene-propylene-diene monomer waterproof layer, a self-adhesive reactive butyl rubber layer is arranged at the bottom end of the ethylene-propylene-diene monomer waterproof layer, and a polyethylene waterproof adhesive layer isolating membrane is arranged at the bottom end of the self-adhesive reactive butyl rubber layer; wherein the ethylene propylene diene monomer waterproof layer is prepared from the following raw materials in parts by mass: 100-200 parts of ethylene propylene diene monomer, 50-100 parts of polyurethane, 10-20 partsof a mixed polyether, 20-30 parts of high-wear-resistant carbon black, 5-10 parts of zinc oxide, 10-15 parts of stearic acid and 5-10 parts of an accelerant. The ethylene-propylene-diene monomer butylself-adhesive waterproof coiled material has the beneficial effects that the toughness of the ethylene-propylene-diene monomer butyl self-adhesive waterproof coiled material is improved, and the situation that after construction tools, building materials and tools for cutting the coiled material fall off, the local waterproof coiled material is damaged is avoided.

Owner:上海豫宏(金湖)防水科技有限公司

Preparation method of strong-autohension polyethylene preservative film

InactiveCN103819791AGood extensibilityImprove toughnessFlexible coversWrappersLow speedPolymer science

The invention discloses a preparation method of a strong-autohension polyethylene preservative film. According to the invention, dioctyl phthalate and dioctyl adipate which are used as plasticizers are combined, and inorganic filler barium carbonate and aluminum oxide are combined, and then the extensibility and the obdurability of the preservative film are improved, so that the autohension of the preservative film is enhanced. The preparation method comprises the following steps: sequentially adding every component into a thermal mixer; starting up the thermal mixer, stirring the materials at high speed when the temperature rises to 90-100 DEG C for 10-14 minutes and then discharging the materials; introducing the materials into a low-speed cold mixer, stirring, reducing the temperature by using jacket cooling water in the cold mixer, and then discharging the materials; pre-heating a threaded rod and a cylinder head grinding tool in an extrusion film blowing machine to 115-125 DEG C, and then adding the mixed materials into the threaded rod in the extrusion film blowing machine for film extrusion.

Owner:WUXI HUANGSHENG PACKING PROD

Method for preparing self-adhesive antibacterial sheath-core fiber by regenerating waste polyester

PendingCN112760748AKeep green and environmental protectionReduce white pollutionMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterFiber

The invention discloses a method for preparing a self-adhesive antibacterial skin-core fiber by regenerating waste polyester. The method is characterized in that antibacterial low-melting-point regenerated polyester is used as a skin layer, regenerated polyester is used as a core layer, and a coaxial self-adhesive antibacterial skin-core structure composite fiber is prepared through melt composite spinning. On one hand, prepared fibers completely adopts the recycled polyester as a raw material, the green and environment-friendly characteristics of the recycled polyester are well maintained, the current white pollution problem of the waste polyester is effectively relieved, meanwhile, energy conservation and emission reduction are achieved, petroleum consumption is reduced, and extremely high environment-friendly benefits are achieved; and on the other hand, nano-silver or cuprous oxide is used as an antibacterial agent to endow the regenerated polyester with a broad-spectrum antibacterial effect, so that the self-adhesion performance and high-value applicability of the regenerated polyester are remarkably improved, the reutilization value of the waste polyester is favorably improved, the regenerated polyester industry is promoted to develop towards high-end application, and then industry development and industry transformation and upgrading are promoted.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com