Patents

Literature

79results about How to "Easy to separate and remove" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

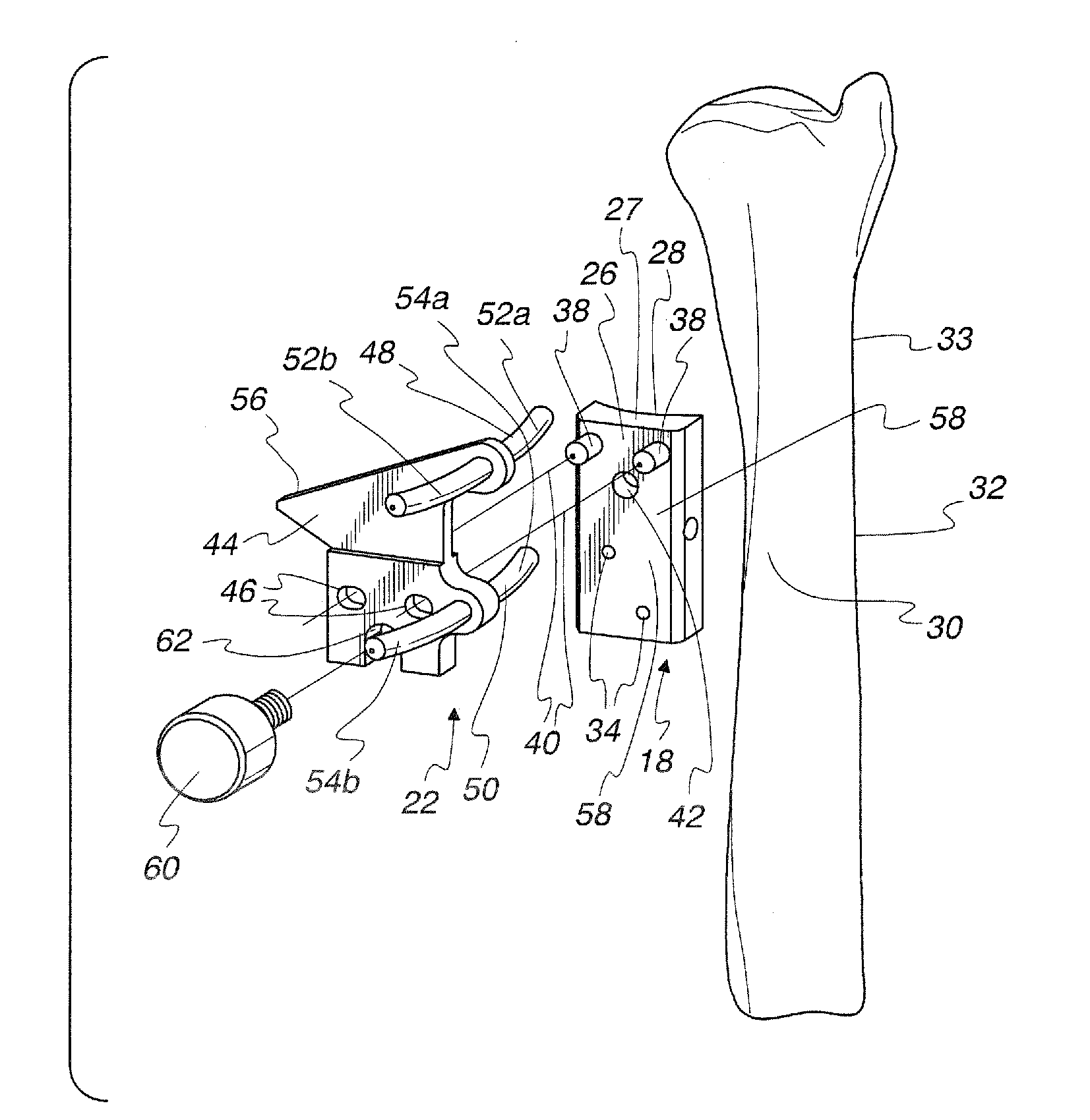

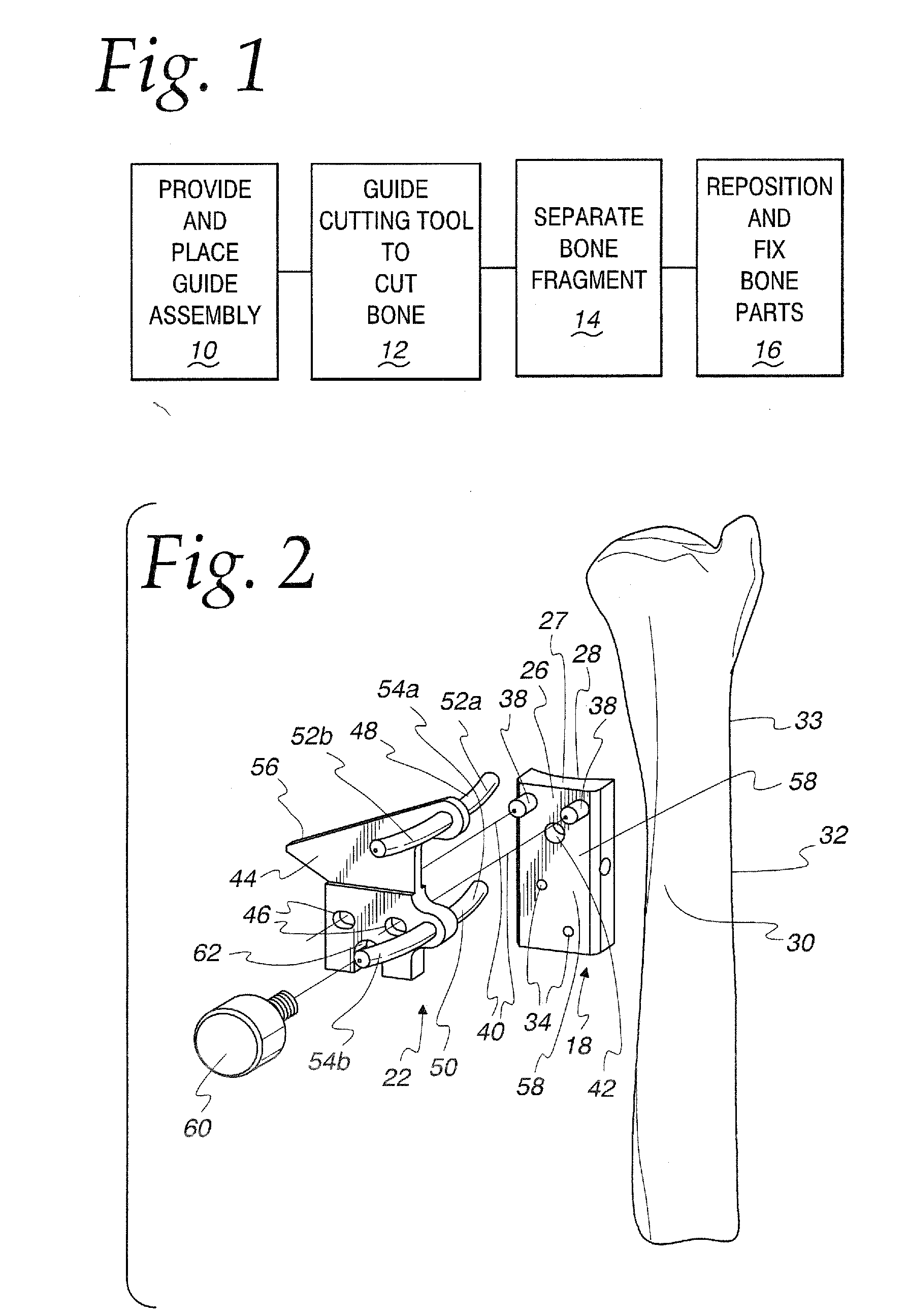

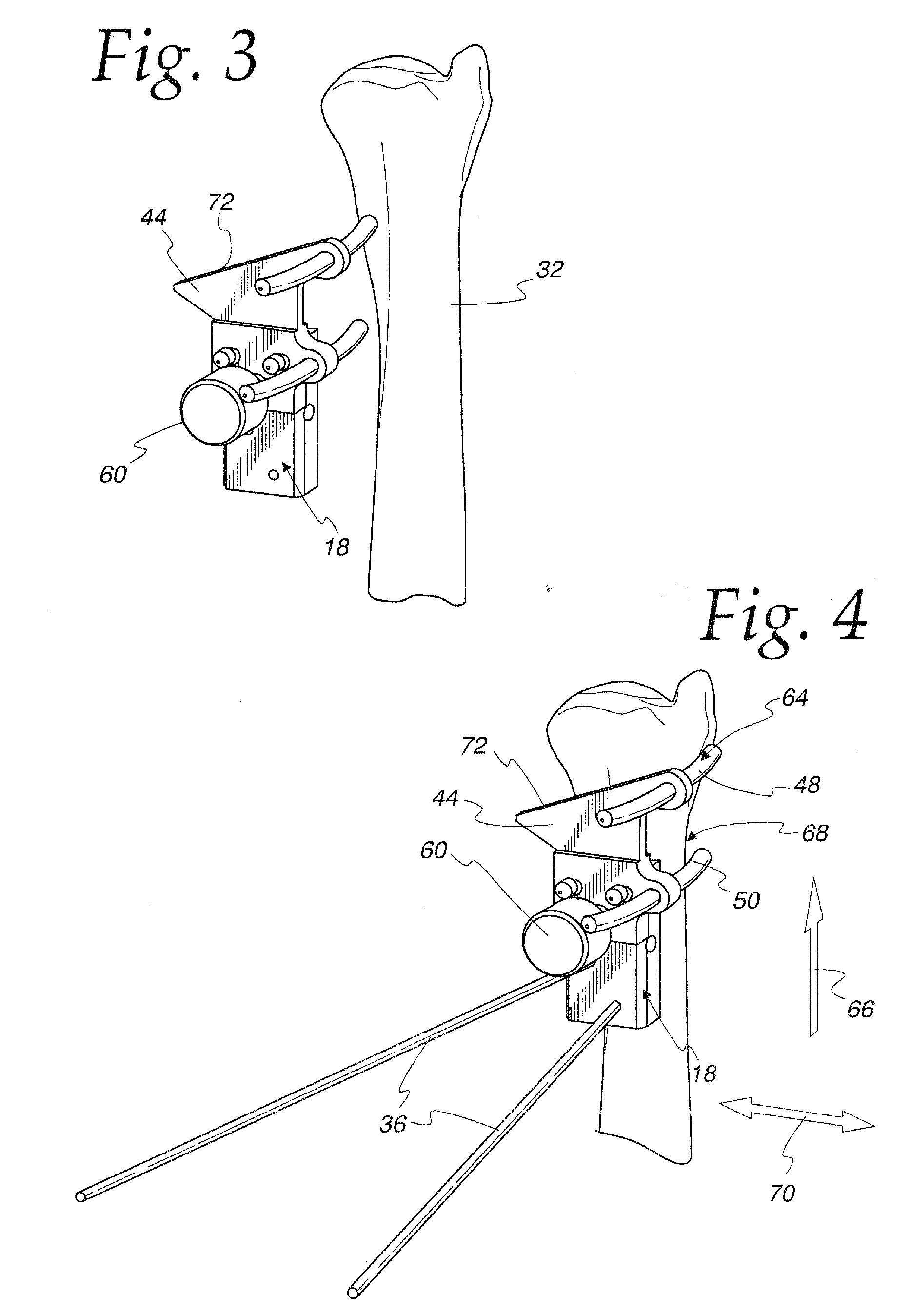

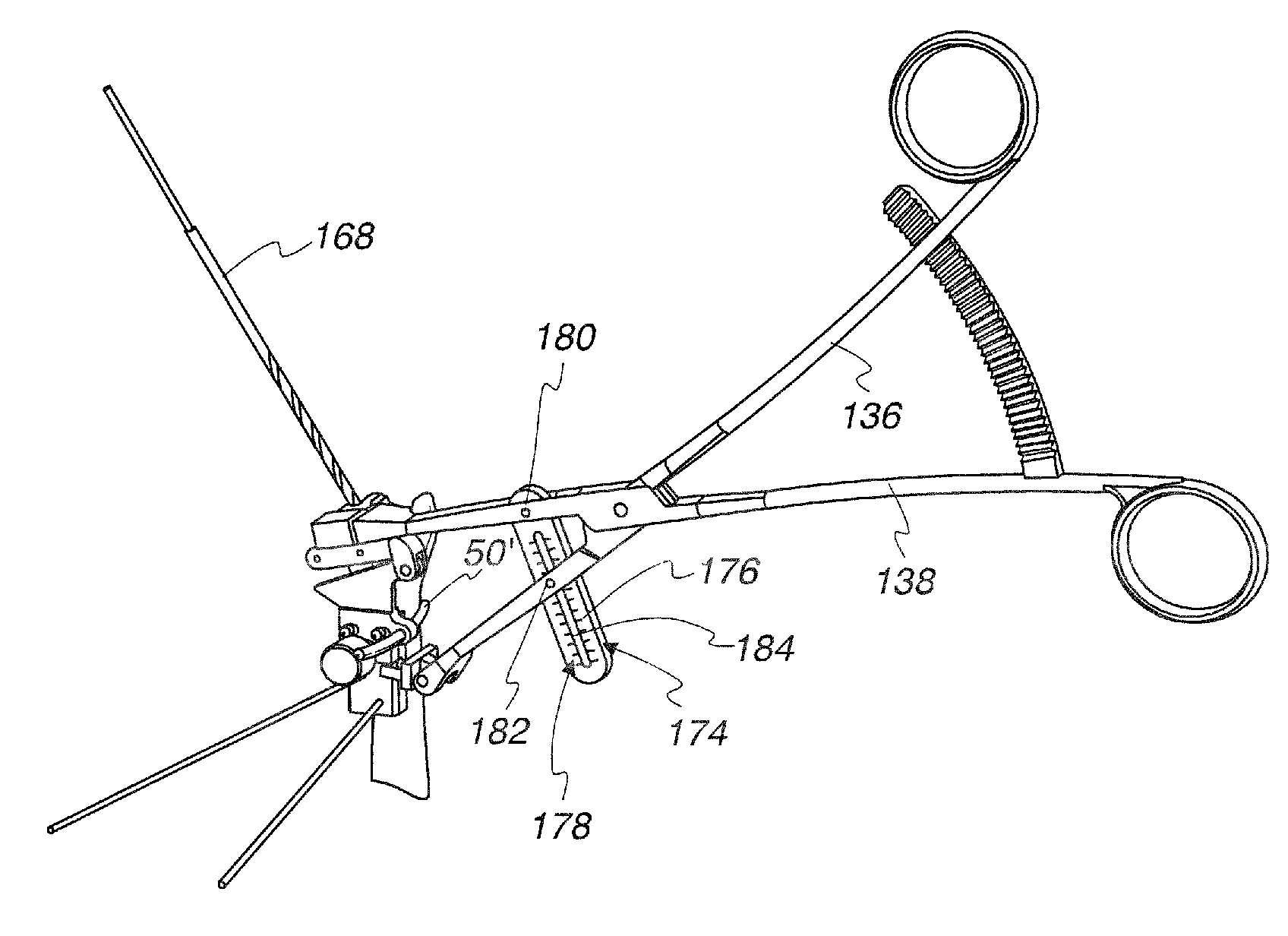

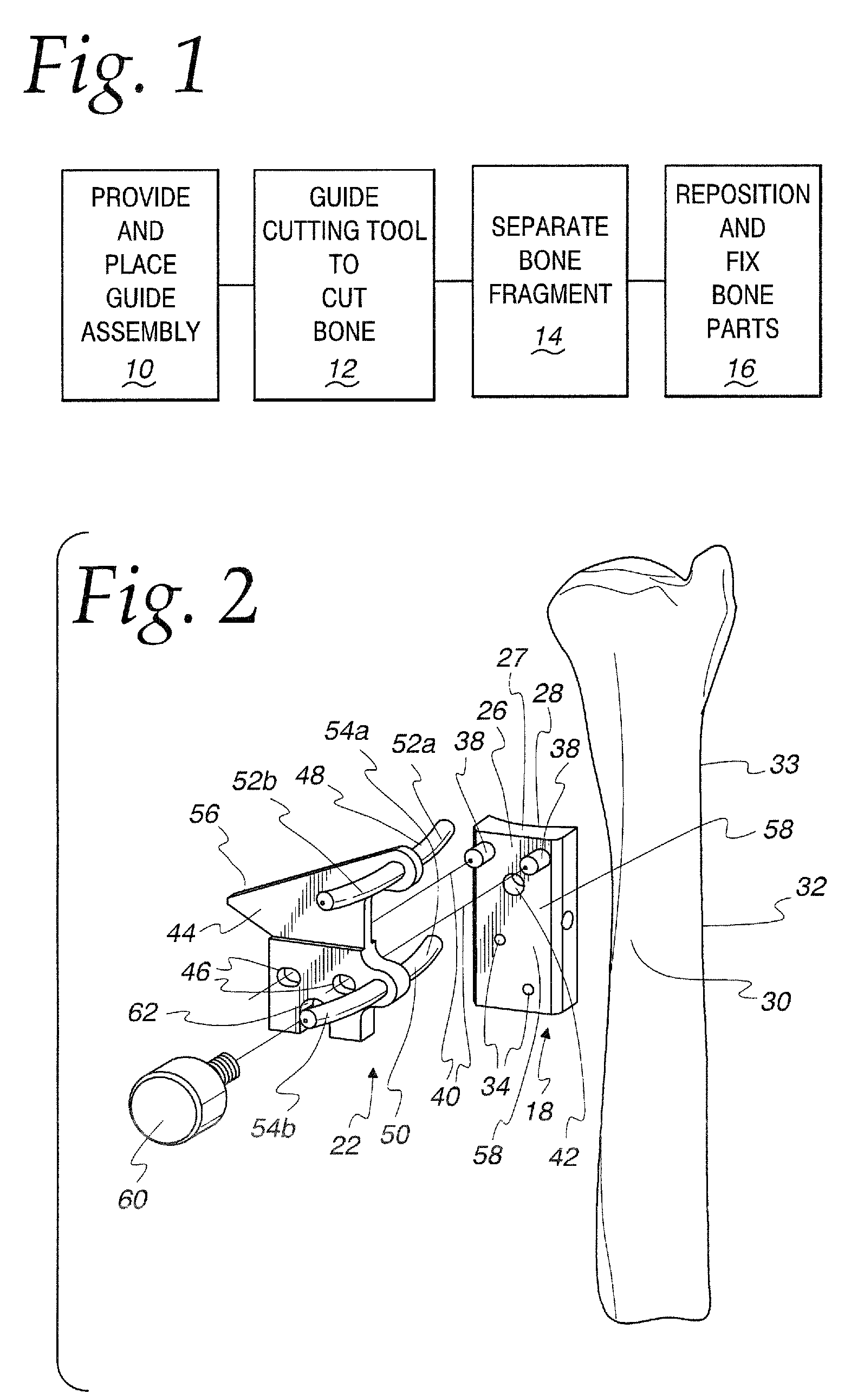

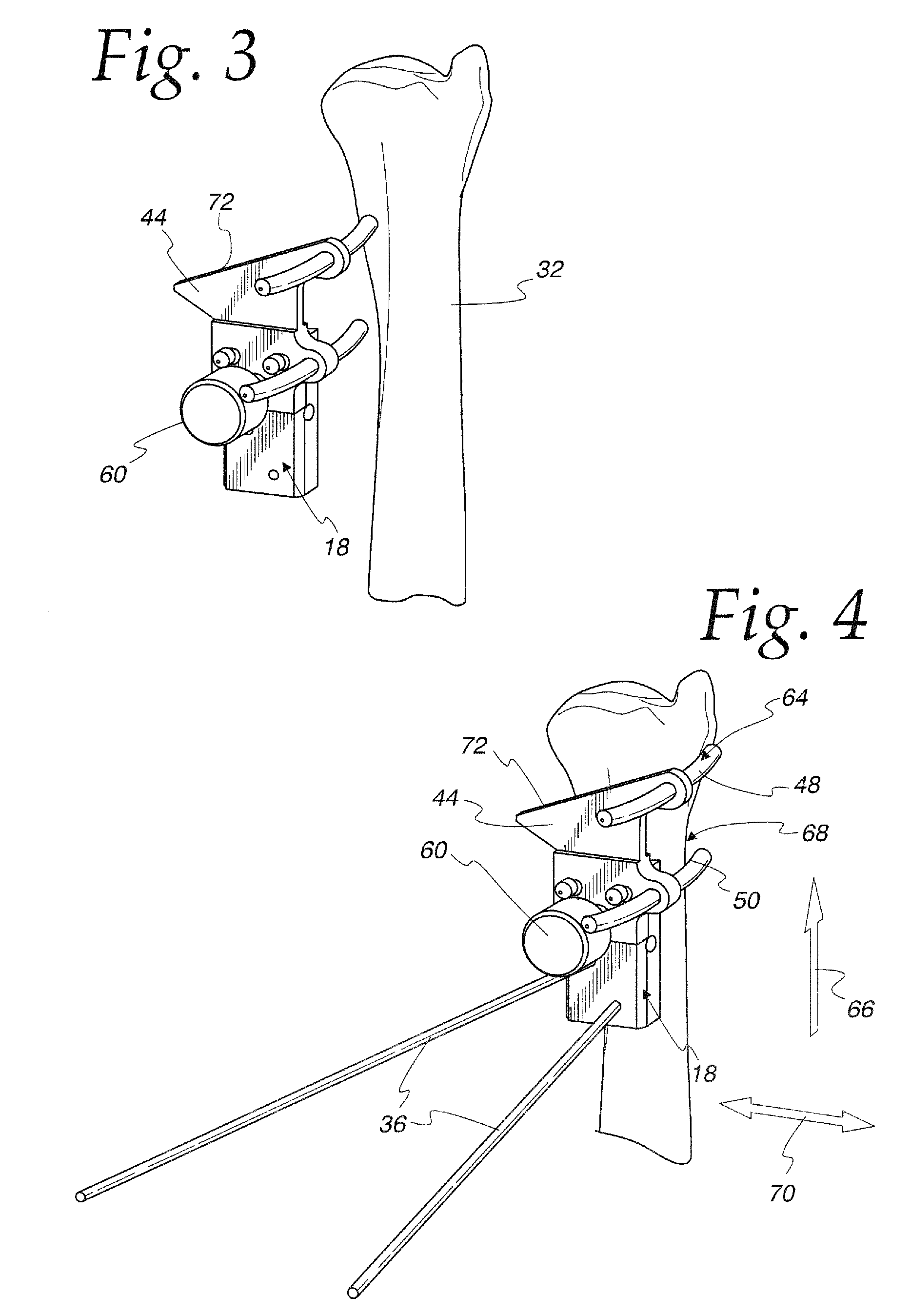

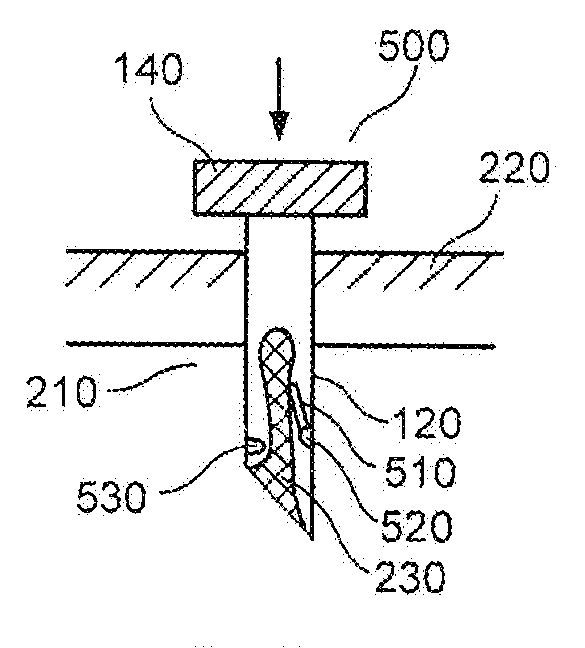

Method of performing osteotomy

InactiveUS20120130383A1Easy to separateEasy to removeNon-surgical orthopedic devicesSurgical sawsEngineeringOsteotomy

A method of performing an osteotomy including the steps of: providing a guide assembly; placing the guide assembly in operative relationship to a bone to be cut so that the guide assembly defines first and second guide edges that are in fixed relationship to each other to each guide movement of a cutting tool; guiding the cutting tool along each of the first and second guide edges to produce first and second cut lines in the bone to facilitate separation of a fragment of the bone from between first and second bone surfaces formed respectively at the first and second cut lines; separating the bone fragment so that a gap with a first width is formed between the first and second bone surfaces; and changing the width of the gap to be less than the first width.

