Patents

Literature

78results about How to "Reduce heat exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

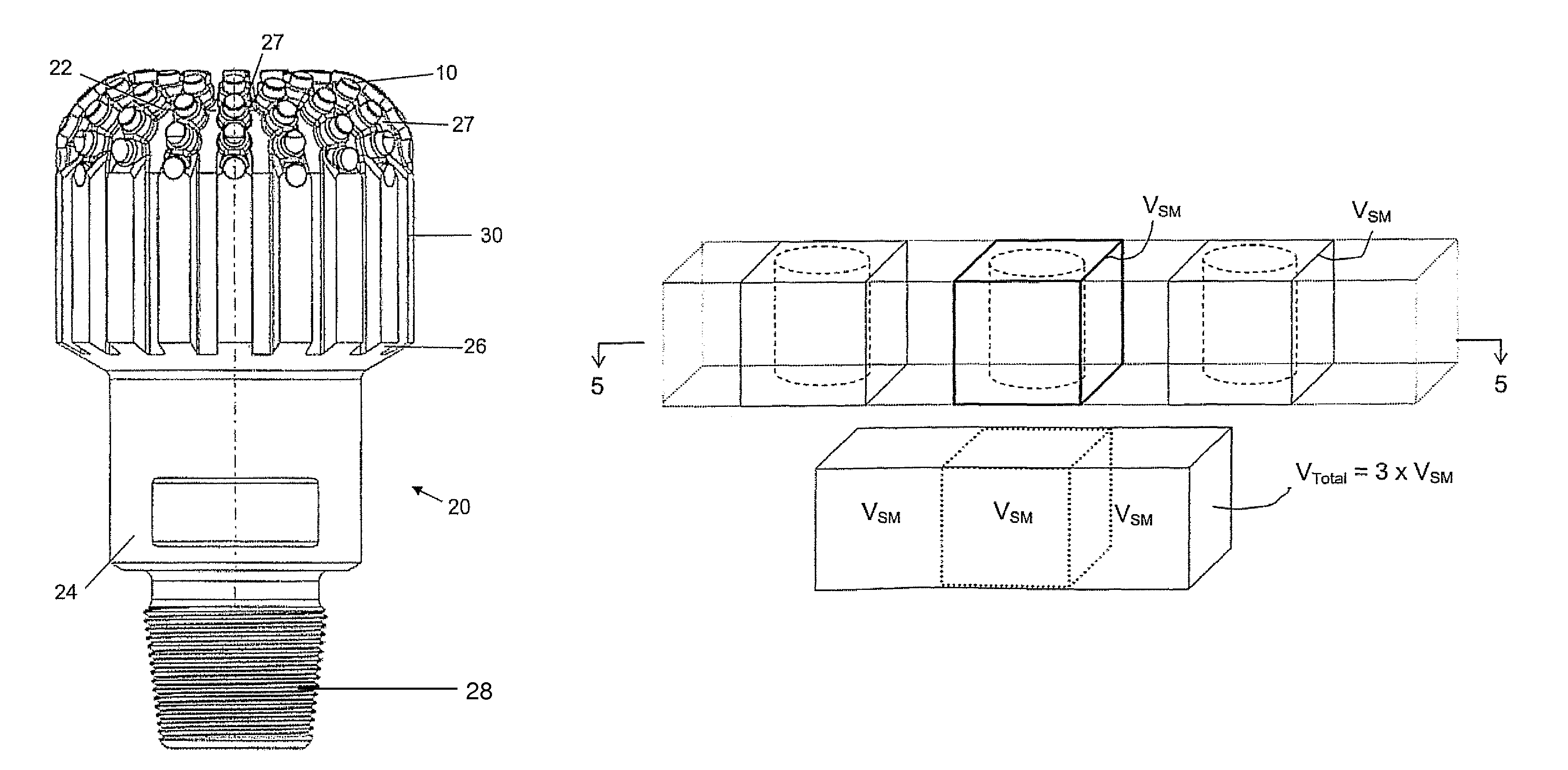

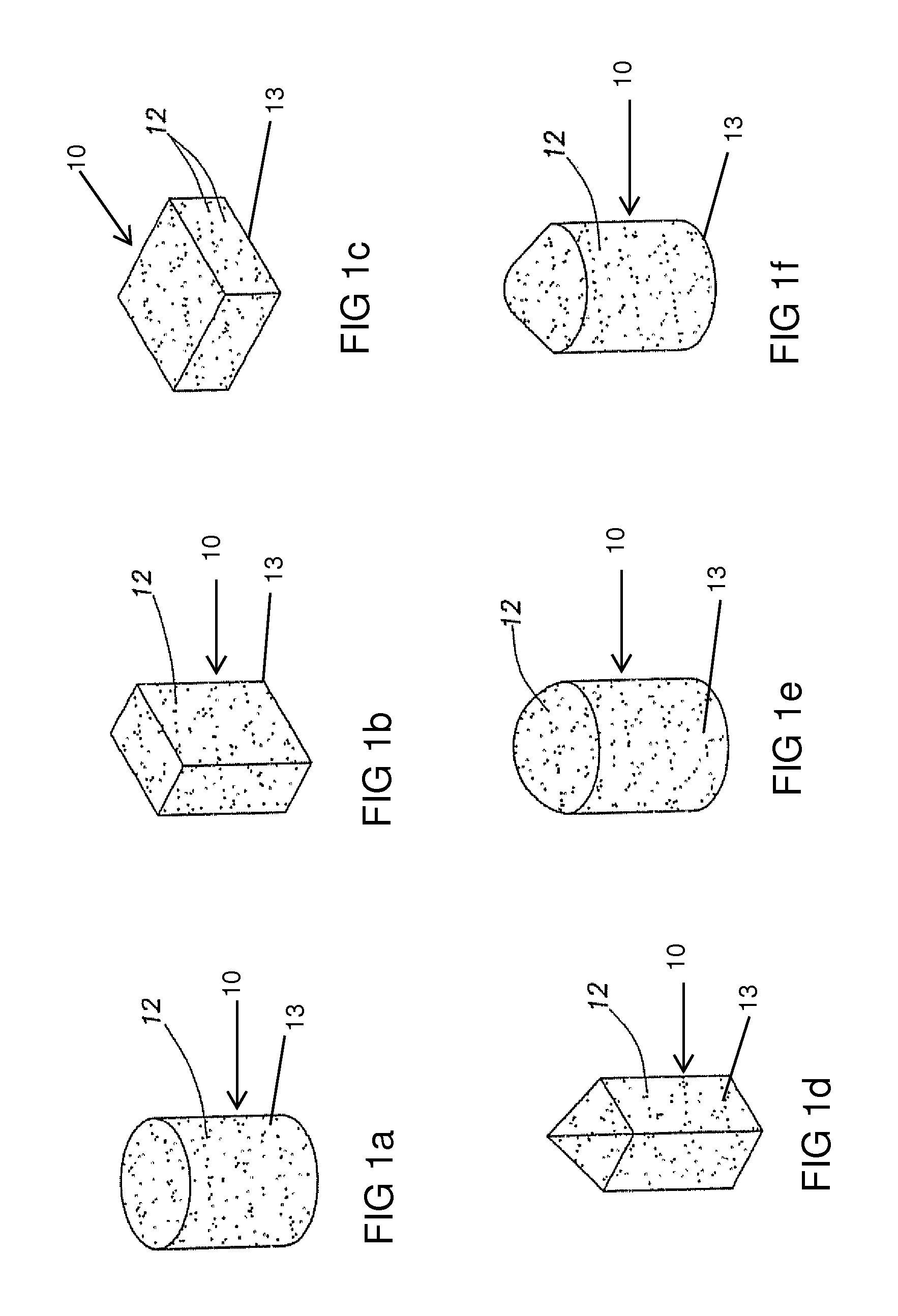

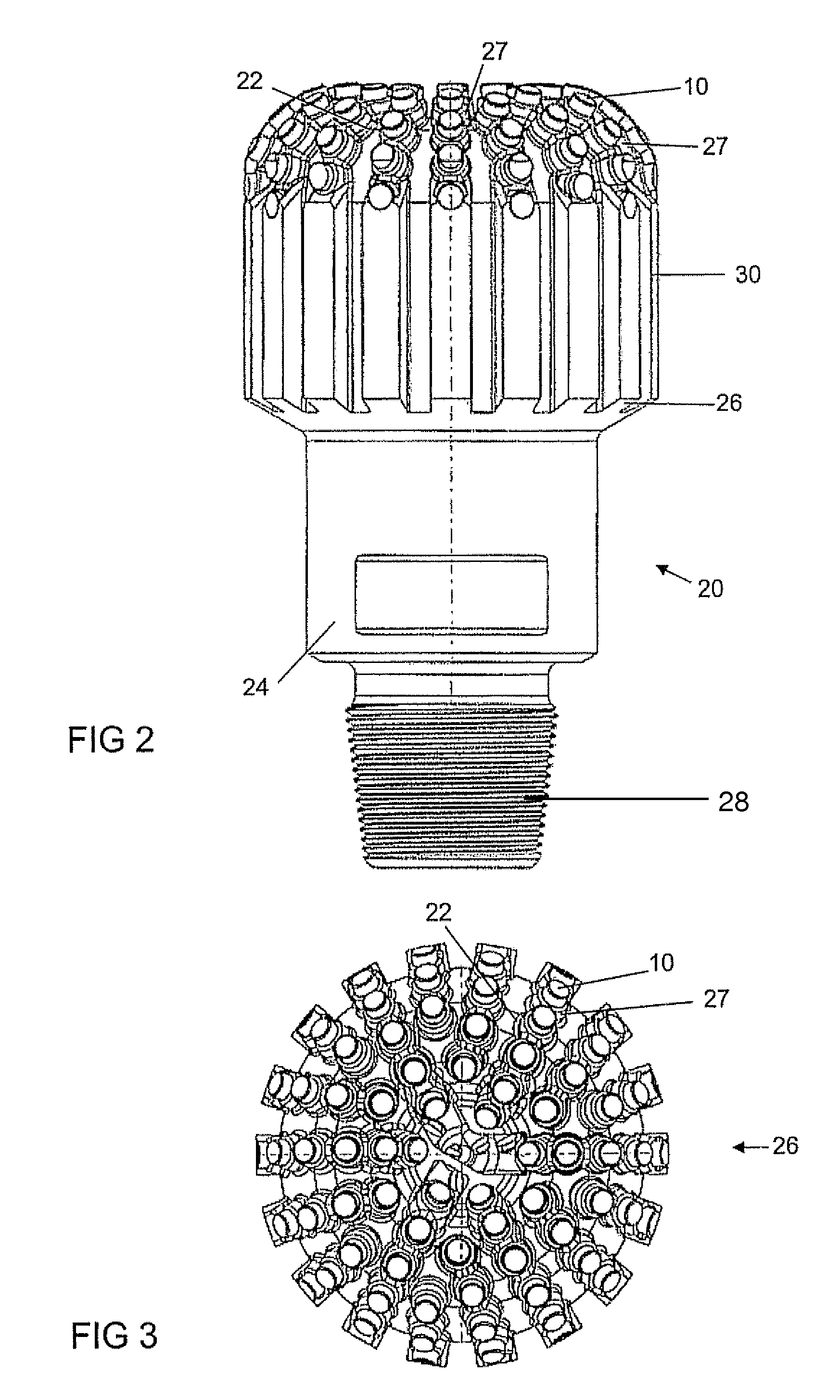

Drill bit with diamond impregnated cutter element

InactiveUS7469757B2Solution to short lifeReduce heat exposureDrill bitsConstructionsKnife bladesOperating life

The present invention provides a bit with cutting structures or inserts that include diamond particles, in which the diamond-impregnated inserts are surrounded by substantially diamond-free support members. The diamond-impregnated inserts are manufactured separately from the bit body. Once formed, the diamond-impregnated inserts are affixed to the substantially diamond-free support members on bit body by brazing or other means of attachment. The total thermal exposure of the diamond particles during manufacture in accordance with the present invention is significantly lower than the total manufacturing-related thermal exposure in previously known diamond-impregnated cutting structures. Furthermore, the substantially diamond-free support members allow the bit to continue cutting through a formation without an increased contact area, as experienced by bits with diamond-impregnated ribs. Thus, the operating life of the cutting structures, and therefore the life of the bit itself, is increased.

Owner:SMITH INT INC

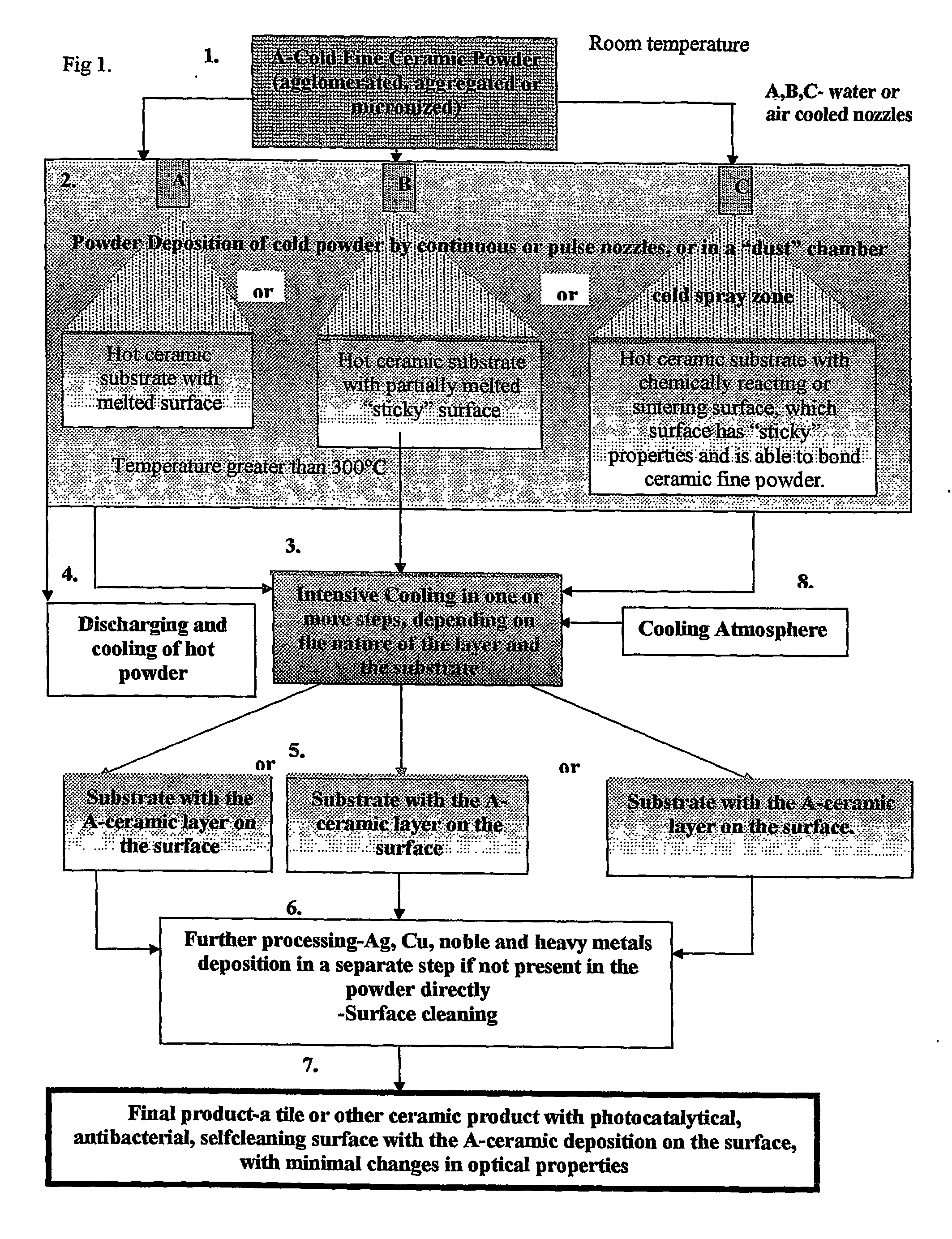

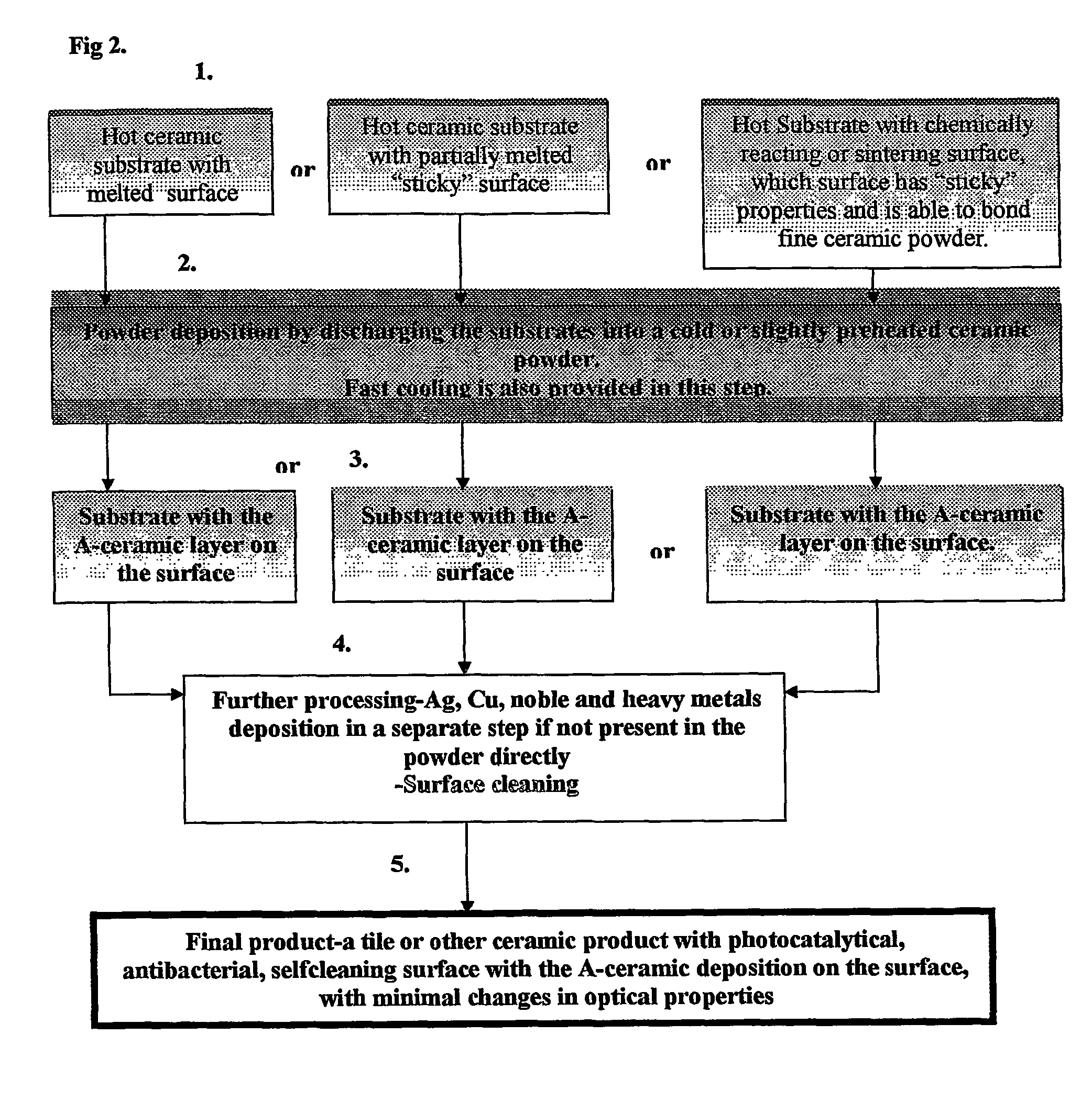

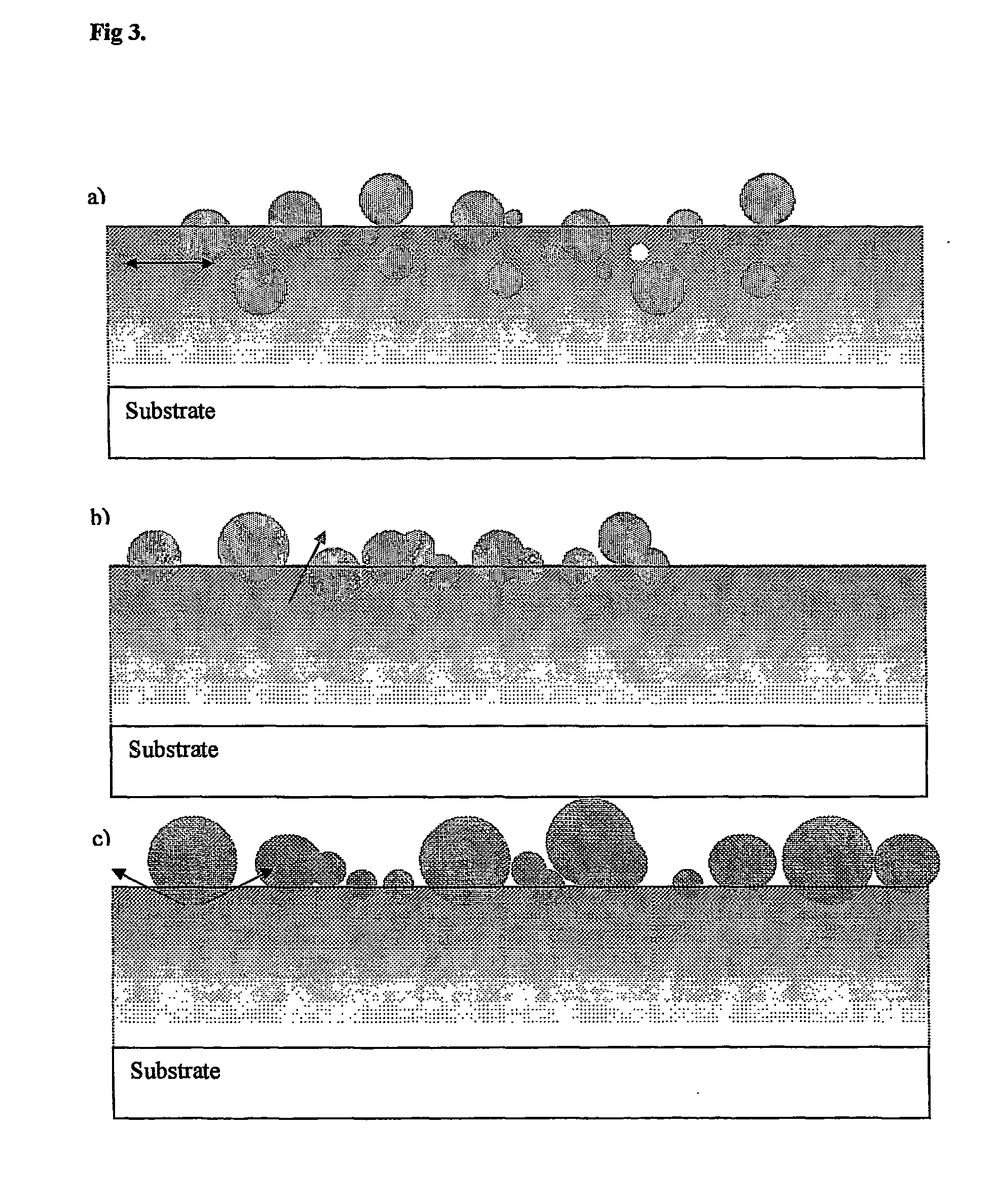

Manufacturing of Photocatalytic, Antibacterial, Selfcleaning and Optically Non-Interfering Sufaces on Tiles and Glazed Ceramic Products

InactiveUS20070275168A1Cheap productionOptimizationPretreated surfacesCoatingsOptical propertyCooling down

The principle of the deposition technique uses ultrafine crystals of ceramic oxides deposited relatively cold on melted or partially melted surfaces of ceramic tiles and other glazed ceramics, creating a spotty deposition without a significant change of optical properties of the surface. Because the desired nano-substance is deposited cold in a solid state form on the hot “sticky” surfaces and rapidly cooled down, deposited material is directly melted into the substrate surface, but its outer side remains unchanged. It allows creating a deposition with the desired parameters, for amplifying and extending the antibacterial protection in the dark, these surfaces may contain noble and heavy metals, deposited either dry as a part of the powder, or in a separate step, directly on the surface by wet depostion followed by drying and calcination.

Owner:PROCHAZKA JAN

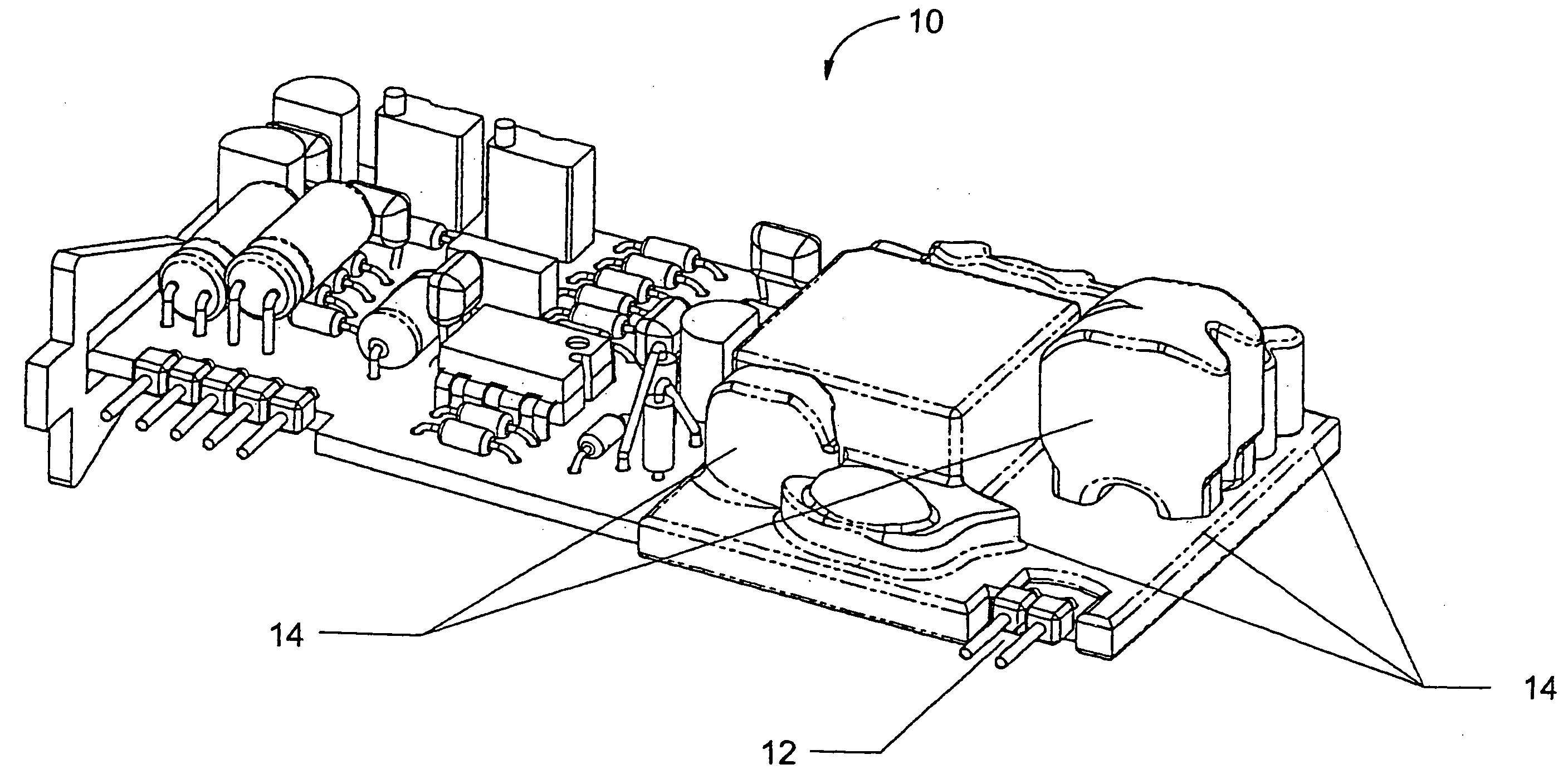

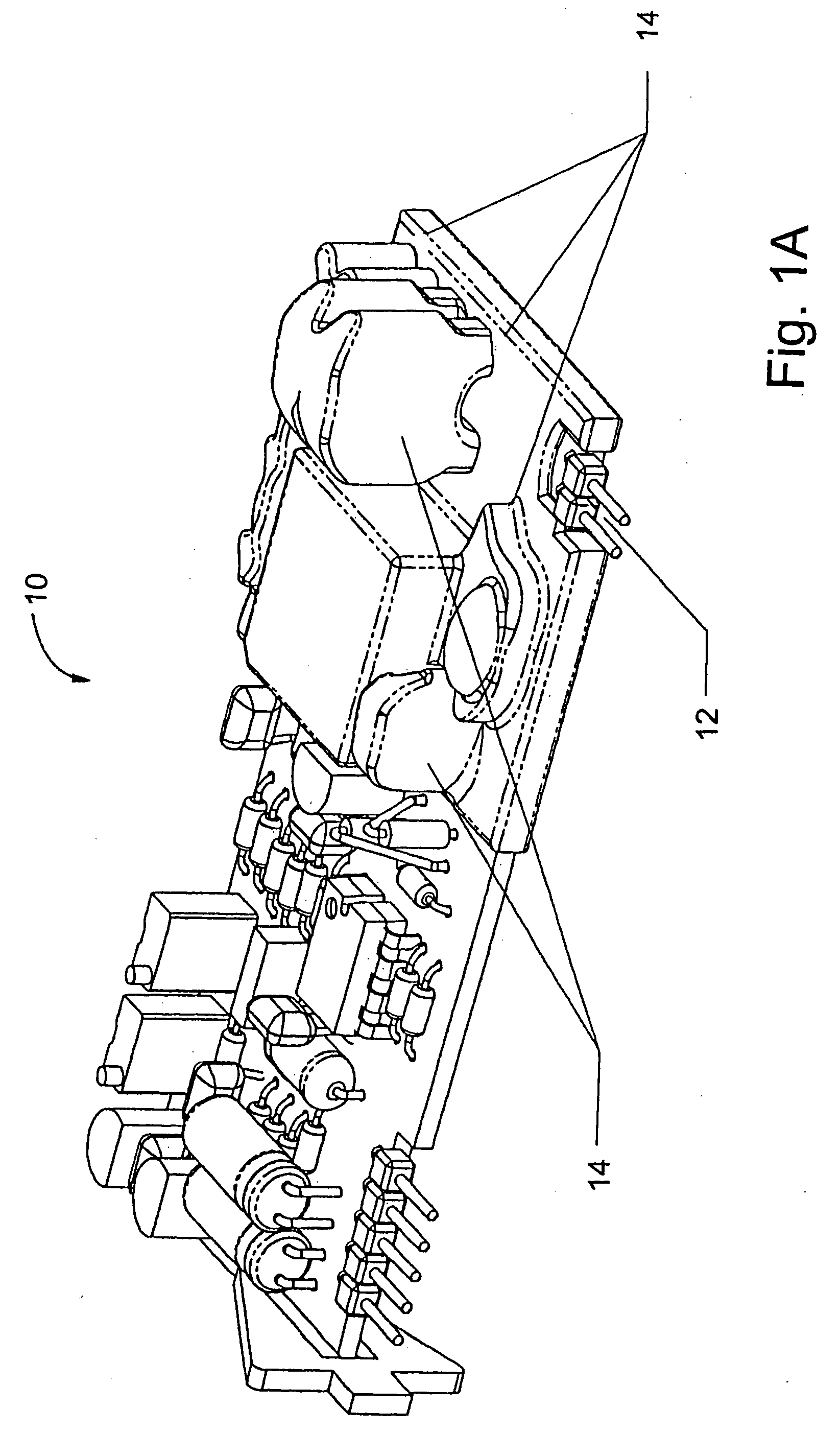

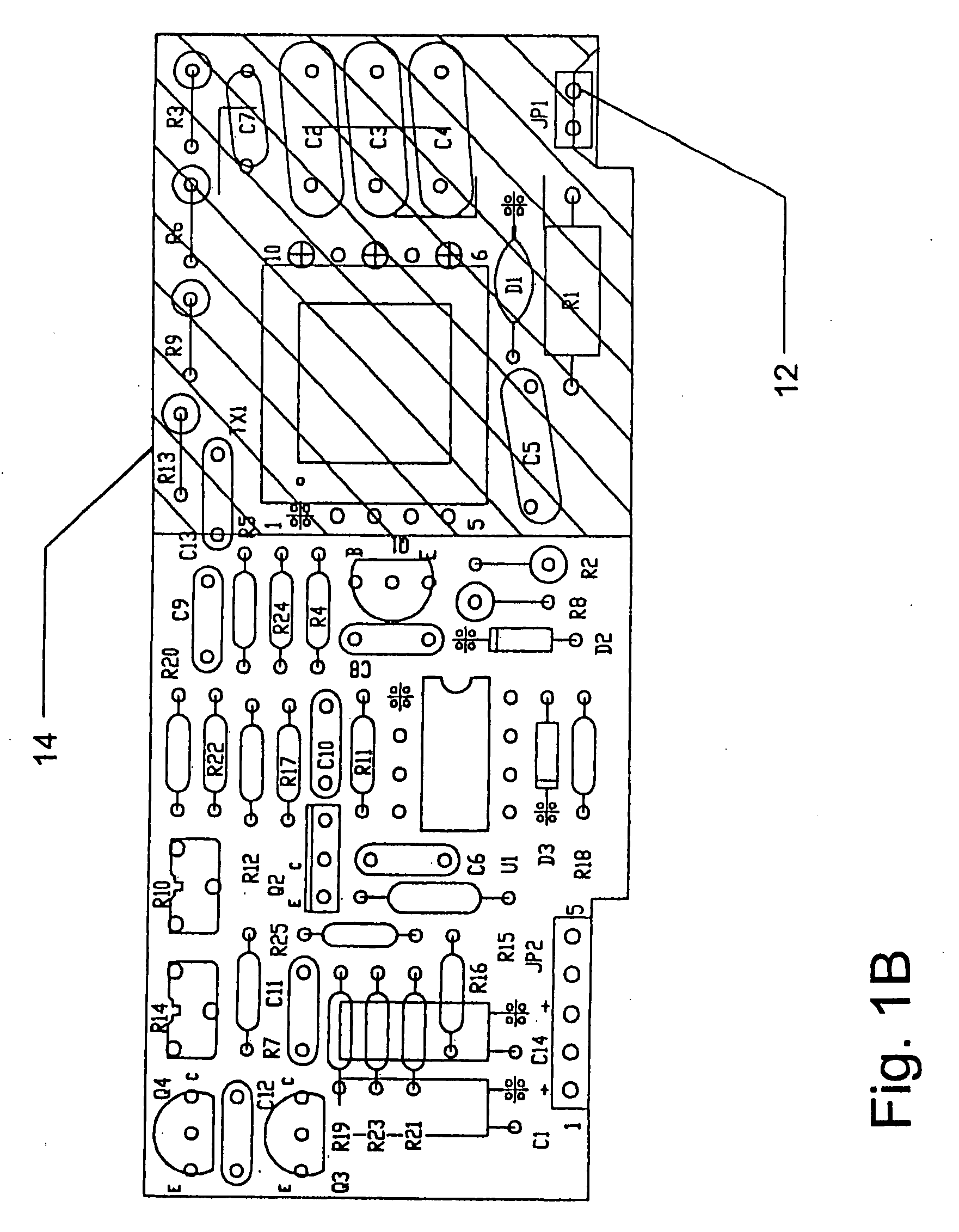

Selective Encapsulation of Electronic Components

InactiveUS20070289129A1Reduce processing timeReduced material requirementsPrinted circuit assemblingLine/current collector detailsRoom temperatureEngineering

A method for the selective encapsulation of electronic components on a printed circuit board comprising, in one embodiment, the steps of delivering the printed circuit board to an encapsulating nest at room temperature; damming the target areas with a dam resin having a latent curing agent and deposited in the shape of walls of predetermined heights, according to the desired fill heights; dispensing a fill resin to fill the dammed areas; and curing the dam and fill resins for a suitable amount of time. In a different embodiment, the invention comprises the additional steps of laying resin beads, each in a position corresponding to the footprint of each target component; and of positioning the target components over the beads and soldering the components.

