Patents

Literature

45results about How to "Improve lapping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

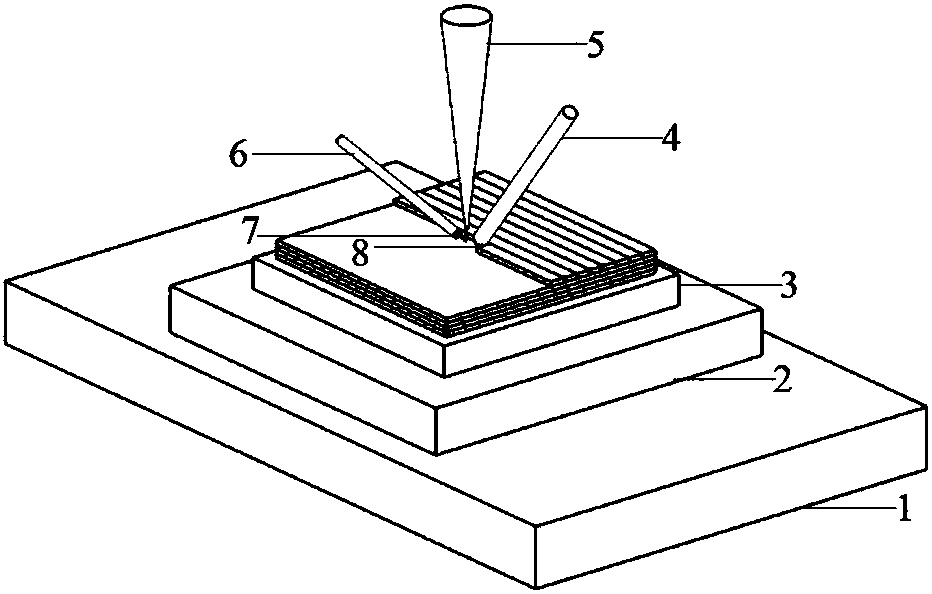

Method for manufacturing a solid aluminum alloy structure through wire filling type additive

ActiveCN108161229AImprove organizationRefined dimensionsArc welding apparatusLaser beam welding apparatusInter layerLap joint

The invention provides a method for manufacturing a solid aluminum alloy structure through a wire filling type additive, and belongs to the field of additive manufacturing. The method aims to solve the problems in the existing aluminum alloy laser filler wire additive manufacturing and electric arc additive manufacturing that the reflectivity of the aluminum alloy to the laser is high, the formingquality is poor caused by unstable electric arc, and the structure of a forming part is large caused by large heat input and the like. A laser-TIG composite heat source is adopted, and the laser andthe electric arc interact, so that on one hand, the heat input can be reduced, the structure of the forming part is refined, and the strength is improved; and on the other hand, the laser can stabilize the electric arc, so that the electric arc is more stable in the multi-layer multi-channel forming process, and the lap joint effect is optimized. According to the method, arc currents and inter-layer arc currents between adjacent welding beads are adjusted, so that the heat input in the continuous forming process is reduced, the appearance size of the obtained forming part is stable, crystal grains are refined, and the forming efficiency is remarkably improved compared with the control interlayer temperature and the interlayer residence time.

Owner:DALIAN UNIV OF TECH

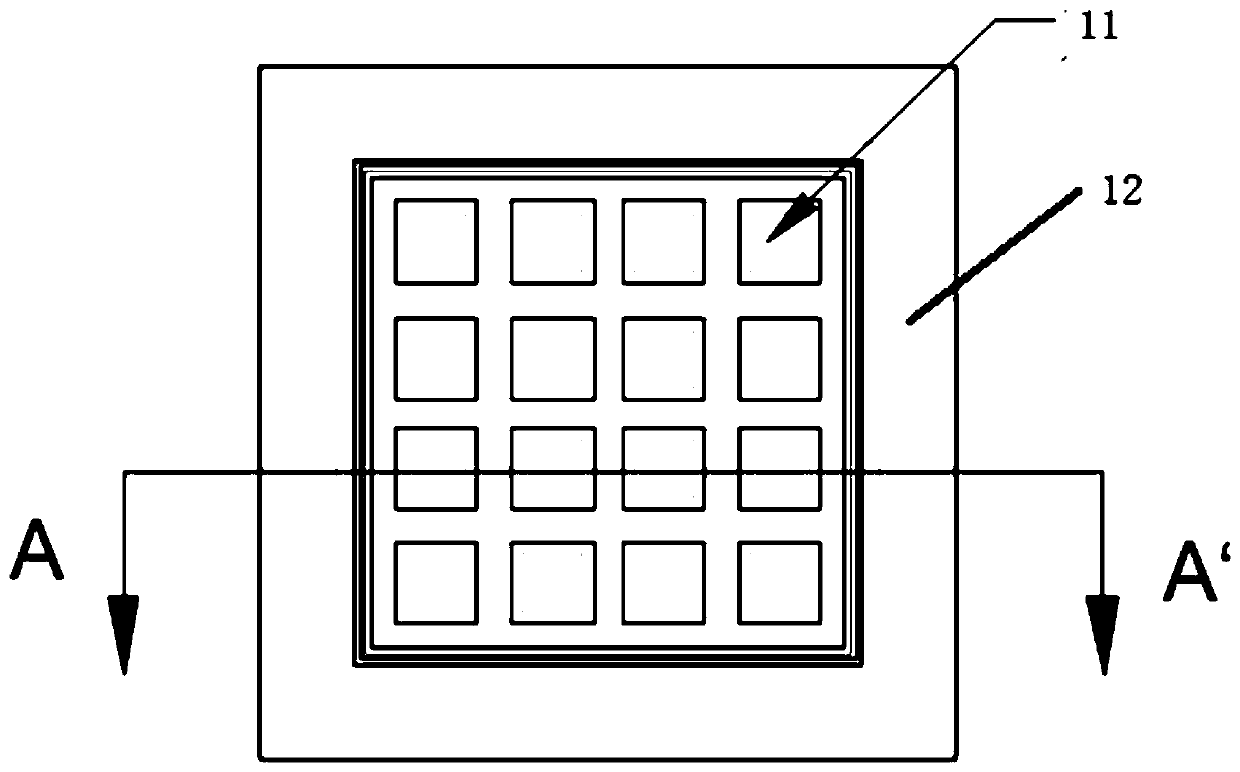

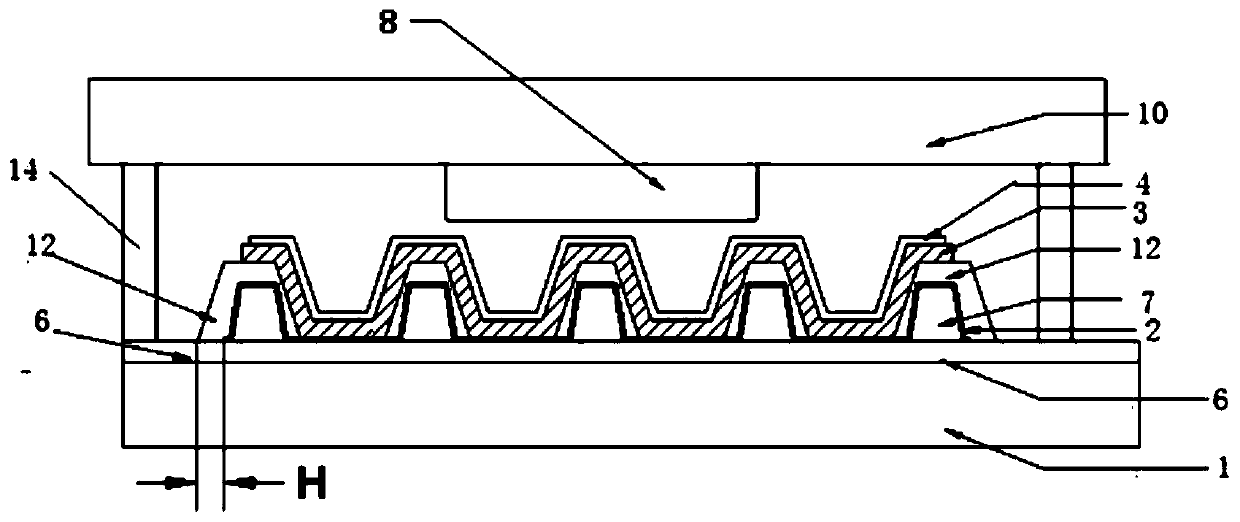

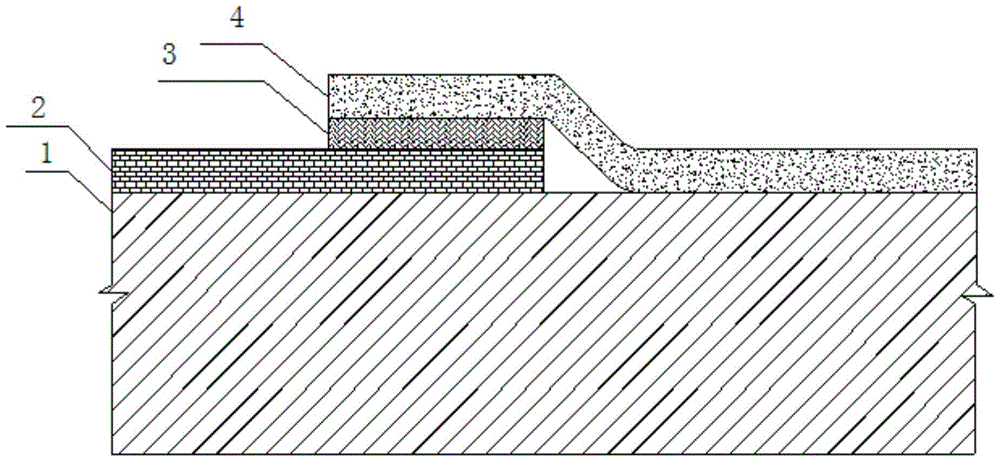

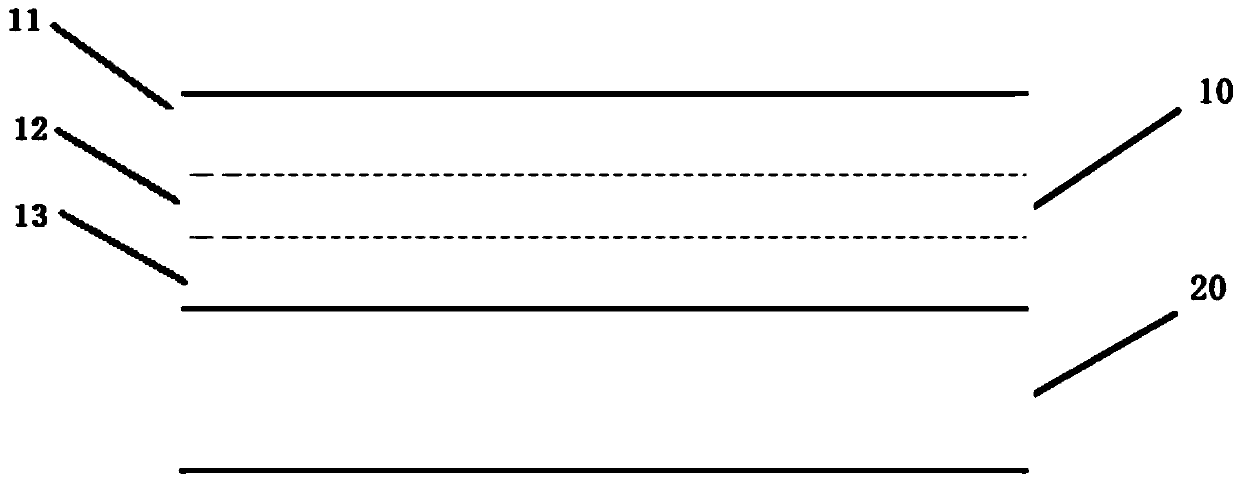

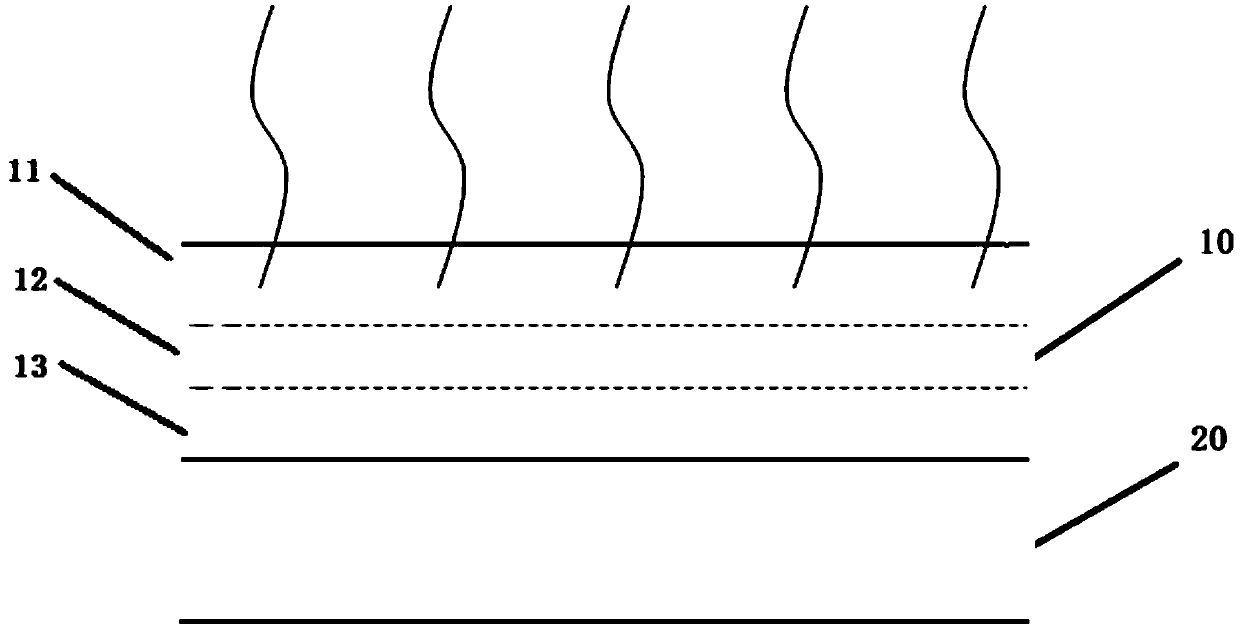

High-stability OLED device and preparation method thereof

InactiveCN109888116APrevent side erosionSolve the phenomenon of "undercut"Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringAuxiliary electrode

The invention provides a high-stability OLED device and a preparation method thereof. The high-stability OLED device comprises a substrate and a packaging cover plate 10, wherein the substrate is divided into a pixel region and a packaging region; the substrate and the packaging cover plate are connected through a sealing medium; a first electrode layer, an organic light-emitting layer and a second electrode layer are overlapped on the pixel region on the substrate; and a buffer layer is arranged between the first electrode layer and the substrate. Through the arrangement of the buffer layer,the lateral erosion phenomenon caused by dry etching of the auxiliary electrode layer is solved, and meanwhile, metal ions of the glass substrate are blocked from permeating into the first electrode layer, and electrochemical corrosion is avoided; by adding the auxiliary electrode, the brightness uniformity of a screen body is improved; a pixel defining layer is simultaneously arranged on the first electrode layer and the auxiliary electrode layer and is in direct contact with the buffer layer, so that a very good surrounding structure is formed for an effective pixel region and / or pixels of the OLED, volatile gas outgas is prevented from being released into the pixels to cause pixel shrinkage, and the reliability of the screen body of the OLED is improved.