Owner:TRIMED

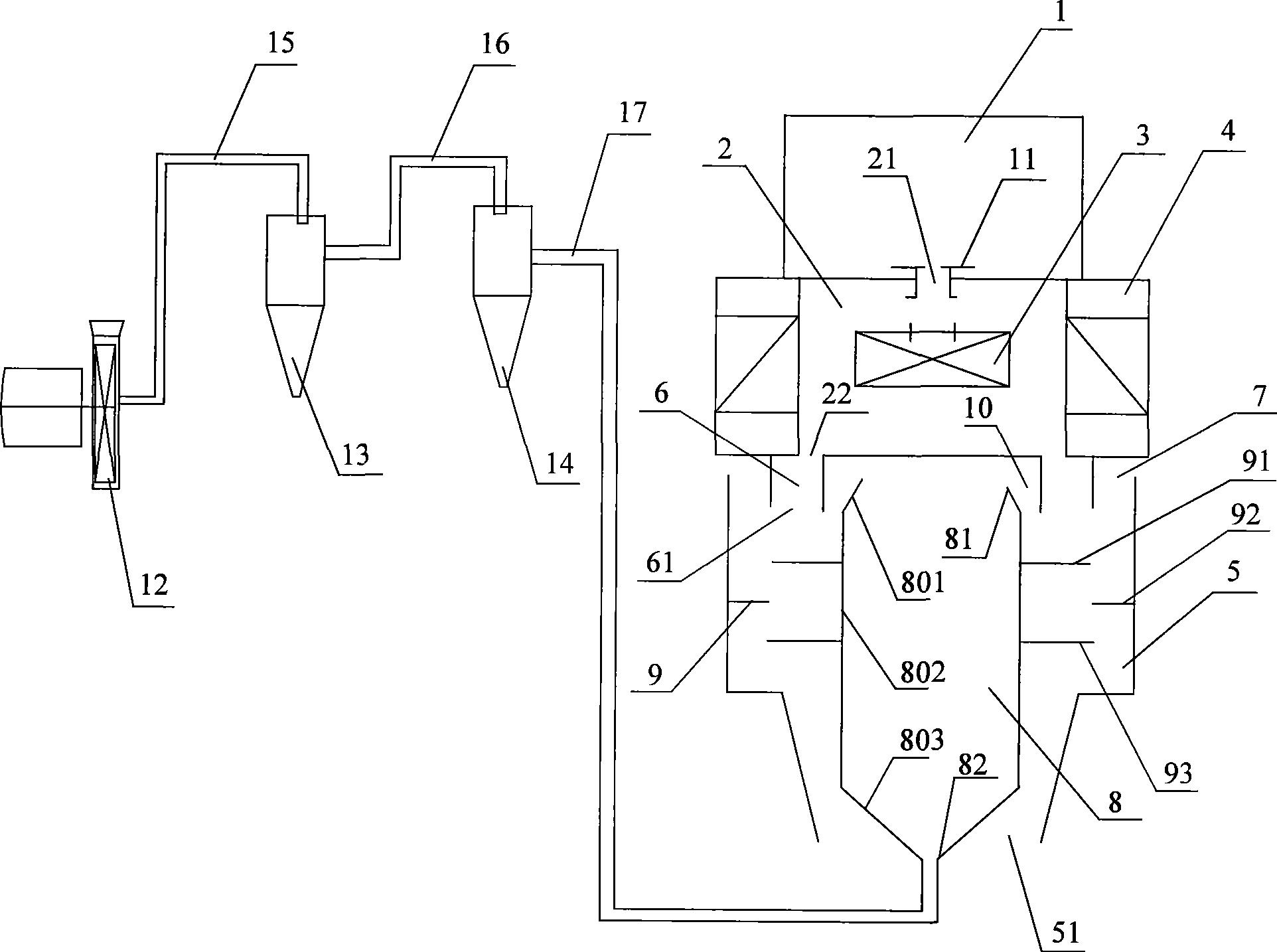

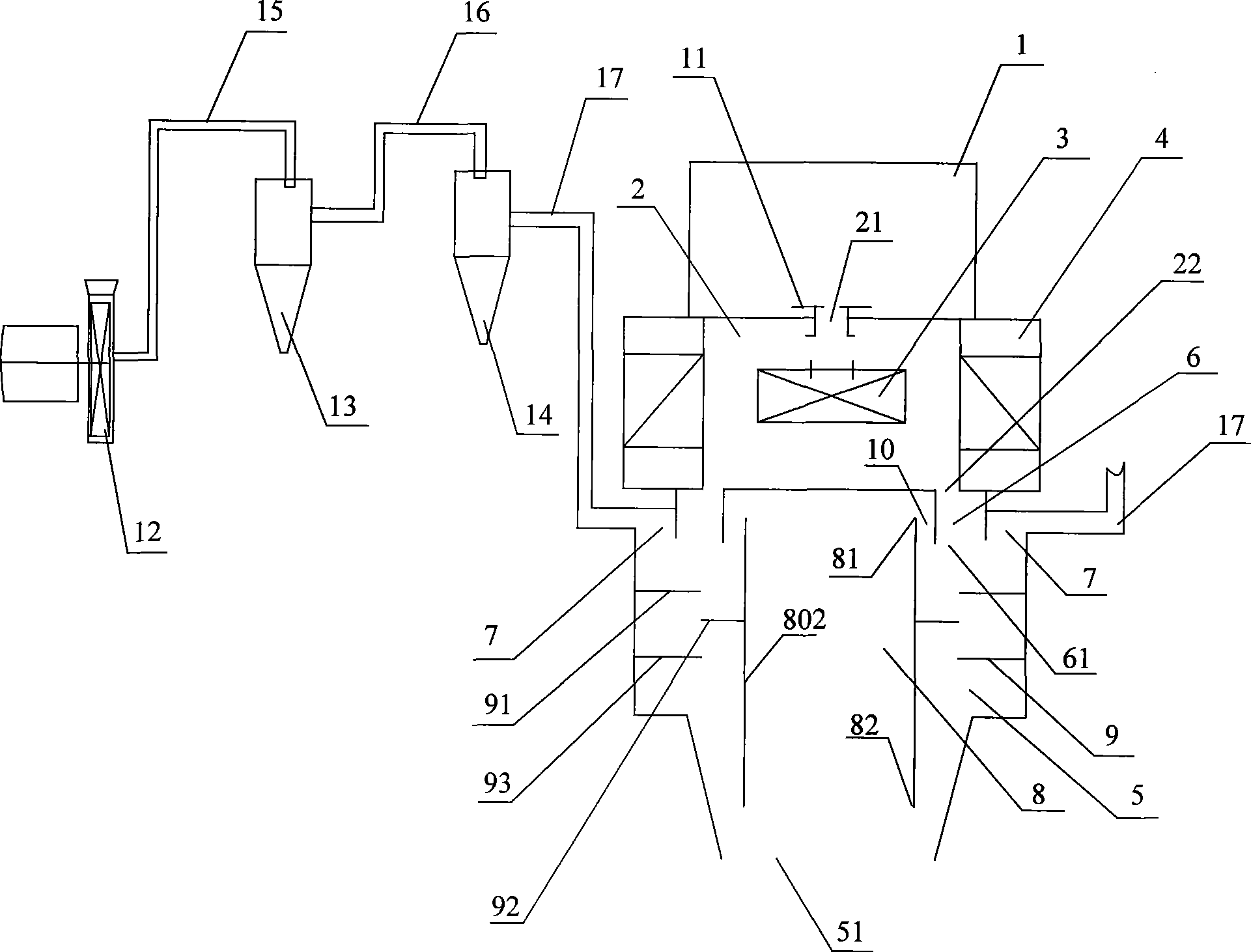

Dry-type sand making method and dry-type sand making machine thereof

The invention discloses a dry sand maker which comprises a hollow crushing cavity (2). A hollow dust removal cavity (5) is arranged under the hollow crushing cavity (2); the upper end of a feeding channel (6) is hermetically connected with a feeding mouth (22) and the lower end (61) thereof is positioned in the dust removal cavity (5) on which an air vent (7) is also arranged; an air duct (8) is arranged in the dust removal cavity (5); the lower end (61) of the feeding channel (6) is staggered with the upper end (81) of the air duct (8) in the horizontal direction; the bottom surface of the dust removal cavity (5) is provided with an outlet (51); a dust absorption component is hermetically connected with the lower end (82) of the air duct (8) or the air vent (7) after passing through the outlet (51). The invention also provides a method for drying sand making simultaneously. By adopting the dry sand maker, the drying sand making can have the advantages of high production efficiency and low environmental pollution.