Owner:LHV POWER

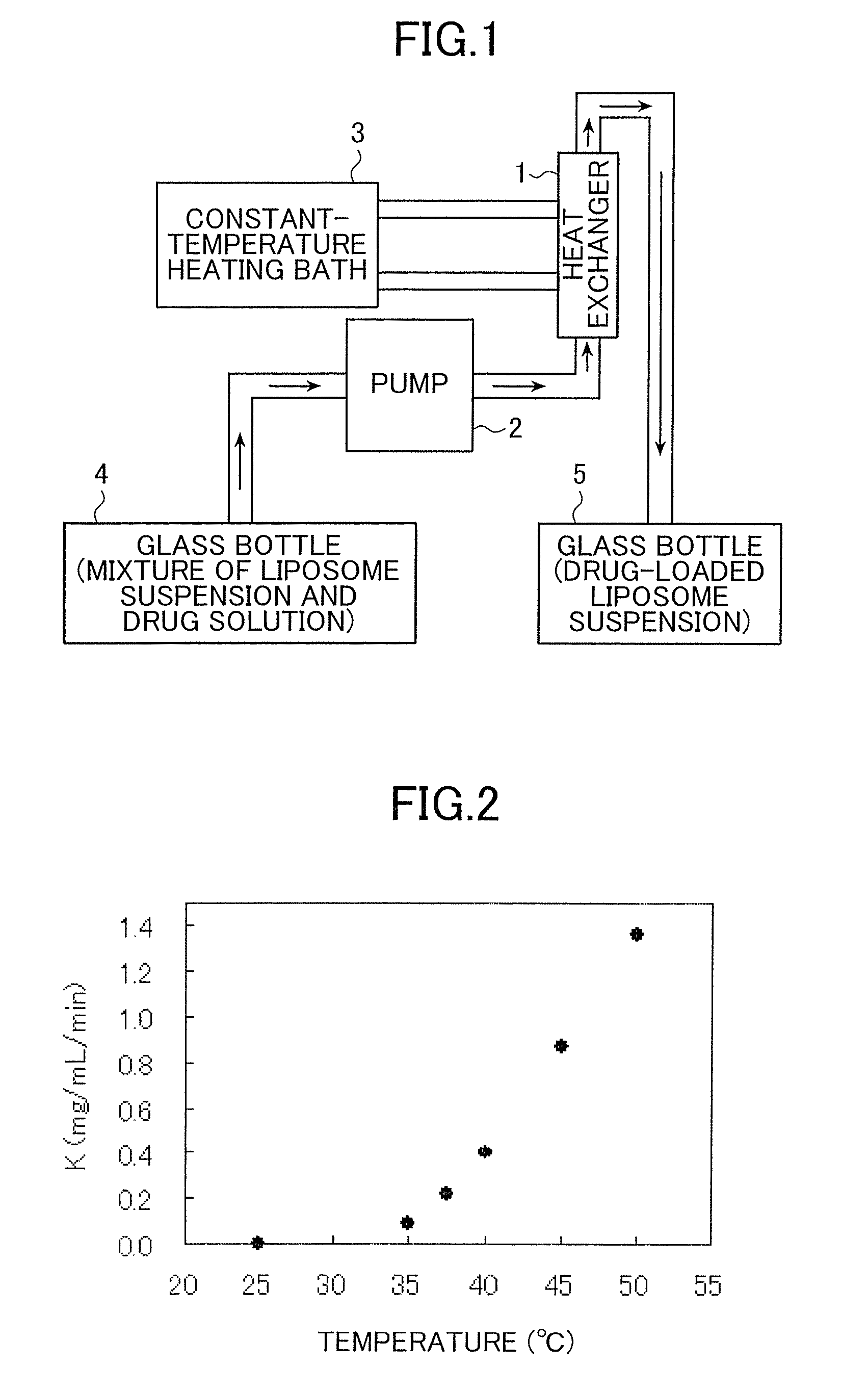

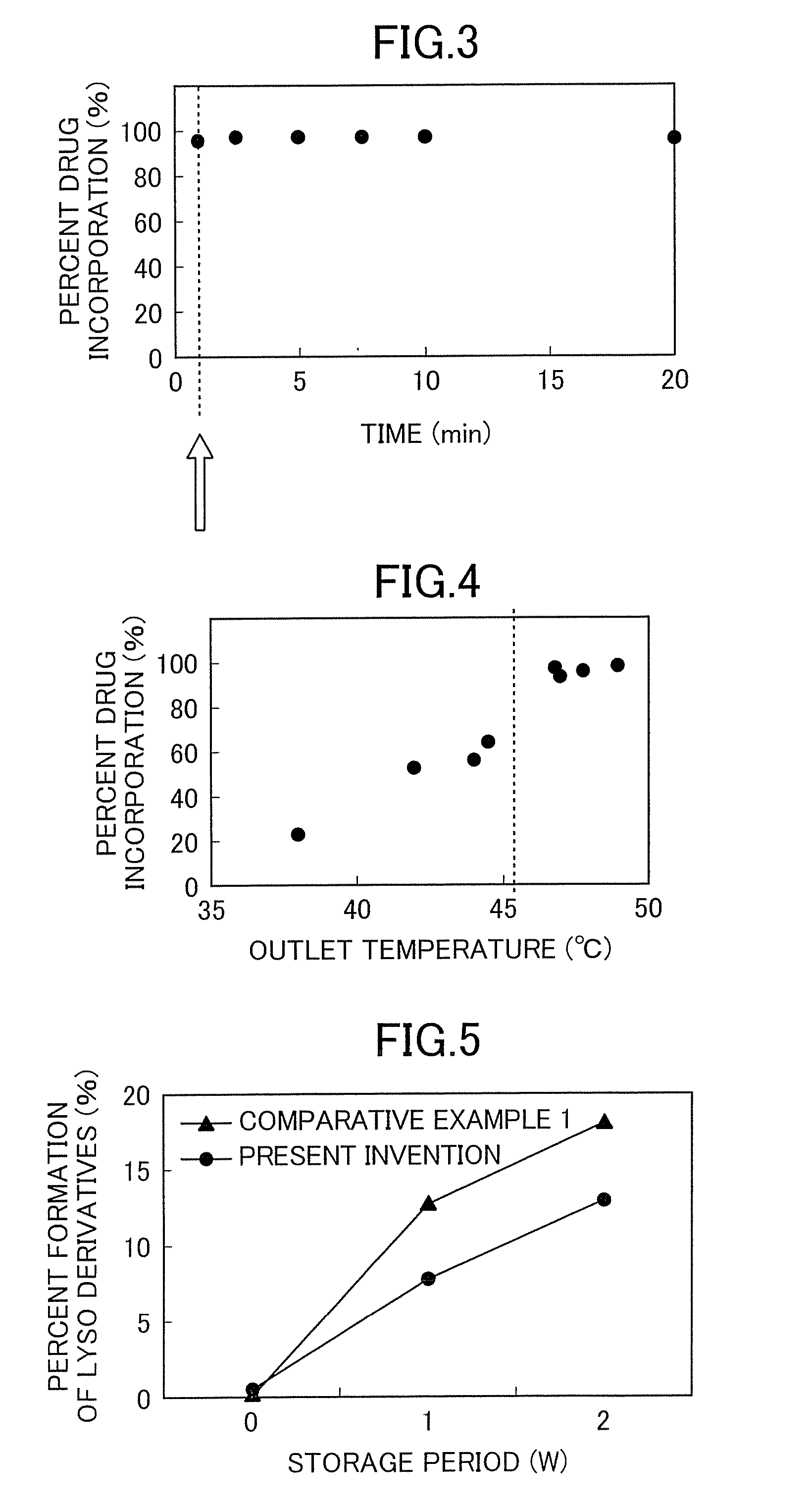

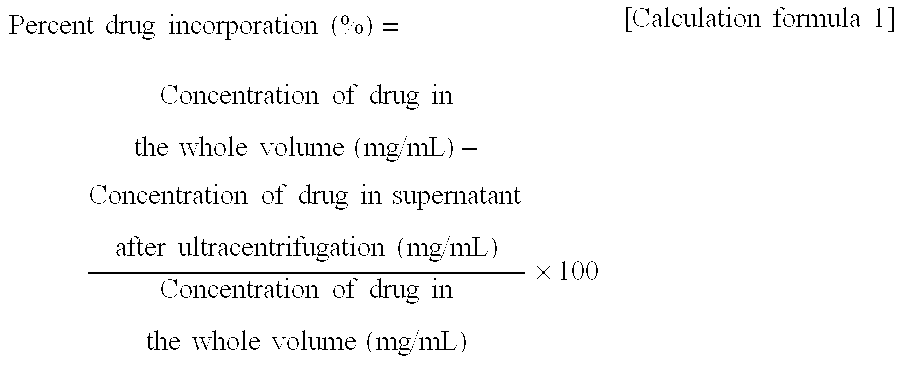

Method for production of liposome preparation

InactiveUS20100021531A1Induces no irregularity in the amount of incorporated drugShorten production timeLiposomal deliveryLipid degradationMembrane configuration

Disclosed is a method which permits simple and easy production of a stable, high-quality liposome preparation suppressed in lipid degradation. This method can significantly shorten production time and can achieve a substantial cost cut-down in medium- to large-scale production, and can also attain the incorporation of a drug in uniform amounts. Specifically disclosed is a method for producing a liposome preparation by using a remote loading method. This method includes a drug incorporation step that heats a mixture of a suspension of liposomes and a drug, the mixture having been prepared beforehand, by rapid heating means to a temperature from not lower than a phase transition point of membranes of the liposomes to not higher than 80° C. to incorporate the drug into the liposomes.

Owner:TERUMO KK

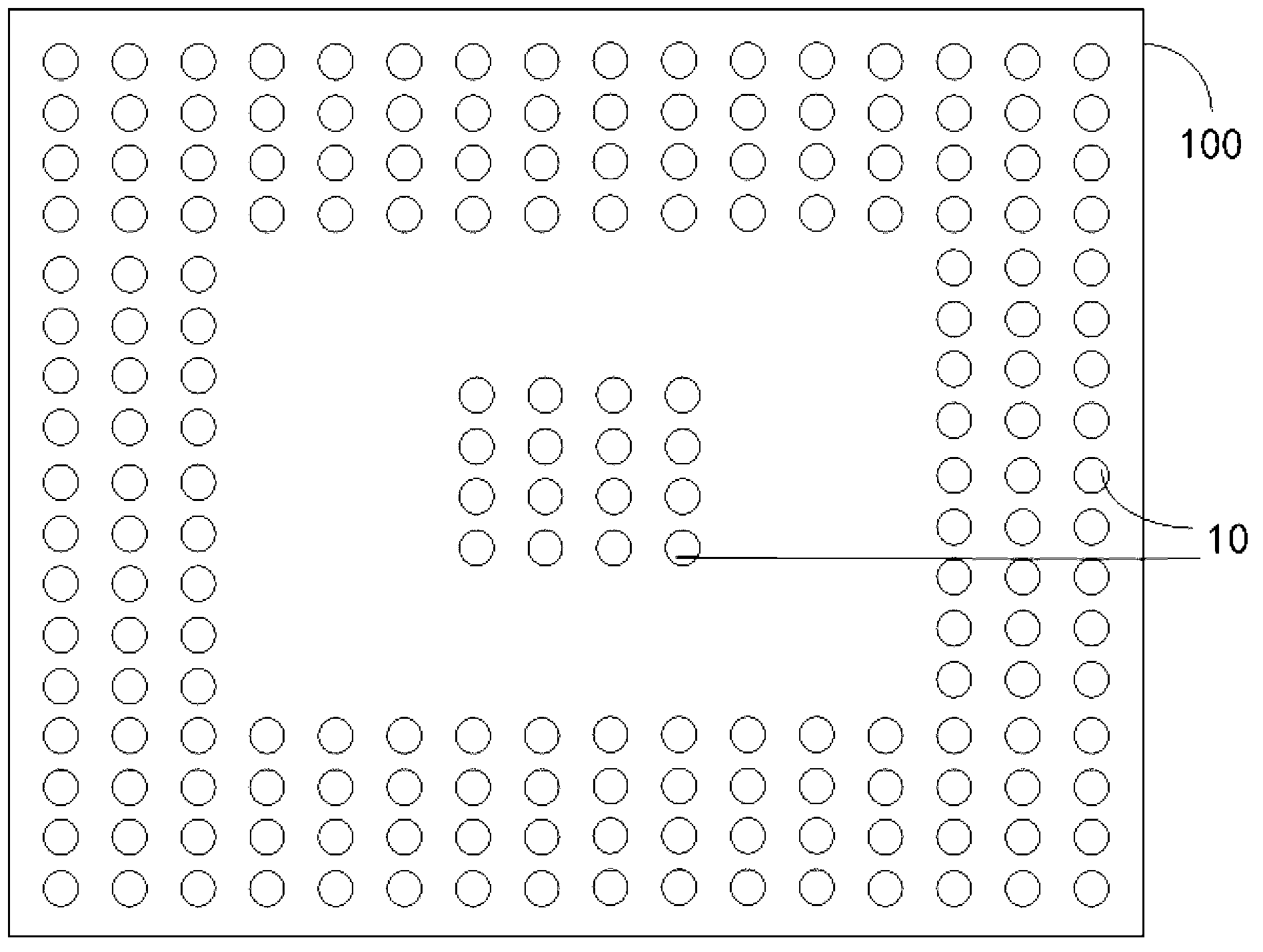

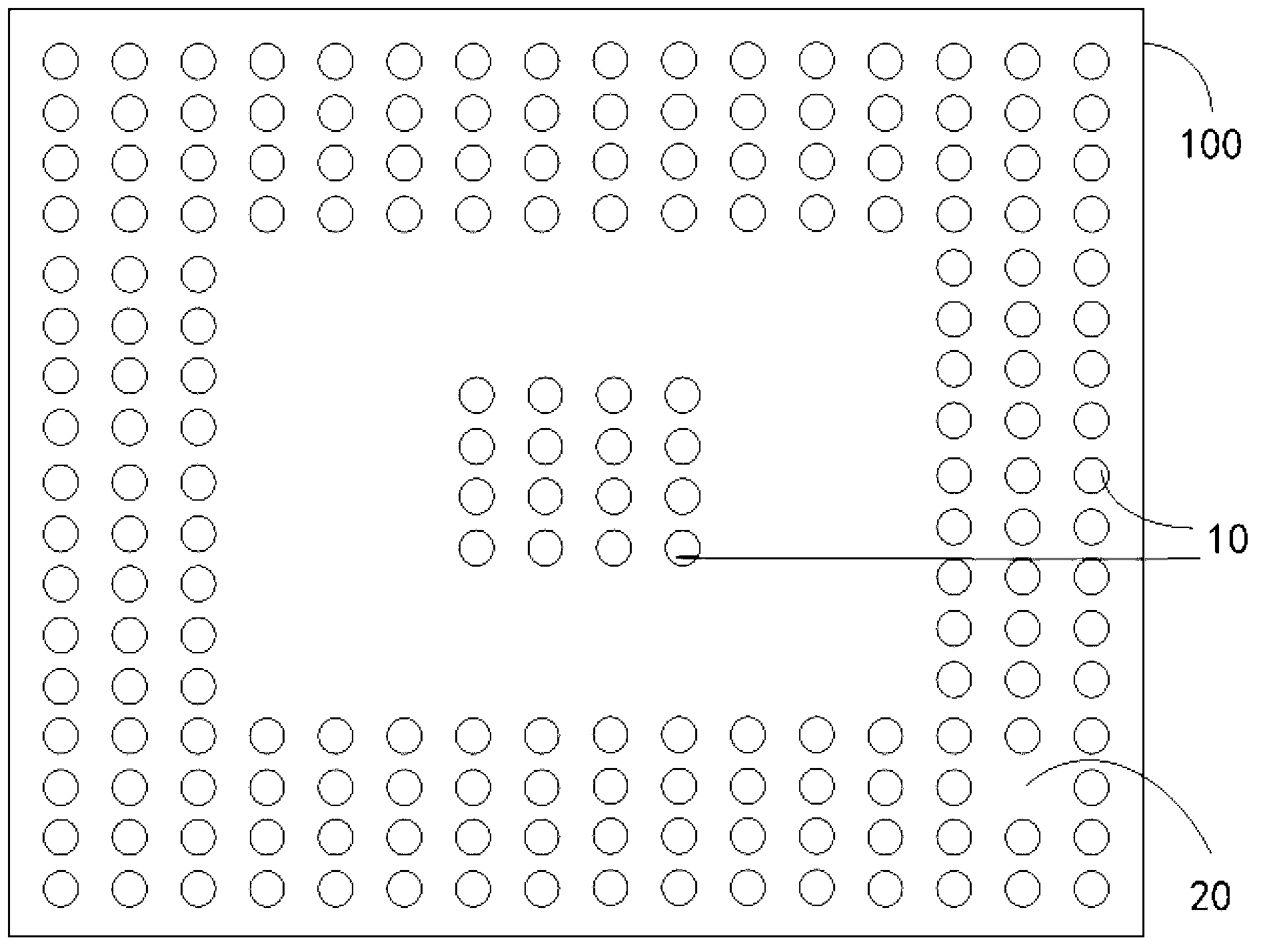

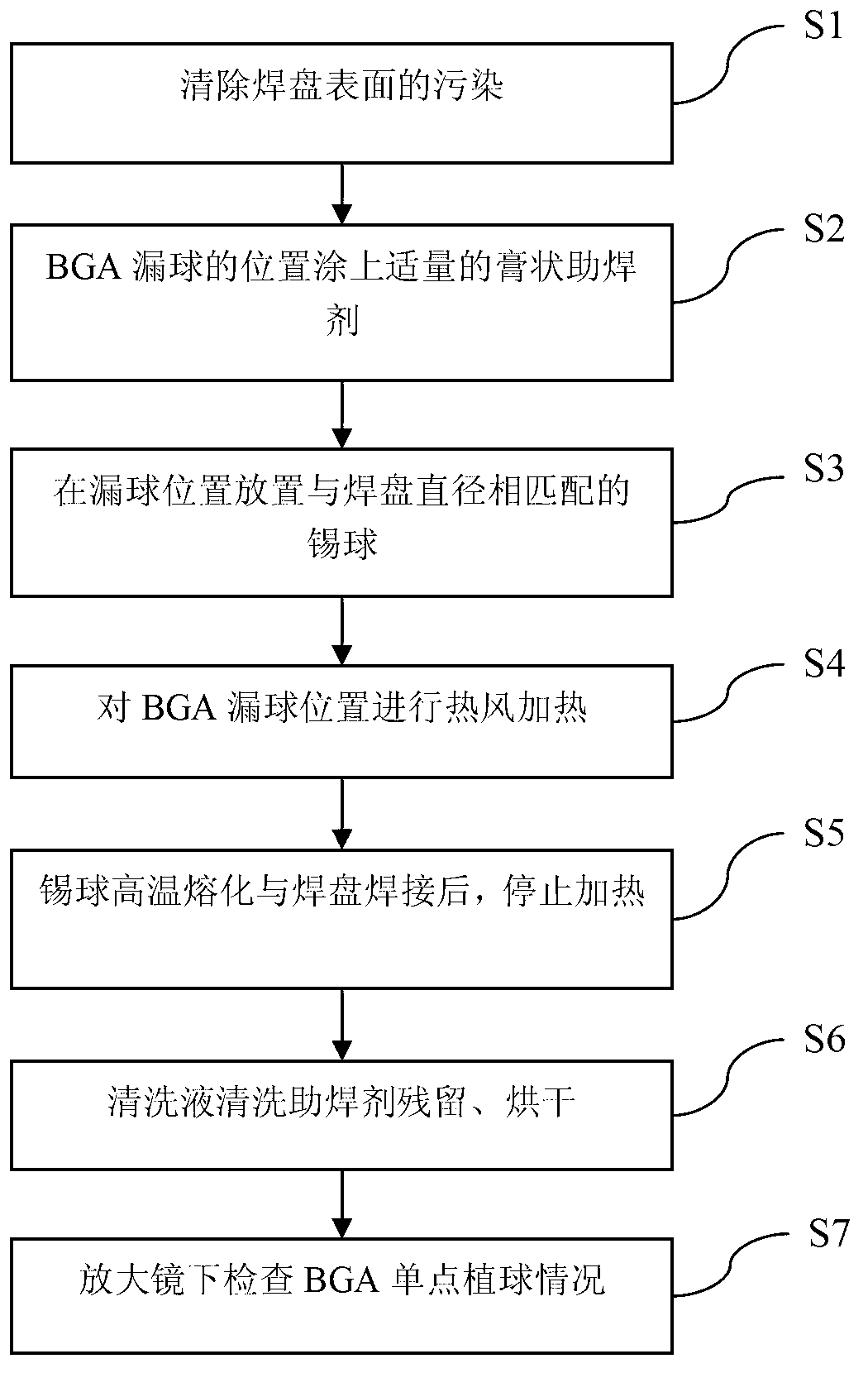

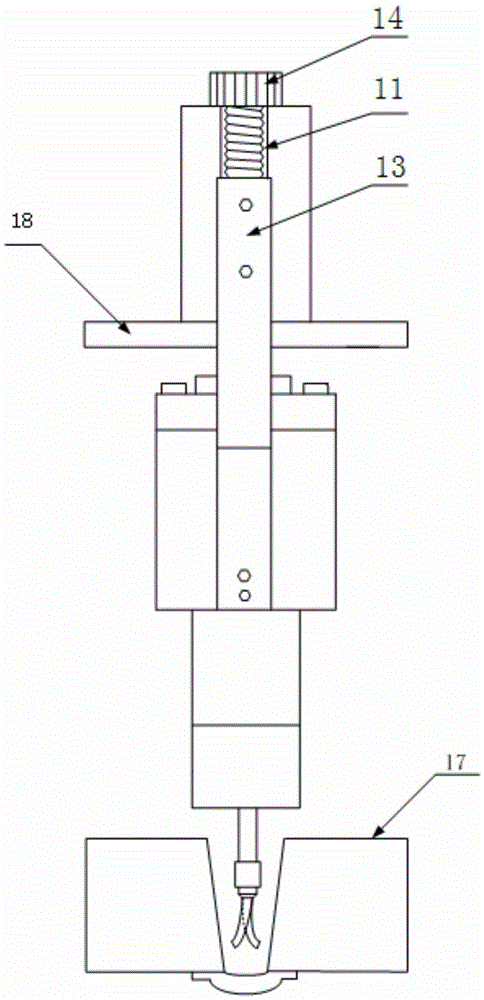

Ball grid array (BGA) balling single-point repair method

ActiveCN103231138AReduce heat exposureLife-span-reducing effectsSoldering apparatusSemiconductor/solid-state device manufacturingSolder ballEngineering

The invention provides a ball grid array (BGA) balling single-point repair method. The BGA balling single-point repair method includes: step one, removing an oxide layer and pollutants on the surface of a ball leaking pad on the bottom surface of a BGA chip; step two, taking paste scaling powder, and spreading the paste scaling powder on the ball leaking pad; step three, placing a solder ball with the diameter matched with that of the pad on the pad coated with the paste scaling powder in the step two; step four, heating the position where the solder ball is placed by using a heat gun in a mode that output air of the heat gun is perpendicular to the bottom surface of the BGA chip; and step five, closing the heat gun after the solder ball is melted, and detecting whether repair is successful after the heat gun is closed.

