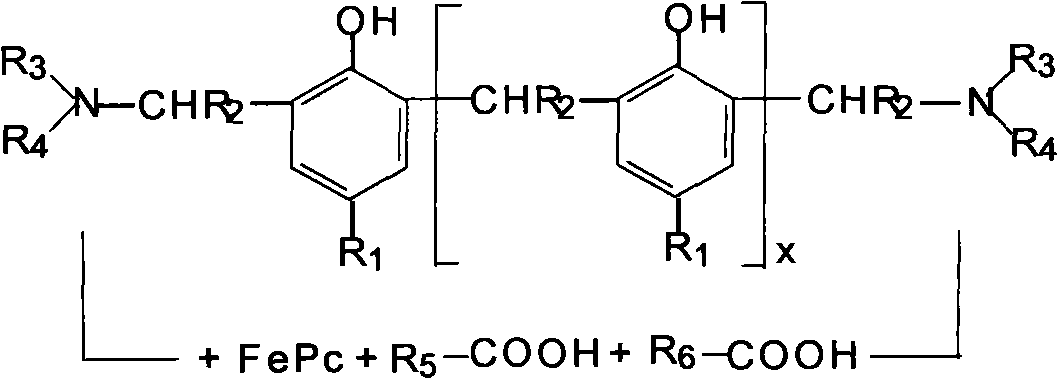

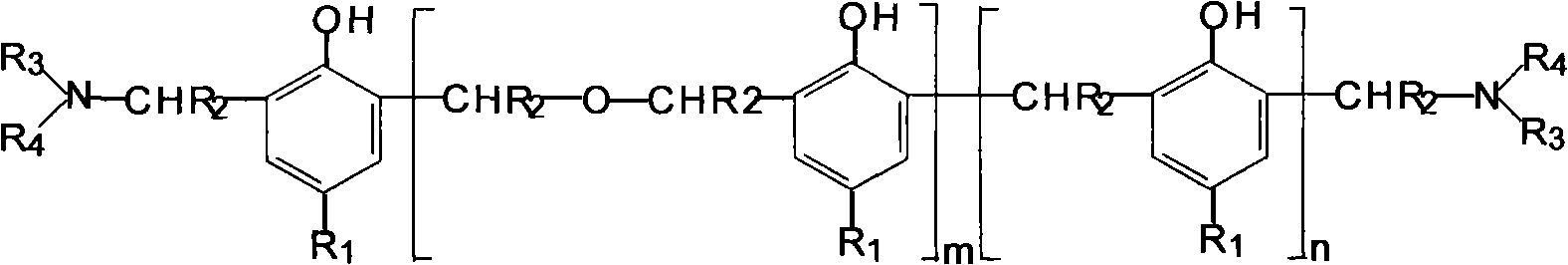

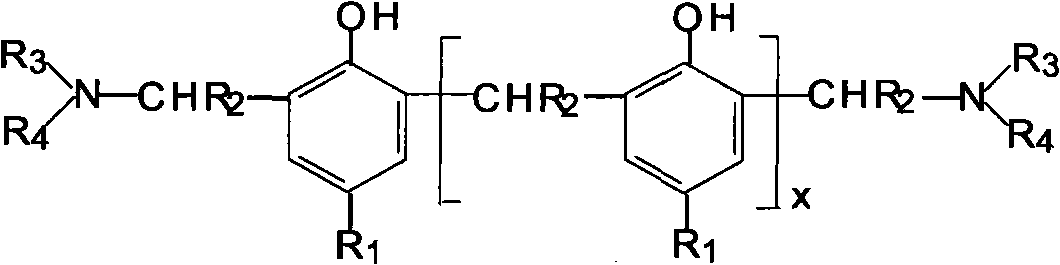

Multifunctional phenolic resin for rubber industry and manufacture method thereof

A technology of phenolic resin and rubber industry, applied in the field of preparation of the multifunctional phenolic resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] On the 1000 ml four-neck reaction flask, install stirring, thermometer, reflux condenser and addition funnel. Add 300 g of p-tert-butylphenol, 194 g of 37% formaldehyde solution, and 2 g of triethylamine catalyst. The temperature was raised to 80°C. 21 g of morpholine was added dropwise through the addition funnel. Reflux for 2 hours. Normal pressure dehydration. When the temperature rises to 170° C., add 80 g of rosin and 40 g of stearic acid. Remove residual water to 180°C, and keep it warm at this temperature for 2 hours. Add FePc 3g. The temperature was raised to 200°C and maintained at this temperature for 2 hours. Drain the resin mass into a stainless steel pan and cool to room temperature. The product is transparent, the softening point is 125℃, dark green.

Embodiment 2

[0042] On the 1000 ml four-neck reaction flask, install stirring, thermometer, reflux condenser and dropping funnel. Add 300 g of p-tert-butylphenol, 194 g of 37% formaldehyde solution, and 2 g of triethylamine catalyst. The temperature was raised to 80°C. 28.1 g of 2-hydroxymethylmorpholine was added dropwise through the addition funnel. Reflux for 2 hours. Normal pressure dehydration. When the temperature rises to 170° C., add 80 g of rosin and 40 g of stearic acid. Remove residual water to 180°C, and keep it warm at this temperature for 2 hours. Add FePc 1.5g. The temperature was raised to 200°C and maintained at this temperature for 2 hours. Drain the resin mass into a stainless steel pan and cool to room temperature. The softening point of the product is 125°C, blue.

Embodiment 3

[0044] On the 1000ml four-neck reaction flask, install stirring, thermometer, reflux condenser and addition funnel. Add 300 g of p-tert-butylphenol, 194 g of 37% formaldehyde solution, and 2 g of triethylamine catalyst. The temperature was raised to 80°C. 26 g of aniline was added dropwise through the addition funnel. Reflux for 2 hours. Normal pressure dehydration. When the temperature rises to 70°C, add 80g of rosin and 40g of stearic acid. Remove residual water to 180°C, and keep warm at this temperature for 1 hour. Add FePc 1.5g. The temperature was raised to 200°C and maintained at this temperature for 2 hours. Drain the resin mass into a stainless steel pan and cool to room temperature. The product is transparent, with a softening point of 136°C and dark blue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com