Covnenient plug type 3D printing spray head

A 3D printing, plug-in technology, applied in the field of 3D printing nozzles, can solve the problems of circuit connection components occupying a large space, expansion tube blockage, easy damage, etc., to save socket space, good lubricity, and low heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

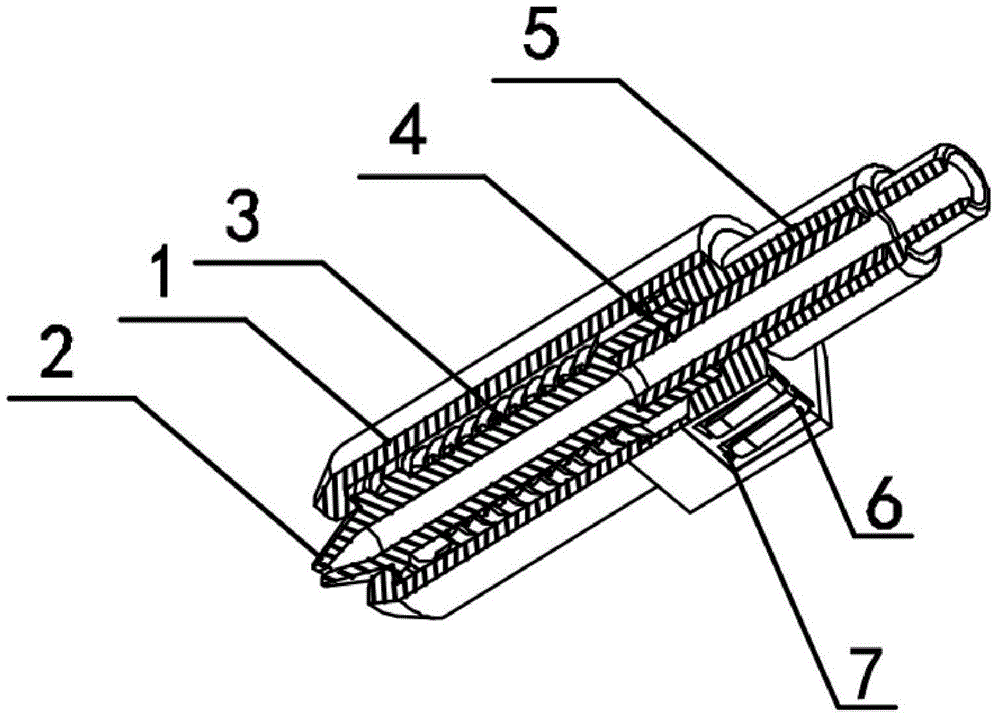

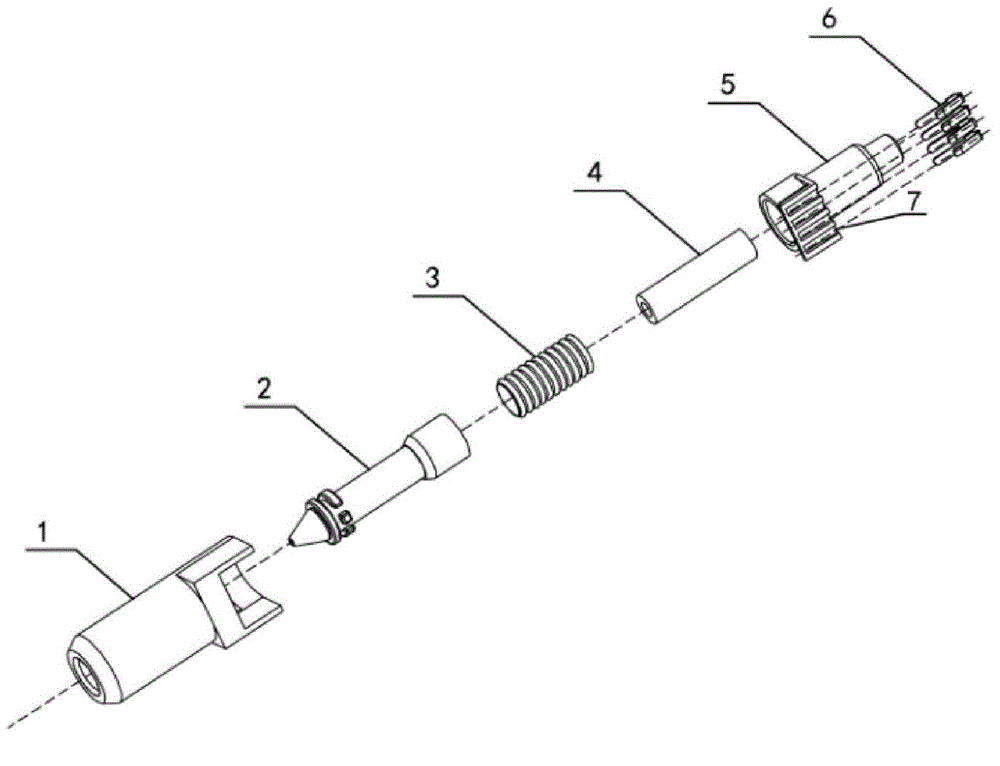

[0014] Embodiment 1: the structural representation of the present invention is as figure 1 As shown, it includes a housing 1 , a nozzle 2 , a heating device 3 surrounding the outer wall of the nozzle 2 , a plastic introduction pipe 4 , a fixing seat 5 and a metal terminal 6 .

[0015] The assembly diagram of the present invention is as follows figure 2 As shown, the fixing seat 5 is provided with a through hole and is fixedly arranged in the cavity of the housing 1, the plastic introduction tube 4 is sleeved in the through hole of the fixing seat 5, and is connected with the through hole of the nozzle 2 to form a consumable The conveying cavity; the fixed seat 5 is provided with a terminal card slot 7, and the metal terminal 6 is fixedly arranged on the terminal card slot 7; the power line of the heating device 3 is connected to the metal terminal 6, and the metal terminal 6. SMD connection with the control circuit of the 3D printing device. In this embodiment, it is directl...

Embodiment 2

[0017] Embodiment 2: the structural representation of the present invention is as figure 1 As shown, it includes a housing 1, a nozzle 2, a heating device 3 surrounding the outer wall of the nozzle 2, a plastic introduction pipe 4, a fixing seat 5 and a metal terminal 6, and a temperature sensor is also provided in the cavity of the housing 3.

[0018] The assembly diagram of the present invention is as follows figure 2 As shown, the fixing seat 5 is provided with a through hole and is fixedly arranged in the cavity of the housing 1, the plastic introduction tube 4 is sleeved in the through hole of the fixing seat 5, and is connected with the through hole of the nozzle 2 to form a consumable Conveying cavity; the fixed seat 5 is provided with a terminal card slot 7, and the metal terminal 6 is fixedly arranged on the terminal card slot 7; the power line of the heating device 3 and the signal line of the temperature sensor are connected to the metal terminal 6 Above, the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com