Owner:JIANGNAN INST OF COMPUTING TECH

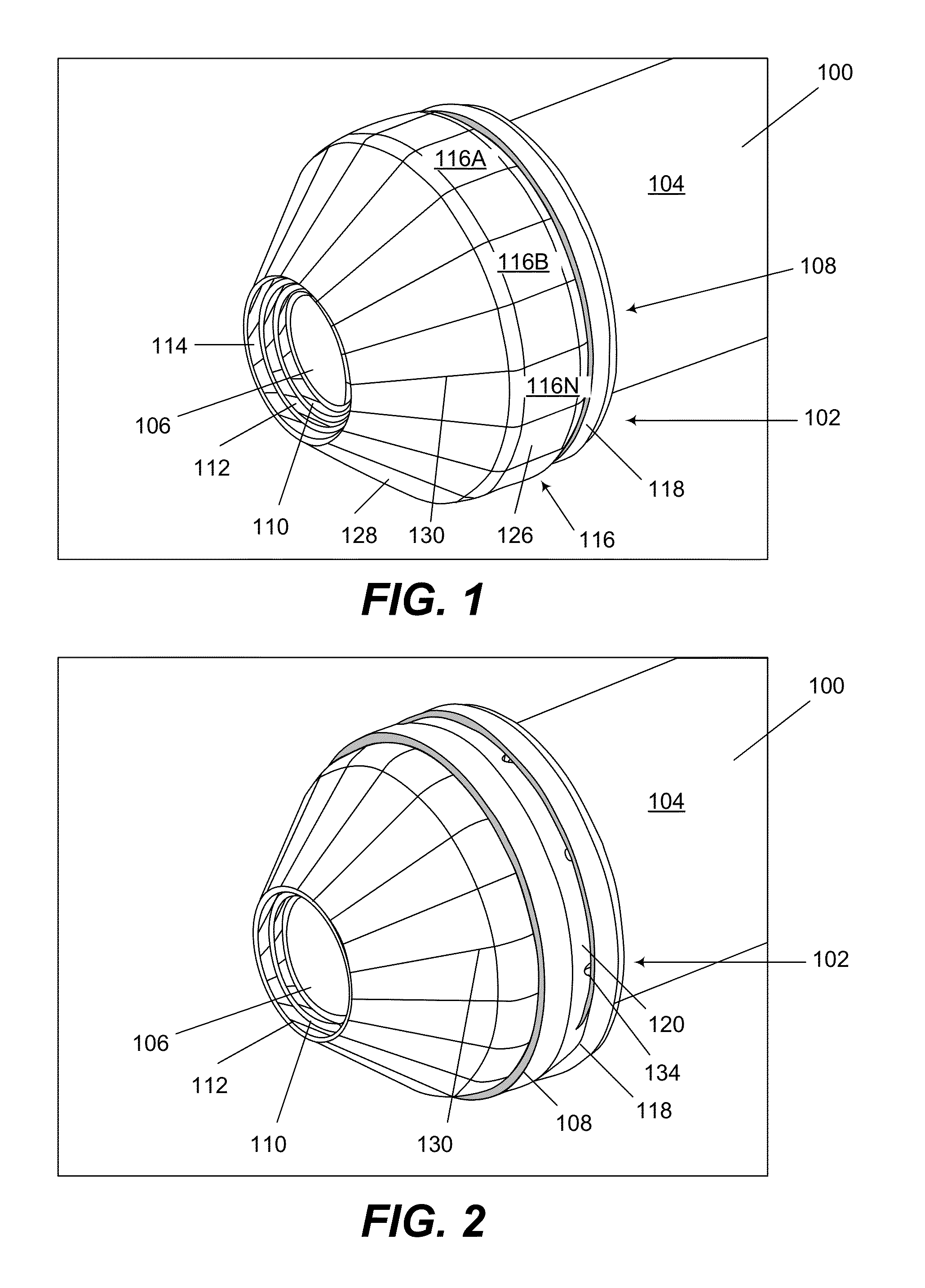

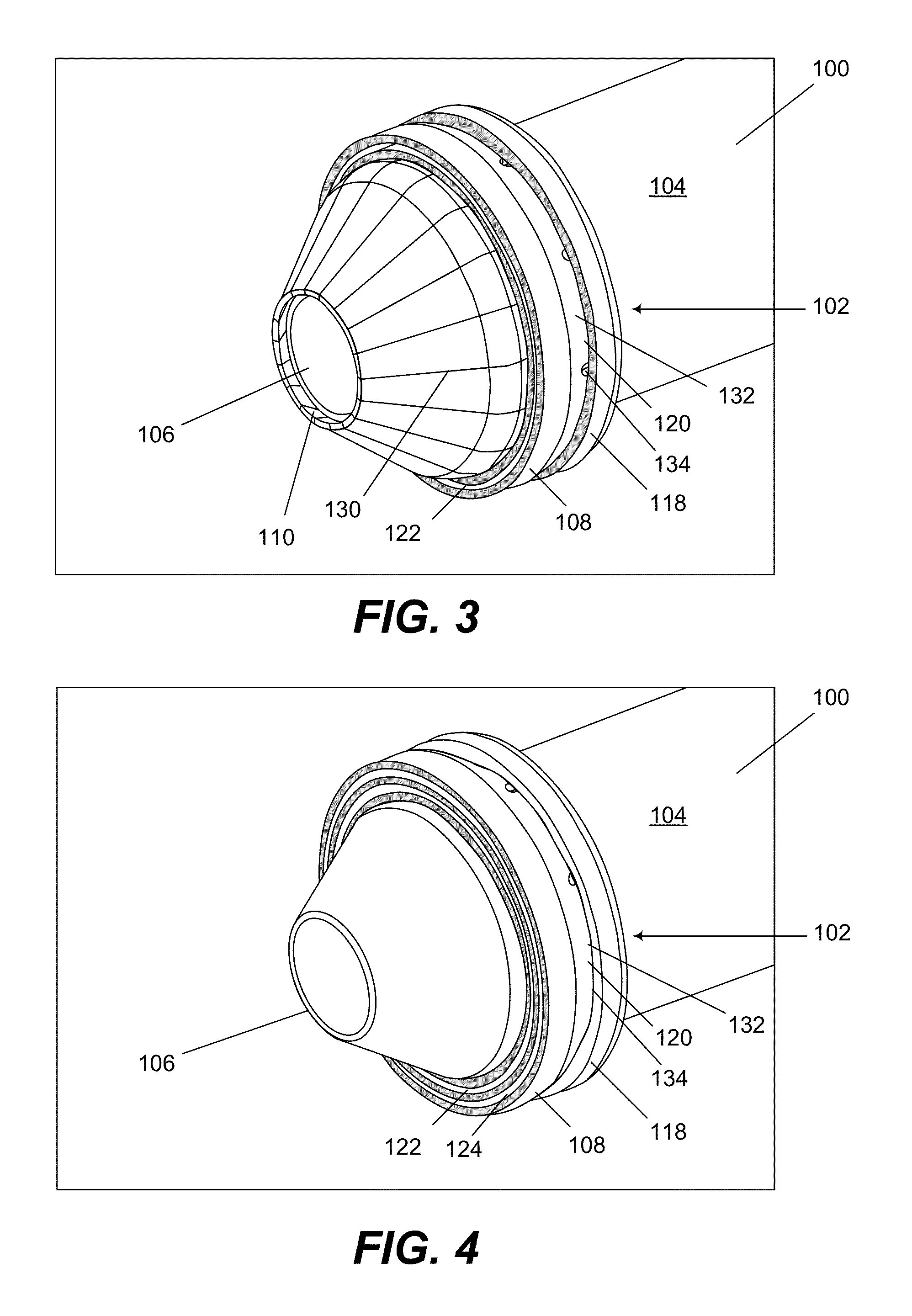

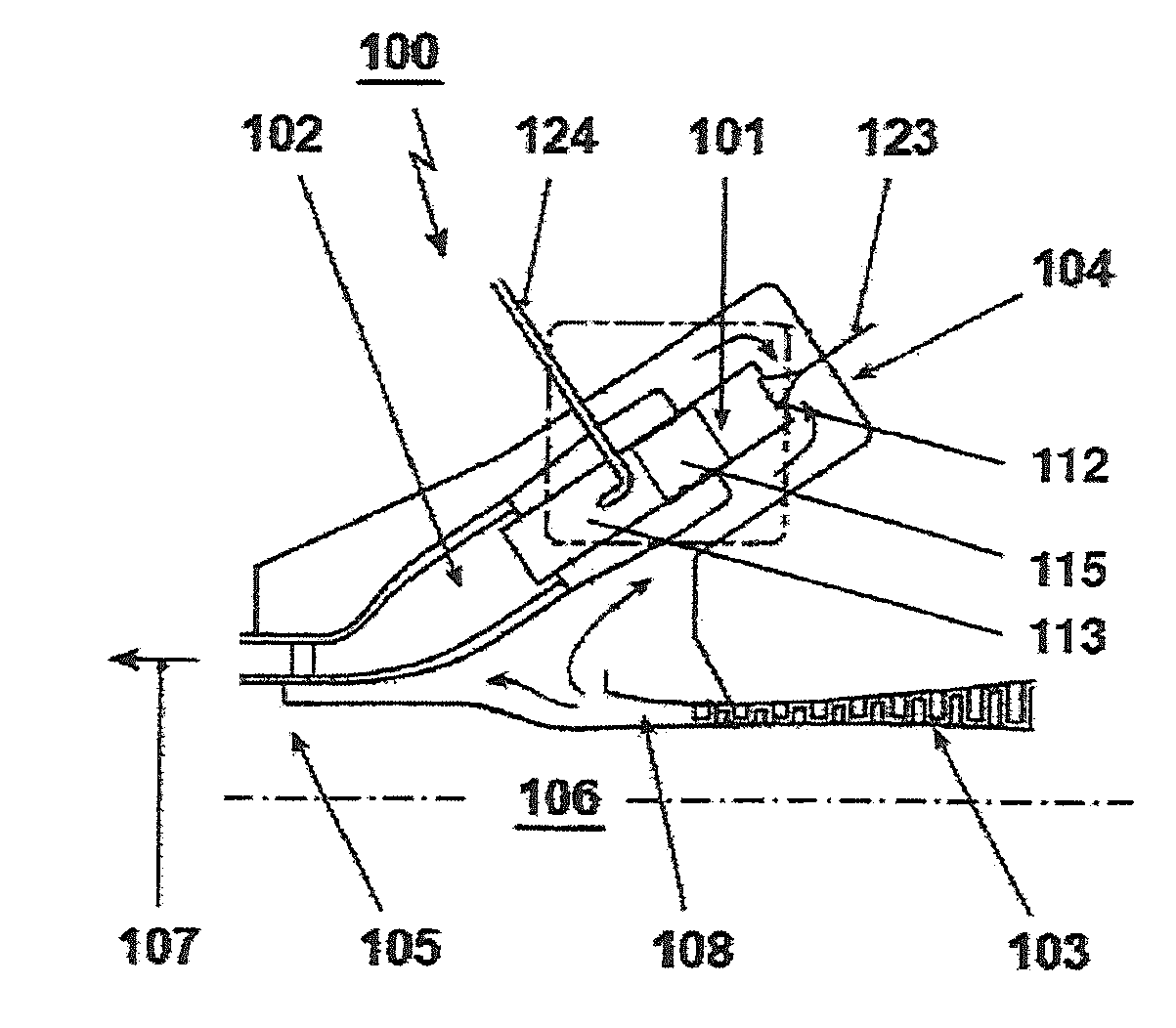

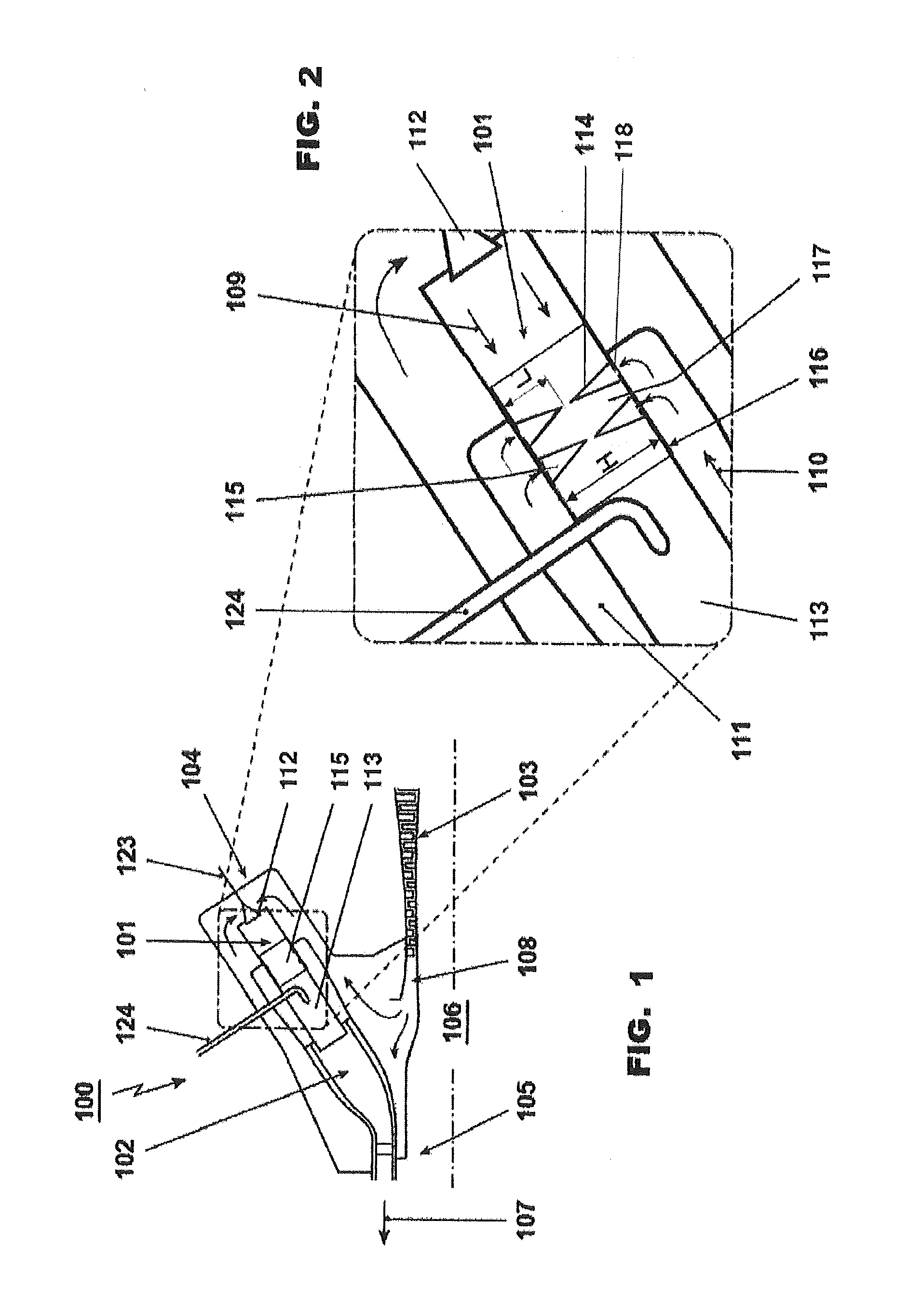

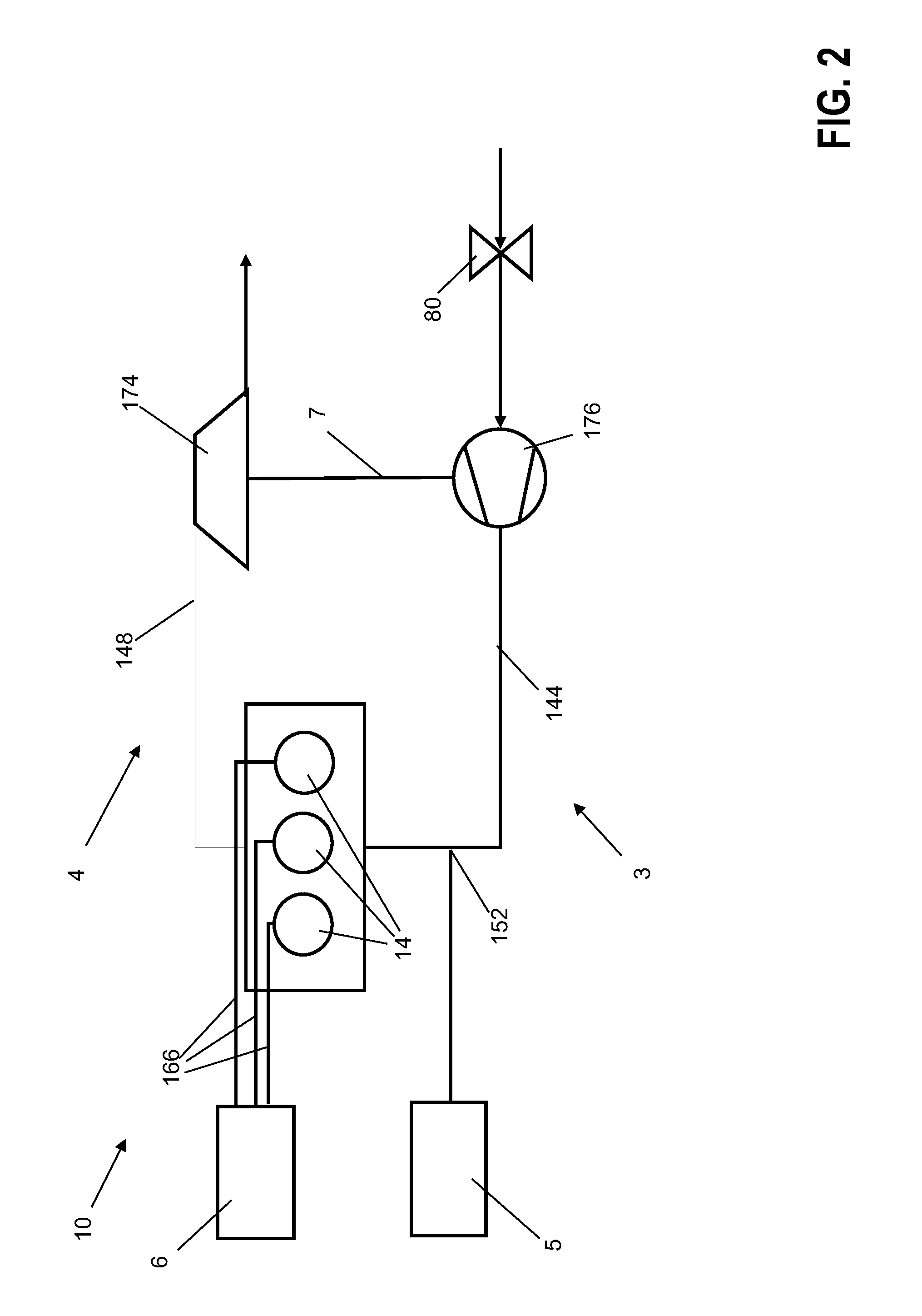

Methods and apparatus for providing a sacrificial shield for a fuel injector

ActiveUS8555647B2Reduce heat exposureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustionInjector

Owner:AIR PROD & CHEM INC

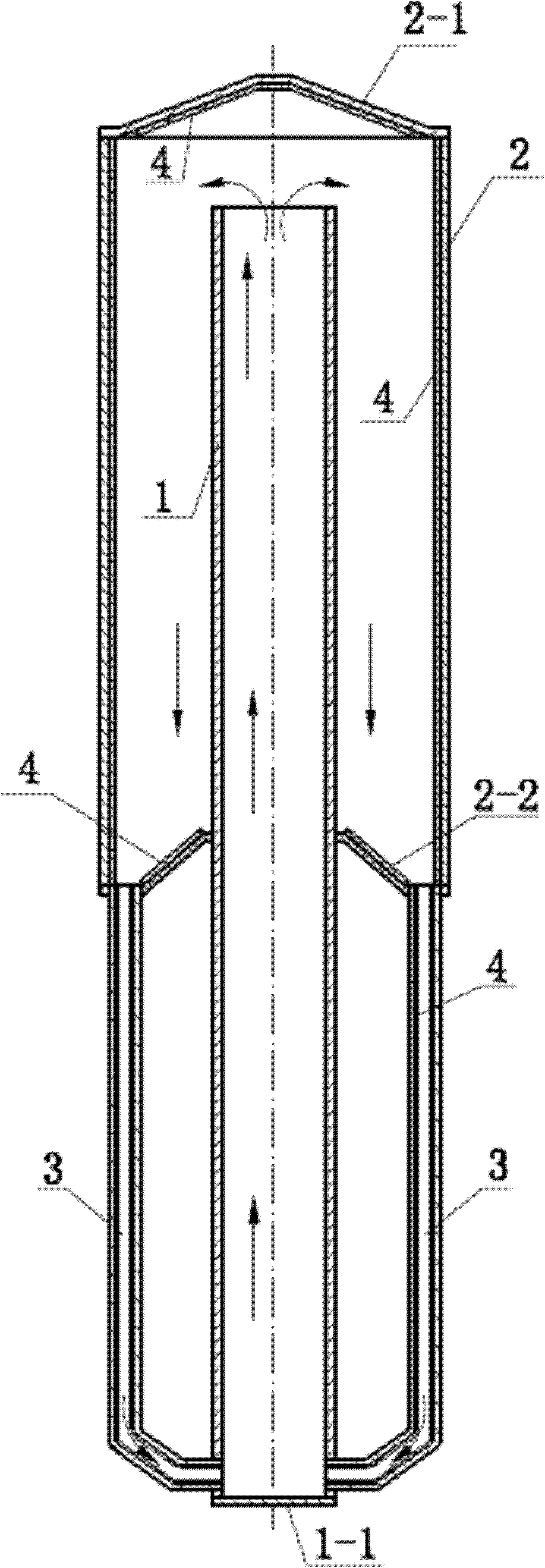

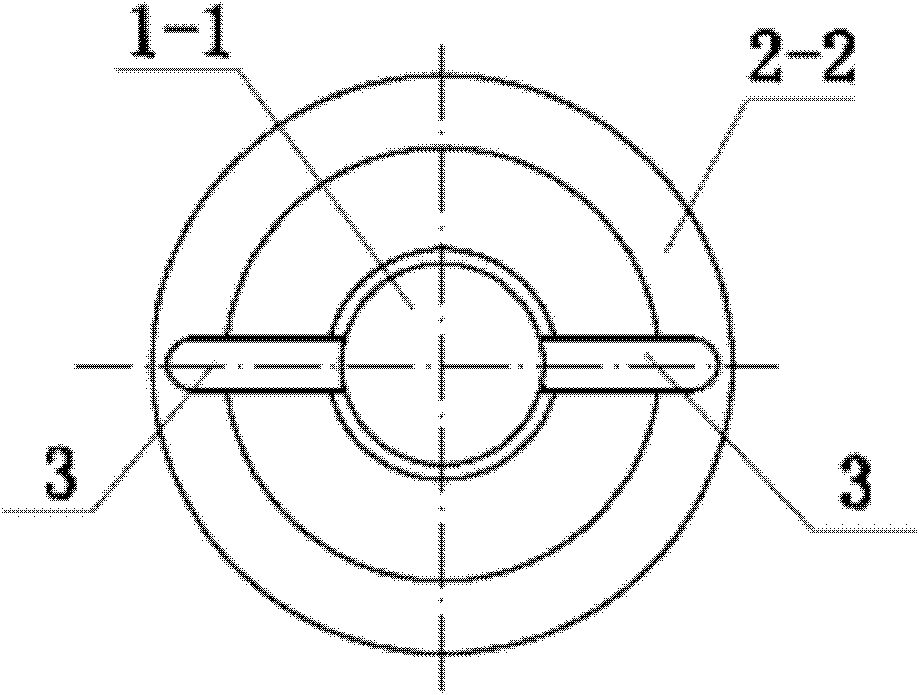

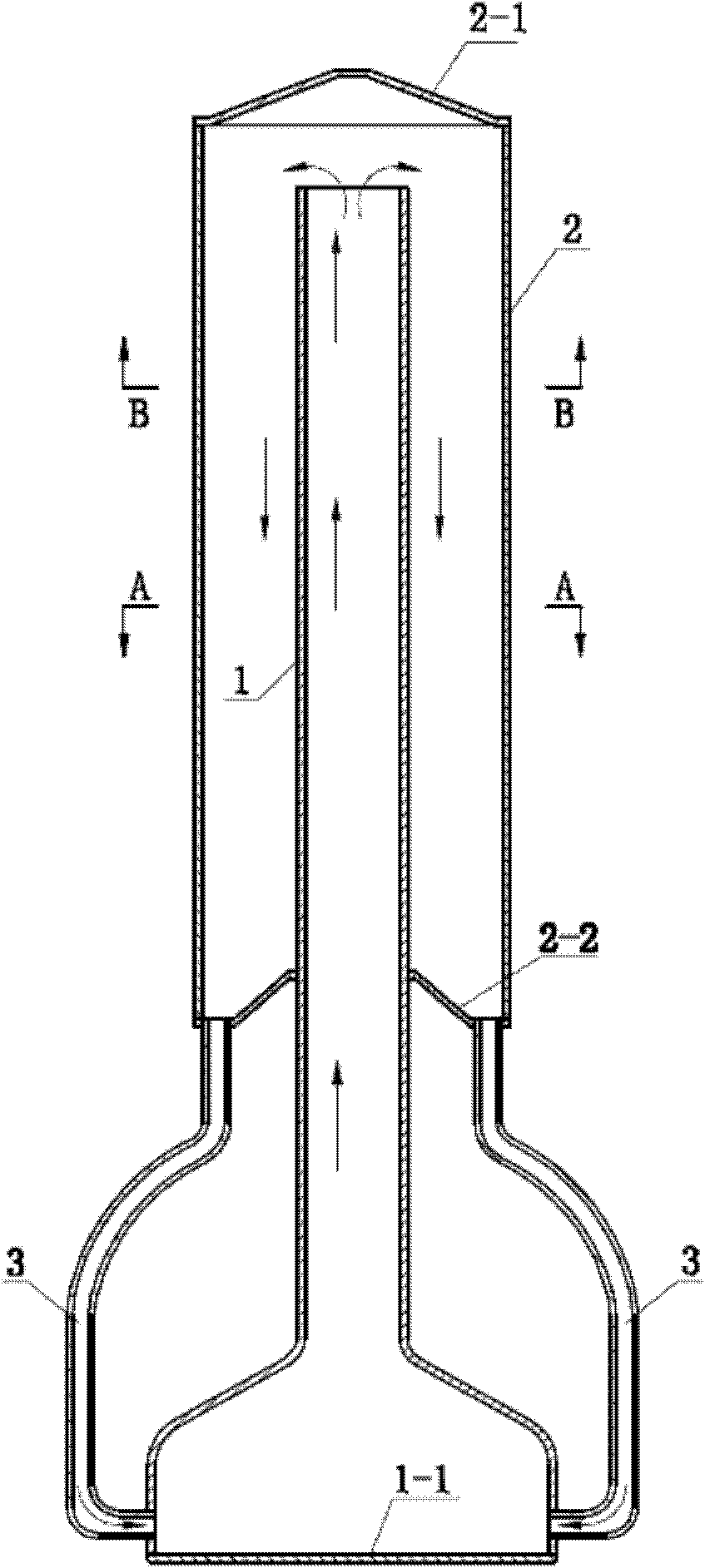

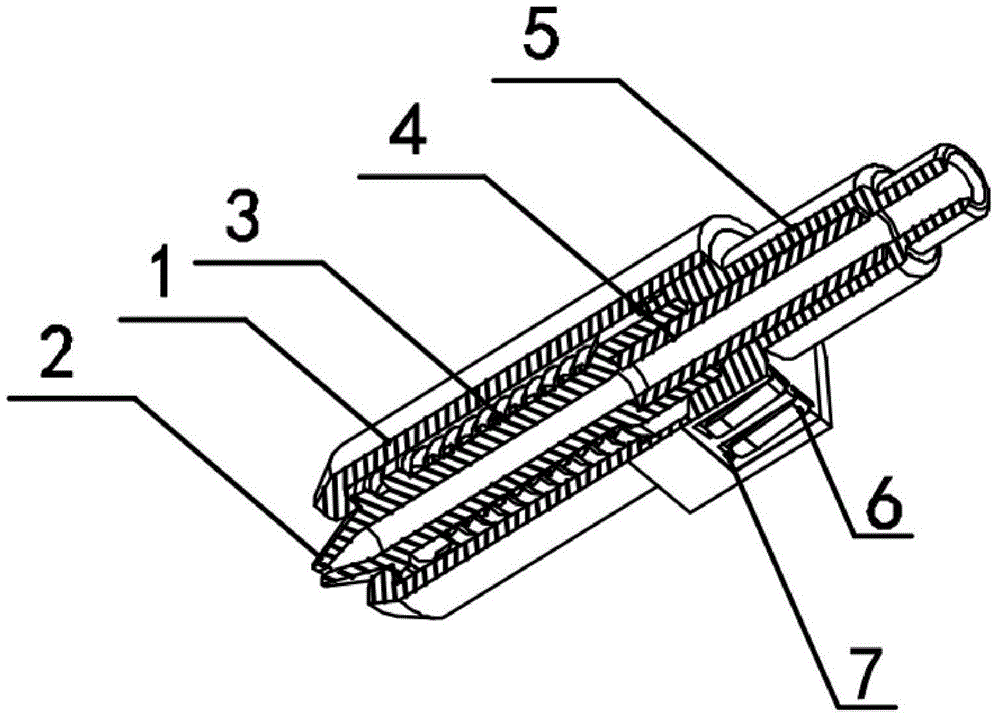

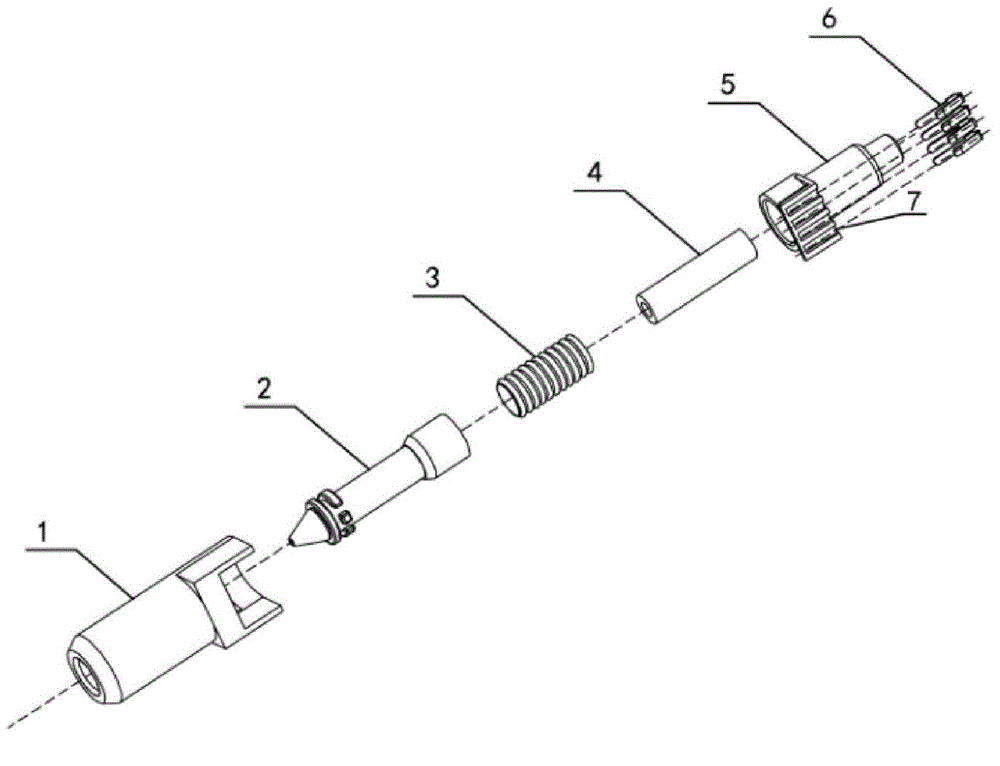

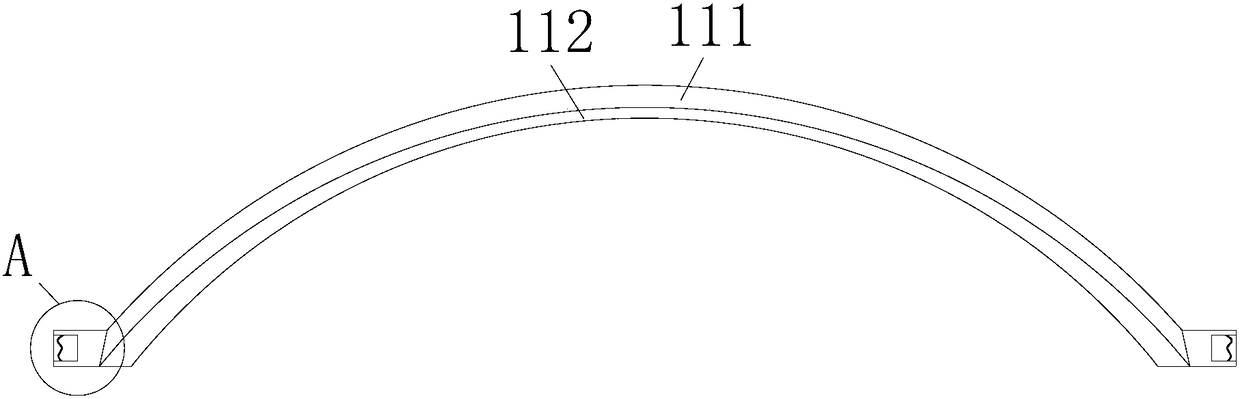

Heat pipe

InactiveCN102141351AImprove heat transfer efficiencyReduce heat exposureIndirect heat exchangersEvaporationEngineering

The invention discloses a heat pipe which is characterized in that the heat pipe comprises an inner pipe (1) and an outer pipe (2), wherein one head of the inner pipe is closed, the other head of the inner pipe is opened, one head of the outer pipe (2) is closed, and the other head of the outer pipe (2) is opened; the opened head of the inner pipe (1) is inserted into the opened head of the outer pipe (2) along an axis and extends near the closed head of the outer pipe (2); a sealing ring (2-2) is arranged at the opened port of the outer pipe (2) and seals an annular opening between the outer pipe (2) and the inner pipe (1); a plurality of return pipes (3) made of a heat-insulating material uniformly pass through the sealing ring (2-2), respectively extend near the closed head of the inner pipe (1) and are respectively communicated with the inner pipe (1); and the outer pipe (2) is a condensing segment of the heat pipe, and a part of the inner pipe (1) arranged at the outside of the outer pipe (2) is an evaporation segment of the heat pipe. A vapor stream and a liquid stream in the heat pipe described by the invention are not mutually influenced, and the heat transfer efficiency is high.

