Continuous sinking-mode efficient 3D printing method and equipment

A 3D printing and high-efficiency technology, applied in the direction of additive processing, etc., can solve the problems of complex methods, affecting the light transmission efficiency and propagation path, and difficulty in printing large-scale parts, achieving simple principles, avoiding the mechanical peeling process, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

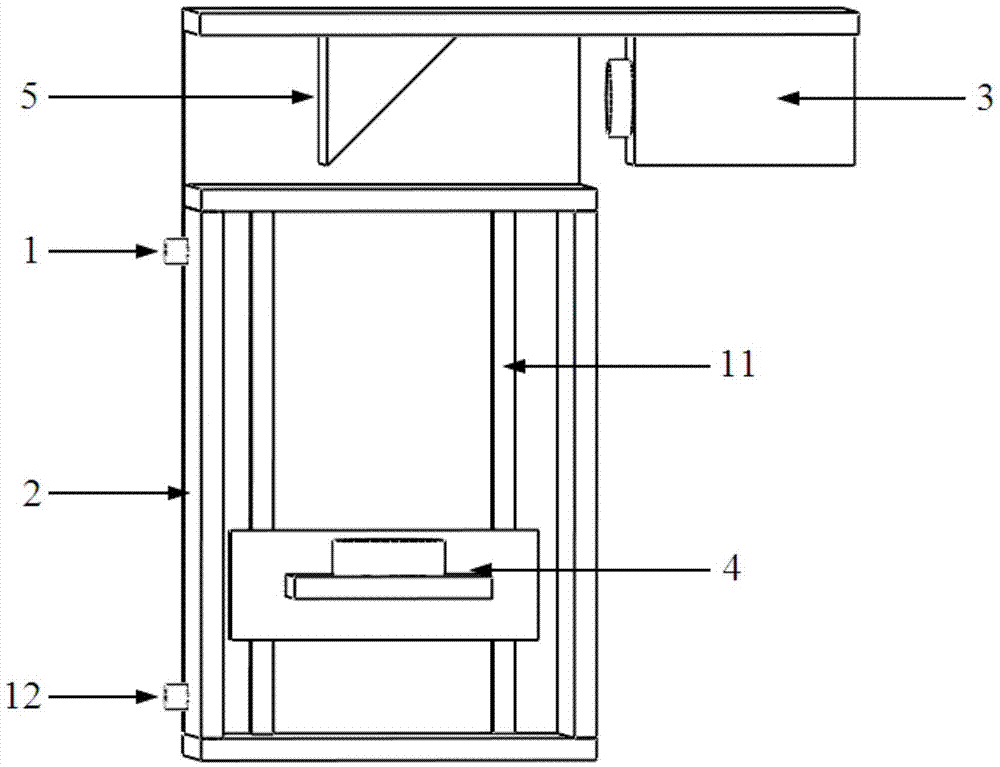

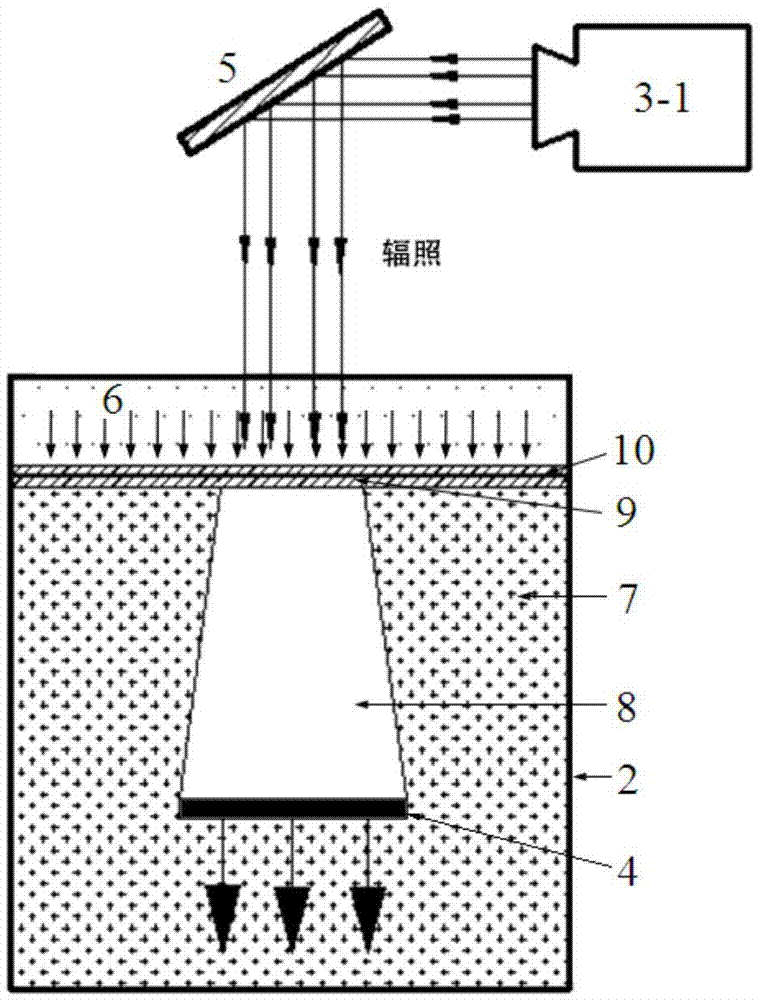

[0040] like figure 2 As shown, the light source 3 in the continuous sinking type high-efficiency 3D printing device is a surface light source 3-1 composed of a plurality of light-emitting units, and the printing method is as follows.

[0041] 1) Load the designed 3D CAD model of the sample into the 3D printing software, input T2O with an initiator concentration of 2wt% in the liquid radical-initiated photosensitive resin 7, select the printing type as surface light source projection, the printing accuracy is 100μm, 3D The printing software outputs the printing parameters such as the descending speed of the printing table 4, the luminous wavelength and emission power of the light source 3, the temperature of injected oxygen and the ambient pressure to the printing device through calculation.

