Body structure GaAs photoconductive switch based on a graphene interface layer and preparation process thereof

A technology of photoconductive switch and graphene layer, which is applied in the direction of sustainable manufacturing/processing, semiconductor devices, and final product manufacturing. Suppress heat accumulation and eliminate the effect of temperature homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

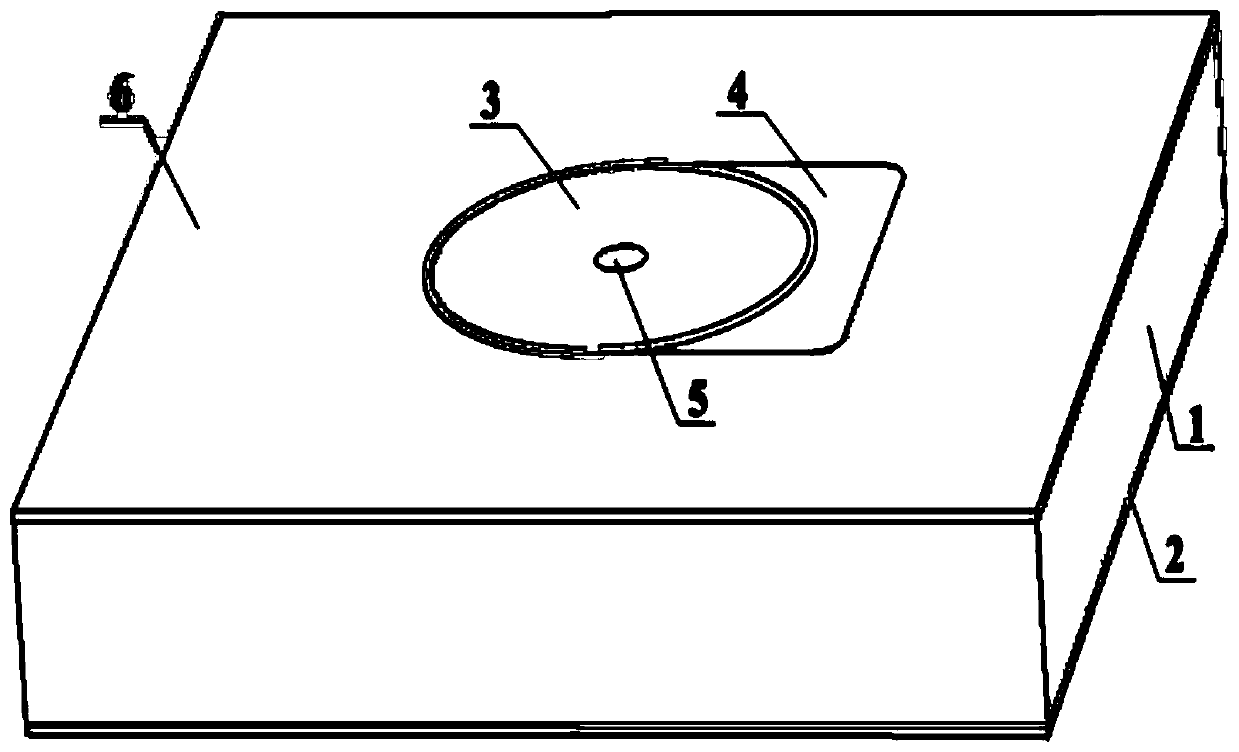

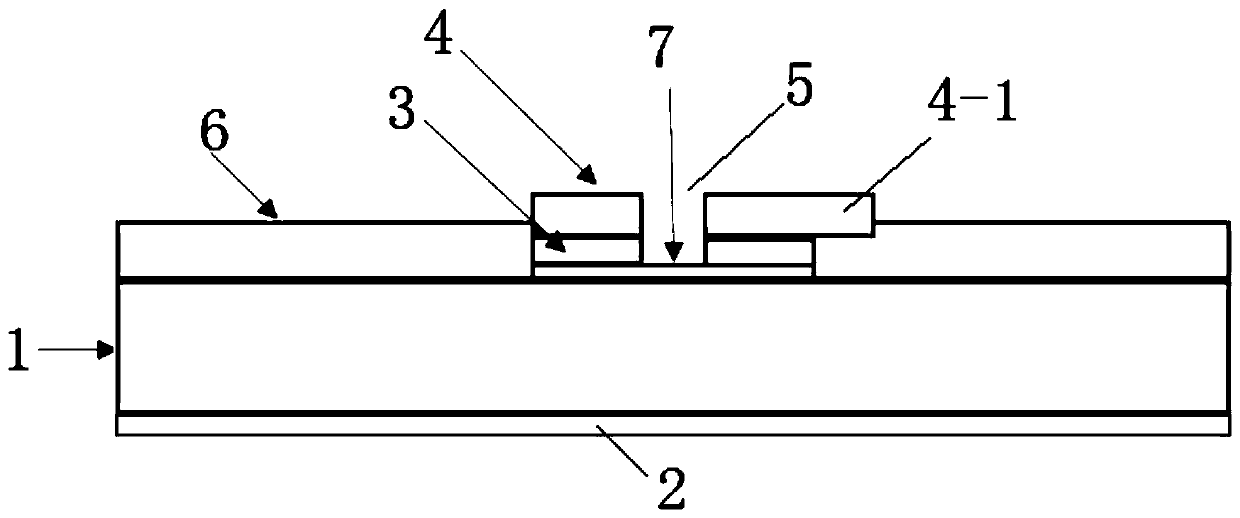

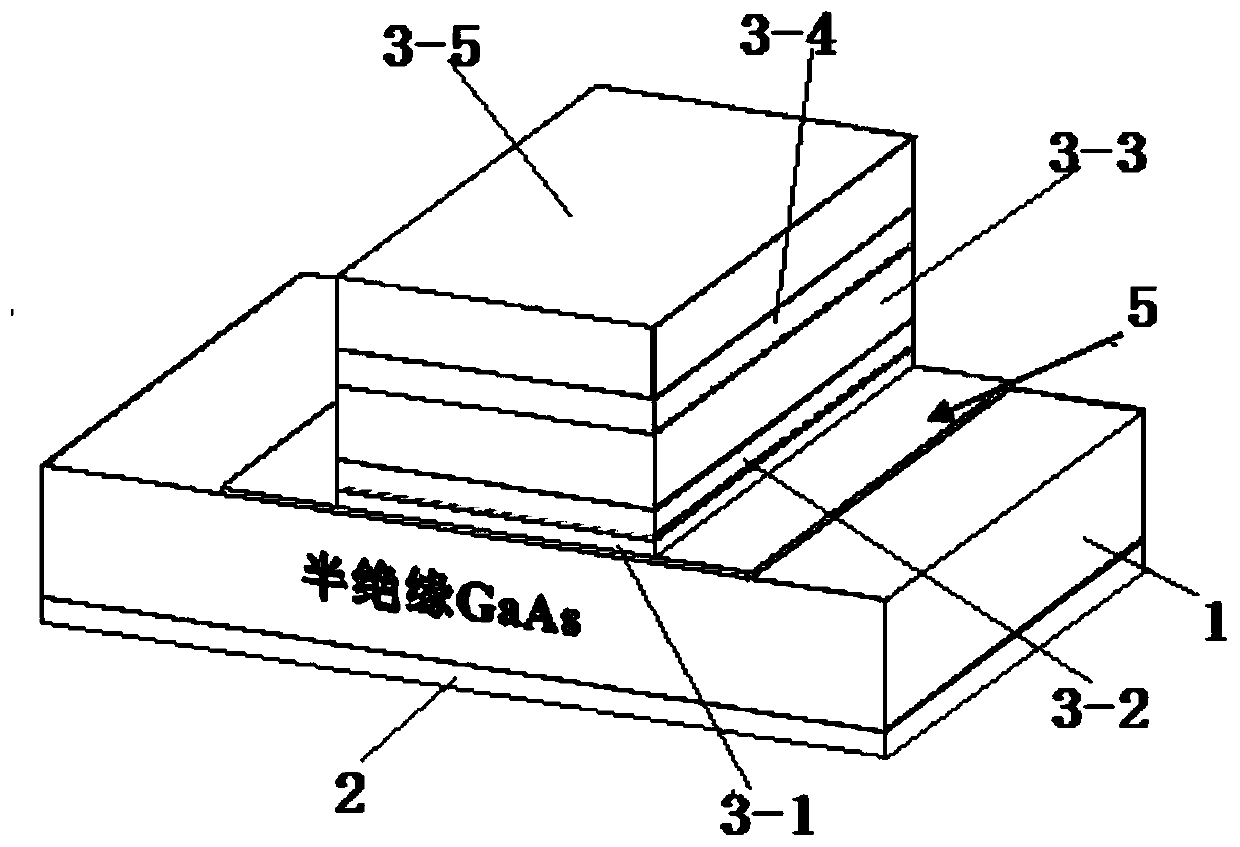

[0089] Choose four-inch crystal orientation The semi-insulating gallium arsenide double polished wafer, with a thickness of 600μm, uses acetone, sulfuric acid and other processes to clean the gallium arsenide surface to remove surface impurities. The device structure diagram is as Figure 1 ~ Figure 2 As shown,

[0090] 1) Preparation of composite structure of CVD graphene and gallium arsenide

[0091] On a Cu foil with a thickness of 25 μm, graphene is grown using a CVD method, and the graphene is transferred to the semi-insulating GaAs surface by a pulling method to obtain the first composite structure.

[0092] 2) Graphicalize the first composite structure:

[0093] The first photolithography (front):

[0094] (1) Apply photoresist AZ-5214 (2) homogenize (3) pre-bake (4) exposure (5) develop (6) post-bake (7) UVO to remove residual glue;

[0095] 3) Then make five layers of metal (front and back) on the surface as electrodes (Ni layer, Ge layer, Au layer, Ni layer and Au layer). Th...

Embodiment 2

[0107] Choose four-inch crystal orientation The gallium arsenide double polished sheet with resistivity ≥10Ωcm and thickness of 600μm. The gallium arsenide surface is cleaned by acetone, sulfuric acid and other processes to remove surface impurities.

[0108] 1) Preparation of composite structure of CVD graphene and gallium arsenide

[0109] On a Cu foil with a thickness of 25 μm, graphene is grown using a CVD method, and the graphene is transferred to the semi-insulating GaAs surface by a pulling method to obtain the first composite structure.

[0110] 2) Graphicalize the first composite structure:

[0111] The first photolithography (front):

[0112] (1) Apply photoresist AZ-5214 (2) homogenize (3) pre-bake (4) expose (5) develop (6) post-bake (7) UVO to remove residual glue;

[0113] 3) Then make five layers of metal (front and back) on the surface as electrodes (Ni layer, Ge layer, Au layer, Ni layer and Au layer). The total thickness of the five layers of metal is 283.5nm;

[0114] ...

Embodiment 3

[0125] Choose four-inch crystal orientation The gallium arsenide double polished sheet with resistivity ≥10Ωcm and thickness of 600μm. The gallium arsenide surface is cleaned by acetone, sulfuric acid and other processes to remove surface impurities.

[0126] 1) Preparation of composite structure of CVD graphene and gallium arsenide

[0127] On a Cu foil with a thickness of 25 μm, graphene is grown using a CVD method, and the graphene is transferred to the semi-insulating GaAs surface by a pulling method to obtain the first composite structure.

[0128] 2) Graphicalize the first composite structure:

[0129] The first photolithography (front):

[0130] (1) Apply photoresist AZ-5214 (2) homogenize (3) pre-bake (4) exposure (5) develop (6) post-bake (7) UVO to remove residual glue;

[0131] 3) Then make five layers of metal (front and back) on the surface as electrodes (Ni layer, Ge layer, Au layer, Ni layer and Au layer). The total thickness of the five layers of metal is 283.5nm;

[0132...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com