High-grade flame-retardant fireproof optical cable

A high-grade flame-retardant and fire-resistant technology, which is applied in the field of high-grade flame-retardant and fire-resistant optical cables, can solve problems such as loss of transmission information, ordinary mica tapes cannot block heat transfer, and large changes in optical fiber attenuation. It achieves excellent heat insulation performance, novel structure, The effect of heat reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

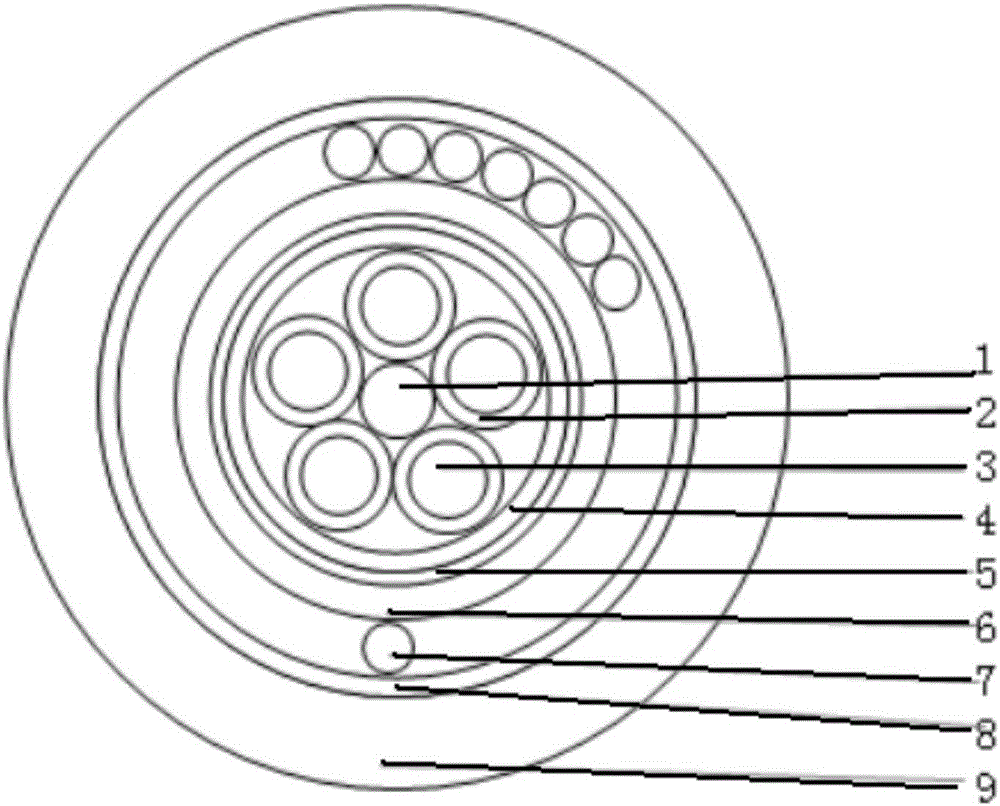

[0032] refer to figure 1 As shown, this embodiment discloses a high-grade flame-retardant and fire-resistant optical cable, which includes a layer-stranded cable core. The layer-stranded cable core includes a strengthening member 1 arranged in the center, and the outer periphery of the central strengthening member 1 is provided with several Sleeve 2 and / or filling rope with the same diameter, the above-mentioned sleeve 2 is sleeved with optical fiber, and the inside of the above-mentioned sleeve 2 is filled with fiber paste or water-blocking yarn, that is, the above-mentioned filled fiber paste 3 or water-blocking yarn is filled in the sleeve 2 and optical fiber The gap between the above-mentioned optical fibers depends on the type and quantity of the actual optical cable design, which is not limited here.

[0033] In this embodiment, the above-mentioned central reinforcement 1 is made of glass fiber reinforced plastic; the above-mentioned casing is a PBT casing, MPP casing or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com