Owner:GUAN YEOLIGHT TECH CO LTD

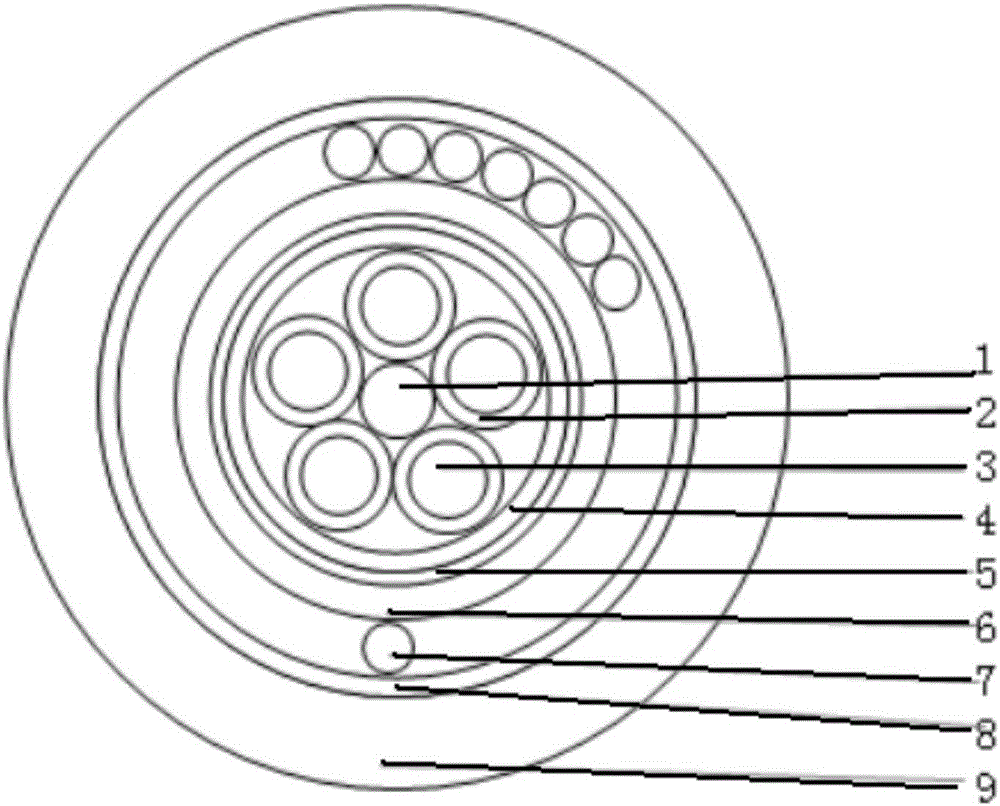

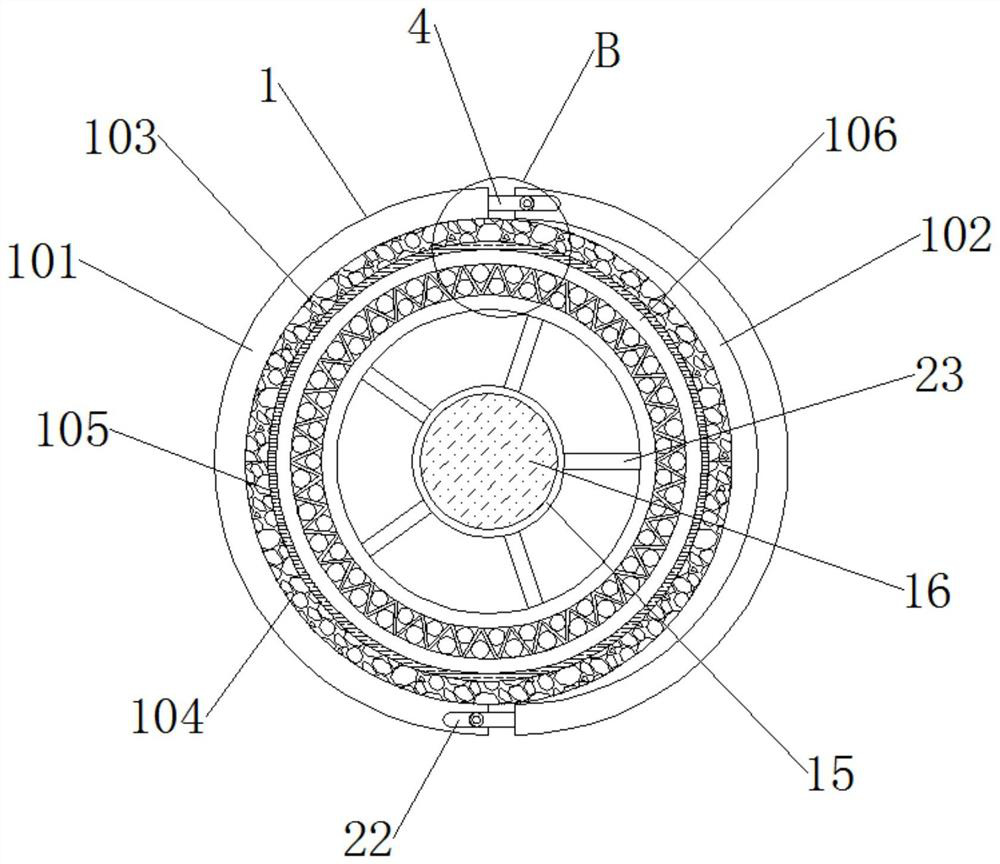

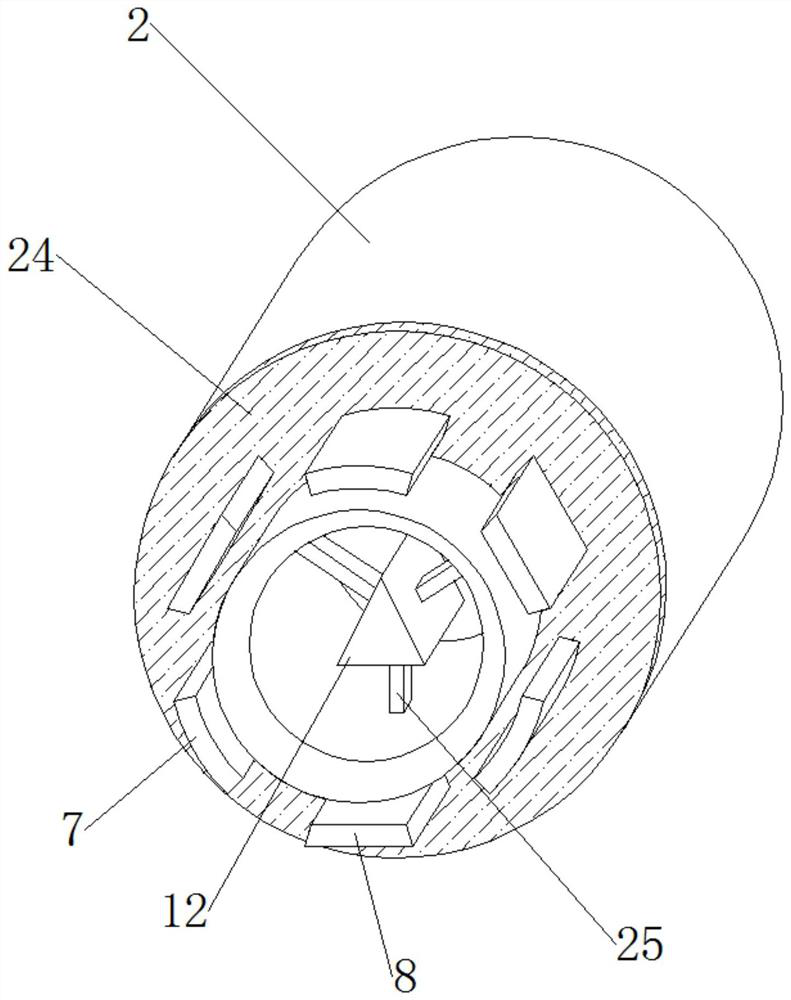

High-grade flame-retardant fireproof optical cable

ActiveCN106125216AHigh viscosityGood compatibilityClimate change adaptationFibre mechanical structuresFiberLow smoke zero halogen

The invention discloses a high-grade flame-retardant fireproof optical cable. The high-grade flame-retardant fireproof optical cable comprises a layer stranded type cable core, the layer stranded type cable core is wrapped by a double-face synthetic mica tape layer, the double-face synthetic mica tape layer is wrapped by a steel plastic composite band layer, the steel plastic composite band layer is externally plastically extruded by a low-smoke halogen-free inner sheath, the low-smoke halogen-free inner sheath is externally provided with at least one armored layer, the armored layer is externally provided with a fireproof layer and a low-smoke halogen oversheath, the low-smoke halogen-free inner sheath and the low-smoke halogen-free oversheath are both prepared by low-smoke halogen-free ceramic polyolefin, and the low-smoke halogen-free ceramic polyolefin comprises 60-70% of matrix polyolefin and 30-40% of an auxiliary agent, wherein the auxiliary agent comprises a plasticizer, white carbon black, 3% of micro-encapsulated red phosphorus, siloxane, 15-28% of a gas-phase fire retardant and 5-7% of a special fire retardant. The ceramic polyolefin is a halogen-free high-oxygen index sheath material and is easily ceramic during high-temperature combustion to form a compact protection layer so as to obstruct flames and heat transfer and accordingly prevent fibers from high-temperature damage.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

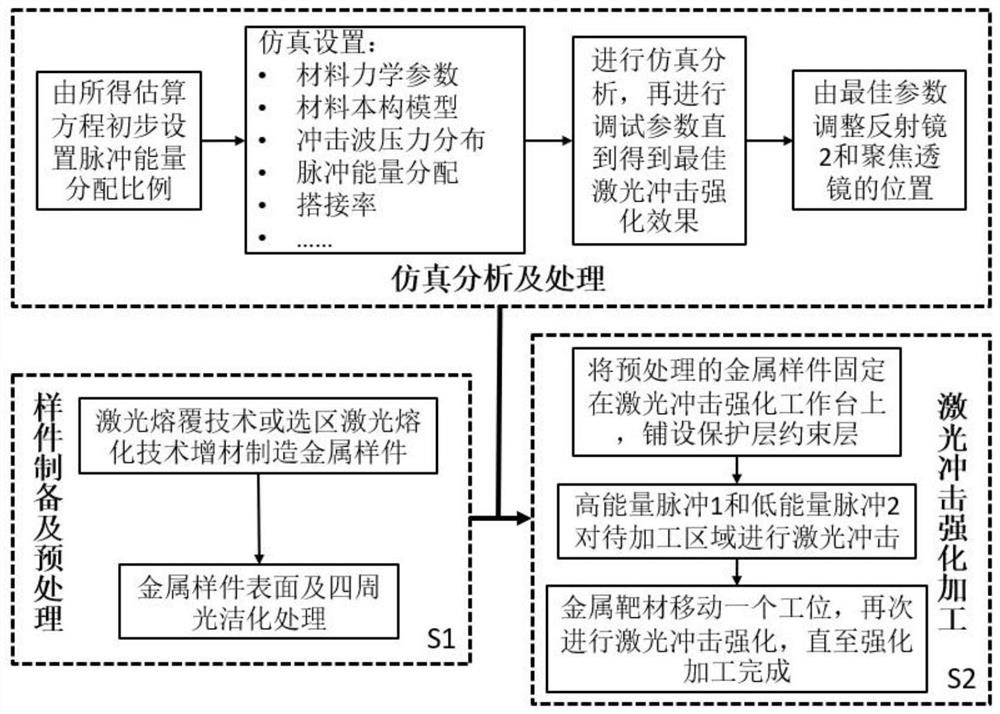

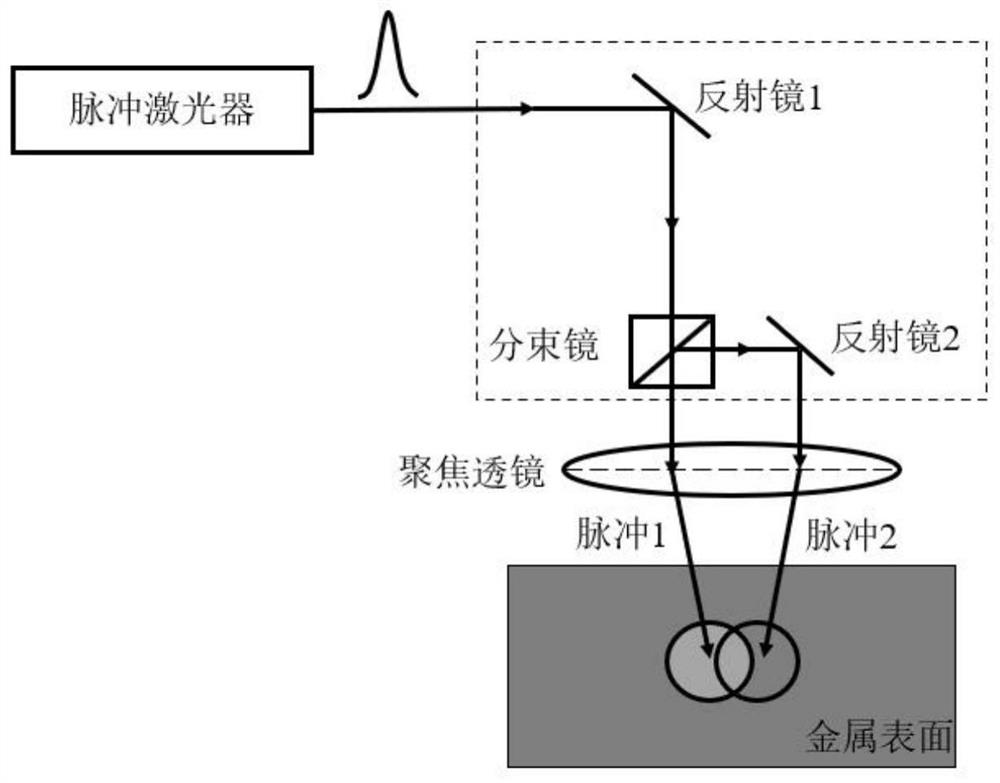

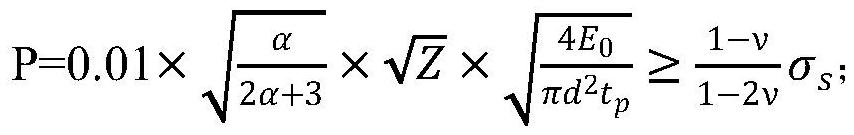

Additive manufacturing metal surface strengthening method based on laser shock peening

InactiveCN113088674ASignificant laser shock strengthening effectReduce work hardeningAdditive manufacturing apparatusLight spotHigh energy

The invention discloses an additive manufacturing metal surface strengthening method based on laser shock peening. The additive manufacturing metal surface strengthening method aims to solve the problems of energy utilization, the lap joint effect, the influence depth of residual compressive stress and the like which commonly exist in the laser shock peening process. The additive manufacturing metal surface strengthening method comprises the steps that firstly, the metal surface manufactured through additive manufacturing is pretreated, and then laser shock peening machining is conducted; simulation treatment and analysis are conducted on the laser shock peening process, the optimal distribution proportion and the light spot lap joint rate of a pulse 1 and a pulse 2 are determined, and the proper mounting positions of a focusing lens and a reflector 2 are adjusted correspondingly; and then a high-energy pulse 1 conducts point-by-point machining strengthening on a to-be-strengthened area, meanwhile, a low-energy pulse 2 conducts pre-machining on a next point-by-point machining area, then a metal target moves by one station, and laser shock peening is conducted again till strengthening machining is completed. According to the additive manufacturing metal surface strengthening method, under the condition that parameters of a laser device are not changed, laser pulse energy is fully utilized, and the laser shock peening effect is comprehensively improved.

Owner:湖南珞佳智能科技有限公司

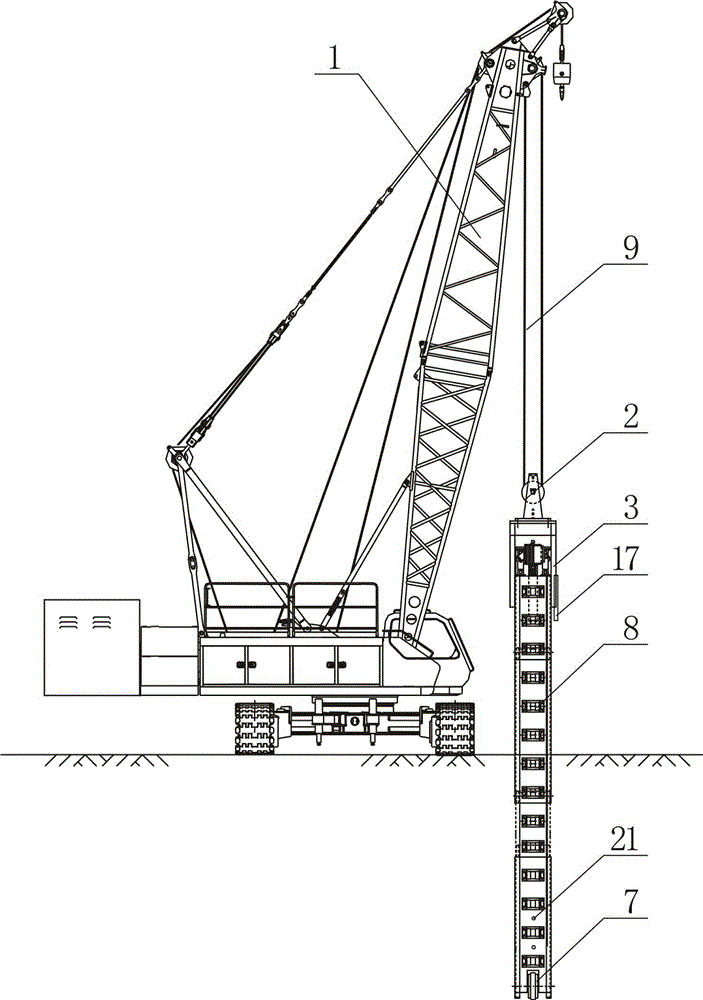

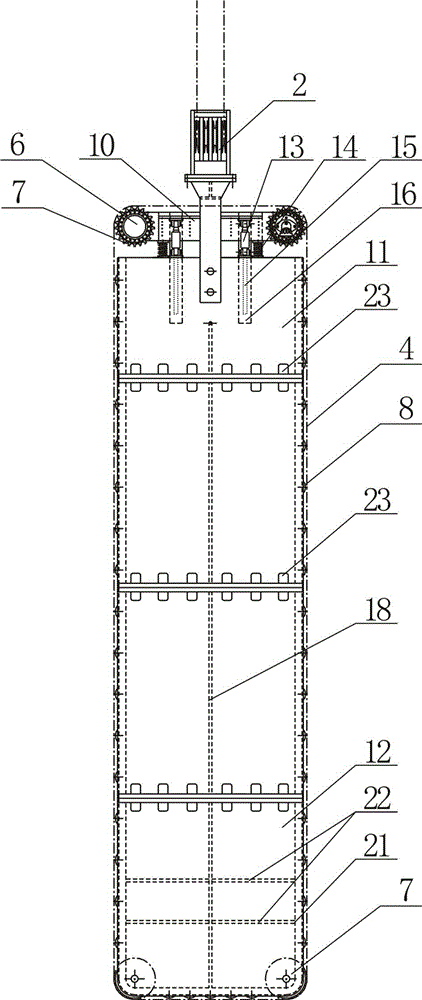

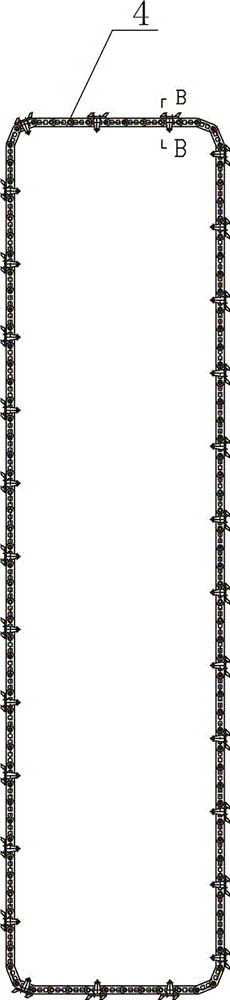

Full-face stirring and cutting wall construction machine

ActiveCN104452804AUniform strengthImprove continuityArtificial islandsSoil-shifting machines/dredgersMotor driveArchitectural engineering

The invention discloses a full-face stirring and cutting wall construction machine. The full-face stirring and cutting wall construction machine mainly comprises a crawler crane, a pulley block, a chain rotating device and a grouting pipe, wherein the chain rotating device mainly comprises a rectangular chain support, a chain, a plurality of knives and a motor; the grouting pipe is arranged on the rectangular chain support; chain wheels are arranged at four corners of the rectangular chain support; a plurality of guiding wheels are distributed on the two sides and the bottom of the rectangular chain support; the chain is arranged on chain wheels and the guiding wheels; the knives are distributed on the surface of the chain at intervals; a crawler crane drives the rectangular chain support to move up and down; the motor drives the chain wheels at the two corners of the upper end of the rectangular chain support to rotate; the chain wheels drive the chain; the chain drives the knives; the knives continuously cut off and stir a rock fracture face; and a plurality of knife dropping preventing mechanisms are distributed on the chain at intervals. The full-face stirring and cutting wall construction machine has the advantages that the full-face stirring and cutting wall construction machine is simple in structure, low in cost, easy to operate, high in efficiency and wide in application range and can adapt to change of rock surfaces of strata.

Owner:钟景尧

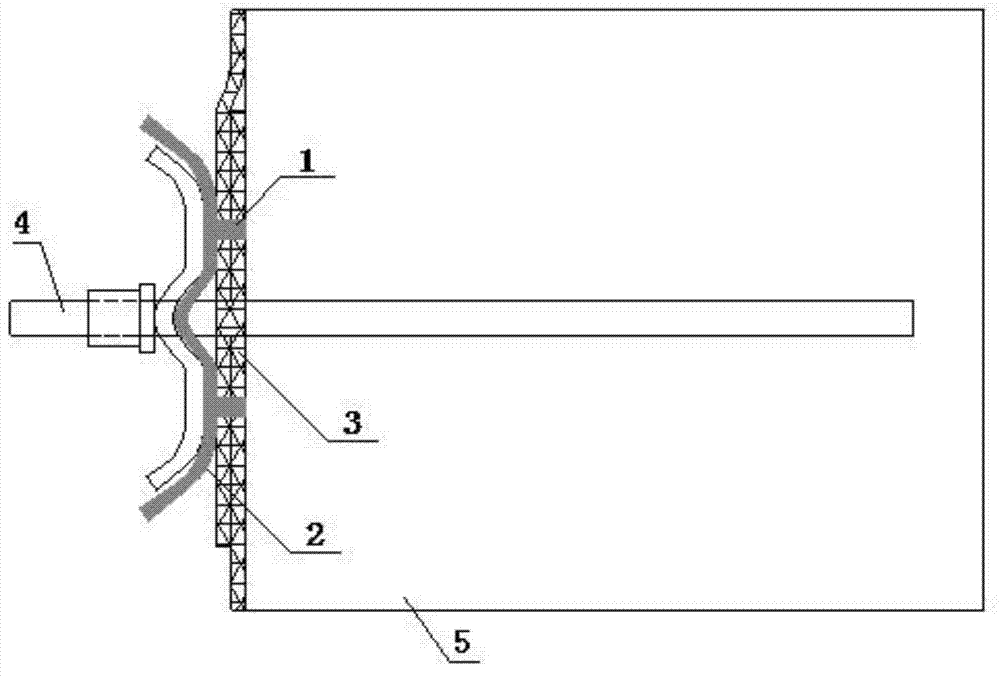

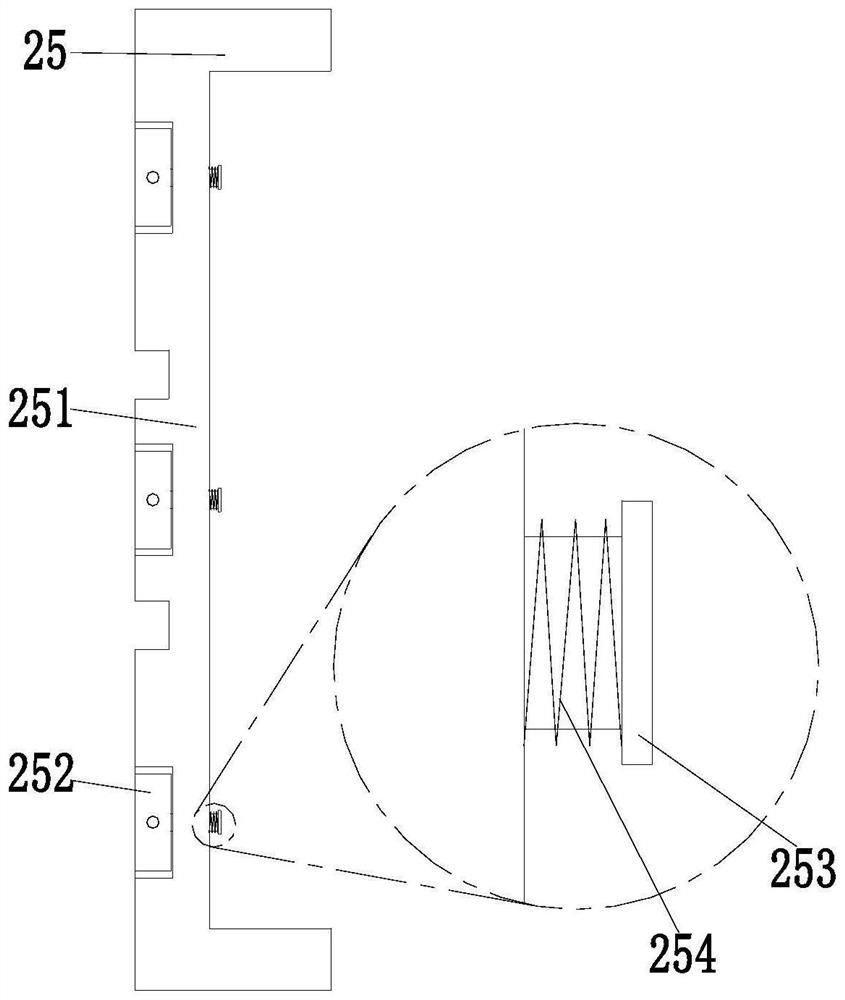

Strengthening structure for integrated bolting with bar and wire mesh

The invention discloses a strengthening structure for integrated bolting with bar and wire mesh. The strengthening structure is disposed on an M-shaped steel strip at metal mesh lap joint of bolting with bar and wire mesh and comprises two rows of connecting nails. The connecting nails are disposed lengthwise along the M-shaped metal mesh and symmetrically distributed on two sides of a groove on the upper surface of the M-shaped metal mesh. The lower end of each connecting nail is fixed to the upper surface of the M-shaped steel mesh. The upper end of each connecting nail is inserted into one mesh of the metal mesh at the metal mesh lap joint. The strengthening structure has the advantages that the when the metal mesh bears acting force of surrounding rock, the connecting nails keep even stress of the metal mesh connection, prevent breakage of part of the metal mesh lap joint caused by stress concentration and effectively prevent pocketing; bolts, the M-shaped steel strip and the metal mesh are integrally connected by the connecting nails, mutual action of the M-shaped steel strip and surrounding rock is enhanced, diffusion range of bolt load to the surrounding rock is increased, and overall strength and reliability of bolting with bar and wire mesh are improved.