Owner:JIANGXI ZHONGGUANG LIGHTING TECH

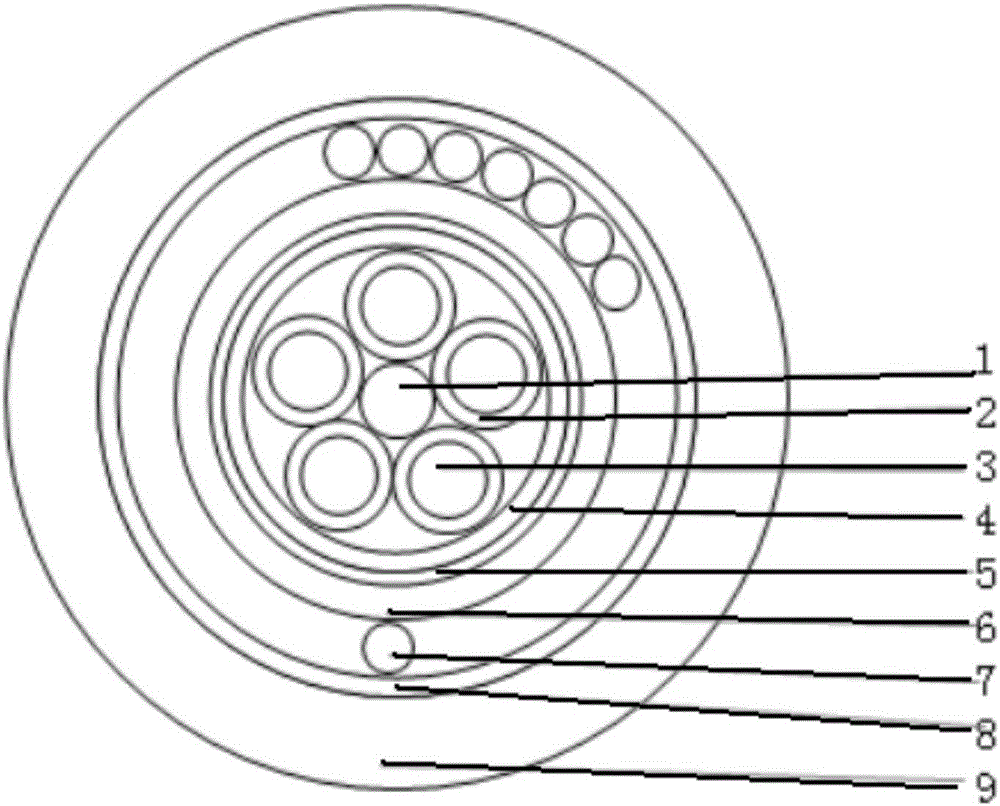

High-grade flame-retardant fireproof optical cable

ActiveCN106125216AHigh viscosityGood compatibilityClimate change adaptationFibre mechanical structuresFiberLow smoke zero halogen

The invention discloses a high-grade flame-retardant fireproof optical cable. The high-grade flame-retardant fireproof optical cable comprises a layer stranded type cable core, the layer stranded type cable core is wrapped by a double-face synthetic mica tape layer, the double-face synthetic mica tape layer is wrapped by a steel plastic composite band layer, the steel plastic composite band layer is externally plastically extruded by a low-smoke halogen-free inner sheath, the low-smoke halogen-free inner sheath is externally provided with at least one armored layer, the armored layer is externally provided with a fireproof layer and a low-smoke halogen oversheath, the low-smoke halogen-free inner sheath and the low-smoke halogen-free oversheath are both prepared by low-smoke halogen-free ceramic polyolefin, and the low-smoke halogen-free ceramic polyolefin comprises 60-70% of matrix polyolefin and 30-40% of an auxiliary agent, wherein the auxiliary agent comprises a plasticizer, white carbon black, 3% of micro-encapsulated red phosphorus, siloxane, 15-28% of a gas-phase fire retardant and 5-7% of a special fire retardant. The ceramic polyolefin is a halogen-free high-oxygen index sheath material and is easily ceramic during high-temperature combustion to form a compact protection layer so as to obstruct flames and heat transfer and accordingly prevent fibers from high-temperature damage.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

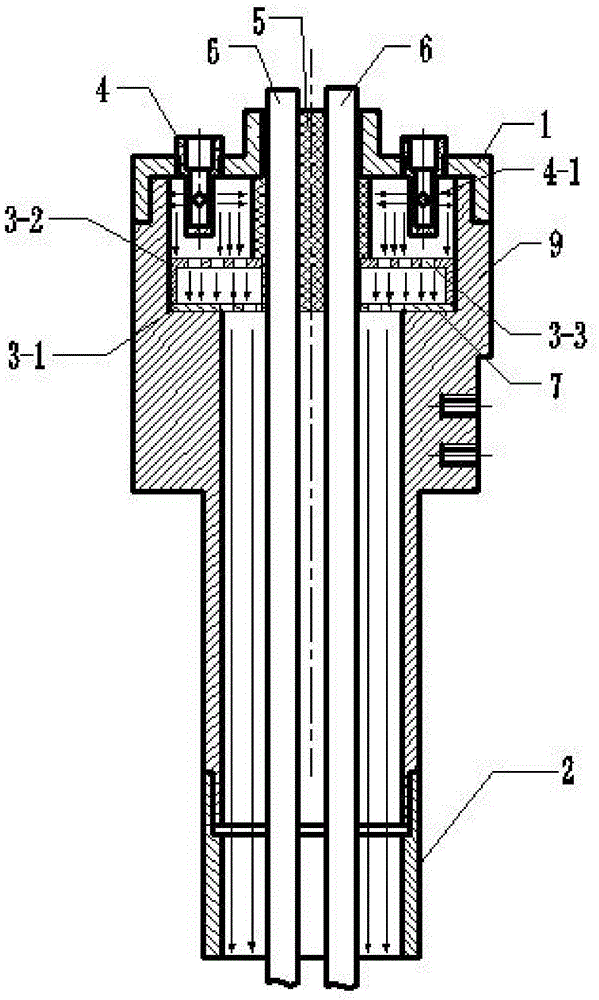

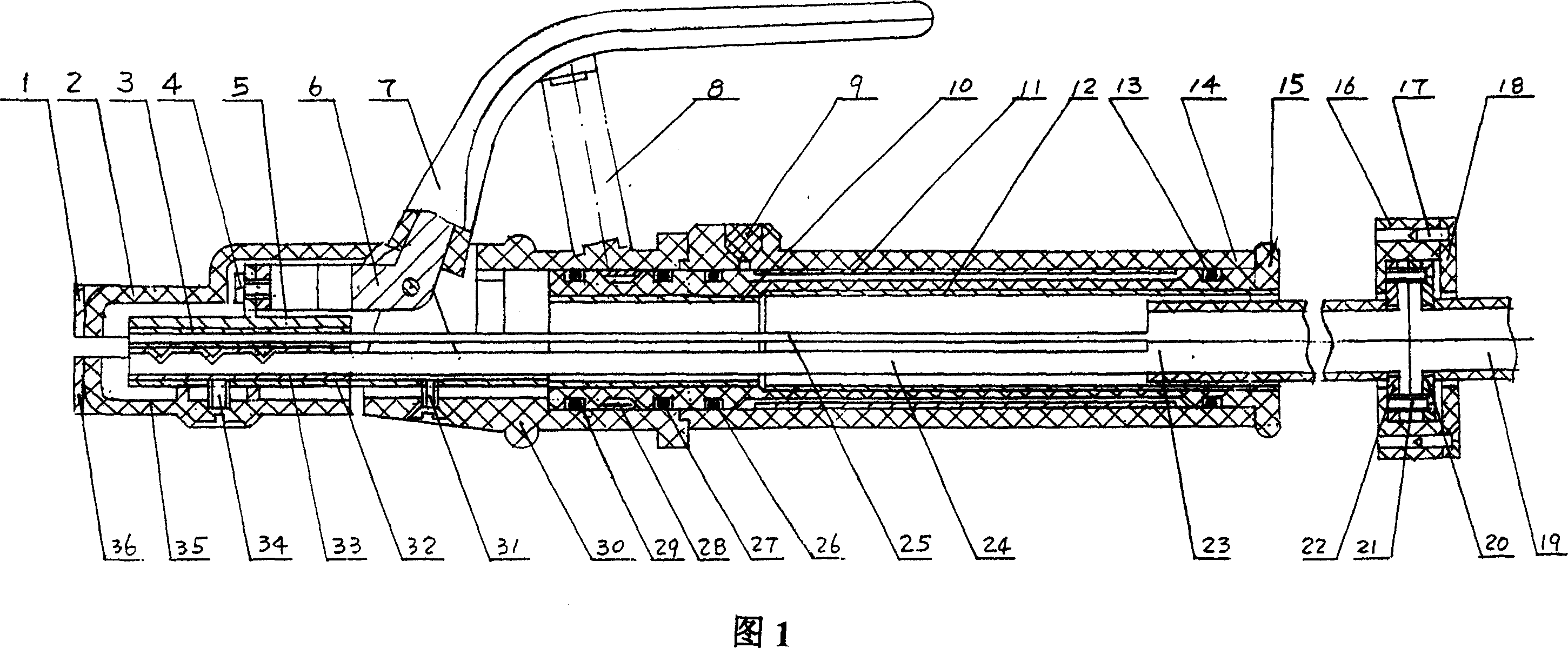

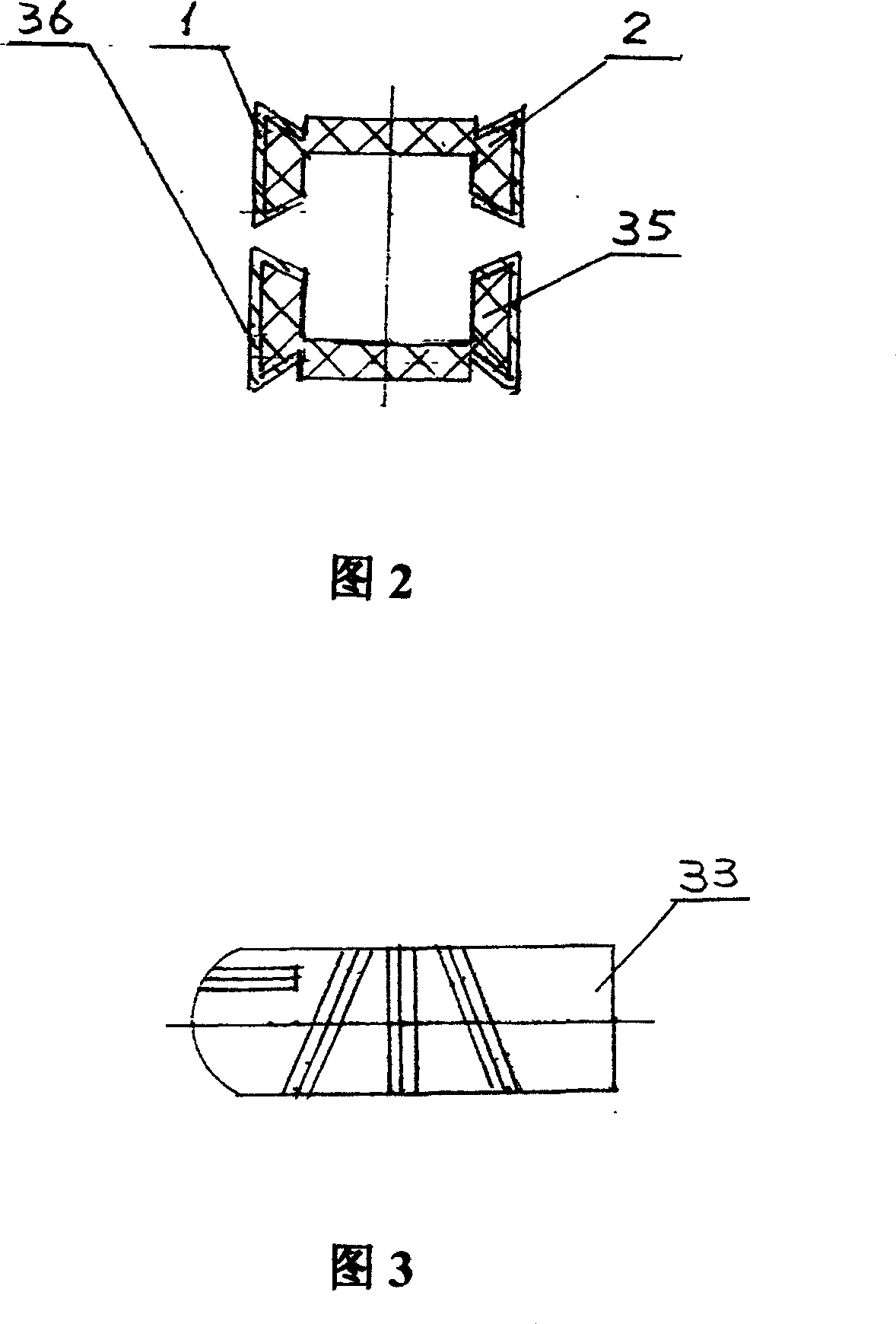

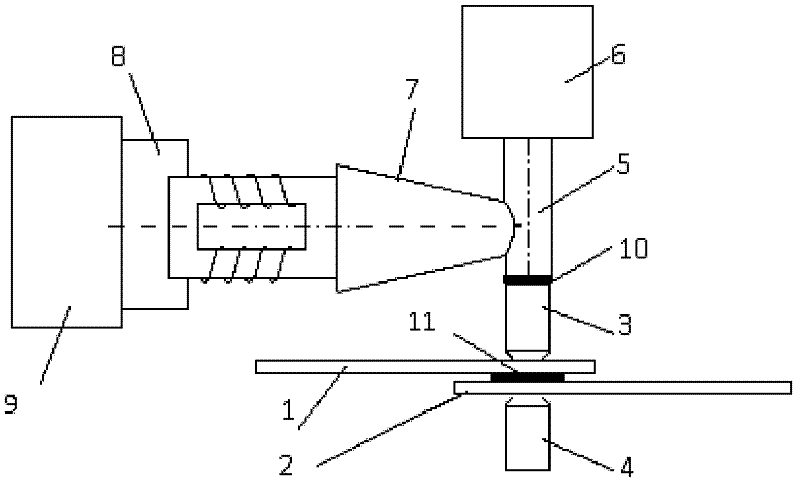

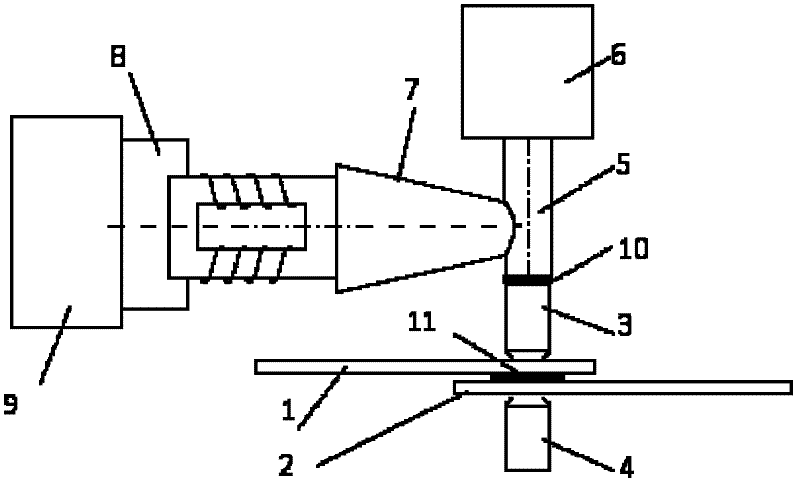

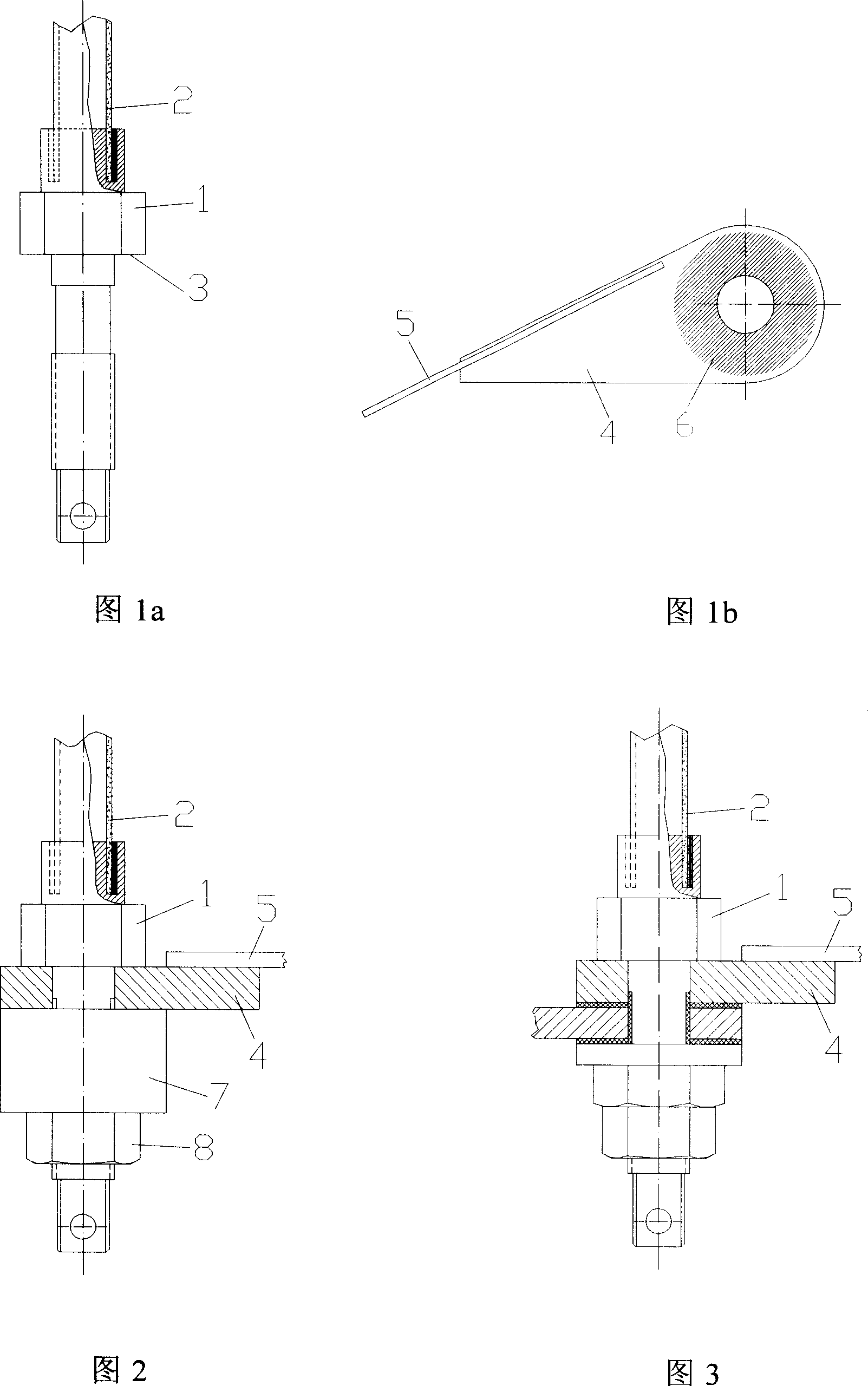

External nozzle twin-wire co-pool narrow-gap GMAW torch

InactiveCN105414722AMeeting protection needsSimple structureShielding gas supply/evacuation devicesElectrode supporting devicesSpray nozzleGas metal arc welding

The invention discloses an external nozzle twin-wire co-pool narrow-gap GMAW (gas metal arc welding) torch, belongs to the technical field of welding, and solves the problems that the conventional twin-wire narrow-gap GMAW torch is complex in structure and poor in welding protection effect. The external nozzle twin-wire co-pool narrow-gap GMAW torch comprises a main welding torch body, two conducting rods, two current contact nozzles, and dual gas sieve plates and gas plugs, wherein the main welding torch body is formed by integrating an upper cover, a gun pipe body and a nozzle into a whole through threaded connection; the gas plugs with holes formed in the radial direction are inserted into the gas inlets of the upper cover; the gas sieve plates with a parallel interval are arranged in the gun pipe body; the guiding rods are inserted into an insulating sleeve; the current contact nozzles are connected to the lower ends of the guiding rods. The external nozzle twin-wire co-pool narrow-gap GMAW torch has the advantages that the holes are punched in the side walls of the gas plugs in the gas inlets, so as to reduce the gas velocity; in the section of gas guiding, the dual gas sieve plates are adopted for further reducing the gas velocity and uniformly mixing gas; both the current contact nozzles point to narrow-gap side walls, so as to promote fusion of the side walls; in the welding process, the nozzle is arranged above a narrow-gap groove, so as to achieve an excellent narrow-gap twin-wire GMAW technology in the state of a common welding pool.

Owner:HARBIN INST OF TECH

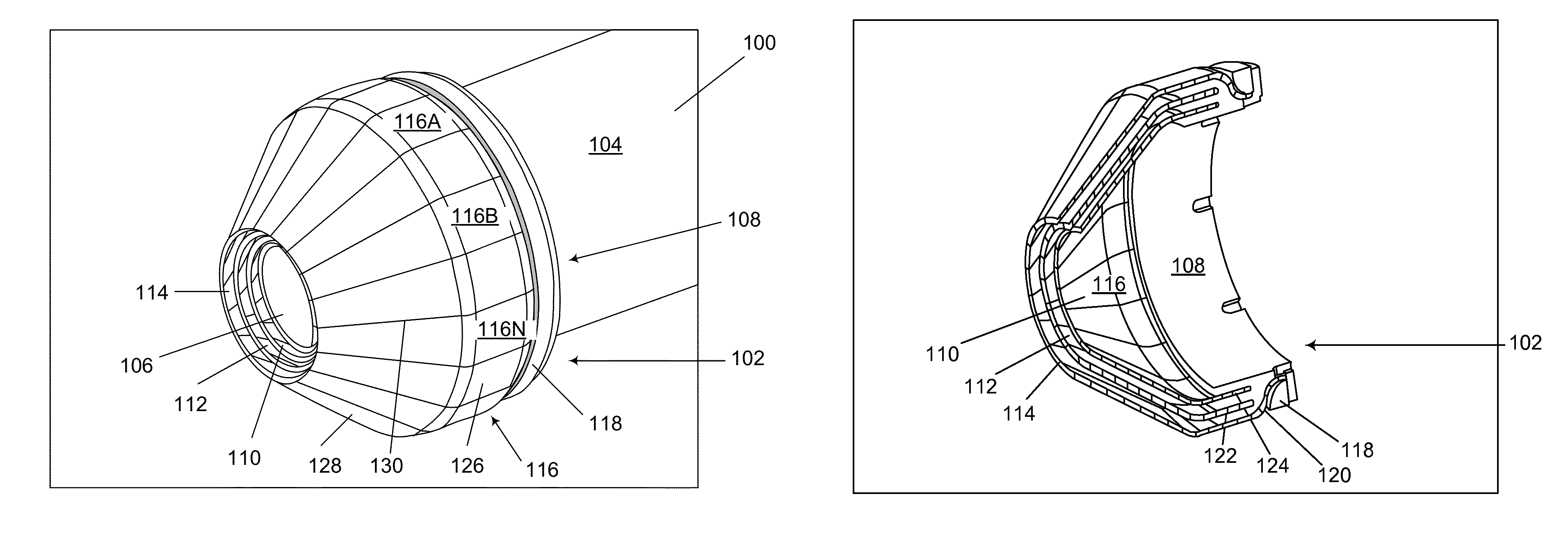

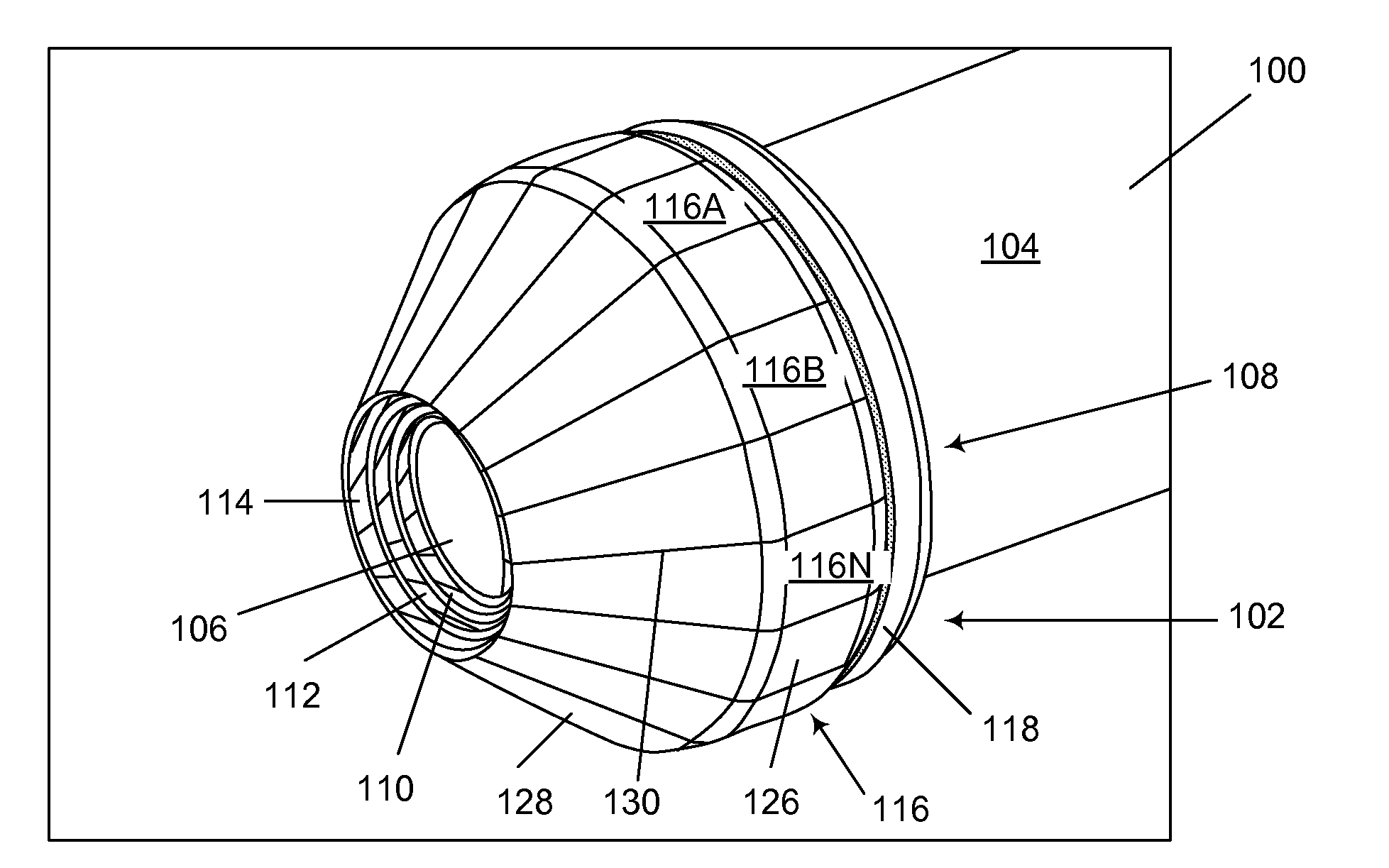

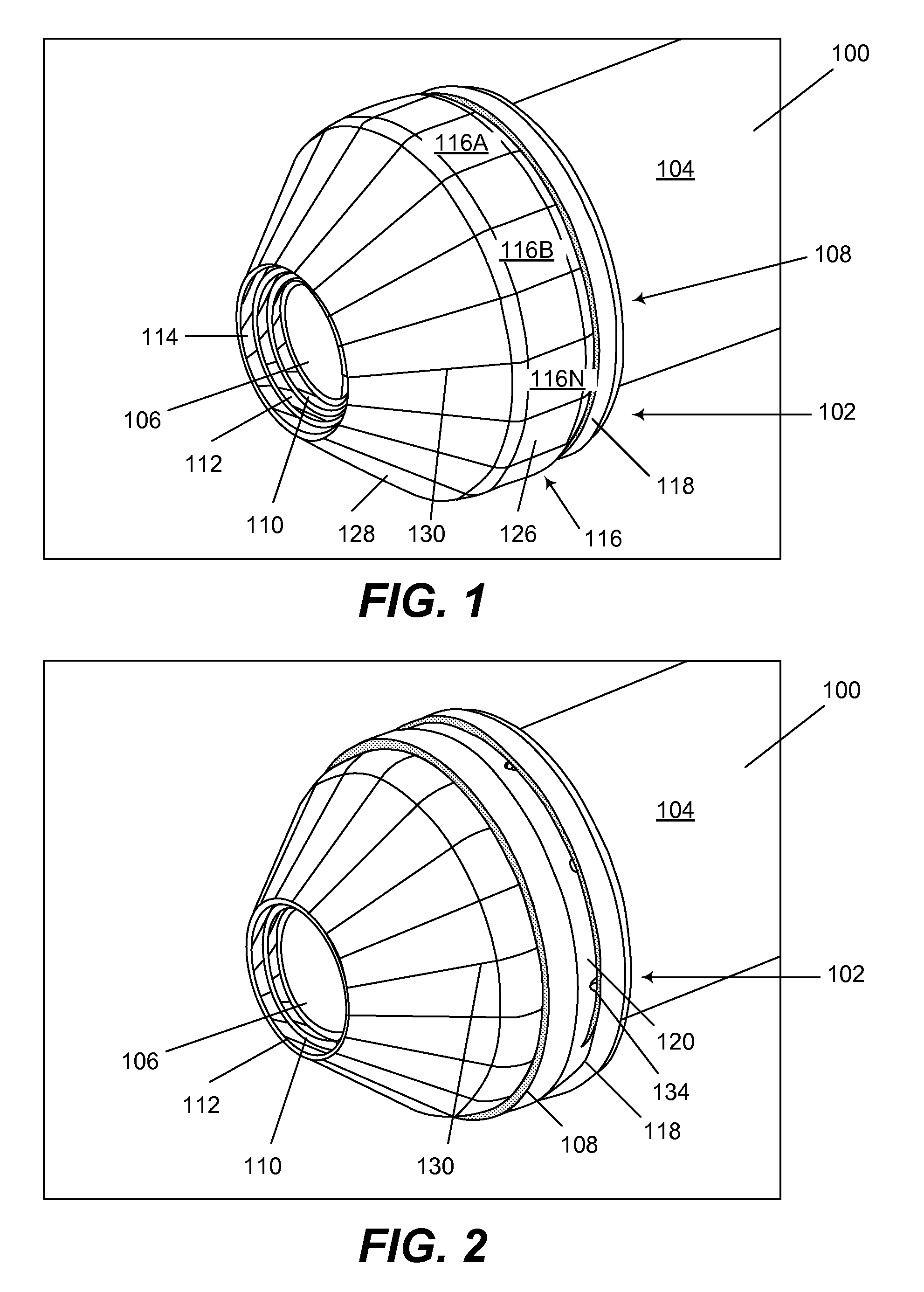

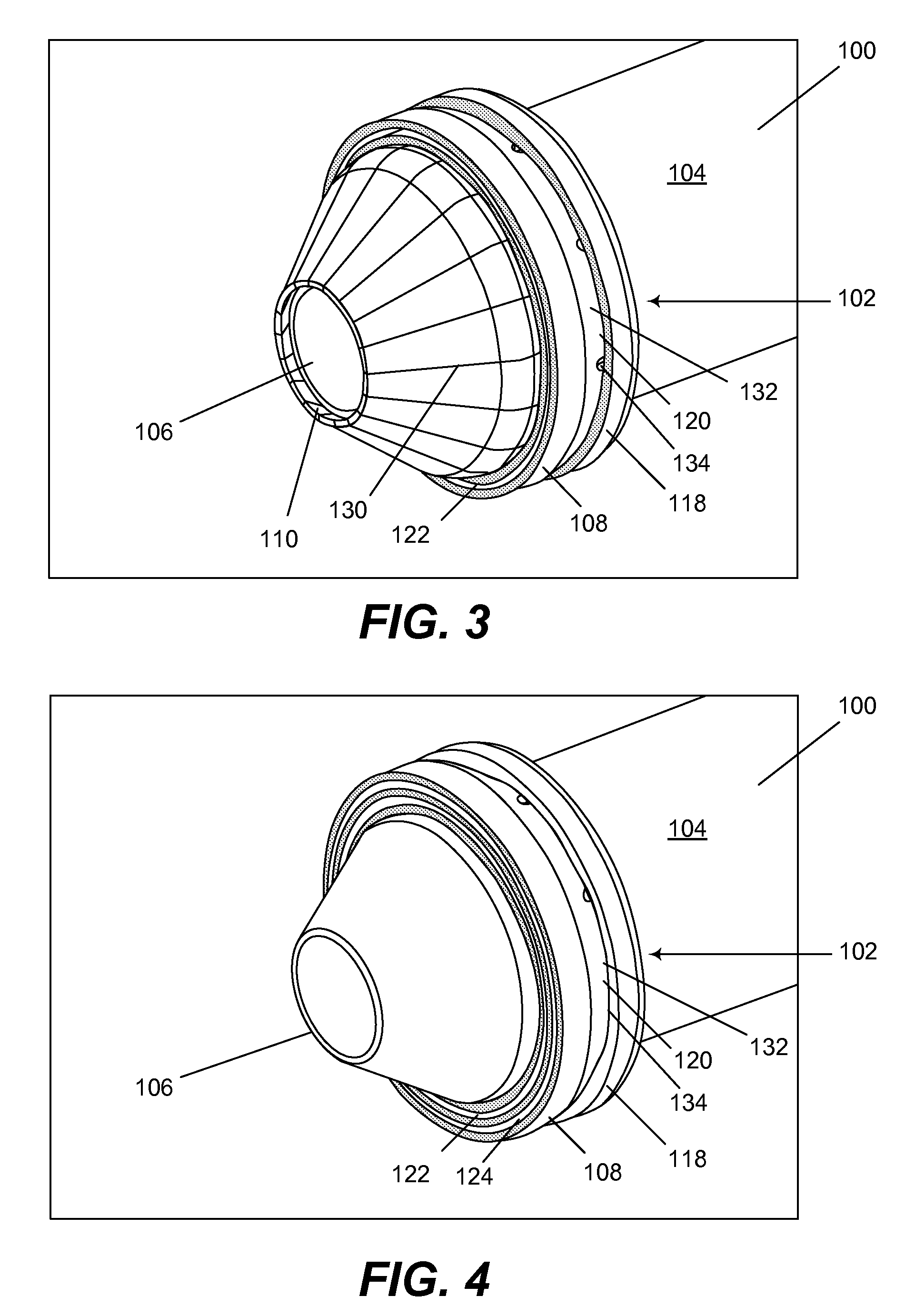

Methods and Apparatus for Providing A Sacrificial Shield For A Fuel Injector

ActiveUS20100229558A1Reduce heat exposureTurbine/propulsion fuel supply systemsSpray nozzlesCombustionInjector

Embodiments of methods and apparatus for providing a sacrificial shield for a fuel injector are provided. According to one example embodiment, a method for shielding a fuel injector associated with a combustion device is provided. The method can include providing at least one shield support device operable to mount to a tip of a fuel injector. The method can also include mounting a plurality of shields to the at least one support device, wherein each of the plurality of shields is spaced apart from each respective adjacent shield by at least one segmentation, and wherein each of the plurality of shields is operable to reduce heat exposure to the tip of the fuel injector.

