Rubber material containing phenolic tackifying resin

A technology for tackifying resins and rubber materials, which is applied in the field of rubber materials containing phenolic tackifying resins. It can solve the problems of trapping air and affecting the quality of finished products, and achieve the effects of slow migration speed, improved physical and mechanical properties, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

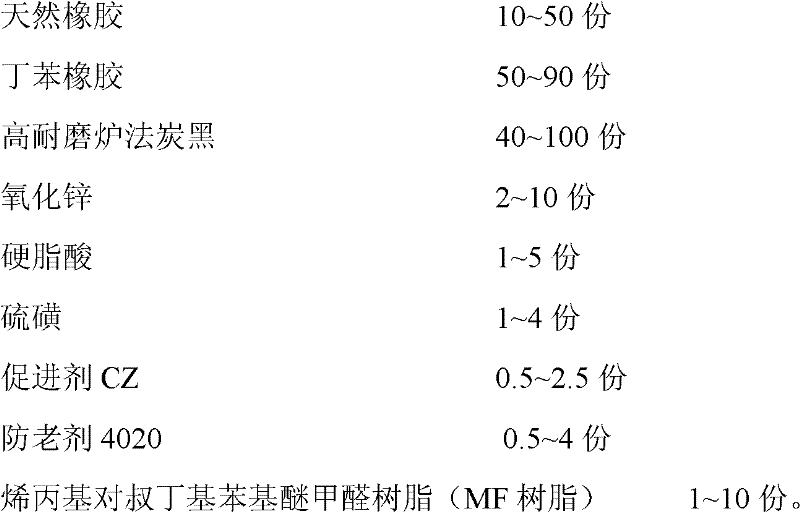

Method used

Image

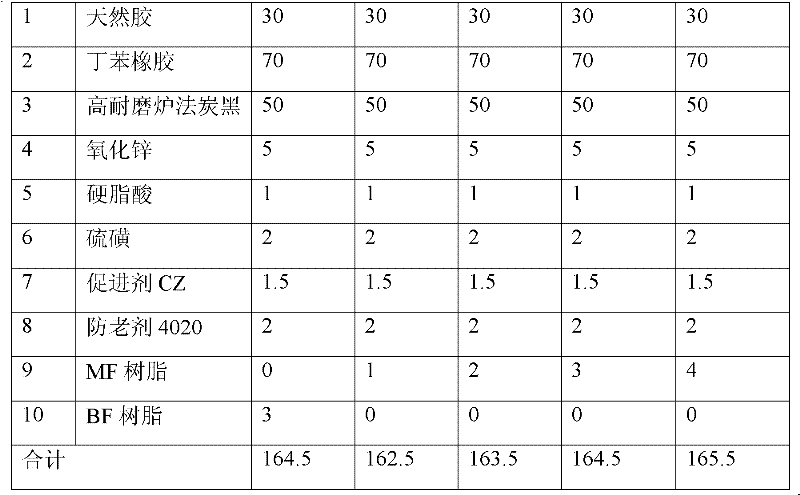

Examples

Embodiment 1

[0014] Mix p-tert-butylphenol and formaldehyde in a molar ratio of 1:1, heat up to 90°C to dissolve it completely, add hydrochloric acid until the reaction boils for 3 hours, dissolve with toluene, wash with hot water until neutral, and press The resin and allyl chloride were mixed at a molar ratio of 5:1, dissolved in ethanol, and 1M potassium hydroxide solution was added to adjust the pH to 10. After heating for 30min, extract with toluene, add 0.5M hydrochloric acid for washing, and let stand for stratification. , the upper layer was washed with distilled water to pH 7, and allyl-p-tert-butylphenyl ether formaldehyde resin was obtained after distillation under reduced pressure, the yield was 89%, and the purity was 98.2%.

Embodiment 2

[0016] Mix p-tert-butylphenol and formaldehyde in a molar ratio of 1:1, heat up to 100°C to dissolve it completely, add hydrochloric acid to the reaction and boil for 4 hours, dissolve with toluene, wash with hot water until neutral, and press the obtained resin according to The resin and allyl chloride were mixed at a molar ratio of 4:1, dissolved in ethanol, and 1M potassium hydroxide solution was added to adjust the pH to 10. After heating for 60min, extract with toluene, add 0.5M hydrochloric acid for washing, and let stand for stratification. , the upper layer was washed with distilled water to pH 7, and allyl-p-tert-butylphenyl ether formaldehyde resin was obtained after distillation under reduced pressure, the yield was 91%, and the purity was 98.5%.

Embodiment 3

[0018] Mix p-tert-butylphenol with formaldehyde in a molar ratio of 1:1, heat it up to 120°C to dissolve it completely, add hydrochloric acid to the reaction and boil for 4 hours, dissolve with toluene, wash with hot water until neutral, and press The resin and allyl chloride were mixed in a molar ratio of 2:1, dissolved in ethanol, and 1M potassium hydroxide solution was added to adjust the pH to 10. After heating for 60min, extract with toluene, add 0.5M hydrochloric acid for washing, and let stand for stratification. , the upper layer was washed with distilled water to pH 7, and allyl p-tert-butyl phenyl ether formaldehyde resin was obtained after distillation under reduced pressure, the yield was 89.5%, and the purity was 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com