Owner:CHINA UNIV OF MINING & TECH

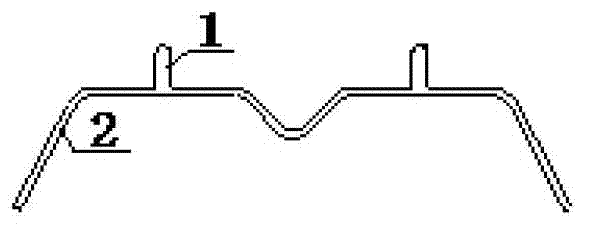

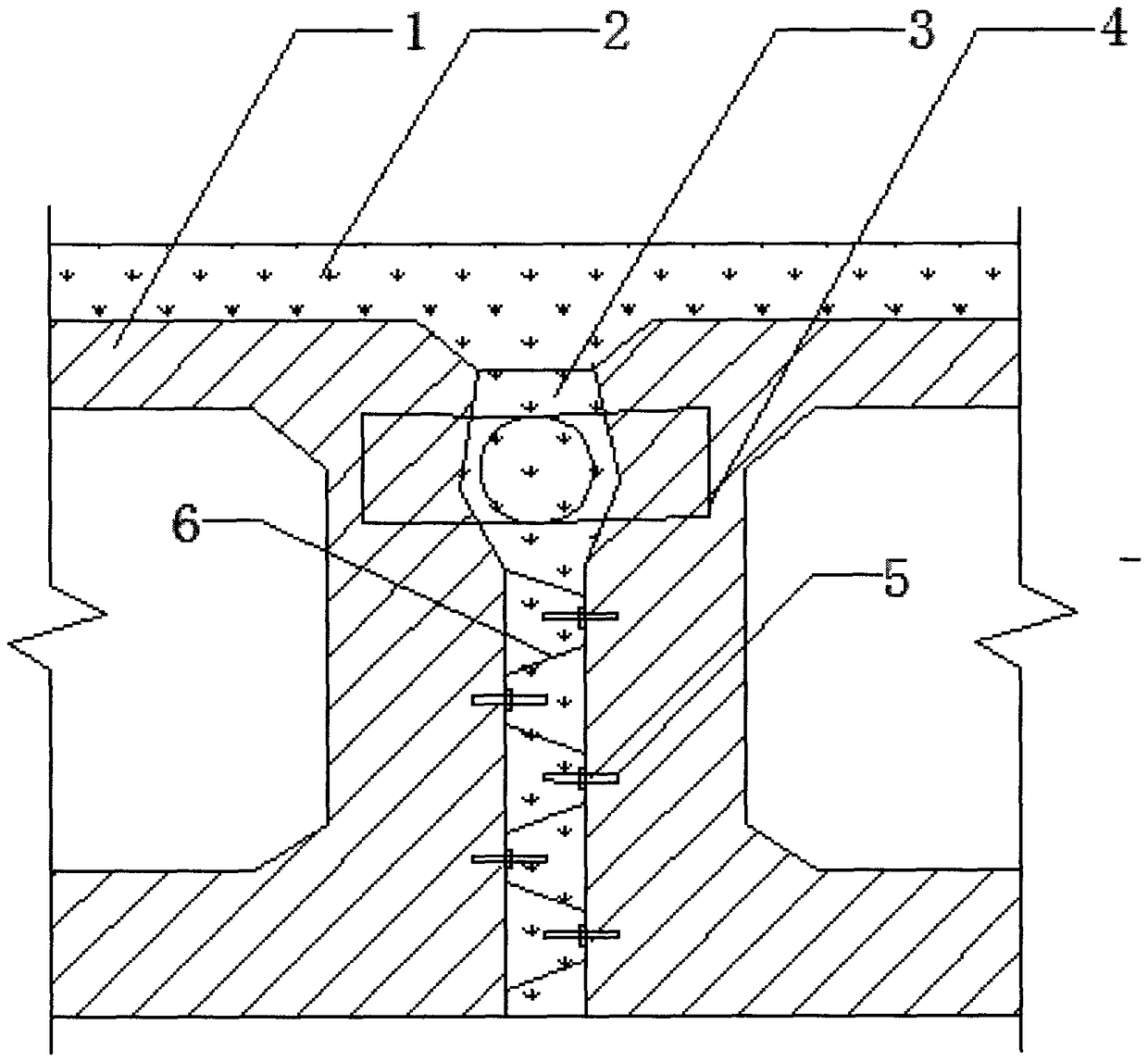

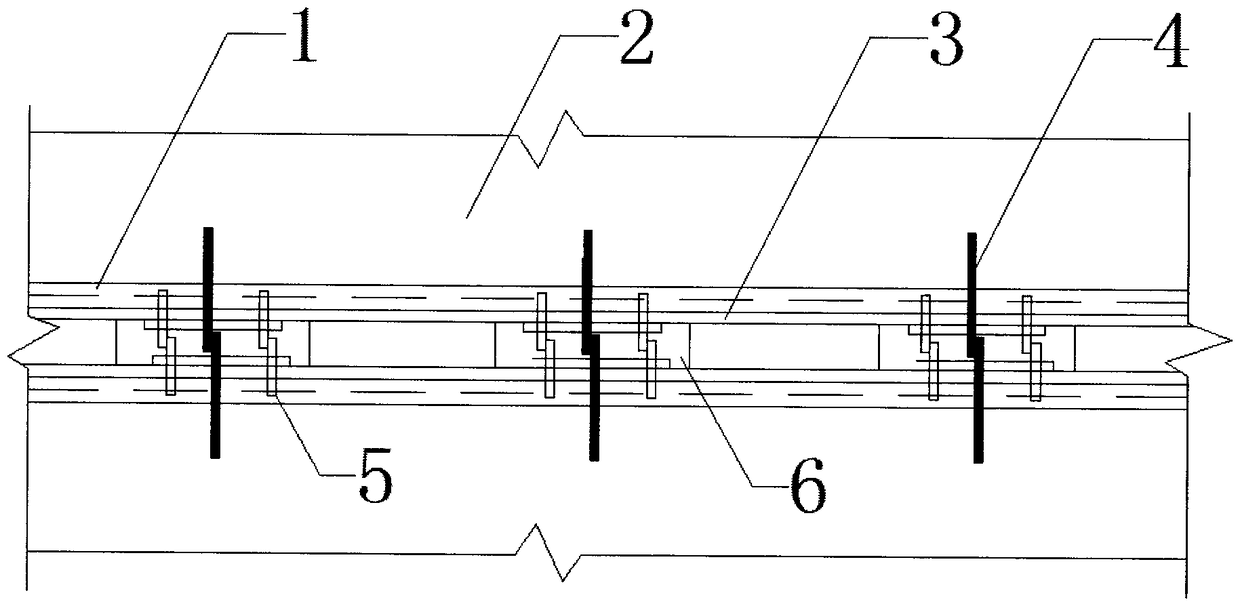

Novel hollow slab funnel hinge joint structure and construction method thereof

InactiveCN109235251AIncreased shear strengthImprove bending resistanceBridge structural detailsBridge erection/assemblySheet steelRebar

The invention discloses a novel hollow slab funnel hinge joint structure and a construction method thereof, and belongs to the technical field of bridge structure design. The structural system is mainly composed of prefabricated hollow slabs which are longitudinally spliced together in the same plane, The concrete pavement layer is composed of a pre-embedded closed U-shaped steel bar and a corrugated steel plate connector, wherein the corrugated steel plate connector comprises a corrugated steel plate and a connecting bolt; the corrugated steel plate is respectively connected with a prefabricated hollow plate through the connecting bolt; and the connecting bolt is a friction type high-strength bolt. The embedded U-shaped reinforcing bar can effectively improve the strength of the joint surface of the prefabricated hollow slab and the hinge joint, the corrugated steel plate connector can improve the shear strength and bending resistance of the joint, It also enhances the integrity of hollow slabs and hinge joints, and overcomes the shortcomings of low tensile strength of hinge joints of domestic assembled hollow slab bridges, easy cracking, not playing a very good role in transverseconnection, insufficient rigidity of the whole hollow slab bridge, and poor integrity of bridges.

Owner:GUANGDONG UNIV OF TECH

Solid construction paint and preparation method thereof

ActiveCN103540178AGood brushabilityGood durability and protectionPolyurea/polyurethane coatingsChemistryHumectant

The invention provides solid construction paint and a preparation method thereof. The construction paint comprises the following components in percentage by weight: 50-82% of a water-based paint, 2-10% of an excipient, 1-10% of a humectant, 1-5% of a neutralizer, and 0-40.5% of deionized water. The preparation method of the construction paint comprises the following steps: mixing and dissolving the excipient, the humectant and the deionized water so as to obtain a first solution; adding the neutralizer into the first solution, and heating the obtained mixture so as to fully react, thereby obtaining a second solution; adding the water-based paint into the second solution, uniformly dispersing the water-based paint so as to obtain a third solution; and pouring the third solution into a grinding tool to carry out cooling forming, thereby obtaining the paint. The paint provided by the invention is a solid paint, and when the paint is used in construction, paint splashing is not caused, so that indoor facilities are not required to be covered, thereby saving the construction time and reducing manpower and material resources; the paint is short in drying time. When the paint is used in construction, no professional device is required, thereby reducing the construction cost.

Owner:李俊强

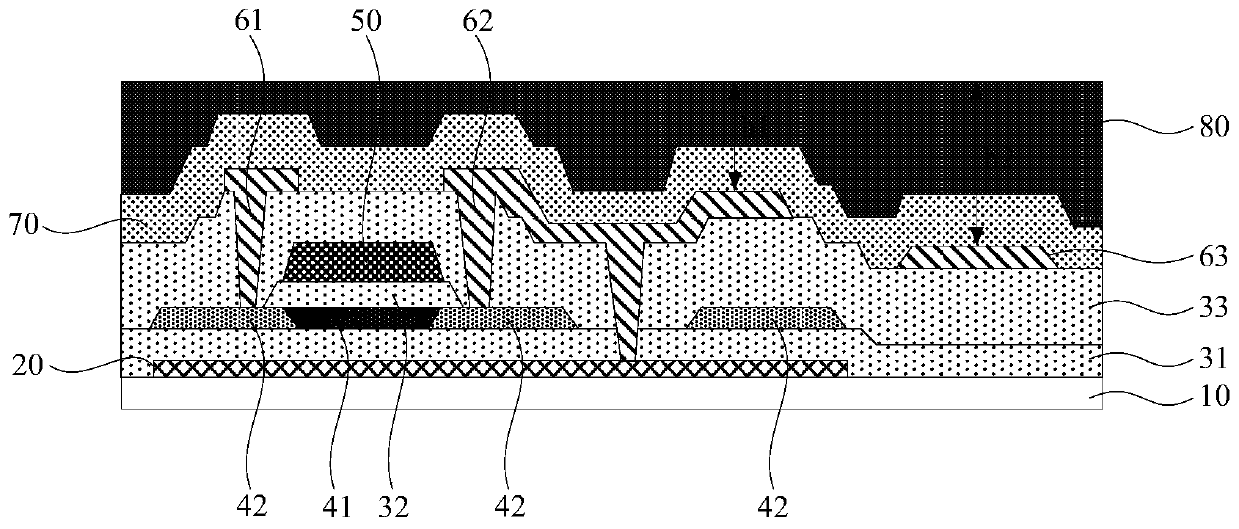

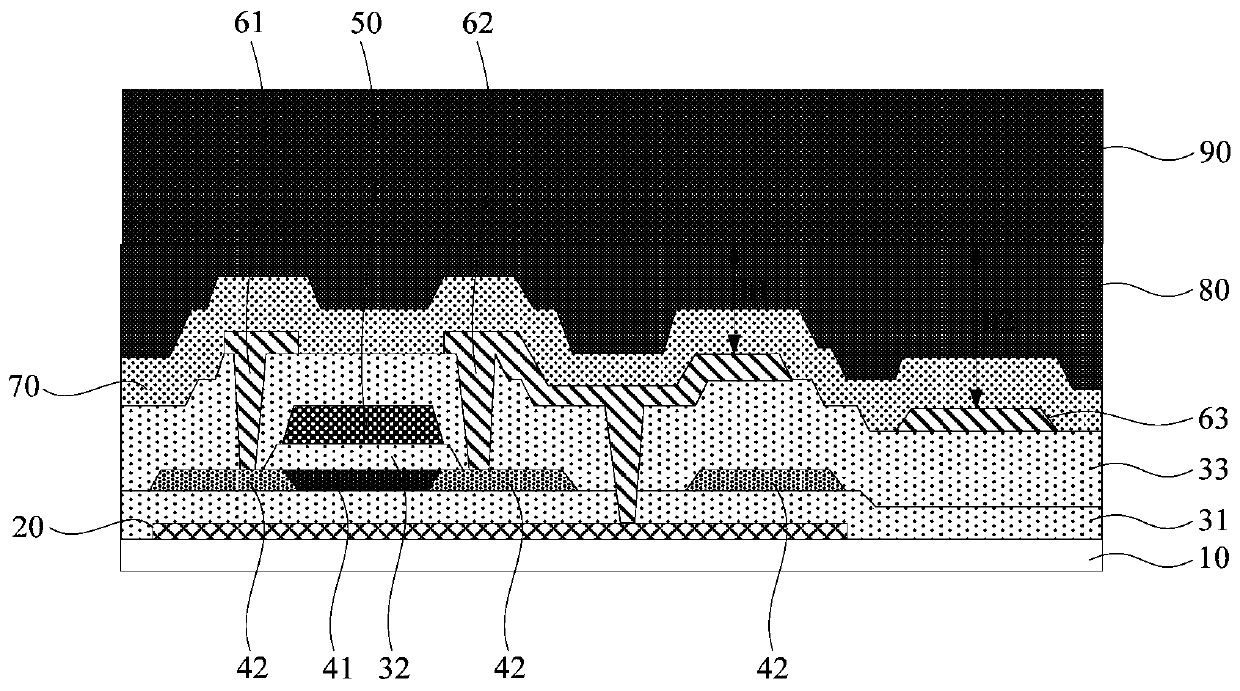

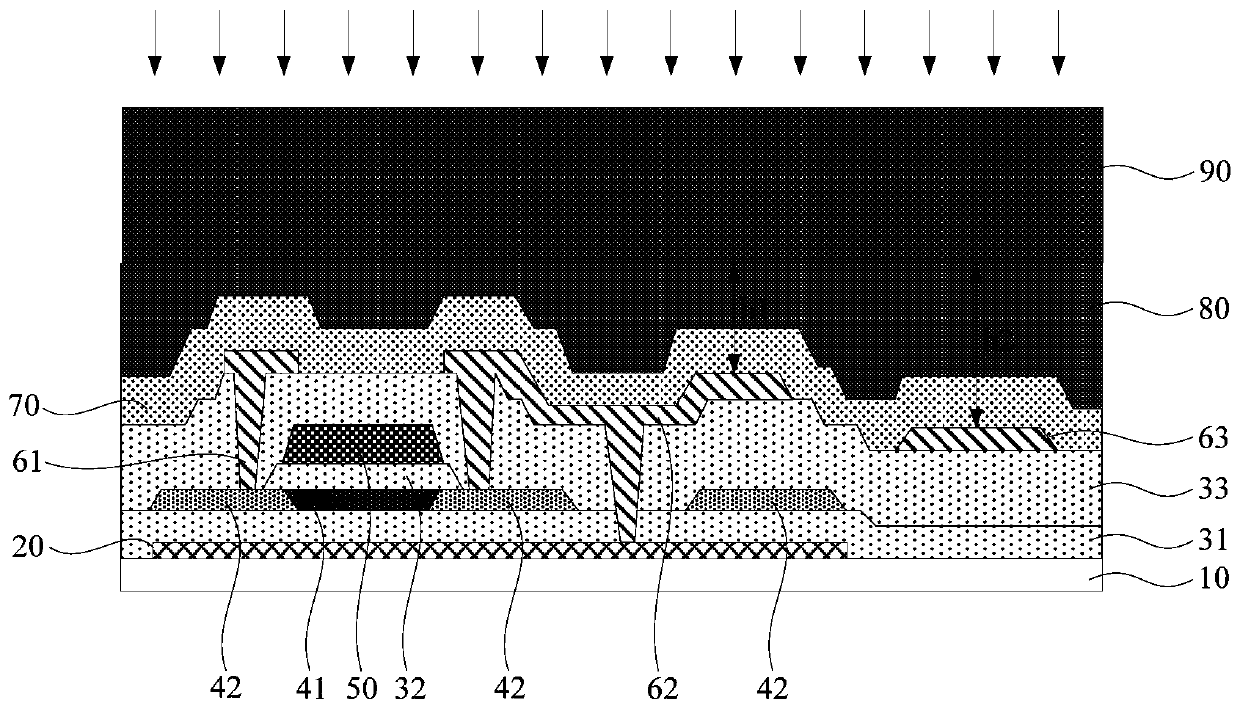

Display substrate, manufacturing method thereof and display device

ActiveCN110767539AAvoid over etchingImprove lapping effectSolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePhotoresist

The invention provides a display substrate, a manufacturing method thereof and a display device, which relate to the technical field of display and solve the problem that when a flat layer is etched at the same time to form a via hole exposing an output electrode and a via hole exposing a compensation cathode pattern, the output electrode is easily over-etched, and subsequent poor lap joint with an anode is caused. The manufacturing method comprises steps: a photoresist layer is exposed, the orthographic projection of a formed photoresist half-reserved area on the substrate is located in the orthographic projection of an output electrode on the substrate, and the orthographic projection of a photoresist complete removal area on the substrate is located in the orthographic projection of a compensation cathode pattern on the substrate; and the photoresist located in the photoresist half-reserved area, a flat layer corresponding to the photoresist half-reserved area and the flat layer corresponding to the photoresist complete removal area are etched, and a first via hole exposing the surface, back to the substrate, of the output electrode and a second via hole exposing the surface, back to the substrate, of the compensation cathode pattern are formed at the same time. The manufacturing method provided by the invention is used for manufacturing the display substrate.

