Methods for purifying and comprehensively utilizing hydrogen sulfide byproduct during production of carbon disulfide by methane method

A carbon disulfide and purification method technology, applied in the direction of hydrogen sulfide, etc., can solve the problems of large number of equipment, high investment cost, unstable operation, etc., and achieve the effect of reducing the number of equipment, reducing leakage points, and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

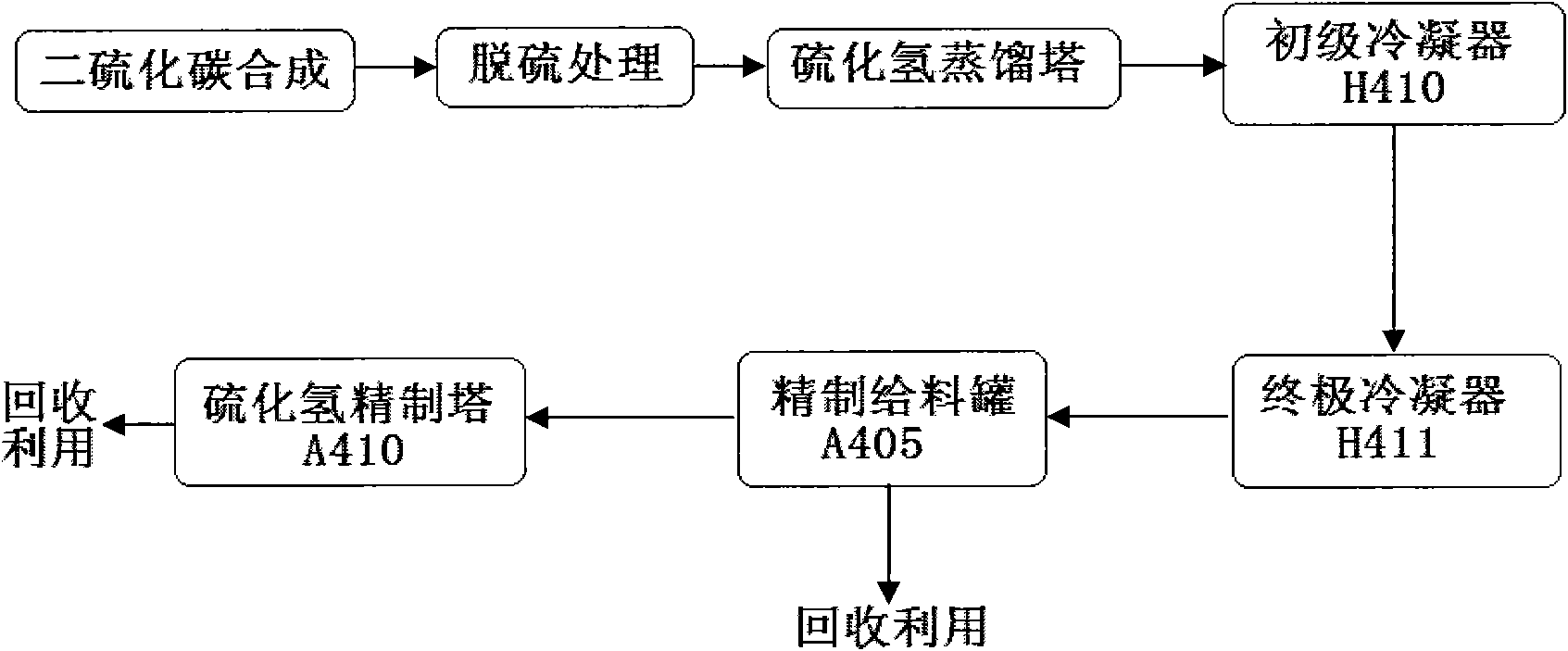

[0039] The product obtained by the reaction of natural gas with methane and ethane as the main components and sulfur is first desulfurized, and then the mixed material after sulfur removal is passed into the hydrogen sulfide distillation tower A-401 for CS 2 and H 2 Preliminary isolation of S. The bottom distillate is CS 2 The product, the overhead distillate is H with a purity of 93-97% 2 S gas.

