Vehicle flame-retardant sound-insulation noise-reduction rubber pad and preparation method thereof

A rubber pad and noise reduction technology, applied in the rubber field, can solve the problems of inability to achieve damping and noise reduction, low density and electrical conductivity, sound insulation, and metal weight is not conducive to weight reduction, etc., to improve anti-aging performance and improve tear resistance. , the effect of large activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with examples.

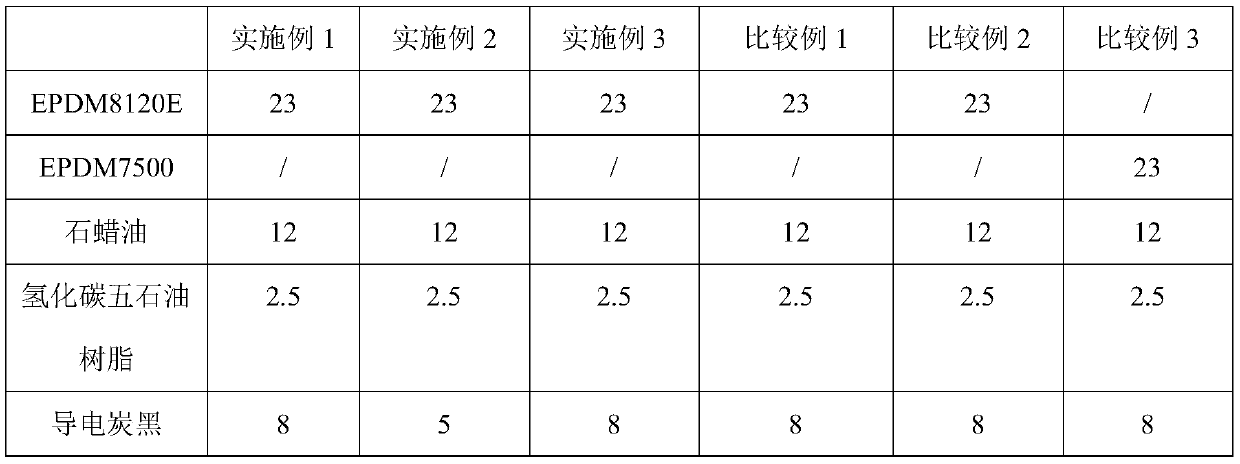

[0019] The raw materials and weight percentages of the flame-retardant sound-insulating and noise-reducing rubber mats for vehicles in each embodiment and comparative example are shown in Table 1.

[0020] Table 1

[0021]

[0022]

[0023] The raw materials of the flame-retardant and sound-proof and noise-reducing rubber mats for vehicles in each embodiment and comparative example were mixed according to the formula, compacted in an internal mixer, and then extruded into sheets through a screw extruder, and cut into Specifies the shape.