Owner:吴核明

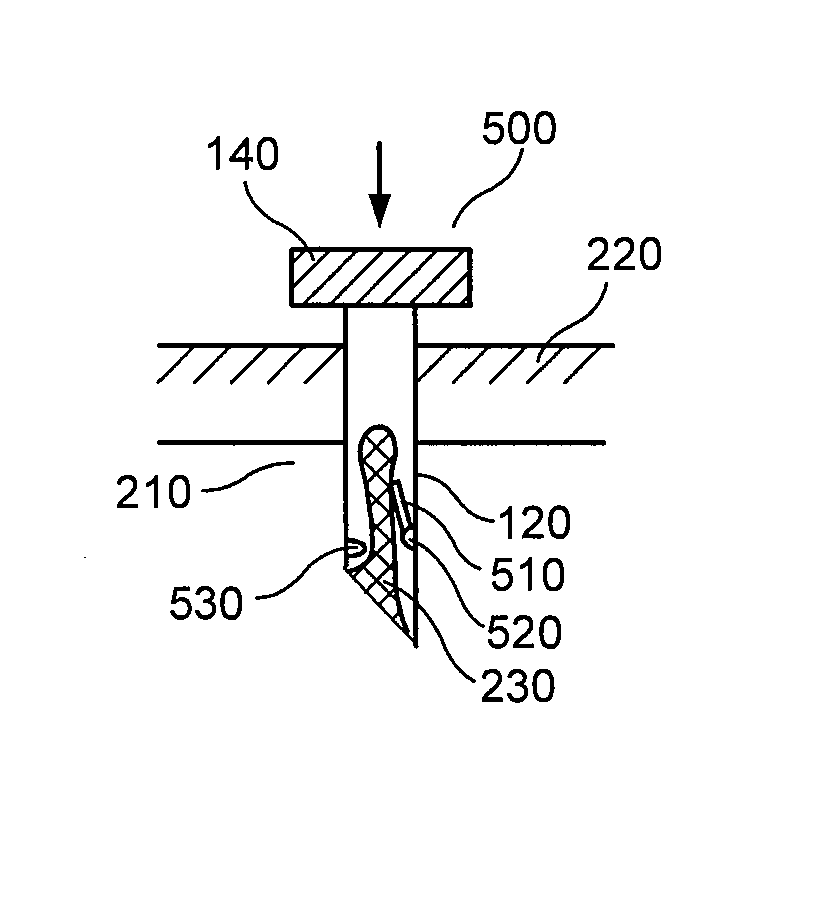

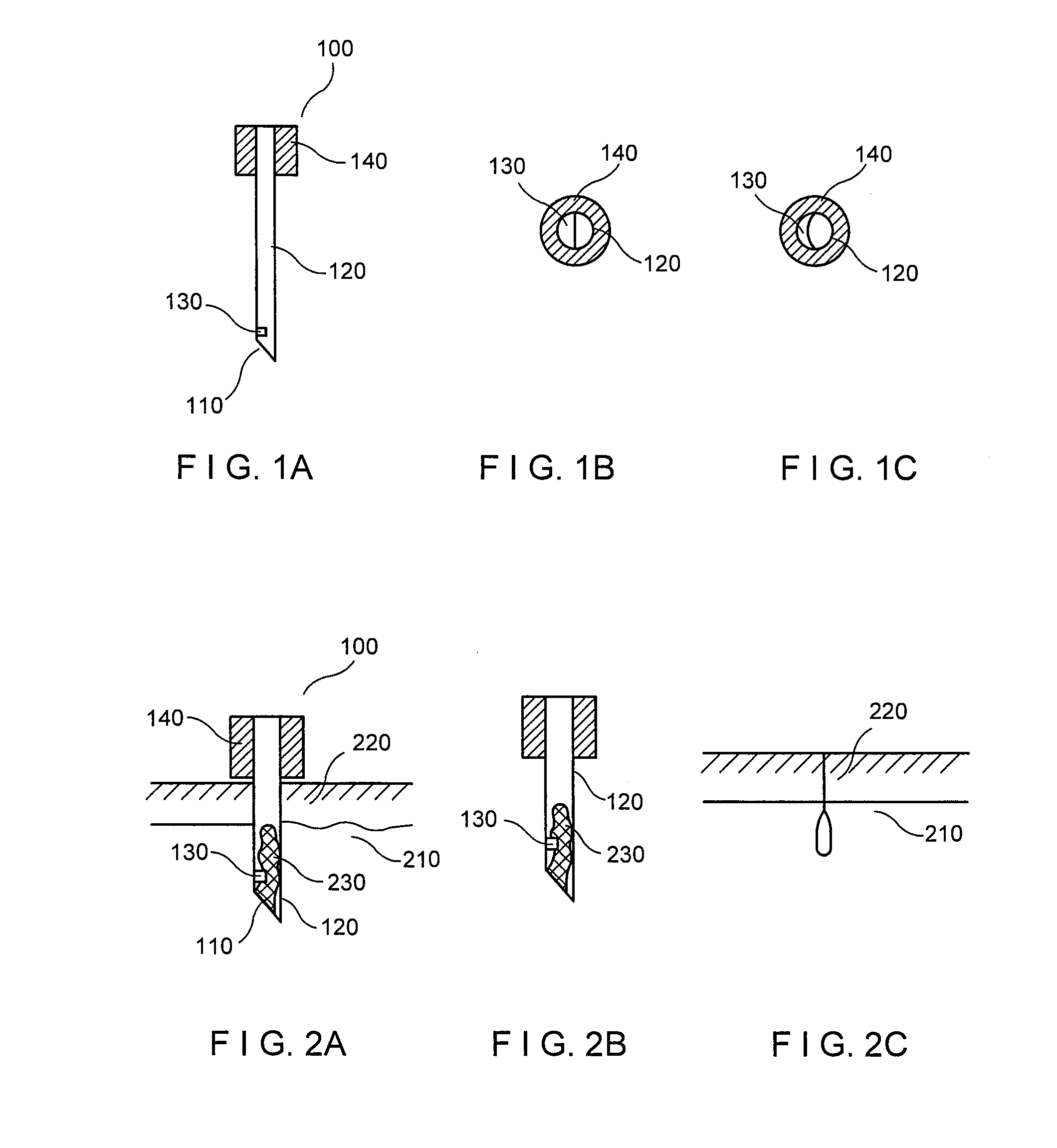

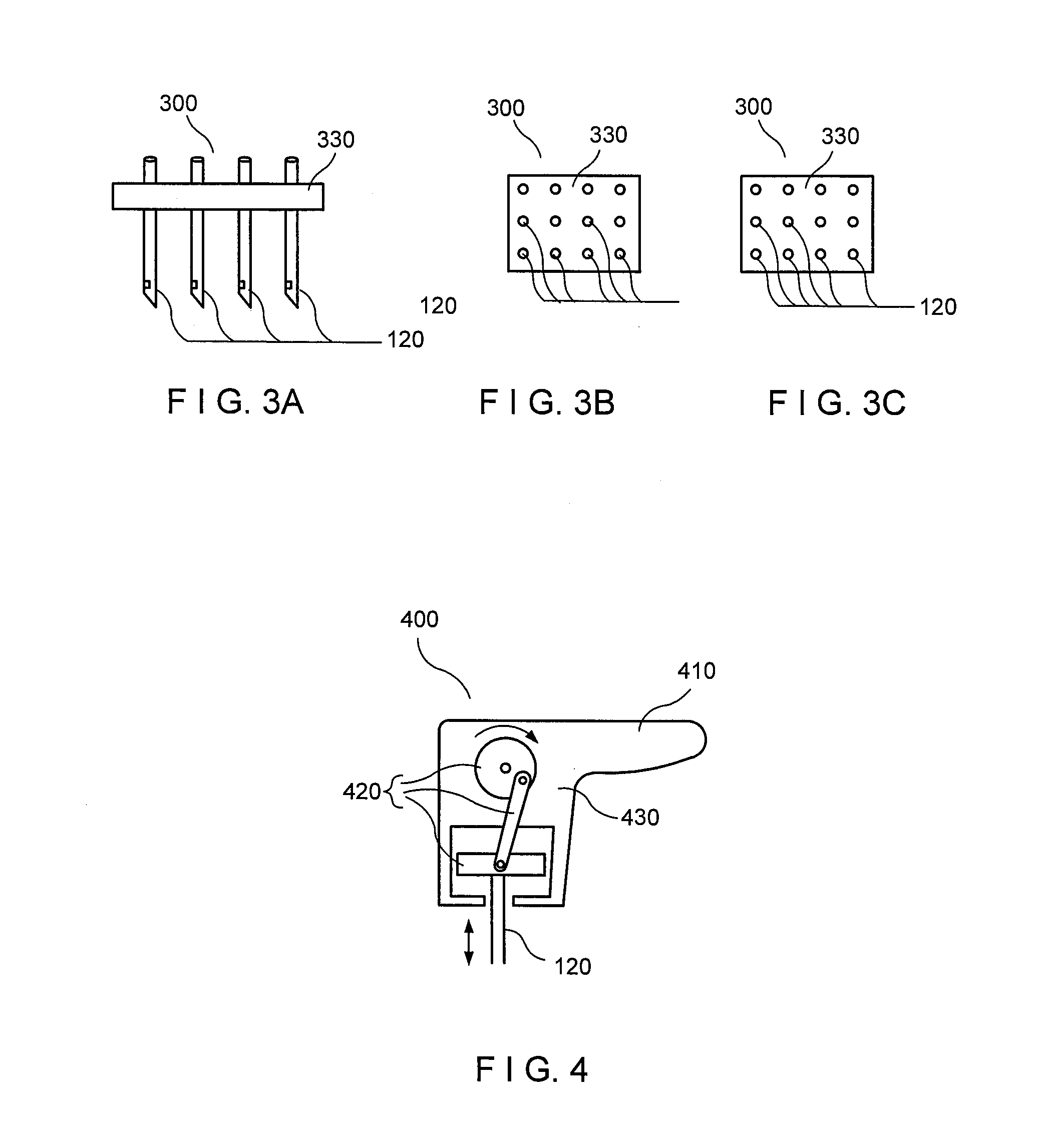

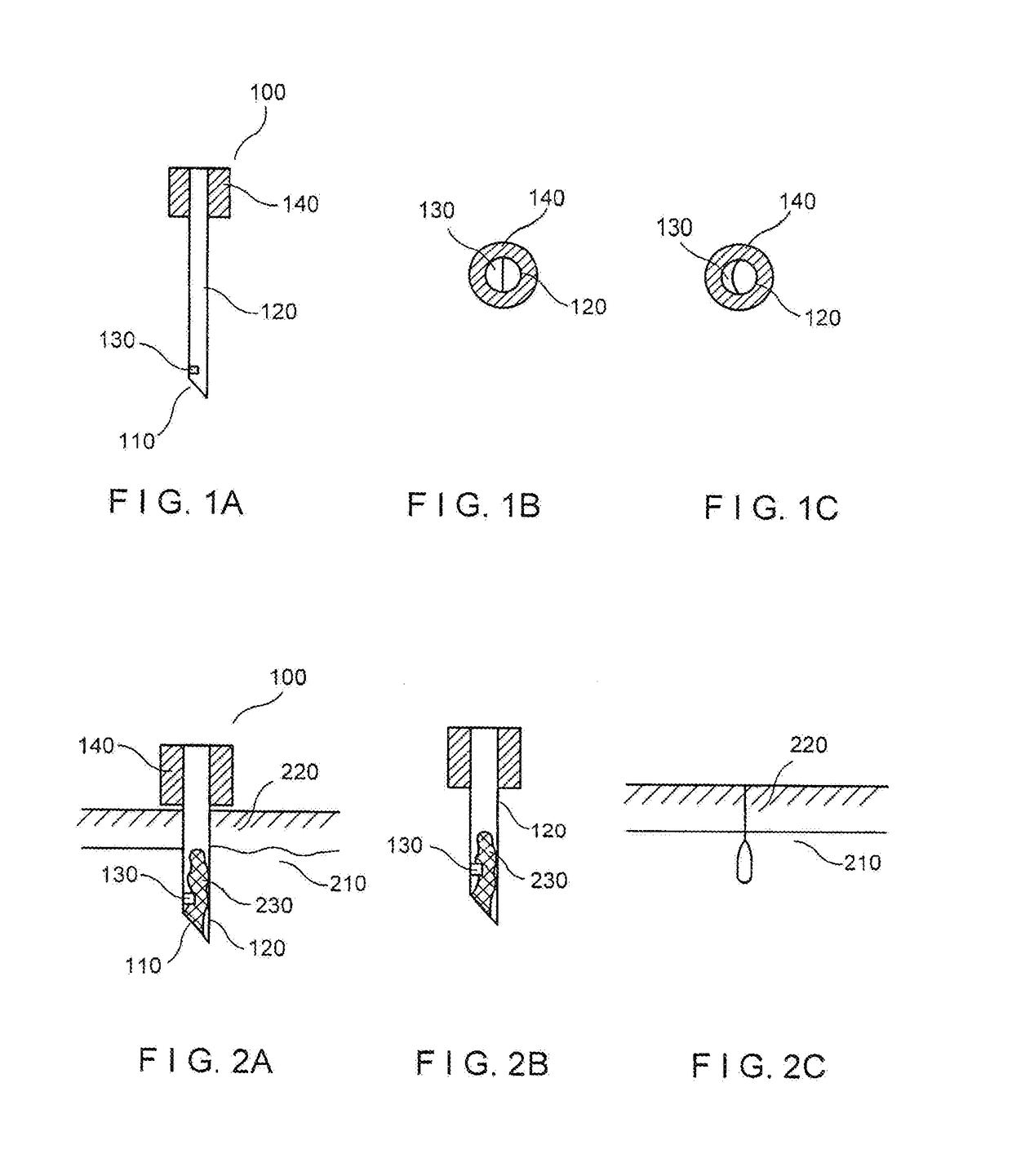

Method and apparatus for damage and removal of fat

InactiveUS20140277055A1Easy to separateEasy to removeSurgical needlesMedical devicesSubcutaneous fatty tissueDistal portion

Exemplary embodiments of method and apparatus are provided for damaging and / or removing portions of subcutaneous fatty tissue while leaving the overlying dermal layer of the skin substantially undamaged. One or more hollow needles can be provided that include an arrangement within the lumen configured to retain or damage portions of fatty tissue that enter the lumen. Properties of the needle can be selected such that the needle can be inserted into skin and pass through the dermal layer, allowing fatty tissue to enter the distal portion of the lumen as it is advanced further, and then leaving the dermis undamaged when withdrawn. Such exemplary apparatus can include a plurality of such needles, a reciprocating arrangement to mechanically advance and withdraw the one or more needles, and / or a vibrating arrangement.