Owner:BOE TECH GRP CO LTD +1

Field machining device and method for small diameter explosive coil

The invention discloses a field machining device and method for a small diameter explosive coil. The machining device is composed of a barrel-shaped plastic bag and a variable diameter coiling block. According to the machining method, by cutting a sealing port in one end of a finished product emulsified explosive coil, a flowing channel is formed; an elastic opening end of the barrel-shaped plastic bag is arranged in the cutting port end of the finished product emulsified explosive coil in a sleeved manner; the cutting port end is made to stretch into a elasticity-free bag body segment portion closely abutting against the barrel-shaped plastic bag; the whole coil of explosive sleeved with the plastic bag is placed in the coiling block; by means of the extruding effect of the coiling block, an emulsified explosive in the explosive coil is extruded into the plastic bag, the plastic bag is made to be filled with the explosives; and the plastic bag and the shrunken finished product explosive coil jointly form the small diameter explosive coil conforming to the engineering requirement, and machining of the explosive coil is completed. The machining device is simple in structure and ingenious in design; and the machining method is convenient and fast in specific operating process. The field machining device and method for the small diameter explosive coil fill up the blank of the machining field of the small diameter explosive coil on the construction field, and the engineering quality of small and medium-sized tunnel contour blasting can be improved easily.

Owner:WUHAN UNIV

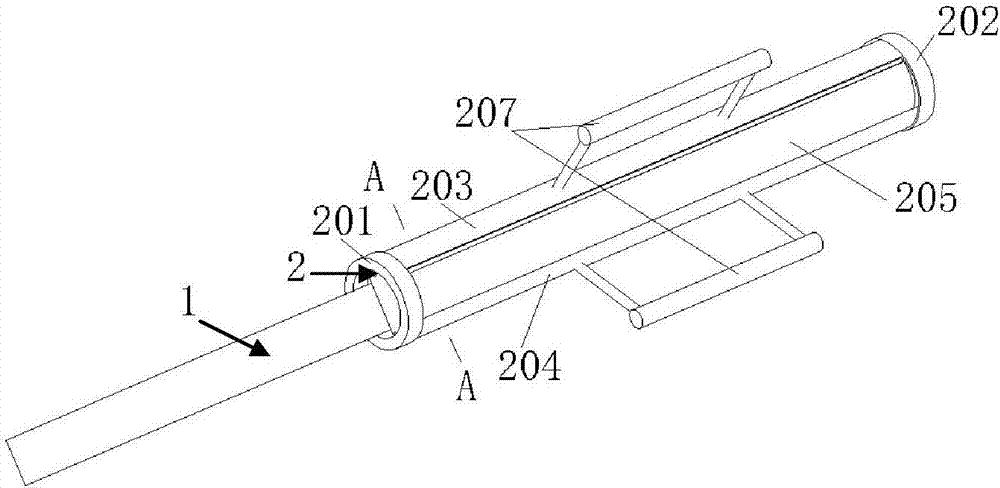

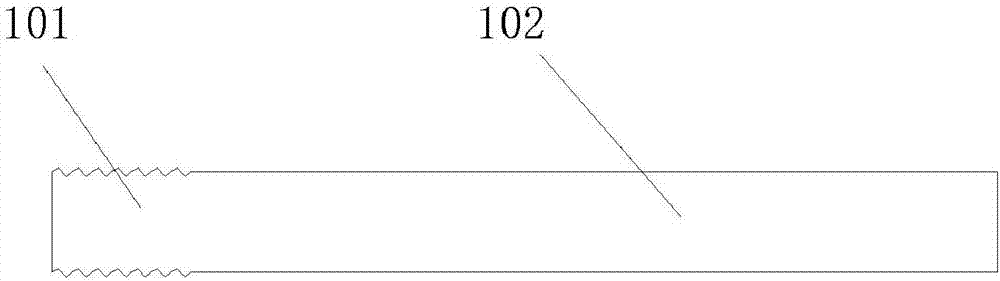

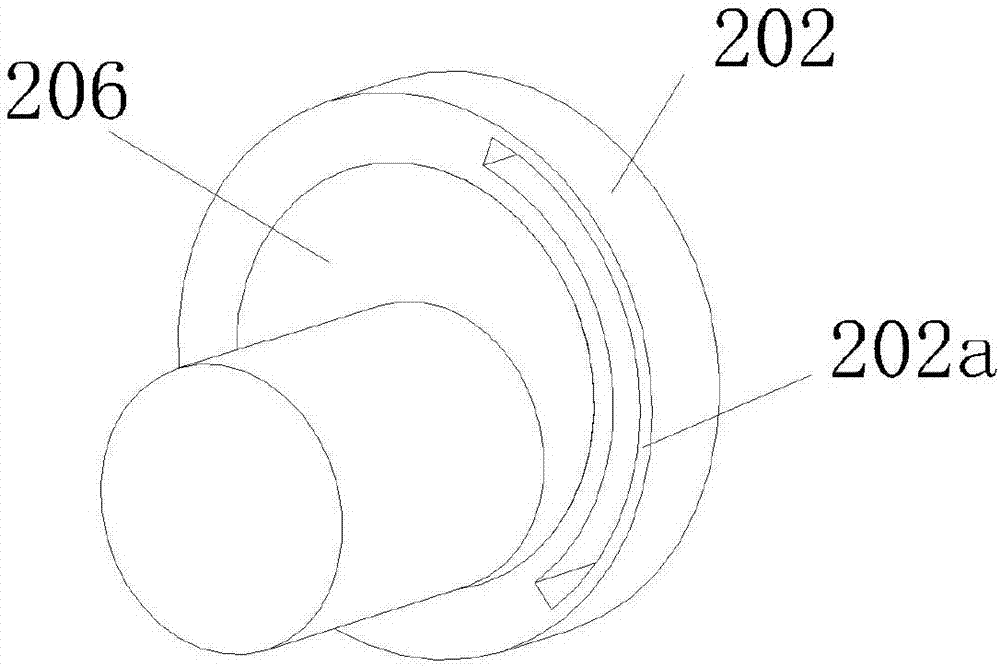

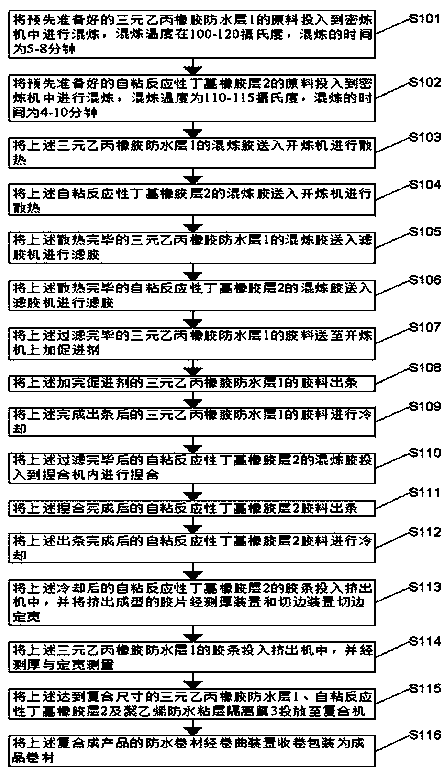

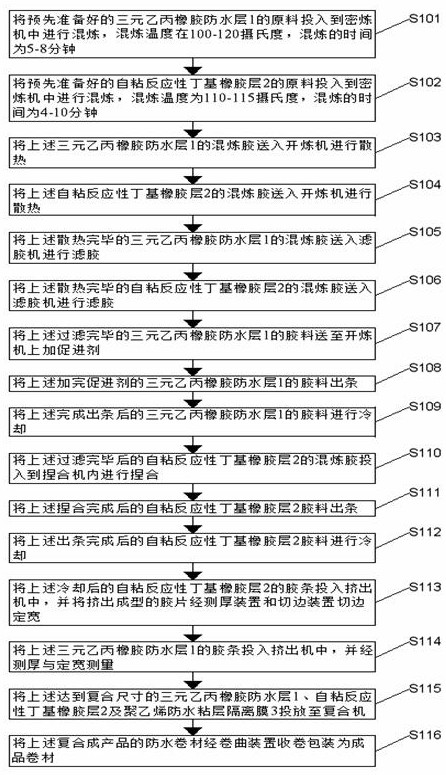

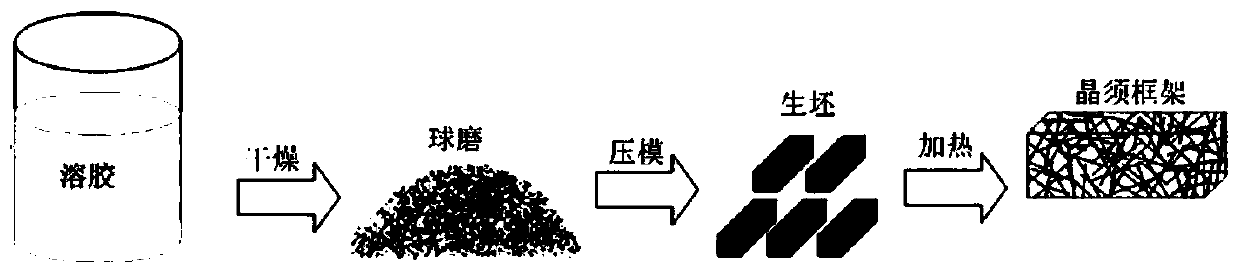

Reaction ethylene-propylene-diene monomer butyl self-adhesive waterproof coiled material and preparation method thereof

ActiveCN110964448AImprove toughnessAvoid breakageNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive

The invention discloses a reaction ethylene-propylene-diene monomer butyl self-adhesive waterproof coiled material and a preparation method thereof. The reaction ethylene-propylene-diene monomer butylself-adhesive waterproof coiled material comprises an ethylene-propylene-diene monomer waterproof layer, a self-adhesive reactive butyl rubber layer is arranged at the bottom end of the ethylene-propylene-diene monomer waterproof layer, and a polyethylene waterproof adhesive layer isolating membrane is arranged at the bottom end of the self-adhesive reactive butyl rubber layer; wherein the ethylene propylene diene monomer waterproof layer is prepared from the following raw materials in parts by mass: 100-200 parts of ethylene propylene diene monomer, 50-100 parts of polyurethane, 10-20 partsof a mixed polyether, 20-30 parts of high-wear-resistant carbon black, 5-10 parts of zinc oxide, 10-15 parts of stearic acid and 5-10 parts of an accelerant. The ethylene-propylene-diene monomer butylself-adhesive waterproof coiled material has the beneficial effects that the toughness of the ethylene-propylene-diene monomer butyl self-adhesive waterproof coiled material is improved, and the situation that after construction tools, building materials and tools for cutting the coiled material fall off, the local waterproof coiled material is damaged is avoided.

Owner:上海豫宏(金湖)防水科技有限公司

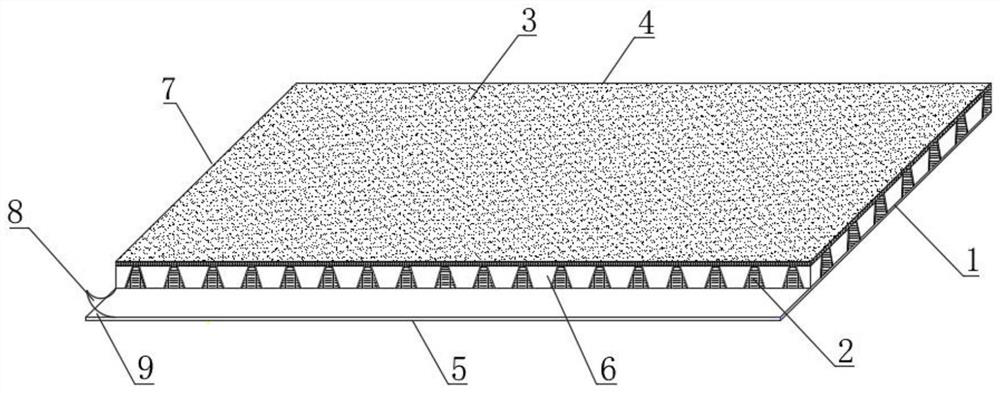

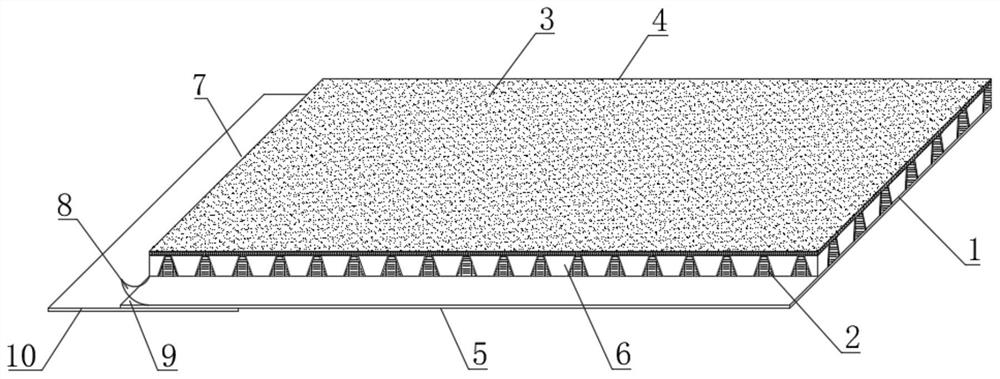

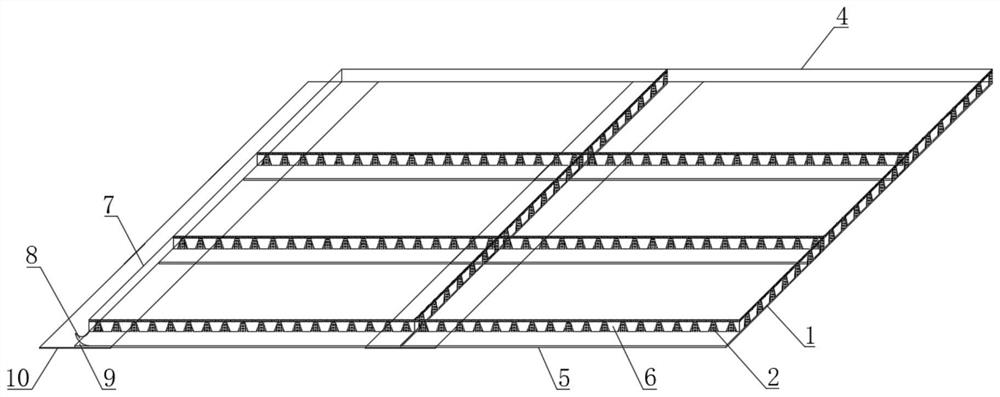

Novel-structure composite waterproof and drainage special-shaped sheet for planted roof and construction process thereof

PendingCN112796468AImprove toughnessTear resistantRoof covering using flexible materialsRoof covering insulationsGeomembraneWater filter

The invention provides a novel-structure composite waterproof and drainage special-shaped sheet for a planted roof and a construction process thereof. The novel-structure composite waterproof and drainage special-shaped sheet for the planted roof comprises a water filtering layer and a waterproof and drainage layer, wherein the waterproof and drainage layer is arranged under the water filtering layer and comprises a waterproof geomembrane; the upper surface, corresponding to the water filtering layer, of the waterproof geomembrane is provided with a plurality of projected casings; spaces among the projected casings form a drainage passage; and at least one edge of the waterproof geomembrane outwards extends out of a lap joint edge. The novel-structure composite waterproof and drainage special-shaped sheet provided by the invention has the advantages that the toughness is good; the tearing resistance and the puncture resistance are realized; the engineering manufacturing cost is reduced; the same-layer drainage design is used, so that the water filtering, the water drainage and the waterproof performance are compounded into a whole; the integration of first drainage and then prevention and waterproof and drainage is really realized; the leakage is thoroughly avoided; and the zero-slope organized drainage is realized.

Owner:青岛门驰建设工程有限公司

Spontaneous heating self-adhesive waterproof coiled material

InactiveCN111519773ARealize self-heatingImprove adhesionFilm/foil adhesivesRoof covering using flexible materialsPolymer scienceIron powder

The invention belongs to the technical field of waterproof coiled materials, and discloses a spontaneous heating self-adhesive waterproof coiled material. The spontaneous heating self-adhesive waterproof coiled material comprises a non-woven fabric breathable layer, a spontaneous heating layer, an isolating membrane and a coiled material waterproof layer, wherein the non-woven fabric breathable layer comprises an outer bag capable of isolating air and a microporous breathable membrane, and the outer bag is attached to the surface of the microporous breathable membrane in a peelable mode; the spontaneous heating layer is attached to the microporous breathable membrane, so that the microporous breathable membrane is located between the outer bag and the spontaneous heating layer; the spontaneous heating layer is internally subjected to an oxidation reaction and contains iron powder, a carbon compound, silicic acid mineral particles and a catalyst; the isolating membrane is attached to the side, away from the non-woven fabric breathable layer, of the spontaneous heating layer; and the coiled material waterproof layer is arranged between the isolating membrane and the spontaneous heating layer. According to the spontaneous heating self-adhesive waterproof coiled material, an additional heating device is not needed, the outer bag is torn so that spontaneous heating of the waterproofcoiled material can be achieved, heating is very uniform, the good adhesive performance can be kept in a low-temperature environment, and the adhesive effect between the coiled material and a base surface and the overlapping effect between the coiled materials are improved.

Owner:SHENZHEN ZHUOBAO TECH

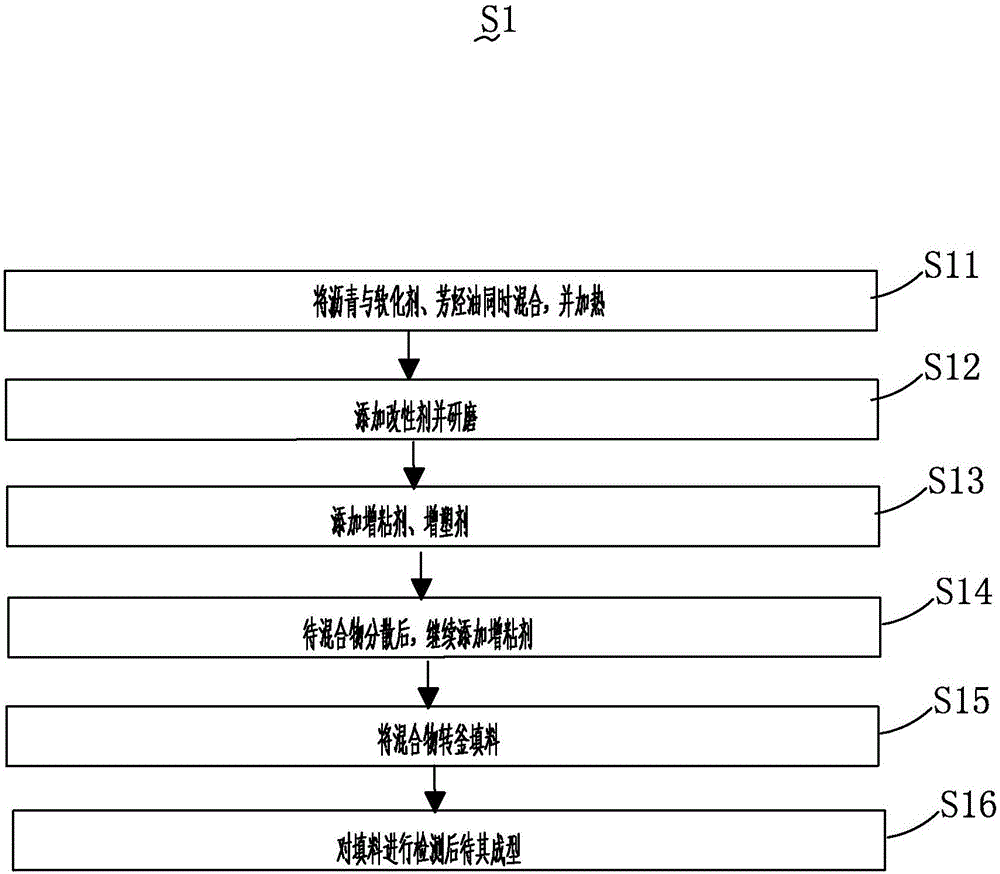

Aromatic hydrocarbon oil asphalt waterproof roll and production process thereof

InactiveCN106634822ALow peel yieldImprove initial tack performanceBituminous material adhesivesMacromolecular adhesive additivesRubber materialBituminous waterproofing

The invention provides an aromatic hydrocarbon oil asphalt waterproof roll and a production process thereof. The aromatic hydrocarbon oil asphalt waterproof roll comprises a pre-paved and wetly-paved asphalt waterproof roll rubber material layer, wherein the pre-paved and wetly-paved asphalt waterproof roll rubber material layer is prepared from the following raw materials: 35%-42% of petroleum asphalt, 4%-10% of a softening agent, 4%-10% of aromatic hydrocarbon oil, 5%-15% of a modifying agent, 1%-10% of a tackifier, 2%-10% of an anti-ageing agent, 2%-6% of a plasticizer and 10%-20% of a filling agent. According to the aromatic hydrocarbon oil asphalt waterproof roll provided by the invention, the bonding performance of the aromatic hydrocarbon oil asphalt waterproof roll can be effectively improved and the bonding capability of overlapping joint in a construction process of the roll is extremely improved; the waterproof effect is improved; and after the waterproof roll is constructed and before a protection layer is formed, an overlapping joint edge of the material can be effectively prevented from falling under the action of day-night temperature difference.

