Electric welding holder

A technology for electric welding tongs and electric welding machines, which is applied to the characteristics of electrodes, electrode support devices, etc., can solve the problems of weakening the heat conduction of electric welding tongs, reducing production efficiency, reducing the heat generation of electric welding tongs, etc., so as to achieve reduced heat reception and reliable contact. , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

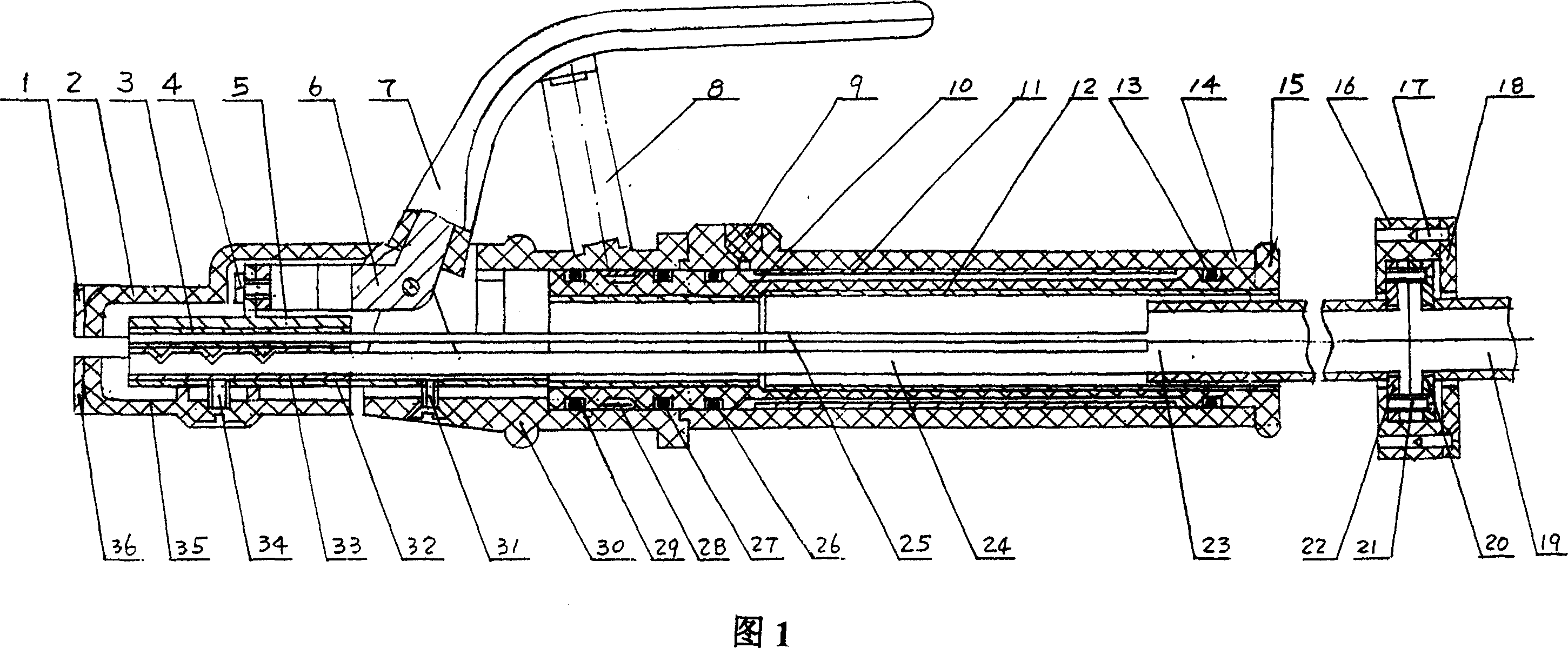

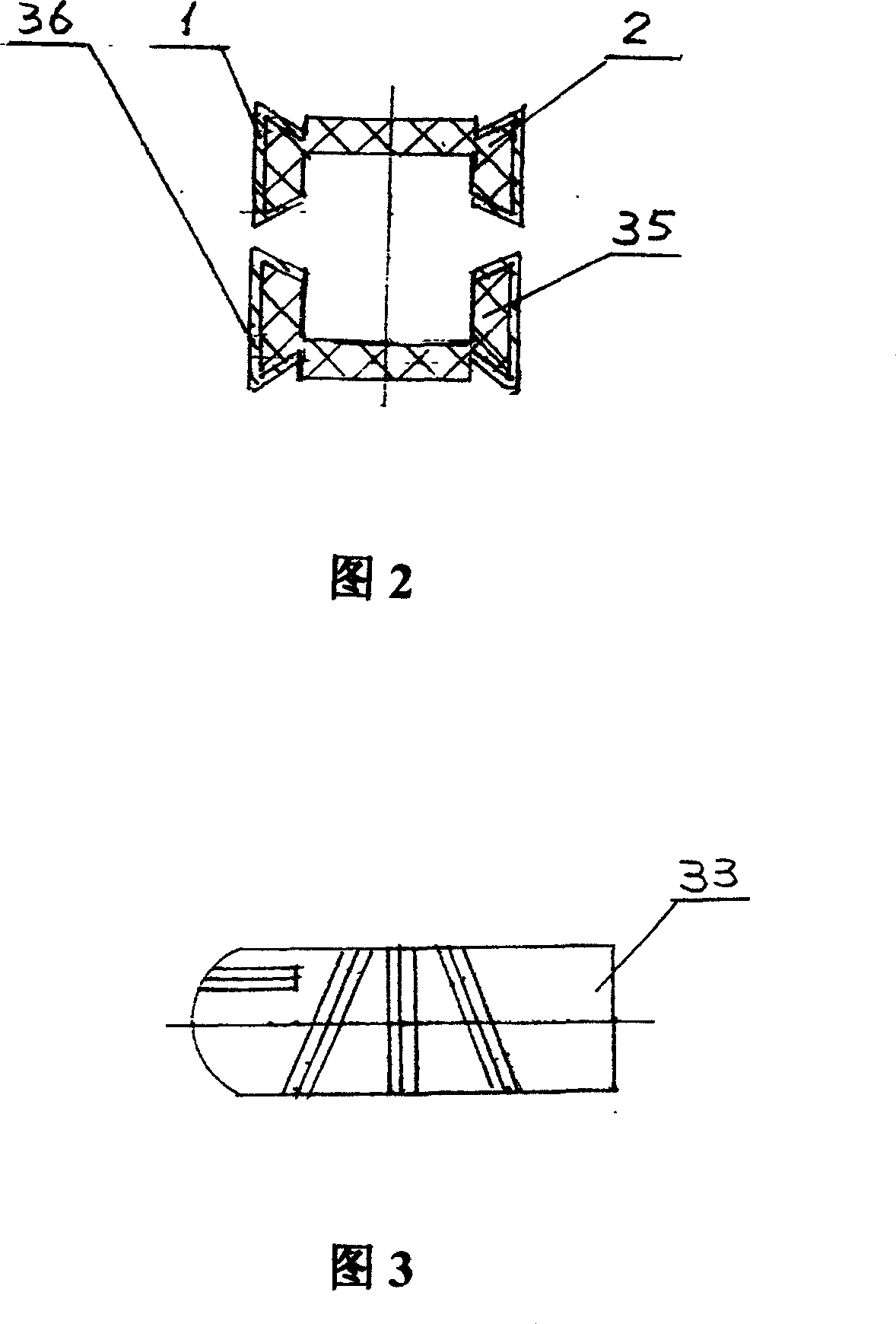

[0021] The specific structure of the present invention will be described in detail according to Figs. 1-3. This device is mainly made up of electric welding pliers body, electric welding pliers mouth cable 23, electric cable 19 connected to electric welding machine and wire joint protective body thereof. Wherein the electric welding pliers body includes an upper anti-burning metal sheet 1, a lower anti-burning metal sheet 36, an upper protective body 2, a lower protective body 35, an upper jaw 3, a lower jaw 33, connecting screws 4, 31, 34, pendulum Frame 5, pressure handle 6, pressure handle body 7, spring 8, rubber plug 9, aluminum foil reflective film 10, 11, 12, "O" type sealing ring 13, 26, 27, 29, handle outer cover 14, handle inner cover 15. Connect the electric welding machine cable 19, the electric welding pliers cable 23, the lower cable strand 24, the upper cable strand 25, the connection sleeve 30, the lower pliers bracket 32 and other parts. The line joint prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com