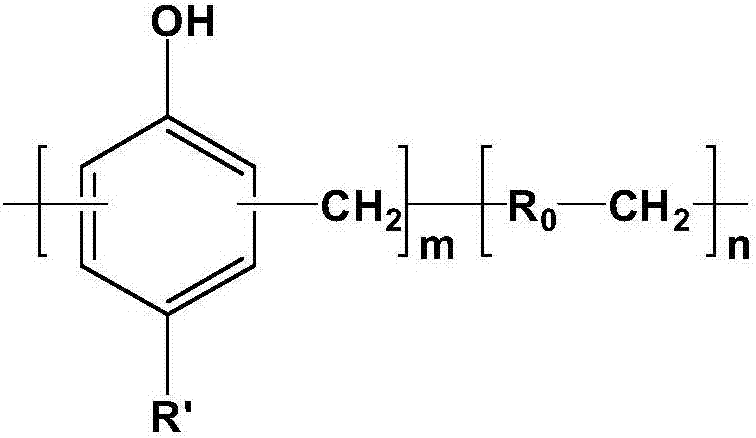

Synthesis and applications of long-acting tackifying phenol formaldehyde resin

A phenolic resin, long-acting technology, used in the field of rubber processing aids, can solve the problems of multiple waste water and organic waste liquid, reduce the density of phenolic hydroxyl groups, complex processes, etc., achieve long-term viscosity increase, reduce dynamic heat generation, phase Good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

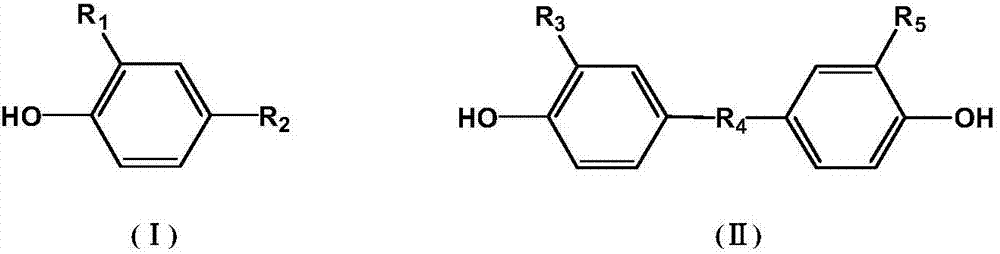

Method used

Image

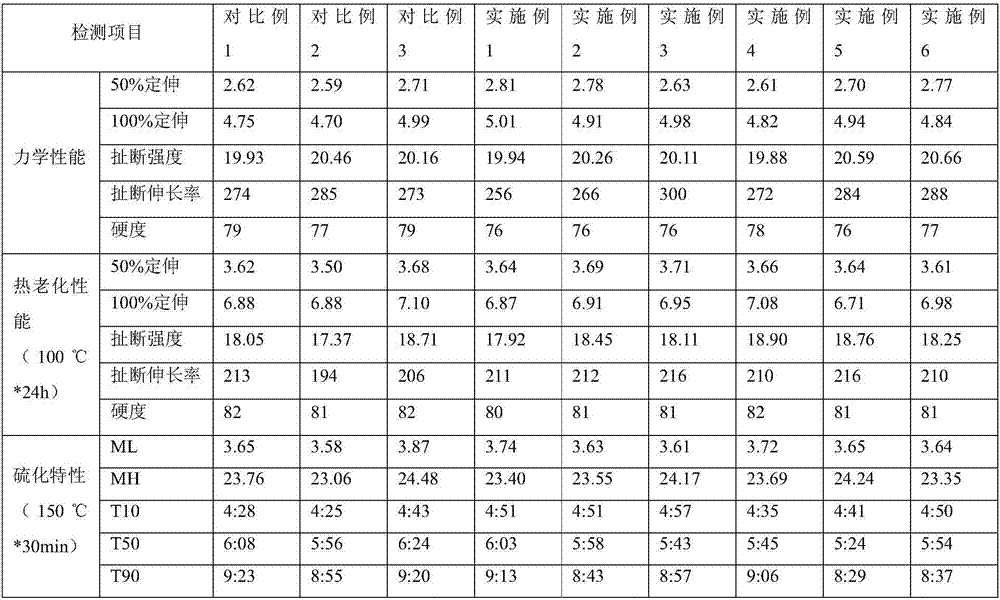

Examples

Embodiment 1~4

[0039] Into the 500ml four-neck reaction flask that can be installed with stirring, thermometer, reflux condenser and adding funnel, drop alkylphenol and 2-allylphenol (see Table 2 for specific materials and consumption), heat up to 90°C and melt, add 2g of oxalic acid, after stirring evenly, add an appropriate amount of formaldehyde (see Table 2 for the specific dosage) into the four-necked bottle, after the dropwise addition, raise the temperature to 100°C, and reflux for 1 to 5 hours. Switch reflux to distillation, add a small amount of defoamer, raise the temperature to 180°C, and dehydrate under normal pressure. When the temperature rises to 180°C, distill under reduced pressure (-90~-95Kpa) to remove residual water. After no fraction flows out, break the vacuum , discharge the resin melt into a stainless steel pan, and cool to room temperature to obtain the long-acting tackifying resin of the present invention.

[0040] Table 2 Embodiment 1~4 raw material formula and res...

Embodiment 5

[0043] Put 150g of p-tert-butylphenol and 25g of 2-allylphenol into a 500ml four-neck reaction flask equipped with stirring, thermometer, reflux condenser and addition funnel, heat up to 90°C and melt, add 2g of triethanolamine, stir After uniformity, 95 g of 37% liquid aldehyde was added into the four-neck flask. After the addition was complete, the temperature was raised to 100° C. and refluxed for 2 hours. Switch reflux to distillation, raise the temperature to 180°C with a small amount of defoamer, and dehydrate under normal pressure. When the temperature rises to 180°C, distill under reduced pressure (-90~-95Kpa) to remove residual water. After no fraction flows out, break the vacuum. After aging at 180°C for 2 hours, the resin melt was discharged into a stainless steel pan and cooled to room temperature to obtain the long-acting tackifying resin of the present invention, with a softening point of 129°C and an iodine value of 20.6.

Embodiment 6

[0045] Put 150g of p-tert-butylphenol and 40g of 2,2'-diallyl bisphenol A into a 500ml four-neck reaction flask equipped with stirring, thermometer, reflux condenser and addition funnel, and heat up to 90°C to melt. Add 2g of triethylamine, stir evenly, add 92g of 37% liquid aldehyde into the four-neck flask, after the addition is complete, heat up to 100°C, add 9g of morpholine, and reflux for 2 hours. Switch reflux to distillation, heat up to 180°C with a small amount of defoamer, and dehydrate under normal pressure. When the temperature rises to 180°C, add 10g of stearic acid, stir well, and then distill under reduced pressure (-90~-95Kpa) to remove residual water. After no distillate flows out, break the vacuum, and after aging for 2 hours at 180°C, discharge the resin melt into a stainless steel pan, cool to room temperature to obtain the long-acting tackifying resin of the present invention, the softening point is 120°C, and the iodine value is 50.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com