Owner:CHENGDU ZHUOBAO NEW BUILDING MATERIAL CO LTD

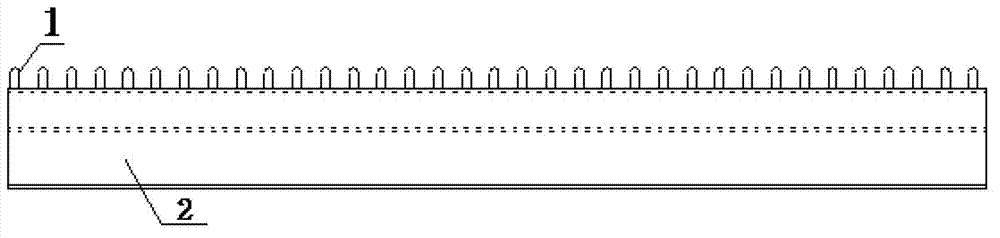

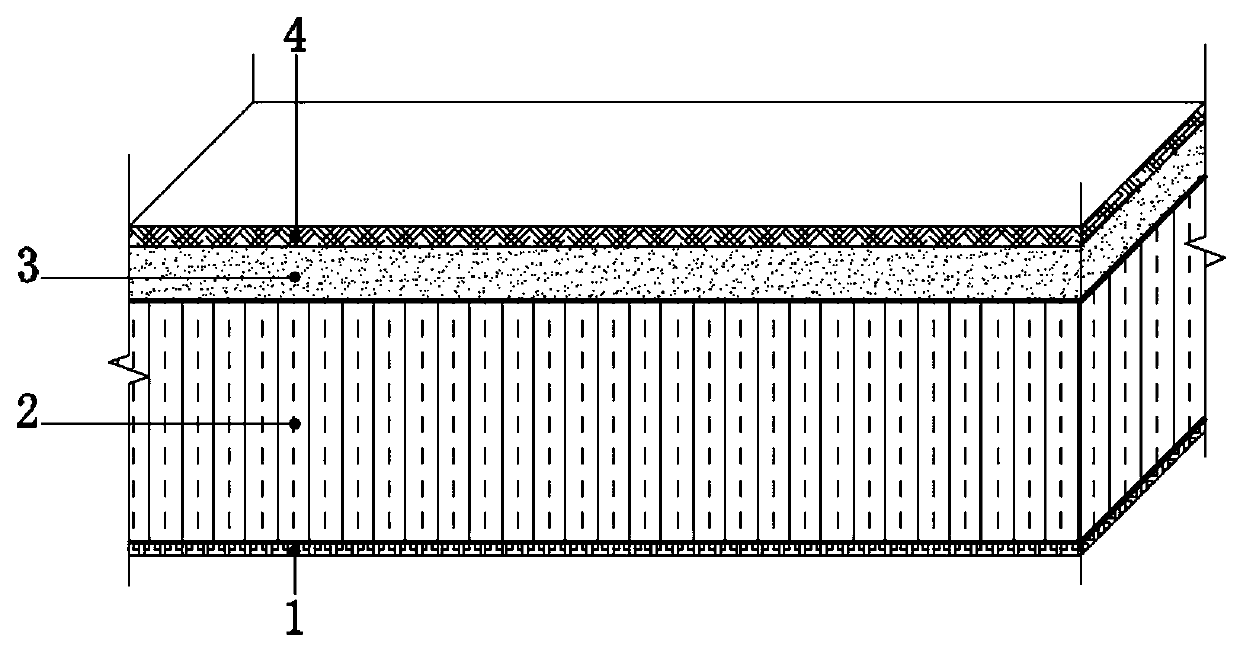

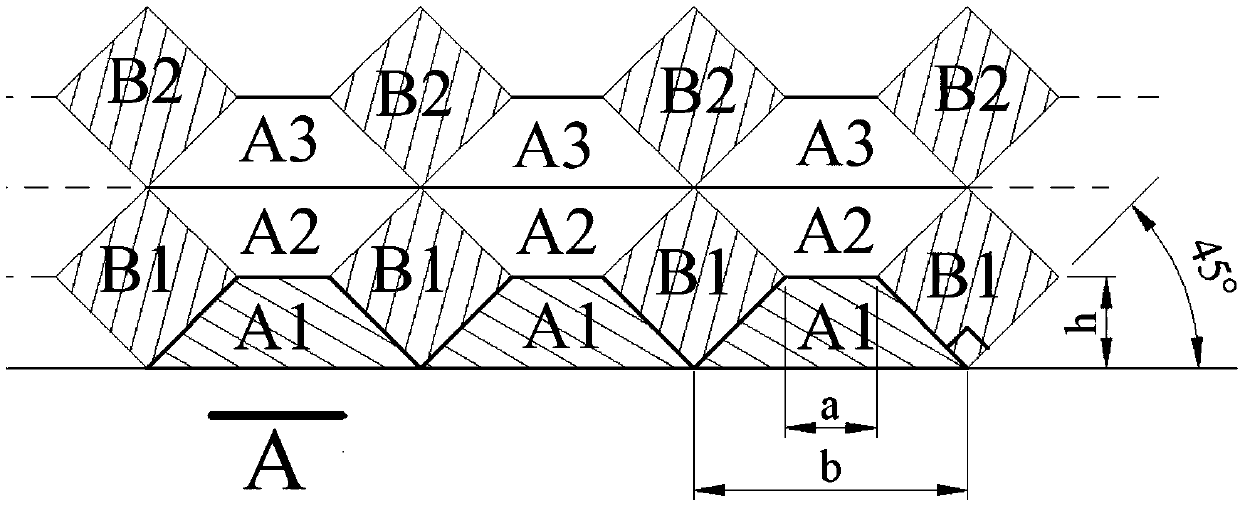

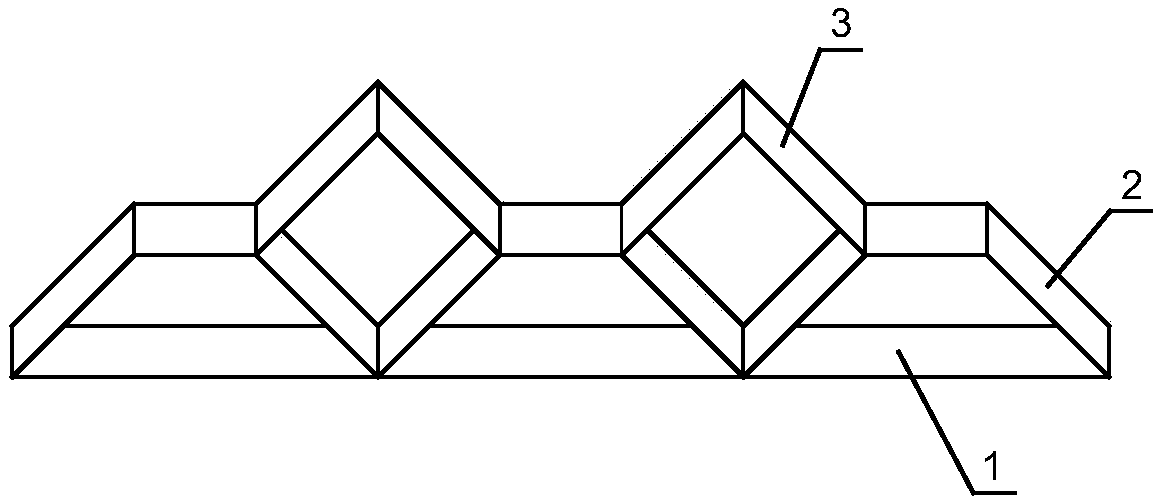

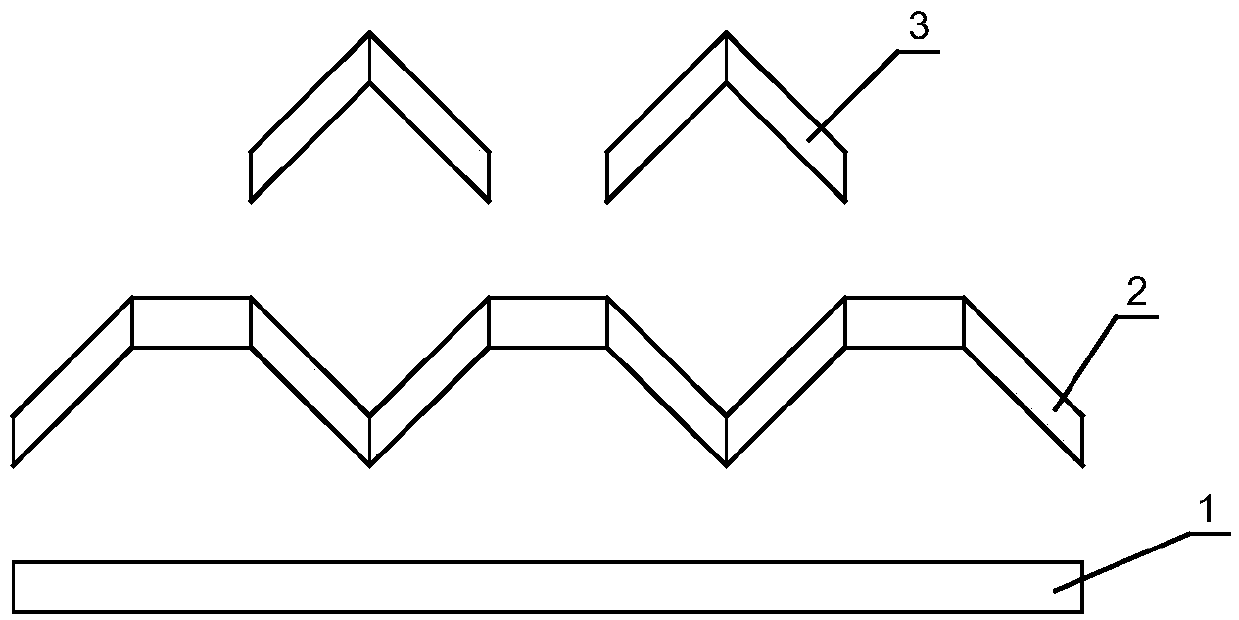

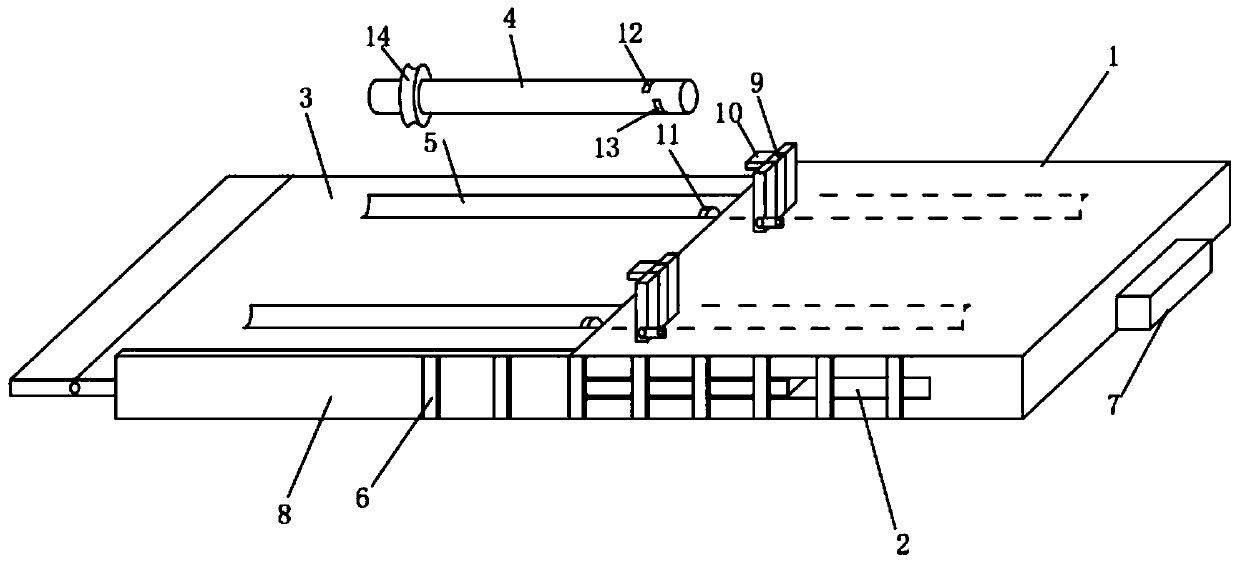

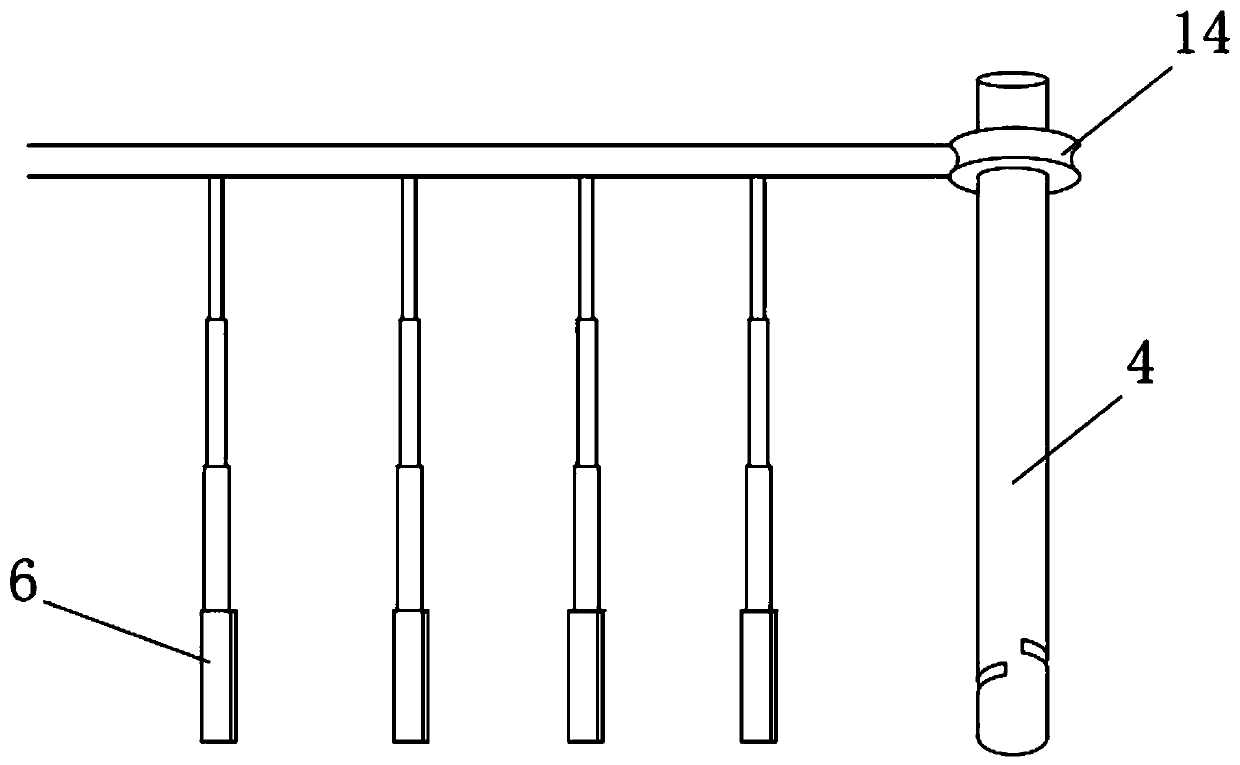

Laminated structure solid-phase additive manufacturing method

ActiveCN109663920AOptimizing the Solid Phase Additive ProcessImprove lapAdditive manufacturing apparatusSolid phasesLap joint

The invention discloses a laminated structure solid-phase additive manufacturing method. The method comprises the following steps that a wire material is heated to a softening state, and a corresponding roller mould with an isosceles trapezoid, a square and a plane shape is adopted by means of external force, in the raw material forming process, filling and repairing are carried out alternately, so that a trapezoid shape, a square shape, an inverted trapezoid shape and a trapezoid shape are formed by the raw materials layer by layer in sequence, additive manufacturing is carried out sequentially and circularly, and the raw materials are columnar wire materials. The method is a solid-phase additive forming method which is free in phase change, stable in lap joint, in extrusion / forging type,compact in structure, precise in forming and low in cost. The technical scheme of the method can be widely applied to short processes, high quality, high efficiency and overall manufacturing of medium and large structural members, the practical bottleneck which is difficult to control in forming and poor in performance reliability in the existing melting additive directly forming high-performanceaerospace component technology at home and abroad is broken through, and a practical new way is developed for high-quality, high-efficiency and directly integral manufacturing of the large and medium-sized and high-performance complex parts.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

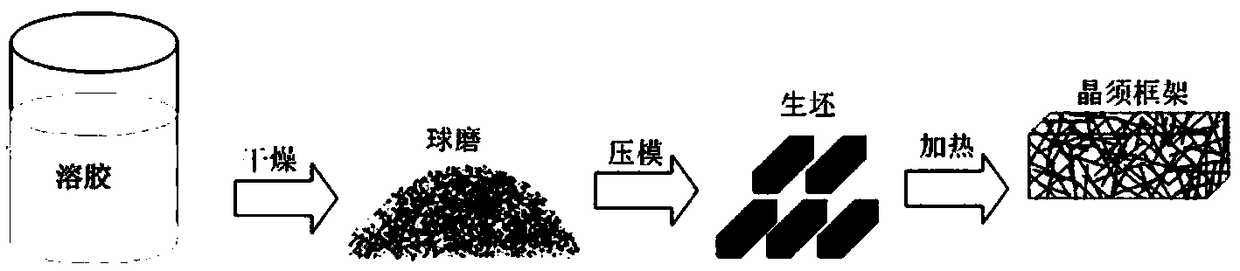

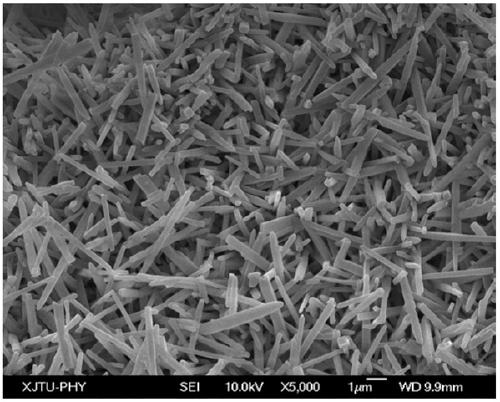

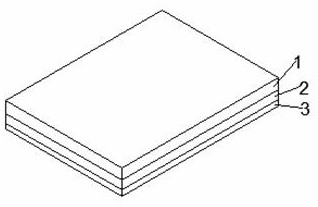

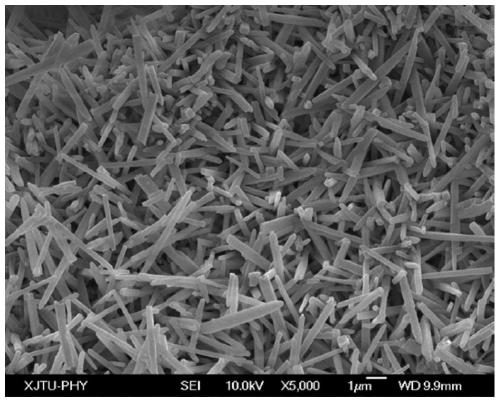

Method used for increasing mullite porous material strength through sol mixing-fine grinding-pressurization

ActiveCN109180174AIncreased in situ reaction rateImprove responseCeramic shaping apparatusCeramicwareDispersed mediaPorosity

The invention discloses a method used for increasing mullite porous material strength through sol mixing-fine grinding-pressurization. The method comprises following steps: 1, sol mixing, and magneticstirring are carried out, hydrofluoric acid is added drop by drop, an obtained precursor colloid is dried to remove a disperse medium so as to obtain a dried colloid; 2, the dried colloid is subjected to ball milling so as to obtain dry colloid fine powder; 3, the dry colloid fine powder is subjected to pressing so as to obtain a block-shaped blank material; and 4, the blank material is subjectedto calcining so as to obtain the mullite porous material. The method is capable of realizing real molecule grade uniform mixing of all reactants, increasing in-suit reaction rate, promoting reactioneffect, and increasing strength without influencing the whole porosity; no complex equipment is needed by the preparation technology; and operation is simple and convenient.

