Track turnout system

A track and turnout technology, applied in the field of track turnout systems, can solve the problems of switching time, limiting vehicle traffic density, increasing track complexity and failure rate, and achieving the effect of reducing adjustment time and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

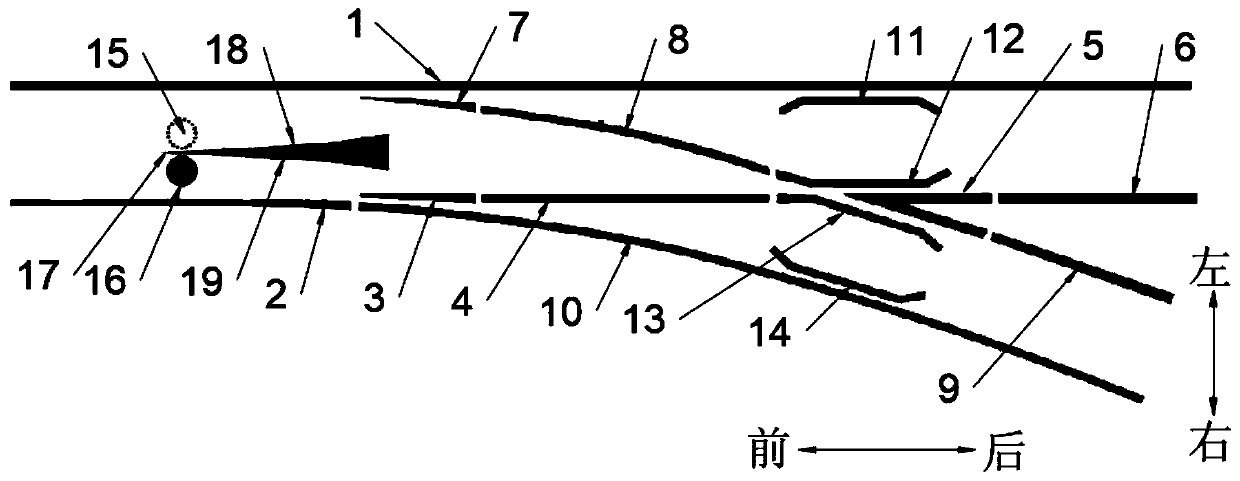

[0027] Such as figure 1 As shown, a track switch system of the present invention is characterized in that it includes: a diverter 17, a straight track, a turning track, a first guide wheel 15 and a second guide wheel 16, and the turning track is placed on the side of the straight track, One end of the turning track meets the straight track, and the splitter 17 is placed between the straight tracks, and the splitter 17 is in front of the intersection of the straight track and the turning track, and a branch center 5 is provided on the rear side of the intersection of the straight track and the turning track , the first guide wheel 15 and the second guide wheel 16 are respectively placed on both sides of the central axis of the front lower end of the rail car running on the straight track or the turning track.

[0028] The left side of the diverter 17 is provided with a first guide surface 18, the right side of the diverter 17 is provided with a second guide surface 19, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com