High-strength puncture-resistant auto-adhesive protective film

A self-adhesive protective film and puncture-resistant technology, which is applied in the field of plastic packaging, can solve problems such as performance defects, and achieve the effects of good compatibility, good compatibility, puncture resistance, and optical transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

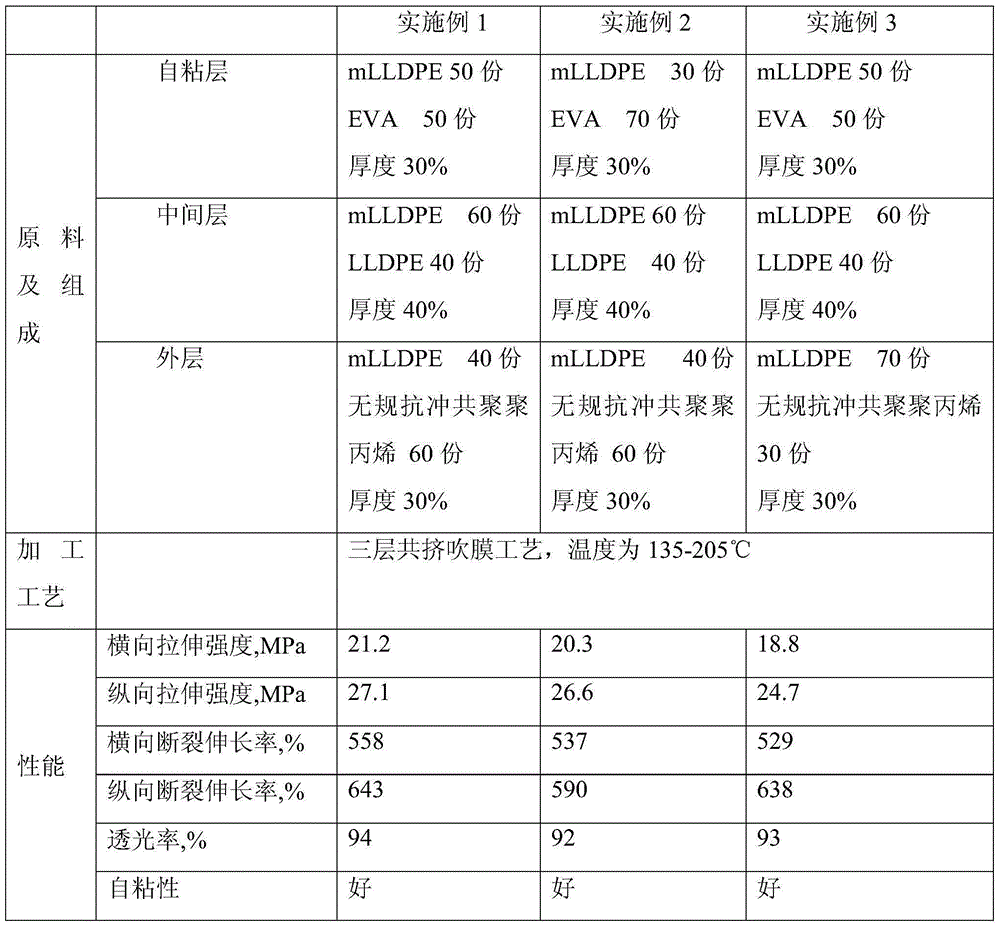

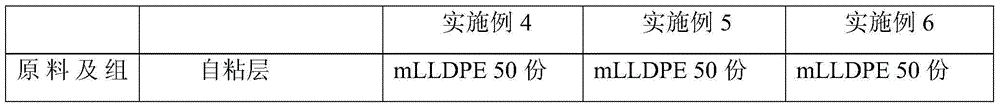

[0021] See Table 1 and Table 2 for the raw material composition and properties of Examples 1-6.

Embodiment 1-5

[0023] The raw material composition and properties of Comparative Examples 1-5 are shown in Table 3 and Table 4 respectively.

[0024] Wherein the melt mass flow rate of the mLLDPE used in Examples 1-3 and Comparative Examples 1-5 is 2.5g / 10min, and the density is 0.925g / cm 3 , Molecular weight distribution Mw / Mn between 5-6. The melt mass flow rate of the mLLDPE used in Examples 4-6 is 28g / 10min, and the density is 0.925g / cm 3 , Molecular weight distribution Mw / Mn between 2-3.

[0025] Table 1 embodiment 1-3 raw material composition and performance

[0026]

[0027] Table 2 embodiment 4-6 raw material composition and performance

[0028]

[0029]

[0030] Table 3 comparative example 1-3 raw material composition and performance

[0031]

[0032]

[0033] Table 4 comparative example 4-5 raw material composition and performance

[0034]

[0035] It can be seen from Comparative Example 1 and Comparative Example 4 that when the self-adhesive layer formulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com