[0042] 2) Add liquid radical-initiated photosensitive resin 7 into the closed trough 2, degas the entire closed trough 2, and after the degassing is completed, add the liquid radical hav...

Embodiment 2

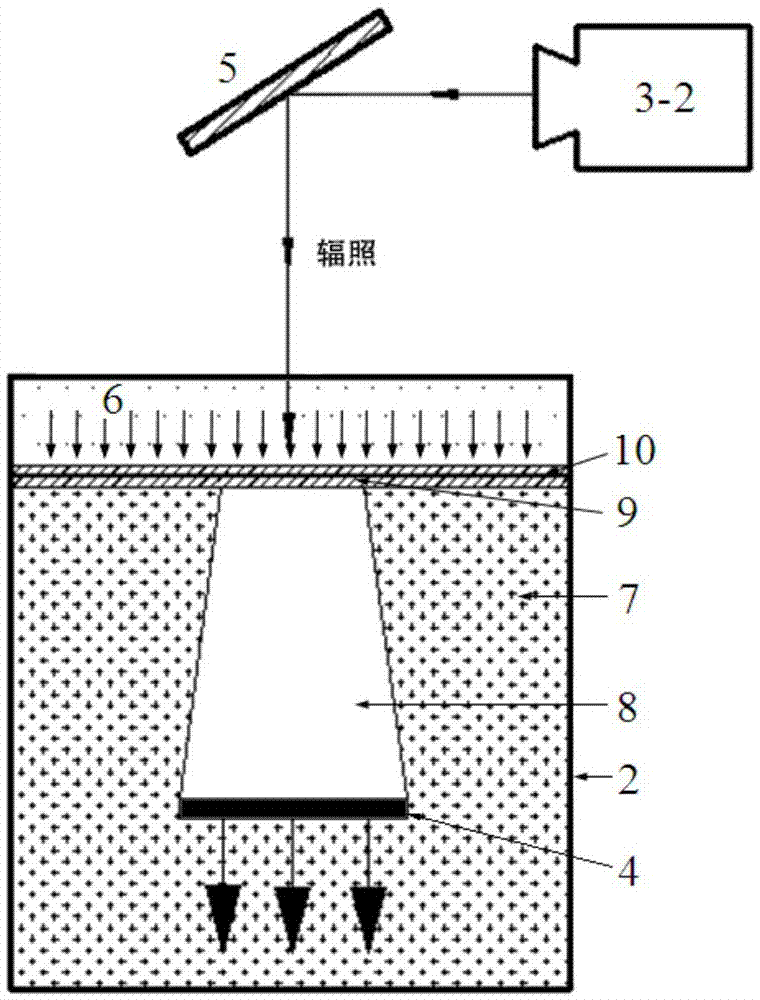

[0045] like image 3 As shown, the light source 3 in the continuous sinking type high-efficiency 3D printing device is a laser light source 3-2 composed of a blue-violet laser and a laser scanning galvanometer, and the printing method is as follows.

[0046] 1) Load the designed 3D CAD model of the sample into the 3D printing software, input T2O with an initiator concentration of 2 wt% in the liquid radical-initiated photosensitive resin 7, and select the printing type as SLA laser printing, the printing accuracy is 50 μm, 3D The printing software outputs the printing parameters such as the descending speed of the printing table 4, the luminous wavelength and emission power of the light source 3, the temperature of injected oxygen and the ambient pressure to the printing device through calculation.

[0047] 2) Add liquid radical-initiated photosensitive resin 7 into the closed trough 2, degas the entire closed trough 2, and after the degassing is completed, add the liquid radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com