Owner:THE GENERAL HOSPITAL CORP

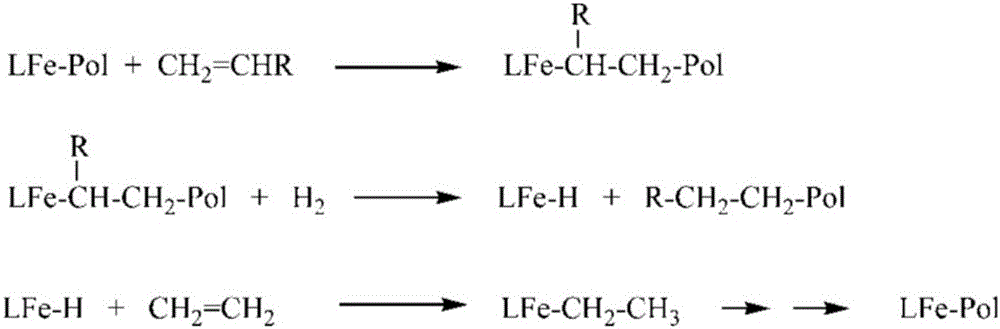

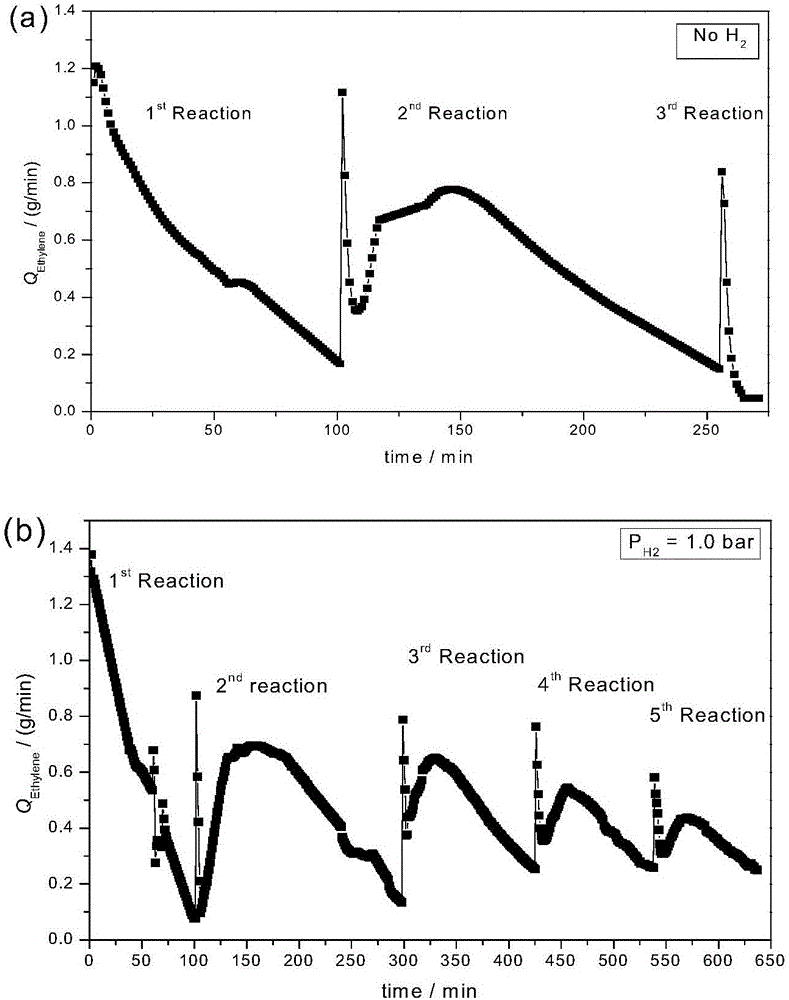

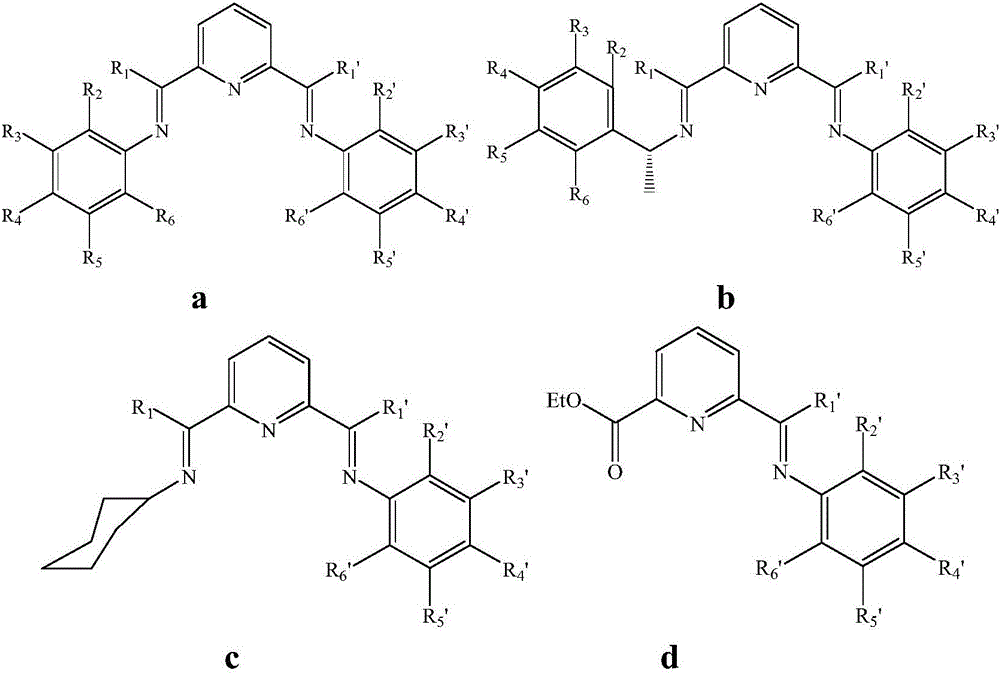

Method for enhancing yield of linear alpha-olefins

InactiveCN105884565AReduced inactivation rateHigh reactivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsOrganic solventHydrogen

The invention discloses a method for enhancing yield of linear alpha-olefins. The method comprises the following steps: introducing hydrogen into a catalytic-reaction-medium-containing oligomerization reactor as an activator, controlling at appropriate reaction temperature, introducing a vinyl monomer, keeping the reaction pressure, and carrying out oligomerization to prepare the high-grade linear alpha-olefins. The oligomerization reactor is selected from one or more of stirred tank reactors or tubular reactors, and can adopt series or parallel operation of single or multiple reactors. The hydrogen is added one or more of one-step addition, batch addition or sectionalized addition mode. The catalytic reaction medium is composed of a main catalyst, a cocatalyst and an organic solvent, wherein the main catalyst is selected from late-transition iron catalysts. The method is simple and feasible, is easy to implement, and can obviously enhance the yield of linear alpha-olefins, thereby greatly lowering the cocatalyst consumption of the unit product, and being beneficial to lowering the production cost and enhancing the economic benefits.

Owner:ZHEJIANG UNIV

Method of performing osteotomy

InactiveUS8939984B2Easy to separate and removeNon-surgical orthopedic devicesSurgical sawsBone splintersOsteotomy

A method of performing an osteotomy including the steps of: providing a guide assembly; placing the guide assembly in operative relationship to a bone to be cut so that the guide assembly defines first and second guide edges that are in fixed relationship to each other to each guide movement of a cutting tool; guiding the cutting tool along each of the first and second guide edges to produce first and second cut lines in the bone to facilitate separation of a fragment of the bone from between first and second bone surfaces formed respectively at the first and second cut lines; separating the bone fragment so that a gap with a first width is formed between the first and second bone surfaces; and changing the width of the gap to be less than the first width.

Owner:TRIMED

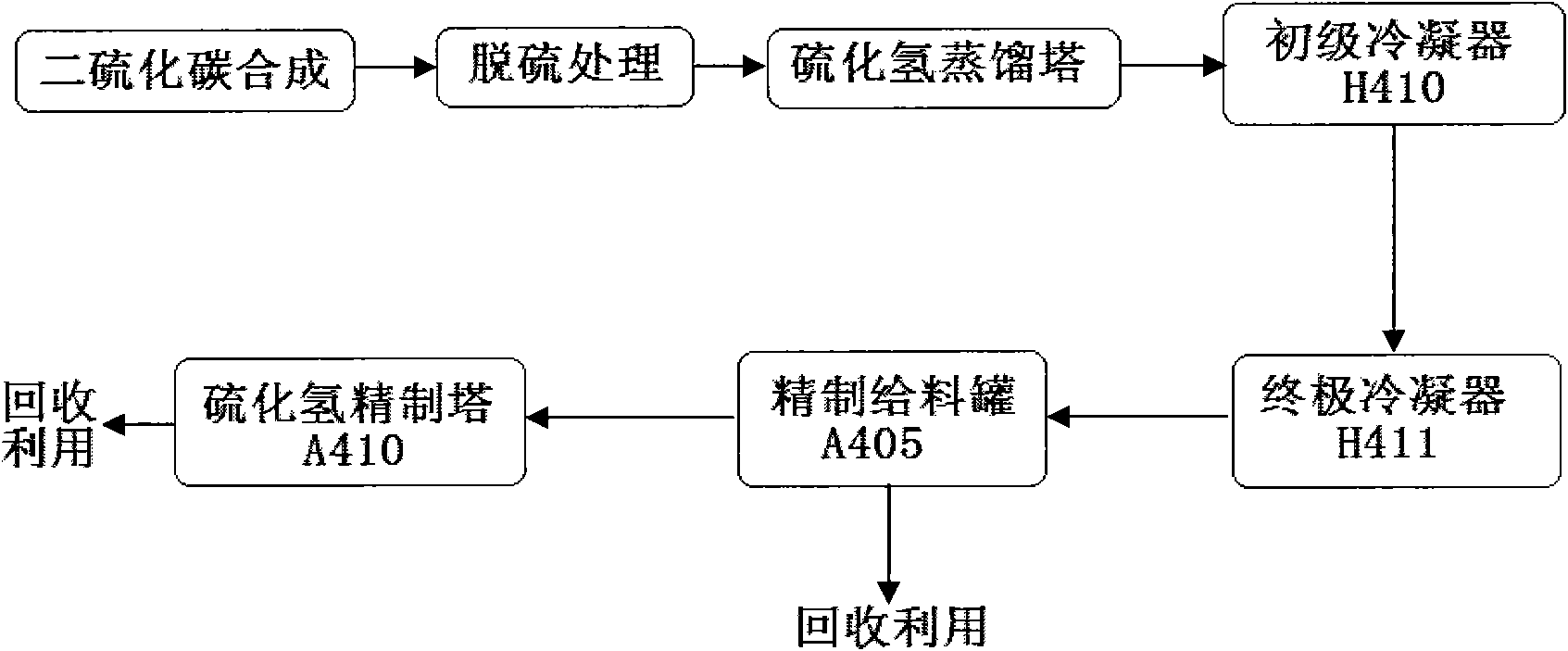

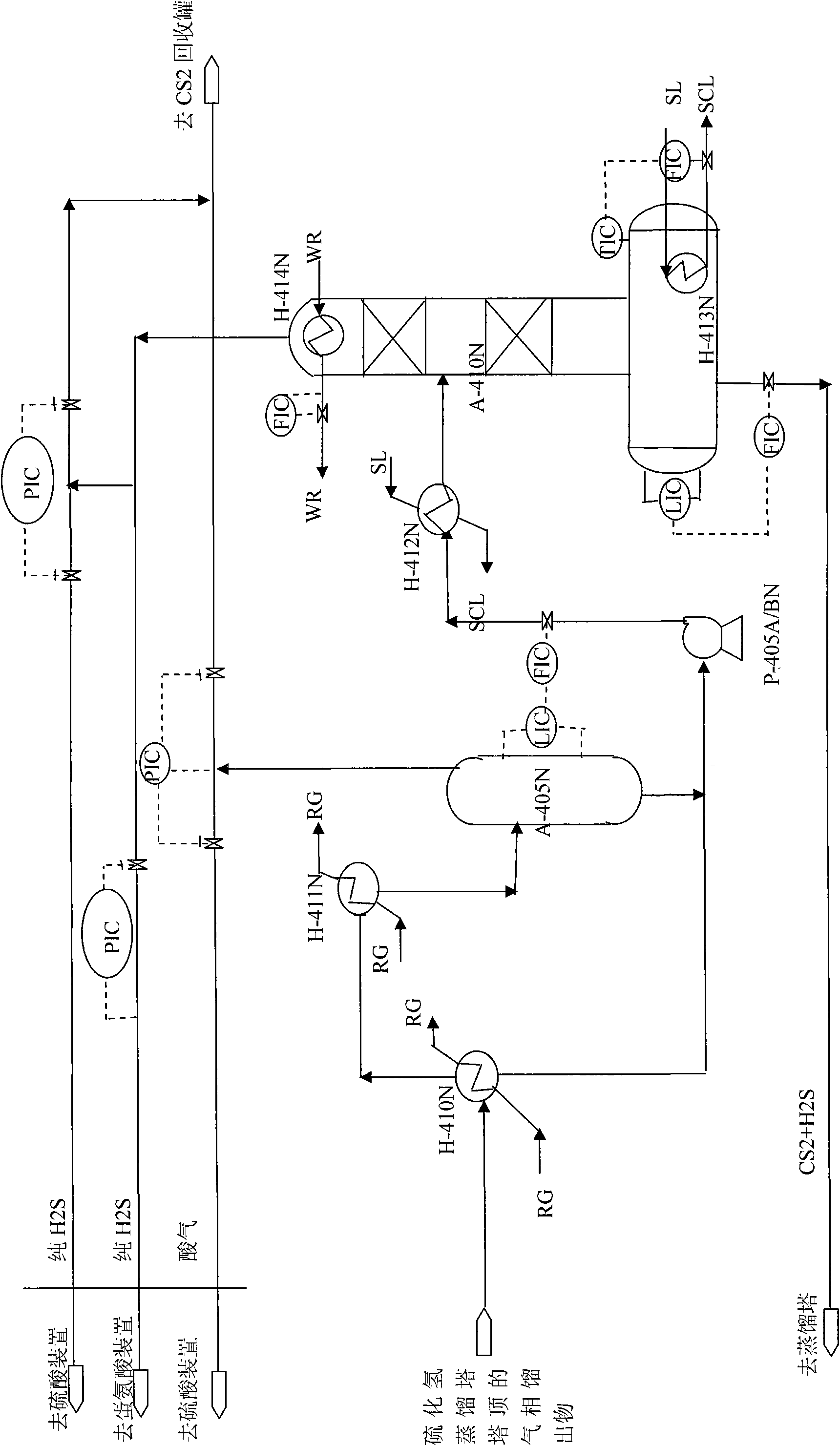

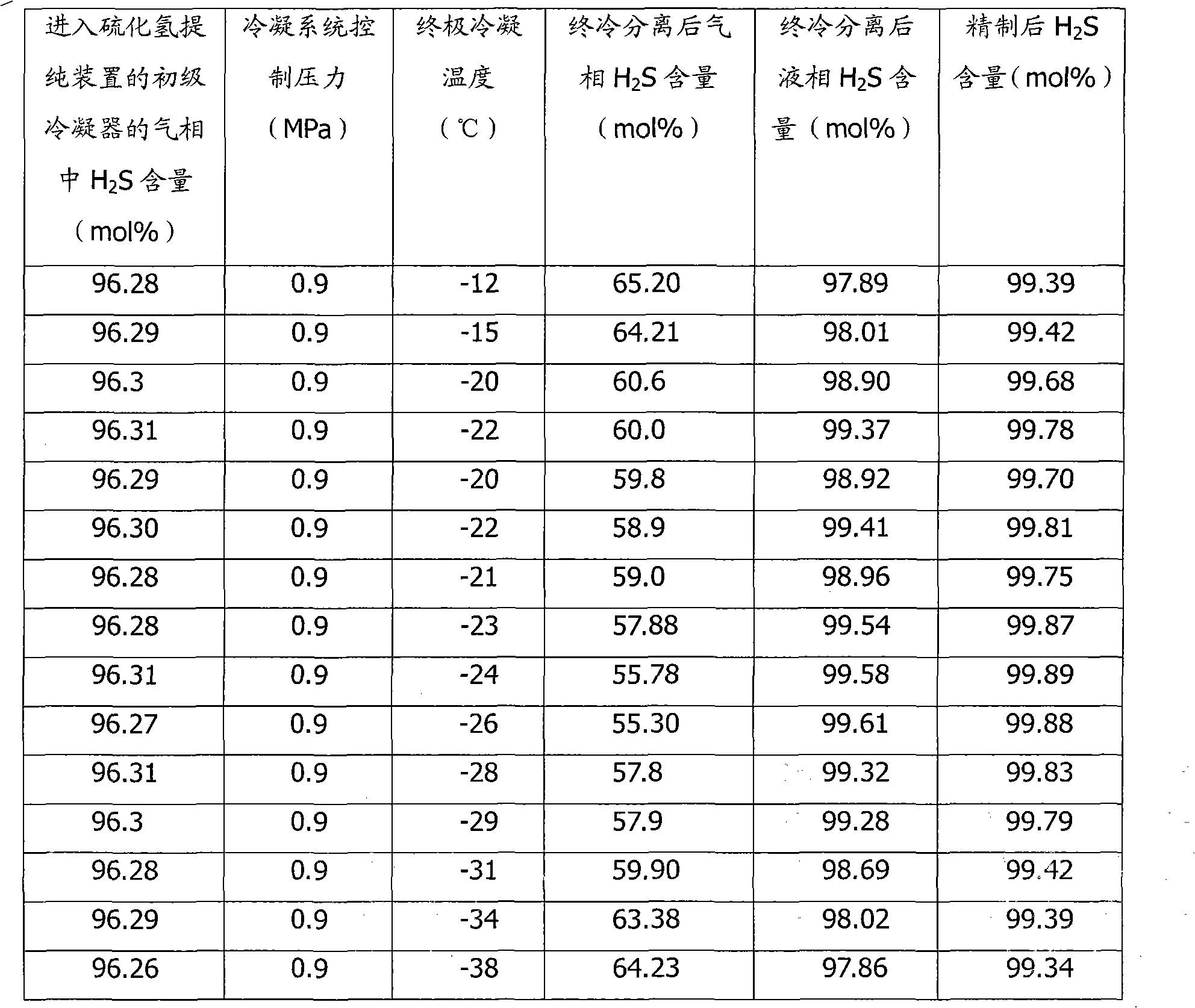

Methods for purifying and comprehensively utilizing hydrogen sulfide byproduct during production of carbon disulfide by methane method

ActiveCN102153053AOvercoming a large number of devicesOvercome stabilityHydrogen sulfidesGas phaseDistillation

The invention relates to a method for purifying a byproduct, namely hydrogen sulfide, during production of carbon disulfide by a methane method, and a method for comprehensively utilizing the byproduct. The method for purifying the byproduct comprises the following steps of: initially separating a mixture of desulfured products through a hydrogen sulfide distillation tower, and further purifying a gaseous phase product; performing two-stage condensation on a gaseous phase distillate at the top of the hydrogen sulfide distillation tower through a primary condenser and an ultimate condenser; and further purifying by using a refining feeding pot and a hydrogen sulfide refining tower so as to finally obtain the high-purity hydrogen sulfide. By adoption of constant-pressure two-level condensation, a lower condensation temperature can be reached to contribute to separation and elimination of inert gases in acidic gases, and the number of sets of equipment is decreased, the safety is enhanced and the equipment investment is reduced at the same time; meanwhile, by the methods, the minimum emission of waste gases and waste liquid during whole purification is realized, so the method is clean and environment-friendly.