Owner:AIR PROD & CHEM INC

Electric welding holder

InactiveCN100348356CLow calorific valueClosely connectedElectrode supporting devicesEngineeringElectric cables

This invention relates to an electrode holder, which comprises electrode holder body, spout cable grip and cable grip for connecting the electric welding machine, wherein the electrode holder body comprises connecting sleeve, knob inner and outer sleeves, and tong spout; between the connecting sleeve and knob inner sleeve, and between the inner and outer sleeve are sealed by collar seal individually; the up spout is hinged in the press handle through screw; the T-shape connectors of two kinds of cable grip are fixed and connected through protective adaptor, and the spout cable grip has up and low split-conductor cables, which connect up and low spout individually. Such structure can ensure the temperature of handle external surface perfect when working, and decrease the caloric power greatly; besides, it can obstruct and damp heat conduction between each part.

Owner:周光明

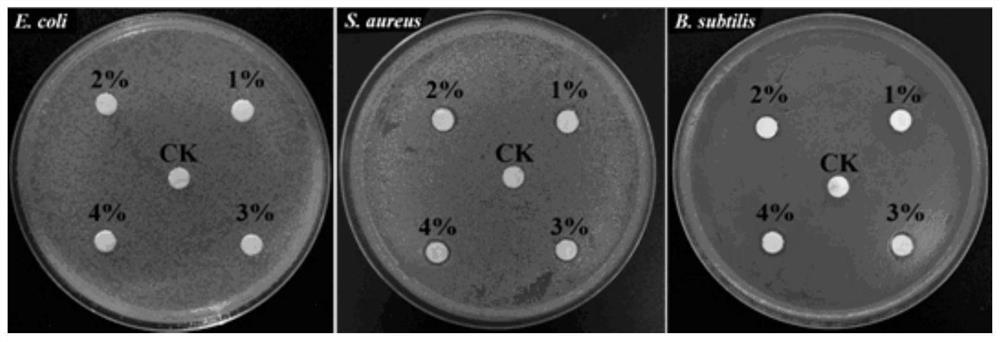

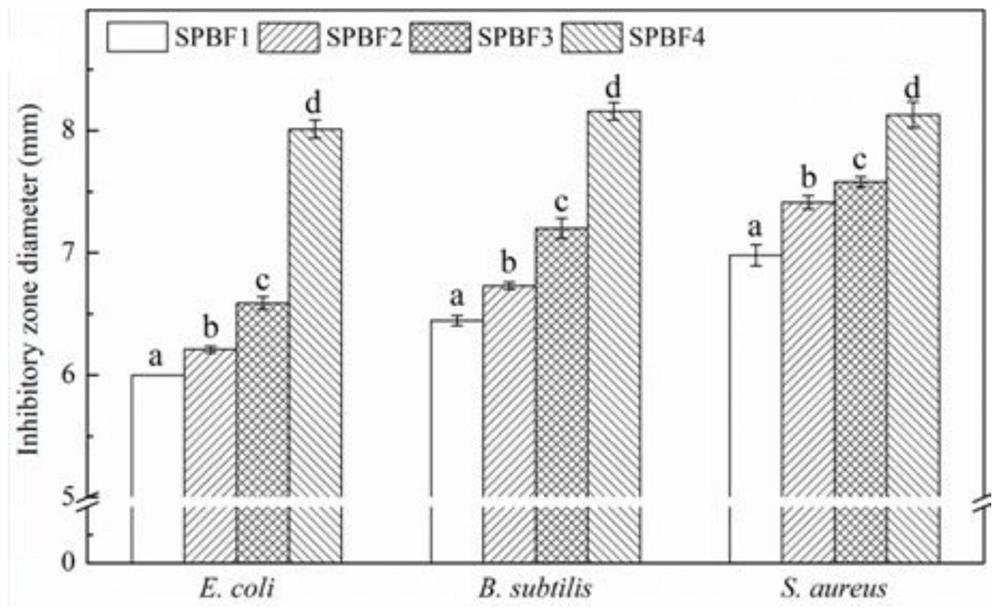

Fully-degradable antibacterial food packaging film and preparation method thereof

ActiveCN113234307AAvoid damageOptimize processing temperatureBio-packagingPolymer scienceBiodegradable polyester

The invention belongs to the field of food packaging, and particularly relates to a full-degradable antibacterial food packaging film and a preparation method thereof. The packaging film is prepared from 20-50 parts of starch, 50-80 parts of biodegradable polyester, 5-40 parts of plasticizer, 1-10 parts of compatibilizer, 2-20 parts of organic modified montmorillonite, 1-5 parts of lubricant and 0.5-12 parts of natural antibacterial agent. The food packaging film is prepared through one-step extrusion granulation, and is obtained by adopting an extrusion blow molding film making process. The full-degradable antibacterial food packaging film produced by the invention has excellent antibacterial property, mechanical property and barrier property, the used antibacterial agent is high in safety, the adopted film preparation mode is continuous and efficient, and the full-degradable antibacterial food packaging film is suitable for commercial production and can be applied to various food packaging scenes.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Platinum-catalyzed silicone drug delivery devices and methods of use thereof

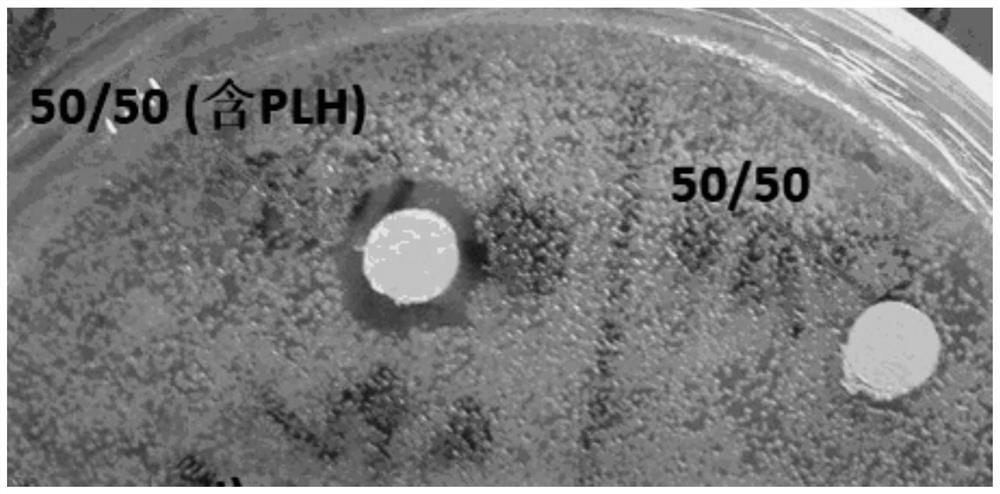

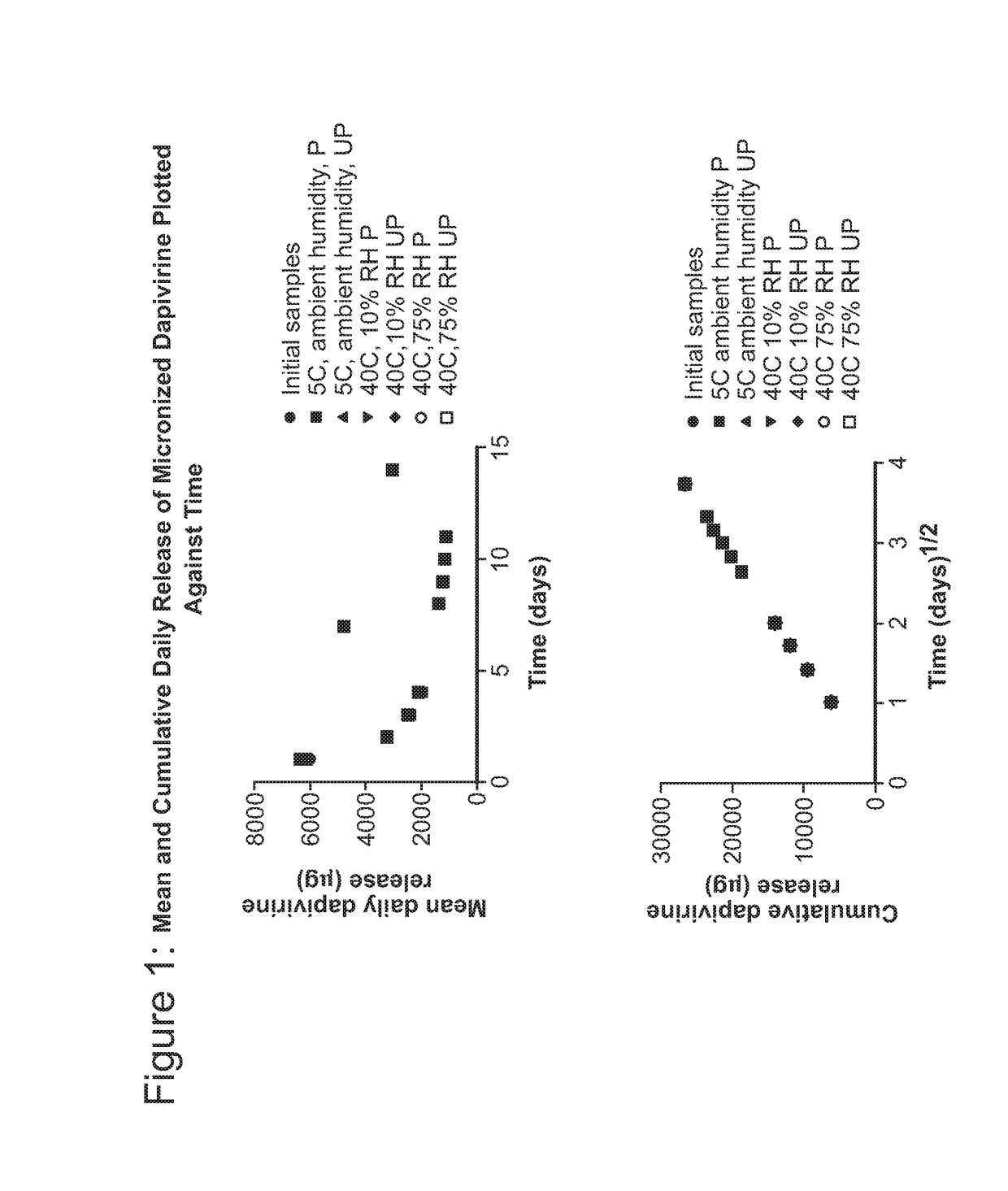

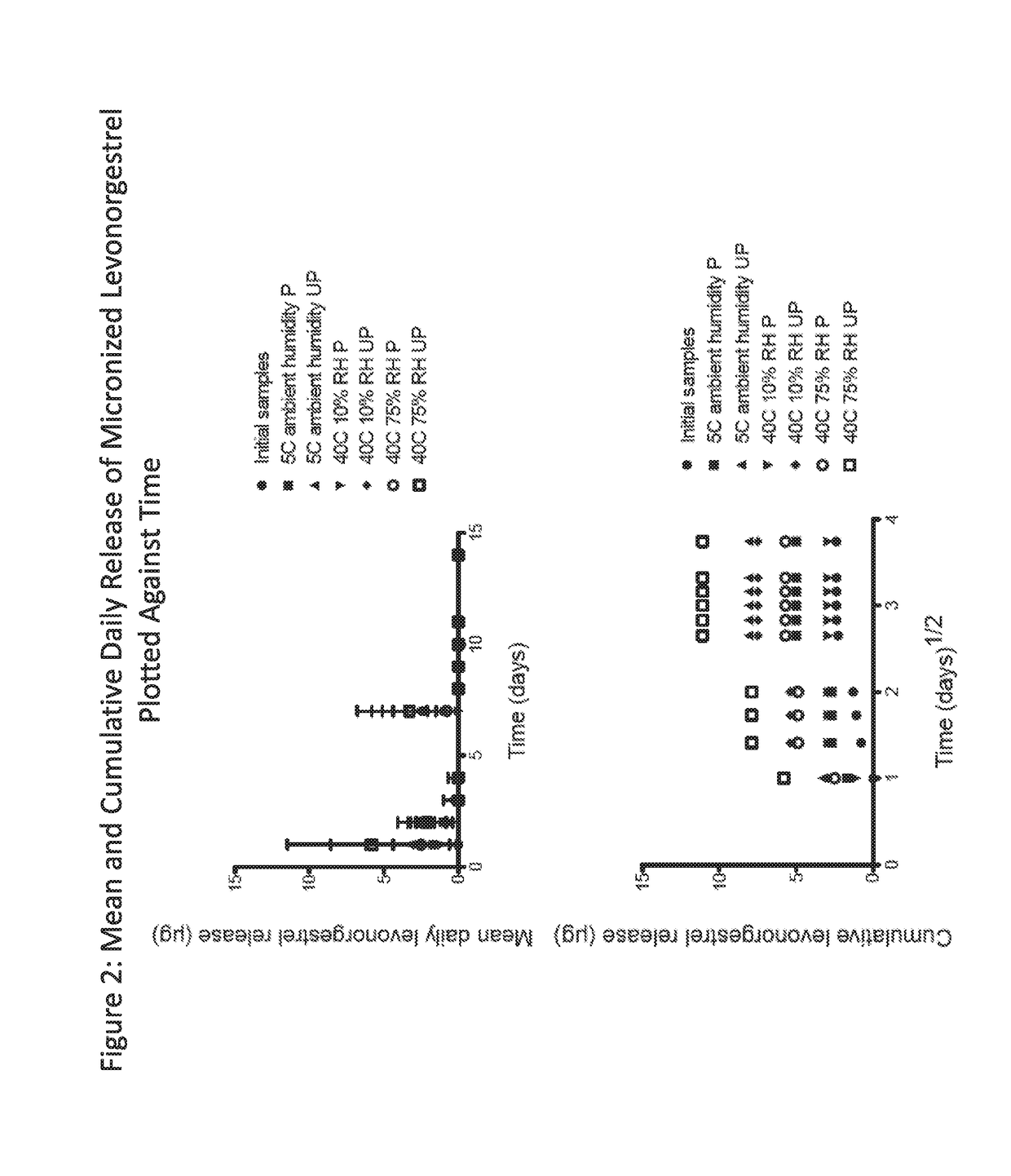

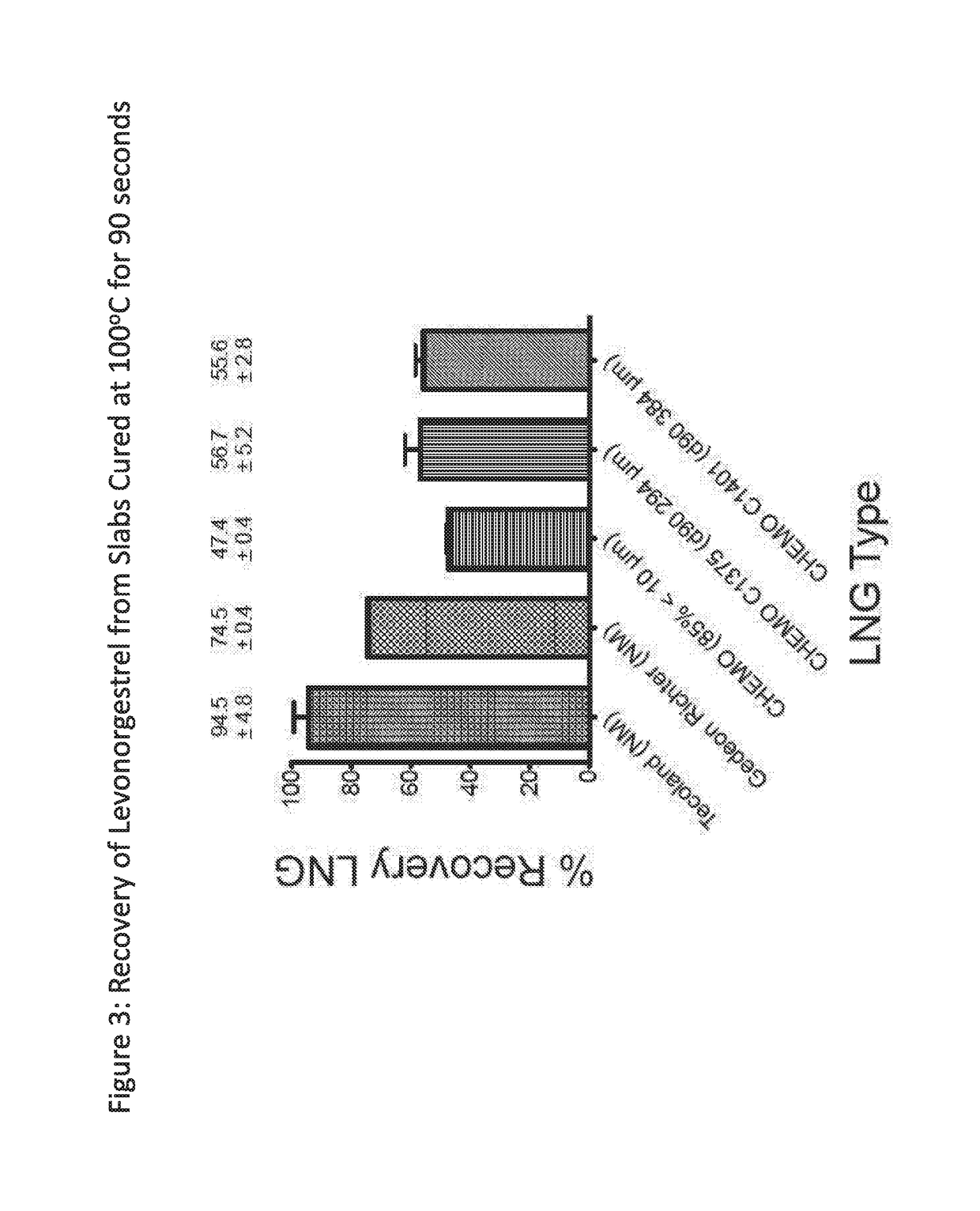

InactiveUS20170224823A1Reduce the binding forcePromote recoveryOrganic active ingredientsInorganic non-active ingredientsIntravaginal administrationAdditive ingredient

The present invention provides intravaginal drug delivery devices, such as intravaginal rings, comprising active pharmaceutical ingredients (APIs) having terminal alkene, alkyne or carbonyl functionalities. The devices of the invention exhibit increased recovery of the active pharmaceutical ingredient from platinum-catalyzed silicone polymers due to the optimization of drug particle size and cure conditions. The present invention also provides methods of preventing unintended pregnancy in a female human, methods of preventing unintended pregnancy in a female human and HIV infection in a female human, and methods of preparing intravaginal drug delivery devices.

Owner:INT PARTNERSHIP FOR MICROBICIDES

Three-dimensional (3D) printing nozzle for preventing pipe expansion blockage

InactiveCN104015361AImprove the lubrication effectBroaden your optionsConfectionerySweetmeatsPolytetrafluoroethyleneMelting point

The invention discloses a three-dimensional (3D) printing nozzle for preventing pipe expansion blockage. The 3D printing nozzle comprises a nozzle and a heating device which is wound around the outer wall of the nozzle, and also comprises a high-temperature-resistant plastic lead-in pipe of which the melting point is higher than melting points of consumables, wherein a through hole of the plastic lead-in pipe is butted with a through hole of the nozzle to form a consumable conveying cavity; the plastic lead-in pipe is preferably a polytetrafluoroethylene pipe. The consumable is led in through the plastic lead-in pipe and enters the heated nozzle to be molten into jelly. Although the consumable is heated to slightly expand before entering the through hole in front of the nozzle due to the heat conduction effect, a phenomenon of the pipe expansion even blockage caused by heat conduction of heating and cooling devices in the process of allowing the consumable to enter the through hole in front of the nozzle can be well eliminated due to three factors that the plastic lead-in pipe is low in heat conductivity coefficient, the lubricating property of the lead-in pipe is high and micro deformation is generated after the pipe is heated. Therefore, the 3D printing nozzle can be compatible with consumables of various materials, and the selection range is widened.

Owner:句容利威尔电器有限公司

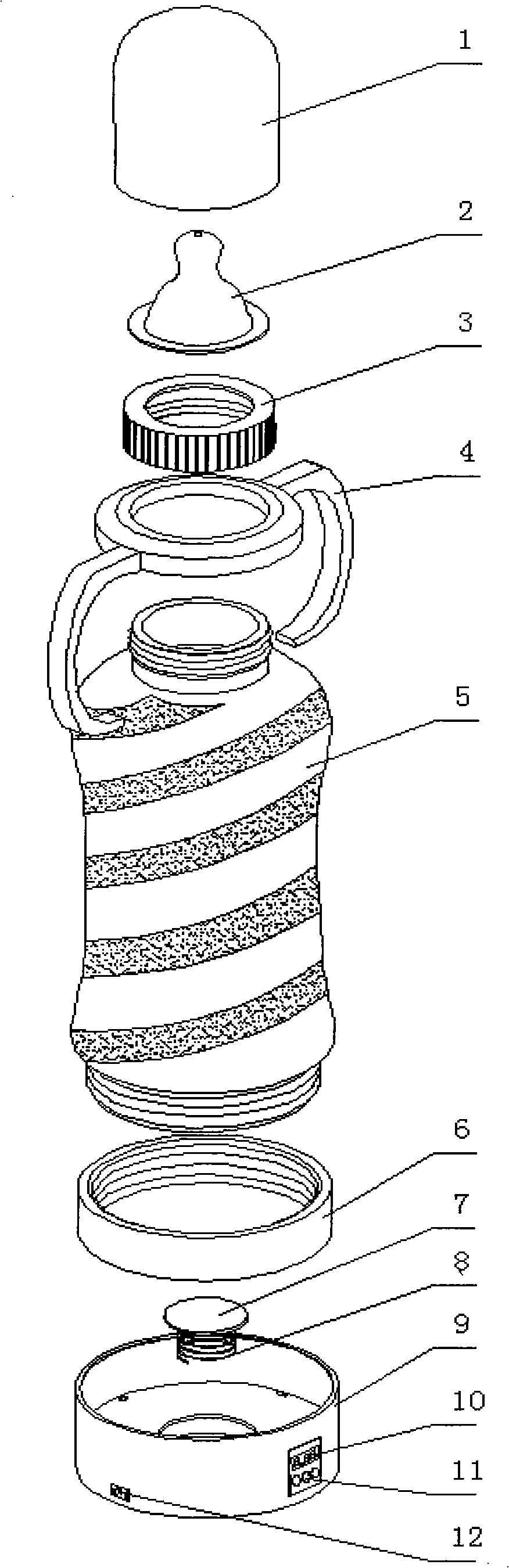

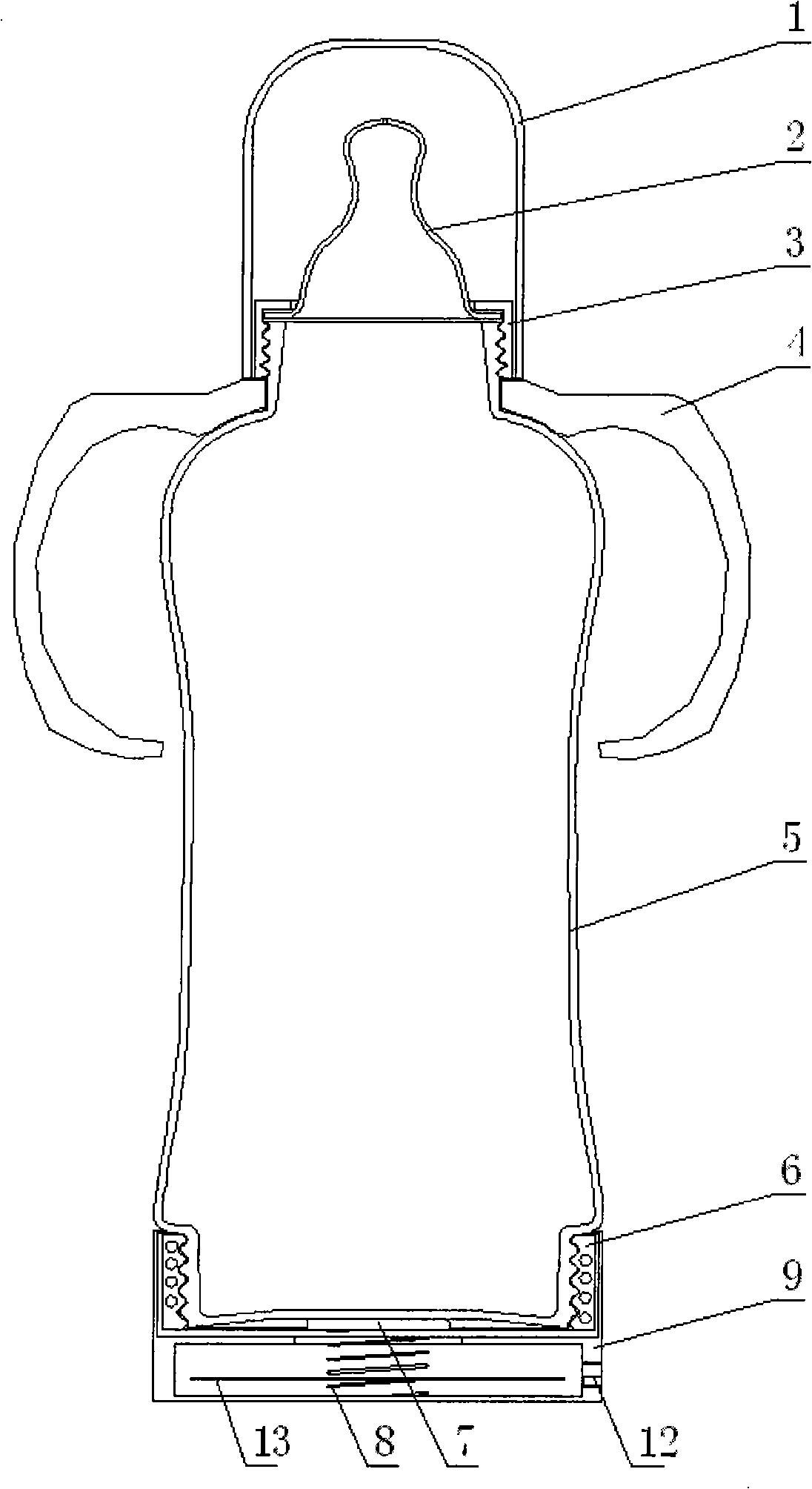

Thermal insulation nursing bottle

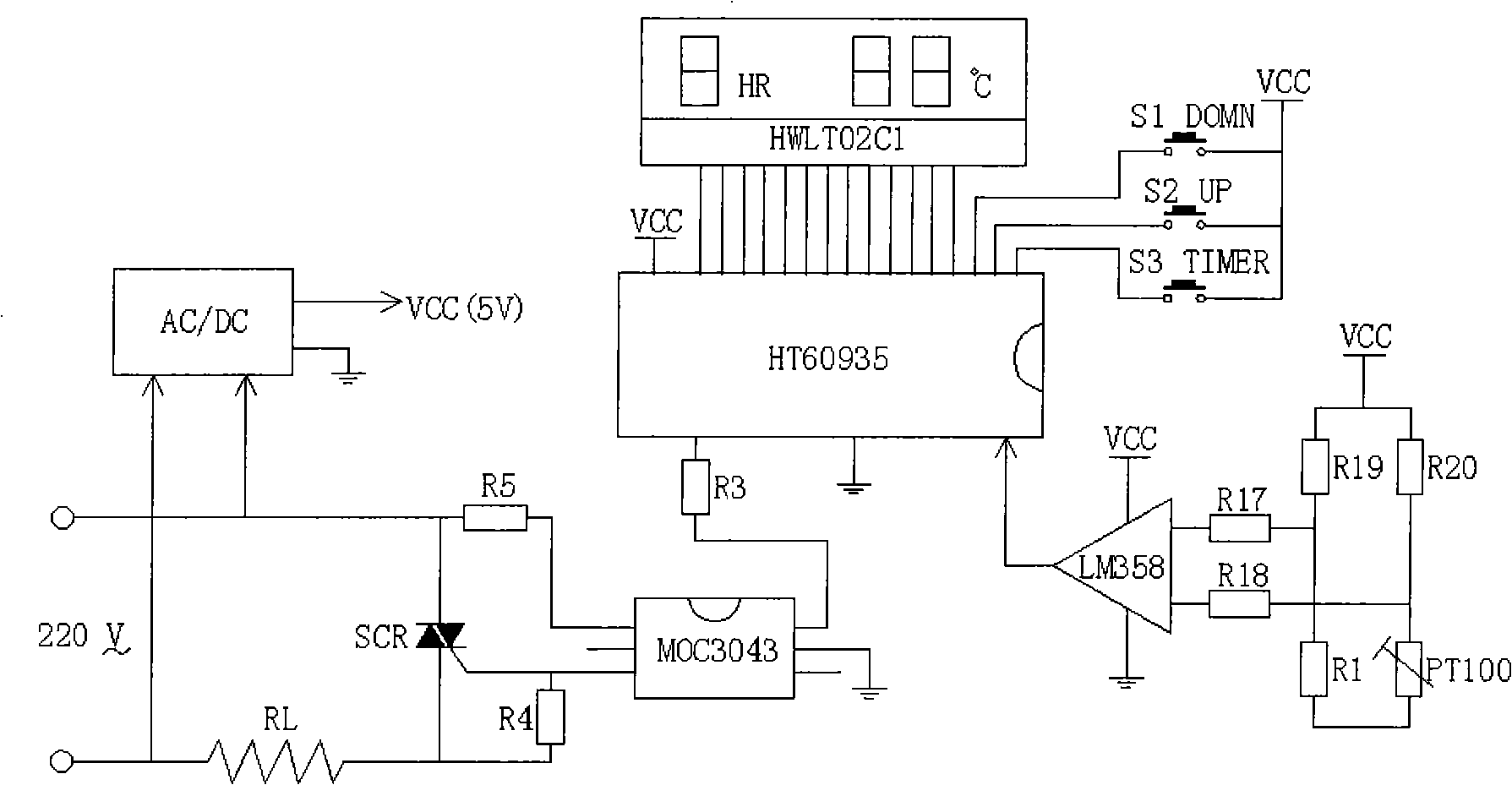

InactiveCN101268987AReduce volumeReduce weightElectric heatingFeeding-bottlesKey pressingLiquid-crystal display

The invention discloses a heat preservation nursing bottle which belongs to nursling articles for daily use, the heat preservation nursing bottle comprises a nipple, a bottle cap and a bottle body; an attemperator is arranged at the lower part of the bottle body and includes a base, and a ring-shaped heater which is tightly contacted with the bottle body is fixed at the upper part of the base; the center of the base is fixed with a temperature sensor which props against the bottom of the bottle body by a spring; the side of the base is provided with a mains jack, a liquid crystal display device and a control keystoke, and a control circuit board that adopts a microprocessor as the core is arranged inside the lower part of the base. The heat preservation nursing bottle can accurately regulate the temperature of the milk and the timing time by the keystoke, and the reserved holding temperature, the current temperature of the milk and the time can be displayed on the liquid crystal display device; at the same time, the heat preservation nursing bottle has the advantages of small volume, light weight, low price and strong performance, etc.

