Reaction ethylene-propylene-diene monomer butyl self-adhesive waterproof coiled material and preparation method thereof

A self-adhesive waterproof membrane, ethylene propylene butyl technology, applied in the direction of adhesive, adhesive type, asphalt material adhesive, etc., can solve the surface layer damage of waterproof membrane, weak toughness, and weakened waterproof function of waterproof membrane and other problems to achieve the effect of improving lap performance, improving self-adhesion and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

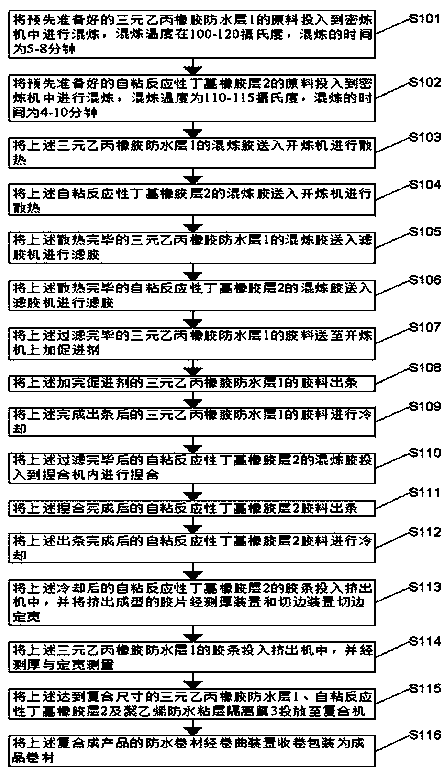

Method used

Image

Examples

Embodiment 1

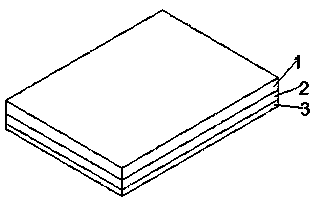

[0057] A reactive EPDM self-adhesive waterproof coiled material, the reactive EPDM self-adhesive waterproof coiled material comprises an EPDM waterproof layer 1, and the bottom end of the EPDM waterproof layer 1 is set There is a self-adhesive reactive butyl rubber layer 2, and the bottom end of the self-adhesive reactive butyl rubber layer 2 is provided with a polyethylene waterproof adhesive layer isolation film 3;

[0058] Wherein, the EPDM waterproof layer 1 is made of the following raw materials in parts by mass: EPDM rubber 100g, polyurethane 50g, mixed polyether 10g, high wear-resistant carbon black 20g, zinc oxide 5g, stearin 10g acid, 5g accelerator, 30g phenolic resin glue, 10g binder, 20g glycerol monostearate, 10g reinforcing agent, 5g talcum powder;

[0059] Wherein, the self-adhesive reactive butyl rubber layer 2 is made of the following raw materials in parts by mass: 100 g of butyl rubber, 10 g of light calcium sulfate, 20 g of tackifying resin, 30 g of asphalt...

Embodiment 2

[0084] A reactive EPDM self-adhesive waterproof coiled material, the reactive EPDM self-adhesive waterproof coiled material comprises an EPDM waterproof layer 1, and the bottom end of the EPDM waterproof layer 1 is set There is a self-adhesive reactive butyl rubber layer 2, and the bottom end of the self-adhesive reactive butyl rubber layer 2 is provided with a polyethylene waterproof adhesive layer isolation film 3;

[0085] Wherein, the EPDM waterproof layer 1 is made of the following raw materials in parts by mass: EPDM rubber 150g, polyurethane 75g, mixed polyether 15g, high wear-resistant carbon black 25g, zinc oxide 7.5g, hard 12.5g fatty acid, 7.5g accelerator, 35g phenolic resin glue, 12.5g binder, 25g glycerol monostearate, 12.5g reinforcing agent, 12.5g talcum powder;

[0086] Wherein, the self-adhesive reactive butyl rubber layer 2 is made of the following raw materials in parts by mass: butyl rubber 150g, light calcium sulfate 15g, tackifying resin 25g, asphalt 37....

Embodiment 3

[0111] A reactive EPDM self-adhesive waterproof coiled material, the reactive EPDM self-adhesive waterproof coiled material comprises an EPDM waterproof layer 1, and the bottom end of the EPDM waterproof layer 1 is set There is a self-adhesive reactive butyl rubber layer 2, and the bottom end of the self-adhesive reactive butyl rubber layer 2 is provided with a polyethylene waterproof adhesive layer isolation film 3;

[0112] Wherein, the EPDM waterproof layer 1 is made of the following raw materials in parts by mass: EPDM rubber 200g, polyurethane 100g, mixed polyether 20g, high wear-resistant carbon black 30g, zinc oxide 10g, stearin 15g acid, 10g accelerator, 40g phenolic resin glue, 15g binder, 30g glycerol monostearate, 15g reinforcing agent, 15g talcum powder;

[0113] Wherein, the self-adhesive reactive butyl rubber layer 2 is made of the following raw materials in parts by mass: butyl rubber 200g, light calcium sulfate 20g, tackifying resin 30g, asphalt 45g, modified p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com