Edging and bending die for refrigerator door panel

A technology for bending molds and door panels, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of short mold life, surface strain, and non-flat corners of refrigerator door panels, so as to prevent scrapping and improve Molding speed, effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

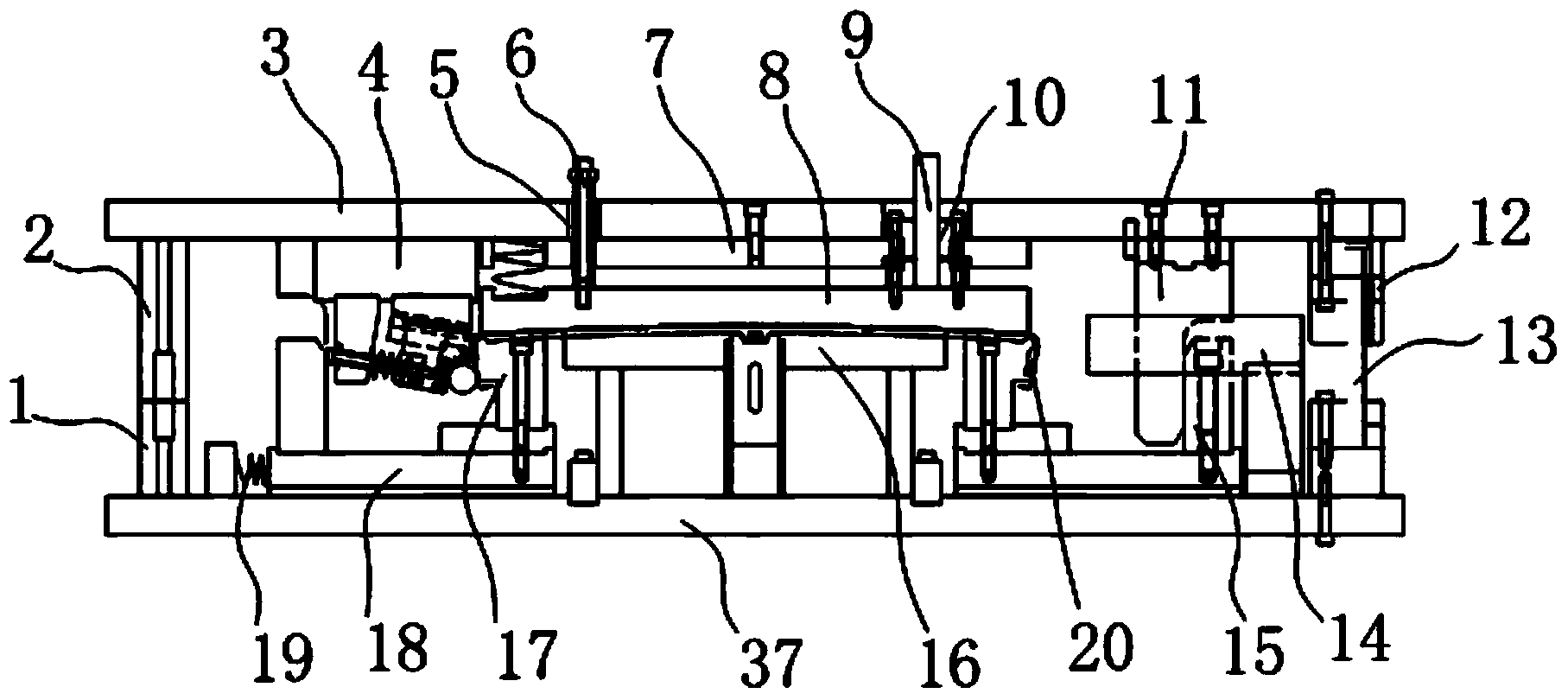

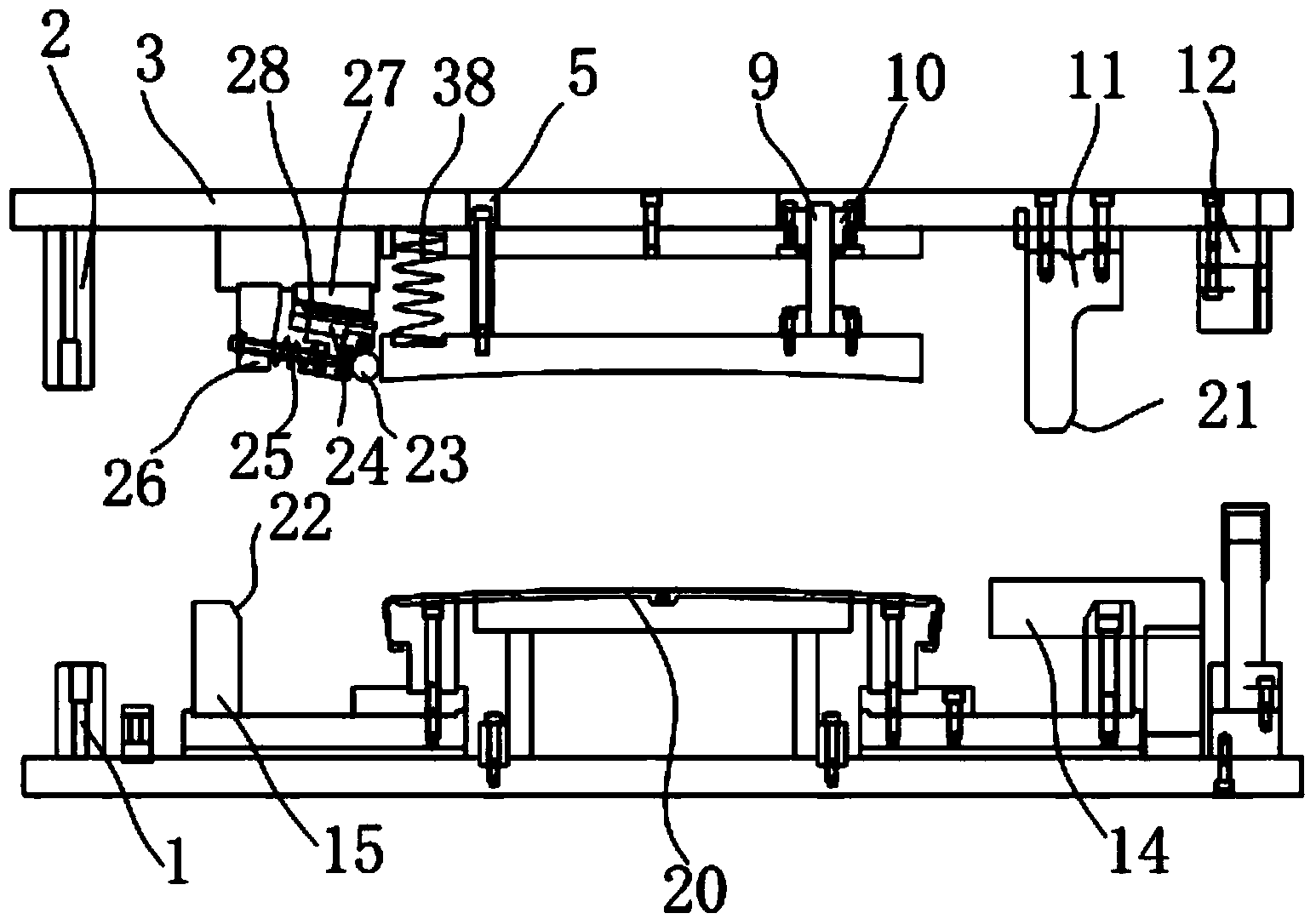

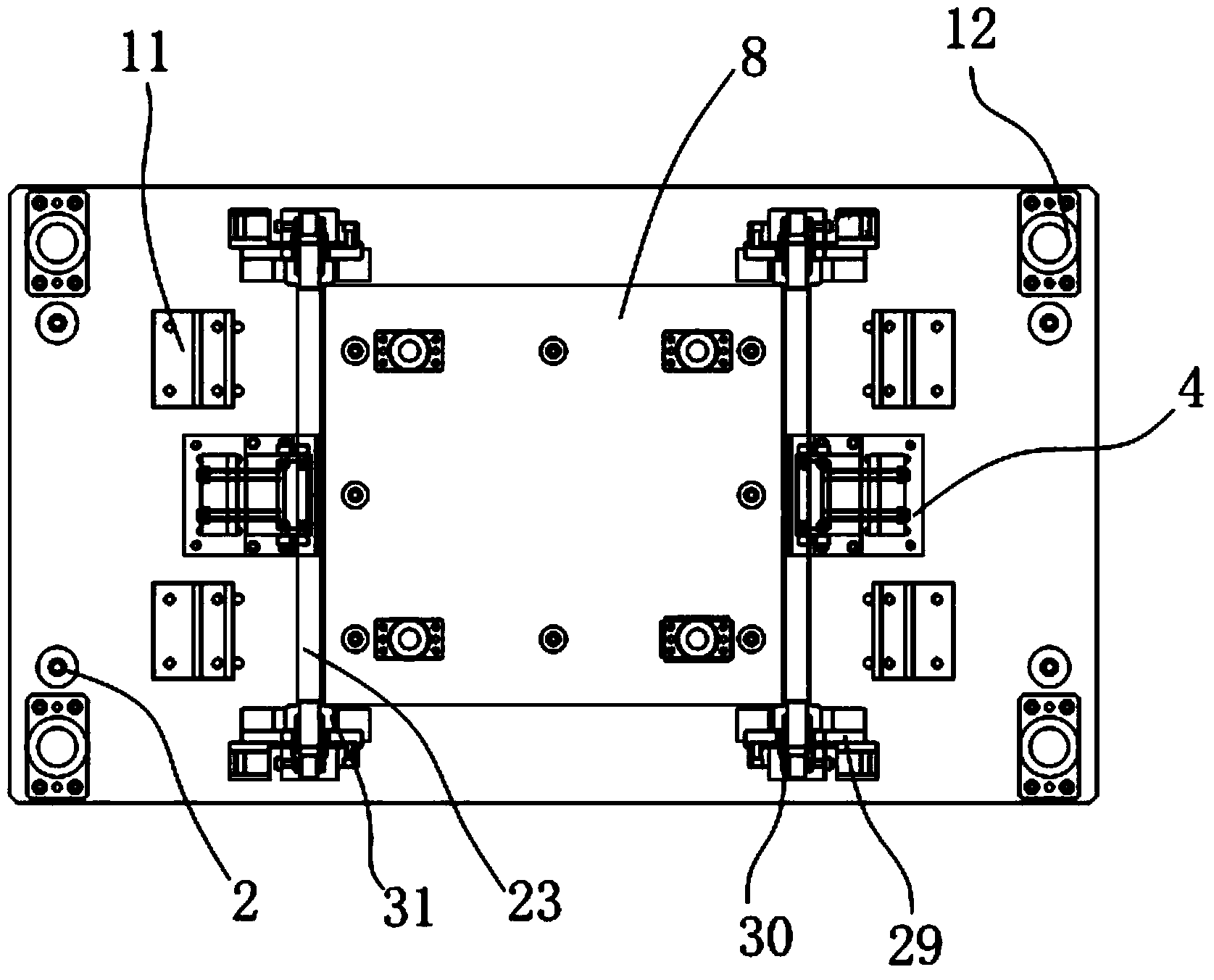

[0016] Describe an embodiment below in conjunction with accompanying drawing, the present invention is further described.

[0017] Embodiment: In the figure, the refrigerator door panel hemming bending mold includes an upper template 3 and a lower template 37, and the upper template 3 is symmetrically fixed with two drive blocks 11 sequentially from the outside to the inside, and the lower template 37 is symmetrical There are two large slides 18, and each large slide 18 is fixed with a traction block 15 and a bending bar 17 from the outside to the inside. The bending bar 17 is provided with a curved surface. When the mold is closed, the outer surface of the driving block 11 and the traction block The inner surface of 15 cooperates, the end of the outer surface of the driving block 11 is provided with a first guiding slope 21 , and the end of the inner surface of the traction block 15 is provided with a second guiding inclined surface 22 . The lower template 37 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com