Owner:吉林三源化工有限公司

Method for preparing long chain fatty acid polyamide based on catalysis of calcium oxide

InactiveCN102060727ALow priceHigh catalytic activityOrganic compound preparationCarboxylic acid amides preparationLong chain fatty acidOrganic solvent

The invention relates to a method for preparing long chain fatty acid polyamide based on catalysis of calcium oxide, comprising the steps of adding natural oil and organic solvent into a reaction vessel firstly; dropwise adding polyethylene polyamine into the vessel; then adding calcium oxide powder into the vessel while stirring; heating reactant in the vessel; cooling the reactant to room temperature, then filtering the reactant in the container, washing, so as to obtain filtrate; and removing organic solvent in the filtrate by steaming, so as to obtain light yellow waxy solids, namely the long chain fatty acid polyamide. The catalyst in the invention can be easily removed after reaction, thus reducing process difficulty and processing cost and the method has the advantages of being efficient, simple and convenient.

Owner:XI'AN PETROLEUM UNIVERSITY

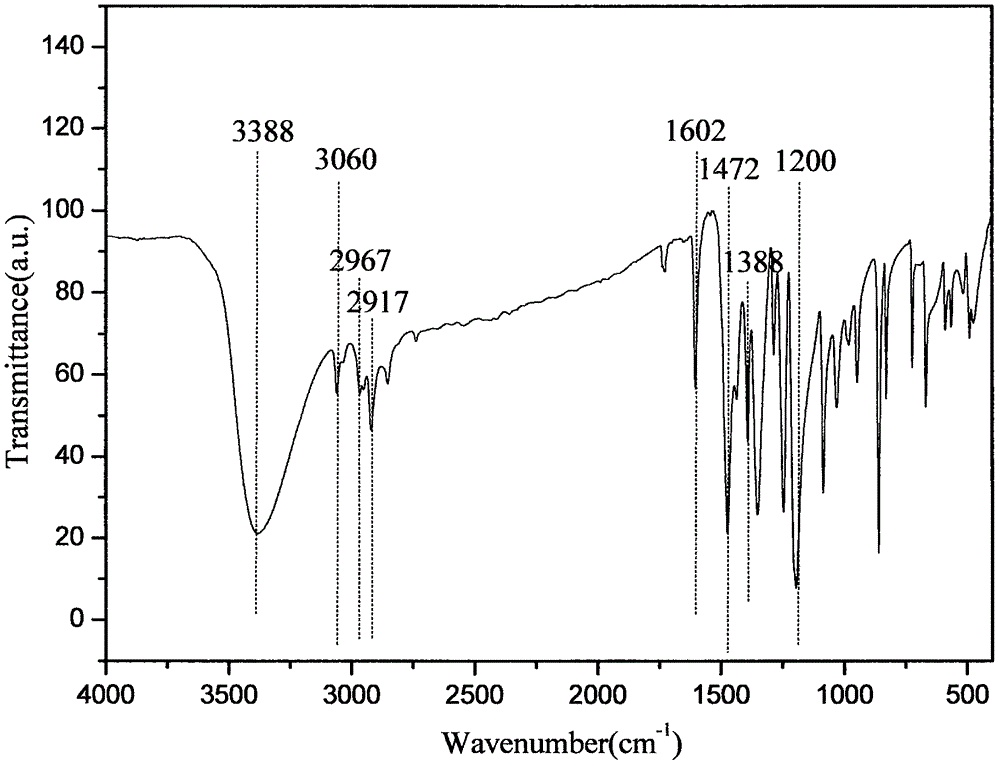

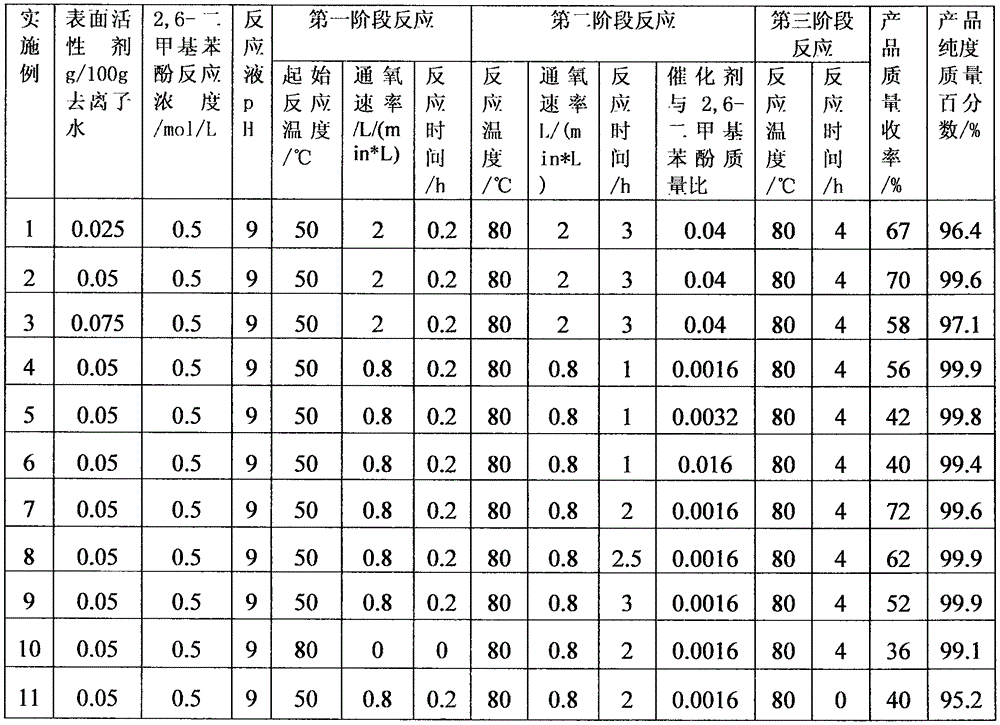

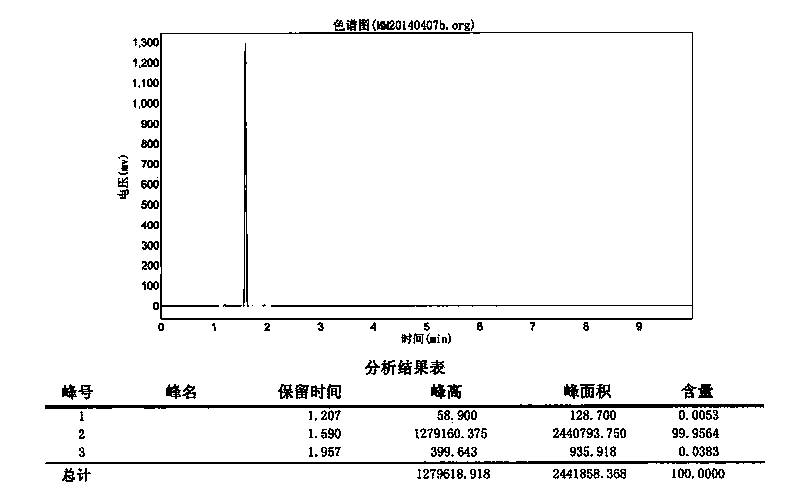

Method for synthesizing high purity 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol

InactiveCN106831350AEasy to separate and removeImprove product quality requirementsOrganic chemistryOrganic compound preparationEpoxyEmulsion

The invention discloses a method for synthesizing high purity 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol. In alkaline emulsion reaction conditions, three stages of combination reactions are performed, 2,6-dimethylphenol is oxidized and coupled into 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol, the 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol is cooled to form a 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol precipitation product in alkaline emulsion, the 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol precipitation product is filtered and washed with water to obtain the high purity 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol product with the product yield of 60-70% and purity mass percent up to 99%, alkaline emulsion filtrate and water washing liquid are recycled after recovery and deployment, a copper salt catalyst is small in amount, soluble in water and easy to remove, and product quality requirements of 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol diglycidyl ether biphenyl epoxy molding compounds in microelectronics industry can be met.

Owner:XIANGTAN UNIV

Method for preparing high-purity high-quality hexamethyldisiloxane

ActiveCN103951692APromote hydrolysis and condensationImprove condensation efficiencySilicon organic compoundsChemical recyclingPtru catalystHydrolysate

The invention discloses a method for preparing high-purity high-quality hexamethyldisiloxane. The preparation method comprises the following steps: (1) dropwise adding trimethylsilyl chloride to a hydrolysis reaction kettle to which water and a condensation catalyst are added in advance, and carrying out heating reflux; (2) layering the product into a demixer after hydrolysis reaction is finished, wherein the condensation catalyst is at the lowest layer and can be separated and recycled; concentrated acid water is at the middle layer, chlorine hydride can be recovered by a hydrochloric acid analysis technology; a hydrolysate at the upper layer is washed with water and neutralized to neutral by using a carbonate solution, an oil phase is separated out of the hydrolysate at the upper layer after the hydrolysate at the upper layer is washed with water for a plurality of times; (3) removing water from the oil phase separated in the step (2) by using a water removal agent, stirring and filtering; (4) fractionating and collecting fraction with the temperature of 99-102 DEG C, so as to obtain the hexamethyldisiloxane of which the purity is greater than 99.9% (mass fraction). The preparation method disclosed by the invention has the advantages that the reaction speed is high, the utilization rate of trimethylsilyl chloride is high and the yield and quanlity of hexamethyldisiloxane are high.

Owner:浙江中天东方氟硅材料股份有限公司

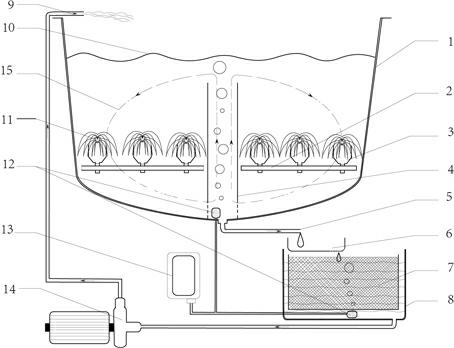

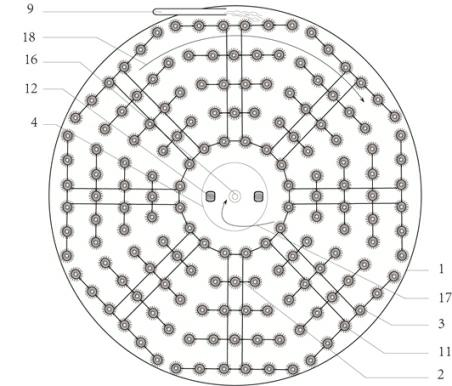

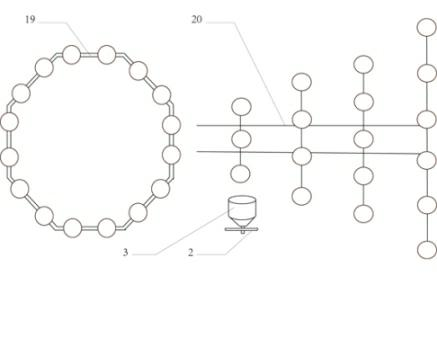

Cultivating method of Sea anemone parents

InactiveCN102550452AEasy to manageImprove hatchabilityClimate change adaptationPisciculture and aquariaGameteMilt

The invention relates to a cultivating method of sea anemone parents, comprising the following steps: collecting sea anemones which are healthy, vigorous, and unharmed, and have complete tentacles and intact foots; placing the anemones in a parent cultivating system to make the anemones spawn and produce milt; collecting fertilized eggs after the gametes being fertilized; and transferring the fertilized eggs to a nursery pond to perform embryo cultivation and breed. According to the invention, the cultivating method of sea anemone parents has advantages that the feeding is convenient to manage, the cultivating method is convenient for long-term cultivation and is easy to observe, the cultivating effect is good, the water is recycled, the fertilized eggs are collected continuously and the like, the technical difficulty that the sinkable fertilized eggs from anemones in a life form collected by digging are hard to collect efficiently is solved, the hatching rate of the fertilized eggs is high, the residual feeds and the undigested residuals are easy to clear away, and the cultivating method has strong operability and good practicability.