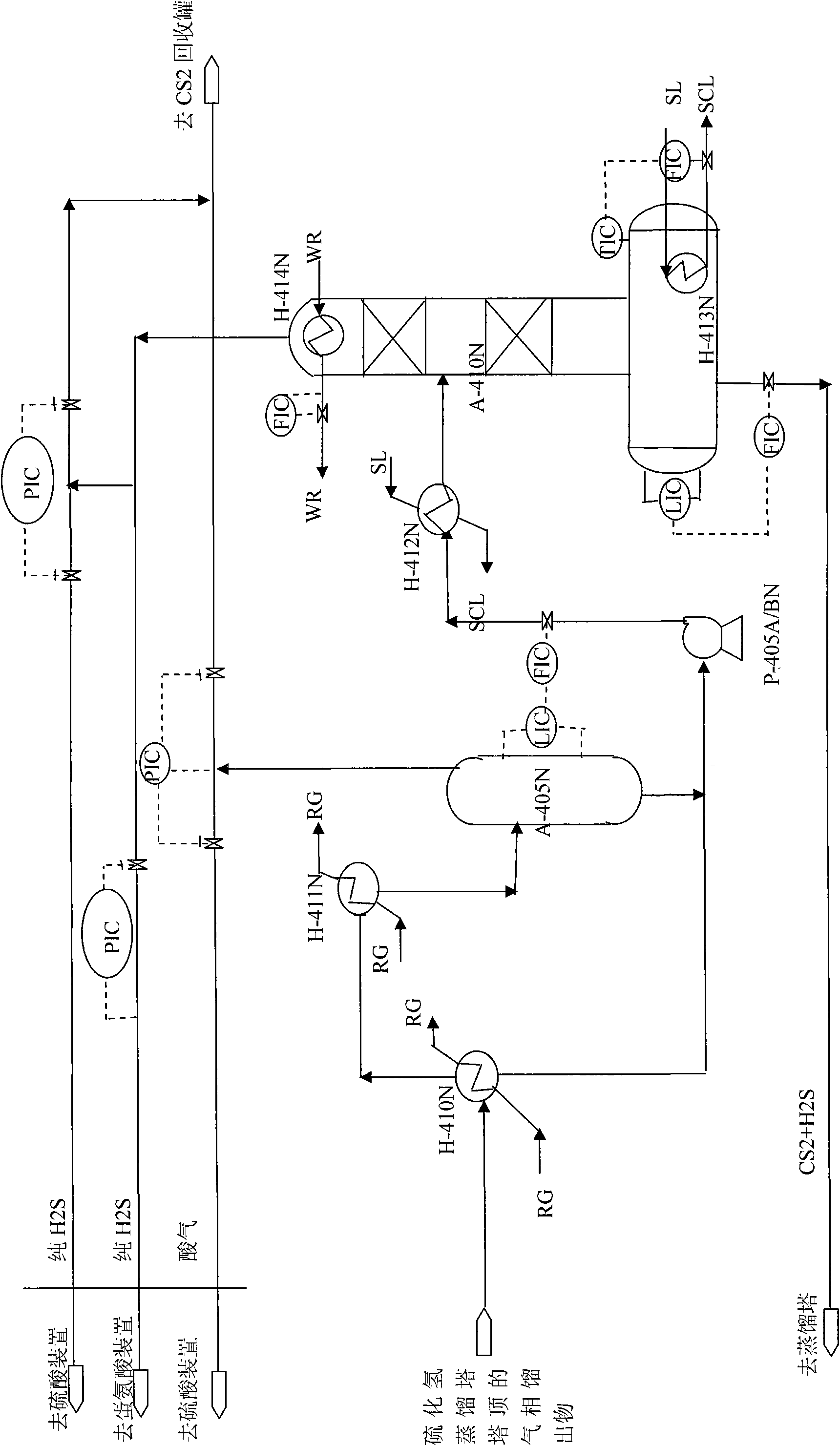

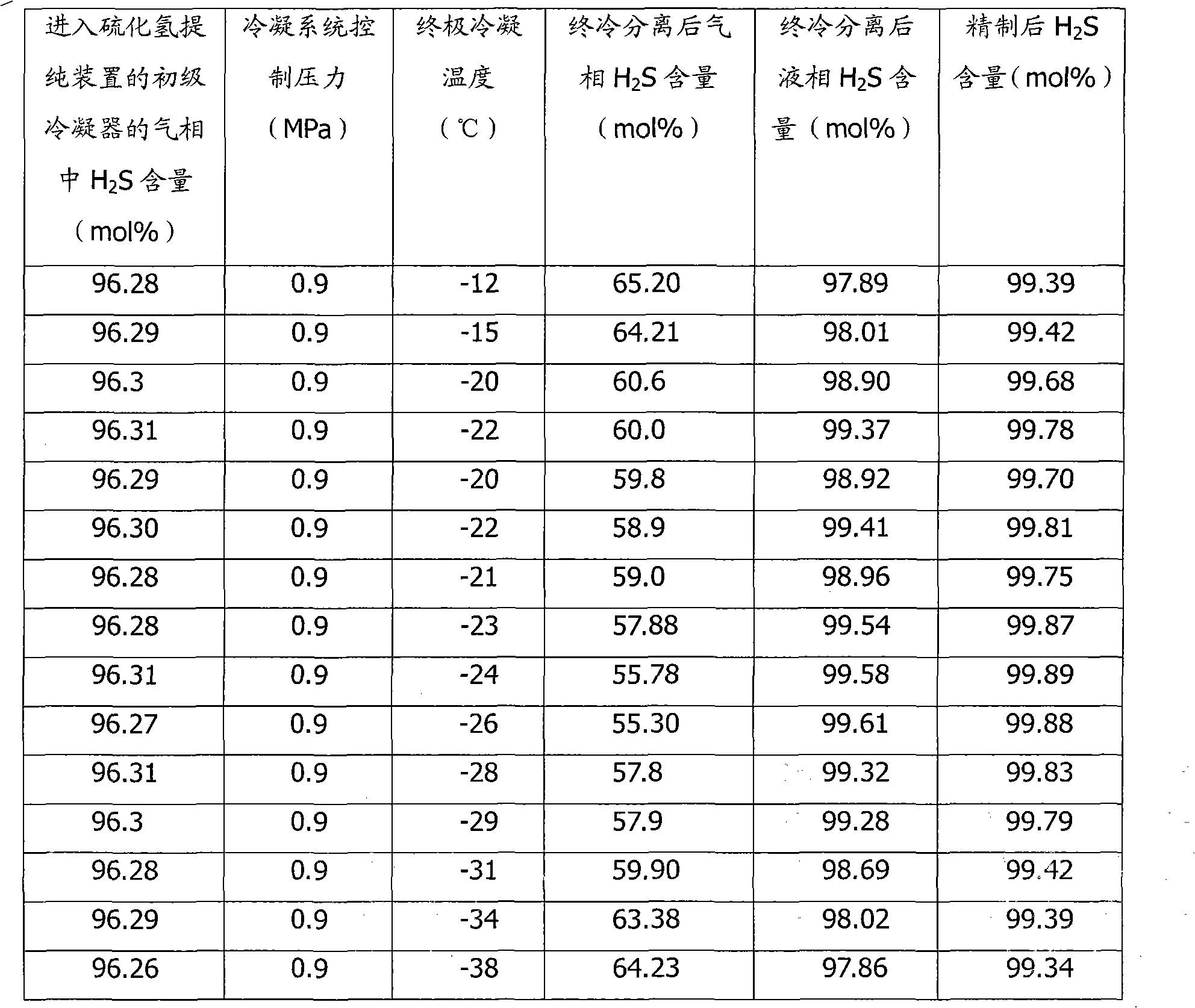

[0040] refer to figure 1 As shown, the gas phase mixture obtained from the top of the hydrogen sulfide distillation column A-401 is partially condensed in the primary condenser H-410, and the liquid phase H 2 S flows into the inlet of the refined feed pump P-405A / B located at the bottom of the refined feed tank A-405 through the refined feed pump P-405A / B, and the gas phase flows into the final condenser H-411 for further condensation, and all condensed materials Sent to the refining feed tank A-405 to separate inert gases such as methane and nitrogen, wherein the condensed liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com