Owner:XIAN AERONAUTICAL UNIV

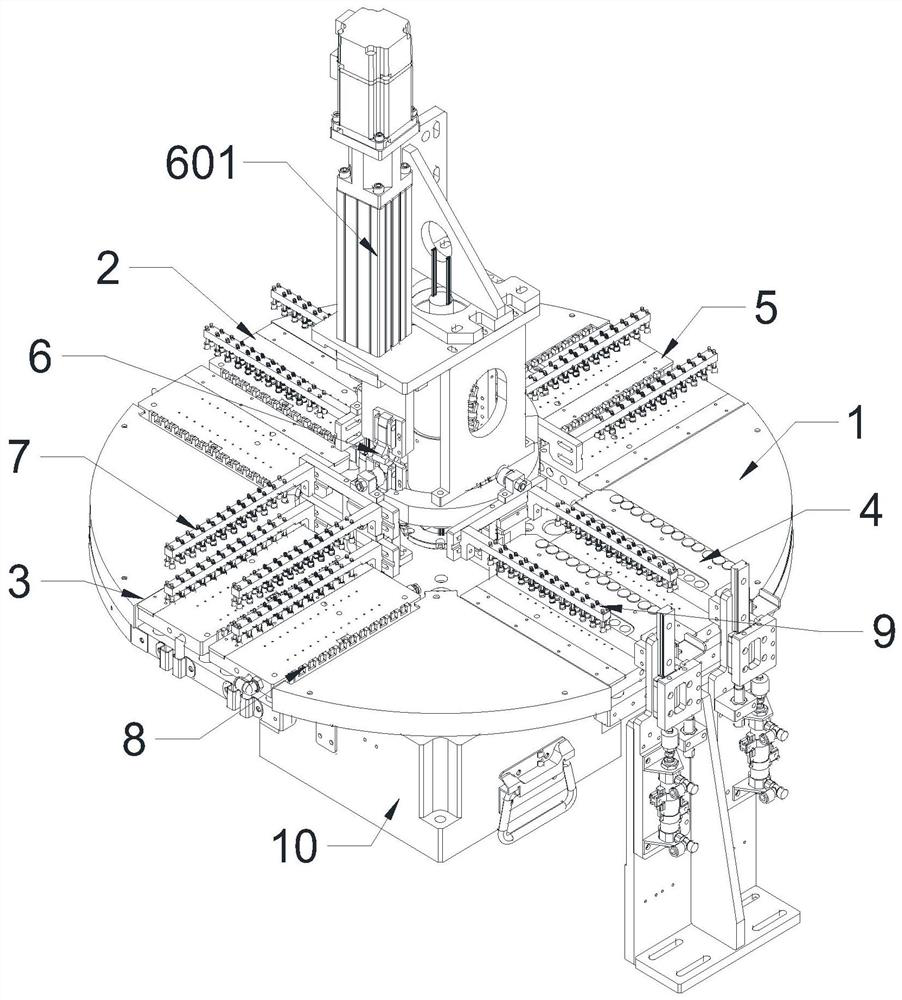

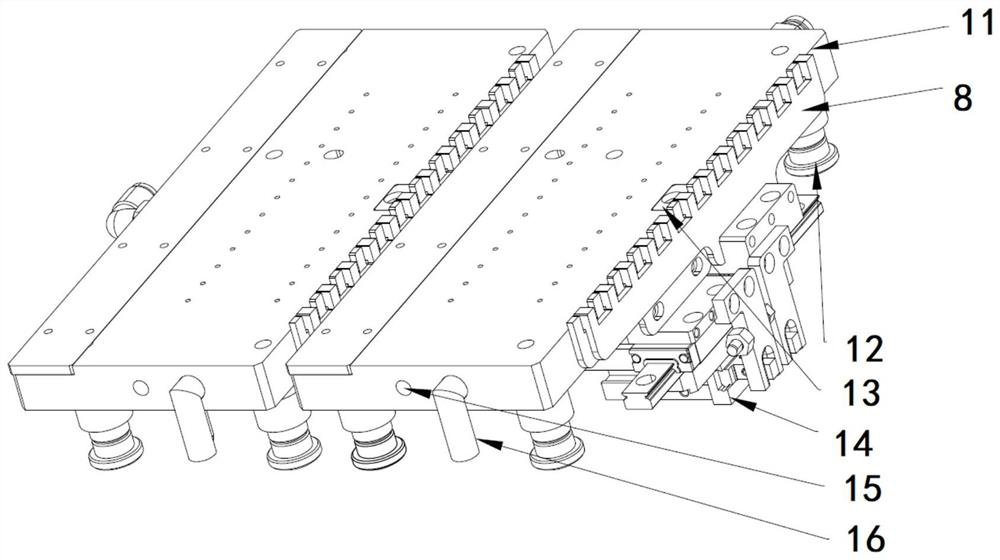

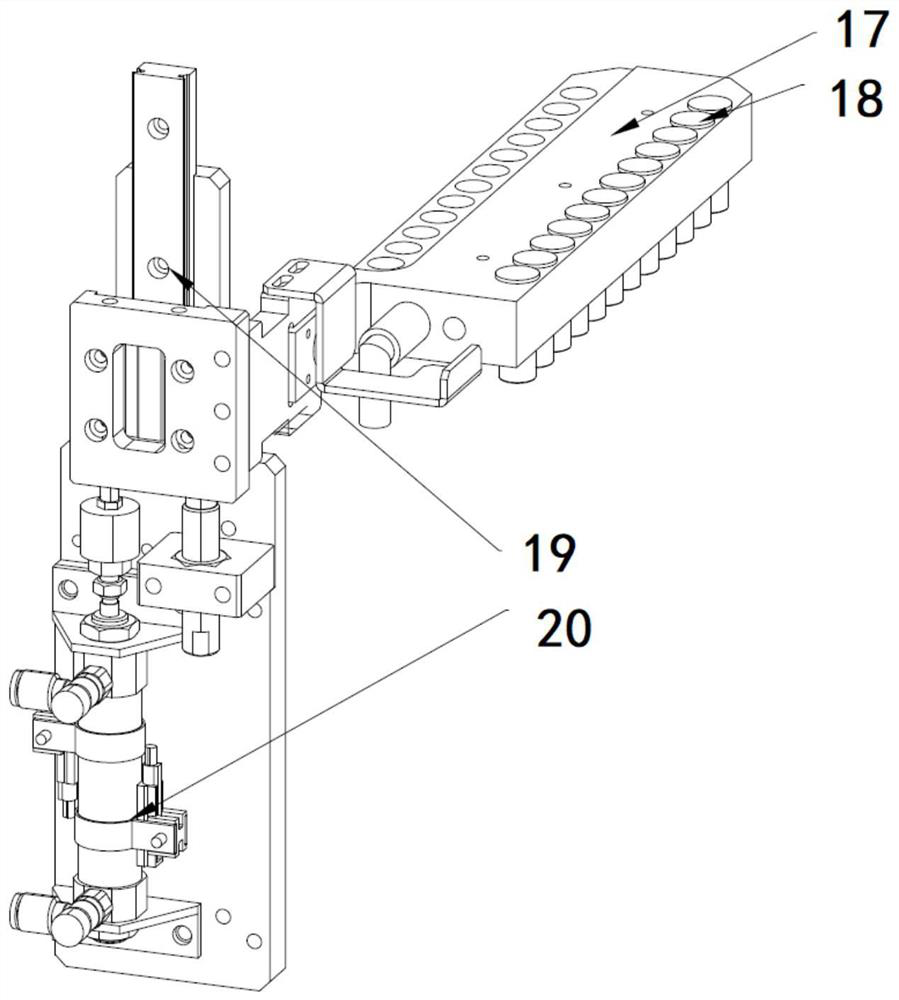

Flat welding strip pre-welding rotary table welding device

ActiveCN113210918AImprove efficiencyIncrease production capacityFinal product manufactureWelding/cutting auxillary devicesElectrical batteryEngineering

The invention discloses a flat welding strip pre-welding rotary table welding device, and relates to the technical field of photovoltaic module production. The flat welding strip pre-welding rotary table welding device comprises a rotary table, a first station, a second station, a third station, a fourth station, a pressing mechanism, a welding strip positioning structure and a welding strip pre-welding mechanism, wherein the rotary table is used for controlling the conversion of the welding strip positioning structure; welding tables, positioning clamps and positioning blocks are arranged on the rotary table of all the stations, and air suction structures are arranged on the welding tables; the pressing mechanism is used for pressing the welding strip positioning structure, and the pressing mechanism is located on a support tool of a rotating shaft; the welding strip positioning structure is used for positioning a battery piece; and the welding strip pre-welding mechanism comprises a heating block, cylindrical pressing needles, a first guide rail and a lifting driving mechanism, the cylindrical pressing needles are installed in the heating block, the heating block is connected to the first guide rail in a sliding mode, and the heating block is connected to the lifting driving mechanism. The device has the following beneficial effects that (1) the efficiency and the productivity of the device are greatly improved; (2) the operation is convenient and stable; and (3) the welding strip is good in lap joint effect and not prone to dislocation.

Owner:HANGZHOU JOY ENERGY TECH CO LTD

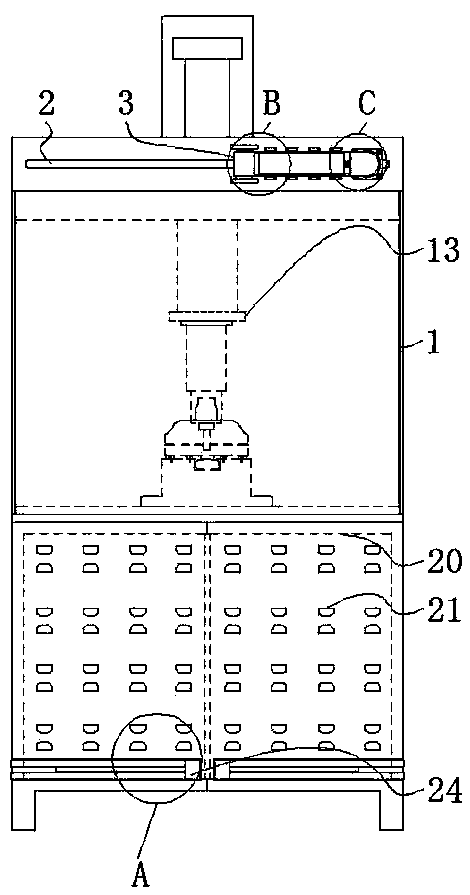

Lap joint device used between floor and construction elevator

The invention provides a lap joint device used between a floor and a construction elevator, and belongs to the technical field of construction elevators. The lap joint device comprises a main board, an auxiliary board, protection columns and guardrails. A gap groove is formed in one side face of the main board. The shape of the auxiliary board is matched with that of the gap groove, and the auxiliary board is arranged in the gap groove of the main board in a sliding and penetrating manner. The protection columns are arranged in containing troughs formed in the face of the auxiliary board, fixed troughs are formed in the top face of the gap trough, when the auxiliary board is inserted into the gap trough, the protection columns are contained by the containing troughs and the fixed troughs together, and when the auxiliary board slides out of the gap trough, the protection columns are erected by means of a stirring mechanism. The multiple guardrails are arranged on the side of the main board in a sliding manner. The safety problem about the manner of achieving lap joint through traditional wood boards in the prior art is solved.

Owner:THE 13TH CONSTR CO LTD OF CHINA NAT CHEM ENG

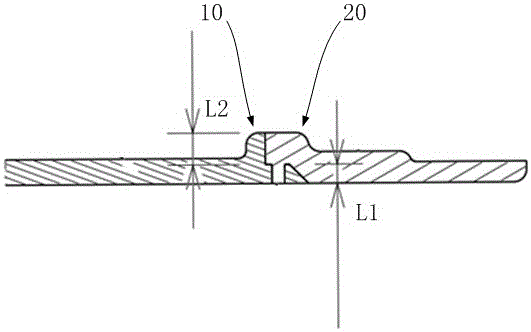

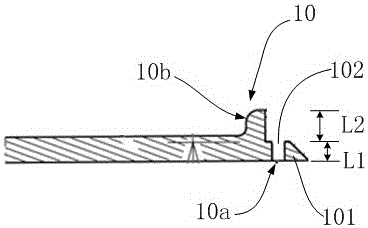

Soft and hard rubber lap joint structure for recycling-prevention partition board

The invention discloses a soft and hard rubber lap joint structure for a recycling-prevention partition board. Two lap joint structures are fixedly arranged at joints of soft rubber and hard rubber respectively, and are matched with each other in a lap joint manner. The soft and hard rubber lap joint structure for the recycling-prevention partition board provided by the invention has the advantages of easy mold forming, good lap joint effect of soft and hard rubber and the like, is high in bonding strength when in use, and is difficult to break at the lap joint position of the soft and hard rubber, the using function is strengthened, the service life is prolonged, the mold structure is simplified, and the production cost is reduced.