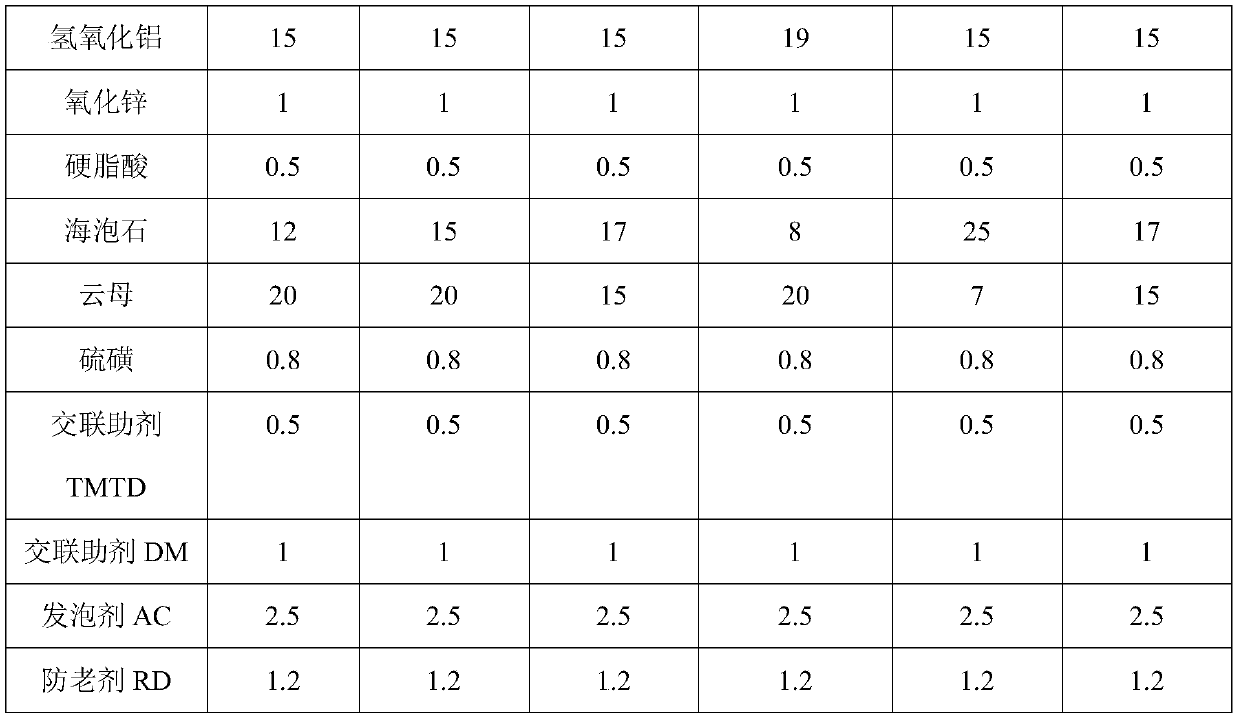

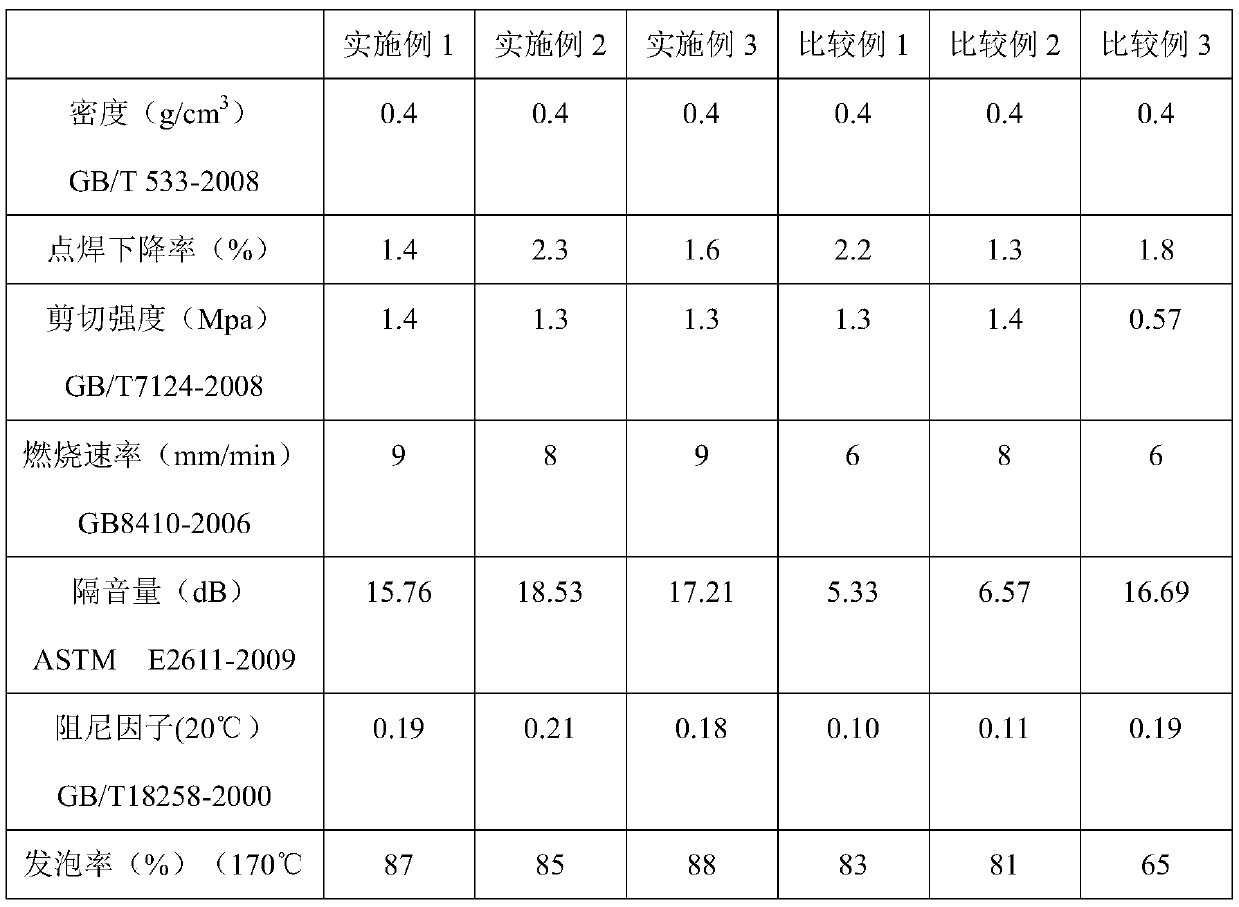

[0024] The performance of the flame-retardant sound-insulating and noise-reducing rubber pad for vehicles in each embodiment and comparative example is as shown in table 2:

[0025] Table 2

[0026]

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com