High-stability OLED device and preparation method thereof

A high-stability, device technology, applied in the field of OLED devices, can solve problems such as pixel shrinkage, and achieve the effects of improving overlap, improving reliability, and avoiding electrochemical corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

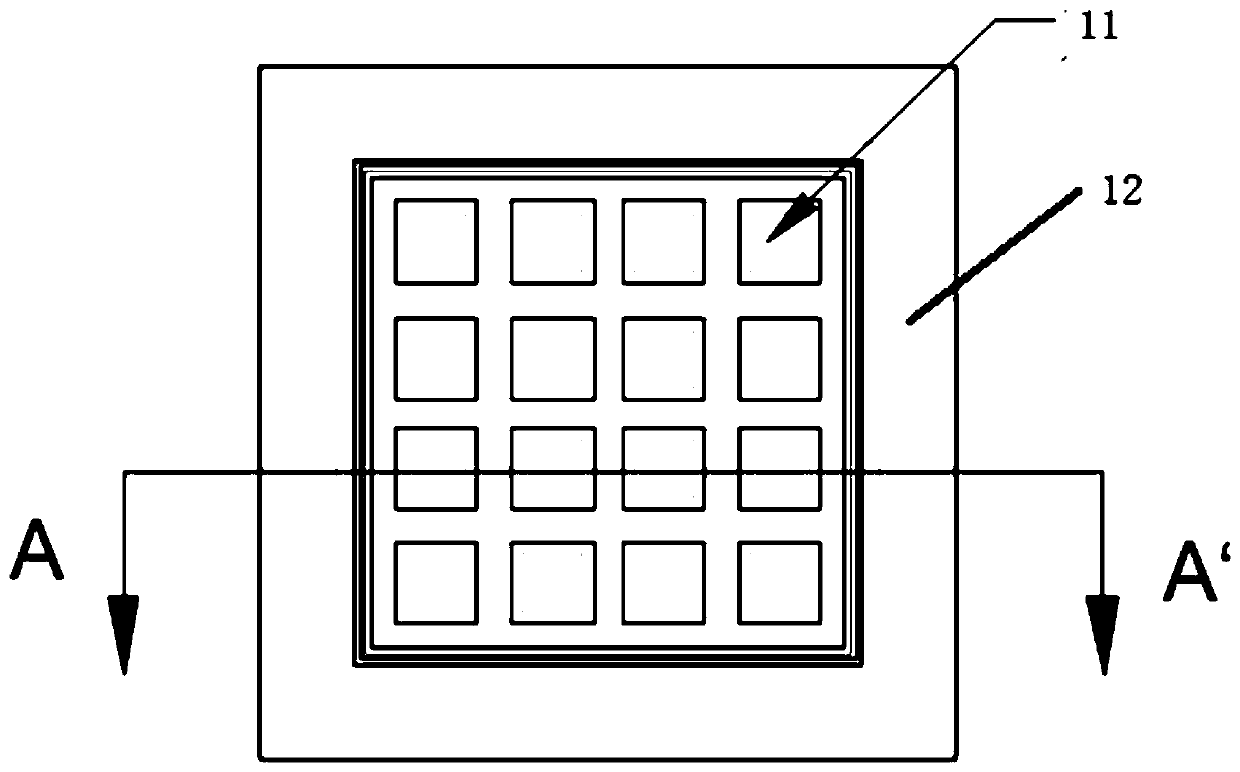

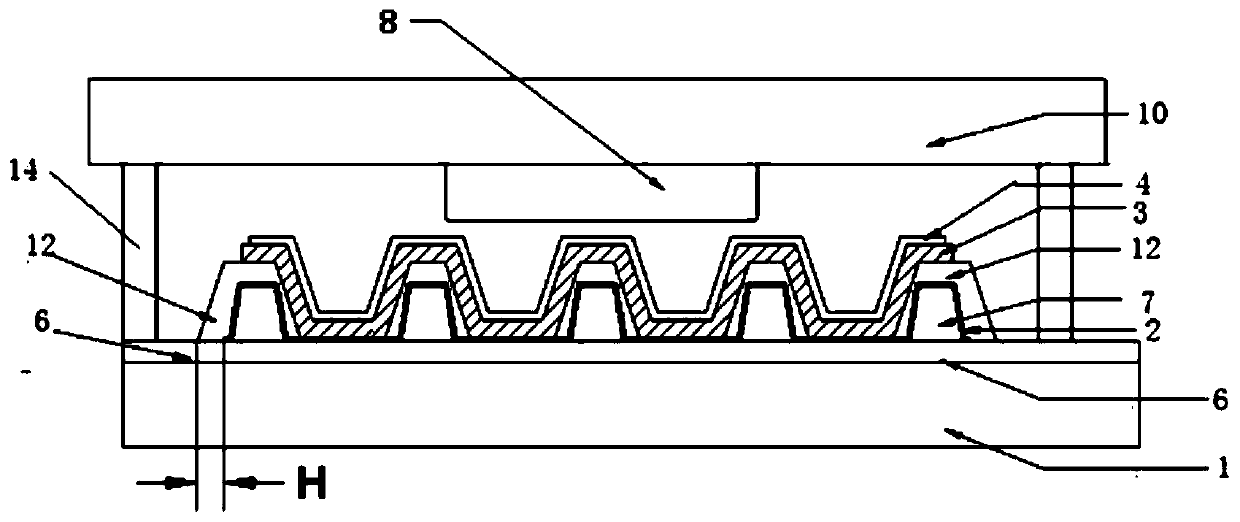

[0050] A preparation method of a highly stable OLED device, such as Figure 1 to Figure 2 shown, including the following steps:

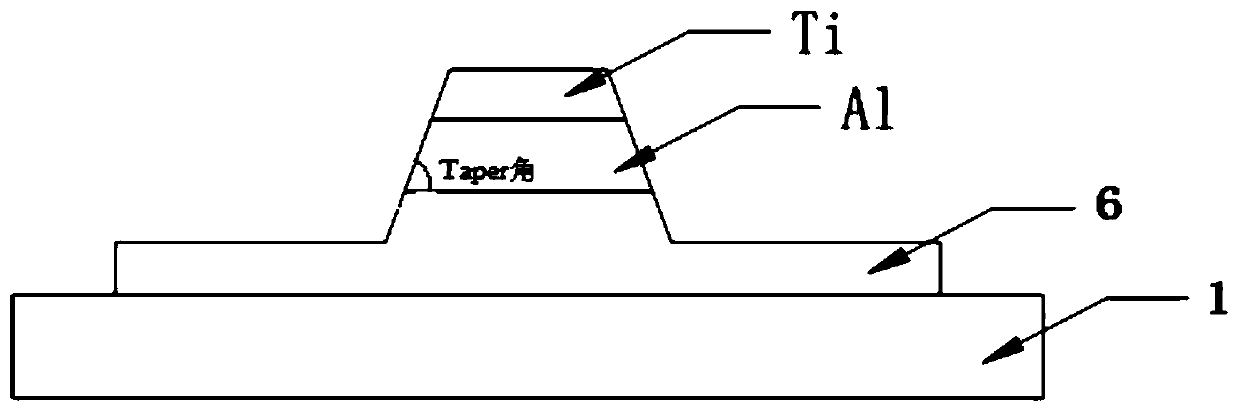

[0051] S1. Divide the pixel area 11 and the encapsulation area surrounding the pixel area 11 on the substrate 1, deposit a buffer layer 6 on the pixel area, prepare an auxiliary electrode layer on the buffer layer 6, and form several auxiliary electrode layers arranged at intervals by etching. The taper angle of the electrode 7 and the auxiliary electrode 7 is 30-70°;

[0052] S2. Prepare the first electrode layer 2 on the basis of step S1, the first electrode layer 2 covers the buffer layer 6 and the auxiliary electrode 7, and remove the first electrode layer between the auxiliary electrode 7 and the packaging area by etching An electrode layer 2 to expose the buffer layer 6;

[0053] S3. On the basis of step S2, deposit a pixel definition layer 12, the pixel definition layer 12 covers the first electrode layer 2 and the buffer layer 6 between th...

Embodiment 1

[0063] Such as figure 1 and figure 2 As shown, a highly stable OLED device provided by the present invention includes a substrate 1 and an encapsulation layer 10. The substrate 1 is divided into a pixel area 11 and an encapsulation area surrounding the pixel area 11. A sealing material layer 14 seals and connects the substrate 1 and the encapsulation layer 10 to form an airtight space. The side of the encapsulation layer close to the substrate 1 is provided with a drying sheet 8 to absorb moisture, and UV glue is used as the sealing material layer 14 to seal the substrate and the encapsulation layer. The packaging cover is used for packaging to improve the reliability of the screen packaging. The thickness of the buffer layer 6 is 50nm-500nm.

[0064] The light-emitting area of the substrate 1 is provided with a buffer layer 6, and a plurality of auxiliary electrodes 7 arranged at intervals are arranged on the buffer layer 6, and the first electrode layer 2 covers the bu...

Embodiment 2

[0087] Such as Figure 5 and Figure 8 As shown, a kind of highly stable OLED device basic structure provided by the present invention is the same as embodiment 1, and its difference is:

[0088] The light-emitting area of the substrate 1 is provided with a buffer layer 6, and the buffer layer 6 is provided with an anti-short circuit layer 13 formed by the first electrode layer, and several auxiliary electrodes 7 arranged at intervals, and the first electrode layer 2 covers The buffer layer 6 and the auxiliary electrode 7 are etched to remove the first electrode layer 2 located on one side or both sides of the auxiliary electrode 7, and the width of the first electrode layer 2 removed by etching is H=10um to expose the buffer layer 6;

[0089] Such as Figure 6 As shown, the pixel defining layer 12 completely covers the first electrode layer 2 on the auxiliary electrode and is provided with an opening exposing at least a part of the first electrode layer 2. The shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com