Table-type medium-frequency mono-side double-point spot welding machine

An intermediate frequency, single-sided technology, applied in the field of tabletop intermediate frequency single-sided double-spot spot welding machines, can solve the problems of increasing spot welding head wear, loss, damage to equipment, etc., to improve work efficiency, spot welding effect, and forming speed. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

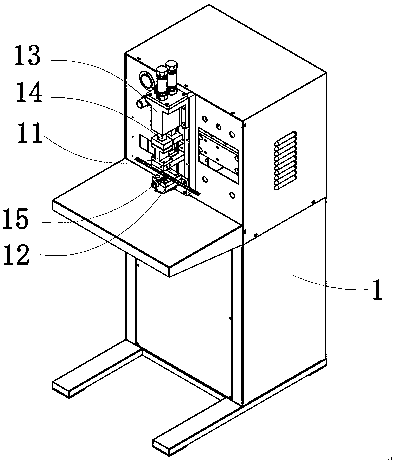

[0018] Such as figure 1 As shown in , an embodiment of the present invention provides a table-top intermediate frequency single-sided double-point spot welding machine, a table-top intermediate frequency single-sided double-point spot welder.

[0019] Includes stand.

[0020] Positive pole spot welding head, negative pole spot welding head and driving device; the negative pole spot welding head and driving device are arranged on the side of the machine base, and the positive pole spot welding head is arranged at the drive output end of the driving device.

[0021] The driving device is an air pressure driving rod, and the driving device is connected with an external power supply.

[0022] The positive electrode spot welding head also includes a positive electrode pressing block, one of the longitudinal sections of the positive electrode pressing block is in the shape of an "I", and the positive electrode pressing block is sleeved on the pneumatic driving rod.

[0023] The nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com