Owner:INST OF OCEANOLOGY & MARINE FISHERIES JIANGSU

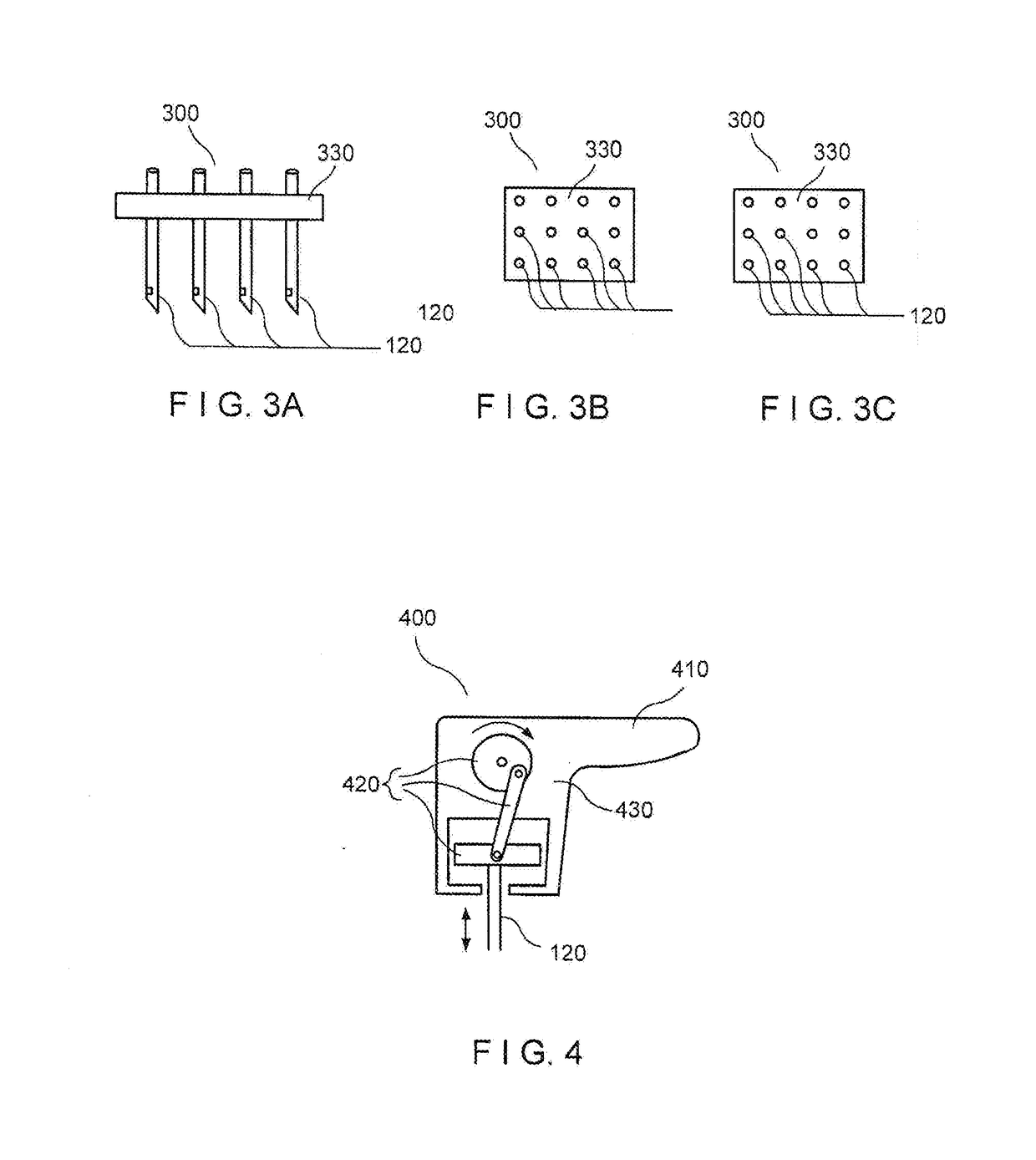

Method and Apparatus for Damage and Removal of Fat

ActiveUS20180193054A1Easy to keepEasy to separate and removeMedical devicesExcision instrumentsSubcutaneous fatty tissueDistal portion

Exemplary embodiments of method and apparatus are provided for damaging and / or removing portions of subcutaneous fatty tissue while leaving the overlying dermal layer of the skin substantially undamaged. One or more hollow needles can be provided that include an arrangement within the lumen configured to retain or damage portions of fatty tissue that enter the lumen. Properties of the needle can be selected such that the needle can be inserted into skin and pass through the dermal layer, allowing fatty tissue to enter the distal portion of the lumen as it is advanced further, and then leaving the dermis undamaged when withdrawn. Such exemplary apparatus can include a plurality of such needles, a reciprocating arrangement to mechanically advance and withdraw the one or more needles, and / or a vibrating arrangement.

Owner:THE GENERAL HOSPITAL CORP

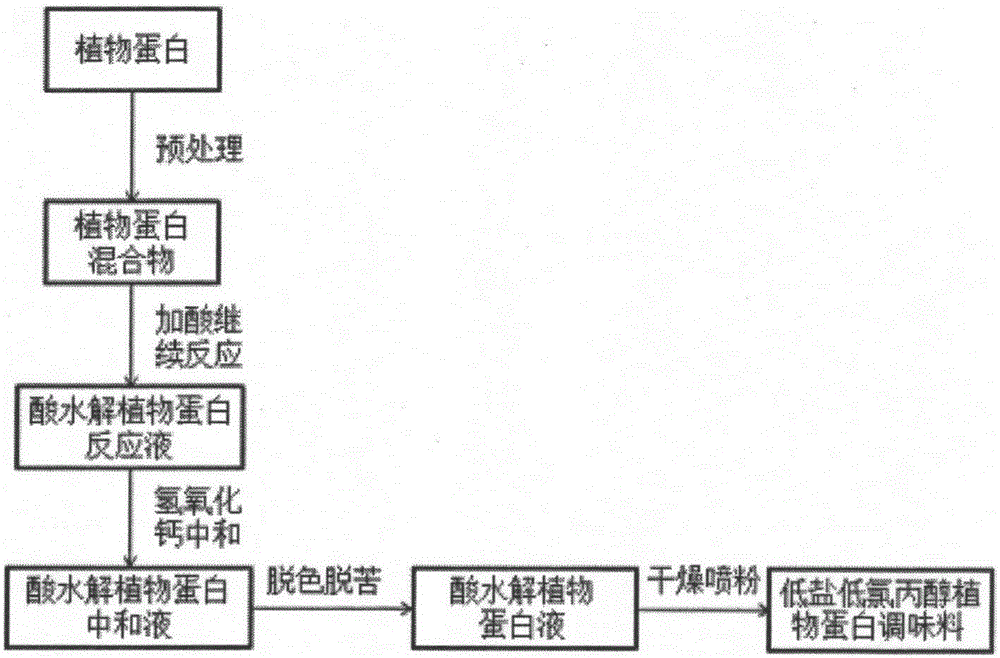

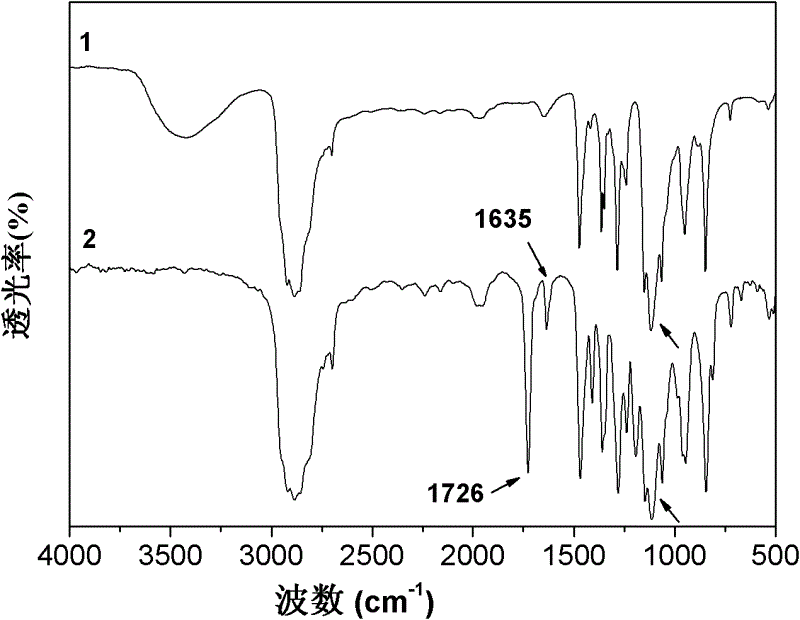

Preparation method of low-salt low-chloropropanol acid hydrolyzed vegetable protein

The invention discloses a preparation method of low-salt low-chloropropanol acid hydrolyzed vegetable protein. The preparation method is characterized by comprising the following steps: pretreating vegetable protein; mixing the pretreated vegetable protein and a sulfuric acid solution and performing acid hydrolysis; neutralizing the hydrolysate with calcium hydroxide, removing color and removing bitterness to obtain acid hydrolysis vegetable protein liquid; spray-drying the acid hydrolysis vegetable protein liquid to obtain low-salt low-chloropropanol acid hydrolysis vegetable protein seasoning. The preparation method is simple and reliable, and high in hydrolysis degree; the sulfuric acid is neutralized by calcium alkali and the obtained sulfuric acid precipitate is easy to separate and remove, so the salt content of the produced vegetable protein seasoning is greatly reduced as compared with that of the traditional acid hydrolysis vegetable protein seasoning; the acid hydrolysis reaction is conducted by using the sulfuric acid instead of hydrochloric acid and chloride ions are not introduced, so production of chloropropanol is reduced from the source, the chloropropanol content of the produced vegetable protein seasoning is greatly reduced as compared with that of the traditional acid hydrolysis vegetable protein seasoning, and the development tendency of low-salt healthy food is met.

Owner:上海爱普食品工业有限公司

Method for synchronously preparing biodiesel and glycerol carbonate under acceleration action of methanol

InactiveCN103436369AReduce solubilityEasy to separate and removeFatty acid chemical modificationOrganic chemistryBiodieselGlycerol

The invention relates to a method for synchronously preparing biodiesel and glycerol carbonate under the acceleration action of methanol, which comprises the following steps: adding natural grease, dimethyl carbonate and methanol into a reaction kettle, adding alkali into the reaction kettle while stirring, heating while stirring, cooling to room temperature, filtering the reaction product in the reaction kettle, and washing with dimethyl carbonate until the filter residue is white, thereby obtaining a filtrate; evaporating the filtrate to remove excessive dimethyl carbonate and methanol under reduced pressure to obtain a light yellow liquid which is a biodiesel crude product; extracting the biodiesel crude product with methanol 2-3 times, wherein the residue is purified biodiesel; and merging the methanol solution, and evaporating to remove methanol to obtain the glycerol carbonate. The invention solves the problem of glycerol residues in the traditional biodiesel production process, and obtains the glycerol carbonate with high added value, thereby being beneficial to upgrading the biodiesel preparation technique; and the invention enhances the economic benefit of the biodiesel industry, and has the advantages of lower technical difficulty and lower processing cost.

Owner:XI'AN PETROLEUM UNIVERSITY

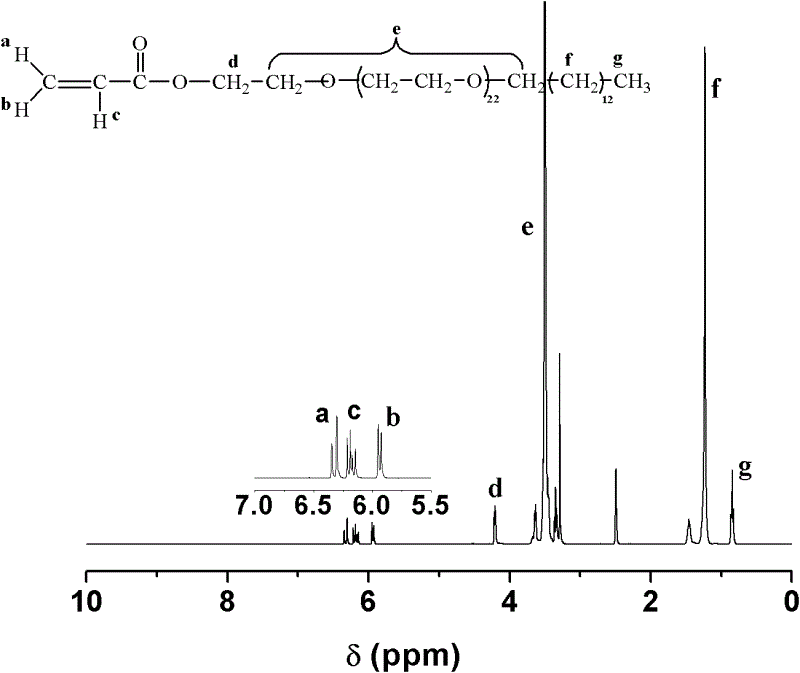

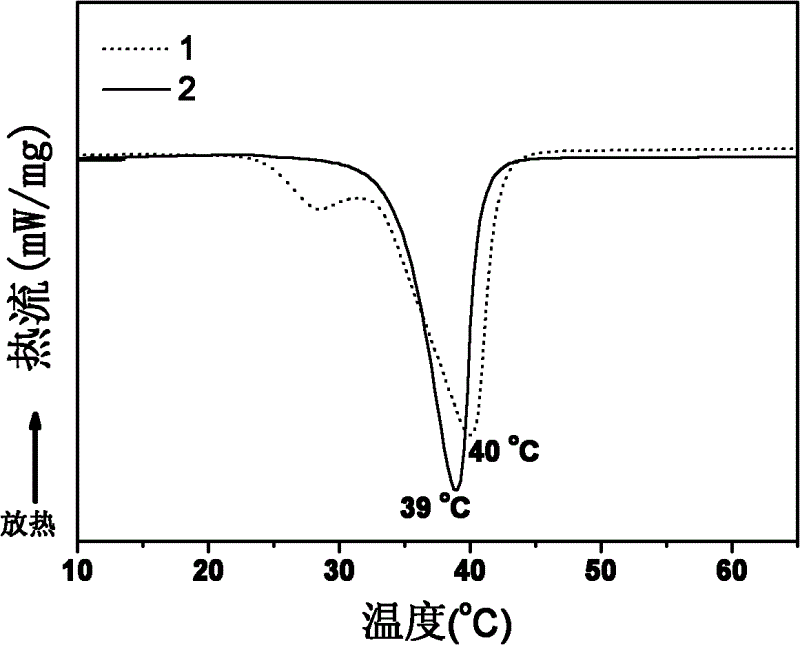

Method for preparing alkyl polyoxyethylene ether acrylate or alkyl polyoxyethylene ether methacrylic ester

InactiveCN102617849AHigh catalytic activity for esterificationHigh yieldOrganic compound preparationTransportation and packagingSolid acidReaction temperature

The invention discloses a method for preparing alkyl polyoxyethylene ether acrylate or alkyl polyoxyethylene ether methacrylic ester. The method includes dehydrating alkyl polyoxyethylene ether by the aid of entrainer at first, adding inhibitor, resin solid acid catalyst and crylic acid or methacrylic ester, heating while controlling reaction temperature to range from 70 DEG C to 120 DEG C, stirring, realizing reaction and removing water generated in the esterification reaction by the aid of azeotropy; and carrying out filtering, and decompressing and distilling filtrate to obtain a target product. During reaction, resin solid acid is used as the catalyst insoluble in a reaction system, is easy to be removed by means of separating solid from liquid after the reaction is completed, and can be reused, accordingly, cost is lowered, and the quality of the product is improved. In addition, the ecologically environment-friendly alkyl polyoxyethylene ether is selectively used as a raw material, and prepared alkyl polyoxyethylene ether acrylic acid (methacrylic acid) ester non-ionic polymerizable surfactant has a fine application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Method for catalytically oxidizing sulfocompound in petroleum product

InactiveCN101962567AIncrease contact areaEasy to separate and removeRefining with oxygen compoundsTreatment with plural serial refining stagesChemistryOil phase

The invention discloses a method for catalytically oxidizing sulfocompound in a petroleum product. The method comprises the following steps of: 1, forming a reaction system by using a catalyst, the petroleum product and an aqueous phase and performing reaction under stirring; 2, separating the top layer of oil phase from the reaction system; and 3, recovering. The method has the characteristics of simple process, low catalyst cost, high recovery percent, mild reaction conditions and high conversion rate of the sulfocompound.