Owner:CHENGDU AEROSPACE MOLD & PLASTIC CO LTD

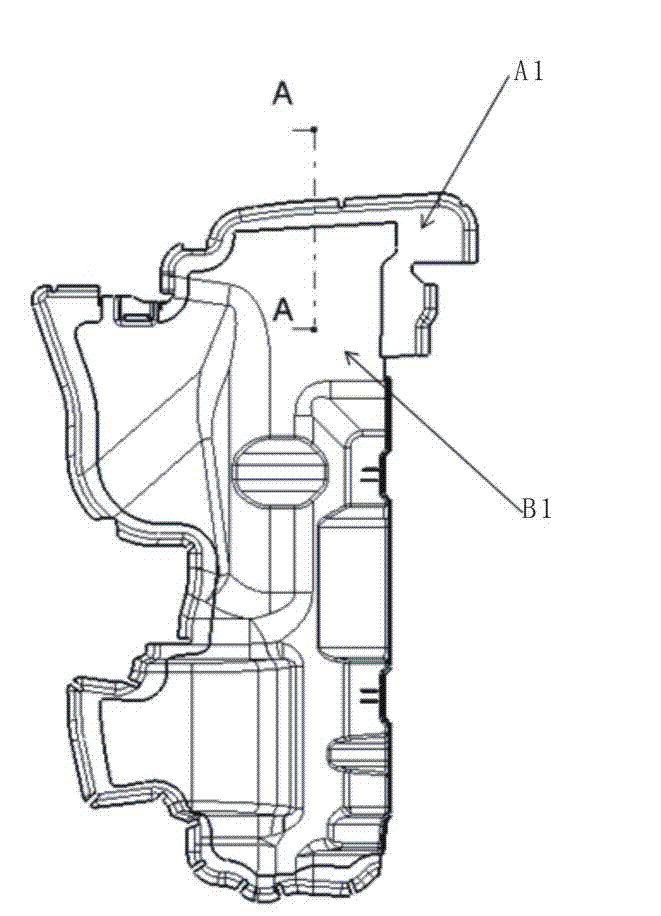

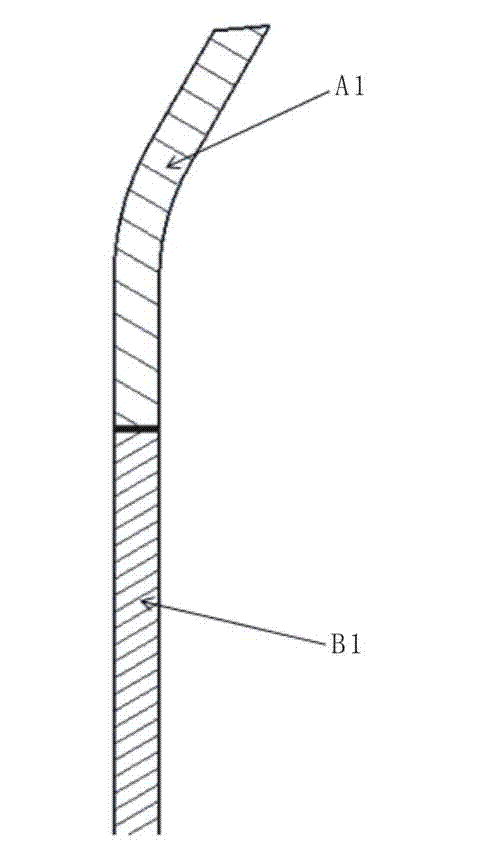

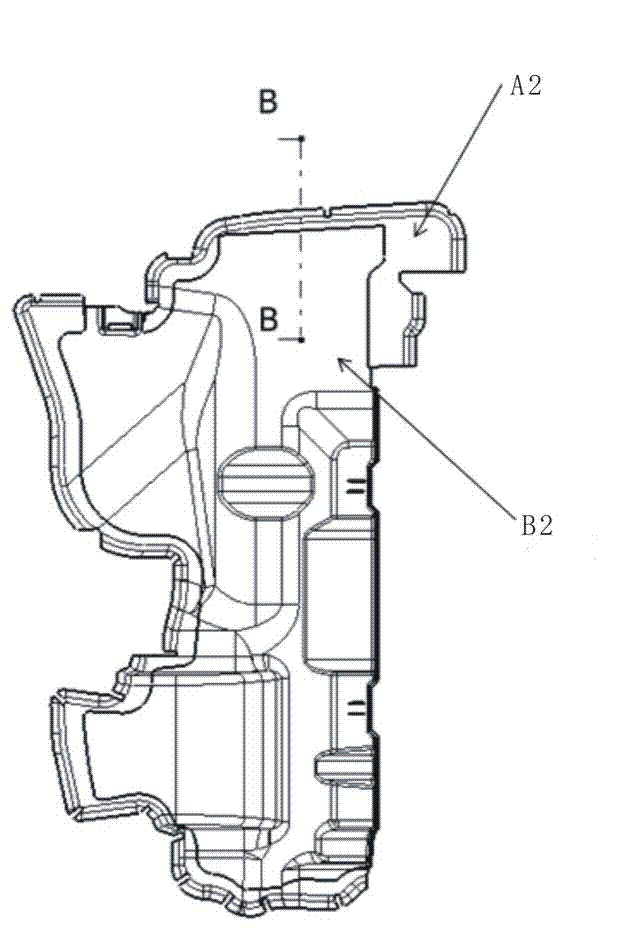

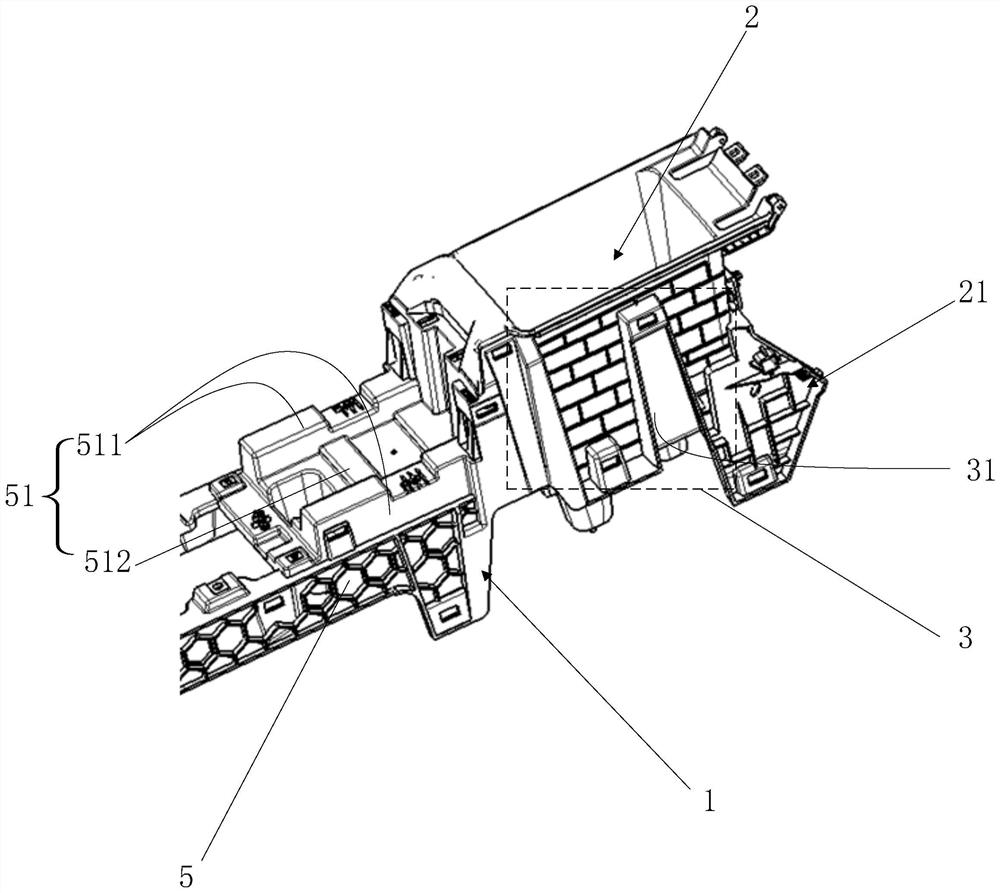

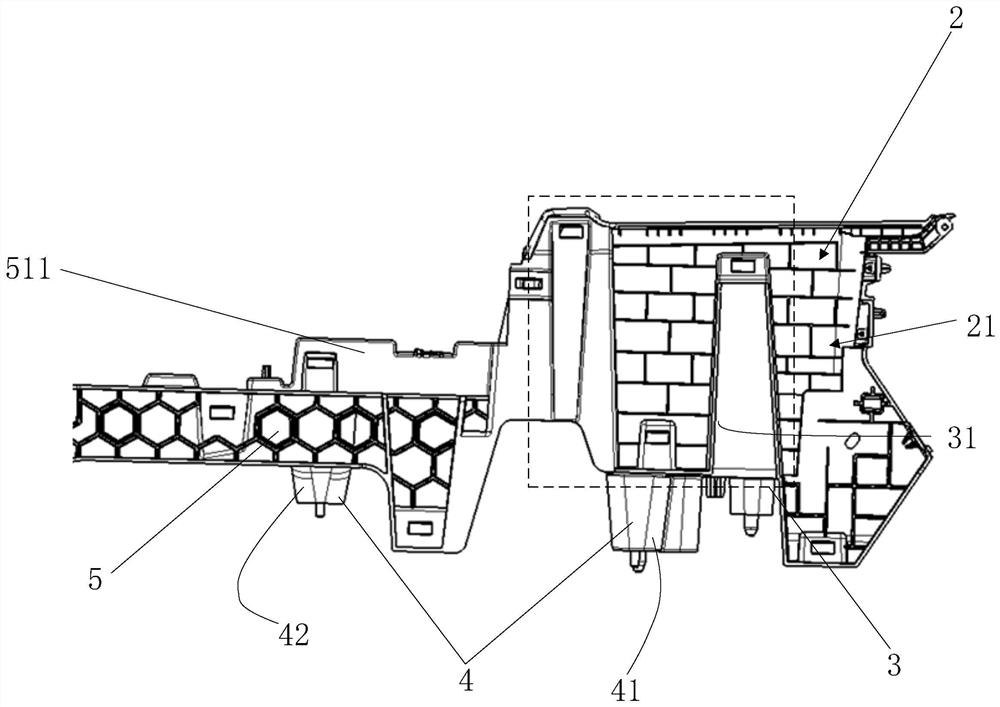

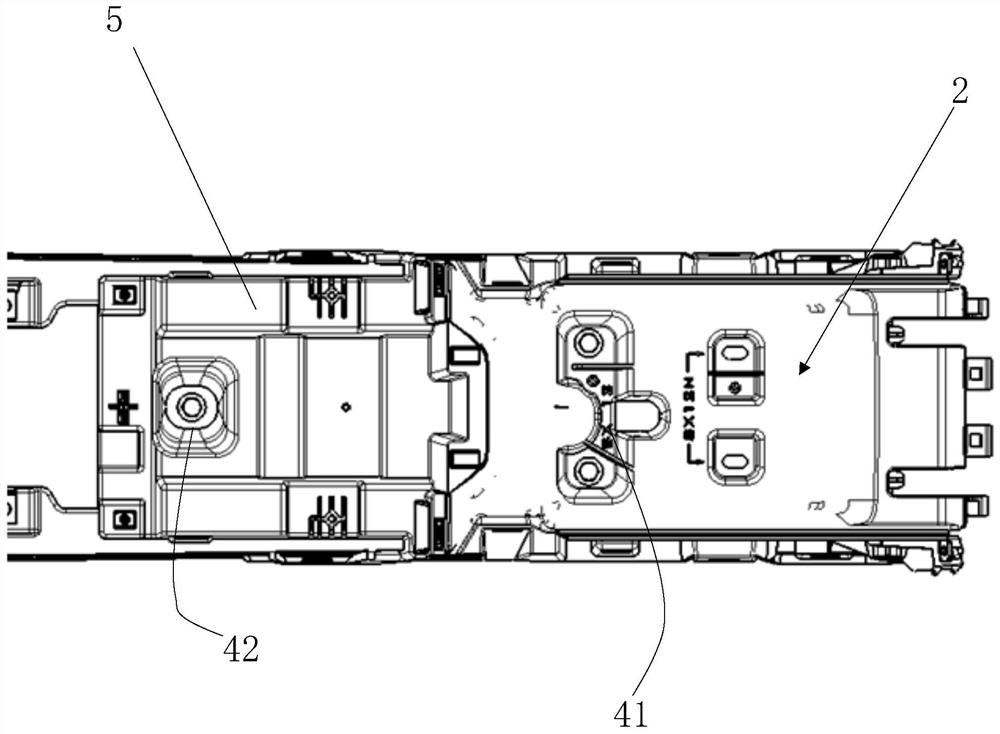

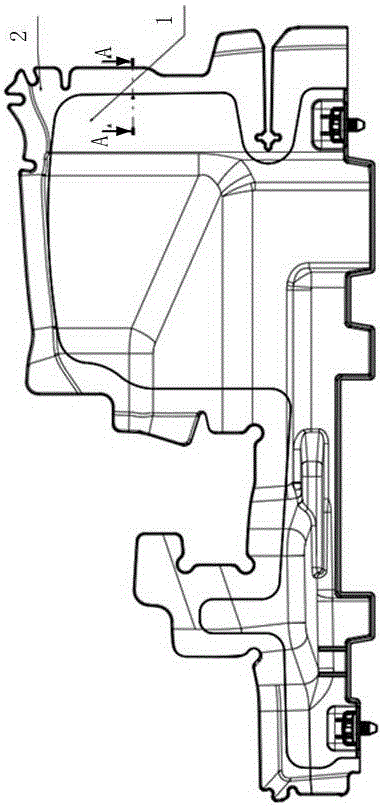

A sub-dashboard skeleton

ActiveCN111361414BQuality improvementImprove side stiffnessPassenger spaceDashboardsEngineeringStructural engineering

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

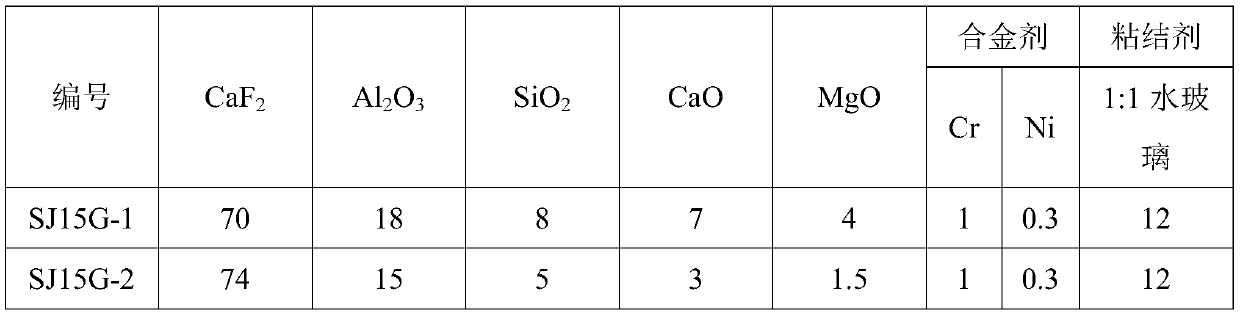

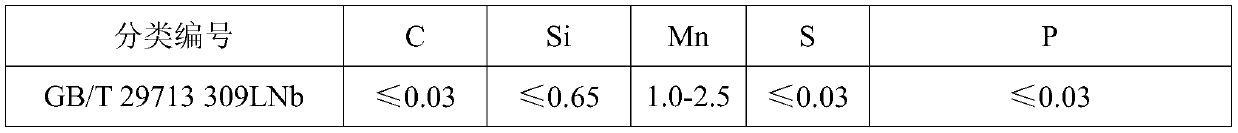

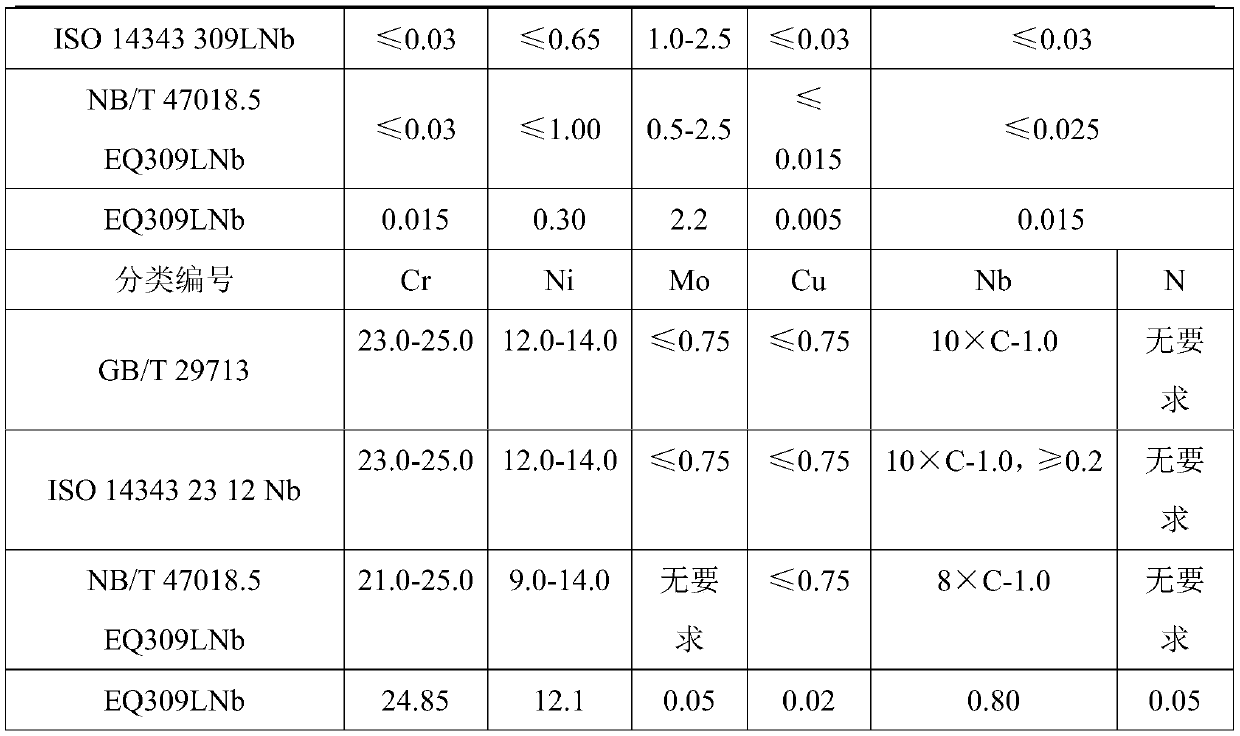

High-efficiency 309Nb single-layer strip surfacing sintering flux used in EQ309LNb welding strip and preparation method thereof

InactiveCN110405381AImprove work efficiencyImprove efficiencyWelding/cutting media/materialsSoldering mediaMetallurgyMonolayer

The invention discloses high-efficiency 309Nb single-layer strip surfacing sintering flux used in EQ309LNb welding strip and a preparation method thereof, and relates to a sintering flux and a preparation method thereof. The sintering flux and the preparation method thereof aims to solve the problem that the sintering flux cannot be welded with the 309Nb welding strip in a matched mode at 400-500mm per minute, and improve the working efficiency. The sintering flux comprises the following components of, in parts by weight, 70-80 parts of CaF2, 15-20 parts of Al2O3, 4-10 parts of SiO2, 2-8 partsof CaO, 1-5 parts of MgO, 1-2 parts of an alloying agent and 10-15 parts of a binding agent. After mixing the above components, granulating and sintering in turn, the sintering flux is obtained. Whenthe sintering flux is matched and welded with the 309 Nb welding strip surfacing, the efficiency is improved by 60-100% compared with that of a common single-layer strip surfacing and the efficiencyis improved by 33-67% compared with that of the high-speed strip-electrode surfacing. The flux and the method are applied to the field of surfacing.

Owner:HARBIN WELL WELDING CO LTD +2

A construction method of lapping bentonite waterproof blanket by using photocuring technology

ActiveCN103669603BEffective overlapSimple processBuilding insulationsUltraviolet lightsWater soluble

The invention provides a construction method for the overlap joint of geosynthetic clay liners by using a photocuring technology. The method comprises the steps that water-soluble ultraviolet light curable resin and photoinitiator are sprayed on the surfaces of the geosynthetic clay liners in sequence, the photoinitiator is irradiated by using ultraviolet light to trigger the curing of the water-soluble ultraviolet light curable resin, and the overlap joint between the geosynthetic clay liners is achieved. The method is simple in technology and low in cost, the overlap joint can be achieved between the geosynthetic clay liners and other materials and among the geosynthetic clay liners in a construction process by using the photocuring resin, the overlap joint effect is good, and leakage does not occurs easily.

Owner:HOHAI UNIV

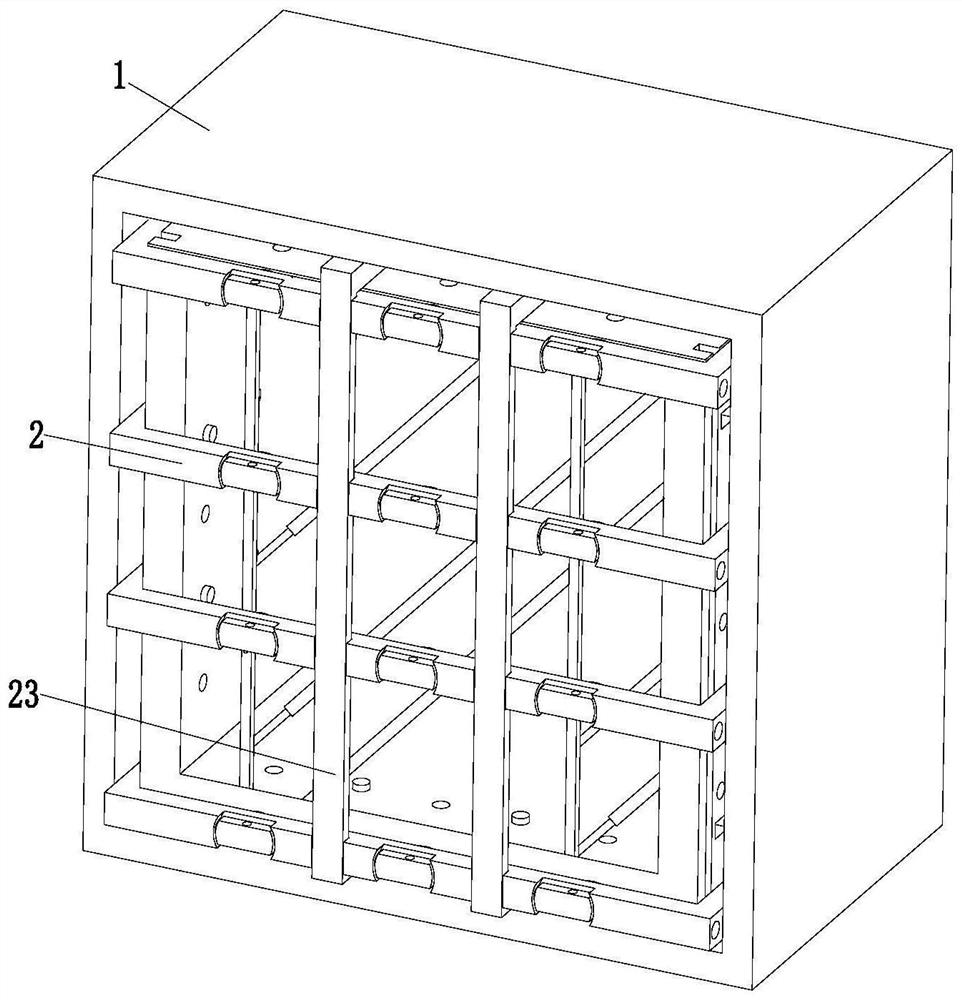

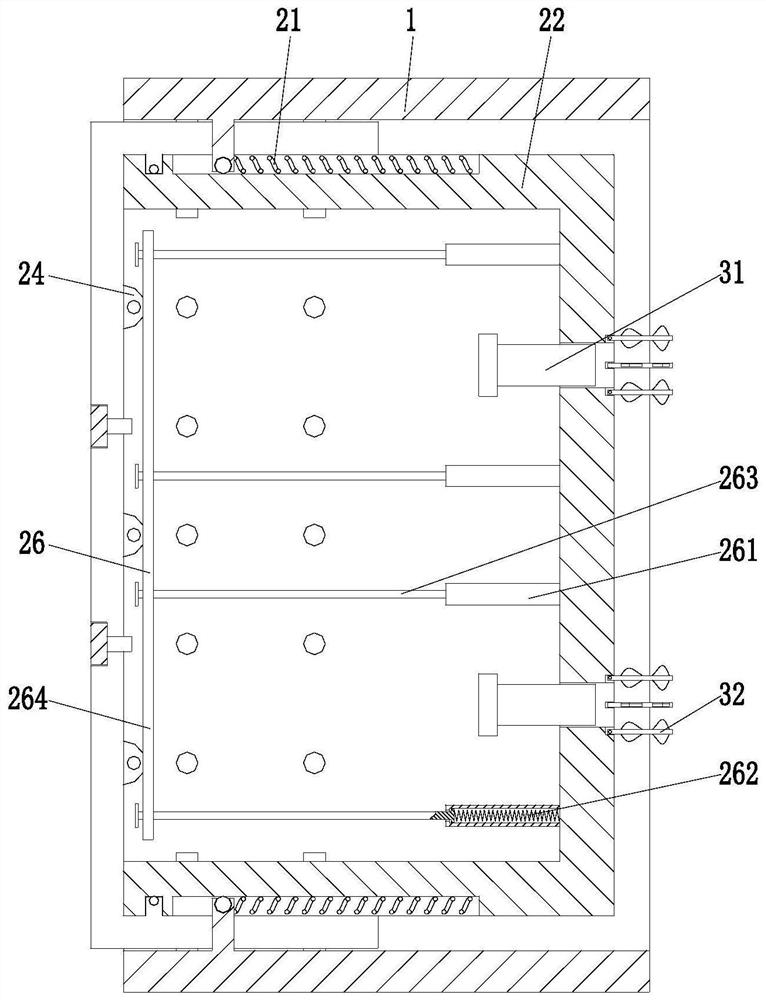

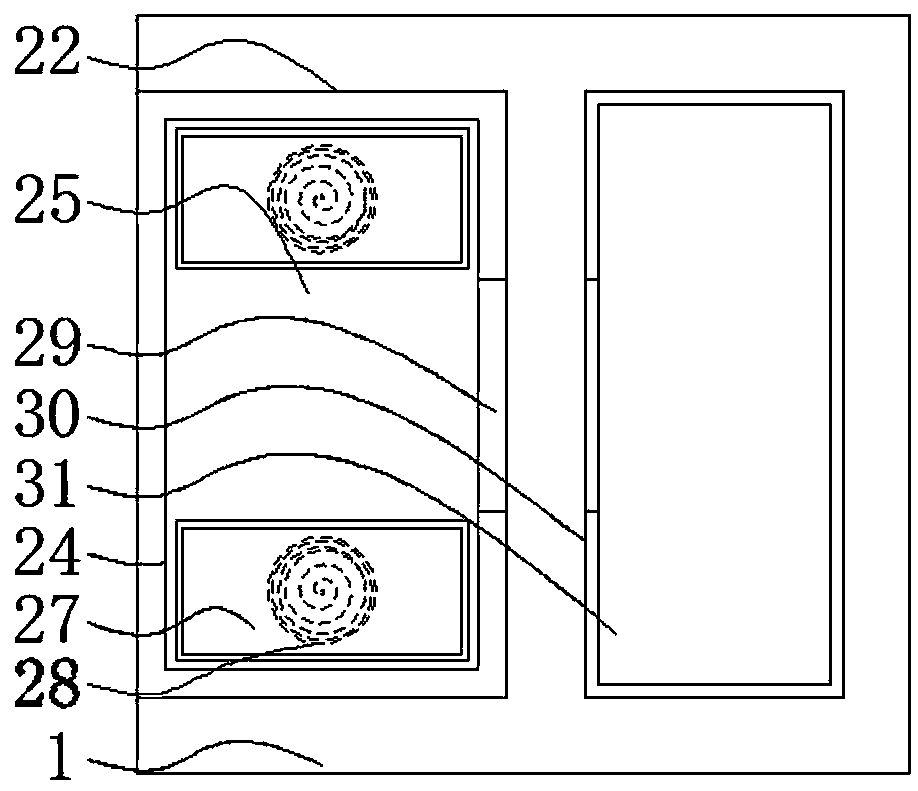

An lcd liquid crystal display splicing screen fixing bracket frame

ActiveCN110767103BImprove lapping effectEasy to fixIdentification meansLiquid-crystal displayEngineering

The invention provides a fixed bracket frame for LCD splicing screen, which includes an outer limiting basket, a clamping mechanism and a fixing mechanism; it is characterized in that: the outer limiting basket is installed on the clamping mechanism through sliding fit, The clamping mechanism is evenly provided with a fixing mechanism inside; the present invention can solve a: the size of the internally divided frame of the existing liquid crystal display splicing screen fixing bracket frame is fixed, and it is difficult to adjust adaptively for display screens of different sizes; The limitation is relatively large; b: the existing liquid crystal display splicing screen fixing support frame has a poor fixing effect on the display screen, which causes the internal display screen to be fixed on the support frame and is easily subject to problems such as wind blowing, shaking and falling off.