Owner:赵永生

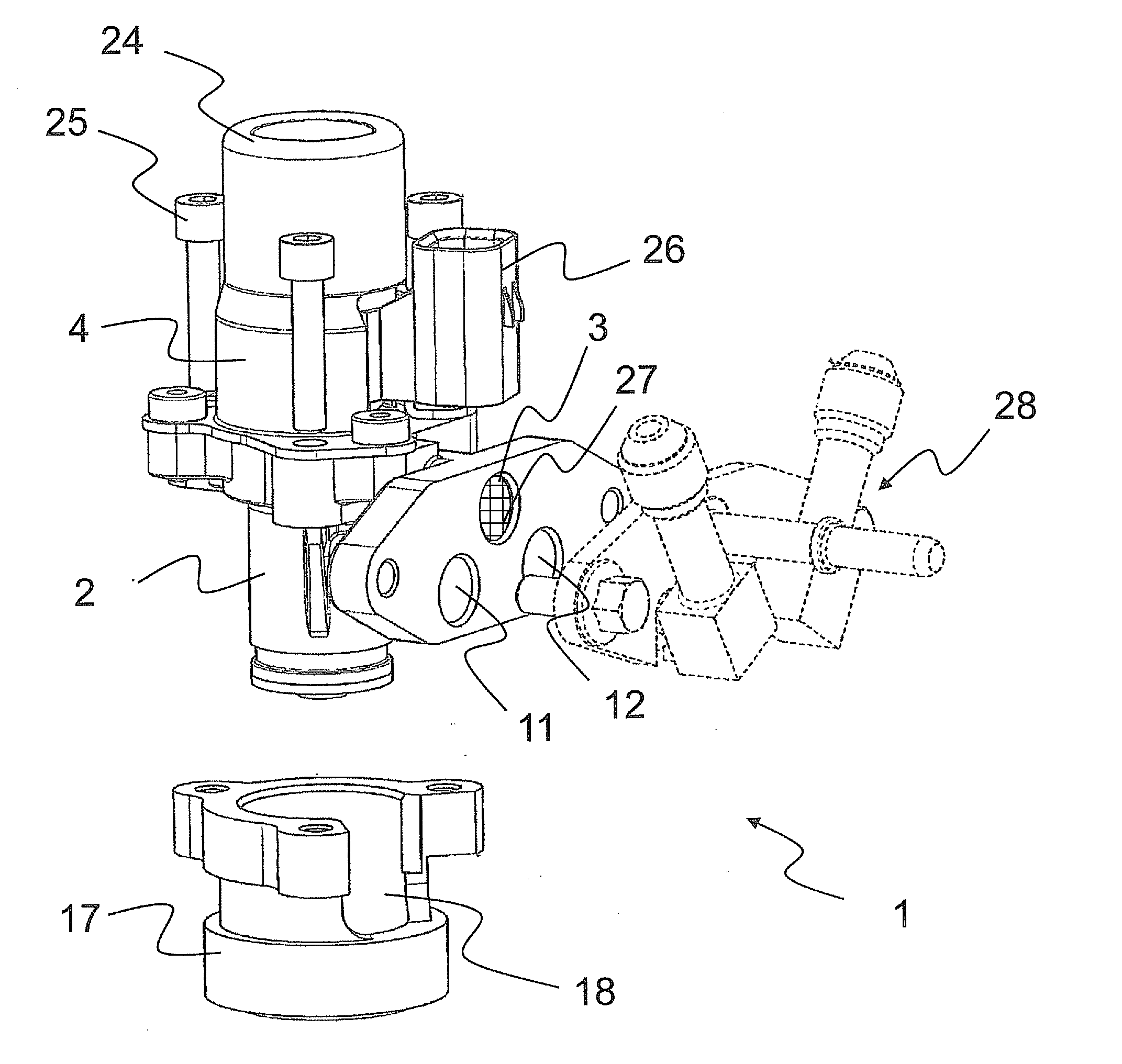

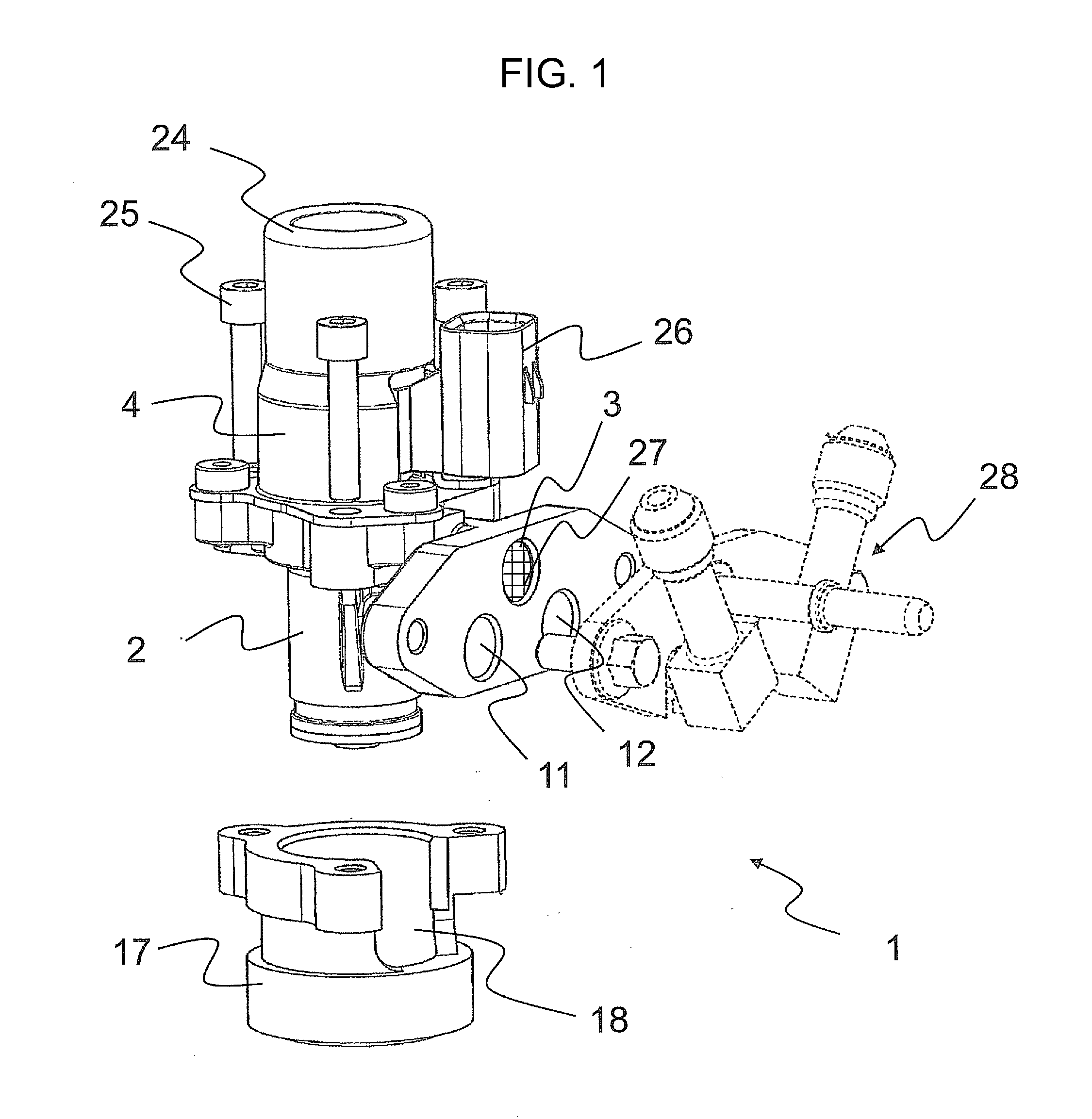

Injector for a urea-water solution

InactiveUS20140034170A1Overcome disadvantagesSufficient protectionInternal combustion piston enginesExhaust apparatusEngineeringAqueous solution

Owner:EMITEC GESELLSCHAFT FUR EMISSIONSTECHNOLOGIE MBH

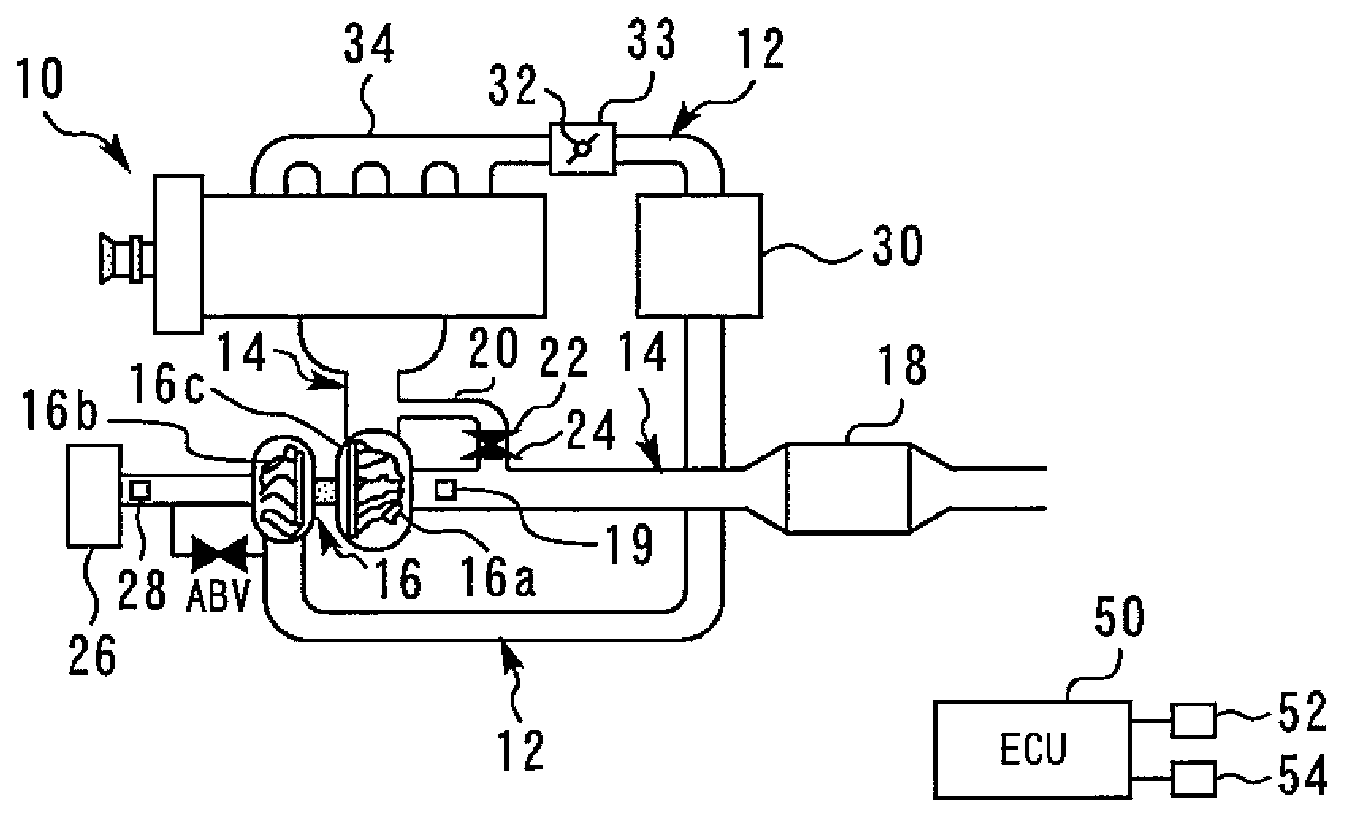

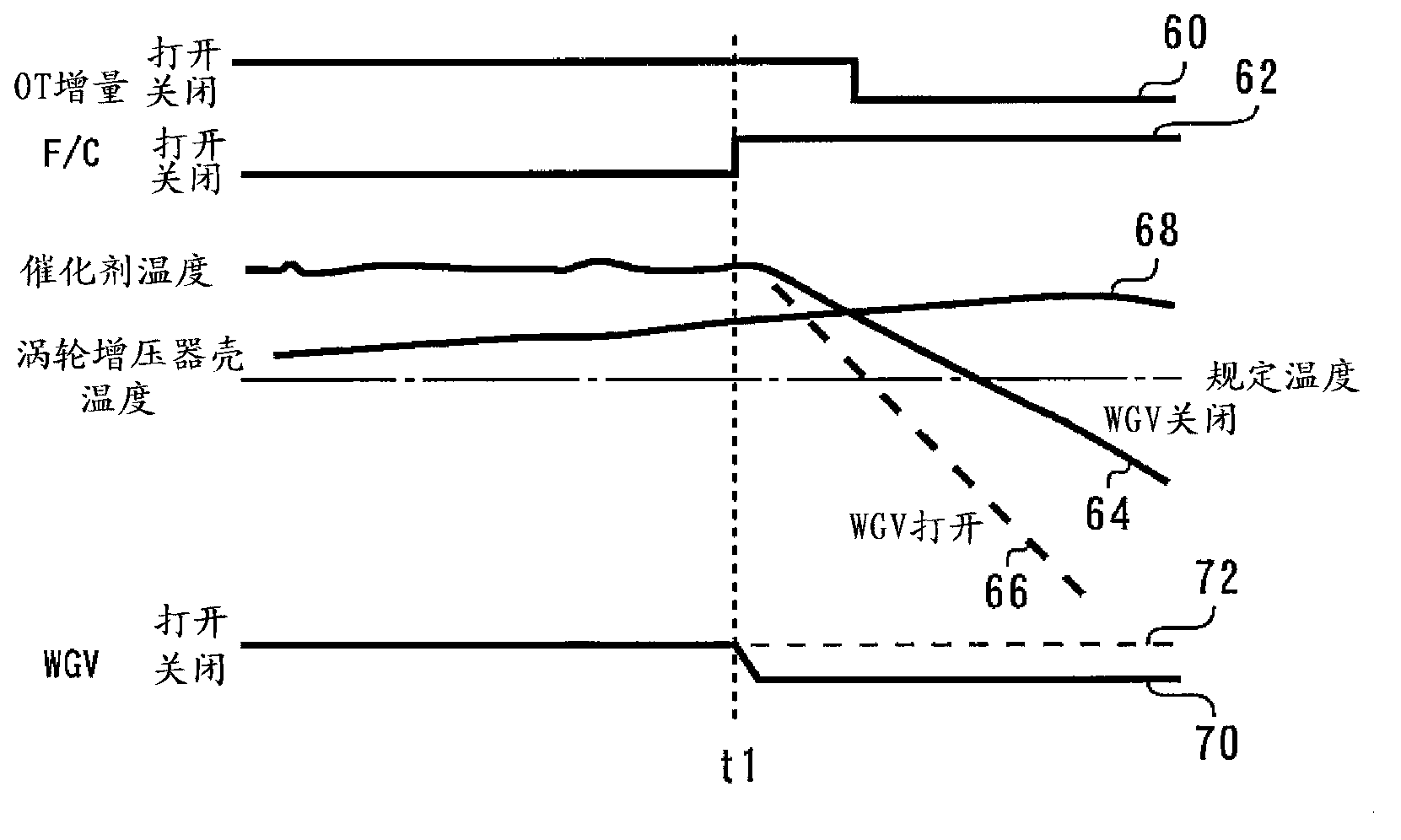

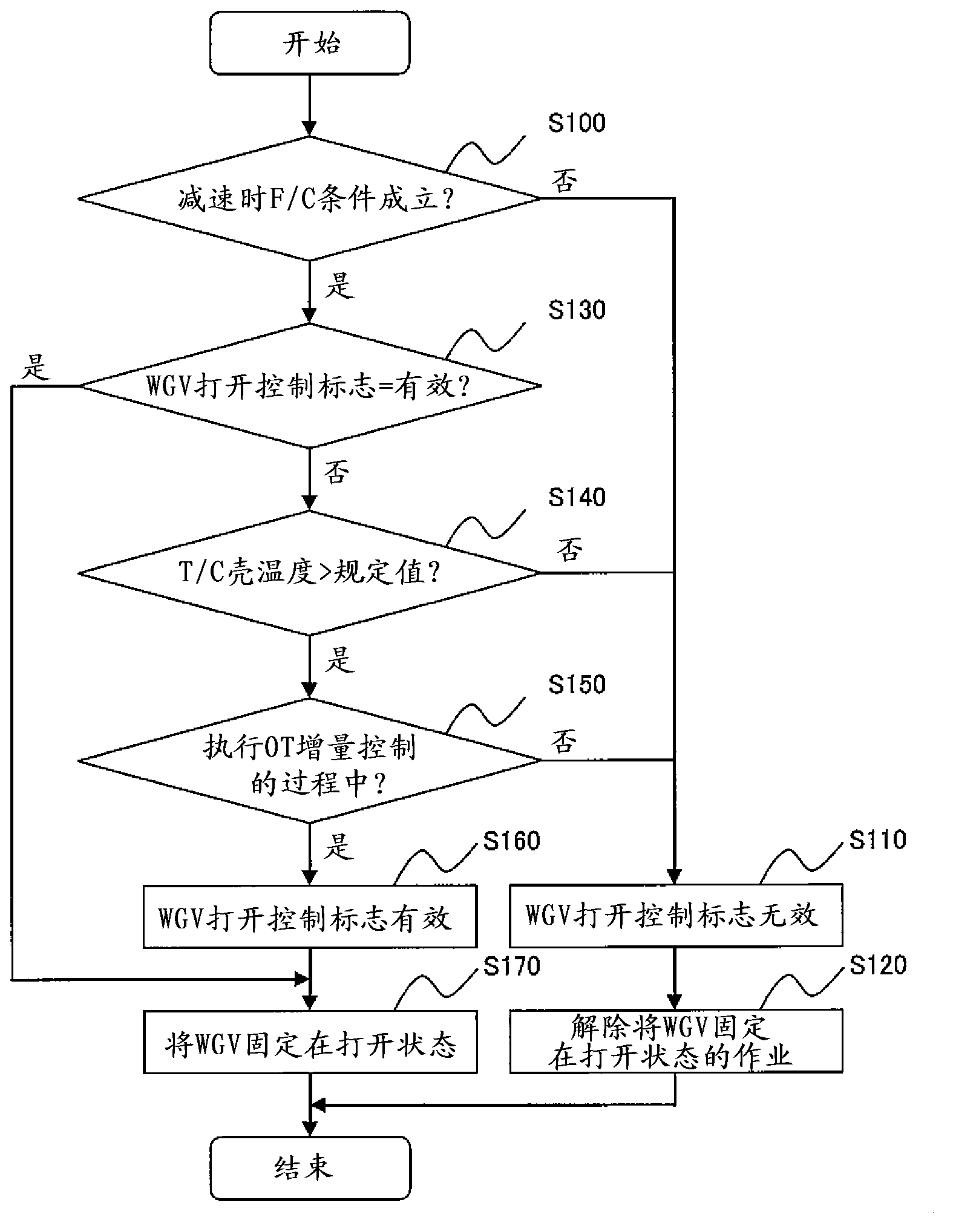

Control device for internal combustion engine

InactiveCN103119268AReduce heat exposureInhibit temperature riseElectrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine cooling

The objective of this invention is to provide a control device for an internal combustion engine capable of suppressing deterioration of the catalyst in an internal combustion engine equipped with a turbocharger when the turbocharger is at a high temperature and when the speed is reduced and the fuel is cut. The internal combustion engine is equipped with: a turbocharger turbine provided in the exhaust passage of the internal combustion engine; a catalyst provided in the exhaust passage farther downstream than the turbine; a bypass passage that bypasses the turbine by connecting the exhaust passage farther upstream from the turbine and the portion of the exhaust passage from the turbine to the catalyst; and a wastegate valve capable of opening / closing the bypass passage. The wastegate valve is opened when the speed is reduced and an operation to cut the fuel is executed, and when the temperature of the turbocharger is higher than a set value.

Owner:TOYOTA JIDOSHA KK

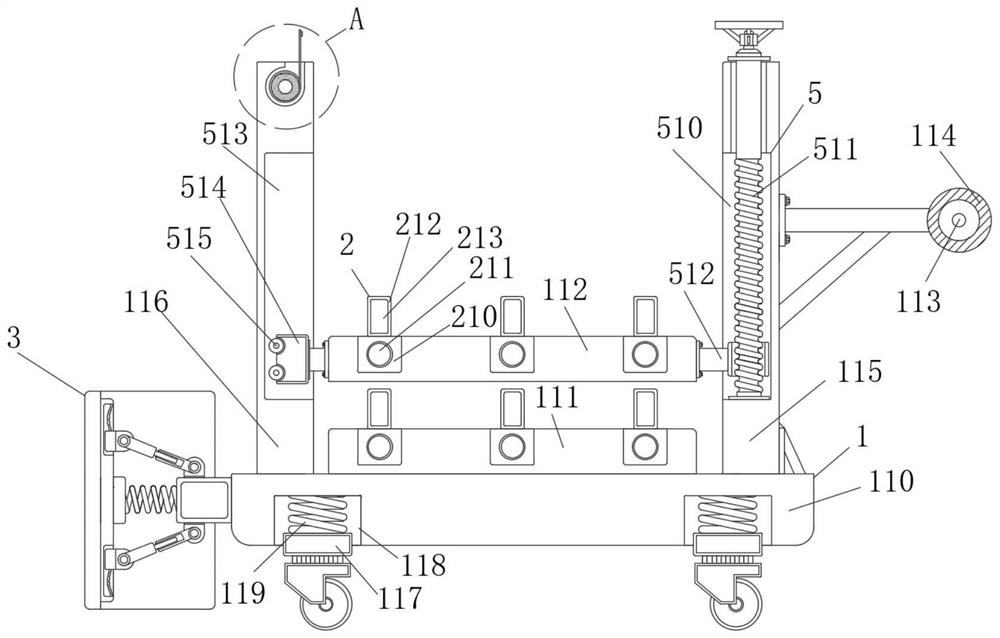

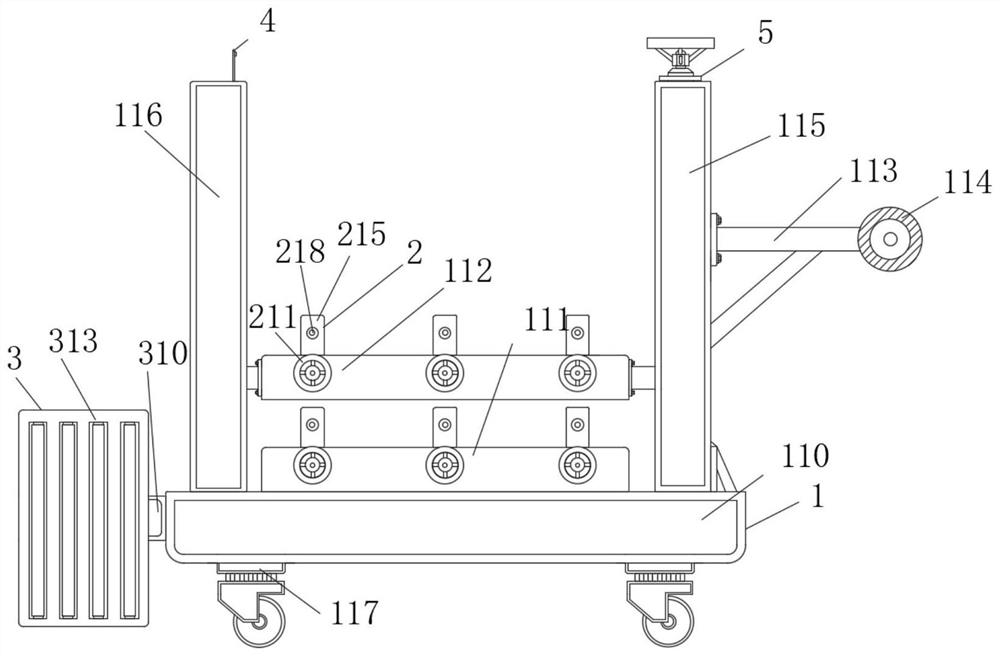

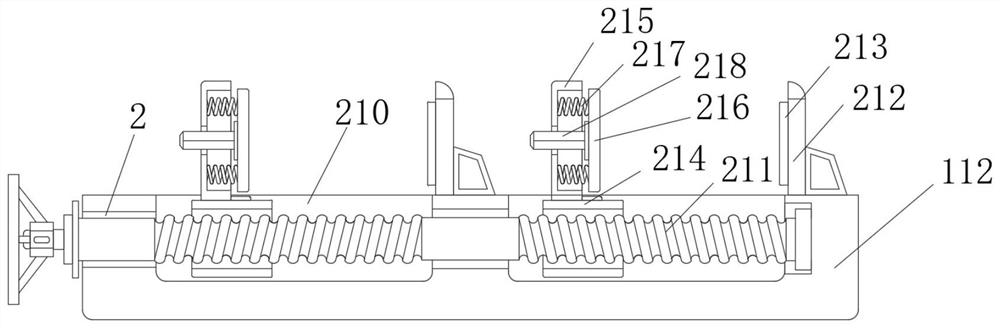

Clamping transportation device with protective structure based on lithium ion battery production

PendingCN112124390AAvoid damageEffectively push awayHand carts with multiple axesHand cart accessoriesEngineeringLithium-ion battery

The invention relates to the technical field of lithium battery transportation, in particular to a clamping transportation device with a protective structure based on lithium ion battery production. The clamping transportation device comprises a device body, the device body comprises a cart seat, a first placing frame is fixedly installed at one end of the cart seat, and a movable plate is fixedlyinstalled at one end of the cart seat on one side of the first placing frame. Through the arrangement of an anti-collision spring, first movable rods, second movable rods, reeds, connecting grooves and an anti-collision plate, the anti-collision spring can be used for achieving a buffering effect during collision, so that the possibility that the battery is damaged is reduced as much as possible;meanwhile, by utilizing the characteristic that the first movable rods and the second movable rods are adjustable, the anti-collision spring can more evenly disperse acting force in and out, and influence on buffering effect of the device caused by offset point collision is avoided; and the anti-collision plate is conical, small impurities on road surface can be effectively pushed away, and influence on normal movement of the device is avoided.

Owner:沈楠

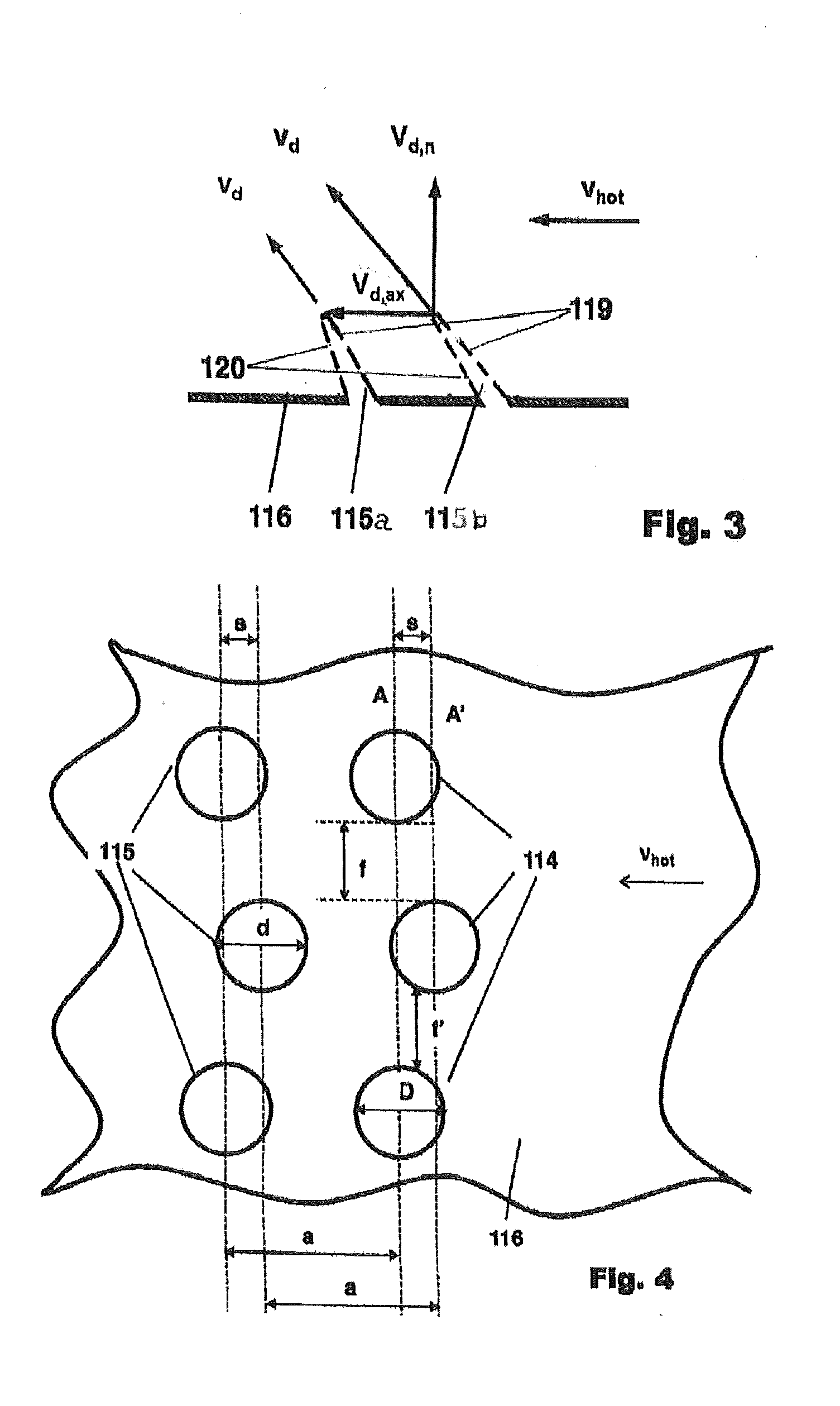

Dilution gas or air mixer for a combustor of a gas turbine

ActiveUS20160069568A1Extended service lifeReduce heat exposureContinuous combustion chamberGas turbine plantsFlueGas turbines

The invention referring to a sequential combustor arrangement including a first burner, a first combustion chamber, a mixer arrangement for admixing a dilution air to the hot gases leaving the first combustion chamber during operation, a second burner, and a second combustion chamber arranged sequentially in a fluid flow connection. The mixer is adapted to guide combustion gases in a hot gas flow path extending between the first combustion chamber. The second burner including a duct having an inlet at an upstream end adapted for connection to the first combustion chamber and an outlet at a downstream end adapted for connection to the second burner. The mixer includes at least one group of injection pipes pointing inwards from the side walls of the mixer for admixing the dilution air to cool the hot flue gases leaving the first combustion chamber. The injection pipes are distributed circumferentially along the side wall of the mixer and wherein the injection pipes having a conical or quasi-conical shape addressed to the center of the mixer.