Owner:XIAN UNIV OF SCI & TECH

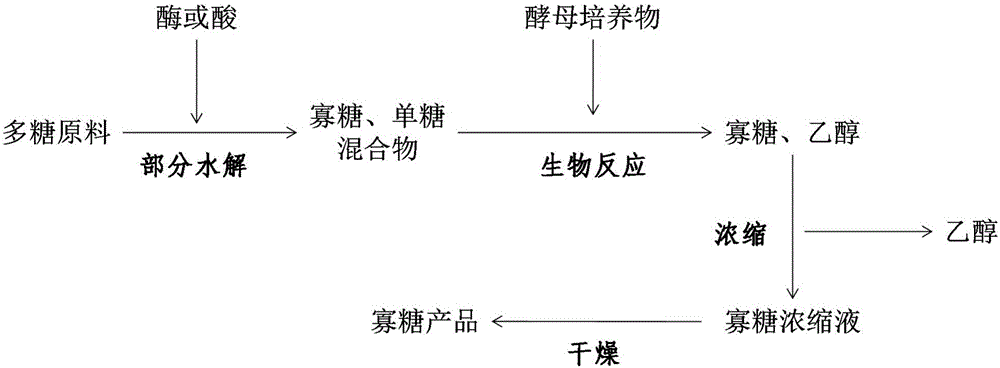

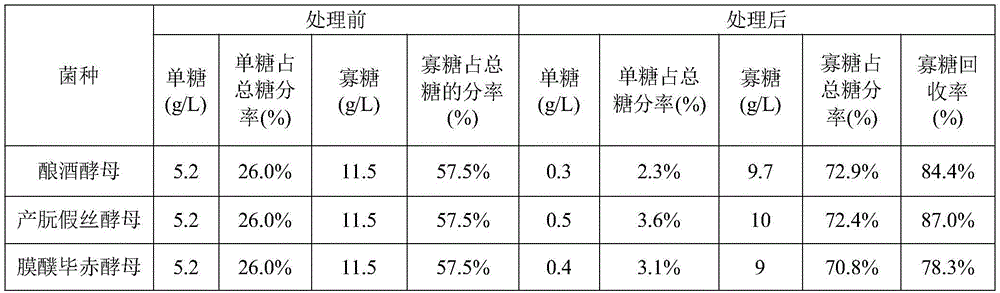

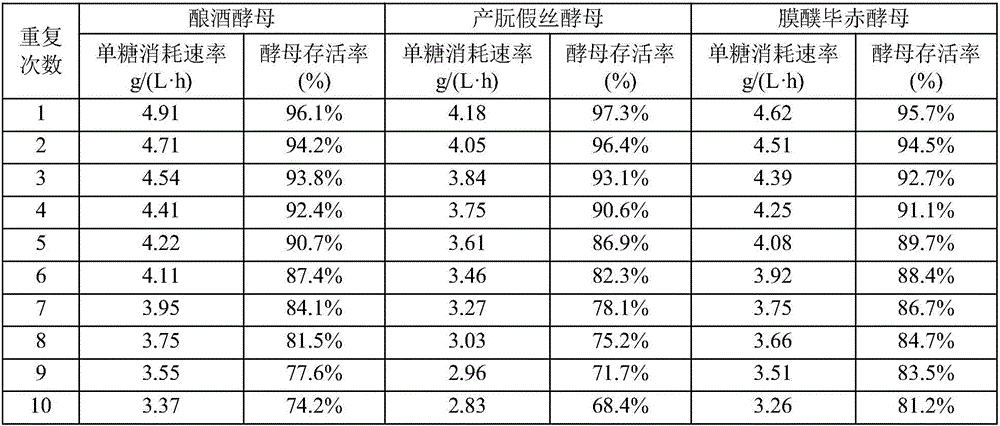

Method for selectively removing monosaccharides and producing oligosaccharides by using yeast culture

InactiveCN105695528AHigh purityReduce extraction costsMicroorganism based processesFermentationHydrolysateOligosaccharide

The invention discloses a method for selectively removing monosaccharides and producing oligosaccharides by using a yeast culture, belonging to the technical field of bioengineering. Since the oligosaccharides and monosaccharides have small differences in physical properties, the conventional separation process can not easily separate the monosaccharides and oligosaccharides. After the polysaccharides are partially hydrolyzed, the obtained hydrolysate contains oligosaccharides and monosaccharides; and in order to obtain the functional oligosaccharides with higher purity, the monosaccharides need to be separated and removed. The microbial reaction is introduced into the biological separation process, the substrate consumption selectivity for the yeast culture is utilized to remove the monosaccharide components and maintain the oligosaccharide components, thereby enhancing the purity of the oligosaccharides and having obvious advantages.

Owner:JIANGNAN UNIV

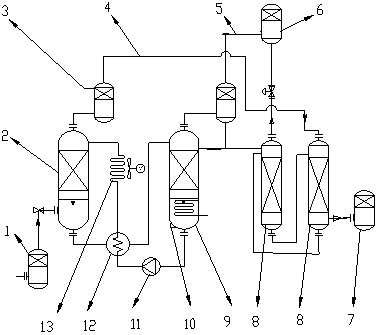

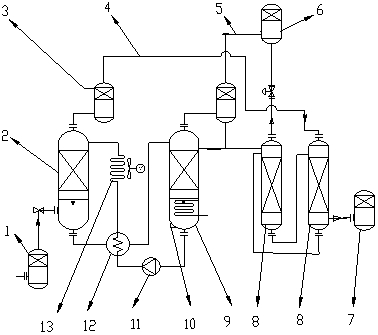

Oil and gas decarburizing and desulfurizing process unit

InactiveCN102527197AEasy to separate and removeImprove recycling efficiencyDispersed particle separationVapor condensationAutomatic controlDesorption

The invention provides an oil and gas decarburizing and desulfurizing process unit which comprises a compressed oil and gas storage tank, a carbon-sulfur gas storage tank, a hydrocarbon storage tank, a primary removal tower, a desorption tower and two refined removal towers, wherein ester absorbers, such as liquid carbonic acid acrylic ester, are stored in the primary removal tower and can absorb carbon-sulfur gas and water, the air pressure in the primary removal tower is 2-20 atmospheres, and the temperature is between 5DEG C and 20 DEG C; the air pressure in the desorption tower is 5-0.2 atmosphere; the refined removal towers contain granular absorbing materials, such as molecular sieve, which can be used for absorbing the carbon-sulfur gas and water, and the carbon-sulfur gas absorbed by the absorbing materials can be completely released to flow into the carbon-sulfur gas storage tank when the absorbing material isheated. The whole technological process or local process can operate under the control of an automatic control system. Two-level adsorption adopted in the unit can better remove the carbon-sulfur gas, water and solid wastes out of the oil and gas to obtain basically pure hydrocarbon gas. The whole unit is compact in line structure and is lower in use and maintenance costs and can be applied to small and medium-sized oil fields.

Owner:SHANGHAI YIJING ENERGY TECH

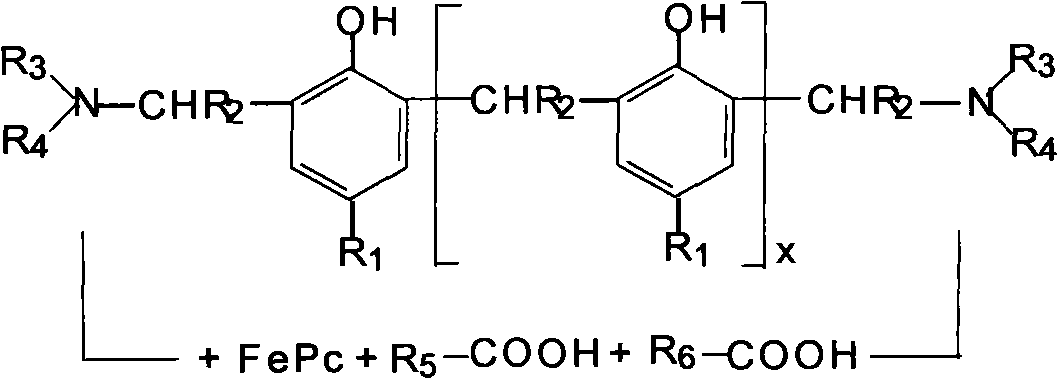

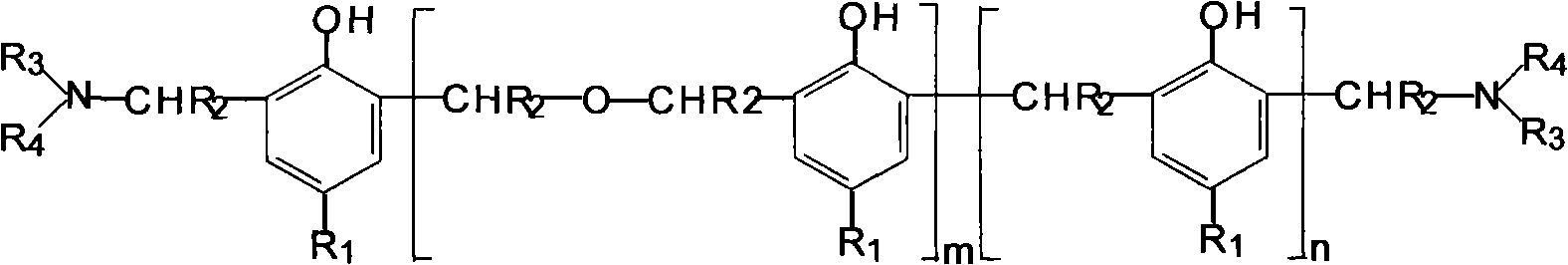

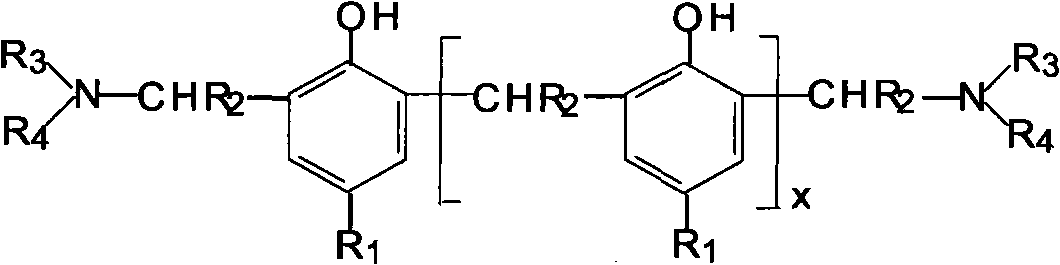

Multifunctional phenolic resin for rubber industry and manufacture method thereof

The invention provides a multifunctional phenolic resin for a rubber industry and a manufacture method thereof. Nitrogen-containing compound is introduced to a condensation resin structure of alkylphenol and aldehyde. Phthalocyanine iron (II), abietic acid, and fatty acid which have chemical peptized activity and contained in rubber are improved so that rubber peptization is improved and the rubber has the best self-adhesive property and retainability.

Owner:RACHEM CHINA CO LTD

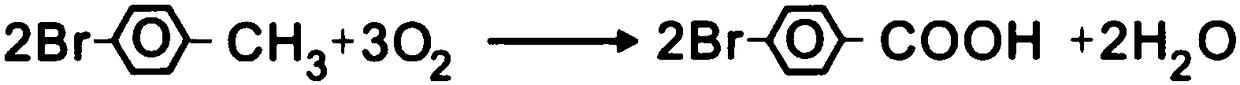

Method for preparing 4-bromobenzoic acid

InactiveCN108558636AHigh yieldHigh purityOrganic compound preparationCarboxylic compound separation/purificationAcetic acidBromobenzoic Acids

The invention relates to a method for preparing 4-bromobenzoic acid and belongs to the technical field of compound production and preparation. The method comprises the following steps: by taking bromotoluene as an initial raw material, glacial acetic acid as a solvent and oxygen as an oxidant, carrying out catalytic oxidation on parabromotoluene by using a liquid-phase oxidation method under the action of a catalyst, controlling a reaction temperature to 75-85 DEG C, terminating the reaction when the content of the parabromotoluene in the reaction system accounts for 0.5wt% of an initial content, cooling, filtering so as to obtain a crude product and filtrate of 4-bromobenzoic acid, and further purifying the crude product of the 4-bromobenzoic acid at one step, thereby obtaining a finishedproduct. The melting point of the finished product of the 4-bromobenzoic acid is 252-254 DEG C. In addition, the 4-bromobenzoic acid prepared by using the method is high in yield, that is, the yieldis up to 98% or greater, meanwhile, the finished product is high in purity, that is, the purity is up to 99% or greater, the defects that a product prepared by using a conventional preparation methodis low in purity and low in yield can be overcome, and in addition, the method provided by the invention is simple and easy in raw material obtaining, low in cost and wide in application prospect.

Owner:黄石市利福达医药化工有限公司

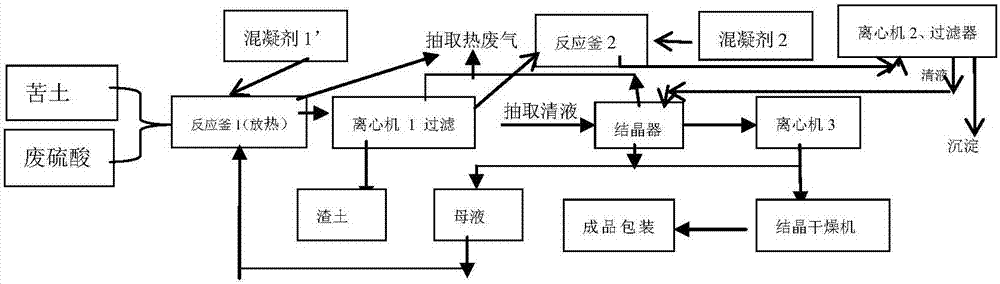

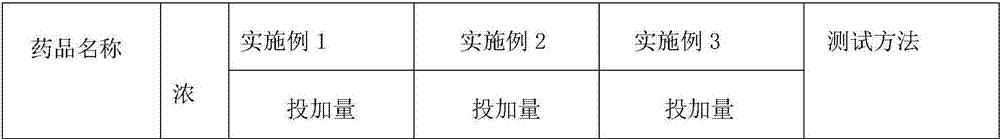

Method for producing magnesium sulfate from colored waste sulfuric acid in ion exchange resin production

ActiveCN107473436ASolve the use problemOvercoming utilizationTreatment involving filtrationMagnesium sulfatesFlocculationNational standard

The invention discloses a method for producing colorless or white magnesium sulfate from colored waste sulfuric acid produced in an ion exchange resin production process and magnesia powder through a reaction, wherein the waste sulfuric acid is black and yellowish-brown, the mass percentage concentration is 20%-80%, and the average chroma is 400-1000 times / water; the magnesia powder contains 75%-91% by weight of magnesia. According to the method, on the premise that the conventional magnesium sulfate production equipment and process are basically unchanged, organic and inorganic substances capable of effectively changing colloidal particle potential E of coloring substances (colloidal organic substances) of the waste sulfuric acid are introduced to form a coagulant, so that sulfuric acid coloring substances react with the coagulant, flocculation and precipitation are produced, the coloring substances are separated and removed conveniently, and the colorless or white magnesium sulfate product is produced. Sulfonated colored waste sulfuric acid in ion exchange resin production can be conveniently used for preparing the magnesium sulfate product meeting national standards, waste is changed into wealth by means of comprehensive utilization, COD in waste sulfuric acid liquid can be reduced substantially, the COD in the waste acid is reduced by 80%, and environmental pollution is reduced.

Owner:JIANGSU JIANYA ENVIRONMENTAL PROTECTION TECH CO LTD

Method and composition for removing coatings which contain hazardous elements

InactiveUS6969303B1Easy to separate and removeAvoid environmentGrinding machinesAbrasive machine appurtenancesAluminium sulfateCalcium silicate

A method for removing a coating on a surface by applying a treatment composition layer to the coating to be removed. The treatment composition layer is made up of (Is) a first material selected from the compounds of sodium and potassium silicates, sodium and potassium phosphate, calcium silicate, iron and aluminum sulfates. An abrasive is injected against the coating to be removed so that the treatment composition layer and coat to be removed are removed and any hazardous material in the layer to be removed is contained.

Owner:NEXTEC INC

Walnut-oil refining technology

InactiveCN108192727AEasy to removeEasy to separate and removeFatty-oils/fats refiningPhosphoric acidEdible oil

The invention relates to the field of edible oil refining, and discloses a walnut-oil refining technology. The walnut-oil refining technology is characterized by including the steps that walnut crudeoil prepared through physical squeezing or chemical extraction is filtered, impurities are removed, peptized impurities in the walnut crude oil are removed through phosphoric acid, alkali liquid is added into the walnut crude oil after degumming, alkali refining is carried out, then degummed oil after alkali refining is separated through a centrifugal machine, an emulsified material is removed, and alkali refining oil is prepared; the alkali refining oil is washed two times, the alkali refining oil after secondary washing is led into a vacuum drier and dehydrated, and dried oil is prepared; the dried oil is led into a filtering machine, carclazyte and filter aid are added and used for decolorizing, decolorized oil is prepared through filtering, and finished product oil is prepared. By means of the walnut-oil refining technology, the problems that an existing walnut-oil preparing refining technology is incomplete, and the peptized substances and other impurities in the walnut crude oilcannot be well removed are solved.

Owner:洛阳康贝源食品股份有限公司

Supersonic pre-treatment process of refractory gold ore containing As.S. etc.

InactiveCN1194109CEasy to separate and removeEasy cyanide percolation extractionProcess efficiency improvementCavitationSulfur

A technological process of the present invention includes: soaking the gold ore to be treated in alkali water aqua in a reaction container; setting the container in a focusing type supersonic function tank; regulating the focusing supersonic head to frequency 40-55 kHz and irradiation period 40-90 min; changing the alkali soaking liquid into alkali oxidizing soaking liquid; and regulating the focusing supersonic head to frequency 55-70 kHz and irradiation period 100 min. The present invention has the obvious advantages of easy separation of As, S and other components in supersonic cavitation effect, short treatment period, low cost, etc.

