Process for manufacturing graph in circuit burying mode

A pattern and line technology, which is applied in the field of pattern making process, can solve the problems of line side etching and uneven bottom edge of the line, and achieve the effect of avoiding the side etching problem, smooth line edge and uniform line width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

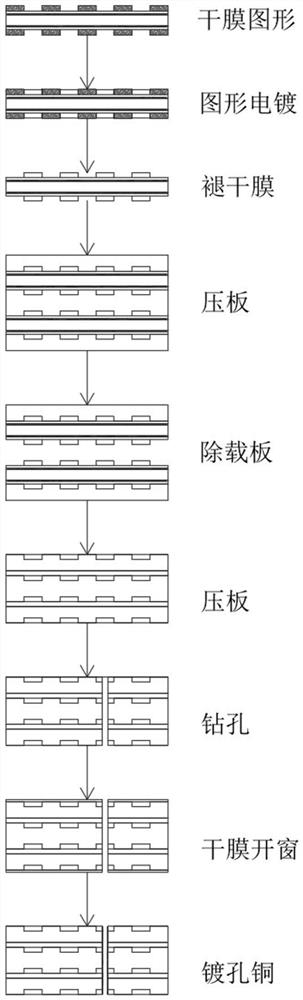

[0028] A process for making graphics in the form of buried lines, comprising the following steps:

[0029] S1. Making the carrier core board: Paste the copper layer on both sides of the carrier board with an adhesive. The adhesive used in S1 is epoxy adhesive or acrylic acid adhesive. Use the carrier core board to replace the conventional core board , the carrier core board is composed of a carrier board, an adhesive layer and a copper layer. After pressing the board, the strength of the adhesive layer will decrease, and the copper layer and the carrier layer can be directly separated;

[0030] S2. Make dry film graphics: attach the dry film to both sides of the carrier core board, and make the graphics to be plated on the dry film, use the graphics electroplating method to make the required graphics on the carrier core board, and use the graphics electroplating method to make Graphics, there is no traditional etching process in the follow-up;

[0031] S3. Graphic electroplat...

Embodiment 2

[0042] A process for making graphics in the form of buried lines, comprising the following steps:

[0043] S1. Making the carrier core board: Paste the copper layer on both sides of the carrier board with an adhesive. The adhesive used in S1 is epoxy adhesive or acrylic adhesive;

[0044] S2. Make dry film graphics: attach the dry film to both sides of the carrier core board, and make graphics to be plated on the dry film;

[0045] S3. Graphic electroplating: electroplating the carrier core board after the dry film is attached, so that the exposed part of the carrier core board is plated with a copper layer;

[0046] S4, take off the dry film: take off the dry film on the carrier core plate after the copper layer is plated;

[0047] S5. Pressing plate: pressing multiple carrier core plates after copper plating;

[0048] S6. Remove the carrier board: separate the copper layer on the carrier core board from the carrier board, and remove the carrier board;

[0049] S7. Micro-e...

Embodiment 3

[0051] A process for making graphics in the form of buried lines, comprising the following steps:

[0052] S1. Making the carrier core board: Paste the copper layer on both sides of the carrier board with an adhesive. The adhesive used in S1 is epoxy adhesive or acrylic adhesive;

[0053] S2. Make dry film graphics: attach the dry film to both sides of the carrier core board, and make graphics to be plated on the dry film;

[0054] S3. Acid etching: Etch the copper layer not covered by the dry film with an acidic reagent, leaving the copper layer with the desired pattern;

[0055] S4. Film fading: remove the dry film on the surface of the core board after etching to complete the acid etching process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com