Owner:ANSALDO ENERGIA SWITZERLAND AG

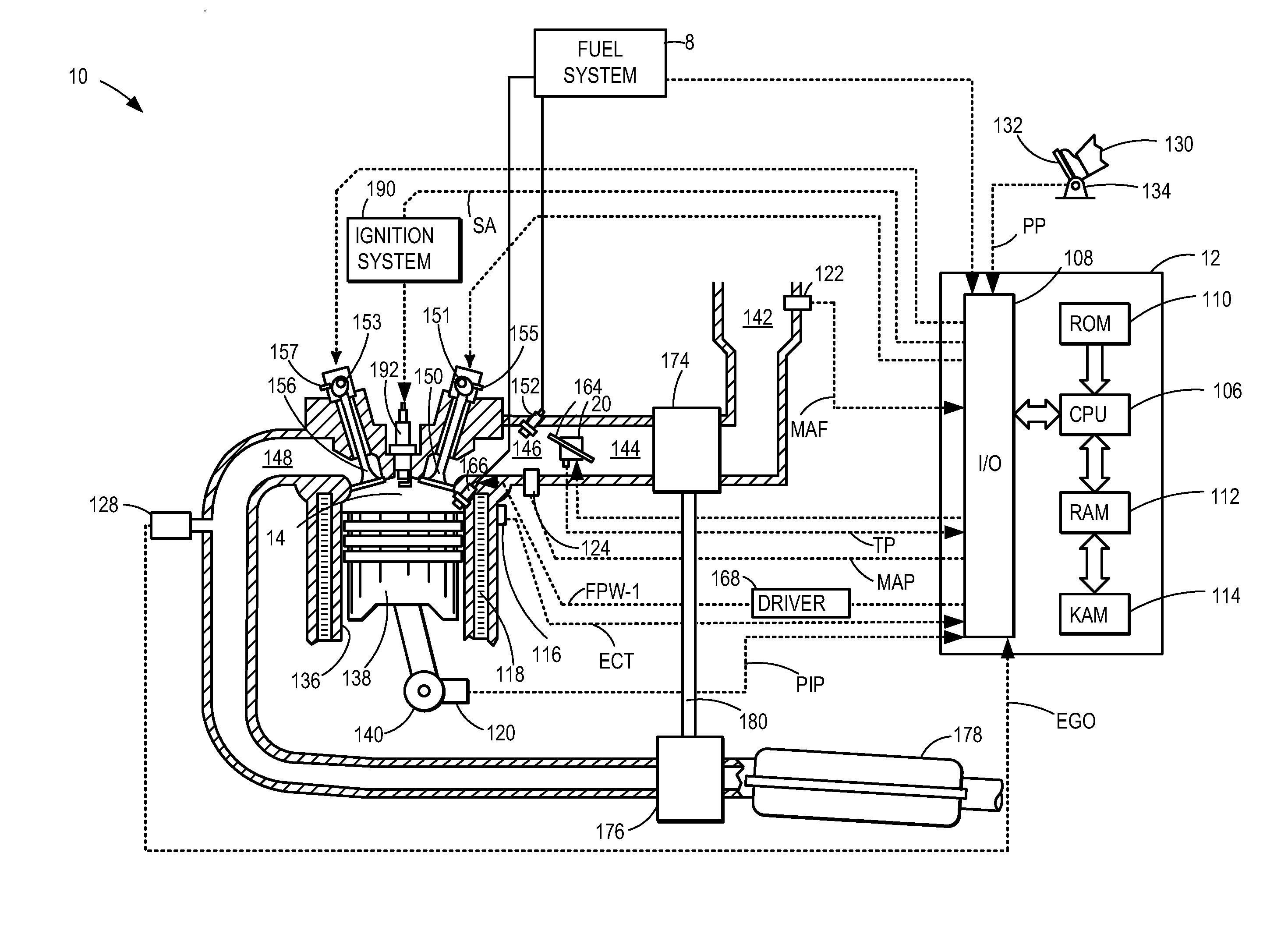

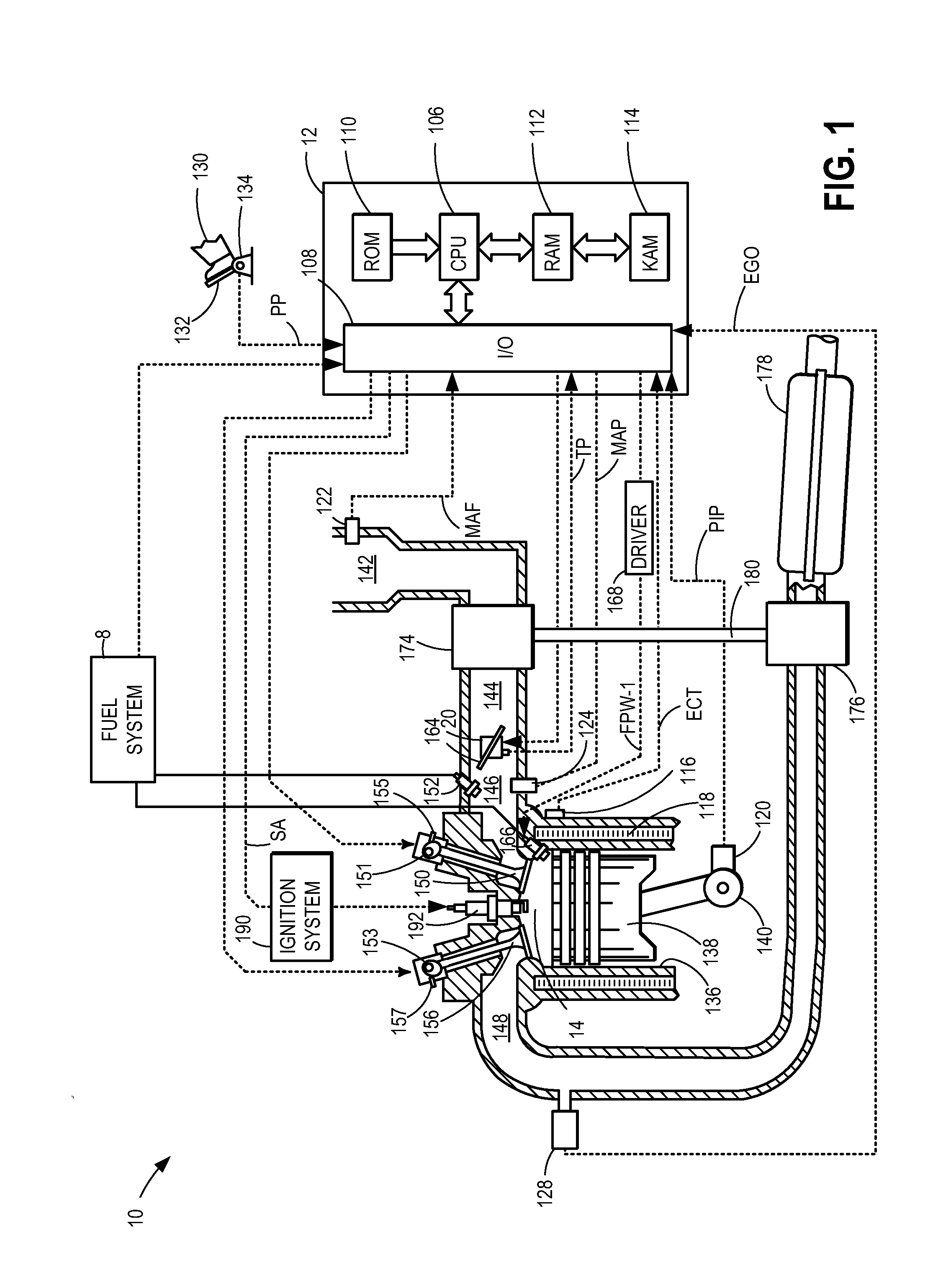

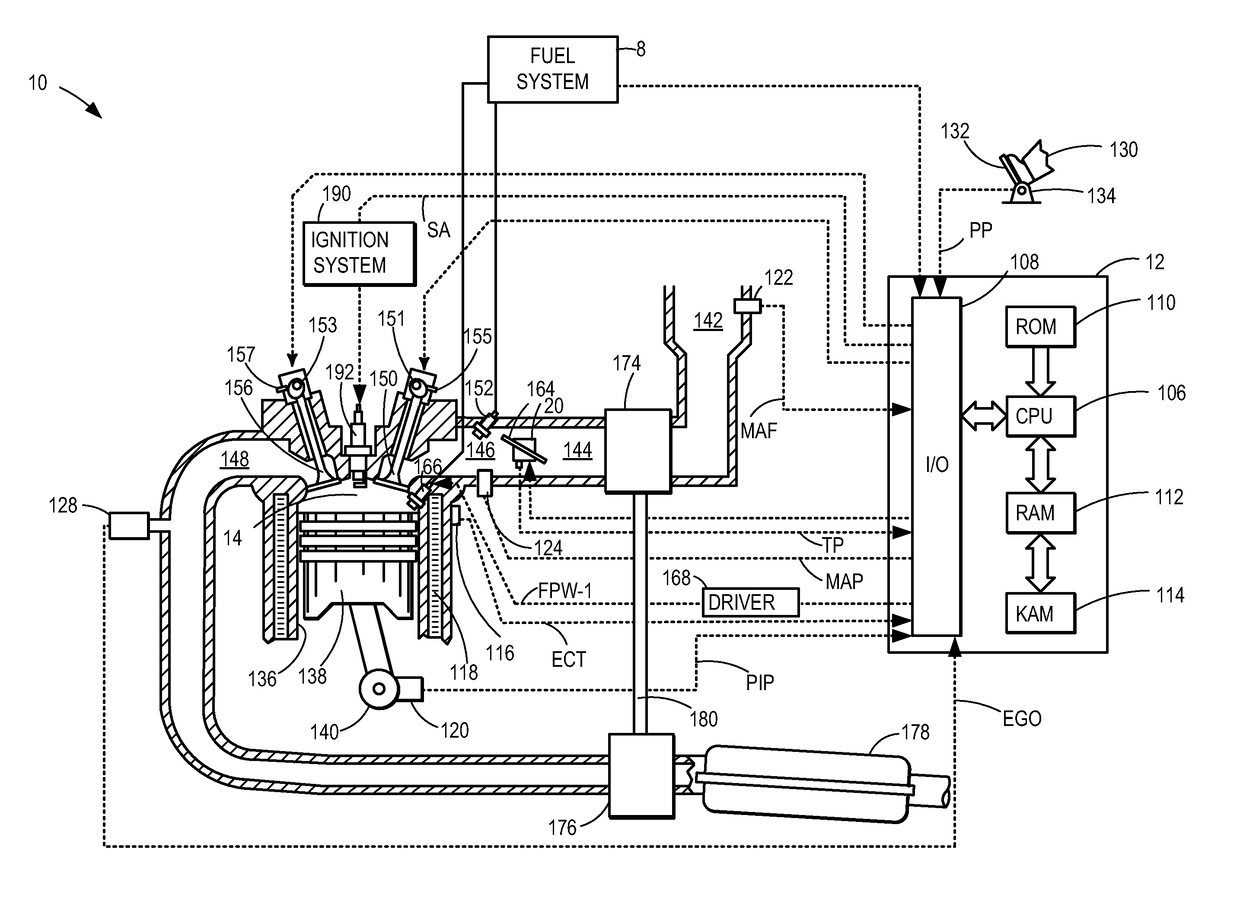

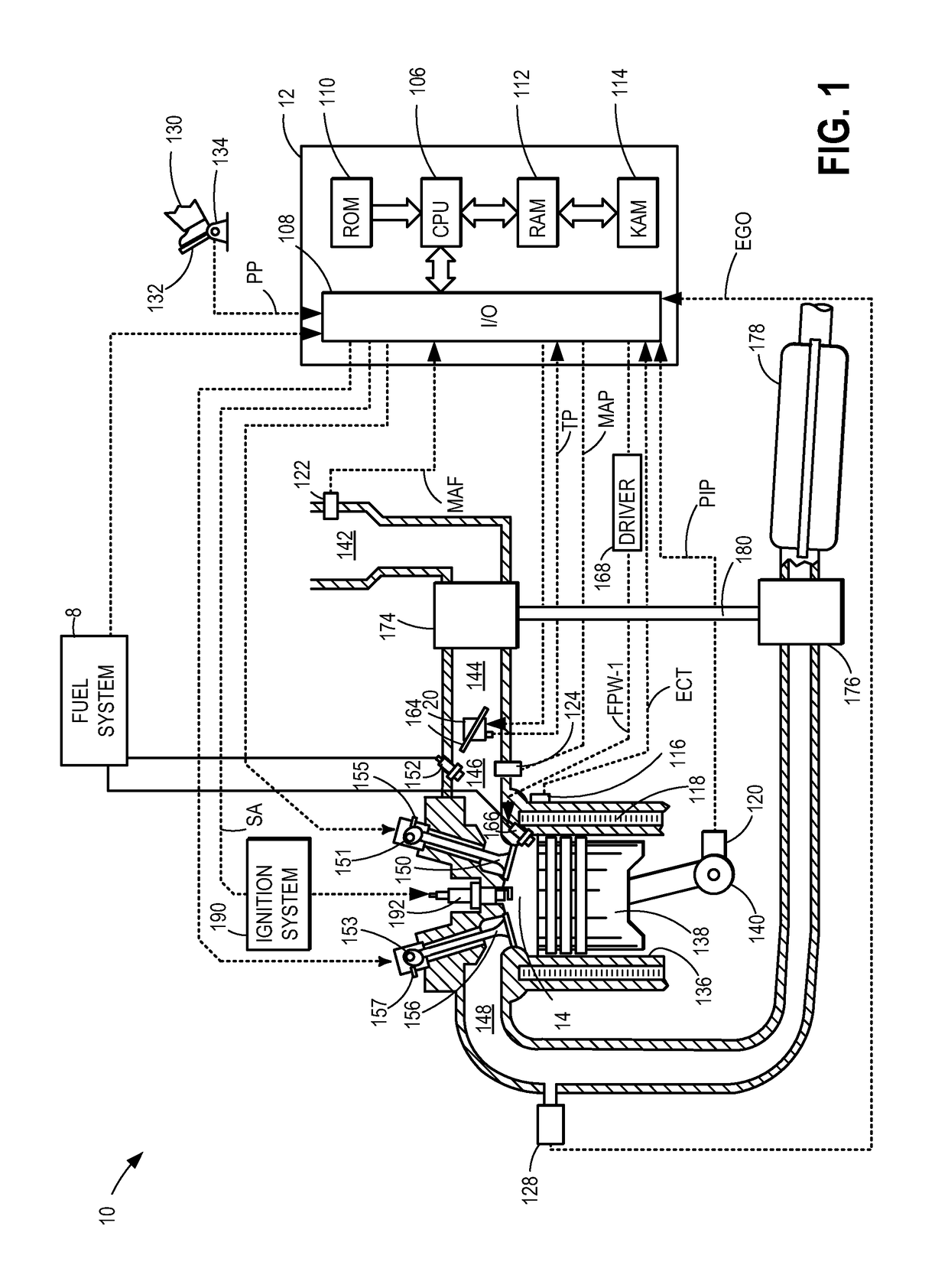

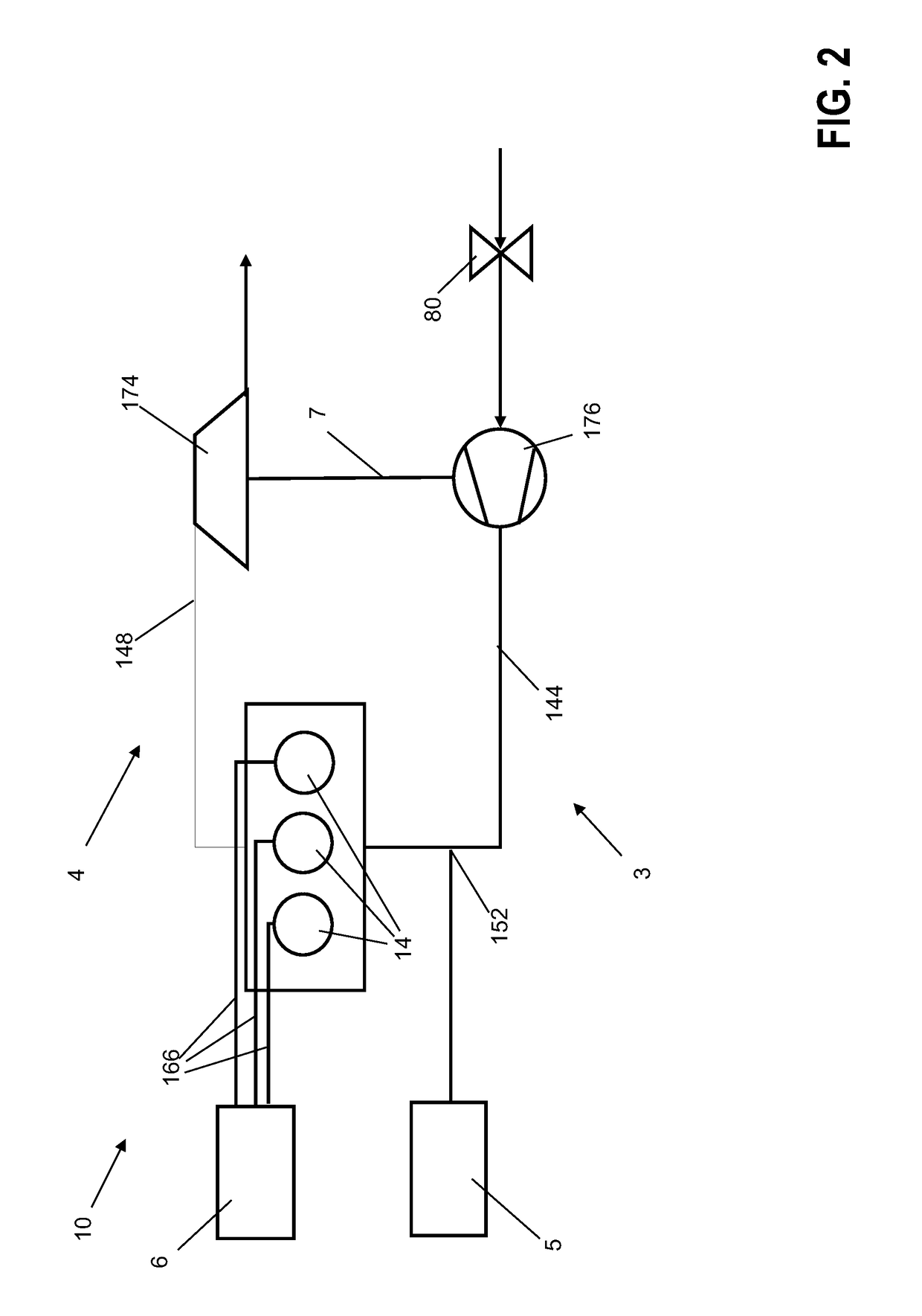

Internal combustion engine which can be operated with liquid and with gaseous fuel and a method for operating an internal combustion engine of this kind

ActiveUS20140102405A1Reduce heat exposureAlleviate cokingInternal combustion piston enginesOutput powerCompressed natural gasExternal combustion engine

The application describes a system for an engine comprising a direct injection nozzle for injecting gaseous fuel into a cylinder of an engine in a second operating mode; an intake injection nozzle for injecting liquid fuel into an intake port of the engine in a first operating mode; and a valve gear suitable to adjust timing of opening and closing of an inlet valve. Preferential injection of a gaseous fuel such as compressed natural gas directly into the cylinder increases efficiency and allows for reduced heat exposure to the lesser used liquid gas injectors mounted in the intake port, reducing coking of these injectors.

Owner:FORD GLOBAL TECH LLC

Ultrasonic composite electric resistance welding method for TC4 and 718 steel

InactiveCN102248313AReduce thermal embrittlementChange contact resistance stateWelding apparatusLap jointElectric resistance welding

The invention discloses an ultrasonic composite electric resistance welding method for TC4 and 718 steel. The ultrasonic composite electric resistance welding method for the TC4 and 718 steel particularly comprises the following steps of: 1) positioning the central part of a lap joint region of a TC4 titanium alloy plate, a metal intermediate transition layer and a 718 steel plate which are required to be welded on the axis of an upper electrode and a lower electrode of a three-phase direct current resistance welding machine; 2) intervening ultrasonic wave and pressurizing; and 3) performing welding operation, namely setting working parameters of an ultrasonic generator and the three-phase direct current resistance welding machine, applying welding pressure on the upper electrode, supplying power for the three-phase direct current resistance welding machine and the ultrasonic generator, switching on a circuit switch of the three-phase direct current resistance welding machine, starting to perform ultrasonic composite resistance welding on the TC4 titanium alloy plate and the 718 steel plate, and finishing the step after the set time is up. By the method, the problems of reduced joint performance and welding joint inclusion caused by intermetallic compounds which cannot be solved in the prior art are solved.

Owner:XIAN UNIV OF TECH

Preparation method of nano-titania photocatalysis coating

ActiveCN108636394AOvercome the disadvantage of poor fluidity and difficult direct sprayingImprove photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsThermal sprayingPhotocatalytic degradation

The invention discloses a preparation method of a novel nano-titania photocatalysis coating. The method comprises the steps that through a flame thermal spraying method, a pre-prepared suspension solution containing metal powder and nano-titania powder is used as a spraying raw material and sprayed on a pretreated matrix, and the nano-titania photocatalysis coating is obtained, wherein the solid-liquid mass ratio of the suspension solution is (1-50):100; the mass ratio of the nano-titania powder to the metal powder is (1-10):1. The preparation method has the advantages of easy operation, few technical processes, low cost and the like and is suitable for industrial production. By means of the preparation method, the thickness of the obtained nano-titania photocatalysis coating is 5-100 microns, the coating is good in photocatalytic performance and particularly good in photocatalytic organism degradation performance, the bonding strength of the coating with the matrix is high, and the coating is high in stability and has high application value and good market prospects in the field of photocatalytic degradation of organic pollutants.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

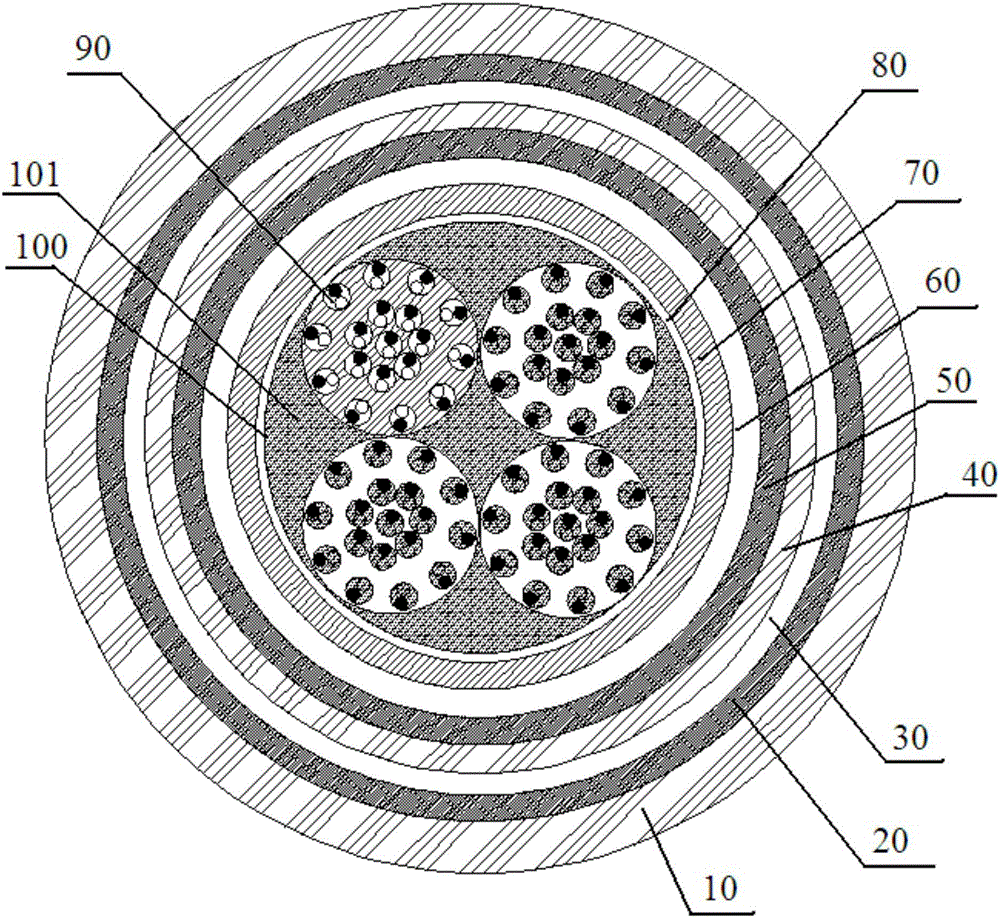

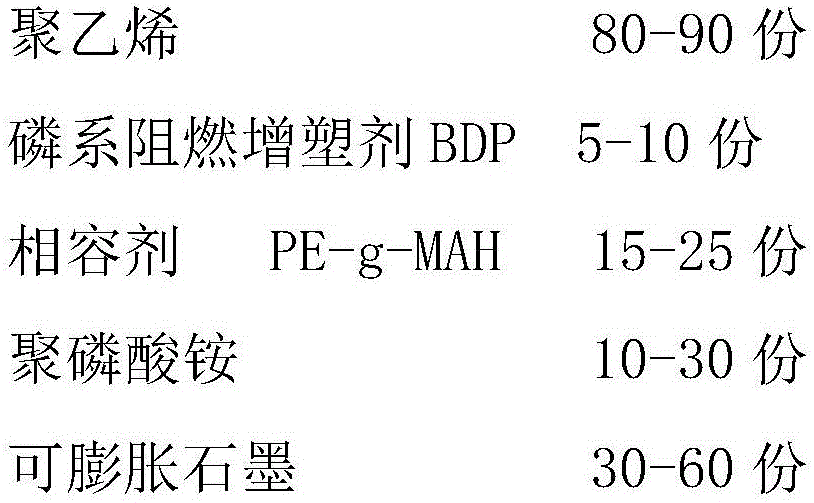

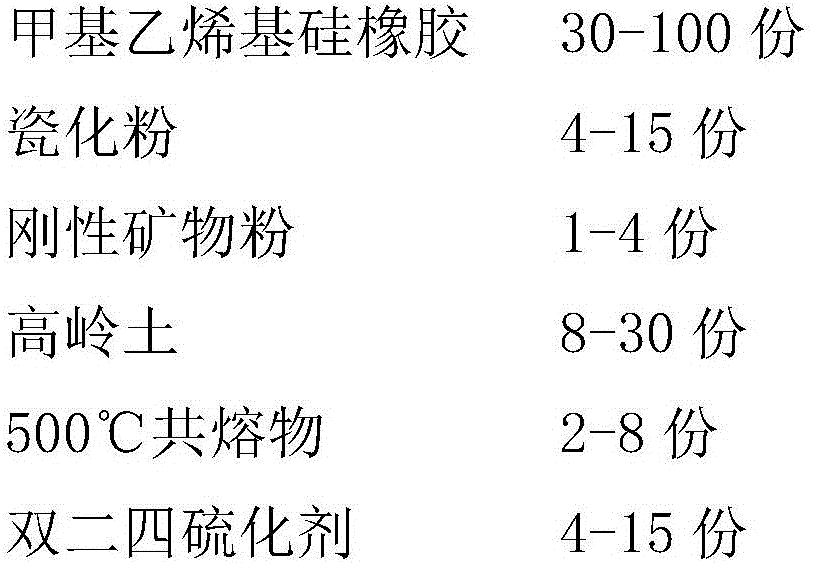

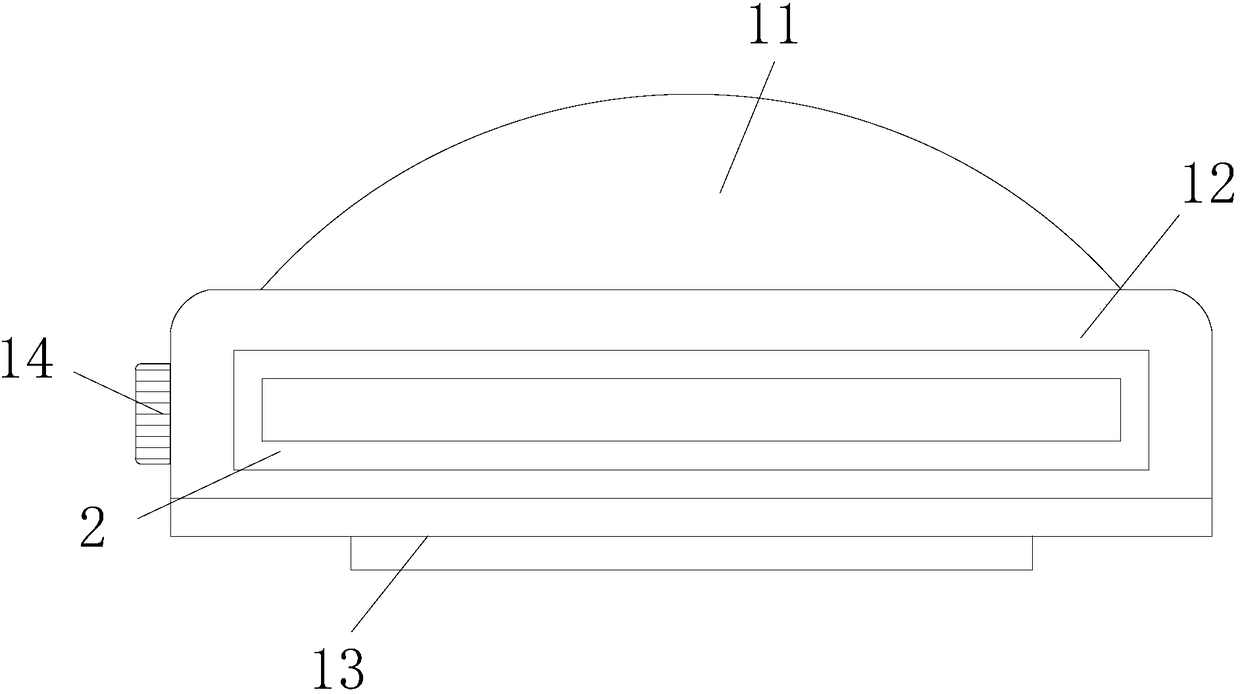

Fireproof flame-retardant rail transit communication cable

ActiveCN106084427AReduce heat exposureKeep the lightingCommunication cablesInsulated cablesEngineeringRail transit

The invention discloses a fireproof flame-retardant rail transit communication cable. The fireproof flame-retardant rail transit communication cable comprises a low-smoke zero-halogen outer sheath, a first fireproof layer, a high-magnetic-conductive steel tape armoring layer, a low-smoke zero-halogen inner sheath, a second fireproof layer, an aluminum sheath, a PE heat insulating layer, a waterproof layer and multiple strands of stranded insulating core wires. A low-smoke zero-halogen polyethylene material is prepared from 80-90 parts of polyethylene, 5-10 parts of phosphorus flame-retardant plasticizer BDP, 15-25 parts of PE-g-MAH, 10-30 parts of ammonium polyphosphate and 30-60 parts of expansible graphite. The second fireproof layer is made of a fireproof silicone rubber material. The fireproof silicone rubber material is prepared from 30-100 parts of methyl vinyl silicone rubber, 4-15 parts of vitrified powder, 1-4 parts of rigid mineral powder, 8-30 parts of kaolin, 2-8 parts of 500DEG C eutectic and 4-15 parts of DCBP. All the layers are retardant to flames, most of heat can be absorbed, and optical fibers can keep optical connectivity for a long time.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Internal combustion engine which can be operated with liquid and with gaseous fuel and a method for operating an internal combustion engine of this kind

ActiveUS9631548B2Reduce heat exposureAlleviate cokingInternal combustion piston enginesOutput powerCompressed natural gasExternal combustion engine

The application describes a system for an engine comprising a direct injection nozzle for injecting gaseous fuel into a cylinder of an engine in a second operating mode; an intake injection nozzle for injecting liquid fuel into an intake port of the engine in a first operating mode; and a valve gear suitable to adjust timing of opening and closing of an inlet valve. Preferential injection of a gaseous fuel such as compressed natural gas directly into the cylinder increases efficiency and allows for reduced heat exposure to the lesser used liquid gas injectors mounted in the intake port, reducing coking of these injectors.