Owner:RENMIN BAIYE TECH CO LTD

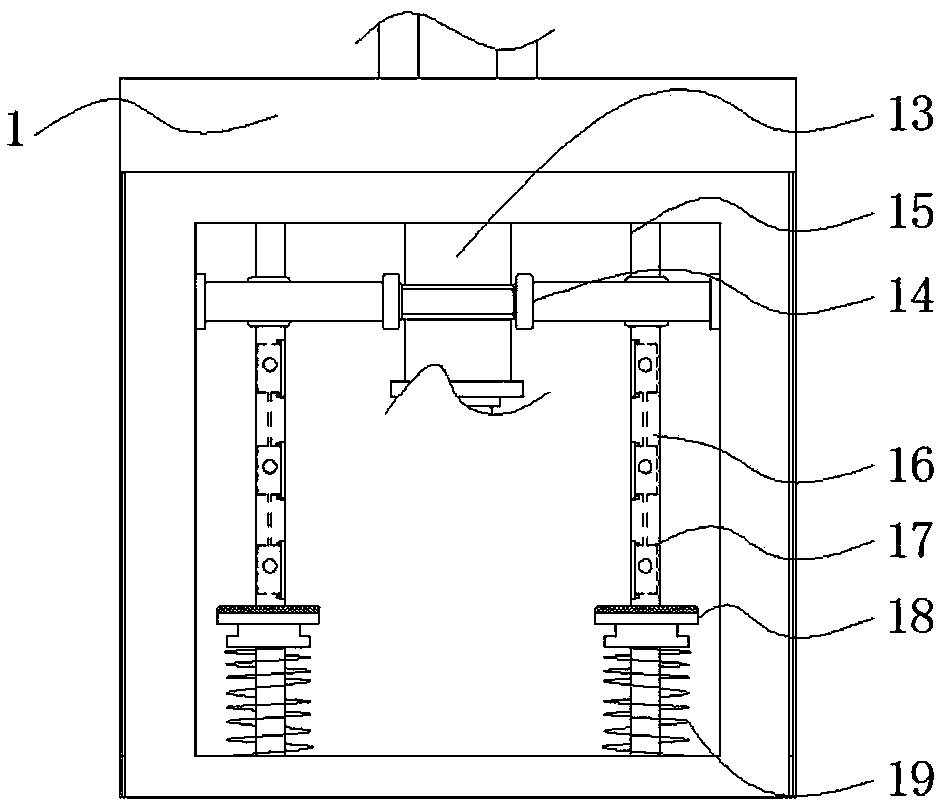

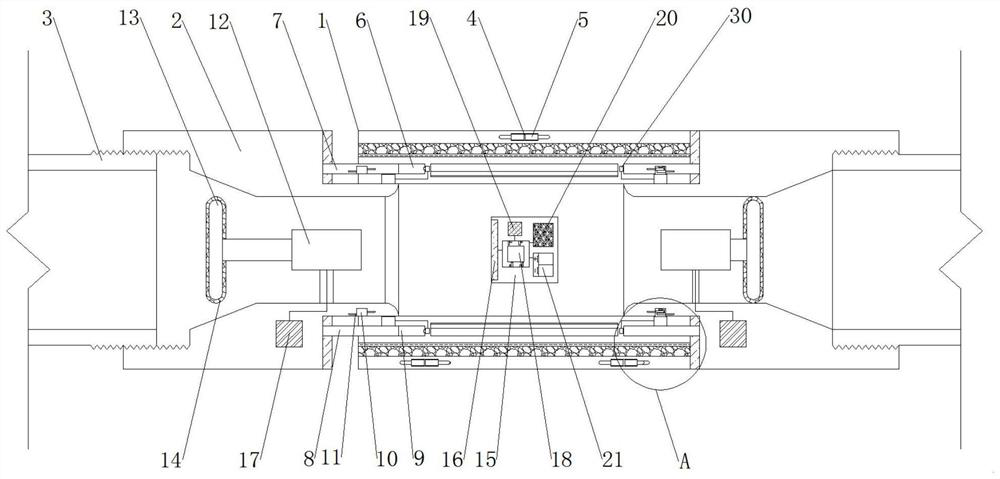

Hydraulic torque converter testing machine provided with track buffer mechanism and capable of being stably pushed

InactiveCN111122153AEasy to assembleImprove assembly performanceMachine gearing/transmission testingStructural engineeringMechanical engineering

The invention relates to a hydraulic torque converter testing machine provided with a track buffer mechanism and capable of being stably pushed. The testing machine comprises a machine body and a buffer mechanism, a transverse slideway penetrates through the outer wall at the top end of the machine body, and an outer hoisting mechanism is installed outside the transverse slideway, a transmission mechanism is arranged at the middle inside the upper end of the machine body, the outside of the transmission mechanism is connected to a limiting outer stop rod, buffer mechanisms are arranged at theleft end and the right end of the limiting outer stop rod, an equipment chamber is formed in the bottom end of the machine body, and a linkage opening is formed on the inner wall of the equipment chamber in a penetrating mode. The beneficial effects of the invention are that: the hydraulic torque converter testing machine with the track buffer mechanism and capable of being stably pushed is equipped with block inner grooves and inner through grooves, cables can be lapped through inner through grooves in outer line adjusting blocks, the bottom ends of the inner through grooves are a wave-shapedstructure, so that the cables can better fit the inner walls of the inner through grooves, at the same time a plurality of groups of outer cable adjusting blocks are arranged, a plurality of cables can be lapped, and the lapping performance of the cables is enhanced.

Owner:上海正源汽车附件有限公司

A kind of reactive ethylene propylene butyl self-adhesive waterproof membrane and its preparation method

ActiveCN110964448BImprove toughnessAvoid breakageNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive

The invention discloses a reaction ethylene-propylene-diene monomer butyl self-adhesive waterproof coiled material and a preparation method thereof. The reaction ethylene-propylene-diene monomer butylself-adhesive waterproof coiled material comprises an ethylene-propylene-diene monomer waterproof layer, a self-adhesive reactive butyl rubber layer is arranged at the bottom end of the ethylene-propylene-diene monomer waterproof layer, and a polyethylene waterproof adhesive layer isolating membrane is arranged at the bottom end of the self-adhesive reactive butyl rubber layer; wherein the ethylene propylene diene monomer waterproof layer is prepared from the following raw materials in parts by mass: 100-200 parts of ethylene propylene diene monomer, 50-100 parts of polyurethane, 10-20 partsof a mixed polyether, 20-30 parts of high-wear-resistant carbon black, 5-10 parts of zinc oxide, 10-15 parts of stearic acid and 5-10 parts of an accelerant. The ethylene-propylene-diene monomer butylself-adhesive waterproof coiled material has the beneficial effects that the toughness of the ethylene-propylene-diene monomer butyl self-adhesive waterproof coiled material is improved, and the situation that after construction tools, building materials and tools for cutting the coiled material fall off, the local waterproof coiled material is damaged is avoided.

Owner:上海豫宏(金湖)防水科技有限公司

Sol mixing-fine grinding-pressure method to improve the strength of mullite porous material

ActiveCN109180174BMolecular level mixing achievedIncreased in situ reaction rateCeramic shaping apparatusCeramicwareHydrofluoric acidPorosity

The invention discloses a method used for increasing mullite porous material strength through sol mixing-fine grinding-pressurization. The method comprises following steps: 1, sol mixing, and magneticstirring are carried out, hydrofluoric acid is added drop by drop, an obtained precursor colloid is dried to remove a disperse medium so as to obtain a dried colloid; 2, the dried colloid is subjected to ball milling so as to obtain dry colloid fine powder; 3, the dry colloid fine powder is subjected to pressing so as to obtain a block-shaped blank material; and 4, the blank material is subjectedto calcining so as to obtain the mullite porous material. The method is capable of realizing real molecule grade uniform mixing of all reactants, increasing in-suit reaction rate, promoting reactioneffect, and increasing strength without influencing the whole porosity; no complex equipment is needed by the preparation technology; and operation is simple and convenient.

Owner:XIAN AERONAUTICAL UNIV

Flexible and hard glue lap joint structure for recycling-preventing partition plate of automobile

The invention relates to the technical field of two-color injection molding for automobiles, in particular to a soft and hard rubber lap structure for an automobile anti-recirculation partition, comprising: hard rubber laps that are respectively fixed and installed at the joints of hard rubber and soft rubber and overlapped with each other The joint part and the soft rubber lap part; the hard rubber lap part is provided with a first boss and a first accommodation groove, and the soft rubber lap part is provided with a second boss accommodated in the first accommodation groove , and a second receiving groove for receiving the first boss. In the car anti-recirculation partition soft and hard rubber lap structure of the present invention, the hard rubber lap part and the soft rubber lap part are all provided with receiving grooves and bosses that cooperate with each other, the lap joint effect is good, and it is not easy to break; In use, the bonding strength is strong, the use function and service life of the overlapping structure are enhanced, the mold structure is simplified, and the production cost is saved.

Owner:WUHAN JIAHUA AUTOMOBILE PLASTIC PROD

Gas online monitoring equipment with water removal function

InactiveCN114088884AEasy to distinguish between installationEasy to fixGas analyser construction detailsLap jointMechanical engineering

The invention discloses gas online monitoring equipment with a water removal function, the equipment comprises a main body cylinder, connecting cylinders and a fixing block, the connecting cylinders are connected to the two sides of the main body cylinder in an embedded manner, a gas conveying pipe is connected to the middle of the left side of each connecting cylinder in an embedded manner, the fixing block is connected to the middle of the interior of each gas conveying pipe in a lap joint manner, and a trapezoidal plate is fixedly connected to the bottom of the right side of each connecting cylinder. Arc-shaped grooves are connected to the two sides of the top of the main body cylinder in an embedded mode, an arc-shaped plate is fixedly connected to the top of the right side of the connecting cylinder, and inserting grooves are formed in the arc-shaped plate and the connecting cylinder, so that the arc-shaped plate and the connecting cylinder are in embedded lap joint through the lifting column by the main body cylinder, and the main body cylinder and the connecting cylinder are better fixed; meanwhile, a small switch and a large switch are arranged, so that installation and fixation between the main body cylinder and the connecting cylinder are more convenient, and different connection modes of the two ends of the connecting cylinder are convenient for workers to carry out distinguished installation, so that the main body cylinder and the gas conveying pipe are better overlapped and fixed by the connecting cylinder, and the overlapping property of equipment is greatly improved.

Owner:陈晓琴

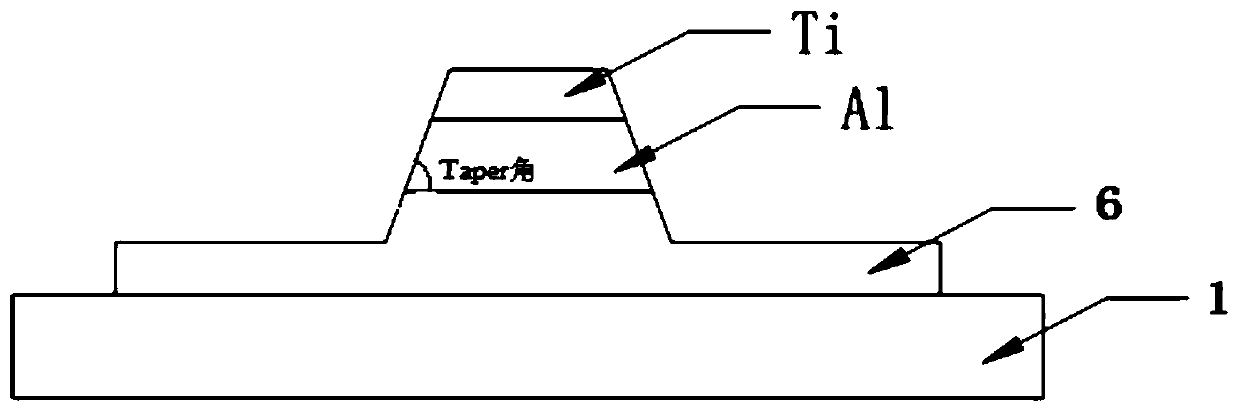

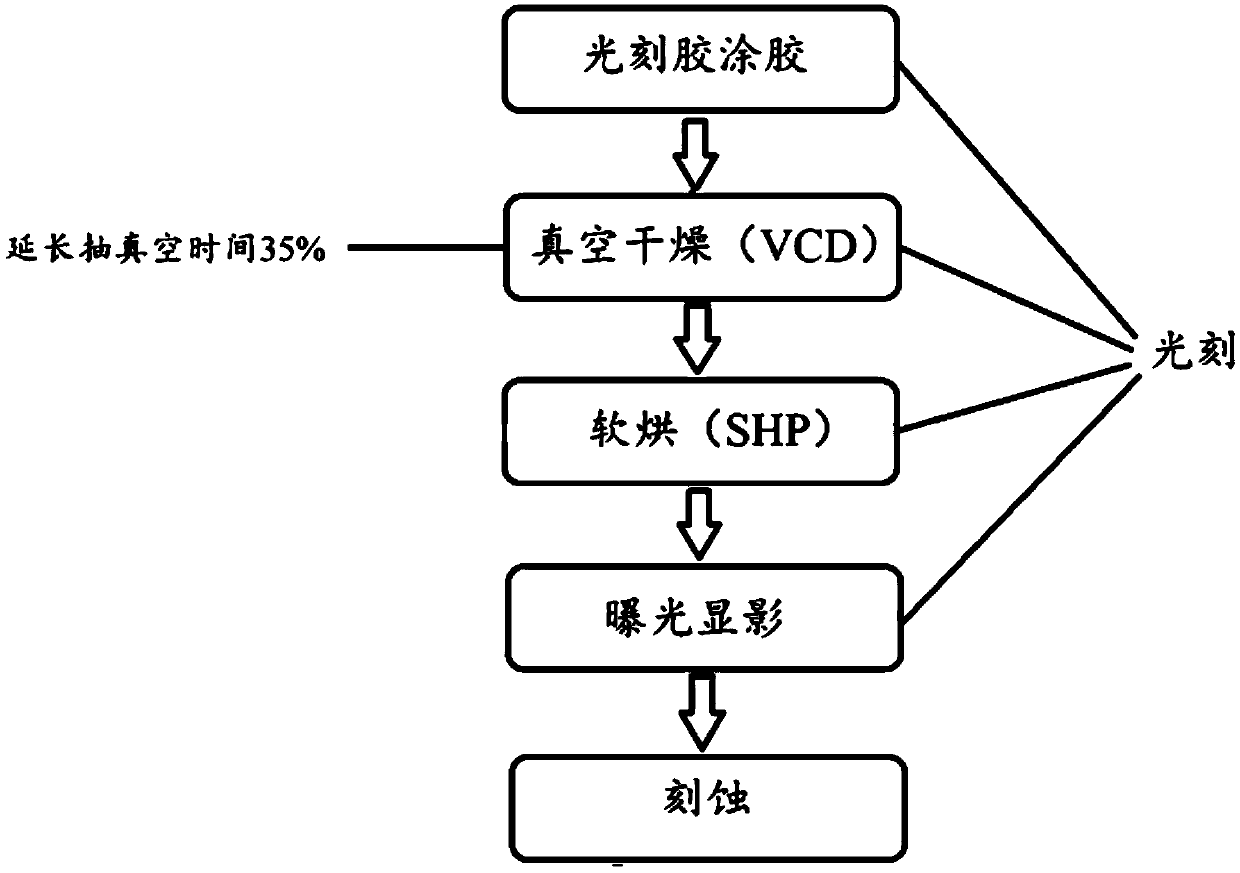

A method for increasing the via slope angle of the via layer

ActiveCN106816365BReduce Key Dimension DistortionImprove lapping effectSemiconductor/solid-state device manufacturingVacuum pumpingCooking & baking

The invention provides a method increasing a through hole slope angle of a through hole layer; the method comprises a lithography step and an etching step; the lithography step comprises the following steps: photoresist gluing, vacuum drying, soft baking and exposure developing; the photoresist gluing step can glue the photoresist on a film; the vacuum drying step can prolong the vacuum-pumping time by 20% to 50%; the photoresist upper hardness is bigger than the lower hardness; in the exposure developing step, the photoresist is exposed and developed so as to form a photoresist through hole with a wide upper side, a narrow middle and a wide lower side; the photoresist forms an extruding middle portion; in the etching step, the photoresist extruding portion is firstly ashed, the whole film surface below the photoresist through hole is ashed in an approximately consistent speed, thus forming a through hole layer through hole with the slope angle between 60-90 degrees. The embodiment provides the method increasing the through hole slope angle of the through hole layer, thus forming the through hole layer through hole with the slope angle between 60-90 degrees, reducing the through hole layer key dimension distortions, and providing the better circuit overlapping effect.

Owner:TRULY HUIZHOU SMART DISPLAY

Solid construction coating and preparation method thereof

ActiveCN103540178BImprove the protective effectIncreased durabilityPolyurea/polyurethane coatingsMaterial resourcesDrying time

The invention provides a solid construction coating and a preparation method thereof. The construction coating comprises: 50% to 82% by weight of water-based paint, 2% to 10% by weight of excipients, and 1% to 10% by weight of moisturizing agents , 1% to 5% by weight neutralizer, 0% to 40.5% by weight deionized water. The preparation method of the construction coating includes: mixing and dissolving excipients, humectants, and deionized water to obtain a first solution; adding a neutralizer, raising the temperature to make the reaction fully obtain a second solution; adding The water-based paint is uniformly dispersed to obtain a third solution; the third solution is poured into a mold for cooling and forming to obtain a paint. The paint provided by the invention is a solid paint, which will not cause paint splashes during construction and use, does not need to cover indoor facilities, saves construction time and reduces manpower and material resources, and has a short drying time. No professional equipment is required for construction and use, which reduces construction costs.

Owner:李俊强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com