Owner:严卓理 +2

Method for synchronously preparing biodiesel and glycerol carbonate under acceleration action of methanol

InactiveCN103436369BReduce solubilityEasy to separate and removeOrganic chemistryFatty acid chemical modificationBiodieselGlycerol

Owner:XI'AN PETROLEUM UNIVERSITY

Dicofol residue rapid detection method and kit thereof

ActiveCN107941793AImprove color renderingHigh sensitivityMaterial analysis by observing effect on chemical indicatorSolid phasesChemistry

The invention discloses a dicofol residue rapid detection method and a kit thereof. The dicofol residue rapid detection method comprises the following steps: extracting a sample, extracting a solid phase, after extracting a sample extract through a solid-phase extraction column, eluting the sample extract by an eluate, adding 2,2-dipyridine, a strong alkaline solution and tetramethylammonium hydroxide in the eluted eluate, and performing a chromogenic reaction and colorimetric determination to obtain the dicofol amount. According to the invention, sample detection can be completed by only 20 min, dipyridine having the characteristics of odorlessness and safety is taken as a reaction developer, and an experiment method realizes green environmental protection; tetramethylammonium hydroxide is added as a reaction catalyst, so that the chromogenic reaction can be completed in two minutes, and the chromogenic effect is enhanced; the method determines the dicofol content by comparing the colors, sensitivity is high, and the method can be widely used for rapidly detecting dicofol in samples such as vegetables, fruits, and tea.

Owner:GUANGDONG DAYUAN OASIS FOOD SAFETY TECH CO LTD +1

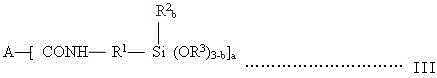

A kind of synthesis technique of alkoxysilane containing amide group

ActiveCN102786546BSynthetic fitAvoid corrosionGroup 4/14 element organic compoundsPolymer sciencePtru catalyst

The invention provides a process for synthesizing amidoalkylalkoxysilane. Carboxylate and aminoalkylalkoxysilane are used as raw materials for heating and reflux reaction. If necessary, sodium alkoxide can be added as a catalyst to make amidation reaction between ester and amino group to generate amidoalkylalkoxysilane target product and by-products alcohol. After the reaction is completed, use a small amount of chlorosilane to neutralize the sodium alkoxide catalyst, then distill under normal pressure to remove alcohols and other low boilers, and then distill under reduced pressure to remove unreacted high boiling point raw materials. The conversion rate of the target product can reach more than 90%, and the by-product alcohol in the process will not hydrolyze the alkoxy silicon groups in the raw materials and products. The target product can also be further purified by rectification, and can be used as a coupling agent, a crosslinking agent, or a monomer for synthesizing silicone resin.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

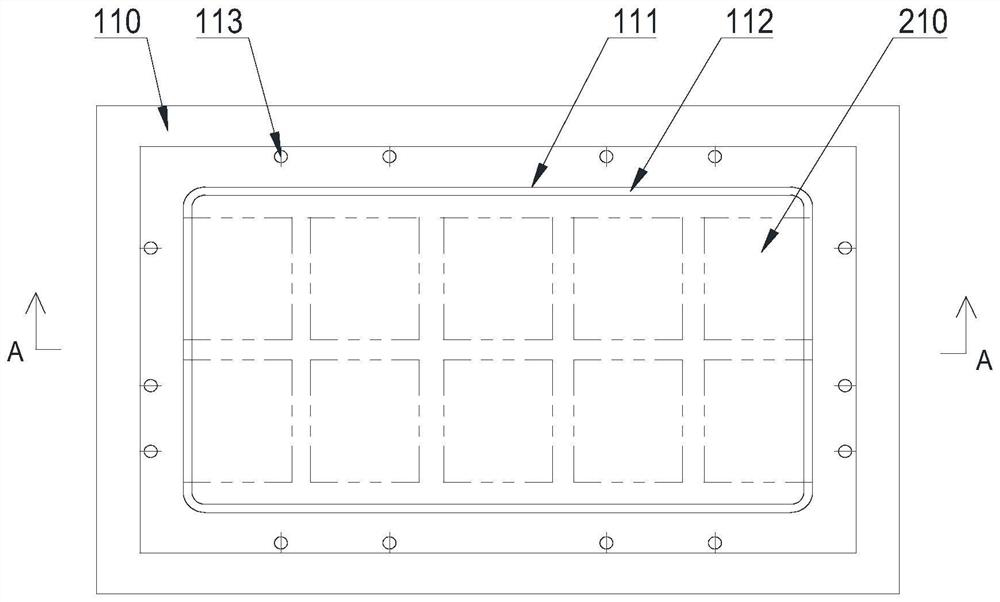

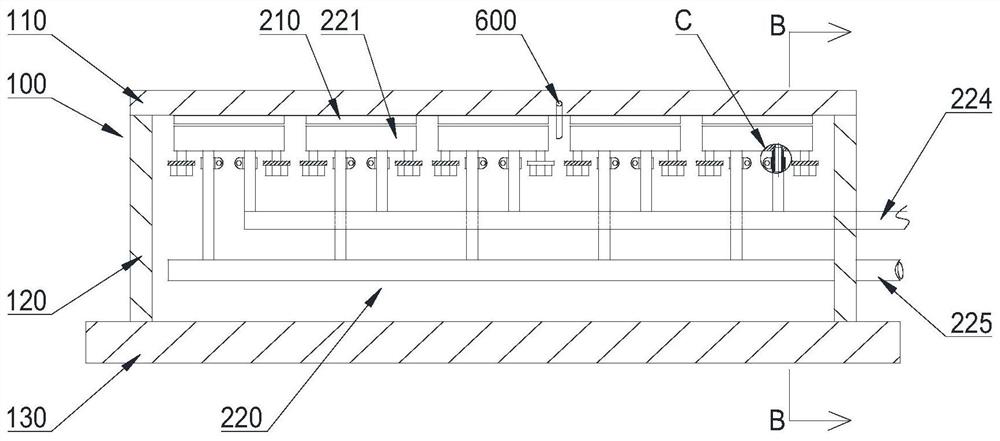

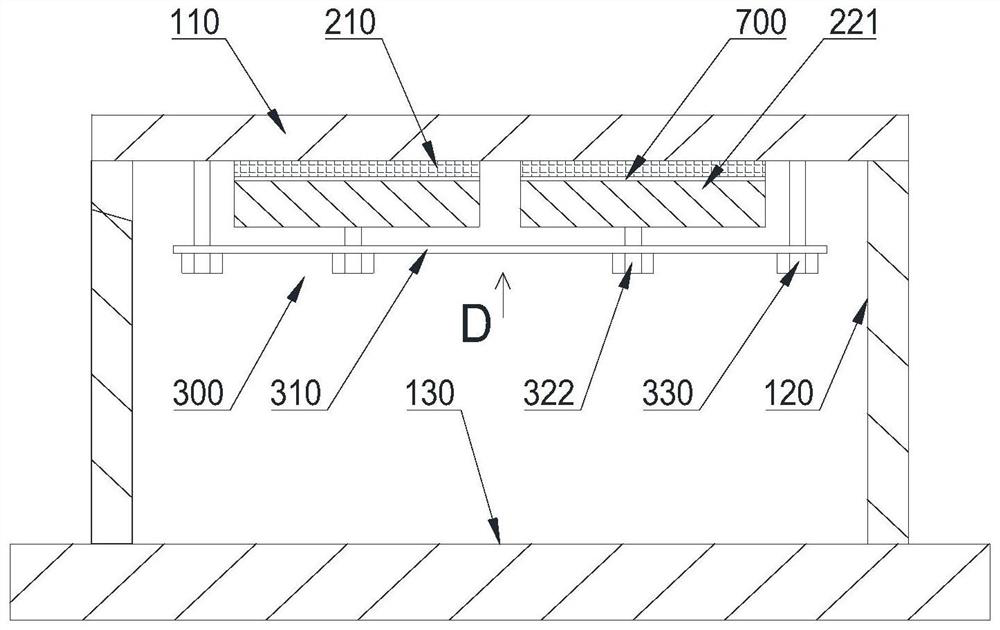

Thin-wall weak-rigidity part machining and fixing method and temperature control machining platform

PendingCN112008459ARealize high-precision adjustmentRealize cooling and heatingMachine tool componentsMachines using electric/magnetic effectsTemperature controlMachine parts

The invention discloses a thin-wall weak-rigidity part machining and fixing method and a temperature control machining platform. The temperature control machining platform comprises a platform frame body; a panel is arranged on the upper part of the platform frame body; and a refrigerating and heating assembly is fixedly installed below the panel; the refrigerating and heating assembly comprises arefrigerating sheet set and a heat dissipation device; the refrigeration sheet set comprises at least one semiconductor refrigeration sheet; the semiconductor refrigeration sheet is tightly attachedto the lower surface of the panel and can switch between a refrigeration mode and a heat dissipation mode; the heat dissipation device is tightly attached to the lower surface of the semiconductor refrigeration plate and is used for dissipating heat generated by the semiconductor refrigeration plate in the refrigeration mode. According to the method, the temperature of a bonding agent is adjustedthrough a semiconductor refrigeration plate; and when the bonding agent is solidified or softened, a machined part can be fixedly connected to the platform in a natural state, the connection speed ishigh, no extra stress is generated, stress resilience can be effectively avoided, and the machined part can be conveniently separated and taken down from the platform after the bonding agent is softened and thinned.

Owner:湖北三江航天江北机械工程有限公司

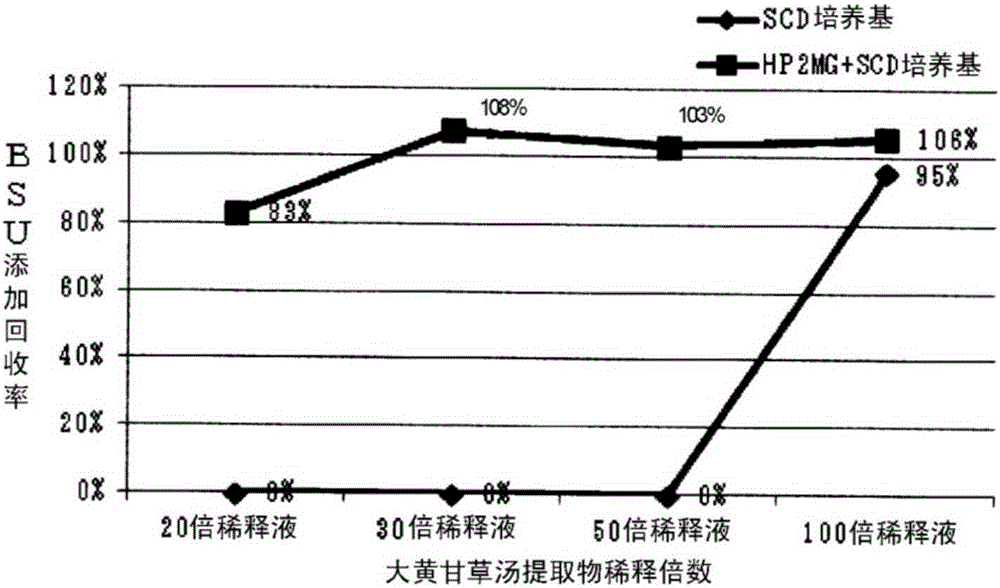

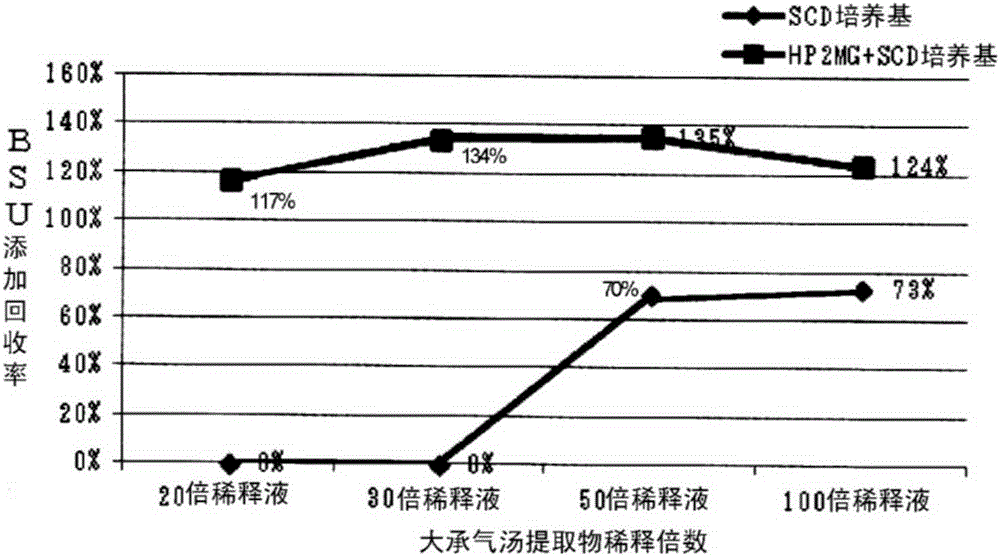

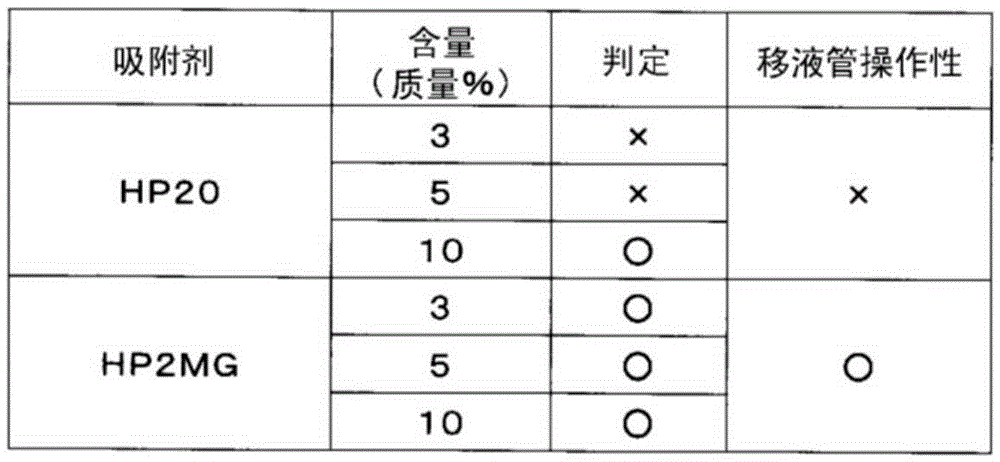

Microorganism detection method

ActiveCN105324490AAccurate identificationEasy to separate and removeSamplingMicrobiological testing/measurementMicroorganismMeth-

Owner:TSUMURA

Method for synchronously preparing biodiesel and glycerol carbonate by using alkali-earth oxide as catalyst

ActiveCN103436368BLow priceHigh catalytic activityFatty acid chemical modificationBiofuelsSolubilityBiodiesel

Owner:玉门祥天新能源产业发展有限公司

Method for treating copper drawing waste fluid with hydrothermal process

ActiveCN108048201ASimple stepsImprove processing efficiencyWater/sewage treatment by centrifugal separationSpecific water treatment objectivesThermal insulationOperability

The invention particularly relates to a method for treating a copper drawing waste fluid with a hydrothermal process. The method comprises following steps: step (1) heating and thermal insulation: thecopper drawing waste fluid is taken and added to a hydrothermal reaction kettle, a copper corrosion inhibitor is added, a thermal insulation sealed reaction is performed, the heating temperature is controlled at 80-200 DEG C, and the thermal insulation reaction time is 1-10 h; step (2) copper removal: the copper drawing waste fluid subjected to thermal insulation treatment is transferred to a centrifugal separator, centrifugal separation is performed on liquid and solid phases, and a liquid phase is obtained; step (3) measurement of oil phase content; step (4) adjustment and recycling: a proper oil phase or water phase is supplemented, so that the mass percentage of the oil phase in the copper drawing waste fluid without copper is adjusted to the required concentration, and then, the copper corrosion inhibitor is supplemented. By means of the method for treating the copper drawing waste fluid with the hydrothermal process, 95% or above of copper ions can be removed, the treatment efficiency is high, zero emission and recycling are realized, the process is simple, the operability is high, and the method is suitable for large-scale popularization and application and has great significance in environmental protection.

Owner:NORTHWEST UNIV(CN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com