Oil and gas decarburizing and desulfurizing process unit

A desulfurization process, oil and gas technology, applied in steam condensation, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as poor effect, high energy consumption, complex system, etc., achieve low equipment maintenance costs, convenient operation and management, Effect of High Recovery Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

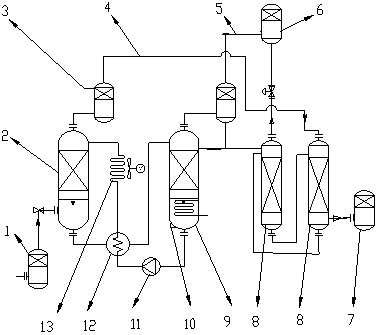

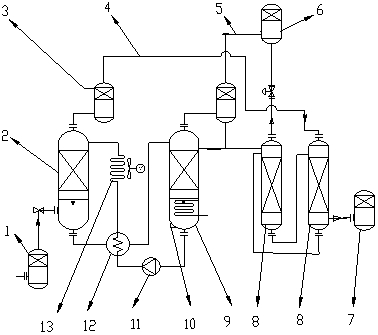

[0028] As shown in the accompanying drawings, the device contains a compressed oil and gas storage tank 1, a carbon and sulfur gas storage tank 6, a hydrocarbon storage tank 7, an initial stripping tower 2, and a desorption tower 9, and also contains two fine stripping towers 8; the initial stripping tower There is liquid methyl carbonate acrylate absorbent in 2, the air pressure in the first stripping tower 2 is 5-10 atmospheric pressure, also contains the temperature control device 13 of absorbent in the early stripping tower 2, keeps the temperature of absorbent to be 5-10 The top of the first stripping tower 2 has an outlet A to connect to the fine stripping tower 8, and the first stripping tower 2 has another outlet B for the absorbent that has absorbed carbon and sulfur gas and moisture to flow into the desorption tower 9. The air pressure in the desorption tower 9 is a negative pressure of 0.8-0.3 atmospheric pressure, and the top of the desorption tower 9 has an outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com