Owner:FORD GLOBAL TECH LLC

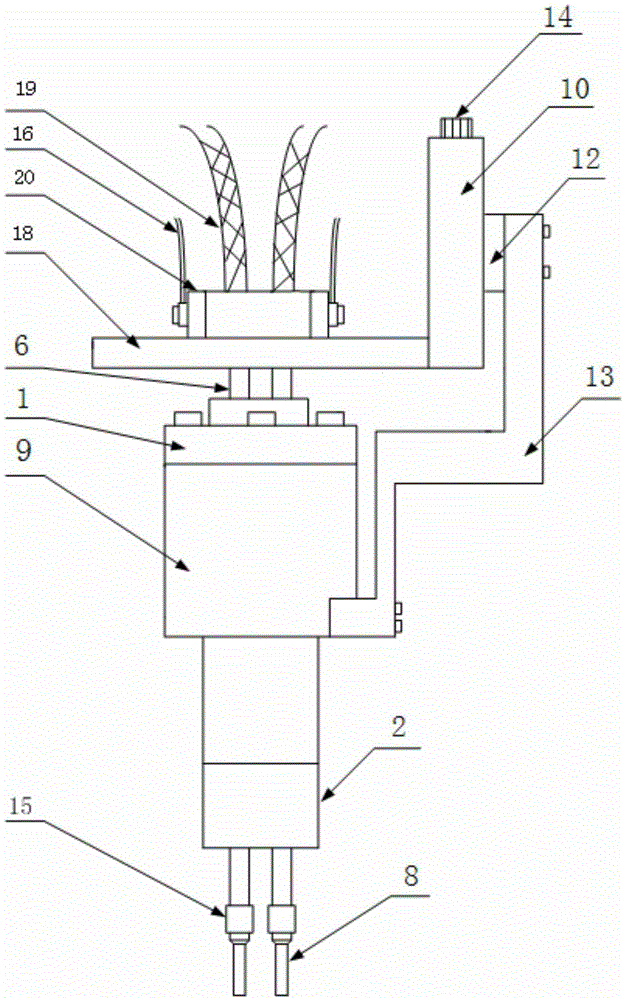

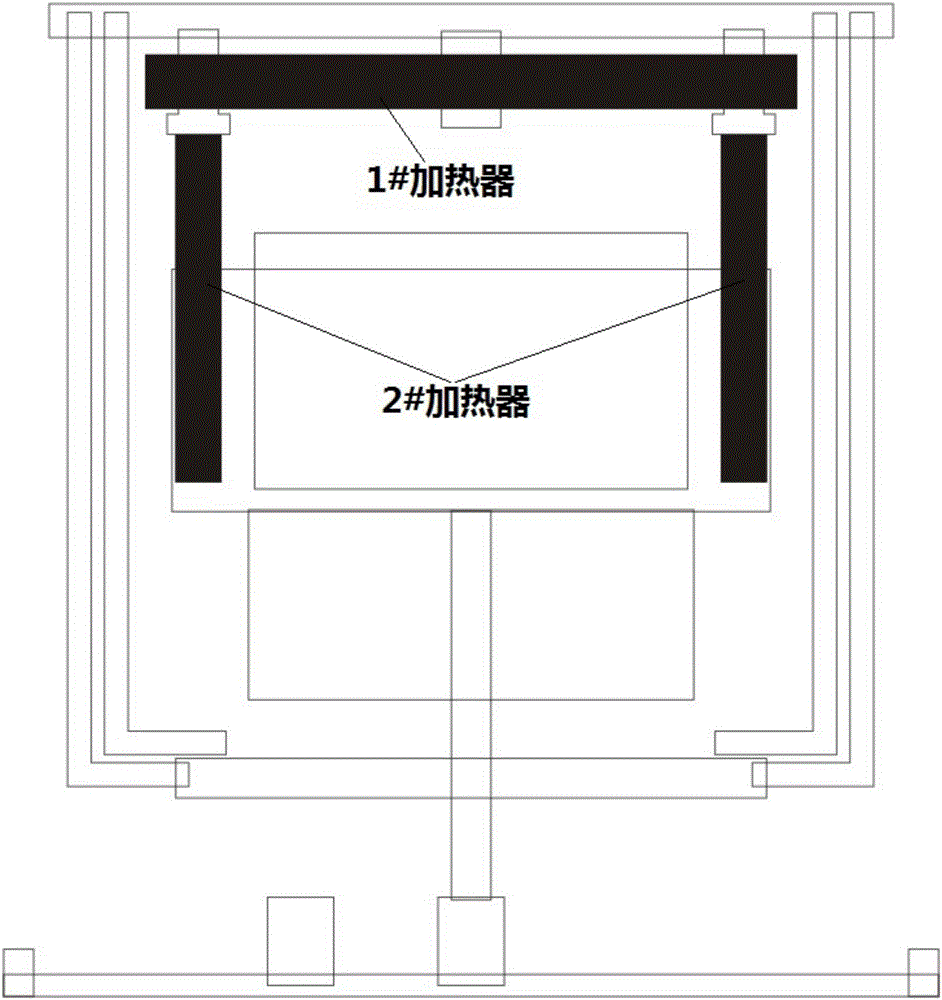

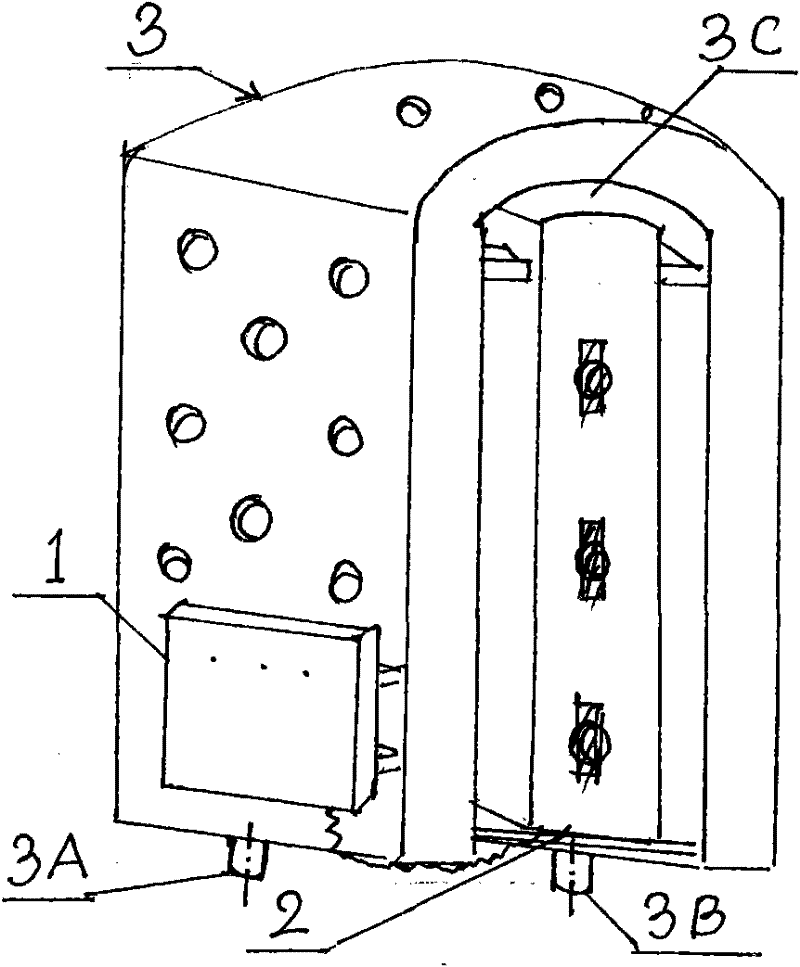

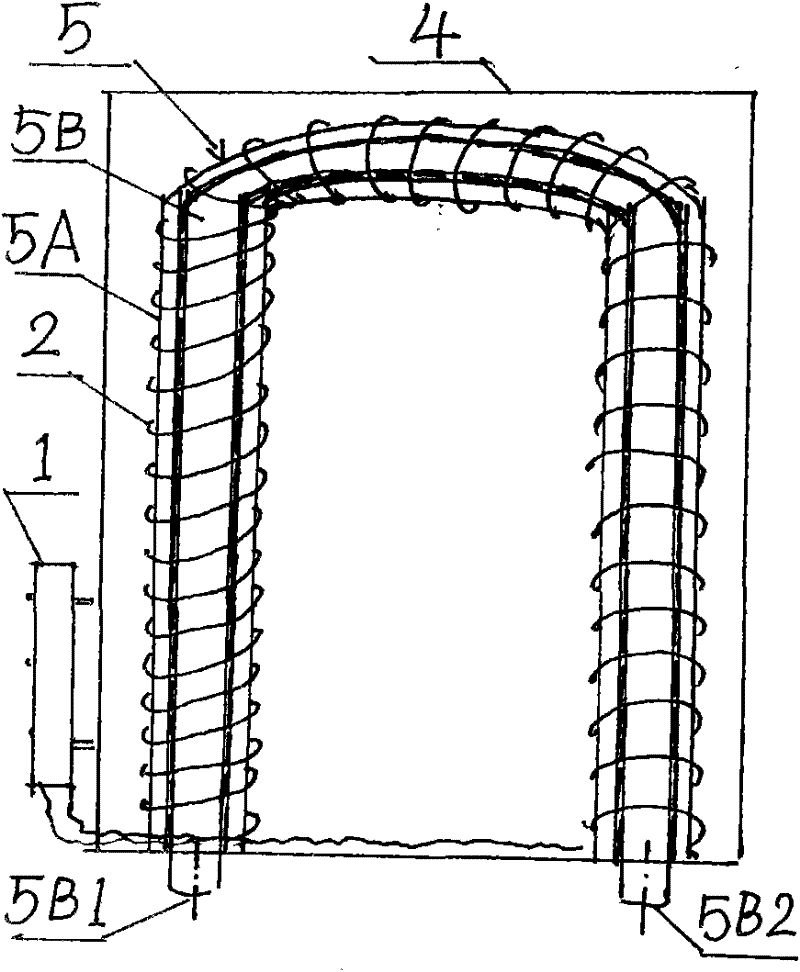

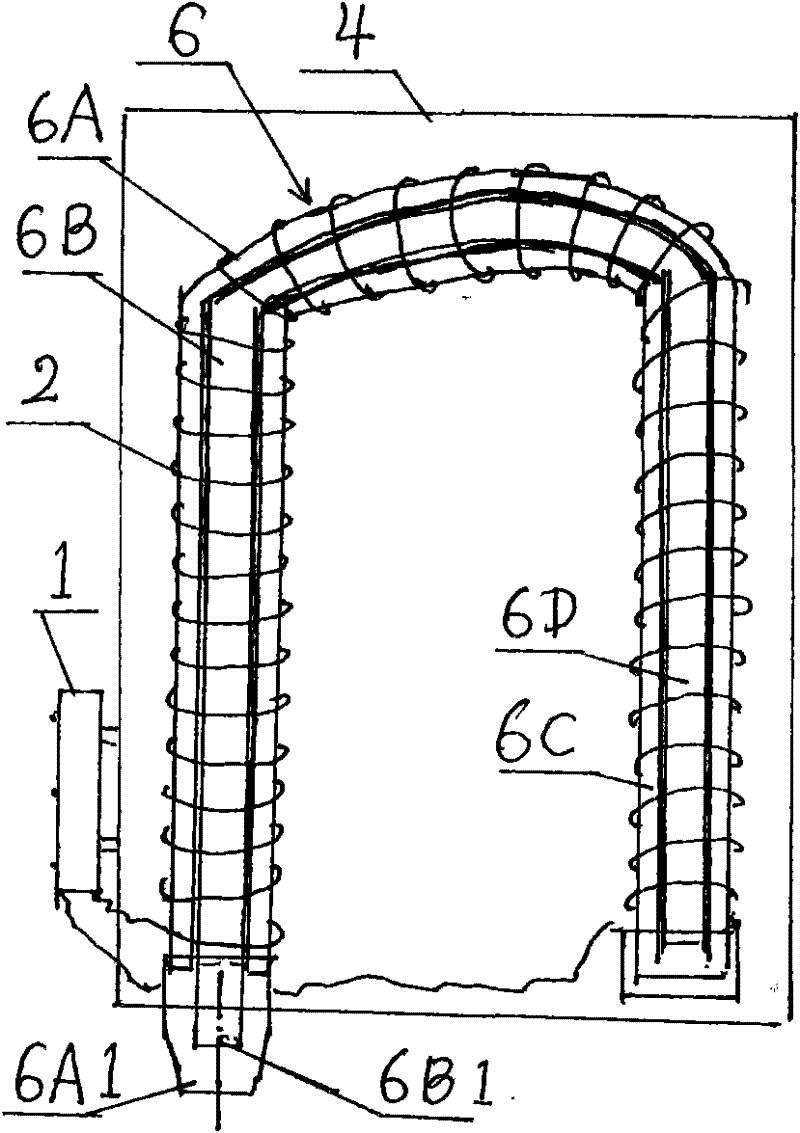

Method and device for semi-molten ingot casting of polycrystalline silicon

InactiveCN106087043AReduce heat exposureExtended service lifePolycrystalline material growthAfter-treatment detailsIngot castingMetallurgy

The invention discloses a method and device for semi-molten ingot casting of polycrystalline silicon. Crushed aggregates of the polycrystalline silicon are evenly laid at the bottom of a quartz crucible and then sequentially vacuumized and heated, and a heated fragment layer is obtained; the temperature of an ingot furnace heater rises, the power ratio of a top heater and a side heater is adjusted to let the bottom have continuous refrigerating capacity, and it is guaranteed that seed crystal is not molten; after the temperature is reduced, the power ratio of the top heater and the side heater is adjusted, the temperature is kept unchanged to grow crystal; the temperature of the ingot furnace heater continues to be reduced, the power ratio coefficient of the top heater and the side heater is adjusted to control the crystal growth speed to grow crystal; after the crystal grows, annealing and cooling are performed sequentially, and the semi-molten ingot casting of polycrystalline silicon is obtained. According to the method and device for semi-molten ingot casting of the polycrystalline silicon, the heater structure does not need to be changed, the operation is simple, and the goal of effectively discharging impurities and improving product quality can be achieved through specific process parameters.

Owner:CHINA UNITED NORTHWEST INST FOR ENG DESIGN & RES

Electromagnetic type water heater and electromagnetic resistance dual-core water heater

InactiveCN102235739ALarge heating areaIncrease profitWater heatersThermal waterElectromagnetic shielding

The invention discloses an electromagnetic type water heater and an electromagnetic resistance dual-core water heater, wherein the electromagnetic type water heater is formed by connecting a double-wall or sleeve or box-shaped magnetism-conductive water discharge body, a resonance coil and an integrated controller by virtue of power lines; and the electromagnetic resistance dual-core water heater is formed by connecting the water inlet of a resistance water heater and the water outlet of the electromagnetic type water heater, or placing the resistance water heater in the electromagnetic type water heater to be connected with and the integrated controller by virtue of power lines. For the electromagnetic type water heater and the electromagnetic resistance dual-core water heater, the magnetic energy in various directions of an electromagnetic field are scientifically utilized so that the energy efficiency is improved, and heat insulation is carried out on the resonance coil and the integrated controller by utilizing a heat insulation material and temperature difference of cold and hot water, and a dual-core simple and reliable technical structure in which a low-middle temperature zone is heated by electromagnetic energy and a mid-high temperature zone is subjected to resistance heating is adopted, thereby efficiently solving the problems that the resonance coil and the integrated controller are low in energy efficiency, low in hot water temperature, high in cost and the like, and can be easily damaged due to overheat. The electromagnetic type water heater and the electromagnetic resistance dual-core water heater have the obvious beneficial effects that the energy consumption is low, the cost is low, energy is saved, the hot water temperature is high, and more applications can be met.

Owner:陈土和

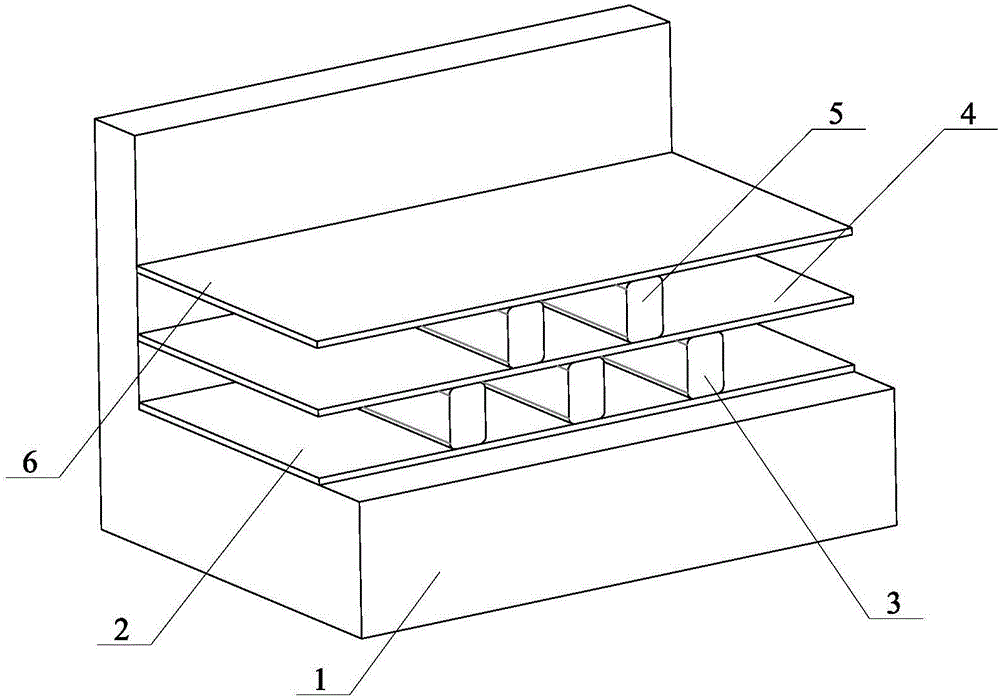

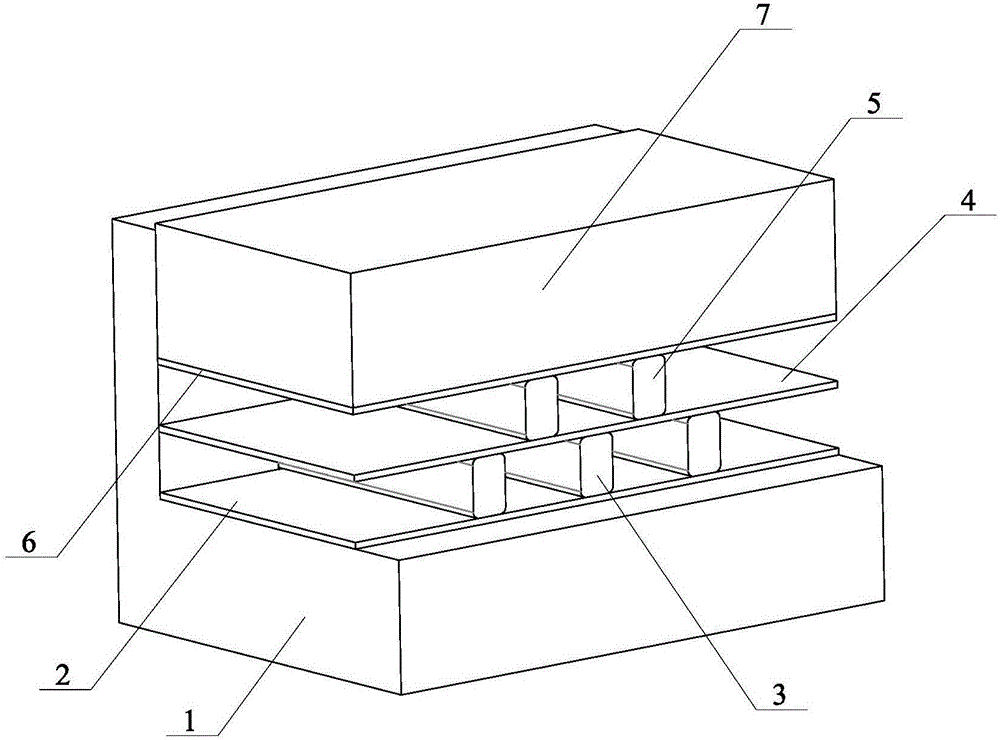

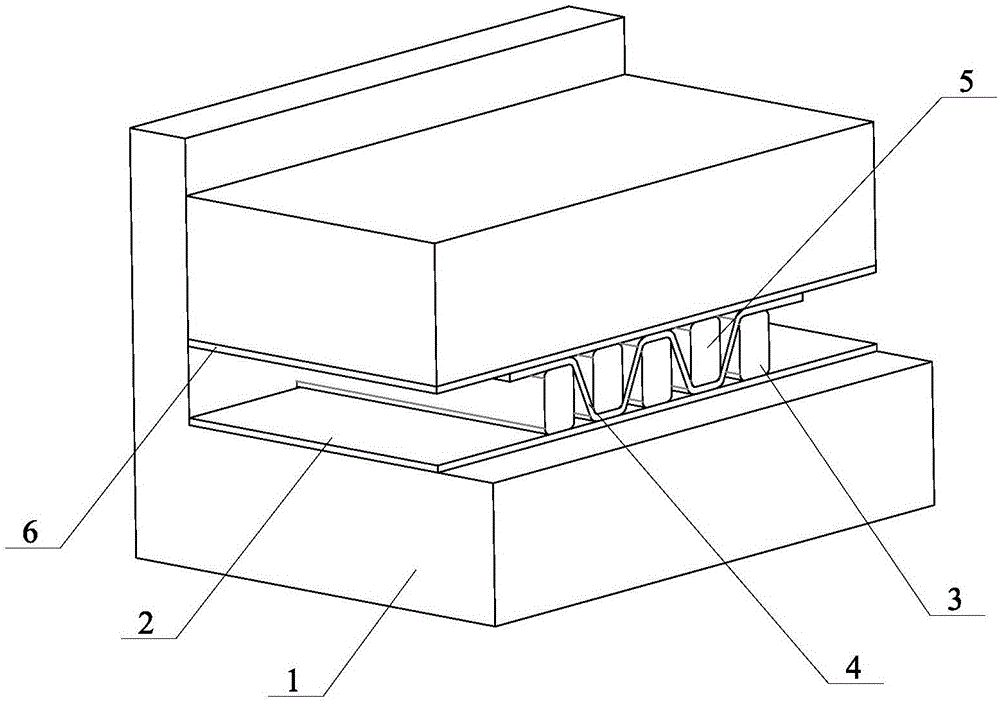

Thermal bending/diffusion bonding technology method for three-layer corrugated structure of TiAl base alloy

InactiveCN105945417AReduce heat exposureReduce energy consumptionWelding/soldering/cutting articlesNon-electric welding apparatusAlloyEnergy consumption

The invention relates to a thermal bending / diffusion bonding technology method, in particular to a thermal bending / diffusion bonding technology method for a three-layer corrugated structure of a TiAl base alloy so as to solve the problems that according to an existing thermal bending / diffusion bonding combined technology for preparing a three-layer corrugated structural piece, the procedure time is long, energy consumption is high, and the production efficiency is low. The method comprises the first step of surface treatment, the second step of placement of the three-layer corrugated structure and the third step of the thermal bending and diffusion combined technology, wherein in the third step, the thermal bending / diffusion bonding of the three-layer corrugated structural piece is conducted in a vacuum furnace, the vacuum degree is 10-3-10-4Pa, and after the temperature in the vacuum furnace ranges from 1,000 DEG C to 1,050 DEG C and is stable, an upper pressing head moves downwards at the speed of 1 mm / min, and an upper panel, a core veneer and a lower panel are pressed to form a corrugated core veneer; and after the corrugated core veneer is formed, the pressure is gradually increased, the pressure between the core veneer and the panels reaches 20 MPa, then, the pressure is kept unchangeable, and under the conditions of the constant temperature and the constant pressure, the current state is maintained for 2-3 h. The technology method is used for thermal bending / diffusion bonding of the three-layer corrugated structure.

Owner:HARBIN INST OF TECH

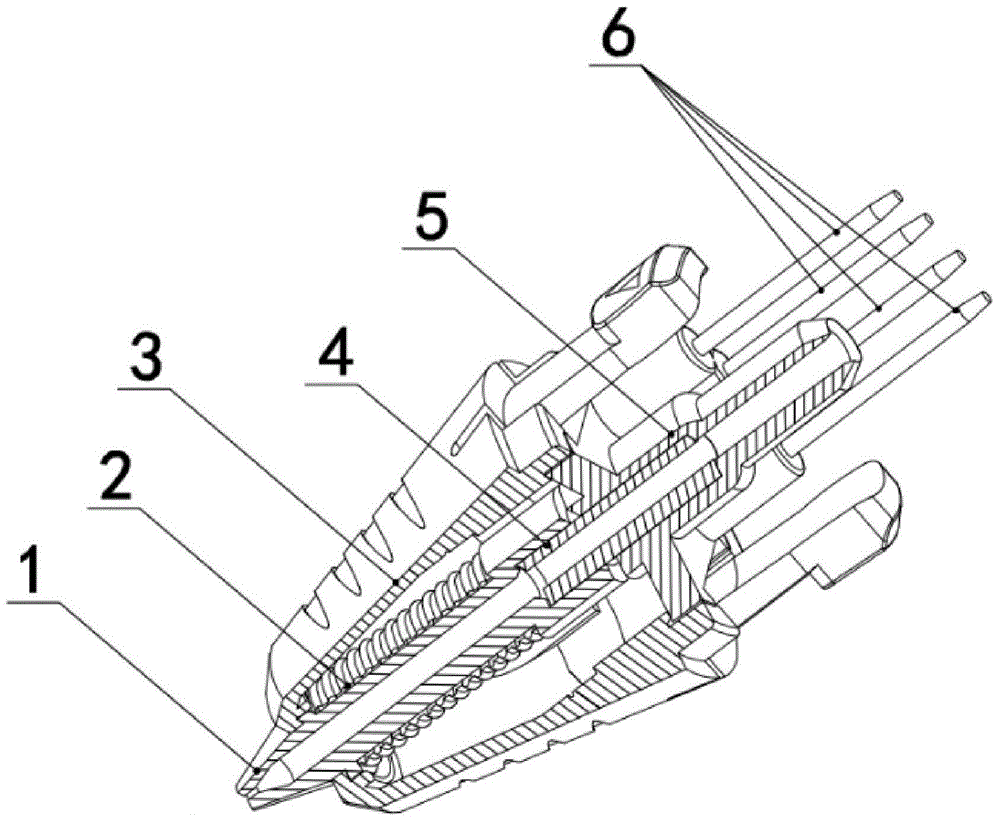

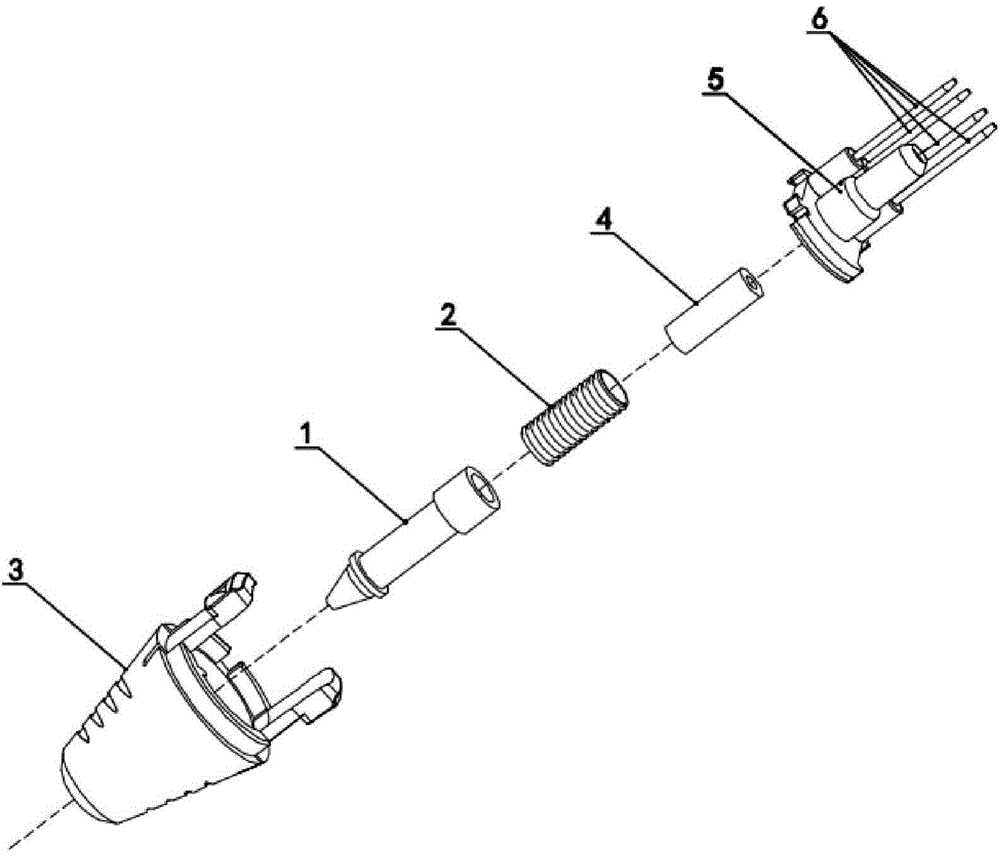

Covnenient plug type 3D printing spray head

InactiveCN104015364AReduce heat exposureEliminate tube expansion and even blockageSpray nozzleEngineering

The invention discloses a convenient plug type 3D printing spray head. The spray head comprises a shell, a nozzle, a heating device surrounding the outer wall of the nozzle, a fixed seat, a plastic introducing pipe and a metal terminal, wherein the fixed seat is provided with a through hole and is fixedly arranged in a cavity of the shell, and the plastic introducing pipe is arranged in the through hole of the fixed seat in a sleeving manner and is abutted with a through hole of the nozzle to form a consumable conveying cavity; a terminal clamping trough is formed in the fixed seat, and the metal terminal is fixedly arranged on the terminal clamping trough; a power supply wire of the heating device is connected to the metal terminal, and the metal terminal is in patch connection with a control circuit of 3D printing equipment; the melting point of the plastic introducing pipe is higher than that of a consumable. According to the convenient plug type 3D printing spray head, the problem that the consumable expands to block the pipe before being introduced into the through hole of the nozzle is solved; meanwhile, the metal terminal connected with the heating device is arranged in the clamping trough of the fixed seat, and the metal terminal is directly in the patch connection with a PCB (printed circuit board) of the control circuit of the printing equipment, so that the problems that a circuit connecting device is large in occupying space, is unstable and is easy to damage in inserting-plugging processes of the spray head are solved.

Owner:句容利威尔电器有限公司

Superconductive current lead welding method

InactiveCN1981967AReduce the difficulty of welding operationReduce the temperatureSoldering apparatusElectrical conductorCopper

A method for welding the leading superconductor wire includes such steps as soldering a superconductor onto a transition copper block while applying a thin tin layer to another surface of said copper block to be soldered and soldering between two transition copper blocks by use of the solder with low smelting point.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

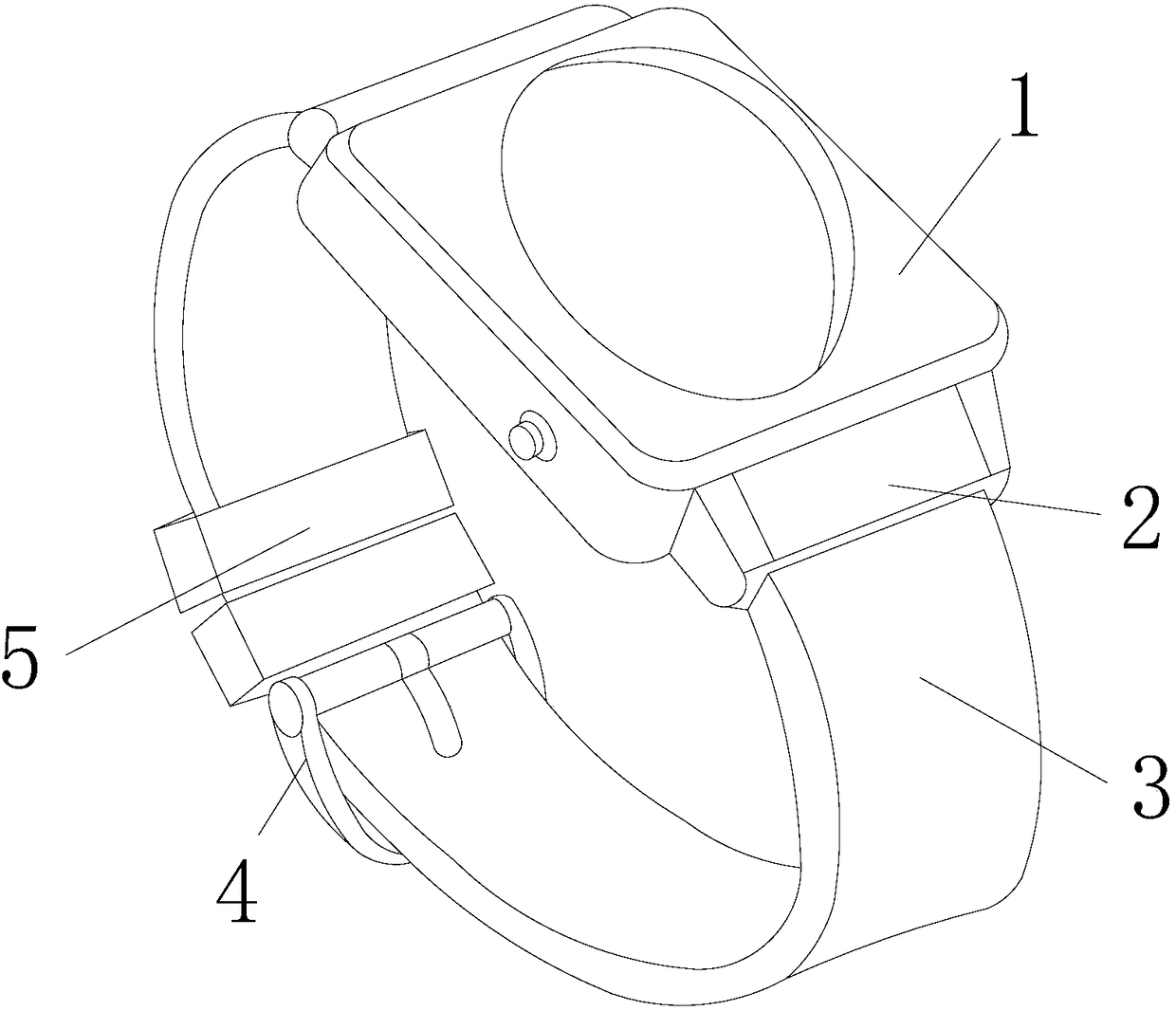

Deflection type astronomical watch device for sunshine heat dissipation by pressure

ActiveCN109188885AReduce heatExtended service lifeClockwork casesWatch crystals/clock glassesCold airAir compression

The invention discloses a deflection type astronomical watch device for sunshine heat dissipation by a pressure. The structure comprises a sunshine heat dissipation hole air compression device, a watchband connecting block, a watchband, a fixing buckle and a fixing ring. The sunshine heat dissipation hole air compression device comprises an astigmatism concave sheet, a dial body, an air compression device and an adjusting dial needle. The device has the following benefits: sunshine can be deflected by the astigmatism concave sheet, so that the sunshine entering the dial is spread out, the phenomenon of focusing is avoided, the heating degree of the surface is effectively reduced, the dial is amplified, and the observation effect is improved; the pressure between the dial and a protective shell is increased by an air bag and a sealing rubber plate, so that sea air is prevented from invasion; the hot air flow is changed into cold air before entering by a straight plate, an upper skew plate, a transverse plate and a lower skew plate, so that heat of the watch can be dissipated; the contact area of the watch and the arm is reduced by a heat dissipation device, and the arm is effectively prevented from sweating.

Owner:深圳市时进钟表有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com